Review of the Strengthening Methods and Mechanical Properties of Recycled Aggregate Concrete (RAC)

Abstract

1. Introduction

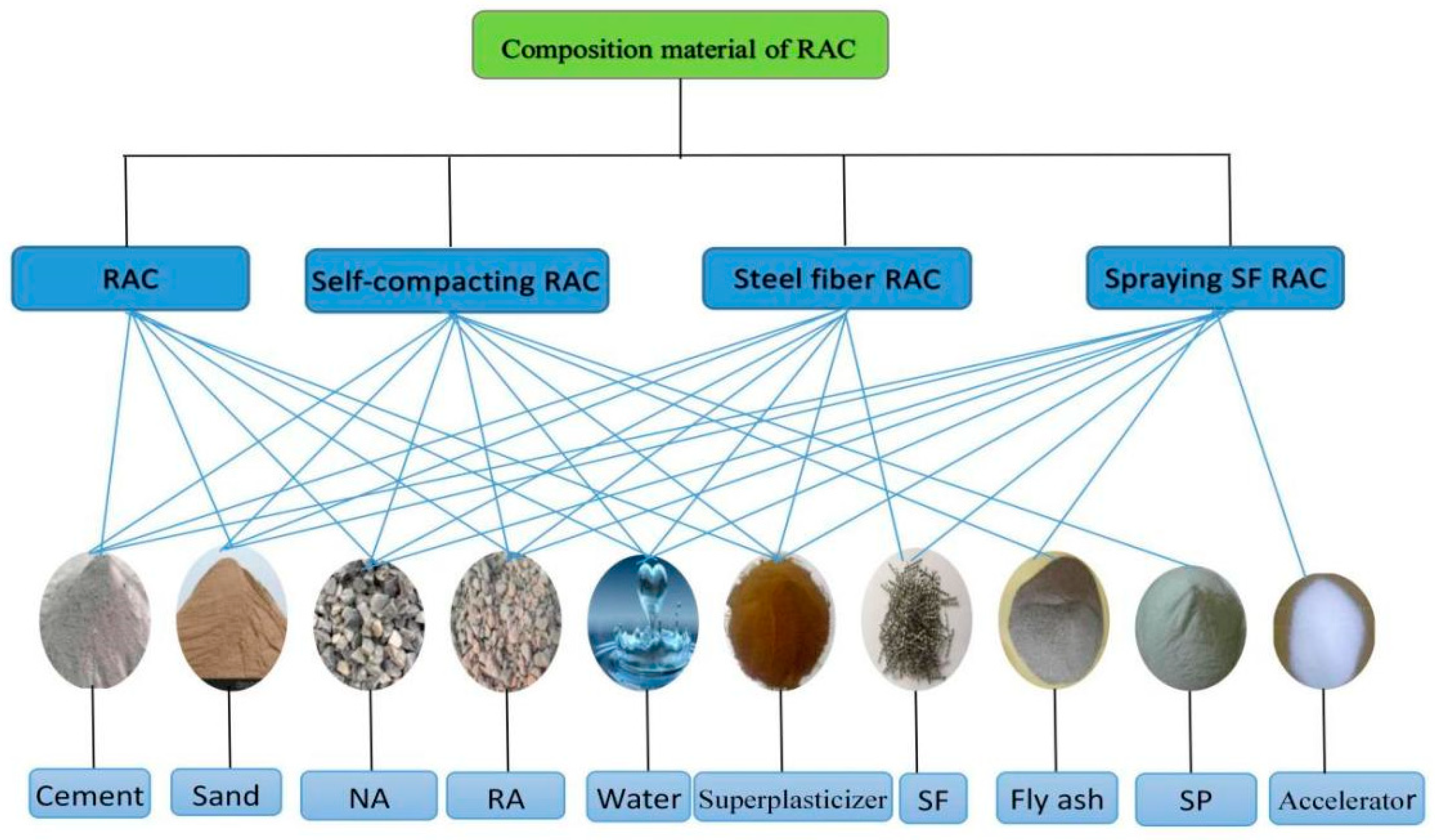

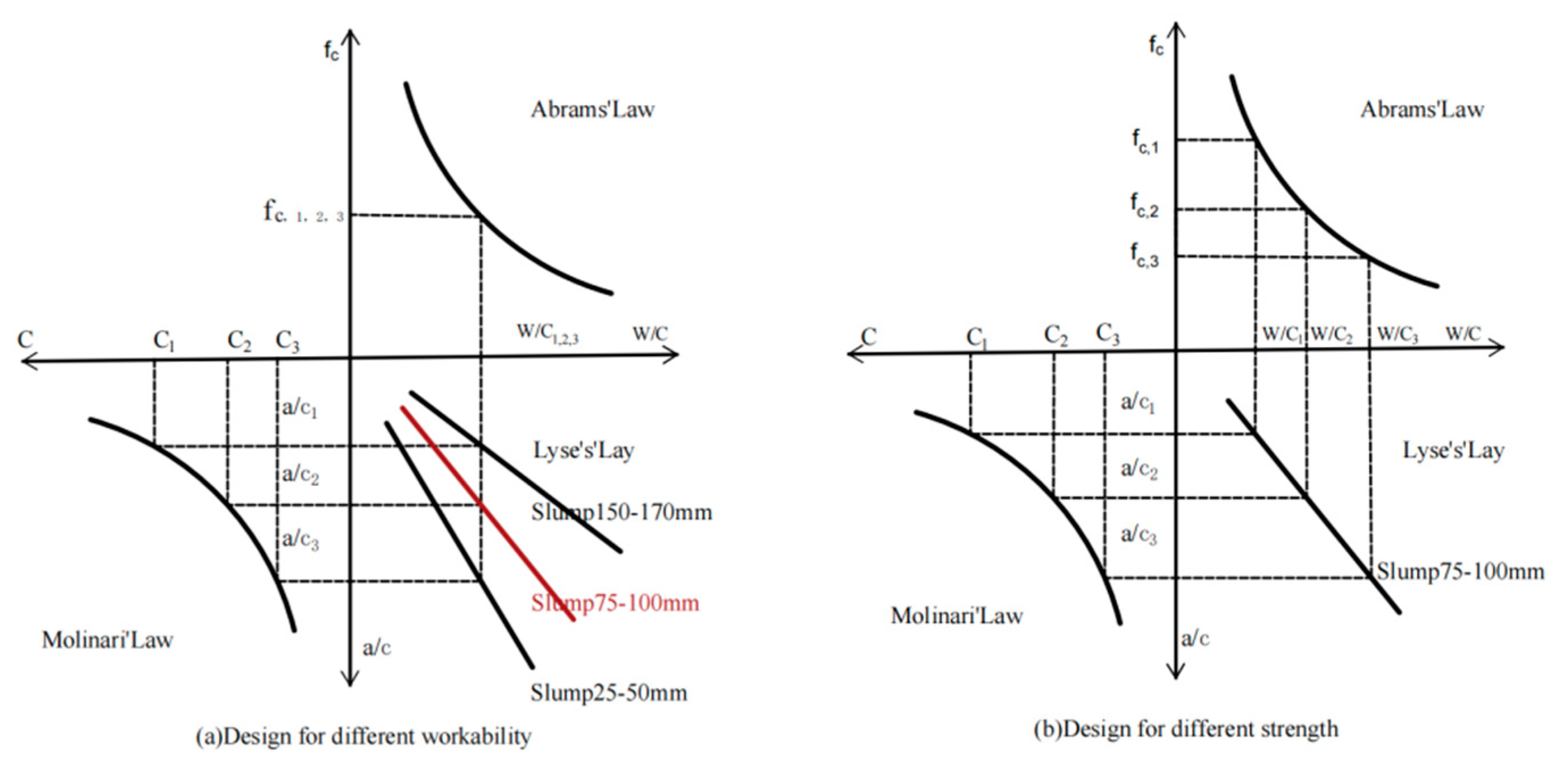

2. Technical Route of RAC Mix Design

3. Method to Improve Performance of RAC and Determine the Dosage of Composition Material

3.1. Recycled Aggregate (RA)

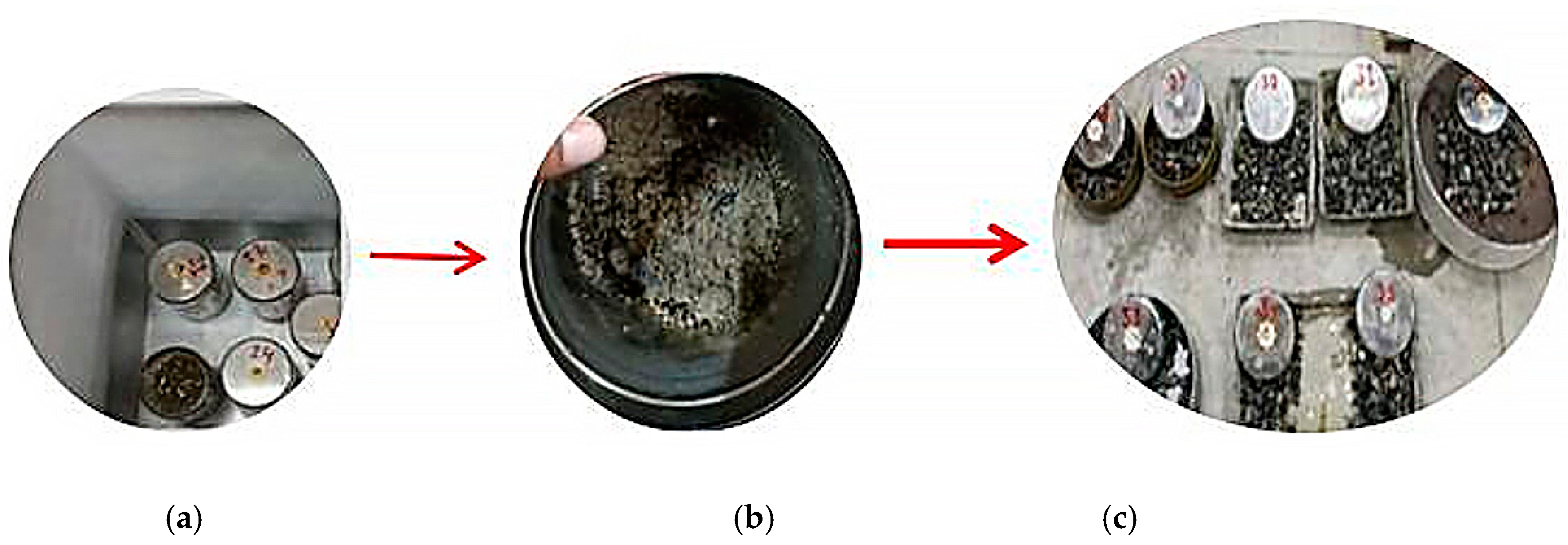

3.1.1. Treatment of RA

3.1.2. Amount of RA

3.2. Steel Fiber

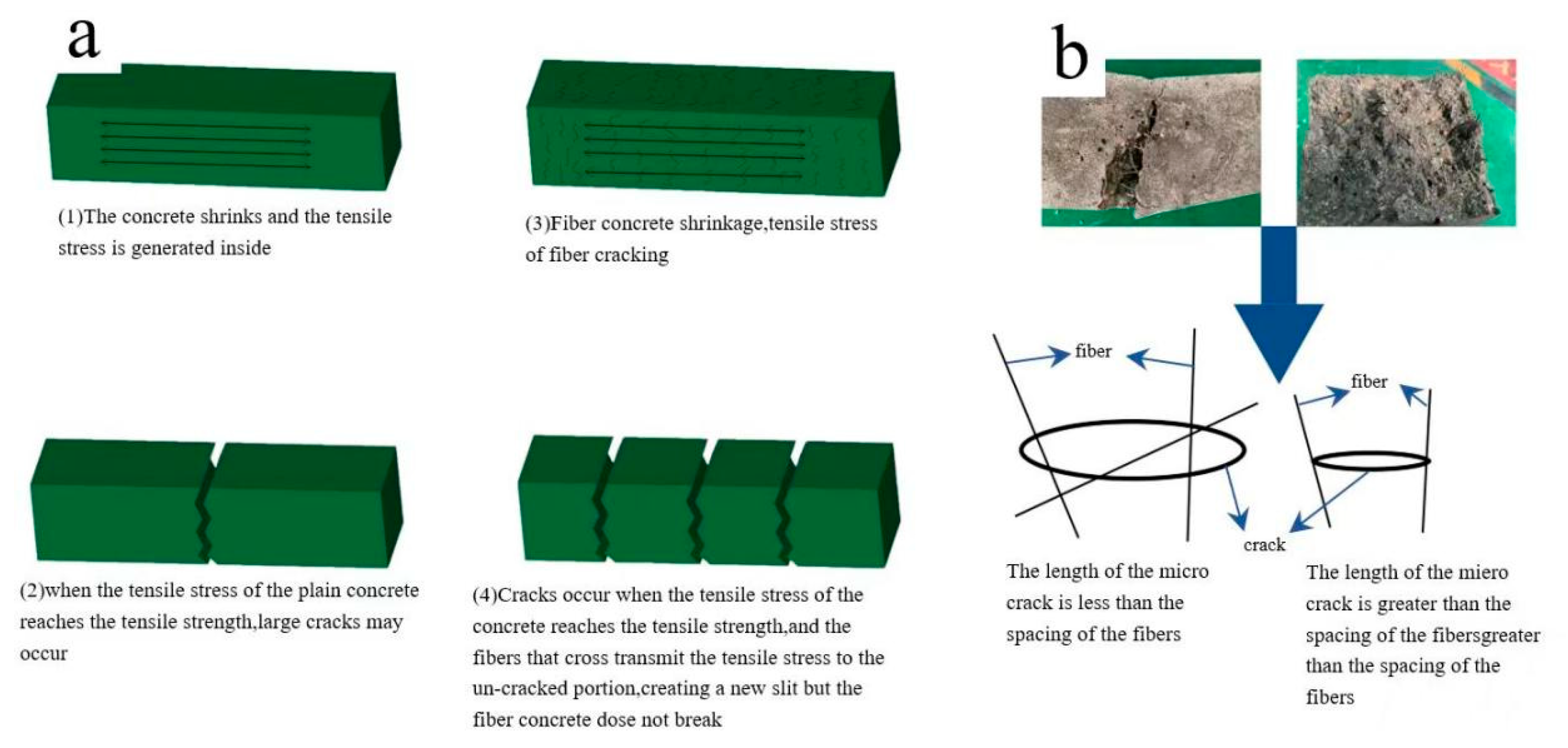

3.2.1. Crack Resistance Theory of Steel Fiber

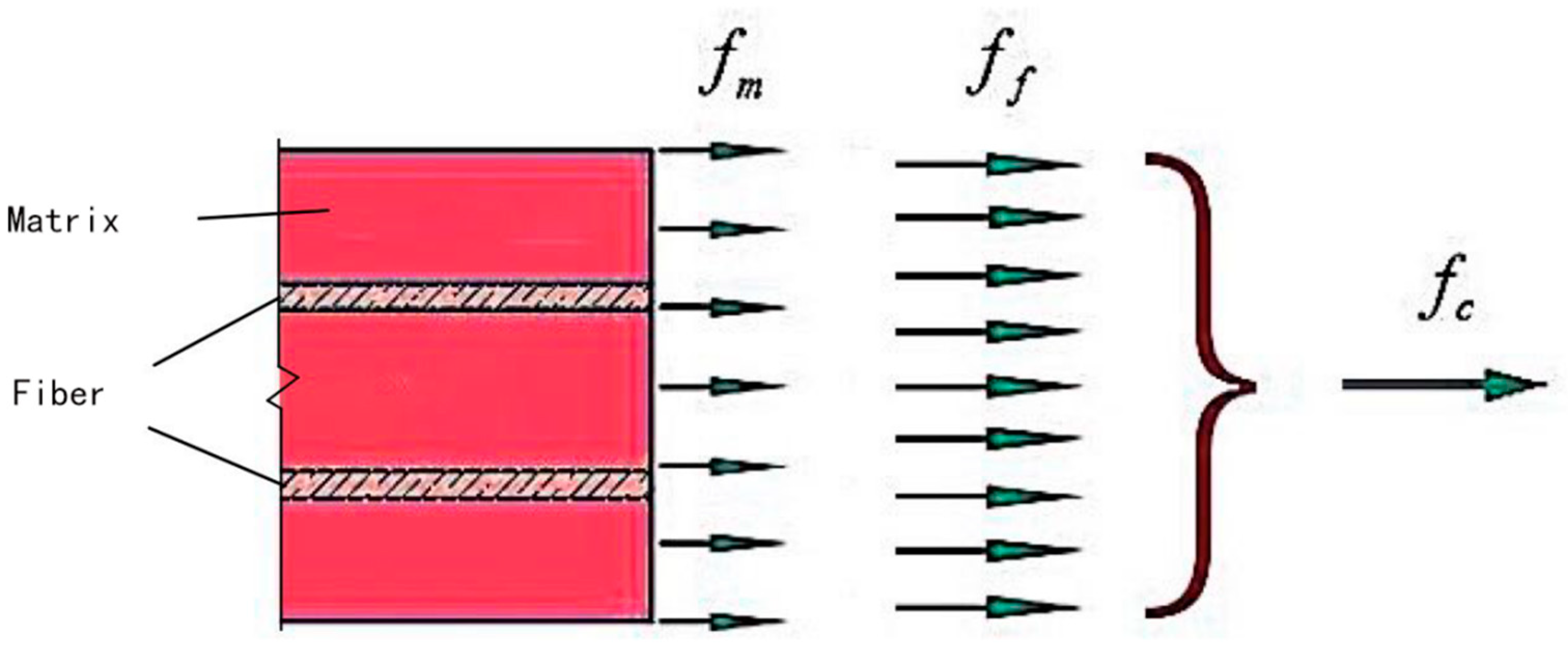

3.2.2. Composite Mechanical Reinforcement Theory of Steel Fiber

3.2.3. Theoretical Mechanical Reinforcement of Steel Fiber Spacing

3.2.4. Steel Fiber Content

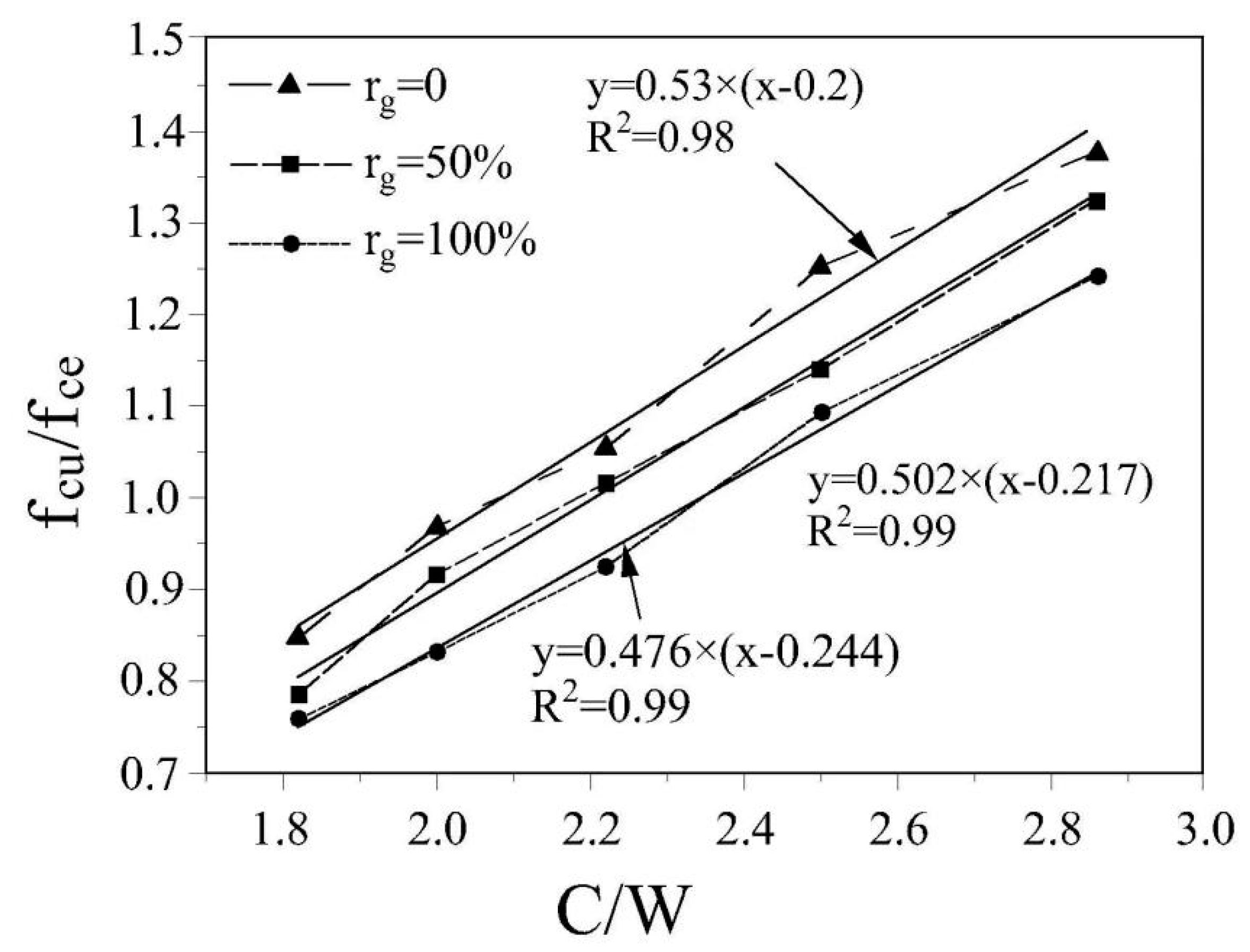

3.3. Water/Cement Ratio

3.4. Unit Water Consumption

3.5. Cement

3.6. Sand Ratio

3.7. Annexing Agent

4. Mechanical Properties of RAC

4.1. Compressive Performance

4.2. Bending and Shear Properties

5. The Durability of RAC

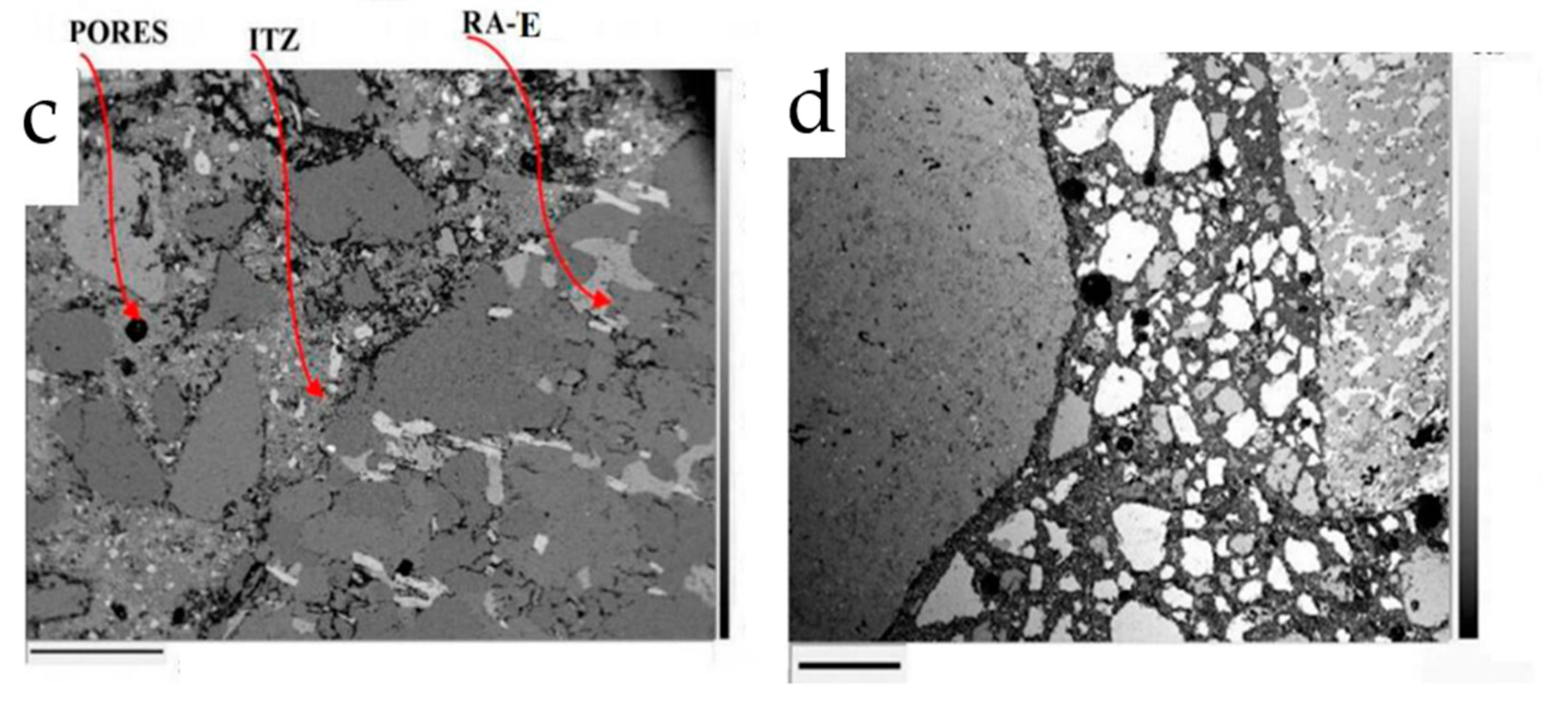

6. Microanalysis of RAC with an Optimized Mix Ratio

7. Conclusions

- Research is lacking on the use of RA for shotcrete, which is widely used in tunnel construction, slope support, and other fields. It is important to investigate the mixture design, mechanical properties, and durability of shotcrete recycled concrete or shotcrete SF recycled concrete.

- There is no unified understanding of the replacement rate of RA with different qualities. It is necessary to define the upper limit of the replacement rate of RA with different qualities and the effect of enhancing the mechanical properties of auxiliary materials, so as to promote the extensive application of RAC. In order to reduce the cost of using them in various chemical or physical treatments, the effective water in the recipe must be established and the quality of RA aggregates should be checked more frequently compared to NA.

- Many methods exist for the mix design of RAC, and each has its advantages. It is necessary to reach a consensus to understand the advantages of different methods and standardize the mix design of RAC.

- It is necessary to determine how to handle the treatment and reuse of harmful RA and building material to prevent exposure to harmful substances after break-down and adverse impacts on the environment.

- Research is also lacking on the alkali-aggregate reaction of RAC, which occurs when the alkaline substance in the concrete reacts with the active ingredient, causing expansion of material or water absorption. Internal cracking occurs due to expansion stress. Commonly, the concrete-alkali-aggregate reaction causes cracking of the coarse aggregate, which is more destructive than the damage to the cement mortar colloid or the over-bond layer between the cement mortar and aggregate. However, RA is generated by the demolition of concrete structures, and the alkalinity is neutralized. If an alkali-aggregate reaction occurs, damage will occur. Therefore, it can be assumed that RAC is relatively resistant to the alkali-aggregate reaction, although this has not been confirmed by studies to date.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Marie, I.; Quiasrawi, H. Closed-loop recycling of recycled concrete aggregates. J. Clean. Prod. 2012, 37, 243–248. [Google Scholar] [CrossRef]

- Radonjanin, V.; Malešev, M.; Marinković, S.; Al Malty, A.E.S. Green recycled aggregate concrete. Constr. Build. Mater. 2013, 47, 1503–1511. [Google Scholar] [CrossRef]

- Zhang, W.; Ingham, J.M. Using Recycled Concrete Aggregates in New Zealand Ready-Mix Concrete Production. J. Mater. Civ. Eng. 2010, 22, 443–450. [Google Scholar] [CrossRef]

- Lim, W.F.; Chew, K.C.; Zayed, T.; Lee, Y.P.K.; Low, G.L.; Ting, S.K.; Ho, N.Y. Efficient Utilization of Recycled Concrete Aggregate in Structural Concrete. J. Mater. Civ. Eng. 2013, 25, 318–327. [Google Scholar]

- De Juan, M.S.; Gutiérrez, P.A. Study on the influence of attached mortar content on the properties of recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 872–877. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M.; Chan, C.H. New approach in measuring water absorption of recycled aggregates. Constr. Build. Mater. 2008, 22, 364–369. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Sánchez De Rojas, M.I.; Frías, M. Influence of mixed recycled aggregate on the physical—Mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- Li, J.S.; Xiao, H.N.; Zhou, Y. Influence of coating recycled aggregate surface with pozzolanic powder on properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 1287–1291. [Google Scholar] [CrossRef]

- Han, S.; Li, Q. Effect of physical and chemical strengthening on shrinkage performance of recycled concrete. Compr. Util. Fly Ash 2016, 2, 3–7. [Google Scholar]

- Wang, L.; Gu, Y. Study on the Influence of Nanometer Strengthening technology on the durability of recycled concrete. Concrete 2014, 7, 48–51. [Google Scholar]

- Shima, H.; Tateyashiki, H.; Matsuhashi, R.; Yoshida, Y. An advanced concrete recyc1ing technology and its applicability assessment through input-output analysis. J. Adv. Concr. Technol. 2005, 3, 53–67. [Google Scholar] [CrossRef]

- Sui, Y.W.; Mueller, A. Development of thermo-mechanical treatment for recycling of used concrete. Mater. Struct. 2012, 45, 1487–1495. [Google Scholar] [CrossRef]

- Ryu, J. Improvement on strength and impermeability of recycled concrete made with crushed concrete coarse aggregate. J. Mater. Sci. Lett. 2002, 21, 1565–1567. [Google Scholar] [CrossRef]

- Zhan, B.; Xuan, D.; Poon, C.S. Enhancement of recycled aggregate properties by accelerated CO2 curing coupled with lime water soaking process. Cem. Concr. Compos. 2018, 89, 230–237. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Zaetang, Y.; Sata, V.; Wongsa, A.; Chindaprasirt, P. Properties of pervious concrete containing recycled concrete block aggregate and recycled concrete aggregate. Constr. Build. Mater. 2016, 111, 15–21. [Google Scholar] [CrossRef]

- Carneiro, J.A.; Lima, P.R.L.; Leite, M.B.; Toledo Filho, R.D. Compressive stress–strain behavior of steel fiber reinforced-recycled aggregate concrete. Cem. Concr. Compos. 2014, 46, 65–72. [Google Scholar] [CrossRef]

- Senaratne, S.; Gerace, D.; Mirza, O.; Tam, V.W.; Kang, W.H. The costs and benefits of combining recycled aggregate with steel fibres as a sustainable, structural material. J. Clean. Prod. 2016, 112, 2318–2327. [Google Scholar] [CrossRef]

- Yang, H.; Ding, Y. Comparative analysis of physical and mechanical properties of different kinds of fiber reinforced concrete. Constr. Technol. 2018, 20, 6–9. [Google Scholar]

- Qiao, H.; Li, J. Effect of fiber mixing method on frost resistance of concrete. Silic. Notif. 2019, 17, 495–500. [Google Scholar]

- Somna, R.; Jaturapitakkul, C.; Chalee, W.; Rattanachu, P. Effect of the Water to Binder Ratio and Ground Fly Ash on Properties of Recycled Aggregate Concrete. J. Mater. Civ. Eng. 2012, 24, 16–22. [Google Scholar] [CrossRef]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Liang, Y.; Ye, Z.; Vernerey, F.; Xi, Y. Development of Processing Methods to Improve Strength of Concrete with 100% Recycled Coarse Aggregate. J. Mater. Civ. Eng. 2015, 27, 04014163. [Google Scholar] [CrossRef]

- Tam, C.T.; Akbarnezhad, A.; Zhang, M.H.; Ong, K.C.G. Effects of the Parent Concrete Properties and Crushing Procedure on the Properties of Coarse Recycled Concrete Aggregates. J. Mater. Civ. Eng. 2013, 25, 1795–1802. [Google Scholar]

- Butler, L.; West, J.S.; Tighe, S.L. Effect of recycled concrete coarse aggregate from multiple sources on the hardened properties of concrete with equivalent compressive strength. Constr. Build. Mater. 2013, 47, 1292–1301. [Google Scholar] [CrossRef]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Mas, B.; Cladera, A.; Olmo, T.D.; Pitarch, F. Influence of the amount of mixed recycled aggregates on the properties of concrete for non-structural use. Constr. Build. Mater. 2012, 27, 612–622. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Wang, Y. Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach. Constr. Build. Mater. 2007, 21, 1928–1939. [Google Scholar] [CrossRef]

- GB14684-2011; Building Sand. China Standard Press: Beijing, China, 2011.

- Larsen, R.J.; Marx, M.L. An Introduction to Mathematical Statistics and Its Application, 2nd ed.; Prentice-Hall: Vandy, NJ, USA, 1986. [Google Scholar]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. A novel mix design methodology for Recycled Aggregate Concrete. Constr. Build. Mater. 2016, 122, 362–372. [Google Scholar] [CrossRef]

- Zhang, L. Mix Design and Performance Calculation Method of Steel Fiber Recycled Concrete; Zhengzhou University: Zhengzhou, China, 2017; p. 20. [Google Scholar]

- Khemissa, M.; Mahamedi, A. Cement and lime mixture stabilization of an expansive overconsolidated clay. Appl. Clay Sci. 2014, 95, 104–110. [Google Scholar] [CrossRef]

- Lee, C.; Lee, K.; Choi, H.; Choi, H.P. Characteristics of thermally-enhanced bentonite grouts for geothermal heat exchanger in South Korea. Sci. China-Technol. Sci. 2010, 53, 123–128. [Google Scholar] [CrossRef]

- Zhao, Z.G.; Qu, X.L.; Li, F.X.; Wei, J.X. Effects of steel slag and silica fume additions on compressive strength and thermal properties of lime-fly ash pastes. Constr. Build. Mater. 2018, 183, 439–450. [Google Scholar] [CrossRef]

- Rajhans, P.; Panda, S.K.; Nayak, S. Sustainable self compacting concrete from C&D waste by improving the microstructures of concrete ITZ. Constr. Build. Mater. 2018, 163, 557–570. [Google Scholar]

- Rajhans, P.; Panda, S.K.; Nayak, S. Sustainability on durability of self compacting concrete from C&D waste by improving porosity and hydrated compounds: A microstructural investigation. Constr. Build. Mater. 2018, 174, 559–575. [Google Scholar]

- Gholampour, A.; Ozbakkaloglu, T. Time-dependent and long-term mechanical properties of concretes incorporating different grades of coarse recycled concrete aggregates. Eng. Struct. 2018, 157, 224–234. [Google Scholar] [CrossRef]

- Shahidan, S.; Azmi, M.A.M.; Kupusamy, K.; Zuki, S.S.M.; Ali, N. Utilizing construction and demolition (C&D) waste as recycled aggregates (RA) in concrete. Procedia Eng. 2017, 174, 1028–1035. [Google Scholar]

- Falek, K.; Aoudjane, K.; Kadri, E.H.; Kaoua, F. Influence of recycled aggregates on the mechanical and tribological behavior of concrete. Energy Procedia 2017, 139, 456–461. [Google Scholar] [CrossRef]

- Kabir, S.; Al-Shayeb, A.; Khan, M.I. Recycled construction debris as concrete aggregate for sustainable construction materials. Procedia Eng. 2016, 145, 1518–1525. [Google Scholar] [CrossRef][Green Version]

- Koenders, E.; Pepe, M.; Martinelli, E. Compressive strength and hydration processes of concrete with recycled aggregates. Cem. Concr. Res. 2014, 56, 203–212. [Google Scholar] [CrossRef]

- Surya, M.; Vvl, K.R.; Lakshmy, P. Recycled aggregate concrete for transportation infrastructure. Procedia-Soc. Behav. Sci. 2013, 104, 1158–1167. [Google Scholar] [CrossRef]

- Tabsh, S.W.; Abdelfatah, A.S. Influence of recycled concrete aggregates on strength properties of concrete. Constr. Build. Mater. 2009, 23, 1163–1167. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vazquez, E.; Mari, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Wang, L.; Wang, J.; Qian, X.; Chen, P.; Xu, Y.; Guo, J. An environmentally friendly method to improve the quality of recycled concrete aggregates. Constr. Build. Mater. 2017, 144, 432–441. [Google Scholar] [CrossRef]

- Saravanakumar, P.; Abhiram, K.; Manoj, B. Properties of treated recycled aggregates and its influence on concrete strength characteristics. Constr. Build. Mater. 2016, 111, 611–617. [Google Scholar] [CrossRef]

- Zhan, B.; Poon, C.S.; Liu, Q.; Kou, S.; Shi, C. Experimental study on CO2 curing for enhancement of recycled aggregate properties. Constr. Build. Mater. 2013, 67, 3–7. [Google Scholar] [CrossRef]

- Gupta, P.K.; Rajhans, P.; Panda, S.K.; Nayak, S.; Das, S.K. Mix Design Method for Self-Compacting Recycled Aggregate Concrete and Its Microstructural Investigation by Considering Adhered Mortar in Aggregate. Am. Soc. Civ. Eng. 2019, 32, 04019371. [Google Scholar] [CrossRef]

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. China Building Industry Press: Beijing, China, 2006.

- Liu, Y. Research on Mechanical Properties and Penetration Resistance Mechanism of Steel Fiber Concrete; University of Science and Technology of China: Shenzhen, China, 2006. [Google Scholar]

- Wang, C.; Wu, K. Research on mechanical Properties of Steel fiber and carbon fiber concrete. J. Build. Mater. 2003, 17, 61–63. [Google Scholar]

- Cheng, X. Study on Strengthening Mechanism and Fracture Toughness of Steel Fiber Concrete; Hohai University: Nanjing, China, 2005. [Google Scholar]

- Zhu, Y. Mechanical Properties of Steel Fiber Shotcrete and Its Application in Single Layer Lining of Tunnel; Chongqing University: Chongqing, China, 2009. [Google Scholar]

- Sun, M.Q.; Mao, Q.Z. Size effect and loading rate dependence of the pressure sensitivity of carbon fiber reinforced concrete. J. Wuhan Univ. Technol. 1998, 13, 58–61. [Google Scholar]

- Craig, A.; William, G.; Habib, J.D. Testing and Analysis of Partially Composite Fiber Reinforced Polymer-Glulam-Concrete Bridge. J. Bridge Eng. 2004, 19, 1084–1092. [Google Scholar]

- Tripathi, D.; Jones, F.R. Measurement of the Load-bearing Capability of the Fiber/Matrix Interface by Single Fiber Fragmentation. Compos. Sci. Technol. 1997, 57, 925–934. [Google Scholar] [CrossRef]

- Guo, Y. Research on Toughening Energy of Steel Fiber Concrete and Application of Toughness Characteristics in Calculation of Underground Structure; Southwest Jiaotong University: Chengdu, China, 2008. [Google Scholar]

- Lin, X.; Yang, G. Steel Fiber High Strength and Ultra-High Strength Concrete; Science Press: Beijing, China, 2002; pp. 35–90. [Google Scholar]

- Gao, D.; Zhang, L.; Nokken, M.; Zhao, J. Mixture Proportion Design Method of Steel Fiber Reinforced Recycled Coarse Aggregate Concrete. Materials 2019, 12, 375. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y. Design Method of Shotcrete Mix Ratio; Northeast: College of Resources and Civil Engineering, Northeast University: Shenyang, China, 2013; pp. 84–86. [Google Scholar]

- Guo, Y.; Li, Q. Simple design method for the mixture ratio of recycled coarse aggregate concrete. J. Shenyang Jianzhu Univ. 2017, 33, 1030–1038. [Google Scholar]

- Hua, J.; Wangb, K.; Gauntb, J.A. Behavior and mix design development of concrete made with recycled aggregate from deconstructed lead-contaminated masonry materials. Constr. Build. Mater. 2013, 40, 1184–1192. [Google Scholar] [CrossRef]

- Levy, S.M.; Helen, P. Durability of recycled aggregates concrete: A safe way tosustainable development. Cem. Concr. Res. 2004, 34, 1975–1980. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Helene, P.R.L.; Kang, S.H. Designing concrete mixtures for strength, elastic modulus and fracture energy. Mater. Struct. 1993, 26, 443–452. [Google Scholar]

- Li, Q.; Gao, S.; Xue, S. Green Concrete Technology; China Building Materials Industry Press: Beijing, China, 2014. [Google Scholar]

- Monalisa, B.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste and its use in concrete-A break through towards sustainability in construction sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Çakır, Ö. Experimental analysis of properties of recycled coarse aggregate (RCA) concrete with mineral additives. Constr. Build. Mater. 2014, 68, 17–25. [Google Scholar] [CrossRef]

- Yu, J.; Liang, R.; Qin, Y.-J. Experimental study on the performance of C30 recycled coarse aggregate concrete. Archit. Sci. 2015, 31, 59–63. [Google Scholar]

- Corinaldesi, V. Mechanical and elastic behavior of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Zhu, H.; Dai, J.; Bai, G. Test and Analysis of thermal conductivity of recycled concrete. J. Build. Mater. 2015, 18, 852–857. [Google Scholar]

- Houria, M.; Oussama, K.; Hocine, O.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregate on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar]

- Sallehan, I.; Mahyuddin, R. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar]

- Cui, H.; Shi, X.; Memon, S.A.; Xing, F.; Tang, W. Experimental Study on the Influence of Water Absorption of Recycled Coarse Aggregates on Properties of the Resulting Concretes. J. Mater. Civ. Eng. 2015, 27, 04014138. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Barra, M.; Abbas, A. Influence of the pre-saturation of recycled coarse concrete aggregates on concrete properties. Mag. Concr. Res. 2011, 63, 617–627. [Google Scholar] [CrossRef]

- Tam, V.; Gao, X.F.; Tam, C.M. Microstructural analysis of recycled aggregate concrete produced from two-stage mixing approach. Cem. Concr. Res. 2005, 35, 1195–1203. [Google Scholar] [CrossRef]

- Guo, Y.; Li, Q.; Su, D.; Gao, S.; Yue, G. Formula for Predicting water consumption of recycled coarse aggregate concrete based on multiple factors. Silic. Bull. Chin. Ceram. Soc. 2008, 37, 1937–1940. [Google Scholar]

- Zhou, A. Experimental study on the performance of common mortar for waste concrete production. China Silic. Bull. 2017, 36, 620–624. [Google Scholar]

- Guo, Y.-X.; Li, Q.-Y.; Wang, W.-Q. Research on quality Improvement Technology of recycled coarse aggregate. Concrete 2015, 6, 134–138. [Google Scholar]

- GB/T 25177-2010; Recycled Coarse Aggregate for Concrete. Ministry of Housing and Urban Construction of China: Beijing, China, 2010.

- Zhang, C.; Song, F.; Liu, F. Orial Handbooks of Building Construction; China Building Industry Press: Beijing, China, 2011. [Google Scholar]

- DB37/T 5208-2021; Technical Specification for Recycled Concrete Structures. Ministry of Housing and Urban and Rural Construction in People’s Republic of China: Beijing, China, 2016.

- Fang, Y. Experimental Research on Stressing Performances of Recycled Concrete Simply-Supported Beams; Central South University of Forestry and Technology: Changsha, China, 2009; pp. 14–18. [Google Scholar]

- Yang, W. Research on Mix Proportion and Physical Stress for Drying Shrinkage of Recycled Concrete Perforated Brick; Zhengzhou University: Zhengzhou, China, 2007; pp. 24–31. [Google Scholar]

- Hu, L.; Liang, J.-G. Effect of aggregate gradation on drying shrinkage of recycled concrete perforated brick. New Build. Mater. 2011, 4, 24–27. [Google Scholar]

- Hao, T.; Liu, L. Research on shear strength of recycled aggregates concrete perforated brick masonry. New Build. Mater. 2016, 7, 51–53. [Google Scholar]

- Zhang, X.; Deng, S.-C. Experimental research on unit water in recycled concrete. Concrete 2004, 10, 38–40. [Google Scholar]

- Zhang, X. Calculation of water usage per unit volume of recycled concrete. J. Cent. South For. Univ. 2005, 5, 102–106. [Google Scholar]

- Wang, M.; Yu, F.; Yin, C. Research on Additional Water of Mix Proportion for Recycled Aggregate Concrete. In Proceedings of the International Conference on Smart City and Systems Engineering (ICSCSE), Xiamen, China, 29–30 December 2018; pp. 328–331. [Google Scholar]

- Kumar, A. Thermal Spray Removal of Lead-Containing Paint of Steel Structures; Construction Engineering Research Lab (ARMY): Champaign, IL, USA, 1999. [Google Scholar]

- Kominsky, J.R. Field Demonstration of Lead-Based Paint Removal and Inorganic Stabilization Technologies. U.S. Environmental Protection Agency, Washington, DC, EPA/600/R-01/055 (NTIS PB2002-102037). 2001. Available online: https://cfpub.epa.gov/si/si_public_record_report.cfm?dirEntryId=99482&Lab=NRMRL (accessed on 5 July 2022).

- Jacobs, D.E.; Mielke, H.; Pavur, N. The high cost of improper removal of lead-based paint from housing: A case report. Environ. Health Perspect. 2003, 111, 185–186. [Google Scholar] [CrossRef] [PubMed]

- Garrels, R.M.; Christ, C.K. Solutions, minerals, and equilibria. Harper Row N. Y. 1965, 32, 34–37. [Google Scholar]

- Brookins, D.G. Eh–pH Diagrams for Geochemistry; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Cao, X.; Ma, L.Q.; Chen, M.; Hardison, D.W.; Harris, W.G. Weathering of lead bullets and their environmental effects at outdoor shooting ranges. J. Environ. Q. 2003, 32, 526–634. [Google Scholar] [CrossRef]

- ASTM (American Society for Testing and Materials). Annual Book of ASTM Standards; ASTM (American Society for Testing and Materials): Torrance, PA, USA, 2010. [Google Scholar]

- Wang, K.; Gaunt, J.A.; Hu, J. Sequestering lead in paint by utilizing deconstructed masonry materials as recycled aggregate in concrete. Strateg. Environ. Res. Dev. Prog. (SERDP) Proj. SI 2008, 44, 1548. [Google Scholar]

- Epa, U.S. Toxicity characteristics leaching procedure, Method 1311. Test Methods Eval. Solid Waste 1992, 23, 1989. [Google Scholar]

- Kosmatka, S.H.; Kerkhoff, B.; Panarese, W.C. Design and Control of Concrete Mixture, 14th ed.; Portland Cement Association: Skokie, IL, USA, 2002. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; ELBS and Longman: London, UK, 1996. [Google Scholar]

- Hu, J.; Wang, K.; Gaunt, J.A. Sequestering lead by utilizing lead based paint contaminated masonry materials as recycled aggregate in concrete. Resour Conserv Recy 2010, 54, 1453–1460. [Google Scholar] [CrossRef]

- California Code of Regulations. California State of Waste Extraction Test (WET) Procedures. 2005. Available online: https://govt.westlaw.com/calregs/Document/I84C9412C5B6111EC9451000D3A7C4BC3?viewType=FullText&originationContext=documenttoc&transitionType=CategoryPageItem&contextData=(sc.Default) (accessed on 5 July 2022).

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B. Proposed method for determining the residual mor-tar. J. ASTM Int. 2007, 5, 1–12. [Google Scholar] [CrossRef]

- Fathifazl, G.; Abbas, A.; Razaqpur, A.G.; Isgor, O.B.; Fournier, B.; Foo, S. New mixture proportioning method for con-crete made with coarse recycled concrete aggregate. J. Mater. Civ. Eng. 2009, 21, 601–611. [Google Scholar] [CrossRef]

- Belin, P.; Habert, G.; Thiery, M.; Roussel, N. Cement paste content and water absorption of recycled concrete coarse aggregates. Mater. Struct. Constr. 2013, 47, 1451–1465. [Google Scholar] [CrossRef]

- JGJ55-2011; Code for Design of Common Concrete Mix. China Building Industry Press: Beijing, China, 2011.

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar] [CrossRef]

- Wenda, C.; Dong, C. New Concrete and Its Application; Jindun Press: Beijing, China, 2001. [Google Scholar]

- Liu, J.; Huang, H. Influence of fly ash on the properties of steel fiber concrete. Compr. Util. Fly Ash 2002, 1, 44–45. [Google Scholar]

- DL/T5055-1996; Technical Specification for Fly Ash in Hydraulic Concrete. Ministry of Electric Power Industry of China: Beijing China, 2011.

- Wardeh, G.; Ghorbel, E.; Gomart, H. Mix design and properties of recycled aggregate concretes: Applicability of Eurocode 2. Int. J. Concr. Struct. Mater. 2015, 9, 1–20. [Google Scholar] [CrossRef]

- EAnike, E.E.; Saidani, M.; Ganjian, E.; Tyrer, M.; Olubanwo, A.O. Evaluation of conventional and equivalent mortar volume mix design methods for recycled aggregate concrete. Mater. Struct. 2020, 53, 22. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, L.; Nokken, M. Compressive behavior of steel fiber reinforced- recycled coarse aggregate concrete with equivalent compressive strength. Constr. Build. Mater. 2017, 141, 235–244. [Google Scholar] [CrossRef]

- Wedding, P.; Rasheeduzzafar; Khan, A. Recycled concrete-a source for new aggregate. Cem. Concr. Aggregates 1984, 6, 17–27. [Google Scholar] [CrossRef]

- Ravindrajah, R.S.; Loo, Y.H.; Tam, C.T. Strength evaluation of recycled-aggregate concrete by in-situ tests. Mater. Struct. 1988, 21, 289–295. [Google Scholar] [CrossRef]

- Katz, A. Properties of concrete made with RA from partially hydrated old concrete. Cem. Concr. Res. 2003, 33, 703–711. [Google Scholar] [CrossRef]

- Bairagi, N.; Ravande, K.; Pareek, V. Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recycl. 1993, 9, 109–126. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of RAC. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Liu, C.; Fan, Z.Y.; Chen, X.N.; Zhu, C.; Wang, H.Y.; Bai, G.L. Experimental study on bond behavior between section steel and RAC under full replacement ratio. KSCE J. Civ. Eng. 2019, 23, 1159–1170. [Google Scholar] [CrossRef]

- Elhakam, A.A.; Mohamed, A.E.; Awad, E. Influence of self-healing, mixing method and adding silica fume on mechanical properties of RAs concrete. Constr. Build. Mater. 2012, 35, 421–427. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Enhancing the durability properties of concrete prepared with coarse RA. Constr. Build. Mater. 2012, 35, 69–76. [Google Scholar] [CrossRef]

- Fonseca, N.; de Brito, J.; Evangelista, L. The influence of curing conditions on themechanical performance of concrete made with recycled concrete waste. Cem.Concr. Compos. 2011, 33, 637–643. [Google Scholar] [CrossRef]

- Collepardi, M.; Marcialis, A.; Turriziani, R. Penetration of chlo-ride ions into cement pastes and concretes. J. Am. Ceram. Soc. 1972, 55, 534–535. [Google Scholar] [CrossRef]

- Monosi, S.; Moriconi, G.; Alverà, I.; Collepardi, M. Effect of water/cement ratio and curing time on chloride penetration into con-crete. Mater. Eng. 1989, 1, 483–489. [Google Scholar]

- Saetta, A.V.; Scotta, R.V.; Vitaliani, R.V. Analysis of chloride diffusion into partially saturated concrete. ACI Mater. J. 1993, 90, 441–451. [Google Scholar]

- Neville, A. Chloride attack of reinforced concrete: An overview. Mater. Struct. 1995, 28, 63–70. [Google Scholar] [CrossRef]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef] [PubMed]

- Corinaldesi, V.; Moriconi, G. Recycling of rubble from build-ing demolition for low-shrinkage concretes. Waste Manag. 2010, 30, 655–659. [Google Scholar] [CrossRef] [PubMed]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of hardened concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Dhir, R.K.; Limbachiya, M.C.; Leelawat, T. Suitability of re-cycled concrete aggregate for use in BS 5328 designated mixes. Proc. Inst. Civ. Eng. Struct. Build. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Santillán, L.R.; Villagrán Zaccardi, Y.A.; Benito, D.E.; Zega, C.J. Sulfate ingress in recycled concrete immersed in sodium sulfate solution for 10 years. In Proceedings of the Workshop on External Sulfate Attack; Laboratório Nacional de Engenharia Civil, Lisbon, Portugal, 3–4 November 2016. [Google Scholar]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Somna, R.; Jaturapitakkul, C.; Made, A.M. Effect of ground fly ash and ground bagasse ash on the durability of recycled aggregate concrete. Cem. Concr. Compos. 2012, 34, 848–854. [Google Scholar] [CrossRef]

- Hwang, J.P.; Shim, H.B.; Lim, S.; Ann, K.Y. Enhancing the durability properties of concrete containing recycled aggregate by the use of pozzolanic materials. KSCE J. Civ. Eng. 2013, 17, 155–163. [Google Scholar] [CrossRef]

- Mindess, S.; Young, J.F. Concrete, 671; Prentice-Hall: Englewood Cliffs, NJ, USA, 1981. [Google Scholar]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 3rd ed.; McGraw-Hill: New York, NY, USA, 2006; p. 600. [Google Scholar]

- Nawy, E.G. Concrete Construction Engineering Handbook, 2nd ed.; CRC Press: Englewood Cliffs, NJ, USA, 2008; p. 1560. [Google Scholar]

- Zega, C.J.; Di Maio, A.A. Recycled concrete exposed to high temperatures. Mag. Concr. Res. 2006, 58, 675–682. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Recycled concrete made with different natural coarse aggregates exposed to high temperature. Constr. Build. Mater. 2009, 23, 2047–2052. [Google Scholar] [CrossRef]

- Enlin, M.; Jinxing, L.; Shuoshuo, X. Failure analysis and treatments of a loess tunnel being constructed in ground fissure area. Eng. Fail. Anal. 2022, 134, 106034. [Google Scholar]

- He, S.; Lai, J.; Li, Y.; Wang, K.; Wang, L.; Zhang, W. Pile group response induced by adjacent shield tunnelling in clay: Scale model test and numerical simulation. Tunn. Undergr. Space Technol. 2021, 120, 104039. [Google Scholar] [CrossRef]

- Li, Z.; Lai, J.; Li, Y.; Qiu, J.; Shi, Y.; Li, B.; Fan, F. Ground fissure disasters and mitigation measures for hazardsduring metro system construction in Xi’an, China. Arabian J. Geosci. 2022, 15, 5. [Google Scholar] [CrossRef]

- Liu, X.G.; Ma, E.H.; Liu, J. Deterioration of an industrial reinforced concrete structure exposed to high temperatures and dry-wet cycles. Engineering Failure Analysis. Eng. Fail. Anal. 2022, 135, 106122. [Google Scholar] [CrossRef]

- Shi, W.; Qiu, J.L.; Lai, J.X. Immersion mode and spatiotemporal distribution characteristic of water migration in loess tunnel. Arabian J. Geosci. 2022, 15, 654. [Google Scholar] [CrossRef]

- Wang, X.; Fan, F.; Lai, J. Strength behavior of circular concrete-filled steel tube stub columns under axial compression: A review. Constr. Build. Mater. 2022, 322, 126144. [Google Scholar] [CrossRef]

- Xu, S.; Ma, E.; Lai, J.; Yang, Y.; Liu, H.; Yang, C.; Hu, Q. Diseases Failures Characteristics and Countermeasures of Expressway Tunnel of Water-rich Strata: A Case Study. Eng. Fail. Anal. 2022, 134, 106056. [Google Scholar] [CrossRef]

- Zhang, W.; Lai, T.; Li, Y. Risk Assessment of Water Supply Network Operation Based on ANPFuzzy Comprehensive Evaluation Method. J. Pipeline Syst. Eng. Pract. 2022, 13, 04021068. [Google Scholar] [CrossRef]

- Zhang, G.-L.; Zhang, W.-J.; Li, H.-L.; Cao, W.-Z.; Wang, B.-D.; Guo, W.-S.; Gao, P. Waterproofing behavior of sealing gaskets for circumferential joints in shield tunnels: A full-scale experimental investigation. Tunn. Undergr. Space Technol. 2020, 108, 103682. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, S.; Yu, C.; Ma, E.; Kong, F.; Tang, X.; Gao, X.; Zhang, X.; Lai, J. Damage behaviours of new-to-old concrete interfaces and a damage prediction model of reinforced concrete. Eur. J. Environ. Civ. Eng. 2022, 164, 1981459. [Google Scholar] [CrossRef]

- Niu, F.Y.; Cai, Y.C.; Yang, T. Unfavorable Geology and Mitigation Measures for Water Inrush Hazard during Subsea Tunnel Construction: A Global Review. Water 2022, 14, 1592. [Google Scholar] [CrossRef]

- Xu, S.; Nowamooz, H.; Lai, J. Mechanism, Influencing Factors and Research Methods for Soil Desiccation Cracking: A Review. Eur. J. Environ. Civ. Eng. 2022; in press. [Google Scholar]

- Qin, Y.; Lai, J.; Yang, T.; Zan, W.; Feng, Z.; Liu, T. Failure analysis and countermeasures of a tunnel constructed in loose granular stratum by shallow tunnelling method. Eng. Fail. Anal. 2022, 141, 106667. [Google Scholar] [CrossRef]

- Liu, C.; Liu, Y.; Chen, Y. A state-of-the-practice review of three-dimensional laser scanning technology for tunnel distress monitoring. J. Perform. Constr. Facil. 2022, 152, 107752. [Google Scholar]

- Wang, Z.C.; Cai, Y.C.; Fan, Y.; Lai, J.X.; Kong, X.G. Local buckling characteristic of hollow π-type steel-concrete composite support of loess tunnel in hilly-gully region. Eng. Fail. Anal. 2022, 143, 106669. [Google Scholar]

- Qin, Y.; Qiu, J.; Lai, J.; Liu, F.; Wang, L.; Luo, Y.; Liu, T. Seepage Characteristics in Loess Strata Subjected to Single Point Water Supply. J. Hydrol. 2022, 609, 127611. [Google Scholar] [CrossRef]

- Yan, Y.F.; Huang, Q.B.; Liu, T. Failure analysis and deformation mechanism of segmented utility tunnels crossing ground fissure zones with different intersection angles. Eng. Fail. Anal. 2022, 139, 106456. [Google Scholar] [CrossRef]

- Yan, Y.F.; Huang, Q.B.; Wang, Y.L. Failure analysis of urban open-cut utility tunnel under ground fissures environment in Xi’an, China. Eng. Fail. Anal. 2021, 127, 105529. [Google Scholar] [CrossRef]

- He, S.Y.; Lai, J.X.; Zhang, C.P. Damage behaviors, prediction methods and prevention methods of rockburst in 13 deep traffic tunnels in China. Eng. Fail. Anal. 2021, 121, 105178. [Google Scholar] [CrossRef]

- Fang, Q.; Liu, X.; Fang, Q.; Zeng, K.H.; Zhang, X.D.; Zhou, M.Z.; Du, J.M. Centrifuge modelling of tunnelling below existing twin tunnels with different types of support. Undergr. Space 2022. [Google Scholar] [CrossRef]

- Liu, X.G.; Zhang, W.P.; Gu, X.L.; Ye, Z.W. Assessment of Fatigue Life for Corroded Prestressed Concrete Beams Subjected to High-Cycle Fatigue Loading. J Struct. Eng. 2022; in press. [Google Scholar]

- Fan, H.B.; Liu, T.; Zhang, S.Y.; He, H.J.; Zhu, Z.G.; Zhu, Y.Q.; Gao, X.Q. Effects of Jet Grouting Piles on Loess Tunnel Foundation with Centrifugal Model Tests. Int. J. Geomech. 2022; in press. [Google Scholar]

| Classification | Type | Composition | Ref. |

|---|---|---|---|

| Cement | Portland cement | Major (C3S, C2S, C3A, C4AF); minor (CaSO4) | [35] |

| Sulphoaluminate cement | Major (C4A3, Al2O3, CaO, SiO2, C2S, SO3); minor (C4AF, Fe2O3) | [36] | |

| Industrial residue | Fly ash | Major (SiO2, Al2O3, CaO, Fe2O3, MgO, SO3); minor (Na2O, K2O) | [37] |

| Silica fume | Major (SiO2, Al2O3, Fe2O3); minor (MgO, CaO, Na2O) | [37] |

| Countries | Year | Technical Standards | Note |

|---|---|---|---|

| Japan | 1977 | Technical standard for recycled concrete | First put forward |

| United States | 1982 | ASTMC-33-82 | Removal of restrictions on the application of recycled aggregate in construction projects |

| Germany | 1988 | Guidelines for the application of reclaimed aggregate in concrete | The recycled aggregate is divided into 4 grades |

| South Korea | 2003 | Construction waste regeneration promotion method | The use and obligations of the relevant producers for recycled aggregate are clarified |

| Japan | 2005–2007 | JISA5021, JISA5022, JISA5023 | The country’s construction sector is highly leveraged |

| China | 2012 | Suggestions on the transportation management of earthwork sand and gravel for construction garbage | Detailed rules have been drawn up for the management of construction waste in China |

| Category | SC-RA | OP-RA | DP-RA |

|---|---|---|---|

| Particle size distribution | Continuous grain size | Continuous grain size | Continuous grain size |

| Elongated and flaky particle/% | 6 | 4 | 1 |

| Apparent density/(g/cm3) | 2.432 | 2.468 | 2.475 |

| Packing density/(g/cm3) | 1.355 | 1.389 | 1.407 |

| Porosity/% | 44 | 44 | 43 |

| Content ofimpurtities/% | 0.8 | 0.5 | 0.1 |

| Content of harmful substances | Qualified | Qualified | Qualified |

| Alkali aggregate reaction | Qualified | Qualified | Qualified |

| Content of fine powder/% | 1.9 | 1.1 | 0.8 |

| Content of clay particles/% | 0.6 | 0.2 | 0.1 |

| Water absorption/% | 3.7 | 2.3 | 1.7 |

| Crushing index/% | 18 | 15 | 9 |

| Soundness/% | 8.9 | 5.7 | 3.1 |

| Aggregate type | Class II | Class II | Class I |

| Category | Linear Regression Equation | Correlation of Determination (R2) |

|---|---|---|

| βg-ρ0 | βg = −0.238ρ0 + 604.5 | 0.949 |

| βg-ωa | βg = 540.9ωa + 6.635 | 0.999 |

| βg-Qe | βg = 111.6Qe + 4.900 | 0.696 |

| Oxide Composition (%) | PortlandCSA | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | TiO2 |

| 62.96 | 20.96 | 4.54 | 3.48 | 2.91 | 2.77 | - | ||

| 40.00 | 5.55 | 37.50 | 1.50 | 1.75 | 10.00 | 1.25 | ||

| Chemical Composition (%) | PortlandCSA | C3S | C2S | C3A | C4AF | Gypsum | Ca4Al6O12SO4 | |

| 53.71 | 19.58 | 6.14 | 10.59 | 0.78 | - | |||

| 0.42 | 12.59 | 10.64 | - | 1.07 | 73.37 |

| Composition Material | Equation | Symbol Description | Ref. | |

|---|---|---|---|---|

| Amount of RA | (1) | pc: cement density (kg/m3), pf: mineral admixtures (SF and fly ash, SP, etc.) density (kg/m3), pg: (RA and NA) aggregate of the apparent density (kg/m3), ps: fine aggregate of apparent density (kg/m3), pW: water density is 1000 kg/m3, α: percentage of the air content of concrete, α desirable 1 without using air-entraining agent for RAC, α preferable 2 without air-entraining agent for SF reinforced concrete, mc: cement dosage (kg/m3), mf: mineral admixture dosage (kg/m3), ms: sand dosage (kg/m3), mW: unit water consumption (kg/m3). | (1) [52] | |

| Steel fiber content | (2) | fftm, fm: the flexural strength of the SF RAC and the RAC with the same mix ratio respectively, νf: the volume rate of the SF, lf/df: the slenderness ratio of the SF, ft: the splitting strength of the concrete matrix, R: the volume ratio of the SF, fr: the design value of the tensile strength of the SF, fce: the 28-day splitting strength of the cement. | (2–3) [61,62] (4) [63] | |

| (3) | ||||

| (4) | ||||

| Water/cement ratio | (5) | fcu,0: denotes the design compressive strength (MPa) of the concrete or RA, fce: is the 28-day compressive strength(Mpa) of the cement, C/W: the water/cement | (5–6) [64] (7–11) [66,67] | |

| (6) | ||||

| (7) | ||||

| (8) | ratio, αa: cement strength conversion coefficient, αb: (virtual water-cement ratio) are the regression coefficients for data fitting, = fcu,0, A = αa, and B = αb, w: the water consumption of ordinary concrete, : the dosage of RCA (kg·m−3), wa: the water absorption rate of RCA, which is expressed by decimals, k1 and k2 are constants that depended on the material, a/c: the ratio of aggregate to cement, k3 and k4 are constants that depend on the material used, C: the cement content, k5 and k6 are constants that depend on the material. | |||

| (9) | ||||

| (10) | ||||

| (11) | ||||

| Unit water consumption | (12) | : the total water consumption of RAC, βg: the influence coefficient of the absolute water consumption of RAC that has a linear relationship with the performance indices of RAC (Table 4), mw: the unit water consumption (kg/m3), T: the slunp level of ordinary concrete (mm), K: a constant, which is determined by the type and the maximum particle size of the coarse aggregate, T0 the required slump level of RAC, kg: the coefficient related to the type and particle size of RA, wra: the water absorption rate of RA, wna: the water absorption rate of NA. | (12–13) [79] (14) [83] (15–16) [62] (17–24) [92] | |

| (13) | ||||

| (14) | ||||

| (15) | ||||

| (16) | ||||

| (17) | ||||

| (18) | ||||

| (19) | ||||

| (20) | ||||

| (21) | ||||

| (22) | ||||

| (23) | ||||

| Cement | C/W | (24) | ||

| Sand ratio | (25) | mRA: the quality of RA in the drying state, mACSN: the quality of RA completely stripped by a freeze-thaw cycle (Figure 3), βsN: the sand rate of RA after stripping the | (25) [109] (26–29) [62] | |

| (26) | ||||

| (27) | ||||

| (28) | cement mortar from the NAC and represents the sand ratio of RAC. γ: the coefficient of sand ratio surplus, which is the ratio of fine aggregate sand in RAC to the pore volume of the RA and SF. Vs, Vm, Vra and Vf represent the volumes of sand, NA, RA, and SF, respectively. Pna and Pra represent the porosity of NA and RA respectively. Vc and Vw represent the volume of cement and water in RAC respectively,represents the air content of RAC. ms, mra, and mna represent the quality of sand, NA, and RA, respectively. ρs, ρm, and ρna represent the density of sand, NA, and RA, respectively. | |||

| (29) | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wang, Y.; Gao, X.; Zhang, G.; Liu, H.; Ma, C.; Sun, J.; Lai, J. Review of the Strengthening Methods and Mechanical Properties of Recycled Aggregate Concrete (RAC). Crystals 2022, 12, 1321. https://doi.org/10.3390/cryst12091321

Liu C, Wang Y, Gao X, Zhang G, Liu H, Ma C, Sun J, Lai J. Review of the Strengthening Methods and Mechanical Properties of Recycled Aggregate Concrete (RAC). Crystals. 2022; 12(9):1321. https://doi.org/10.3390/cryst12091321

Chicago/Turabian StyleLiu, Chuanqi, Yanjun Wang, Xuyang Gao, Guanglong Zhang, Heng Liu, Chong Ma, Jilin Sun, and Jinxing Lai. 2022. "Review of the Strengthening Methods and Mechanical Properties of Recycled Aggregate Concrete (RAC)" Crystals 12, no. 9: 1321. https://doi.org/10.3390/cryst12091321

APA StyleLiu, C., Wang, Y., Gao, X., Zhang, G., Liu, H., Ma, C., Sun, J., & Lai, J. (2022). Review of the Strengthening Methods and Mechanical Properties of Recycled Aggregate Concrete (RAC). Crystals, 12(9), 1321. https://doi.org/10.3390/cryst12091321