Fatigue and Fracture Behaviors of Short Carbon Fiber Reinforced Squeeze Cast AZ91 at 20 °C and 250 °C

Abstract

:1. Introduction

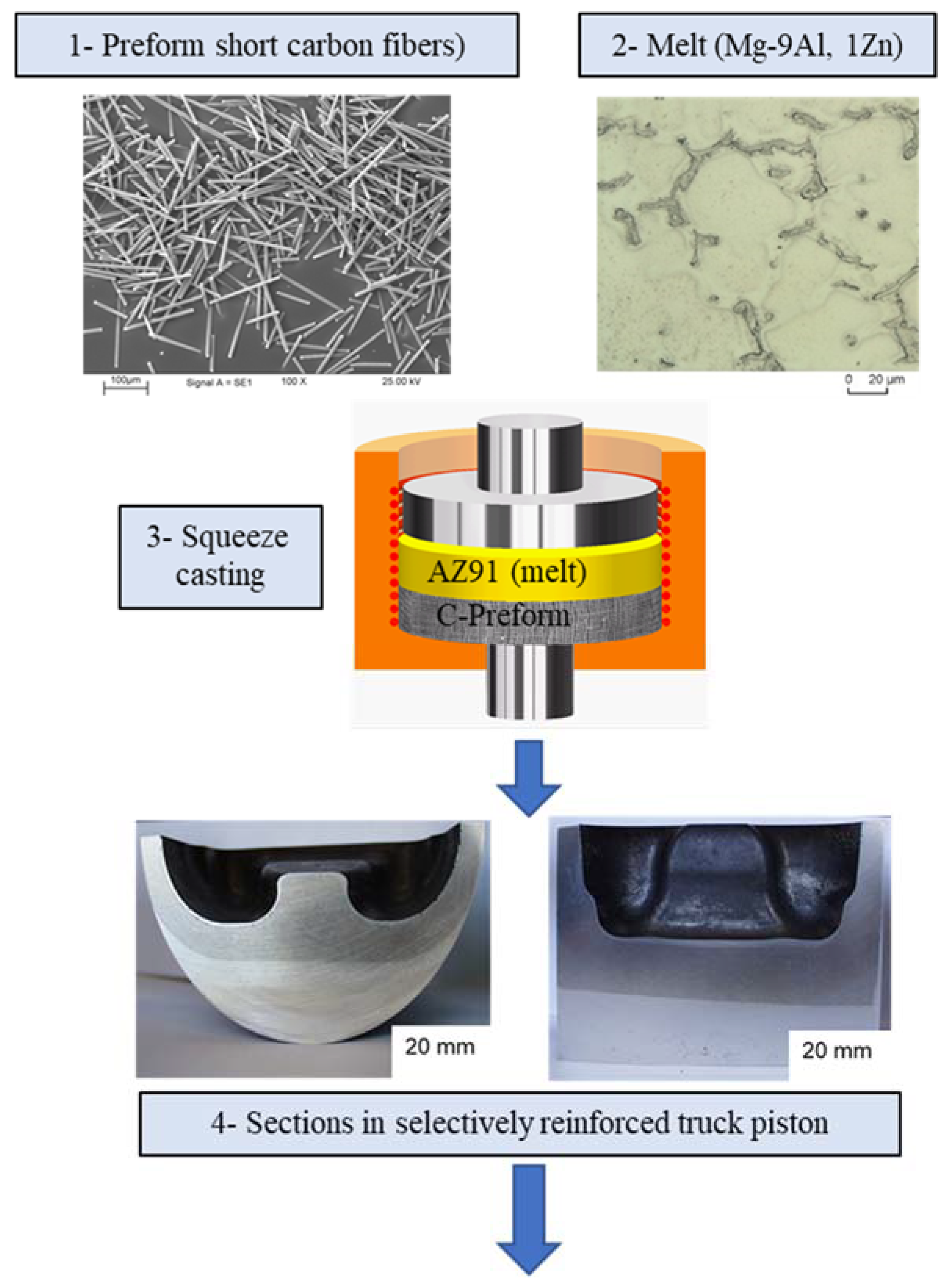

2. Experimental Details

3. Results and Discussion

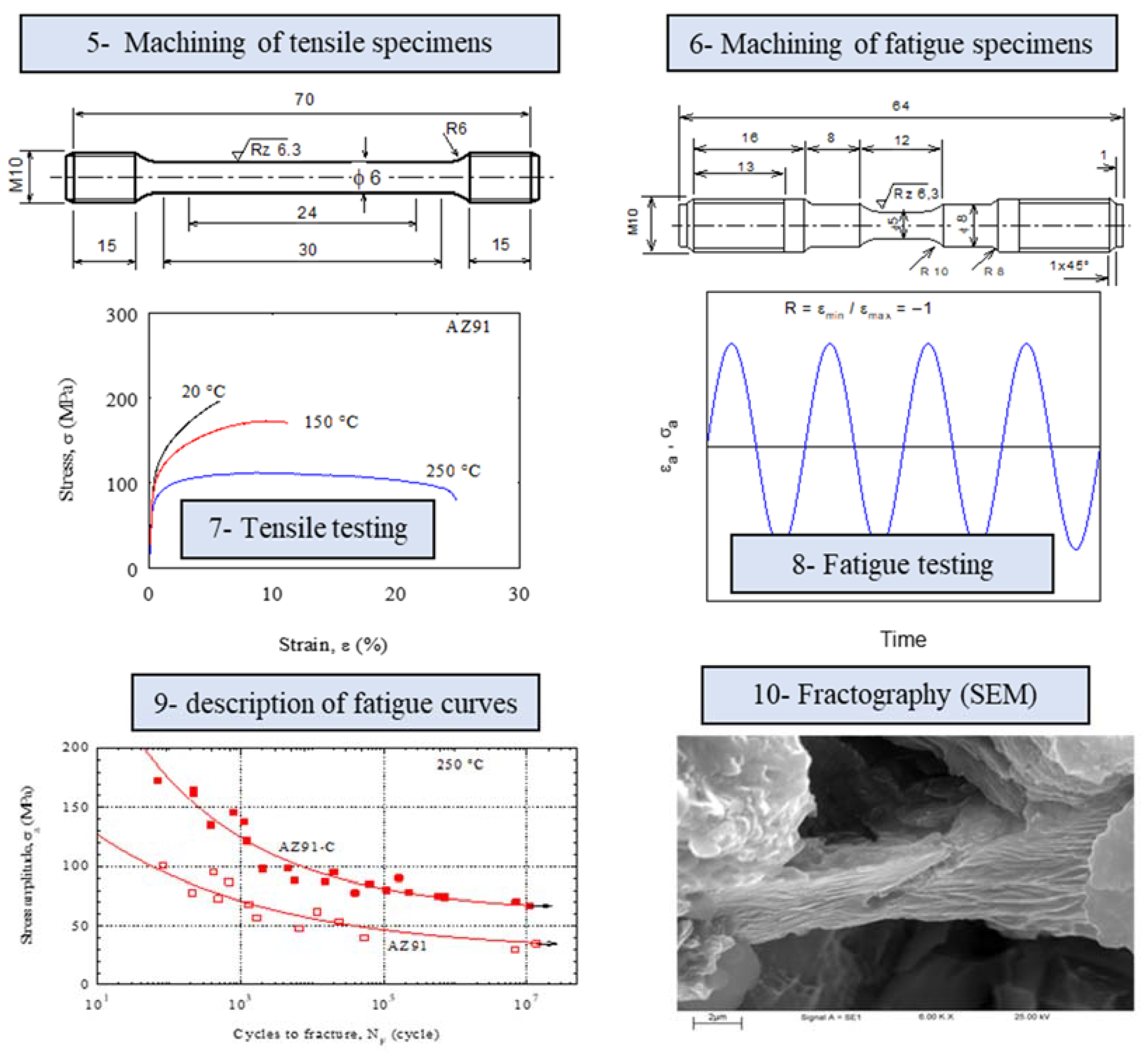

3.1. Microstructure and Hardness Measurement Results

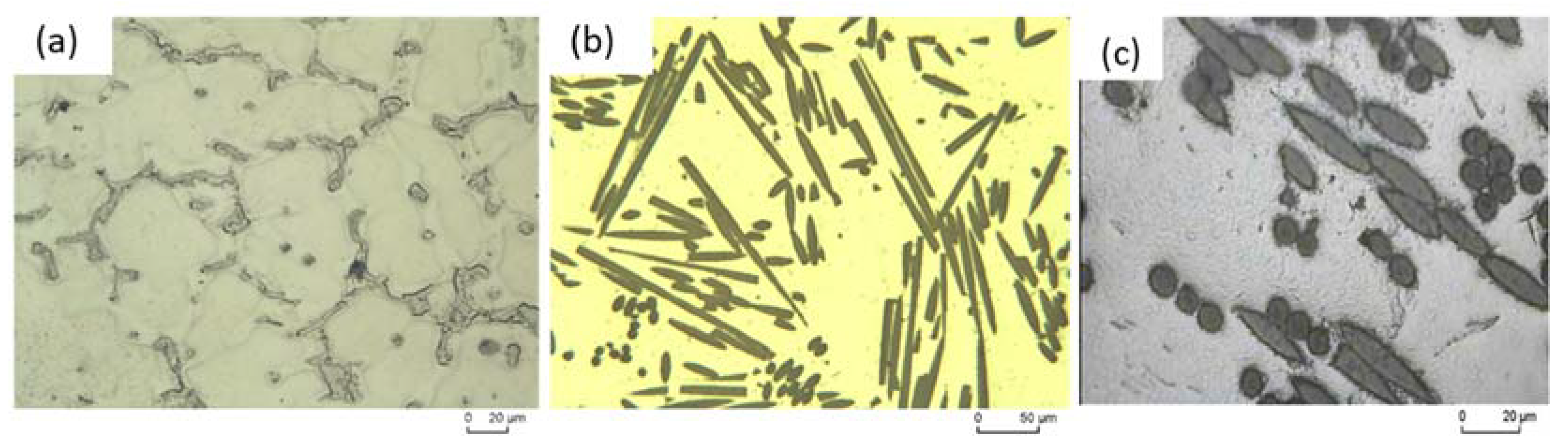

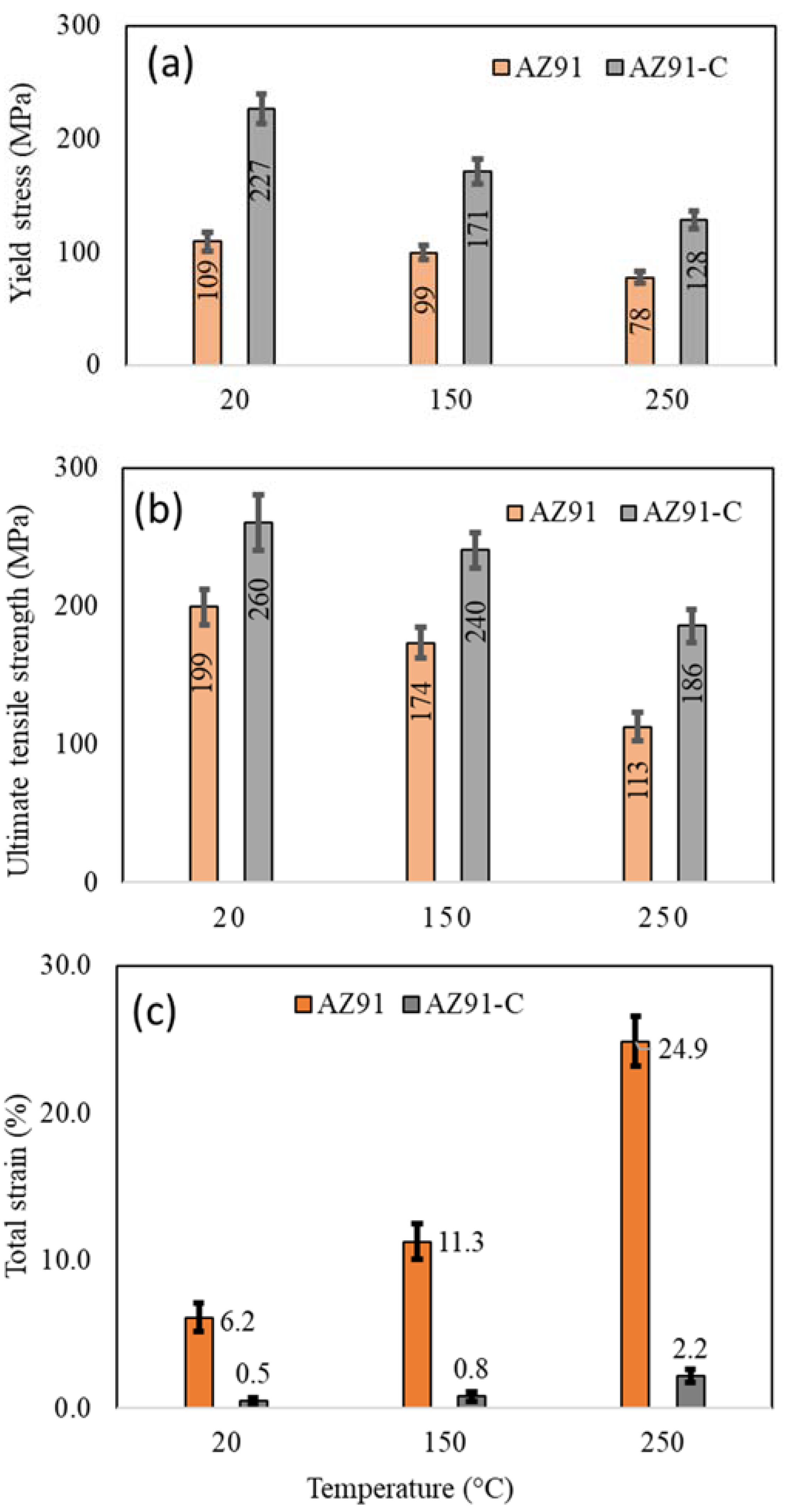

3.2. Results of the Tensile Test

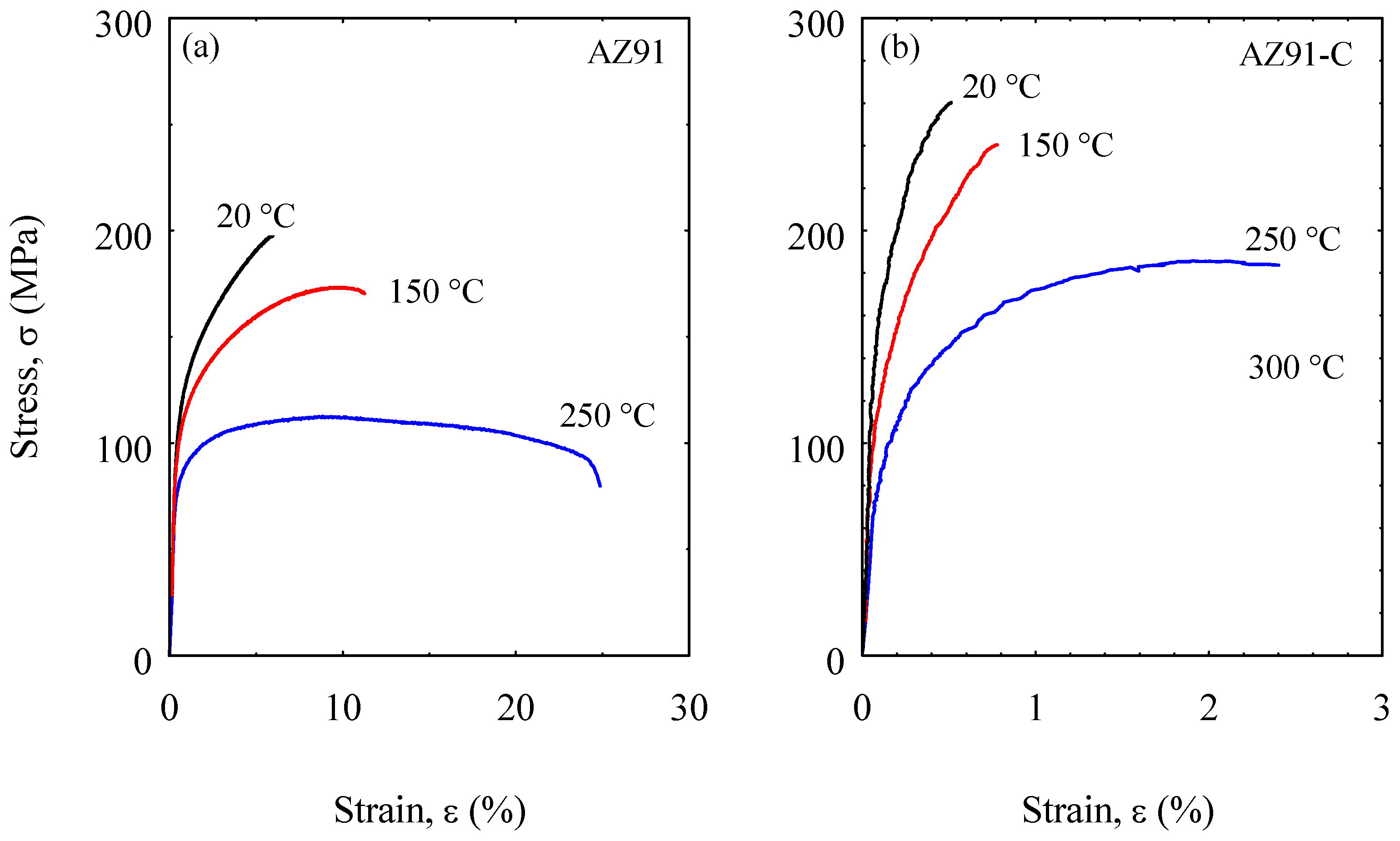

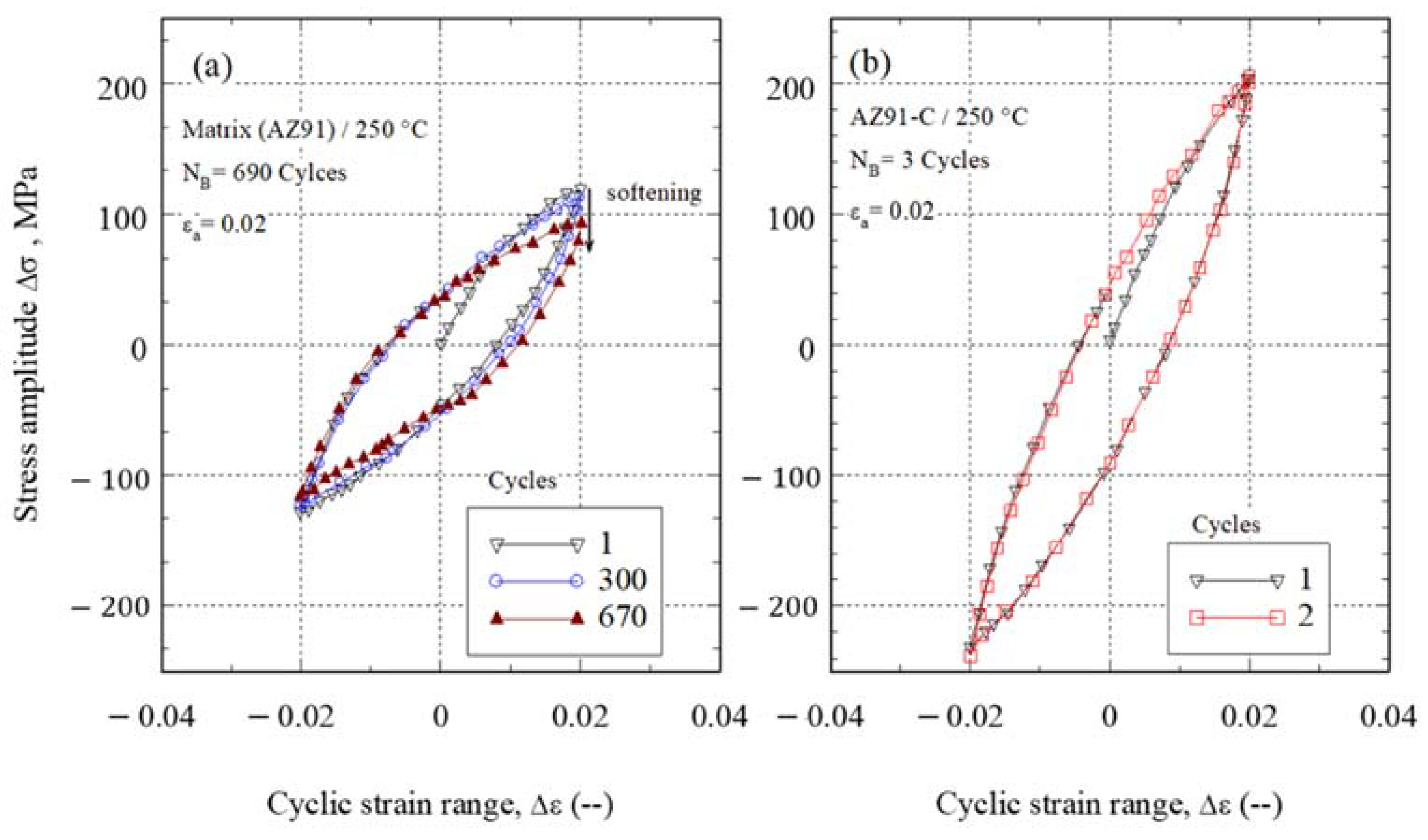

3.3. Fatigue Testing Results

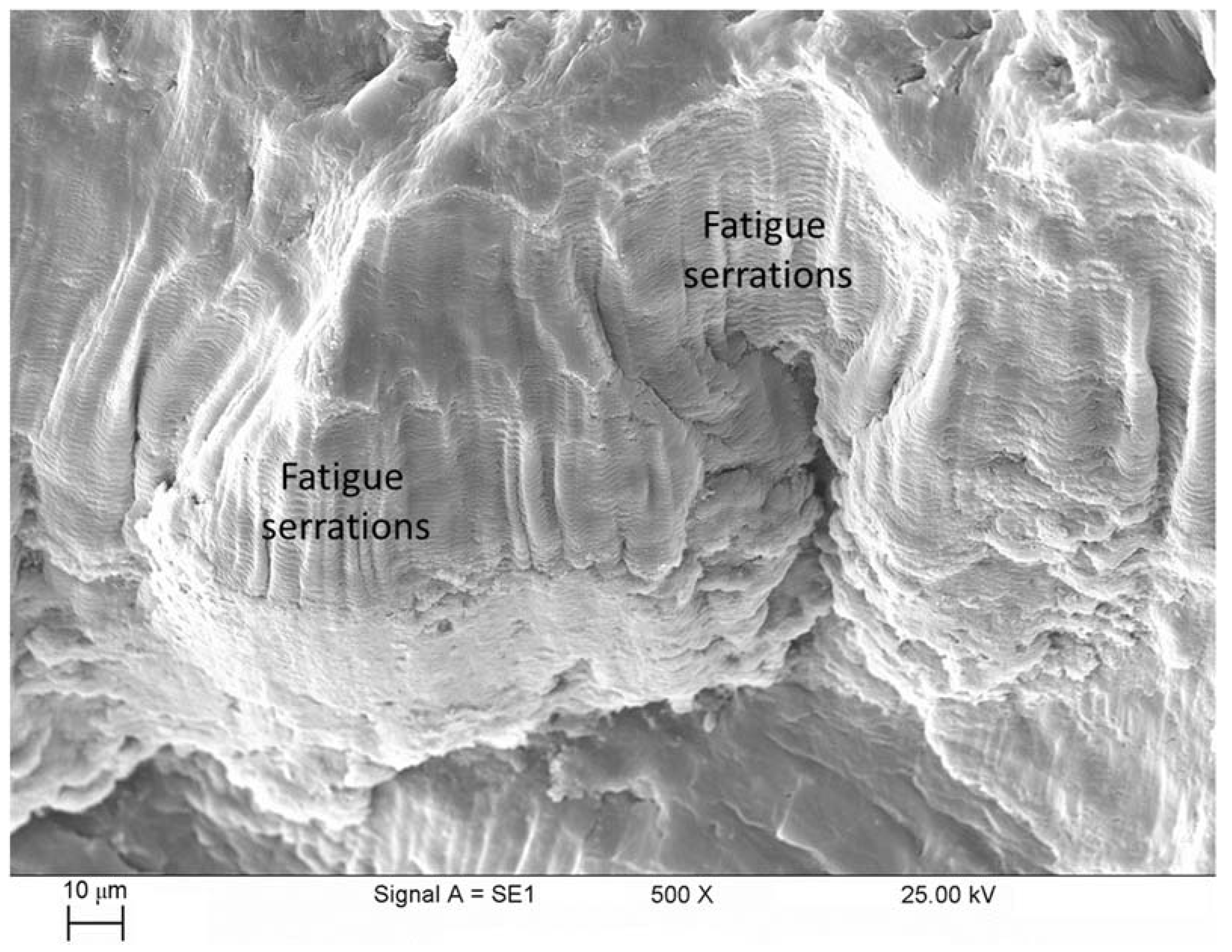

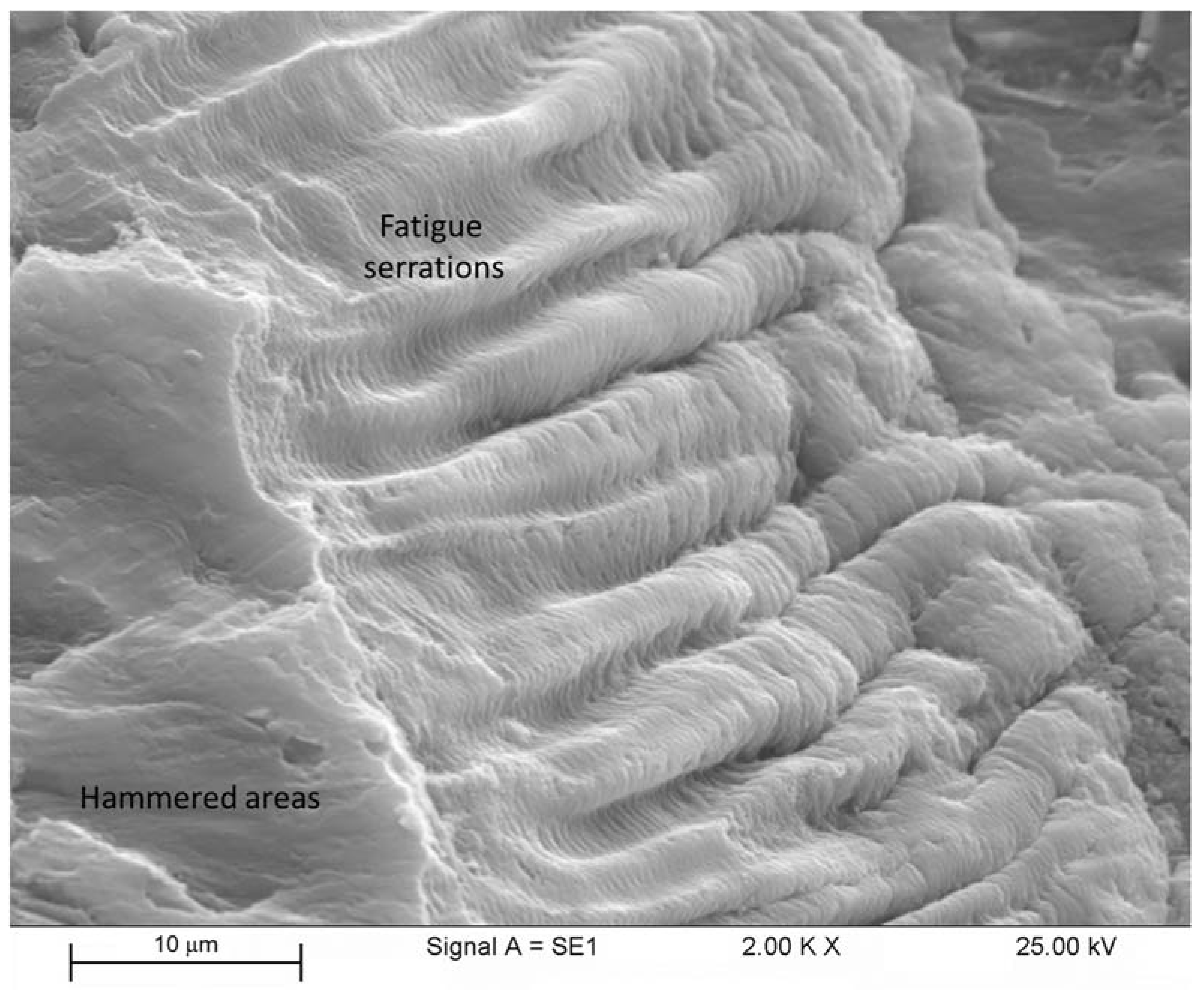

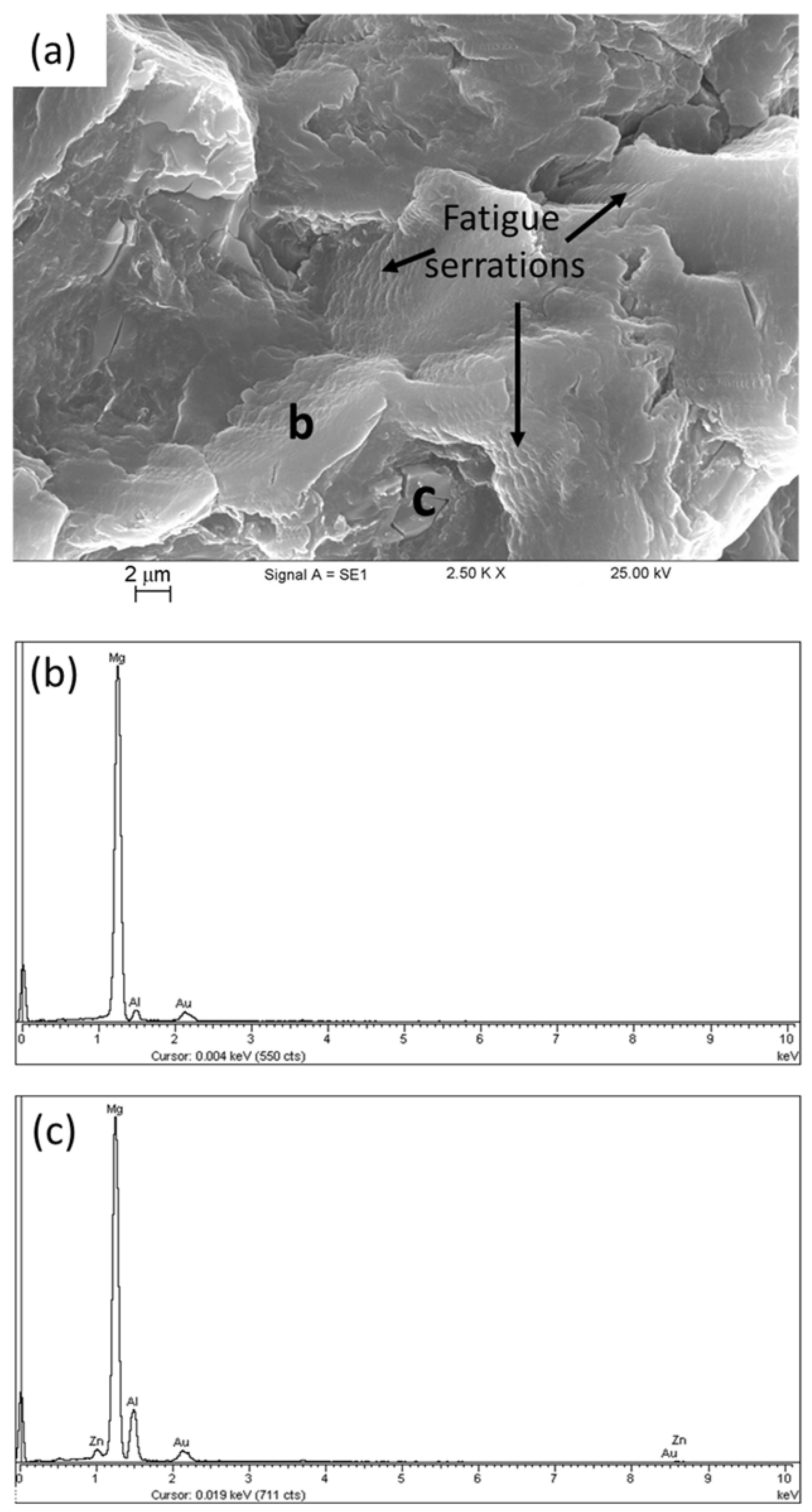

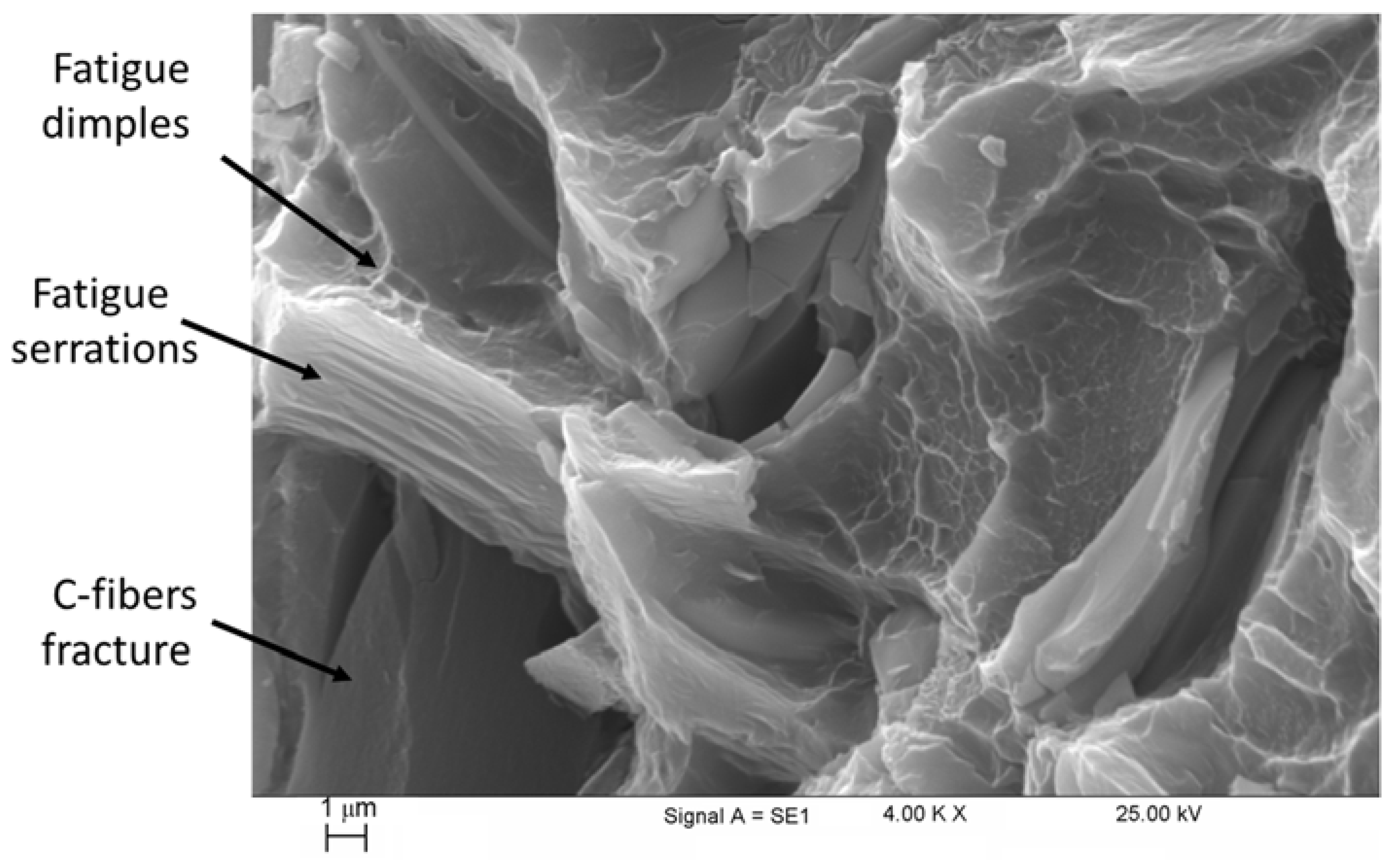

3.4. Fractography (SEM)

4. Conclusions

- (1)

- The hardness value of the unreinforced AZ91 increased from 69.2 ± 2 Hv to 111.53 ± 4 Hv for the reinforced AZ91-C;

- (2)

- A clear improvement in yield stress was achieved at room temperature (108%); this improvement changed to 73% and 64% at 150 °C and 250 °C, respectively. A relatively lower improvement in the ultimate tensile strength was noticed, where the increase in strength ranged between 30% and 64%;

- (3)

- The fatigue strength at HCF range (over 107 cycles) at 250 °C for the AZ91 alloy was 37 MPa, while that for the reinforced AZ91-C reached 55 MPa. The reinforced AZ91-C displayed higher fatigue strength (71.2 MPa) at room temperature;

- (4)

- The hysteresis loops for the strain-controlled fatigue test of AZ91 at 250 °C showed limited material softening;

- (5)

- Diffused fatigue serrations with mixed ductile/brittle modes were observed on unreinforced AZ91’s fracture surface;

- (6)

- Fiber fracture and fiber decohesion were noticed on the composite’s fracture surface both under tensile and fatigue loads. The presence of fatigue serrations and regions exhibiting restricted dimples was detected in metallic magnesium zones.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Joost, W.J.; Krajewski, P.E. Towards Magnesium Alloys for High-Volume Automotive Applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Demirci, E.; Yildiz, A.R. An Investigation of the Crash Performance of Magnesium, Aluminum and Advanced High Strength Steels and Different Cross-Sections for Vehicle Thin-Walled Energy Absorbers. Mater. Test. 2018, 60, 661–668. [Google Scholar] [CrossRef]

- Kumar, D.S.; Sasanka, C.T.; Ravindra, K.; Suman, K.N.S. Magnesium and Its Alloys in Automotive Applications—A Review. Am. J. Mater. Sci. Technol. 2015, 4, 12–30. [Google Scholar] [CrossRef]

- Kulekci, M.K. Magnesium and Its Alloys Applications in Automotive Industry. Int. J. Adv. Manuf. Technol. 2008, 39, 851–865. [Google Scholar] [CrossRef]

- Tan, J.; Ramakrishna, S. Applications of Magnesium and Its Alloys: A Review. Appl. Sci. 2021, 11, 6861. [Google Scholar] [CrossRef]

- Chalisgaonkar, R. Insight in Applications, Manufacturing and Corrosion Behaviour of Magnesium and Its Alloys—A Review. Mater. Today Proc. 2019, 26, 1060–1071. [Google Scholar] [CrossRef]

- Ghaderi, S.H.; Mori, A.; Hokamoto, K. Analysis of Explosively Welded Aluminum-AZ31 Magnesium Alloy Joints. Mater. Trans. 2008, 49, 1142–1147. [Google Scholar] [CrossRef]

- Cao, X.; Jahazi, M.; Immarigeon, J.P.; Wallace, W. A Review of Laser Welding Techniques for Magnesium Alloys. J. Mater. Process. Technol. 2006, 171, 188–204. [Google Scholar] [CrossRef]

- Prasad, S.V.S.; Prasad, S.B.; Verma, K.; Mishra, R.K.; Kumar, V.; Singh, S. The Role and Significance of Magnesium in Modern Day Research-A Review. J. Magnes. Alloy 2022, 10, 1–61. [Google Scholar] [CrossRef]

- Zhai, W.; Bai, L.; Zhou, R.; Fan, X.; Kang, G.; Liu, Y.; Zhou, K. Recent Progress on Wear-Resistant Materials: Designs, Properties, and Applications. Adv. Sci. 2021, 8, 2003739. [Google Scholar] [CrossRef]

- Friedrich, H.; Schumann, S. Research for a “New Age of Magnesium” in the Automotive Industry. J. Mater. Process. Technol. 2001, 117, 276–281. [Google Scholar] [CrossRef]

- Ataya, S.; El-Magd, E. Modeling the Creep Behavior of Mg Alloys with and without Short-Fiber Reinforcement. Comput. Mater. Sci. 2007, 39, 155–159. [Google Scholar] [CrossRef]

- Srinivasan, A.; Ajithkumar, K.K.; Swaminathan, J.; Pillai, U.T.S.; Pai, B.C. Creep Behavior of AZ91 Magnesium Alloy. Procedia Eng. 2013, 55, 109–113. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Liu, Z.H.; Chen, J. Investigation of Uniaxial Low-Cycle Fatigue Failure Behavior of Hot-Rolled AZ91 Magnesium Alloy. Int. J. Fatigue 2013, 48, 122–132. [Google Scholar] [CrossRef]

- Azadi, M.; Farrahi, G.H.; Winter, G.; Eichlseder, W. Fatigue Lifetime of AZ91 Magnesium Alloy Subjected to Cyclic Thermal and Mechanical Loadings. Mater. Des. 2014, 53, 639–644. [Google Scholar] [CrossRef]

- Nascimento, L.; Yi, S.; Bohlen, J.; Fuskova, L.; Letzig, D.; Kainer, K.U. High Cycle Fatigue Behaviour of Magnesium Alloys. Procedia Eng. 2010, 2, 743–750. [Google Scholar] [CrossRef]

- Alsaleh, N.A.; Ataya, S.; Latief, F.H.; Ahmed, M.M.Z.; Ataya, A.; Abdul-Latif, A. LCF and HCF of Short Carbon Fibers Reinforced AE42 Mg Alloy. Materials 2023, 16, 3686. [Google Scholar] [CrossRef]

- Fintová, S.; Trško, L.; Chlup, Z.; Pastorek, F.; Kajánek, D.; Kunz, L. Fatigue Crack Initiation Change of Cast Az91 Magnesium Alloy from Low to Very High Cycle Fatigue Region. Materials 2021, 14, 6245. [Google Scholar] [CrossRef]

- Chen, L.J.; Shen, J.; Wu, W.; Li, F.; Wang, Y.; Liu, Z. Low-Cycle Fatigue Behavior of Magnesium Alloy AZ91. Mater. Sci. Forum 2005, 488–489, 725–728. [Google Scholar] [CrossRef]

- Rettberg, L.H.; Jordon, J.B.; Horstemeyer, M.F.; Jones, J.W. Low-Cycle Fatigue Behavior of Die-Cast Mg Alloys AZ91 and AM60. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2012, 43, 2260–2274. [Google Scholar] [CrossRef]

- Wolf, B.; Fleck, C.; Eifler, D. Characterization of the Fatigue Behaviour of the Magnesium Alloy AZ91D by Means of Mechanical Hysteresis and Temperature Measurements. Int. J. Fatigue 2004, 26, 1357–1363. [Google Scholar] [CrossRef]

- Gu, X.N.; Zhou, W.R.; Zheng, Y.F.; Cheng, Y.; Wei, S.C.; Zhong, S.P.; Xi, T.F.; Chen, L.J. Corrosion Fatigue Behaviors of Two Biomedical Mg Alloys—AZ91D and WE43—In Simulated Body Fluid. Acta Biomater. 2010, 6, 4605–4613. [Google Scholar] [CrossRef] [PubMed]

- Fintová, S.; Kunz, L. Fatigue Properties of Magnesium Alloy AZ91 Processed by Severe Plastic Deformation. J. Mech. Behav. Biomed. Mater. 2015, 42, 219–228. [Google Scholar] [CrossRef] [PubMed]

- Ataya, S.; El-Magd, E. Quasi-Static Behavior of Mg-Alloys with and without Short-Fiber Reinforcement. Theor. Appl. Fract. Mech. 2007, 47, 102–112. [Google Scholar] [CrossRef]

- Ataya, S.; Alsaleh, N.A.; El-Sayed Seleman, M.M. Strength and Wear Behavior of Mg Alloy AE42 Reinforced with Carbon Short Fibers. Acta Metall. Sin. (English Lett.) 2019, 32, 31–40. [Google Scholar] [CrossRef]

- Aravindan, S.; Rao, P.V.; Ponappa, K. Evaluation of Physical and Mechanical Properties of AZ91D/SiC Composites by Two Step Stir Casting Process. J. Magnes. Alloy 2015, 3, 52–62. [Google Scholar] [CrossRef]

- Lü, L.; Lai, M.O.; Gupta, M.; Chua, B.W.; Osman, A. Improvement of Microstructure and Mechanical Properties of AZ91/SiC Composite by Mechanical Alloying. J. Mater. Sci. 2000, 35, 5553–5561. [Google Scholar] [CrossRef]

- Yuan, Q.H.; Zeng, X.S.; Liu, Y.; Luo, L.; Wu, J.B.; Wang, Y.C.; Zhou, G.H. Microstructure and Mechanical Properties of AZ91 Alloy Reinforced by Carbon Nanotubes Coated with MgO. Carbon 2016, 96, 843–855. [Google Scholar] [CrossRef]

- Khandelwal, A.; Mani, K.; Srivastava, N.; Gupta, R.; Chaudhari, G.P. Mechanical Behavior of AZ31/Al2O3 Magnesium Alloy Nanocomposites Prepared Using Ultrasound Assisted Stir Casting. Compos. Part B Eng. 2017, 123, 64–73. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A. Effects of Tungsten Disulfide on Microstructure and Mechanical Properties of AZ91 Magnesium Alloy Manufactured by Stir Casting. J. Alloys Compd. 2020, 817, 153321. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Wu, K.; Wang, L.Y.; Huang, Y.D. Evolutions of Microstructure and Mechanical Properties for SiCp/AZ91 Composites with Different Particle Contents during Extrusion. Mater. Sci. Eng. A 2015, 636, 138–147. [Google Scholar] [CrossRef]

- Kumar, A.; Kumar, S.; Mukhopadhyay, N.K.; Yadav, A.; Sinha, D.K. Effect of TiC Reinforcement on Mechanical and Wear Properties of AZ91 Matrix Composites. Int. J. Met. 2022, 16, 2128–2143. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Xu, F.; Yang, S.; Li, B.; Li, Y.; Huang, Z.; Zheng, Q. An Investigation on Grain Refinement Mechanism of TiB2 Particulate Reinforced AZ91 Composites and Its Effect on Mechanical Properties. J. Alloys Compd. 2019, 780, 237–244. [Google Scholar] [CrossRef]

- Vaidya, A.R.; Lewandowski, J.J. Effects of SiCp Size and Volume Fraction on the High Cycle Fatigue Behavior of AZ91D Magnesium Alloy Composites. Mater. Sci. Eng. A 1996, 220, 85–92. [Google Scholar] [CrossRef]

- Llorca, N.; Bloyce, A.; Yue, T.M. Fatigue Behaviour of Short Alumina Fibre Reinforced AZ91 Magnesium Alloy Metal Matrix Composite. Mater. Sci. Eng. A 1991, 135, 247–252. [Google Scholar] [CrossRef]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Soliman, A.M.; Alsaleh, N.A.; Habba, M.I.A. Wear Characteristics of Mg Alloy AZ91 Reinforced with Oriented Short Carbon Fibers. Materials 2022, 15, 4841. [Google Scholar] [CrossRef]

- Ataya, S.; El-Sayed Seleman, M.M.; Latief, F.H.; Ahmed, M.M.Z.; Hajlaoui, K.; Elshaghoul, Y.G.Y.; Habba, M.I.A. Microstructure and Mechanical Properties of AZ91 Rein-Forced with High Volume Fraction of Oriented Short Carbon Fibers. Materials 2022, 15, 4818. [Google Scholar] [CrossRef]

- Shastri, H.; Mondal, A.K.; Dutta, K.; Dieringa, H.; Kumar, S. Microstructural Correlation with Tensile and Creep Properties of AZ91 Alloy in Three Casting Techniques. J. Manuf. Process. 2020, 57, 566–573. [Google Scholar] [CrossRef]

- Alrasheedi, N.H.; Ataya, S.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z. Tensile Deformation and Fracture of Unreinforced AZ91 and Reinforced AZ91-C at Temperatures up to 300 °C. Materials 2023, 16, 4785. [Google Scholar] [CrossRef]

- Chen, B.; Fu, J.; Zhou, J.; Ma, Y.; Qi, L. Influence of Microstructures on Mechanical Properties of the Csf/Mg Composite Fabricated by Liquid-Solid Extrusion Following Vacuum Pressure Infiltration. J. Alloys Compd. 2023, 935, 168083. [Google Scholar] [CrossRef]

- Hou, L.G.; Wu, R.Z.; Wang, X.D.; Zhang, J.H.; Zhang, M.L.; Dong, A.P.; Sun, B.D. Microstructure, Mechanical Properties and Thermal Conductivity of the Short Carbon Fiber Reinforced Magnesium Matrix Composites. J. Alloys Compd. 2017, 695, 2820–2826. [Google Scholar] [CrossRef]

- Xu, H.; Yang, Z.; Hu, M.; Ji, Z. Effect of Short Carbon Fiber Content on SCFs/AZ31 Composite Microstructure and Mechanical Properties. Results Phys. 2020, 17, 103074. [Google Scholar] [CrossRef]

- Wang, M.; Jin, P.; Wang, J. Hot Deformation and Processing Maps of 7005 Aluminum Alloy. High Temp. Mater. Process. 2014, 33, 369–375. [Google Scholar] [CrossRef]

- Mondal, A.K.; Blawert, C.; Kumar, S. Corrosion Behaviour of Creep-Resistant AE42 Magnesium Alloy-Based Hybrid Composites Developed for Powertrain Applications. Mater. Corros. 2015, 66, 1150–1158. [Google Scholar] [CrossRef]

- WANG, J.; SHI, B.; YANG, Y. Hot Compression Behavior and Processing Map of Cast Mg-4Al-2Sn-Y-Nd Alloy. Trans. Nonferrous Met. Soc. China 2014, 24, 626–631. [Google Scholar] [CrossRef]

- Fan, Y.; Deng, K.; Wang, C.; Nie, K.; Shi, Q. Work Hardening and Softening Behavior of Mg–Zn–Ca Alloy Influenced by Deformable Ti Particles. Mater. Sci. Eng. A 2022, 833, 142336. [Google Scholar] [CrossRef]

- Murashkin, M.; Sabirov, I.; Prosvirnin, D.; Ovid’ko, I.; Terentiev, V.; Valiev, R.; Dobatkin, S. Fatigue Behavior of an Ultrafine-Grained Al-Mg-Si Alloy Processed by High-Pressure Torsion. Metals 2015, 5, 578–590. [Google Scholar] [CrossRef]

- Mokhtarishirazabad, M.; Azadi, M.; Hossein Farrahi, G.; Winter, G.; Eichlseder, W. Improvement of High Temperature Fatigue Lifetime in AZ91 Magnesium Alloy by Heat Treatment. Mater. Sci. Eng. A 2013, 588, 357–365. [Google Scholar] [CrossRef]

- McCormigk, P.G. A Model for the Portevin-Le Chatelier Effect in Substitutional Alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Yazdani, S.; Vitry, V. Using Molecular Dynamic Simulation to Understand the Deformation Mechanism in Cu, Ni, and Equimolar Cu-Ni Polycrystalline Alloys. Alloys 2023, 2, 77–88. [Google Scholar] [CrossRef]

- Cottrell, A.H.; Dexter, D.L. Dislocations and Plastic Flow in Crystals. Am. J. Phys. 1954, 22, 242–243. [Google Scholar] [CrossRef]

- LIU, M.; JIANG, T.; WANG, J.; LIU, Q.; WU, Z.; YU, Y.; SKARET, P.C.; ROVEN, H.J. Aging Behavior and Mechanical Properties of 6013 Aluminum Alloy Processed by Severe Plastic Deformation. Trans. Nonferrous Met. Soc. China 2014, 24, 3858–3865. [Google Scholar] [CrossRef]

- Cuniberti, A.; Tolley, A.; Riglos, M.V.C.; Giovachini, R. Influence of Natural Aging on the Precipitation Hardening of an AlMgSi Alloy. Mater. Sci. Eng. A 2010, 527, 5307–5311. [Google Scholar] [CrossRef]

- Yazdani, S.; Mesbah, M.; Vitry, V. Molecular Dynamics Simulation of the Interaction between Dislocations and Iron–Vanadium Precipitates in Alpha Iron: Effect of Chemical Composition. Crystals 2023, 13, 1247. [Google Scholar] [CrossRef]

- Wang, W.H.; Wu, D.; Chen, R.S.; Zhang, X.N. Effect of Solute Atom Concentration and Precipitates on Serrated Flow in Mg-3Nd-Zn Alloy. J. Mater. Sci. Technol. 2018, 34, 1236–1242. [Google Scholar] [CrossRef]

- Daroonparvar, M.; Khan, M.U.F.; Saadeh, Y.; Kay, C.M.; Kasar, A.K.; Kumar, P.; Esteves, L.; Misra, M.; Menezes, P.; Kalvala, P.R.; et al. Modification of Surface Hardness, Wear Resistance and Corrosion Resistance of Cold Spray Al Coated AZ31B Mg Alloy Using Cold Spray Double Layered Ta/Ti Coating in 3.5 wt % NaCl Solution. Corros. Sci. 2020, 176, 109029. [Google Scholar] [CrossRef]

- Kim, H.-K.; Lee, Y.-I.; Chung, C.-S. Fatigue Properties of a Fine-Grained Magnesium Alloy Produced by Equal Channel Angular Pressing. Scr. Mater. 2005, 52, 473–477. [Google Scholar] [CrossRef]

- CANDAN, S.; CANDAN, E. Comparative Study on Corrosion Behaviors of Mg-Al-Zn Alloys. Trans. Nonferrous Met. Soc. China 2018, 28, 642–650. [Google Scholar] [CrossRef]

- Cheng, K.; Sun, J.; Xu, H.; Wang, J.; Zhou, J.; Tang, S.; Wang, X.; Zhang, L.; Du, Y. On the Temperature-Dependent Diffusion Growth of ϕ-Mg5Al2Zn2 Ternary Intermetallic Compound in the Mg-Al-Zn System. J. Mater. Sci. 2021, 56, 3488–3497. [Google Scholar] [CrossRef]

- Alam, M.E.; Hamouda, A.M.S.; Nguyen, Q.B.; Gupta, M. Improving Microstructural and Mechanical Response of New AZ41 and AZ51 Magnesium Alloys through Simultaneous Addition of Nano-Sized Al2O3 Particulates and Ca. J. Alloys Compd. 2013, 574, 565–572. [Google Scholar] [CrossRef]

- Zhang, G.D.; Chen, R. Effect of the Interfacial Bonding Strength on the Mechanical Properties of Metal Matrix Composites. Compos. Interfaces 1993, 1, 337–355. [Google Scholar] [CrossRef]

- Su, X.F.; Chen, H.R.; Kennedy, D.; Williams, F.W. Effects of Interphase Strength on the Damage Modes and Mechanical Behaviour of Metal–Matrix Composites. Compos. Part A Appl. Sci. Manuf. 1999, 30, 257–266. [Google Scholar] [CrossRef]

- Vidal-Sétif, M.H.; Lancin, M.; Marhic, C.; Valle, R.; Raviart, J.-L.; Daux, J.-C.; Rabinovitch, M. On the Role of Brittle Interfacial Phases on the Mechanical Properties of Carbon Fibre Reinforced Al-Based Matrix Composites. Mater. Sci. Eng. A 1999, 272, 321–333. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, D.; Wu, G.; Li, B.; Li, P. Effect of Mg Content on the Mechanical Properties and Microstructure of Grf/Al Composite. Mater. Sci. Eng. A 2008, 497, 31–36. [Google Scholar] [CrossRef]

| Yield Stress | Ultimate Tensile Strength | |||||

|---|---|---|---|---|---|---|

| Temperature | AZ91 (MPa) | AZ91-C (MPa) | Increase (%) | AZ91 (MPa) | AZ91-C (MPa) | Increase (%) |

| 20 °C | 109 | 227 | 107.89 | 199 | 260 | 30.61 |

| 150 °C | 99 | 171 | 72.21 | 174 | 240 | 38.58 |

| 250 °C | 78 | 128 | 65.16 | 113 | 186 | 64.92 |

| Specimen | No. of Experiments | T (°C) | a | b | c | Max. Dev. | Standard Error, r2 | Fatigue Strength (MPa) at N = 107 |

|---|---|---|---|---|---|---|---|---|

| AZ91 | 16 | 250 | 100 | 2.72 | 37 | 0.976 | 0.961 | 37 |

| AZ91-C | 16 | 20 | 150 | 3.42 | 68.7 | 8.16 | 0989 | 71.2 |

| 17 | 250 | 128 | 3.90 | 50 | 3.79 | 0.995 | 55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrasheedi, N.H.; El-Sayed Seleman, M.M.; Ahmed, M.M.Z.; Ataya, S. Fatigue and Fracture Behaviors of Short Carbon Fiber Reinforced Squeeze Cast AZ91 at 20 °C and 250 °C. Crystals 2023, 13, 1469. https://doi.org/10.3390/cryst13101469

Alrasheedi NH, El-Sayed Seleman MM, Ahmed MMZ, Ataya S. Fatigue and Fracture Behaviors of Short Carbon Fiber Reinforced Squeeze Cast AZ91 at 20 °C and 250 °C. Crystals. 2023; 13(10):1469. https://doi.org/10.3390/cryst13101469

Chicago/Turabian StyleAlrasheedi, Nashmi H., Mohamed M. El-Sayed Seleman, Mohamed M. Z. Ahmed, and Sabbah Ataya. 2023. "Fatigue and Fracture Behaviors of Short Carbon Fiber Reinforced Squeeze Cast AZ91 at 20 °C and 250 °C" Crystals 13, no. 10: 1469. https://doi.org/10.3390/cryst13101469

APA StyleAlrasheedi, N. H., El-Sayed Seleman, M. M., Ahmed, M. M. Z., & Ataya, S. (2023). Fatigue and Fracture Behaviors of Short Carbon Fiber Reinforced Squeeze Cast AZ91 at 20 °C and 250 °C. Crystals, 13(10), 1469. https://doi.org/10.3390/cryst13101469