Controlled Cavity Length and Wide-Spectrum Lasing in FAMACsPb(BrI)3 Ternary Perovskite Vertical-Cavity Surface-Emitting Lasers with an All-Dielectric Dielectric Bragg Reflector

Abstract

:1. Introduction

2. Materials and Methods

2.1. DBR Design and Fabrication

2.2. Synthesis Film

2.2.1. FAMACsPb(Br0.1I0.9)3 Thin Film

2.2.2. MAPbI3 Thin Film

2.3. Cavity Construction

2.4. Photoluminescence (PL) Measurement

3. Results

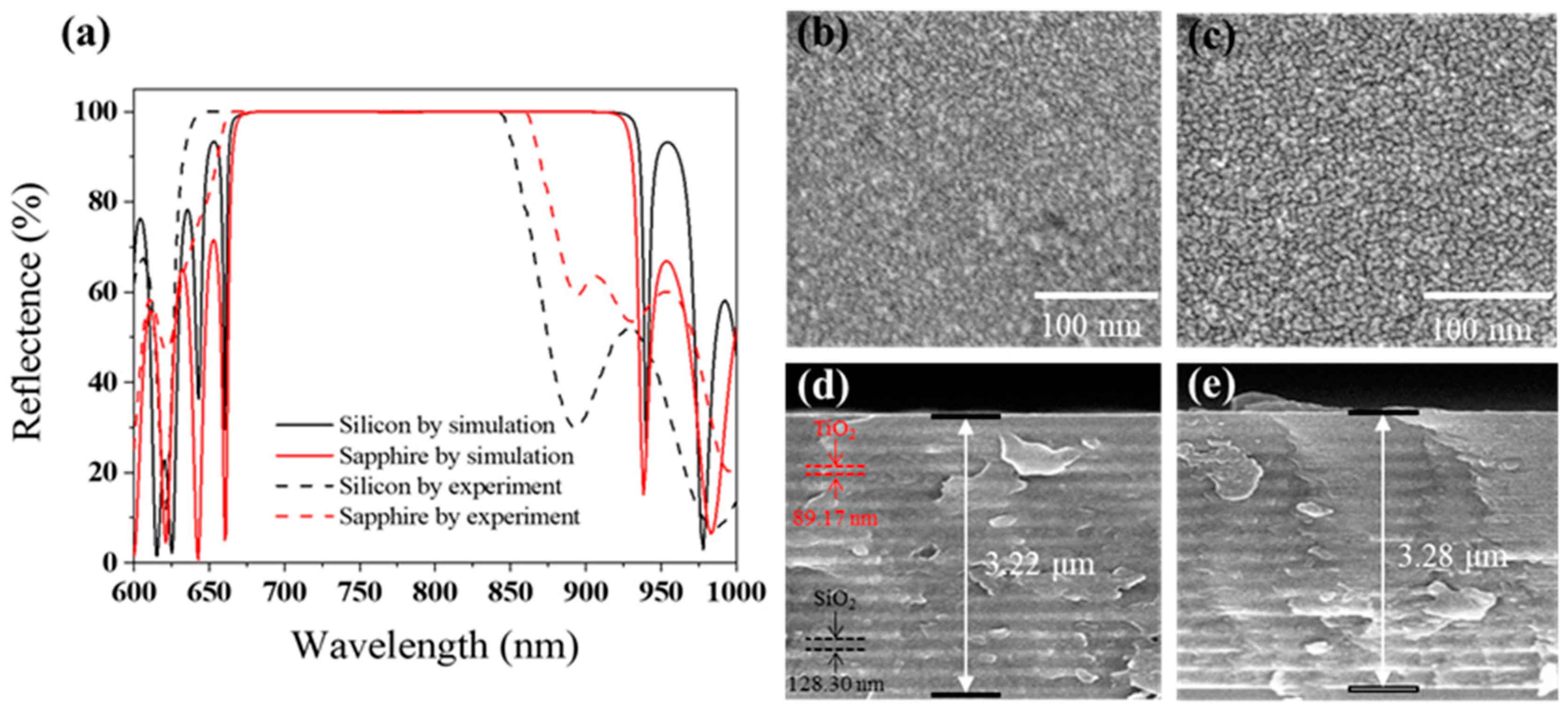

3.1. Characteristics of DBR

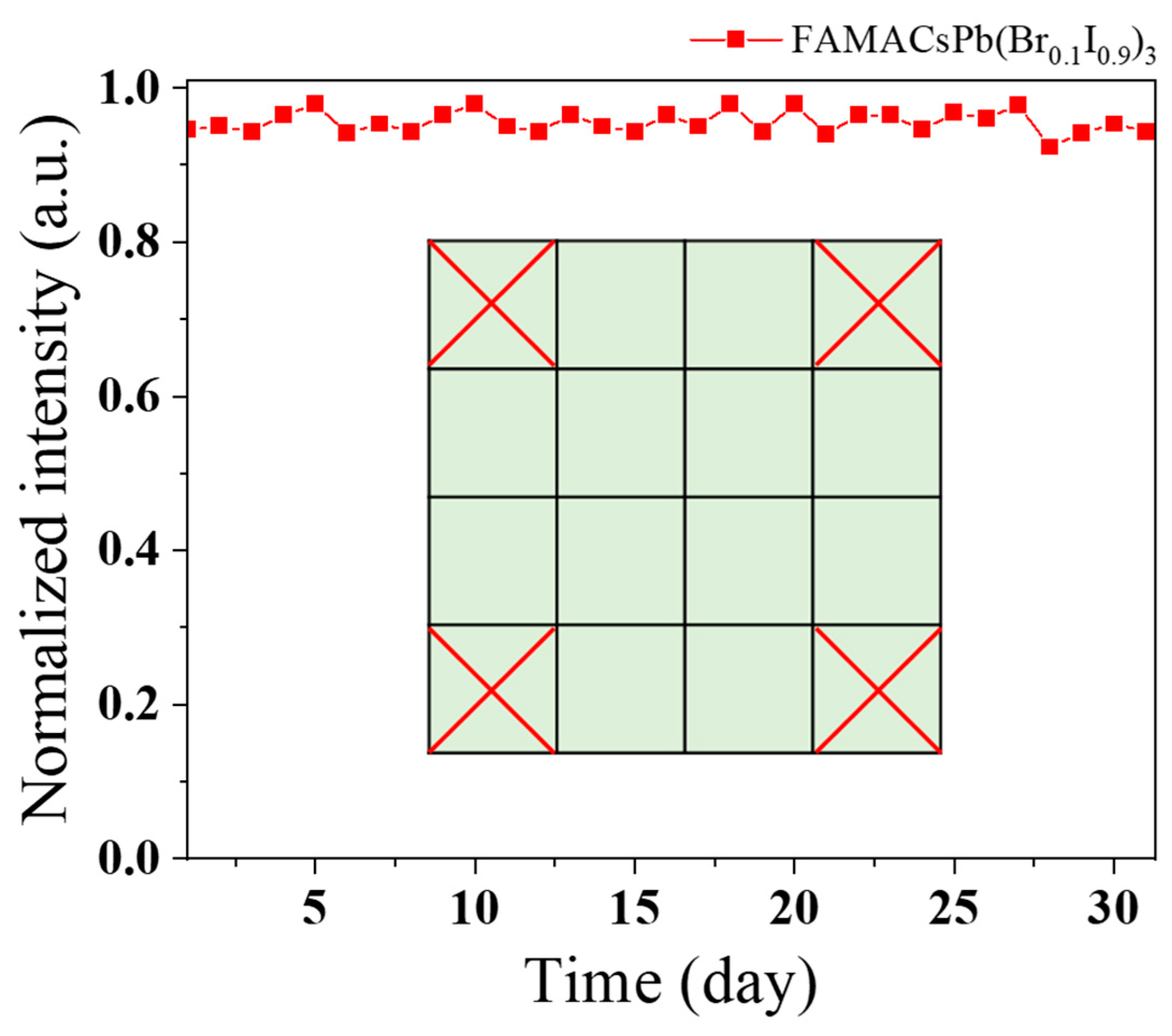

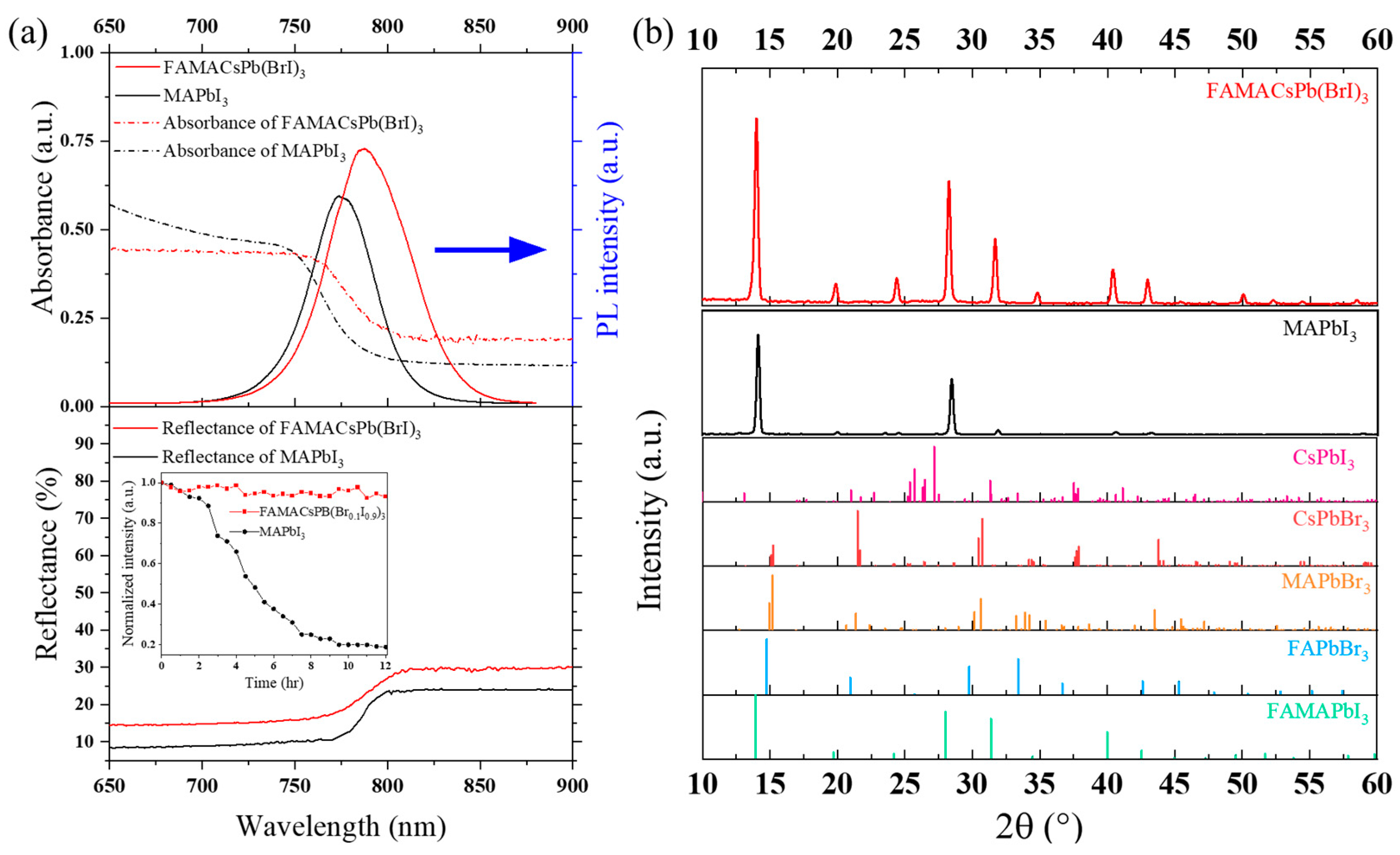

3.2. Properties of FAMACsPb(Br0.1I0.9)3

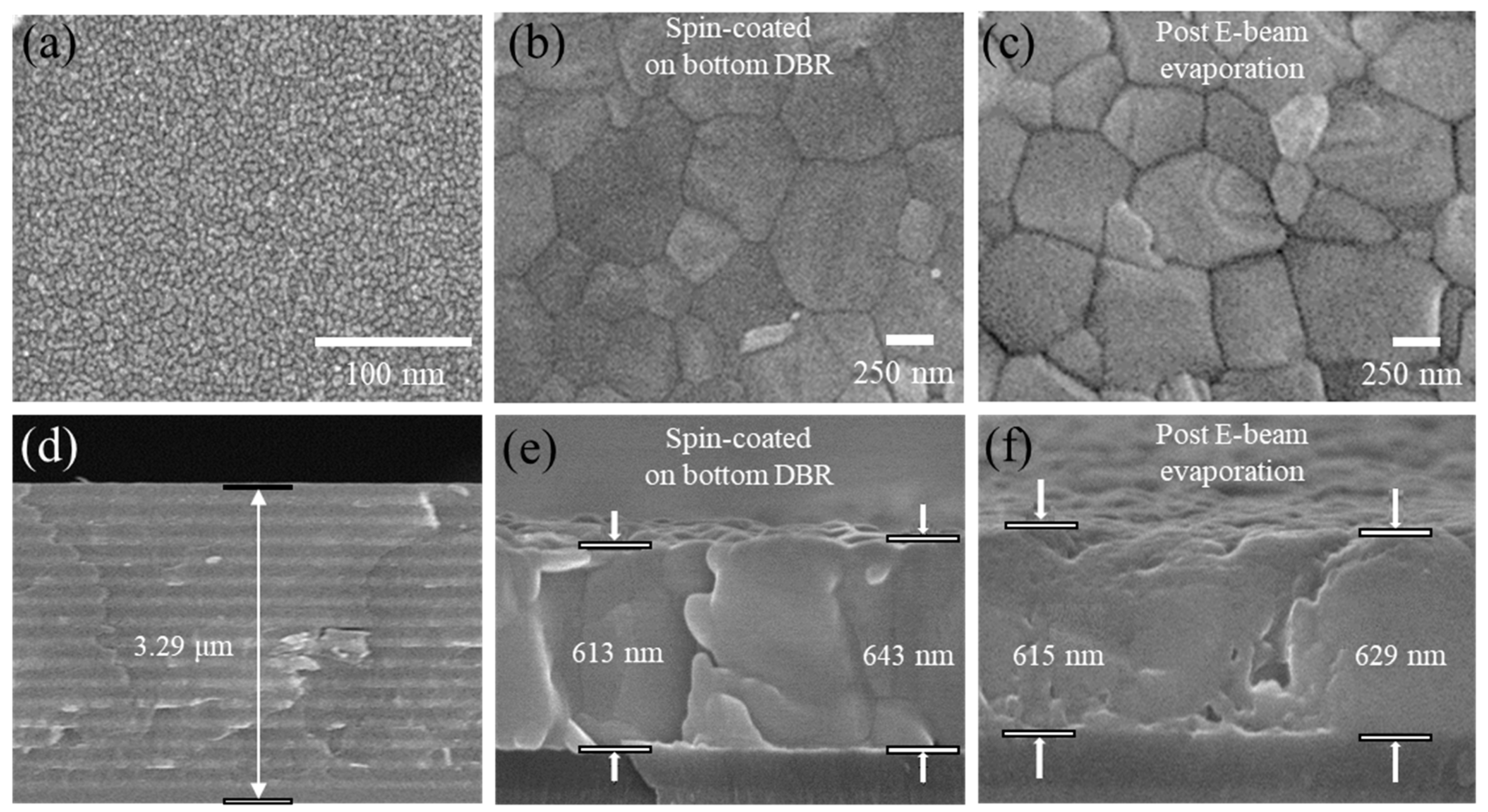

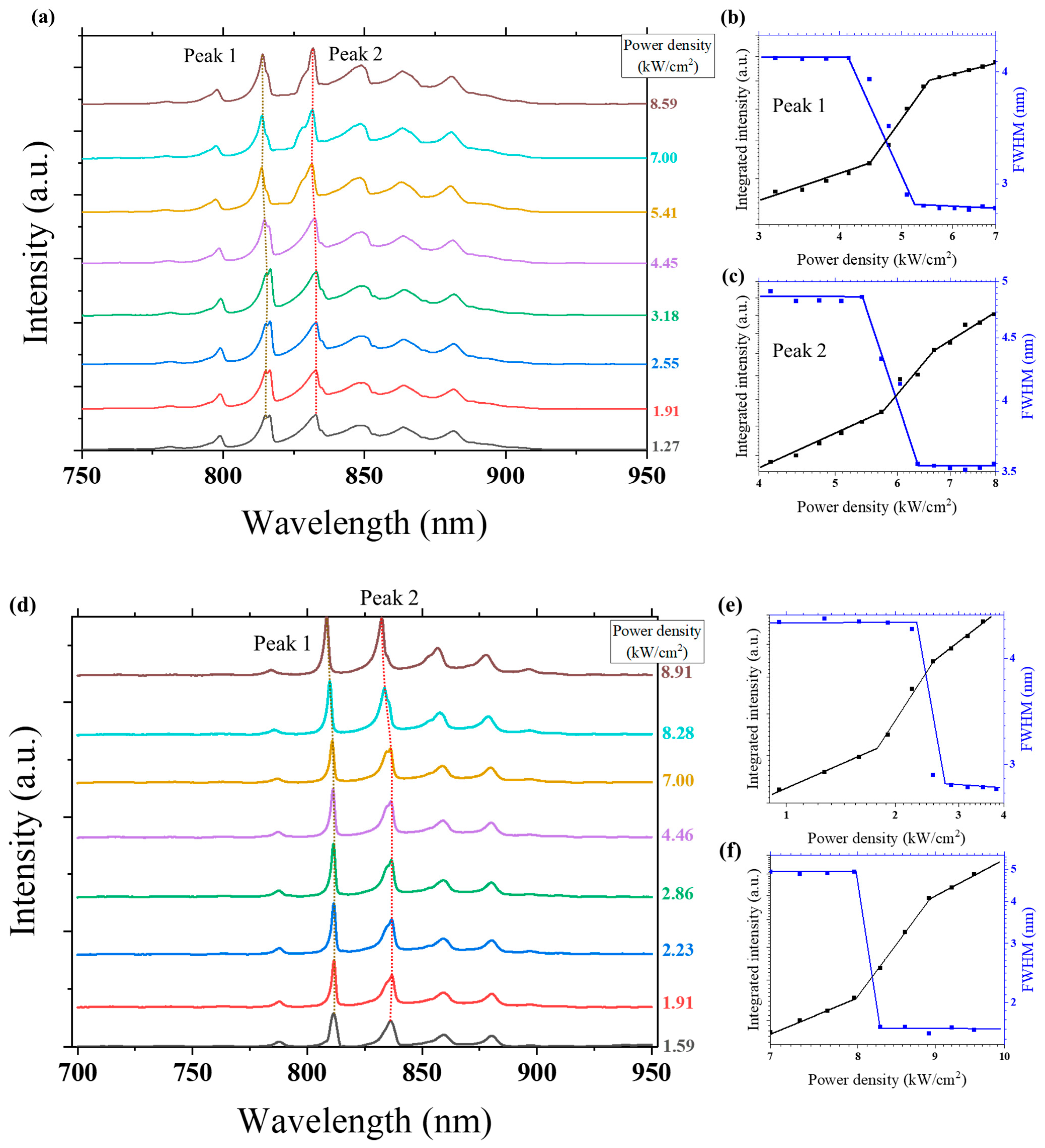

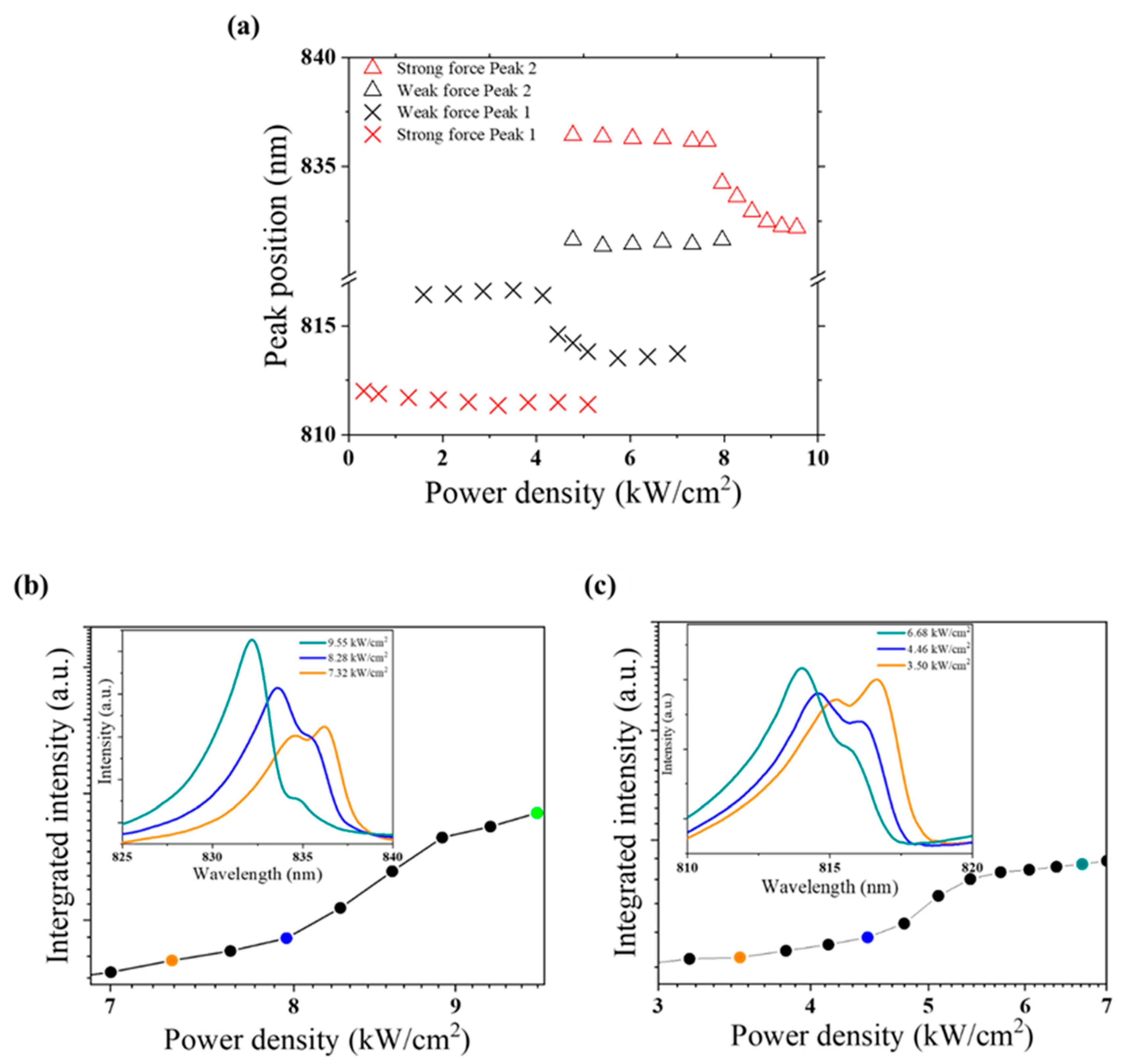

3.3. Properties of Cavity3

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Alhilal, A.; Finley, B.; Braud, T.; Su, D.; Hui, P. Distributed vehicular computing at the dawn of 5G: A survey. arXiv 2020, arXiv:2001.07077. [Google Scholar]

- Alimi, I.A.; Teixeira, A.L.; Monteiro, P.P. Toward an efficient C-RAN optical fronthaul for the future networks: A tutorial on technologies, requirements, challenges, and solutions. IEEE Commun. Surv. Tutor. 2017, 20, 708–769. [Google Scholar] [CrossRef]

- Jung, P.; Baier, P.W.; Steil, A. Advantages of CDMA and spread spectrum techniques over FDMA and TDMA in cellular mobile radio applications. IEEE Trans. Veh. Technol. 1993, 42, 357–364. [Google Scholar] [CrossRef]

- Turin, G.L. Introduction to spread-spectrum antimultipath techniques and their application to urban digital radio. Proc. IEEE 1980, 68, 328–353. [Google Scholar] [CrossRef]

- Pickholtz, R.; Schilling, D.; Milstein, L. Theory of spread-spectrum communications-a tutorial. IEEE Trans. Commun. 1982, 30, 855–884. [Google Scholar] [CrossRef]

- Sacher, W.; Green, W.; Assefa, S.; Barwicz, T.; Pan, H.; Shank, S.; Vlasov, Y.; Poon, J. Coupling modulation of microrings at rates beyond the linewidth limit. Opt. Express 2013, 21, 9722–9733. [Google Scholar] [CrossRef]

- Dedieu, H.; Kennedy, M.P.; Hasler, M. Chaos shift keying: Modulation and demodulation of a chaotic carrier using self-synchronizing Chua's circuits. IEEE Trans. Circuits Syst. II Analog Digit. Signal Process. 1993, 40, 634–642. [Google Scholar] [CrossRef]

- Cuomo, K.M.; Oppenheim, A.V.; Strogatz, S.H. Synchronization of Lorenz-based chaotic circuits with applications to communications. IEEE Trans. Circuits Syst. II Analog Digit. Signal Process. 1993, 40, 626–633. [Google Scholar] [CrossRef]

- Wang, W.-Q.; So, H.C.; Farina, A. An overview on time/frequency modulated array processing. IEEE J. Sel. Top. Signal Process. 2016, 11, 228–246. [Google Scholar] [CrossRef]

- Wan, Y.; Zhang, S.; Norman, J.C.; Kennedy, M.; He, W.; Tong, Y.; Shang, C.; He, J.J.; Tsang, H.K.; Gossard, A.C. Directly modulated single-mode tunable quantum dot lasers at 1.3 µm. Laser Photonics Rev. 2020, 14, 1900348. [Google Scholar] [CrossRef]

- Dagli, N. Wide-bandwidth lasers and modulators for RF photonics. IEEE Trans. Microw. Theory Tech. 1999, 47, 1151–1171. [Google Scholar] [CrossRef]

- Tang, J.; Lane, P.; Shore, K.A. High-speed transmission of adaptively modulated optical OFDM signals over multimode fibers using directly modulated DFBs. J. Light. Technol. 2006, 24, 429. [Google Scholar] [CrossRef]

- Bjork, G.; Yamamoto, Y. Analysis of semiconductor microcavity lasers using rate equations. IEEE J. Quantum Electron. 1991, 27, 2386–2396. [Google Scholar] [CrossRef]

- Duarte, F.J. Tunable Laser Optics; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Jiang, X.F.; Zou, C.L.; Wang, L.; Gong, Q.; Xiao, Y.F. Whispering-gallery microcavities with unidirectional laser emission. Laser Photonics Rev. 2016, 10, 40–61. [Google Scholar] [CrossRef]

- He, L.; Özdemir, Ş.K.; Yang, L. Whispering gallery microcavity lasers. Laser Photonics Rev. 2013, 7, 60–82. [Google Scholar] [CrossRef]

- Mi, Y.; Liu, Z.; Shang, Q.; Niu, X.; Shi, J.; Zhang, S.; Chen, J.; Du, W.; Wu, Z.; Wang, R. Fabry–Pérot Oscillation and Room Temperature Lasing in Perovskite Cube-Corner Pyramid Cavities. Small 2018, 14, 1703136. [Google Scholar] [CrossRef] [PubMed]

- Ma, R.M.; Oulton, R.F.; Sorger, V.J.; Zhang, X. Plasmon lasers: Coherent light source at molecular scales. Laser Photonics Rev. 2013, 7, 1–21. [Google Scholar] [CrossRef]

- Pauzauskie, P.J.; Sirbuly, D.J.; Yang, P. Semiconductor nanowire ring resonator laser. Phys. Rev. Lett. 2006, 96, 143903. [Google Scholar] [CrossRef]

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef]

- Leijtens, T.; Eperon, G.E.; Pathak, S.; Abate, A.; Lee, M.M.; Snaith, H.J. Overcoming ultraviolet light instability of sensitized TiO2 with meso-superstructured organometal tri-halide perovskite solar cells. Nat. Commun. 2013, 4, 2885. [Google Scholar] [CrossRef]

- Tan, Z.-K.; Moghaddam, R.S.; Lai, M.L.; Docampo, P.; Higler, R.; Deschler, F.; Price, M.; Sadhanala, A.; Pazos, L.M.; Credgington, D. Bright light-emitting diodes based on organometal halide perovskite. Nat. Nanotechnol. 2014, 9, 687–692. [Google Scholar] [CrossRef]

- Manser, J.S.; Kamat, P.V. Band filling with free charge carriers in organometal halide perovskites. Nat. Photonics 2014, 8, 737–743. [Google Scholar] [CrossRef]

- Yu, Z.; Sun, L. Recent progress on hole-transporting materials for emerging organometal halide perovskite solar cells. Adv. Energy Mater. 2015, 5, 1500213. [Google Scholar] [CrossRef]

- Dong, C.; Wang, Z.-K.; Liao, L.-S. Progress of triple cation organometal halide perovskite solar cells. Energy Technol. 2020, 8, 1900804. [Google Scholar] [CrossRef]

- Zhu, H.; Fu, Y.; Meng, F.; Wu, X.; Gong, Z.; Ding, Q.; Gustafsson, M.V.; Trinh, M.T.; Jin, S.; Zhu, X. Lead halide perovskite nanowire lasers with low lasing thresholds and high quality factors. Nat. Mater. 2015, 14, 636–642. [Google Scholar] [CrossRef]

- Frost, J.M.; Butler, K.T.; Brivio, F.; Hendon, C.H.; Van Schilfgaarde, M.; Walsh, A. Atomistic origins of high-performance in hybrid halide perovskite solar cells. Nano Lett. 2014, 14, 2584–2590. [Google Scholar] [CrossRef]

- De Wolf, S.; Holovsky, J.; Moon, S.-J.; Loper, P.; Niesen, B.; Ledinsky, M.; Haug, F.-J.; Yum, J.-H.; Ballif, C. Organometallic halide perovskites: Sharp optical absorption edge and its relation to photovoltaic performance. J. Phys. Chem. Lett. 2014, 5, 1035–1039. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.C.; Li, X.; Song, C.; Wan, L.; Usman, K.; Fang, J. Recent advance in solution-processed organic interlayers for high-performance planar perovskite solar cells. Adv. Sci. 2018, 5, 1800159. [Google Scholar] [CrossRef]

- Deng, Y.; Peng, E.; Shao, Y.; Xiao, Z.; Dong, Q.; Huang, J. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers. Energy Environ. Sci. 2015, 8, 1544–1550. [Google Scholar] [CrossRef]

- Kim, J.; Lee, S.-H.; Lee, J.H.; Hong, K.-H. The role of intrinsic defects in methylammonium lead iodide perovskite. J. Phys. Chem. Lett. 2014, 5, 1312–1317. [Google Scholar] [CrossRef]

- Becker, M.; Wark, M. Controlling the crystallization and grain size of sequentially deposited planar perovskite films via the permittivity of the conversion solution. Org. Electron. 2017, 50, 87–93. [Google Scholar] [CrossRef]

- Gratzel, M. The rise of highly efficient and stable perovskite solar cells. Acc. Chem. Res. 2017, 50, 487–491. [Google Scholar] [CrossRef] [PubMed]

- Jang, D.M.; Park, K.; Kim, D.H.; Park, J.; Shojaei, F.; Kang, H.S.; Ahn, J.-P.; Lee, J.W.; Song, J.K. Reversible halide exchange reaction of organometal trihalide perovskite colloidal nanocrystals for full-range band gap tuning. Nano Lett. 2015, 15, 5191–5199. [Google Scholar] [CrossRef] [PubMed]

- Xing, G.; Mathews, N.; Lim, S.S.; Yantara, N.; Liu, X.; Sabba, D.; Grätzel, M.; Mhaisalkar, S.; Sum, T.C. Low-temperature solution-processed wavelength-tunable perovskites for lasing. Nat. Mater. 2014, 13, 476–480. [Google Scholar] [CrossRef]

- Ava, T.T.; Al Mamun, A.; Marsillac, S.; Namkoong, G. A review: Thermal stability of methylammonium lead halide based perovskite solar cells. Appl. Sci. 2019, 9, 188. [Google Scholar] [CrossRef]

- Saliba, M.; Matsui, T.; Seo, J.-Y.; Domanski, K.; Correa-Baena, J.-P.; Nazeeruddin, M.K.; Zakeeruddin, S.M.; Tress, W.; Abate, A.; Hagfeldt, A. Cesium-containing triple cation perovskite solar cells: Improved stability, reproducibility and high efficiency. Energy Environ. Sci. 2016, 9, 1989–1997. [Google Scholar] [CrossRef]

- Smecca, E.; Numata, Y.; Deretzis, I.; Pellegrino, G.; Boninelli, S.; Miyasaka, T.; La Magna, A.; Alberti, A. Stability of solution-processed MAPbI 3 and FAPbI 3 layers. Phys. Chem. Chem. Phys. 2016, 18, 13413–13422. [Google Scholar] [CrossRef]

- Niu, G.; Li, W.; Li, J.; Liang, X.; Wang, L. Enhancement of thermal stability for perovskite solar cells through cesium doping. RSC Adv. 2017, 7, 17473–17479. [Google Scholar] [CrossRef]

- Singh, T.; Miyasaka, T. Stabilizing the efficiency beyond 20% with a mixed cation perovskite solar cell fabricated in ambient air under controlled humidity. Adv. Energy Mater. 2018, 8, 1700677. [Google Scholar] [CrossRef]

- Yang, W.; Su, R.; Luo, D.; Hu, Q.; Zhang, F.; Xu, Z.; Wang, Z.; Tang, J.; Lv, Z.; Yang, X. Surface modification induced by perovskite quantum dots for triple-cation perovskite solar cells. Nano Energy 2020, 67, 104189. [Google Scholar] [CrossRef]

- Available online: https://www.nrel.gov/index.html (accessed on 21 March 2023).

- Zhang, Q.; Shang, Q.; Su, R.; Do, T.T.H.; Xiong, Q. Halide perovskite semiconductor lasers: Materials, cavity design, and low threshold. Nano Lett. 2021, 21, 1903–1914. [Google Scholar] [CrossRef] [PubMed]

- Dong, H.; Zhang, C.; Liu, X.; Yao, J.; Zhao, Y.S. Materials chemistry and engineering in metal halide perovskite lasers. Chem. Soc. Rev. 2020, 49, 951–982. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Zhang, C.; Lee, J.; Han, J.; Nurmikko, A. High-Q, low-threshold monolithic perovskite thin-film vertical-cavity lasers. Adv. Mater. 2017, 29, 1604781. [Google Scholar] [CrossRef]

- Wang, J.; Su, R.; Xing, J.; Bao, D.; Diederichs, C.; Liu, S.; Liew, T.C.; Chen, Z.; Xiong, Q. Room temperature coherently coupled exciton–polaritons in two-dimensional organic–inorganic perovskite. ACS Nano 2018, 12, 8382–8389. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Zou, C.; Mao, C.; Corp, K.L.; Yao, Y.-C.; Lee, Y.-J.; Schlenker, C.W.; Jen, A.K.; Lin, L.Y. CsPbBr3 perovskite quantum dot vertical cavity lasers with low threshold and high stability. Acs Photonics 2017, 4, 2281–2289. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, W.; Xiao, S.; Zhang, N.; Fan, Y.; Qu, G.; Song, Q. Surface-emitting perovskite random lasers for speckle-free imaging. ACS Nano 2019, 13, 10653–10661. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.; Nurmikko, A. Stable green perovskite vertical-cavity surface-emitting lasers on rigid and flexible substrates. ACS Photonics 2017, 4, 2486–2494. [Google Scholar] [CrossRef]

- Alias, M.S.; Liu, Z.; Al-Atawi, A.; Ng, T.K.; Wu, T.; Ooi, B.S. Continuous-wave optically pumped green perovskite vertical-cavity surface-emitter. Opt. Lett. 2017, 42, 3618–3621. [Google Scholar] [CrossRef]

- Zhang, Q.; Ha, S.T.; Liu, X.; Sum, T.C.; Xiong, Q. Room-temperature near-infrared high-Q perovskite whispering-gallery planar nanolasers. Nano Lett. 2014, 14, 5995–6001. [Google Scholar] [CrossRef]

- Mi, Y.; Zhong, Y.; Zhang, Q.; Liu, X. Continuous-wave pumped perovskite lasers. Adv. Opt. Mater. 2019, 7, 1900544. [Google Scholar] [CrossRef]

- Zhu, Y.; Qin, Q.; Xu, F.; Fan, F.; Ding, Y.; Zhang, T.; Wiley, B.J.; Wang, Z.L. Size effects on elasticity, yielding, and fracture of silver nanowires: In situ experiments. Phys. Rev. B 2012, 85, 045443. [Google Scholar] [CrossRef]

- Chueh, C.-C.; Li, C.-Z.; Jen, A.K.-Y. Recent progress and perspective in solution-processed Interfacial materials for efficient and stable polymer and organometal perovskite solar cells. Energy Environ. Sci. 2015, 8, 1160–1189. [Google Scholar] [CrossRef]

- Wang, Z.; Fang, J.; Mi, Y.; Zhu, X.; Ren, H.; Liu, X.; Yan, Y. Enhanced performance of perovskite solar cells by ultraviolet-ozone treatment of mesoporous TiO2. Appl. Surf. Sci. 2018, 436, 596–602. [Google Scholar] [CrossRef]

- Park, J.H.; Seo, J.; Park, S.; Shin, S.S.; Kim, Y.C.; Jeon, N.J.; Shin, H.W.; Ahn, T.K.; Noh, J.H.; Yoon, S.C. Efficient CH3NH3PbI3 perovskite solar cells employing nanostructured p-type NiO electrode formed by a pulsed laser deposition. Adv. Mater. 2015, 27, 4013–4019. [Google Scholar] [CrossRef]

- Xia, R.; Gao, X.X.; Zhang, Y.; Drigo, N.; Queloz, V.I.; Tirani, F.F.; Scopelliti, R.; Huang, Z.; Fang, X.; Kinge, S. An efficient approach to fabricate air-stable perovskite solar cells via addition of a self-polymerizing ionic liquid. Adv. Mater. 2020, 32, 2003801. [Google Scholar] [CrossRef]

- Kim, H.; Lee, J.; Kim, B.; Byun, H.R.; Kim, S.H.; Oh, H.M.; Baik, S.; Jeong, M.S. Enhanced stability of MAPbI3 perovskite solar cells using poly (p-chloro-xylylene) encapsulation. Sci. Rep. 2019, 9, 15461. [Google Scholar] [CrossRef]

- Kakekhani, A.; Katti, R.N.; Rappe, A.M. Water in hybrid perovskites: Bulk MAPbI3 degradation via super-hydrous state. APL Mater. 2019, 7, 041112. [Google Scholar] [CrossRef]

- Wiedemann, D.; Breternitz, J.; Paley, D.W.; Schorr, S. Hybrid perovskite at full tilt: Structure and symmetry relations of the incommensurately modulated phase of methylammonium lead bromide, MAPbBr3. J. Phys. Chem. Lett. 2021, 12, 2358–2362. [Google Scholar] [CrossRef]

- Swainson, I.; Hammond, R.; Soullière, C.; Knop, O.; Massa, W. Phase transitions in the perovskite methylammonium lead bromide, CH3ND3PbBr3. J. Solid State Chem. 2003, 176, 97–104. [Google Scholar] [CrossRef]

- Li, C.; Juarez-Perez, E.J.; Mayoral, A. Atomic-level understanding of a formamidinium hybrid halide perovskite, FAPbBr 3. Chem. Commun. 2022, 58, 12164–12167. [Google Scholar] [CrossRef]

- Huang, Y.; Li, L.; Liu, Z.; Jiao, H.; He, Y.; Wang, X.; Zhu, R.; Wang, D.; Sun, J.; Chen, Q. The intrinsic properties of FA (1− x) MA x PbI 3 perovskite single crystals. J. Mater. Chem. A 2017, 5, 8537–8544. [Google Scholar] [CrossRef]

- Stoumpos, C.C.; Malliakas, C.D.; Kanatzidis, M.G. Semiconducting tin and lead iodide perovskites with organic cations: Phase transitions, high mobilities, and near-infrared photoluminescent properties. Inorg. Chem. 2013, 52, 9019–9038. [Google Scholar] [CrossRef]

- Stoumpos, C.C.; Malliakas, C.D.; Peters, J.A.; Liu, Z.; Sebastian, M.; Im, J.; Chasapis, T.C.; Wibowo, A.C.; Chung, D.Y.; Freeman, A.J. Crystal growth of the perovskite semiconductor CsPbBr3: A new material for high-energy radiation detection. Cryst. Growth Des. 2013, 13, 2722–2727. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Deng, L.-L.; Leng, S.; Guo, X.; Tan, C.-H.; Choy, W.C.; Chen, C.-C. The mechanism of universal green antisolvents for intermediate phase controlled high-efficiency formamidinium-based perovskite solar cells. Mater. Horiz. 2020, 7, 934–942. [Google Scholar] [CrossRef]

- Luo, D.; Su, R.; Zhang, W.; Gong, Q.; Zhu, R. Minimizing non-radiative recombination losses in perovskite solar cells. Nat. Rev. Mater. 2020, 5, 44–60. [Google Scholar] [CrossRef]

- Azzouzi, M.; Yan, J.; Kirchartz, T.; Liu, K.; Wang, J.; Wu, H.; Nelson, J. Nonradiative energy losses in bulk-heterojunction organic photovoltaics. Phys. Rev. X 2018, 8, 031055. [Google Scholar] [CrossRef]

- Bi, P.; Zhang, S.; Chen, Z.; Xu, Y.; Cui, Y.; Zhang, T.; Ren, J.; Qin, J.; Hong, L.; Hao, X. Reduced non-radiative charge recombination enables organic photovoltaic cell approaching 19% efficiency. Joule 2021, 5, 2408–2419. [Google Scholar] [CrossRef]

- Long, R.; Fang, W.; Akimov, A.V. Nonradiative electron–hole recombination rate is greatly reduced by defects in monolayer black phosphorus: Ab initio time domain study. J. Phys. Chem. Lett. 2016, 7, 653–659. [Google Scholar] [CrossRef]

- Erdem, O.; Foroutan, S.; Gheshlaghi, N.; Guzelturk, B.; Altintas, Y.; Demir, H.V. Thickness-tunable self-assembled colloidal nanoplatelet films enable ultrathin optical gain media. Nano Lett. 2020, 20, 6459–6465. [Google Scholar] [CrossRef]

- Pavesi, L.; Dal Negro, L.; Mazzoleni, C.; Franzo, G.; Priolo, d.F. Optical gain in silicon nanocrystals. Nature 2000, 408, 440–444. [Google Scholar] [CrossRef]

- Kundu, S.; Kelly, T.L. In situ studies of the degradation mechanisms of perovskite solar cells. EcoMat 2020, 2, e12025. [Google Scholar] [CrossRef]

- Yang, J.; Siempelkamp, B.D.; Liu, D.; Kelly, T.L. Investigation of CH3NH3PbI3 degradation rates and mechanisms in controlled humidity environments using in situ techniques. ACS Nano 2015, 9, 1955–1963. [Google Scholar] [CrossRef]

- Luo, D.; Yang, W.; Wang, Z.; Sadhanala, A.; Hu, Q.; Su, R.; Shivanna, R.; Trindade, G.F.; Watts, J.F.; Xu, Z. Enhanced photovoltage for inverted planar heterojunction perovskite solar cells. Science 2018, 360, 1442–1446. [Google Scholar] [CrossRef]

- Zheng, X.; Chen, B.; Dai, J.; Fang, Y.; Bai, Y.; Lin, Y.; Wei, H.; Zeng, X.C.; Huang, J. Defect passivation in hybrid perovskite solar cells using quaternary ammonium halide anions and cations. Nat. Energy 2017, 2, 17102. [Google Scholar] [CrossRef]

- Eperon, G.E.; Stranks, S.D.; Menelaou, C.; Johnston, M.B.; Herz, L.M.; Snaith, H.J. Formamidinium lead trihalide: A broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ. Sci. 2014, 7, 982–988. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; Fu, J.; Liang, T.; Ma, W. Recent progress on the stability of perovskite solar cells in a humid environment. J. Phys. Chem. C 2020, 124, 27251–27266. [Google Scholar] [CrossRef]

- Kavokin, A.V.; Baumberg, J.J.; Malpuech, G.; Laussy, F.P. Microcavities; Oxford University Press: Oxford, UK, 2017. [Google Scholar]

- Fox, A.M.; Fox, D.P.A.M. Optical Properties of Solids; Oxford University Press: Oxford, UK, 2001. [Google Scholar]

- Tejada, A.; Peters, S.; Al-Ashouri, A.; Turren-Cruz, S.H.; Abate, A.; Albrecht, S.; Ruske, F.; Rech, B.; Guerra, J.A.; Korte, L. Hybrid Perovskite Degradation from an Optical Perspective: A Spectroscopic Ellipsometry Study from the Deep Ultraviolet to the Middle Infrared. Adv. Opt. Mater. 2022, 10, 2101553. [Google Scholar] [CrossRef]

- Türeci, H.E.; Stone, A.D.; Collier, B. Self-consistent multimode lasing theory for complex or random lasing media. Phys. Rev. A 2006, 74, 043822. [Google Scholar] [CrossRef]

- Beland, R.R. Propagation through atmospheric optical turbulence. Atmos. Propag. Radiat. 1993, 2, 157–232. [Google Scholar]

- Kaushal, H.; Kaddoum, G. Free space optical communication: Challenges and mitigation techniques. arXiv 2015, arXiv:1506.04836. [Google Scholar]

- Cazaubiel, V.; Planche, G.; Chorvalli, V.; Le Hors, L.; Roy, B.; Giraud, E.; Vaillon, L.; Carré, F.; Decourbey, E. LOLA: A 40,000 km optical link between an aircraft and a geostationary satellite. In Proceedings of the ESA/CNES ICSO 2006, Noordwijk, The Netherlands, 27–30 June 2006. [Google Scholar]

- Perlot, N.; Knapek, M.; Giggenbach, D.; Horwath, J.; Brechtelsbauer, M.; Takayama, Y.; Jono, T. Results of the optical downlink experiment KIODO from OICETS satellite to optical ground station Oberpfaffenhofen (OGS-OP). In Proceedings of the Free-Space Laser Communication Technologies XIX and Atmospheric Propagation of Electromagnetic Waves, San Jose, CA, USA, 12 February 2007; Volume 6457, pp. 28–35. [Google Scholar]

| Without Pressure | Weak Pressure (8.428 N/cm2) | Strong Pressure (19.698 N/cm2) | |

|---|---|---|---|

| Center wavelength (nm) | 822.8 | 831.3 | 832.2 |

| Average mode spacing (nm) | 9.3 | 16.7 | 23.1 |

| Cavity length (μm) | 14.05 | 7.99 | 5.79 |

| FWHM (nm) | 7.82 | 3.67 | 1.75 |

| Q factor | 105.22 | 226.95 | 476.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, C.-C.; Chan, P.-W.; Chen, P.; Wu, Z.Y.; Hsu, H.-C.; Lai, W.-C.; Chou, Y.-H. Controlled Cavity Length and Wide-Spectrum Lasing in FAMACsPb(BrI)3 Ternary Perovskite Vertical-Cavity Surface-Emitting Lasers with an All-Dielectric Dielectric Bragg Reflector. Crystals 2023, 13, 1517. https://doi.org/10.3390/cryst13101517

Lin C-C, Chan P-W, Chen P, Wu ZY, Hsu H-C, Lai W-C, Chou Y-H. Controlled Cavity Length and Wide-Spectrum Lasing in FAMACsPb(BrI)3 Ternary Perovskite Vertical-Cavity Surface-Emitting Lasers with an All-Dielectric Dielectric Bragg Reflector. Crystals. 2023; 13(10):1517. https://doi.org/10.3390/cryst13101517

Chicago/Turabian StyleLin, Chiao-Chih, Pei-Wen Chan, Peter Chen, Zong Yu Wu, Hsu-Cheng Hsu, Wei-Chih Lai, and Yu-Hsun Chou. 2023. "Controlled Cavity Length and Wide-Spectrum Lasing in FAMACsPb(BrI)3 Ternary Perovskite Vertical-Cavity Surface-Emitting Lasers with an All-Dielectric Dielectric Bragg Reflector" Crystals 13, no. 10: 1517. https://doi.org/10.3390/cryst13101517