Enhancing the Tunable Sensitivity of a Near-Ultraviolet to Visible to Near-Infrared Photo Irradiance Sensor Using an Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon

Abstract

:1. Introduction

1.1. Three Common Types of Semiconductor-Based Photo Irradiance Sensors

- The PIN PISs consist of an intrinsic semiconductor layer sandwiched between p-doped and n-doped regions. This creates a built-in electric field across the intrinsic region; a reverse bias can further increase this field, causing photo-generated electron–hole pairs to separate. Carrier collection then enables light detection [3].

- MSM PISs function on a similar principle, with the electric field distributed inside the semiconductor region. When illuminated, electron–hole pair generation and separation in the field allow photocurrent generation [4].

- MIS PISs incorporate an insulator layer between the metal contact and the semiconductor. A deep-depletion region formed in the semiconductor of the MIS detector can provide the electric field for the separation of photo-generated electron–hole pairs. Electron–hole pairs created in the depletion region are collected, enabling photodetection. Compared to PIN, the MIS structure has a simpler fabrication process without doping requirements. It also benefits from a lower dark current than MSM detectors due to the insulator layer between the metal and semiconductor [5].

1.2. TCO-High-k-Si Capacitor PIS

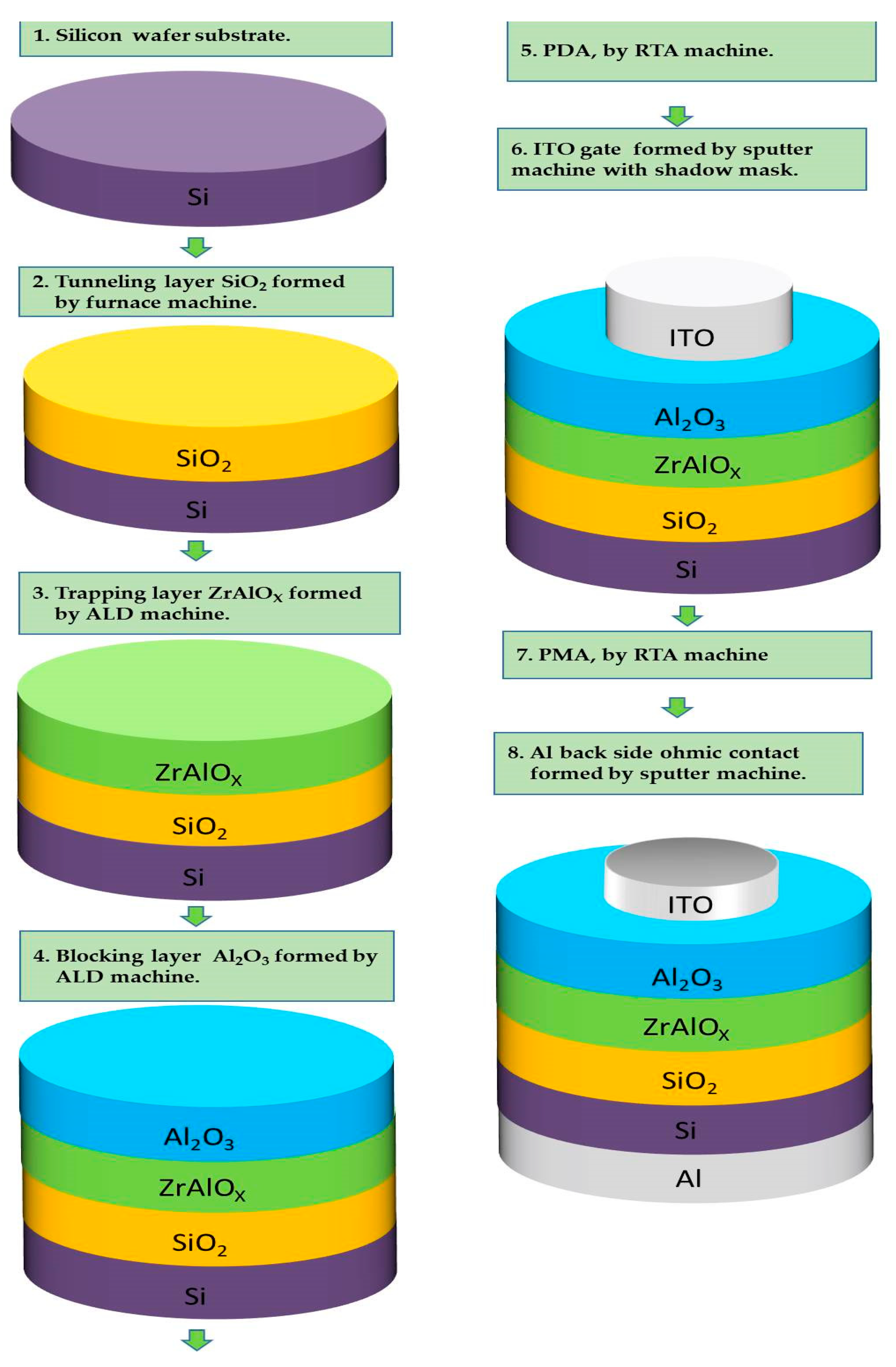

2. Materials and Methods

2.1. Sensor Design and Materials

- Substrate Selection: p-Silicon (100) (15–25 Ω-cm) was chosen as the substrate material for NUV-NIR light absorption and carrier generation.

- Bottom Dielectric: A 3–5 nm SiO2 layer was implemented as the bottom dielectric to minimize interface defects of ZrAlOx and leakage current from ZrAlOx. The thin bottom dielectric also served the purpose of additional substrate path tunneling for the carrier generated by ZrAlOx under light. SiO2 is optically transparent in the NUV-NIR range.

- Middle Dielectric: A 5–15 nm high-k ZrAlOx layer, with a thickness ranging from 5 to 15 nm, was utilized as the middle dielectric. This high-k choice aimed to enhance the speed of the sensor. Additionally, Al-doped ZrO2 was incorporated into this layer to further reduce leakage. Smaller nanocrystalline particles were seen in the ZrAlOx; these might be interpreted as light absorption and carrier production.. ZrAlOx is optically transparent in the NUV-NIR range.

- Top Dielectric: A 10–20 nm high-k Al2O3 layer, with a thickness of 10–20 nm, was employed as the top dielectric. This high-k choice aimed to enhance the speed of the sensor. This thick Al2O3 layer served the purpose of gate leakage reduction in ZrAlOx for the gate tunneling path. Al2O3 is optically transparent in the NUV-NIR range.

2.2. THSC PIS Operation Flow

2.3. IAZAOS PIS Material Inspection

- Material crystallinity was observed using transmission electron microscopy (TEM) (JEOL JEM-2010F, Tokyo, Japan);

- Material crystallinity was observed using X-ray diffraction (XRD) (PANalytical X’Pert Pro);

- For material transmission qualities, optical spectroscopy (Shimadzu-UV-250) was utilized;

- The Olympus-BX63 optical microscope (OM) was used for top-view IAZAOS PIS imaging.

3. Results

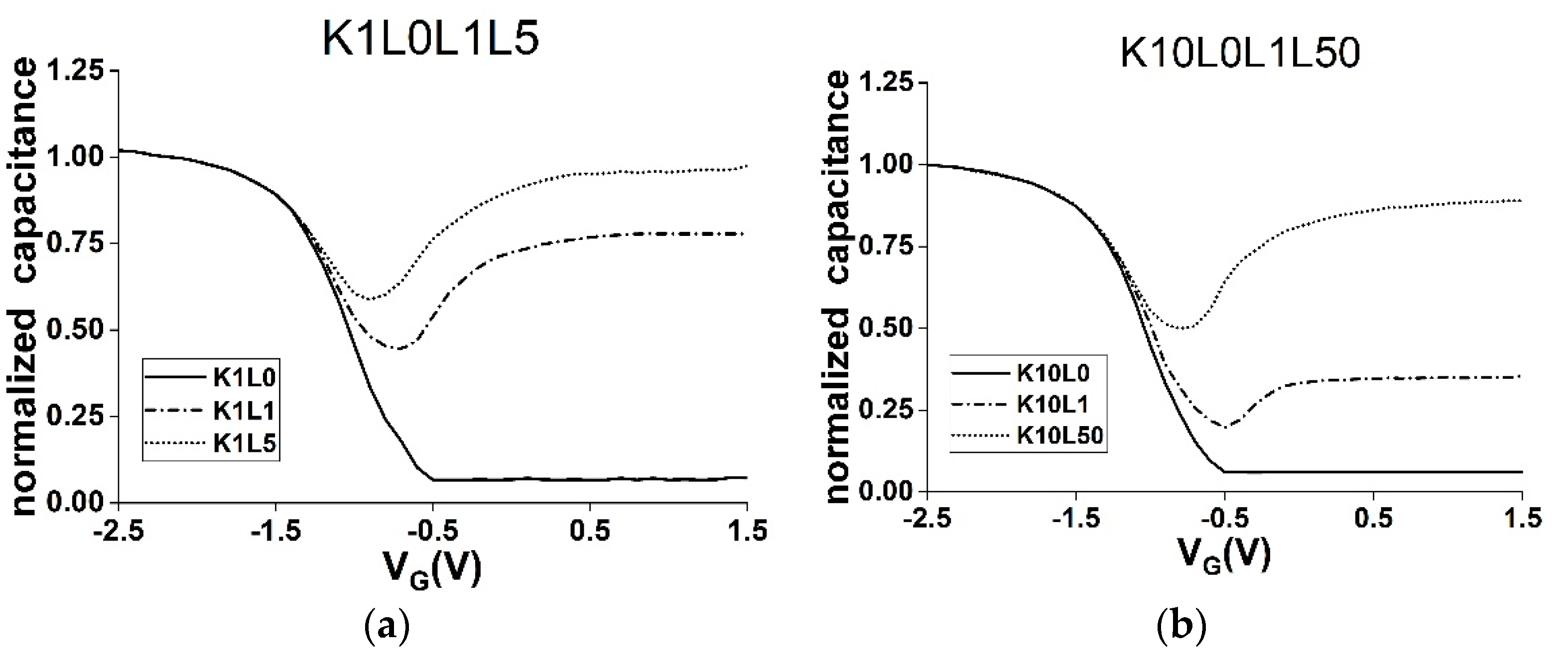

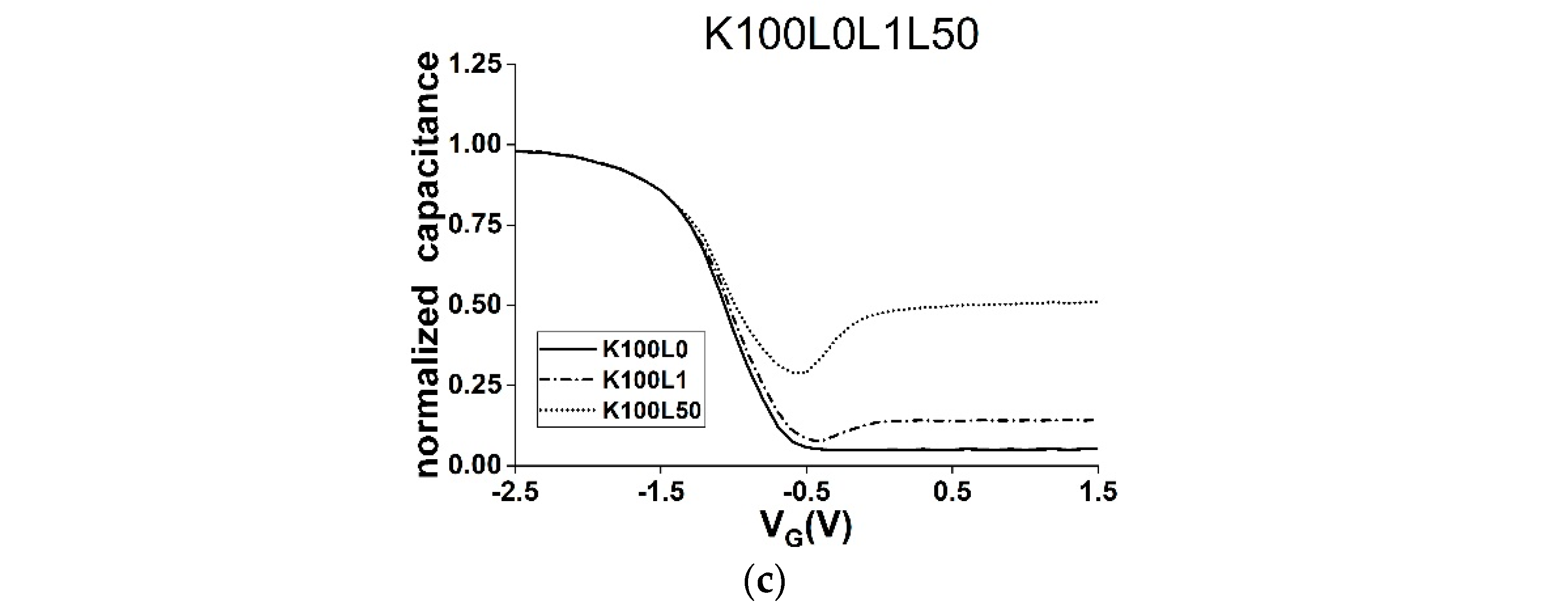

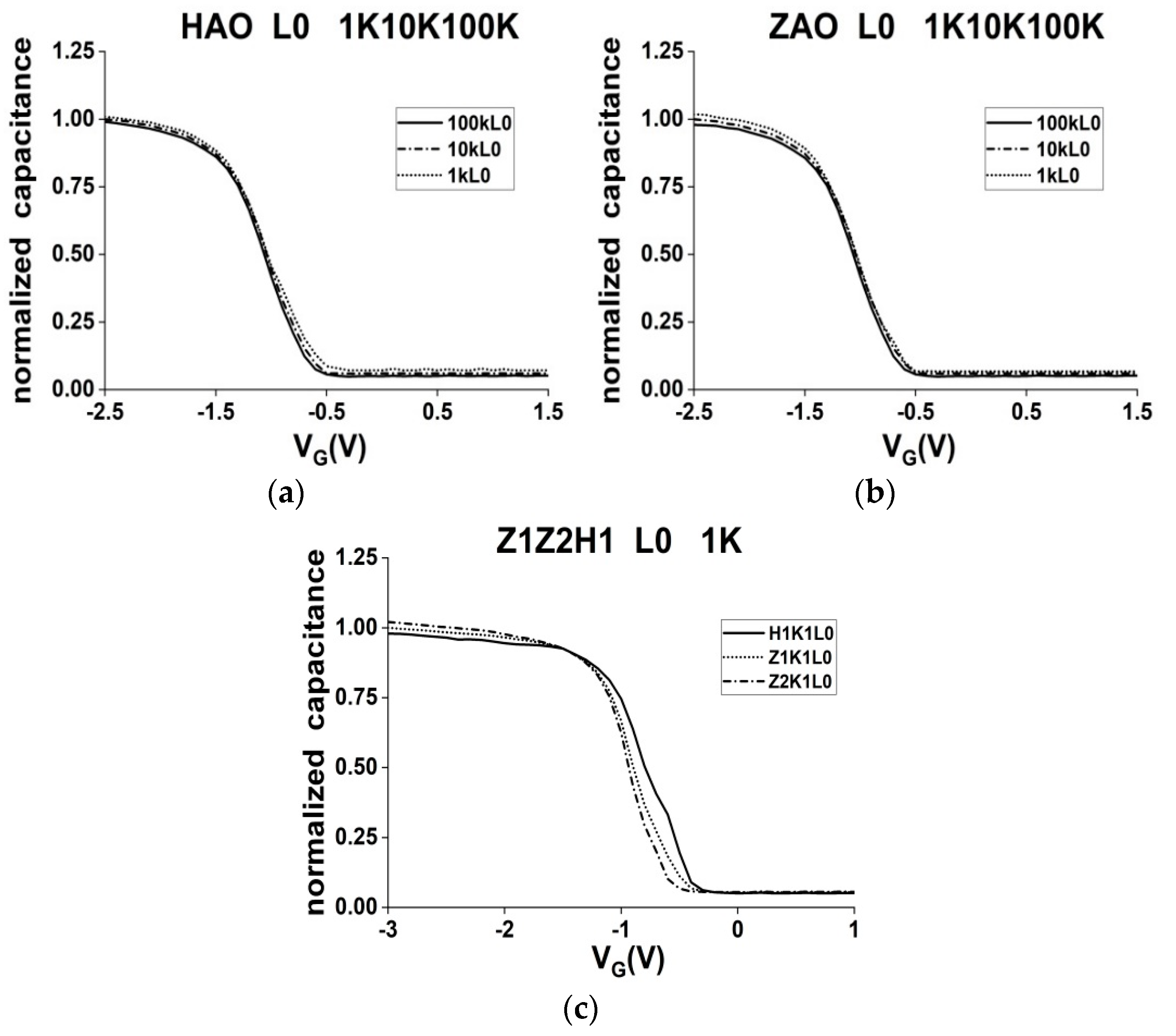

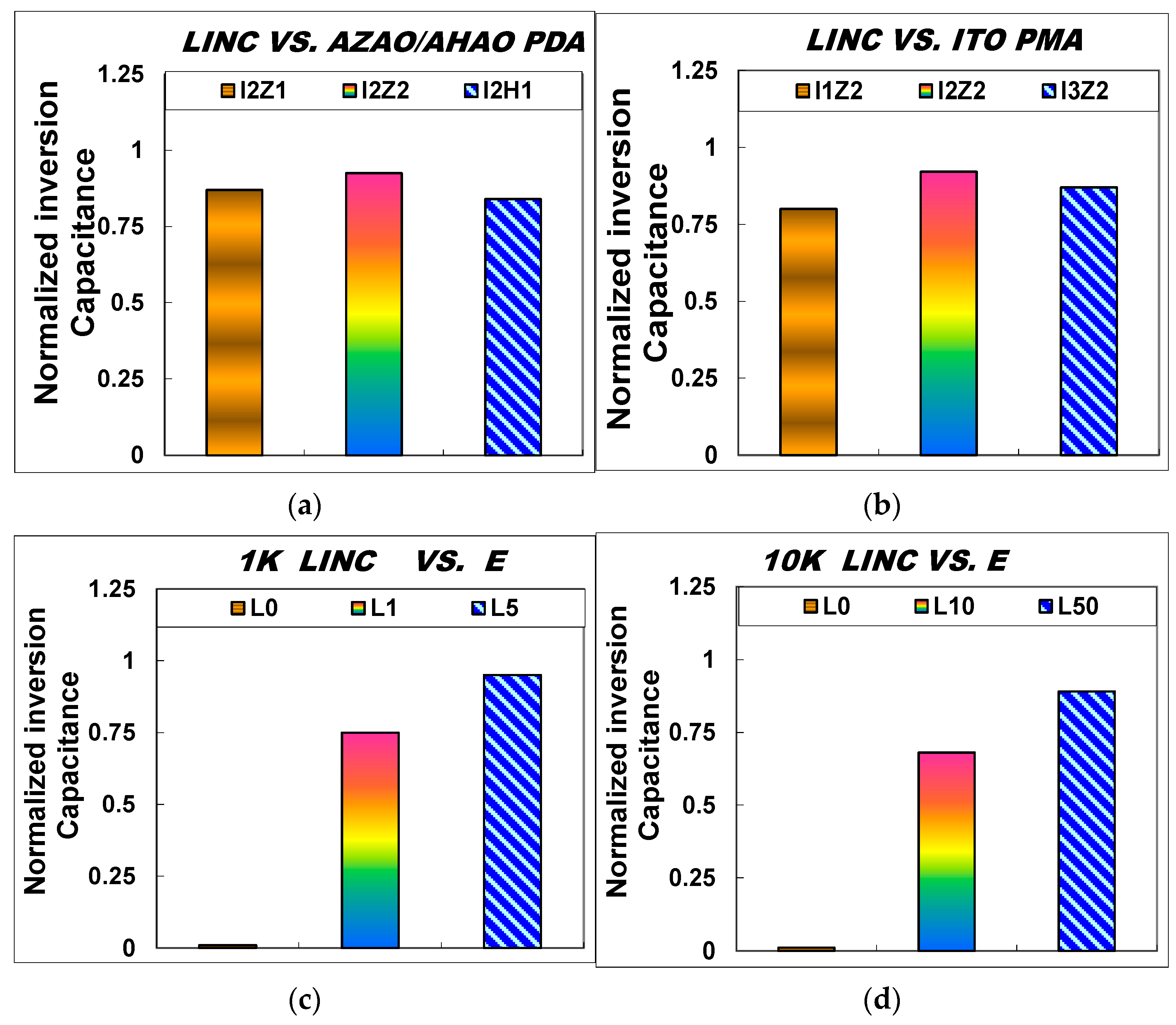

3.1. LINC Increases in IAZAOS

3.2. LINC Comparison for Various IAZAOS at Different UV Wavelengths and Different Annealing Temperatures

3.3. Photo Transmittance and Resistivity Comparison of ITO Films at Different Annealing Temperatures

3.4. XRD and TEM Comparison of ITO Films at Different Annealing Temperatures

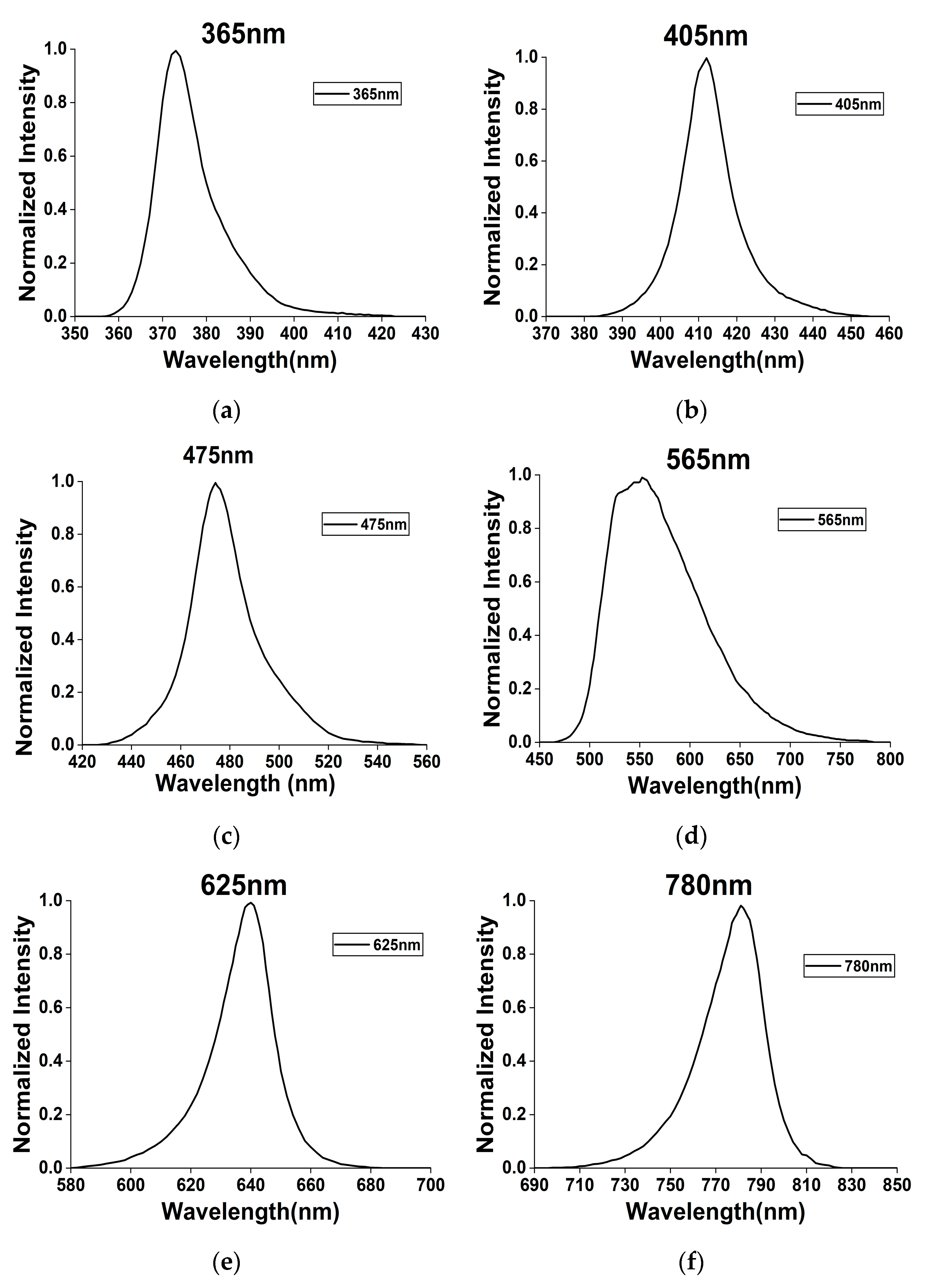

3.5. The Spectra for NIR-VIS-NUV LEDs

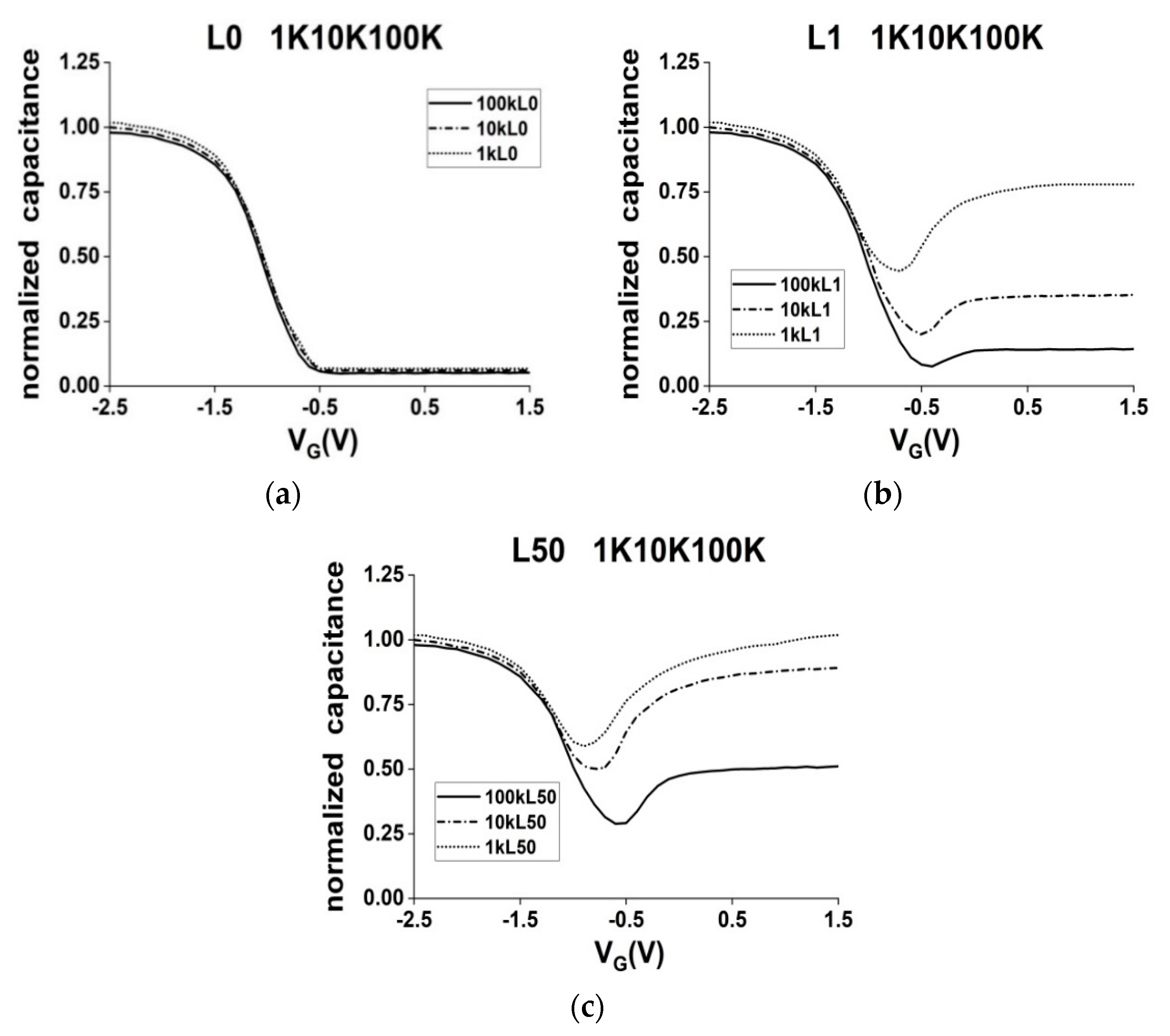

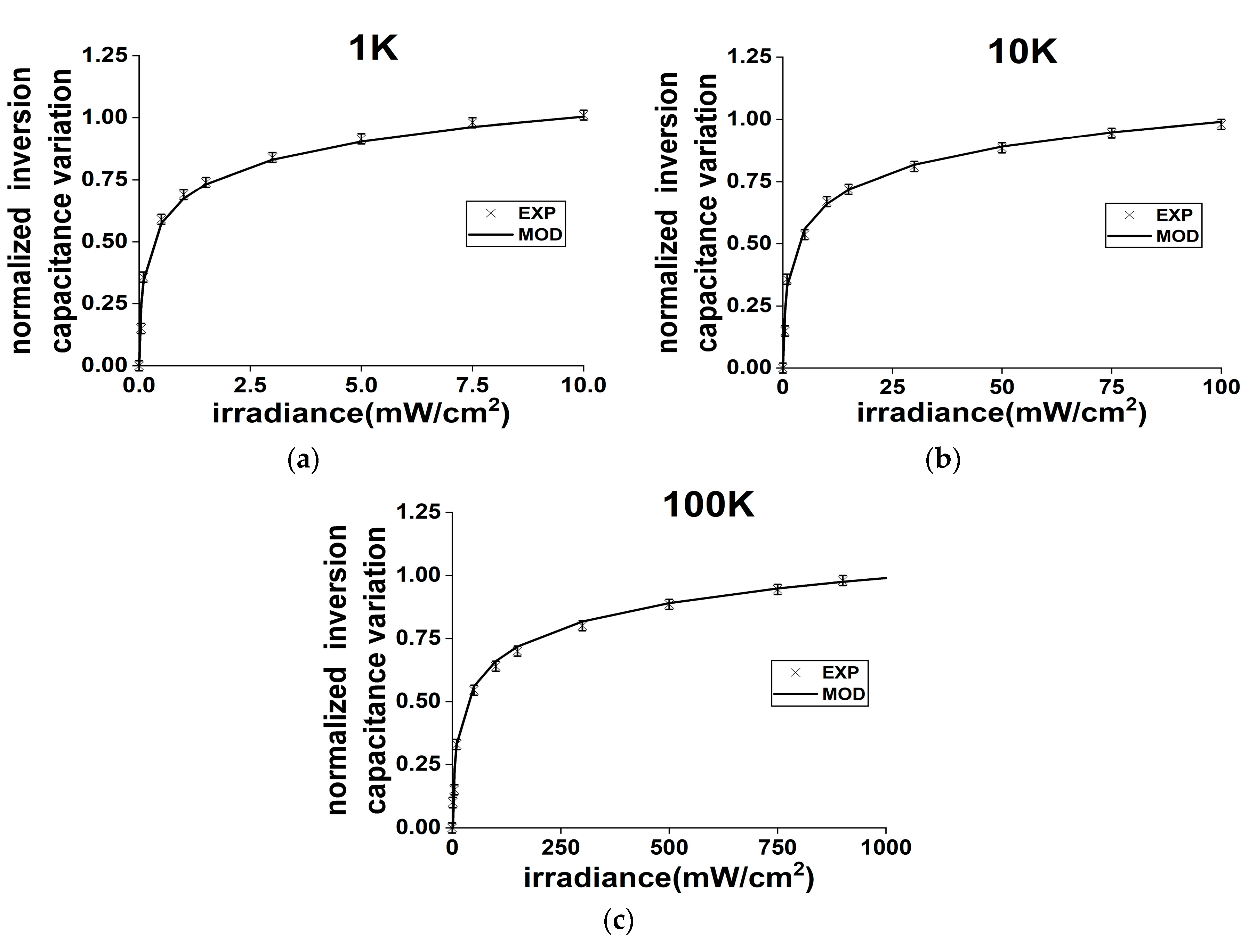

3.6. The Dependence of LINC on Different Measuring Frequencies

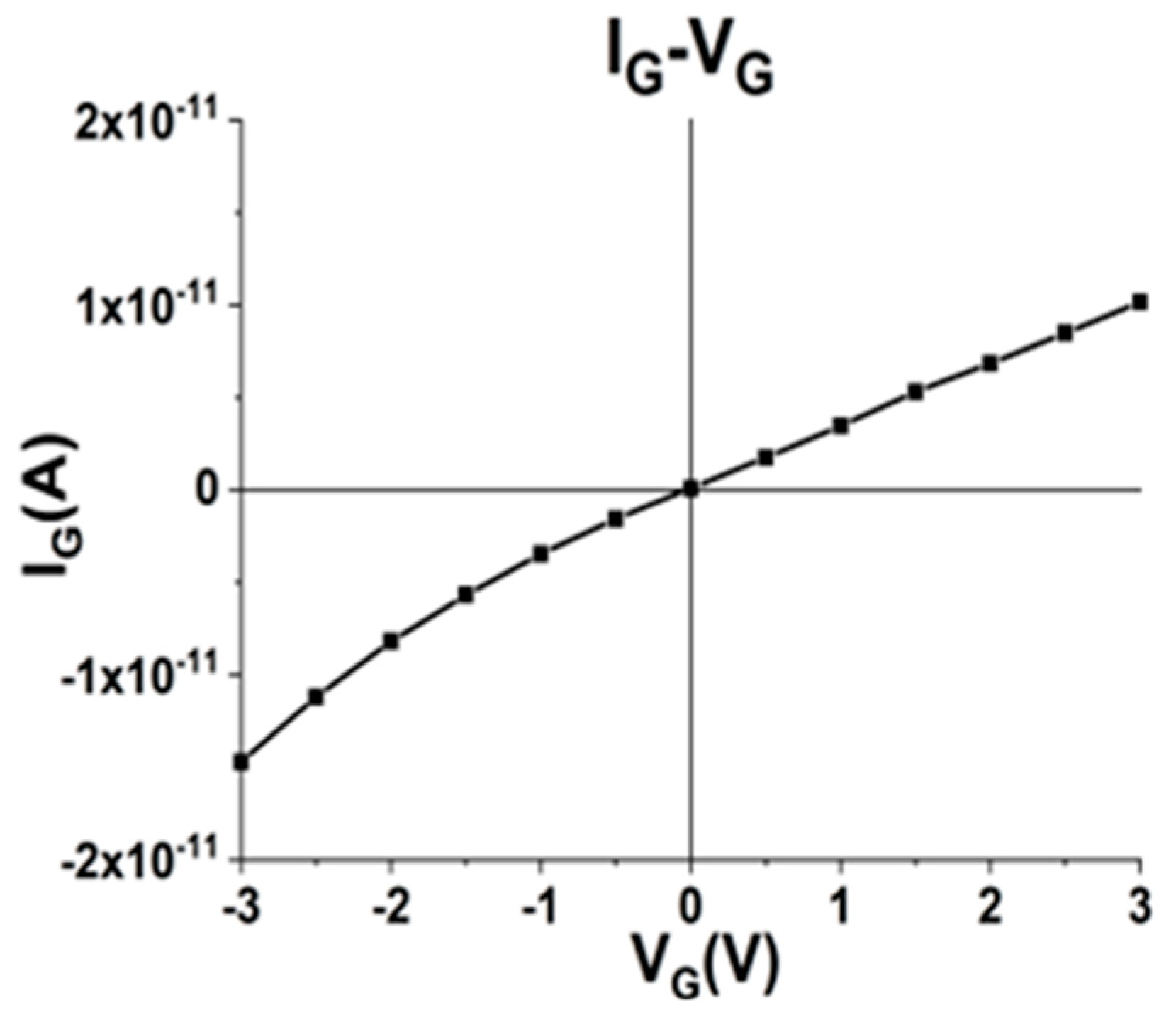

3.7. The I-V of the Device under Light Illumination

3.8. The Photocapacitance Time Response of the IAZAOS PIS

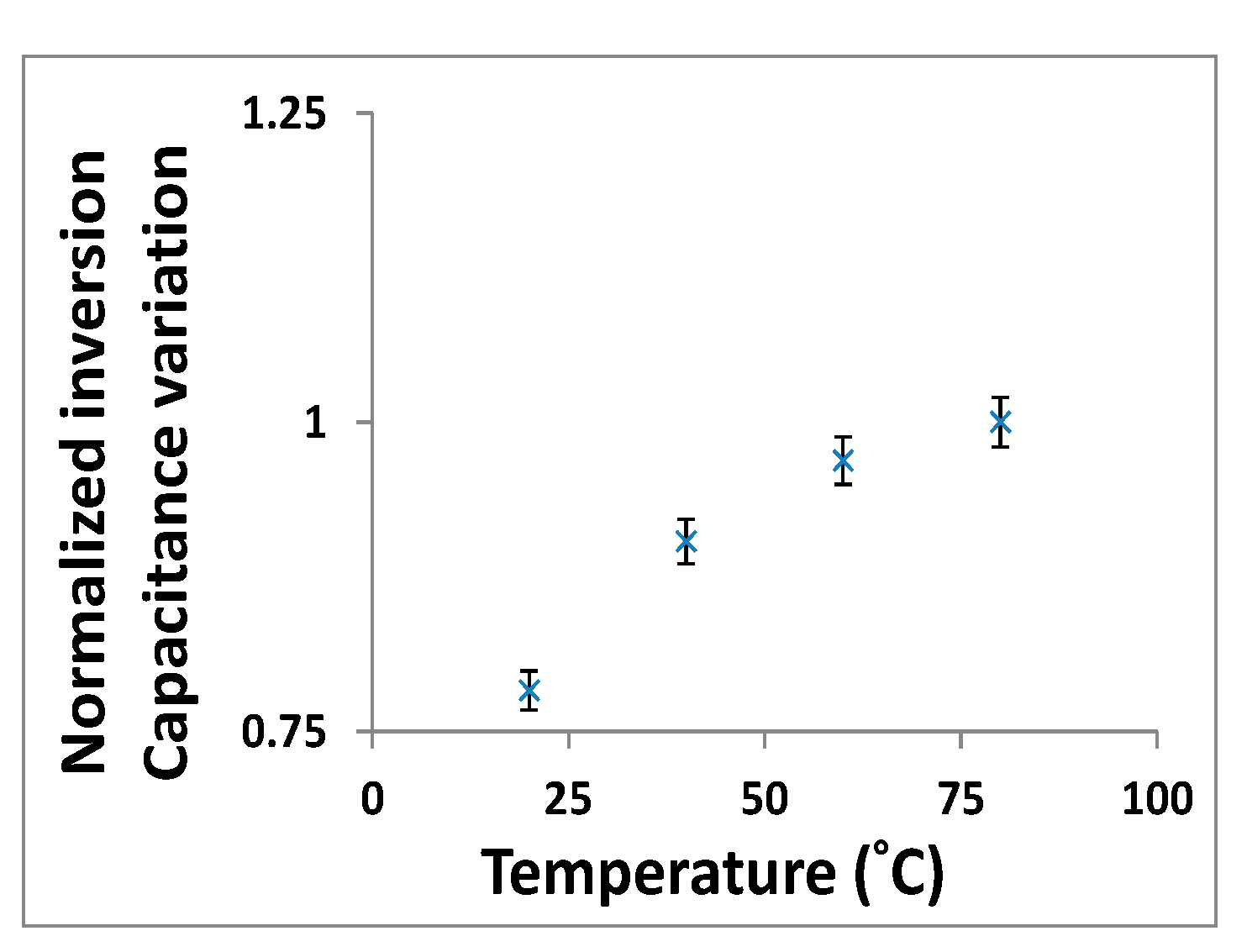

3.9. The Temperature Dependence of Photocapacitance Response for the IAZAOS PIS

4. Discussion

4.1. LINC Change in IAZAOS

4.2. Sensitivity of IAZAOS-I2Z2

4.3. Model for Photo-Induced LINC Shift

= [ INC(E) − INC(0)]/[ACC − INC(0)] = [W × A]log(K × E)

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Klijn, M.E.; Hubbuch, J. Application of ultraviolet, visible, and infrared light imaging in protein-based biopharmaceutical formulation characterization and development studies. Eur. J. Pharm. Biopharm. 2021, 165, 319–336. [Google Scholar] [CrossRef] [PubMed]

- Papalias, T.A.; Wong, M. Making sense of light sensors. EEtimes 2006, 7, 19. [Google Scholar]

- Kasper, E.; Oehme, M. High Speed Germanium Detectors on Si. Phys. Stat. Sol. C 2008, 5, 3144–3149. [Google Scholar] [CrossRef]

- Brennan, K.F.; Haralson, J.; Parks, J.W.; Salem, A. Review of Reliability Issues of Metal-Semiconductor-Metal and Avalanche Photodiode Photonic Detectors. Microelectron. Reliab. 1999, 39, 1873–1883. [Google Scholar] [CrossRef]

- Lee, H.C.; Su, Y.K.; Lin, J.C.; Cheng, Y.C.; Wu, S.L.; Jhou, Y.D. AlInGaN Metal-Insulator-Semiconductor Photodetectors at UV-C 280 nm. Electrochem. Solid-State Lett. 2009, 12, H357–H360. [Google Scholar] [CrossRef]

- Liu, C.W.; Liu, W.T.; Lee, M.H.; Kuo, W.S.; Hsu, B.C. A Novel Photodetector Using MOS Tunneling Structures. IEEE Electron Device Lett. 2000, 21, 307–309. [Google Scholar] [CrossRef]

- Yang, T.; Liu, Y.; Ye, P.D.; Xuan, Y.; Pal, H.; Lundstrom, M.S. Inversion capacitance-voltage studies on GaAs metal-oxide-semiconductor structure using transparent conducting oxide as metal gate. Appl. Phys. Lett. 2008, 92, 2105. [Google Scholar] [CrossRef]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006; p. 663. [Google Scholar]

- Jong, F.C.; Hsieh, W.C. Performance Comparison of SONOS-Type UV TD Sensor Using Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon Oxide-Silicon and Indium Tin Oxide-Aluminum Oxide-Hafnium Aluminum Oxide-Silicon Oxide-Silicon. Crystals 2023, 13, 1092. [Google Scholar] [CrossRef]

- Hsieh, W.C.; Jong, F.C.; Tseng, W.T. Performance Improvement of Total Ionization Dose Radiation Sensor Devices Using IOHAOS with Enhanced UV Transparency ITO Gate. Coatings 2021, 11, 408. [Google Scholar] [CrossRef]

- Hsieh, W.C. Performance Improvement of a Nonvolatile UV TD Sensor Using SAHAOS with a High Temperature Annealed, Partially Nano-Crystallized Trapping Layer. Sensors 2019, 19, 1570. [Google Scholar] [CrossRef]

- Rahman, M.M.; Kim, D.H.; Kim, T.W. Border Trap Characterizations of Al2O3/ZrO2 and Al2O3/HfO2 Bilayer Films Based on Ambient Post Metal Annealing and Constant Voltage Stress. Nanomaterials 2020, 10, 527. [Google Scholar] [CrossRef] [PubMed]

- Hlali, S.; Hizem, N.; Militaru, L.; Kalboussi, A.; Souifi, A. Effect of interface traps for ultra-thin high-k gate dielectric based MIS devices on the capacitance-voltage characteristics. Microelectron. Reliab. 2017, 75, 154–161. [Google Scholar] [CrossRef]

- Misra, D. High k dielectrics on high-mobility substrates: The interface. Electrochem. Soc. Interface 2011, 20, 47–51. [Google Scholar] [CrossRef]

- Xia, P.; Feng, X.; Ng, R.J.; Wang, S.; Chi, D.; Li, C.; He, Z.; Liu, X.; Ang, K.W. Impact and Origin of Interface States in MOS Capacitor with Monolayer MoS2 and HfO2 High-k Dielectric. Sci. Rep. 2017, 7, 40669. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Kim, J.G.; Kim, D.H.; Kim, T.W. Border Trap Extraction with Capacitance- Equivalent Thickness to Reflect the Quantum Mechanical Effect on Atomic Layer Deposition High-k/In0.53Ga0.47As on 300-mm Si Substrate. Sci. Rep. 2019, 9, 9861. [Google Scholar] [CrossRef] [PubMed]

- Jung, H.S.; Lee, S.A.; Rha, S.H.; Lee, S.Y.; Kim, H.K.; Kim, D.H.; Oh, K.H.; Park, J.M.; Kim, W.H.; Song, M.W.; et al. Impacts of Zr Composition in Hf1−xZrxOy Gate Dielectrics on Their Crystallization Behavior and Bias-Temperature-Instability Characteristics. IEEE Trans. Electron Devices 2011, 58, 2094–2103. [Google Scholar] [CrossRef]

- Yang, T.; Xuan, Y.; Zemlyanov, D.; Shen, T.; Wu, Y.Q.; Woodall, J.M.; Ye, P.D.; Aguirre-Tostado, F.S.; Milojevic, M.; McDonnell, S.; et al. Interface studies of GaAs metal-oxide-semiconductor structures using atomic-layer-deposited HfO2/Al2O3 nanolaminate gate dielectric. Appl. Phys. Lett. 2007, 91, 142122. [Google Scholar] [CrossRef]

- Taechakumput, P.; Zhao, C.Z.; Taylor, S.; Werner, M.; Chalker, P.R.; Gaskell, J.M.; Aspinall, H.C.; Jones, A.C.; Chen, S. Thermal Stability of Neodymium Aluminates High- κ Dielectric Deposited by Liquid Injection MOCVD Using Single-Source Het erometallic Alkoxide Precursors. J. Nanomater. 2012, 2012, 891079. [Google Scholar] [CrossRef]

- Tao, J.; Zhao, C.Z.; Zhao, C.; Taechakumput, P.; Werner, M.; Taylor, S.; Chalker, P.R. Extrinsic and Intrinsic Frequency Dis persion of High-k Materials in Capacitance-Voltage Measurements. Materials 2012, 5, 1005–1032. [Google Scholar] [CrossRef]

- Nur, R.; Tsuchiya, T.; Toprasertpong, K.; Terabe, K.; Takagi, S.; Takenaka, M. High responsivity in MoS2 phototransistors based on charge trapping HfO2 dielectrics. Commun. Mater. 2020, 1, 103. [Google Scholar] [CrossRef]

- Yu, H.Y.; Li, M.F.; Kwong, D.L. ALD (HfO2)x (Al2O3) 1-x high-k gate dielectrics for advanced MOS devices application. Thin Solid Films 2004, 462, 110–113. [Google Scholar] [CrossRef]

- Liang, Z.; Zhou, S.; Cai, W.; Fu, X.; Ning, H.; Chen, J.; Yuan, W.; Zhu, Z.; Yao, R.; Peng, J. Zirconium-Aluminum-Oxide Dielectric Layer with High Dielectric and Relatively Low Leakage Prepared by Spin-Coating and the Application in Thin-Film Transistor. Coatings 2020, 10, 282. [Google Scholar] [CrossRef]

- Park, T.J.; Kim, J.H.; Jang, J.H.; Lee, C.K.; Na, K.D.; Lee, S.Y.; Jung, H.S.; Kim, M.; Han, S.; Hwang, C.S. Reduction of Electrical Defects in Atomic Layer Deposited HfO2 Films by Al Doping. Chem. Mater. 2010, 22, 4175–4184. [Google Scholar] [CrossRef]

- Zhang, G.; Samanta, S.K.; Singh, P.K.; Ma, F.J.; Yoo, M.T.; Roh, Y.; Yoo, W.J. Partial Crystallization of HfO2 for Two-Bit/Four-Level SONOS-Type Flash Memory. IEEE Trans. Electron Devices 2007, 54, 3177–3185. [Google Scholar] [CrossRef]

- Ghosh, A.; Mondal, A.; Murkute, P.; Lahiri, R.; Chakrabarti, S.; Chattopadhyay, K.K. GLAD synthesised erbium doped In2O3 nano-columns for UV detection. J. Mater. Sci. Mater. Electron. 2019, 30, 12739–12752. [Google Scholar] [CrossRef]

- Farvid, S.S.; Ju, L.; Worden, M.; Radovanovic, P.V. Colloidal Chromium-Doped In2O3 Nanocrystals as Building Blocks for High-TC Ferromagnetic Transparent Conducting Oxide Structures. J. Phys. Chem. C 2008, 112, 46. [Google Scholar] [CrossRef]

- Tandon, B.; Ashok, A.; Nag, A. Colloidal Transparent Conducting Oxide Nanocrystals: A New Infrared Plasmonic Material. Pramana-J. Phys. 2015, 84, 1087–1098. [Google Scholar] [CrossRef]

- Gao, M.Z.; Job, R.; Xue, D.S.; Fahrner, W.R. Thickness Dependence of Resistivity and Optical Reflectance of ITO Films. Chin. Phys. Lett. 2008, 25, 1380. [Google Scholar]

- Pokaipisit, A.; Horprathum, M.; Limsuwan, P. Vacuum and air annealing effects on properties of indium tin oxide films prepared byion-assisted electron beam evaporation. Jpn. J. Appl. Phys. 2008, 47, 4692–4695. [Google Scholar] [CrossRef]

- Dobrowolski, J.A.; Ho, F.C.; Menagh, D.; Simpson, R.; Waldorf, A. Transparent, conducting indium tin oxide films formed on low or medium temperature substrates by ion-assisted deposition. Appl. Opt. 1987, 26, 5204–5210. [Google Scholar] [CrossRef]

- Wen, A.J.C.; Chen, K.L.; Yang, M.H.; Hsiao, W.T.; Chao, L.G.; Leu, M.S. Effect of substrate angle on properties of ITO films deposited by cathodic arc ion plating with In-Sn alloy target. Surf. Coat. Technol. 2005, 198, 362–366. [Google Scholar] [CrossRef]

- Gibbons, K.P.; Carniglia, C.K.; Laird, R.E.; Newcomb, R.E.; Wolfe, J.D.; Westra, S.W.T. ITO coatings for display applications. In Proceedings of the 54th Annual Conference on the SVC, Tokyo, Japan, 23–25 May 2007; p. 232. [Google Scholar]

- Molzen, W.W. Characterization of transparent conductive thin films of indium oxide. J. Vac. Sci. Technol. 1975, 12, 99–102. [Google Scholar] [CrossRef]

- Meng, L.J.; Placido, F. Annealing effect on ITO thin films prepared by microwave-enhanced dc reactive magnetron sputtering for telecommunication applications. Surf. Coat. Technol. 2003, 166, 44–50. [Google Scholar] [CrossRef]

- Kang, J.; Li, J.; Liu, X. Design of High-Precision Micro-Capacitance Detection System. J. Phys. 2003, 2437, 012081. [Google Scholar] [CrossRef]

| Sensing Element | Range | Response Time |

|---|---|---|

| Photo Resistor | 100 nW/cm2~10 μW/cm2 | 50 ms |

| Photo Diode | 100 nW/cm2~10 mW/cm2 | 6 ns |

| Photo Transistor | 100 μW/cm2~10 mW/cm2 | 15 μs |

| IAZAOS | 10 nW/cm2~1 W/cm2 | 1 ms~10 μs |

| Split | I2Z1 | I2Z2 | I2H1 | I1Z2 | I2Z2 | I3Z2 |

|---|---|---|---|---|---|---|

| PMA Temperatura (°C) | 500 | 500 | 500 | 250 | 500 | 600 |

| PMA Time (s) | 30 | 30 | 30 | 30 | 30 | 30 |

| Gate Material | ITO | ITO | ITO | ITO | ITO | ITO |

| PDA Temperature (°C) | 900 | 1000 | 1000 | 1000 | 1000 | 1000 |

| PDA Time (s) | 45 | 45 | 45 | 45 | 45 | 45 |

| Gate Dielectric Material | AZAO | AZAO | AHAO | AZAO | AZAO | AZAO |

| Symbol | E (mW/cm2) | Frequency (HZ) | Wavelength (nm) |

|---|---|---|---|

| W405L0K1 | 0 | 1K | 405 |

| W405L100K1 | 100 | 1K | 405 |

| W405L100K100 | 100 | 100K | 405 |

| W365L100K100 | 100 | 100K | 365 |

| W625L100K100 | 100 | 100K | 625 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsieh, W.-C.; Chen, B.-M.; Wang, M.-C.; Lee, Y.-S.; Tsai, C.-C. Enhancing the Tunable Sensitivity of a Near-Ultraviolet to Visible to Near-Infrared Photo Irradiance Sensor Using an Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon. Crystals 2023, 13, 1530. https://doi.org/10.3390/cryst13111530

Hsieh W-C, Chen B-M, Wang M-C, Lee Y-S, Tsai C-C. Enhancing the Tunable Sensitivity of a Near-Ultraviolet to Visible to Near-Infrared Photo Irradiance Sensor Using an Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon. Crystals. 2023; 13(11):1530. https://doi.org/10.3390/cryst13111530

Chicago/Turabian StyleHsieh, Wen-Ching, Bing-Mau Chen, Mu-Chun Wang, Yih-Shing Lee, and Chien-Chung Tsai. 2023. "Enhancing the Tunable Sensitivity of a Near-Ultraviolet to Visible to Near-Infrared Photo Irradiance Sensor Using an Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon" Crystals 13, no. 11: 1530. https://doi.org/10.3390/cryst13111530

APA StyleHsieh, W. -C., Chen, B. -M., Wang, M. -C., Lee, Y. -S., & Tsai, C. -C. (2023). Enhancing the Tunable Sensitivity of a Near-Ultraviolet to Visible to Near-Infrared Photo Irradiance Sensor Using an Indium Tin Oxide-Aluminum Oxide-Zirconia Aluminum Oxide-Silicon. Crystals, 13(11), 1530. https://doi.org/10.3390/cryst13111530