Optimization of Wire EDM Process Parameters for Machining Hybrid Composites Using Grey Relational Analysis

Abstract

:1. Introduction

2. Literature Survey

3. Materials and Fabrication

3.1. Materials

3.2. Manufacturing of LM5/ZrO2/Gr Hybrid Composites

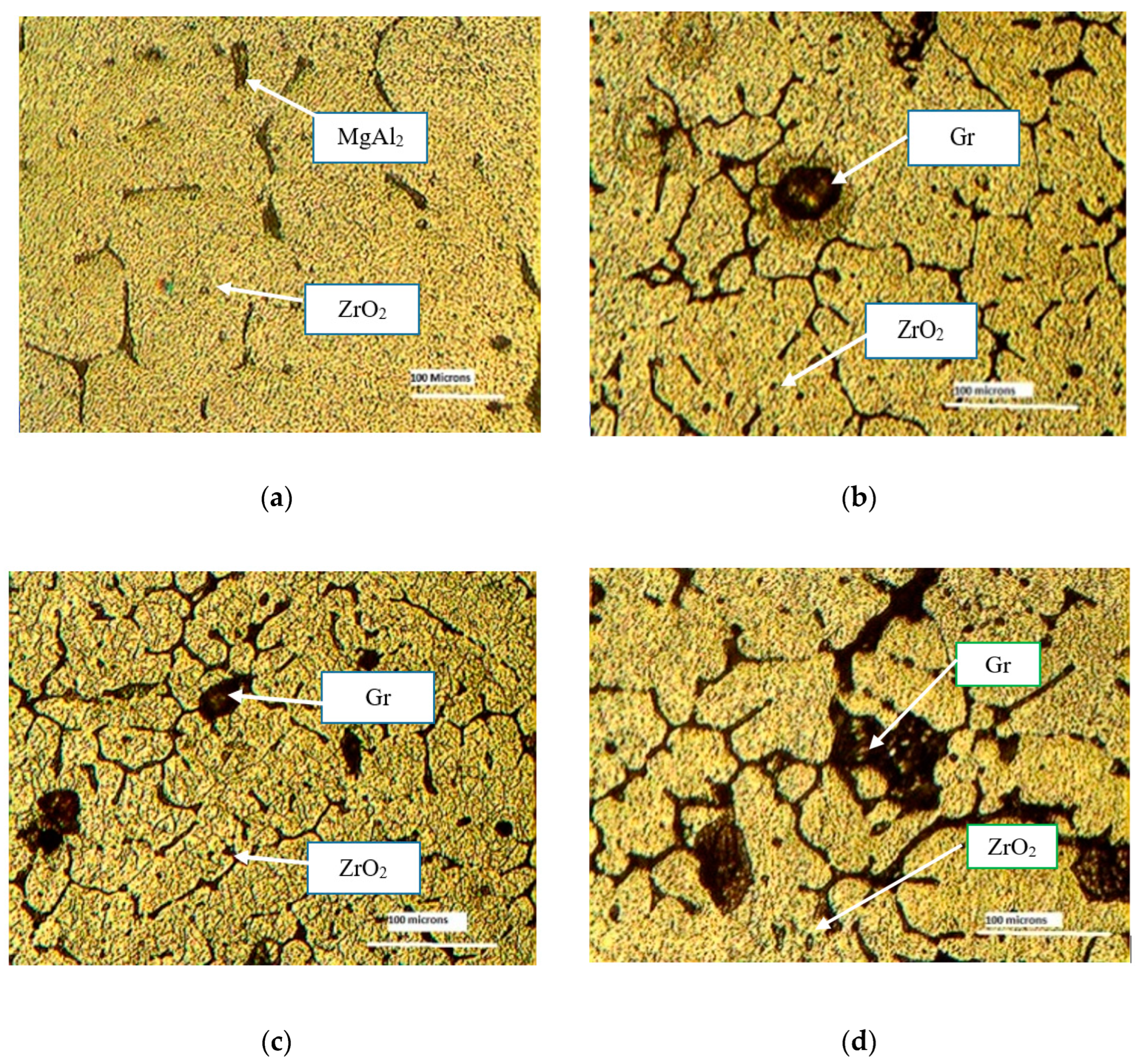

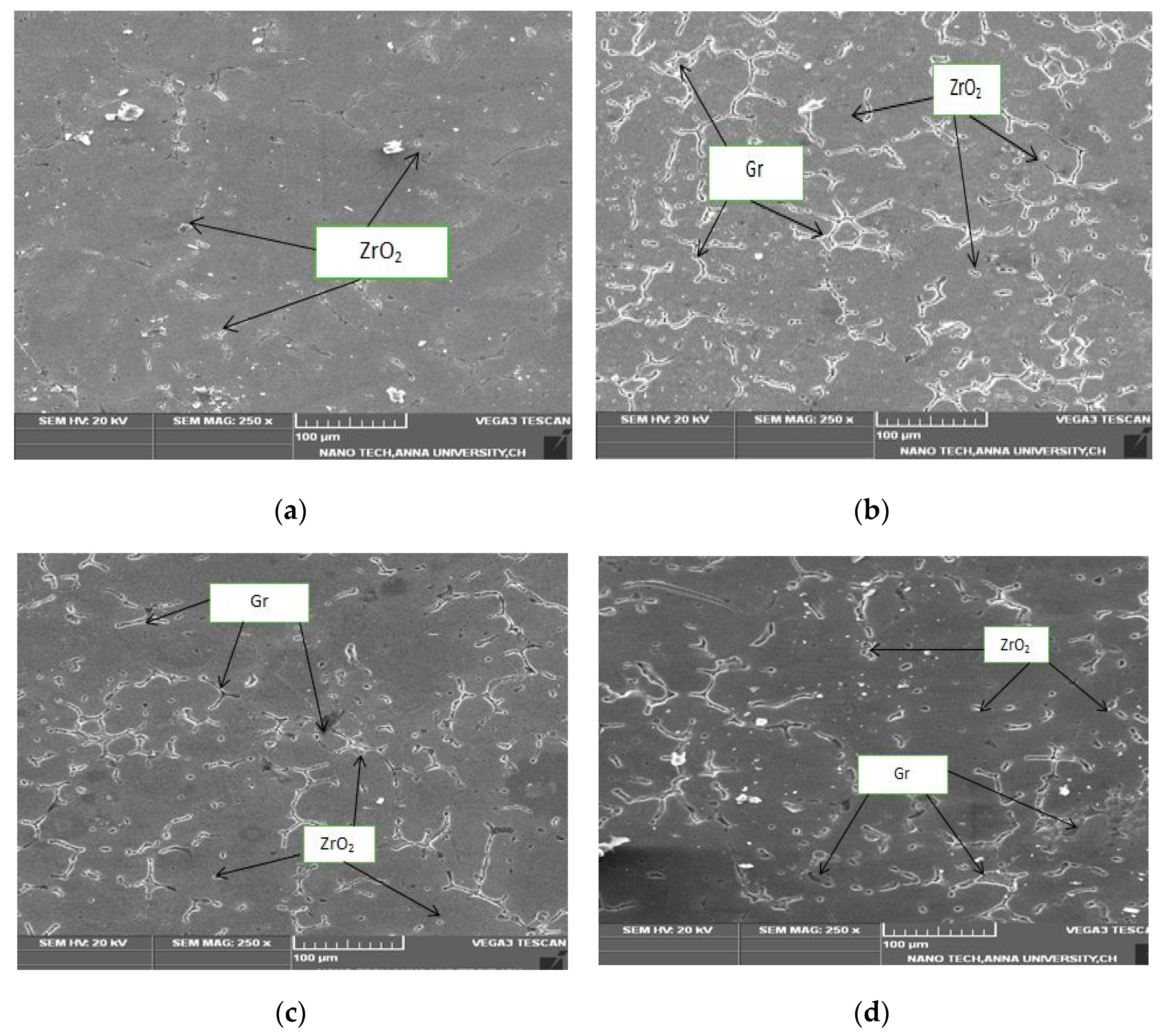

3.3. Microstructural Study of Fabricated Hybrid Composites by Optical Microscopy and SEM

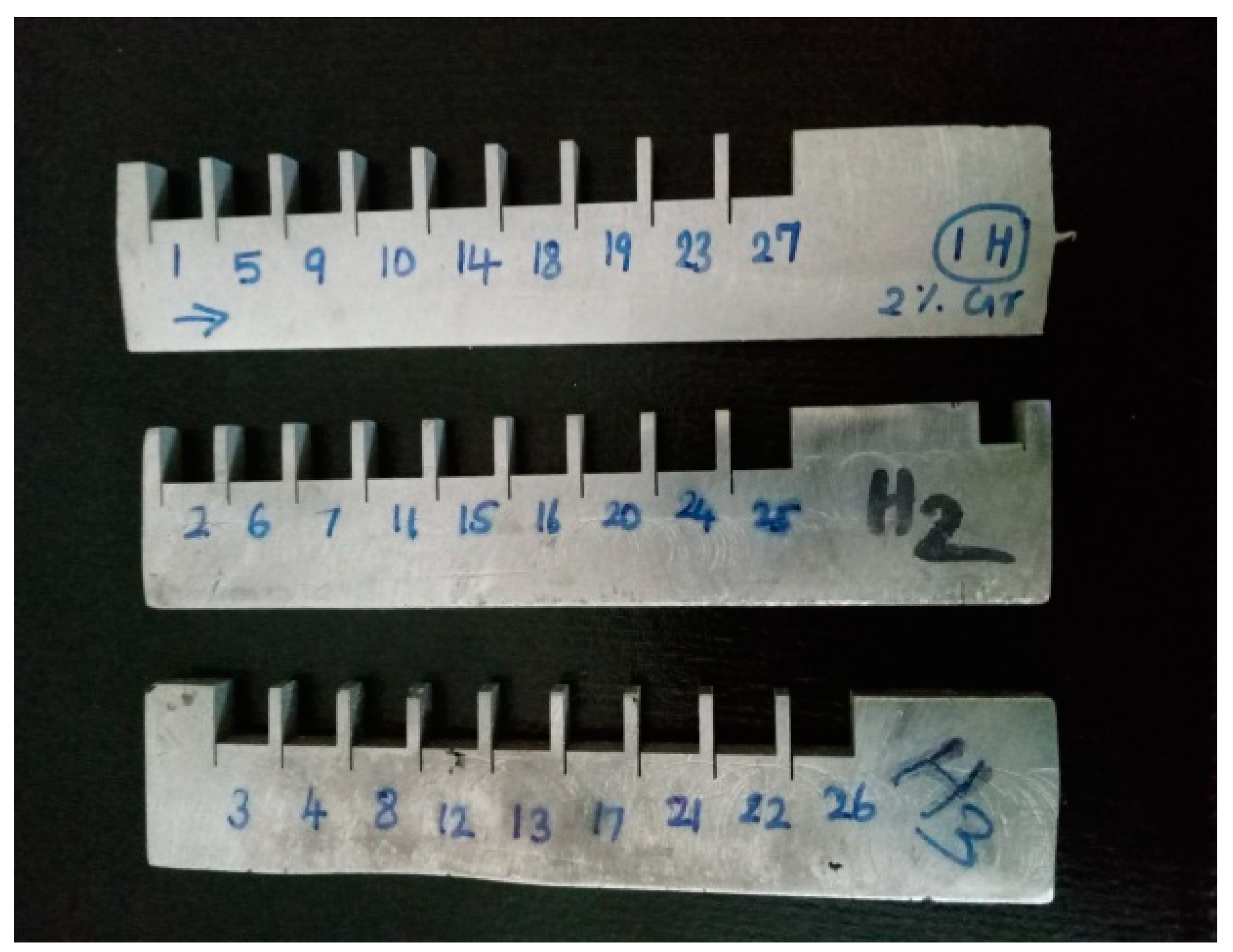

3.4. Wire EDM of LM5/ZrO2/Gr Hybrid Composites

3.5. Design of Experiments

3.6. Grey Relational Analysis

4. Results and Discussions

4.1. Experimental Results

4.2. Analysis and Discussion

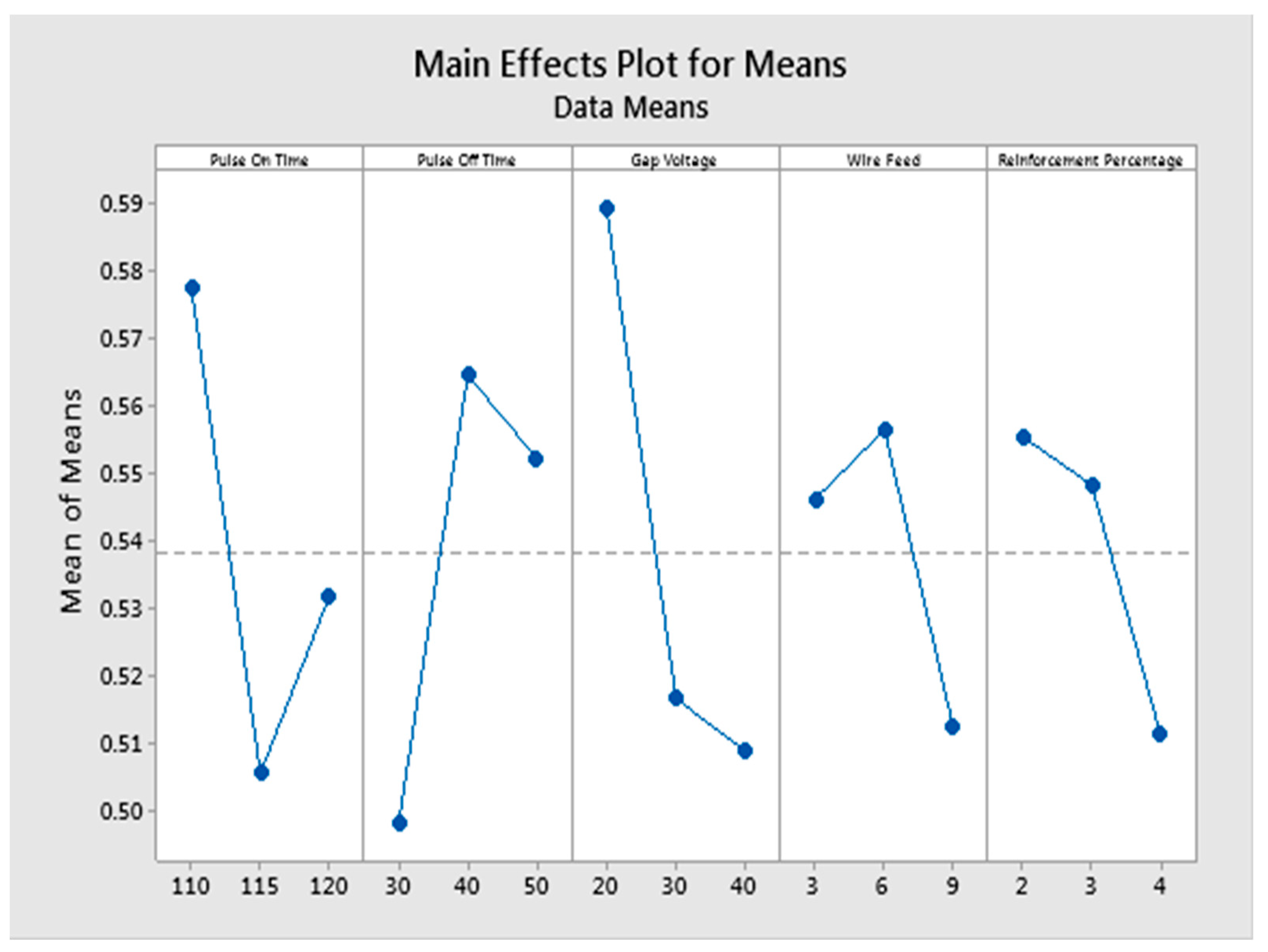

4.3. Optimal Levels for GRG

4.4. Confirmation Experiments

4.5. Effect of Process Parameters on GRG

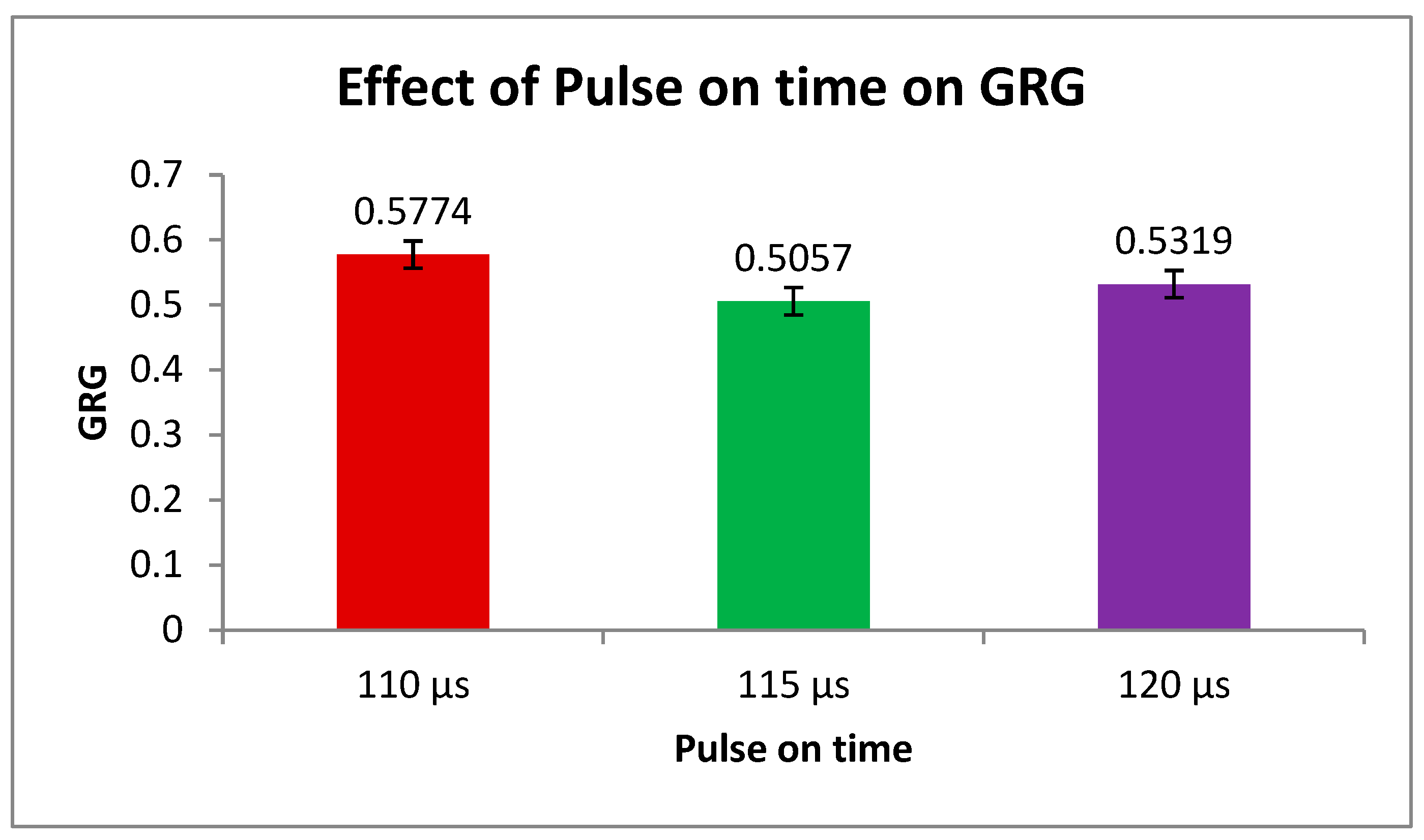

4.5.1. Effect of Pulse on Time on GRG

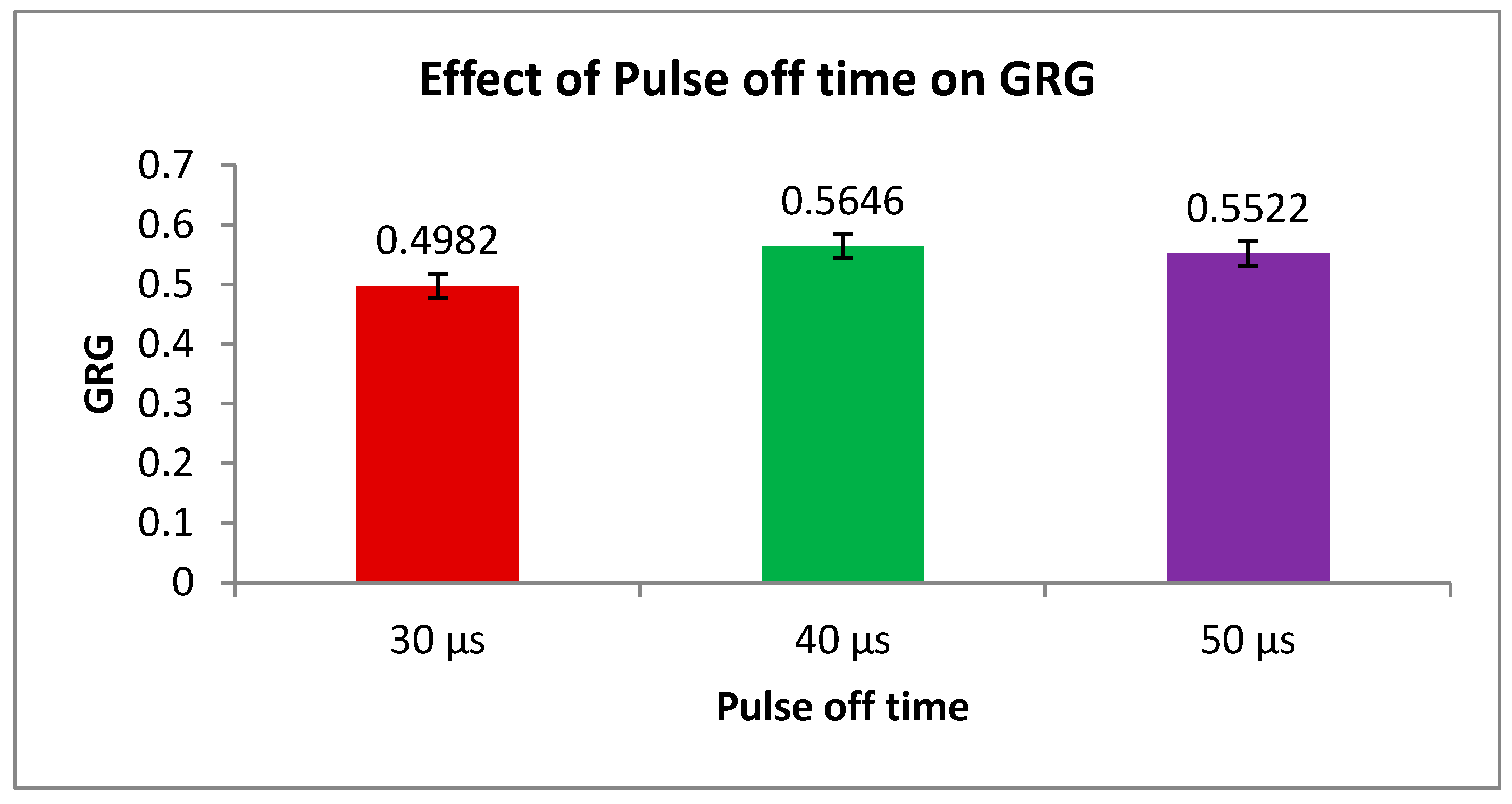

4.5.2. Effect of Pulse off Time on GRG

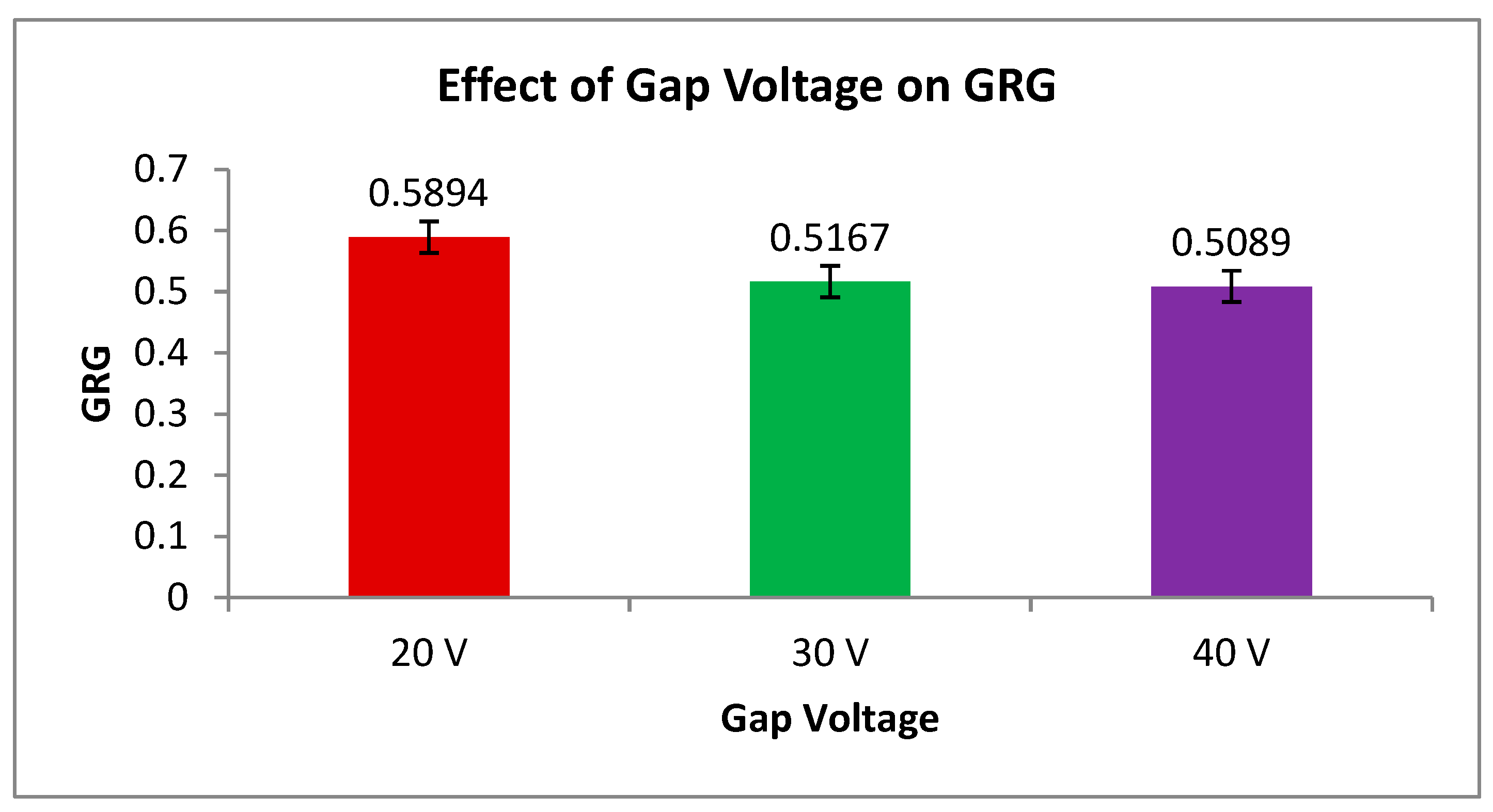

4.5.3. Effect of Gap Voltage on GRG

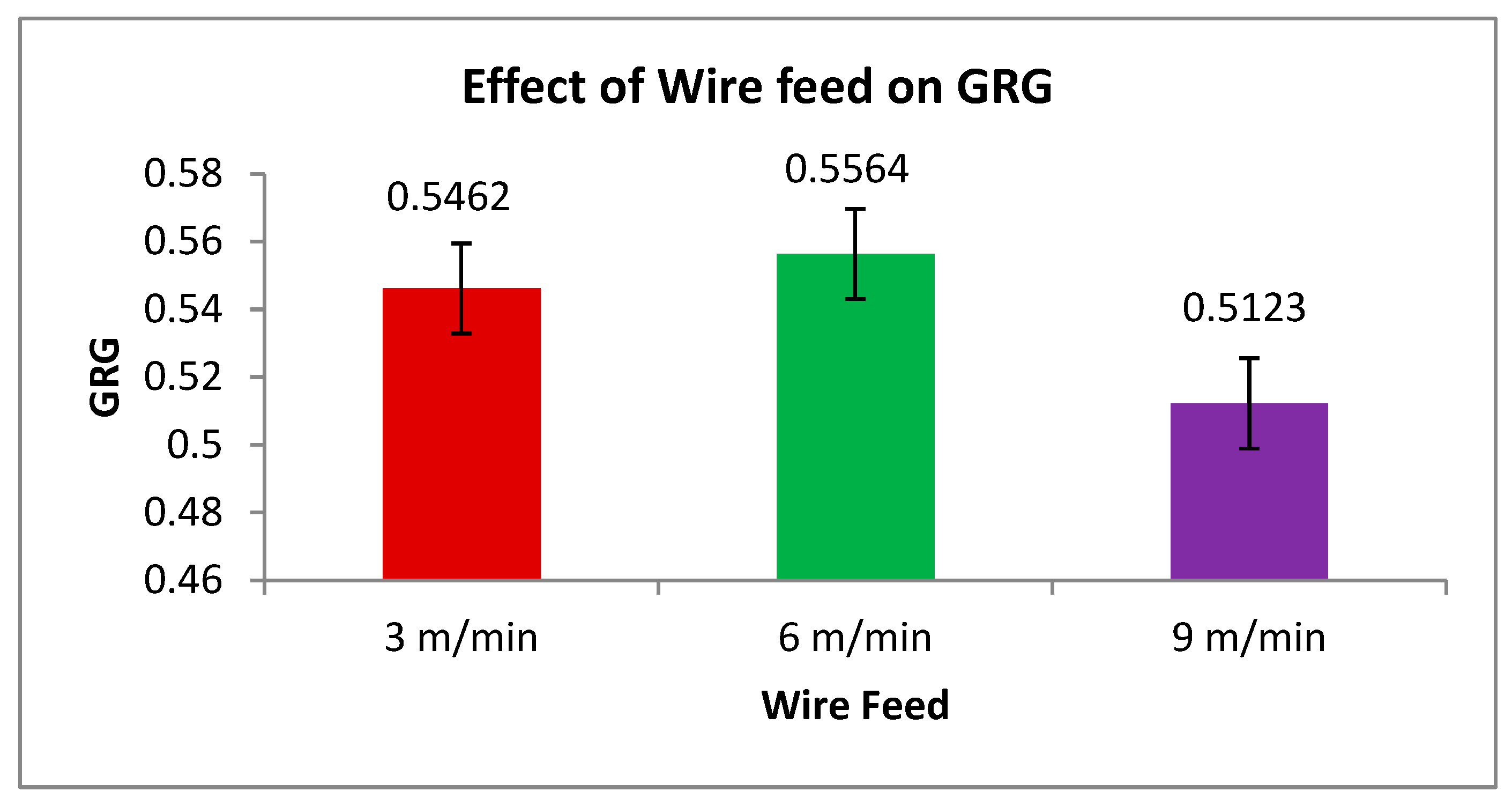

4.5.4. Effect of Wire Feed on GRG

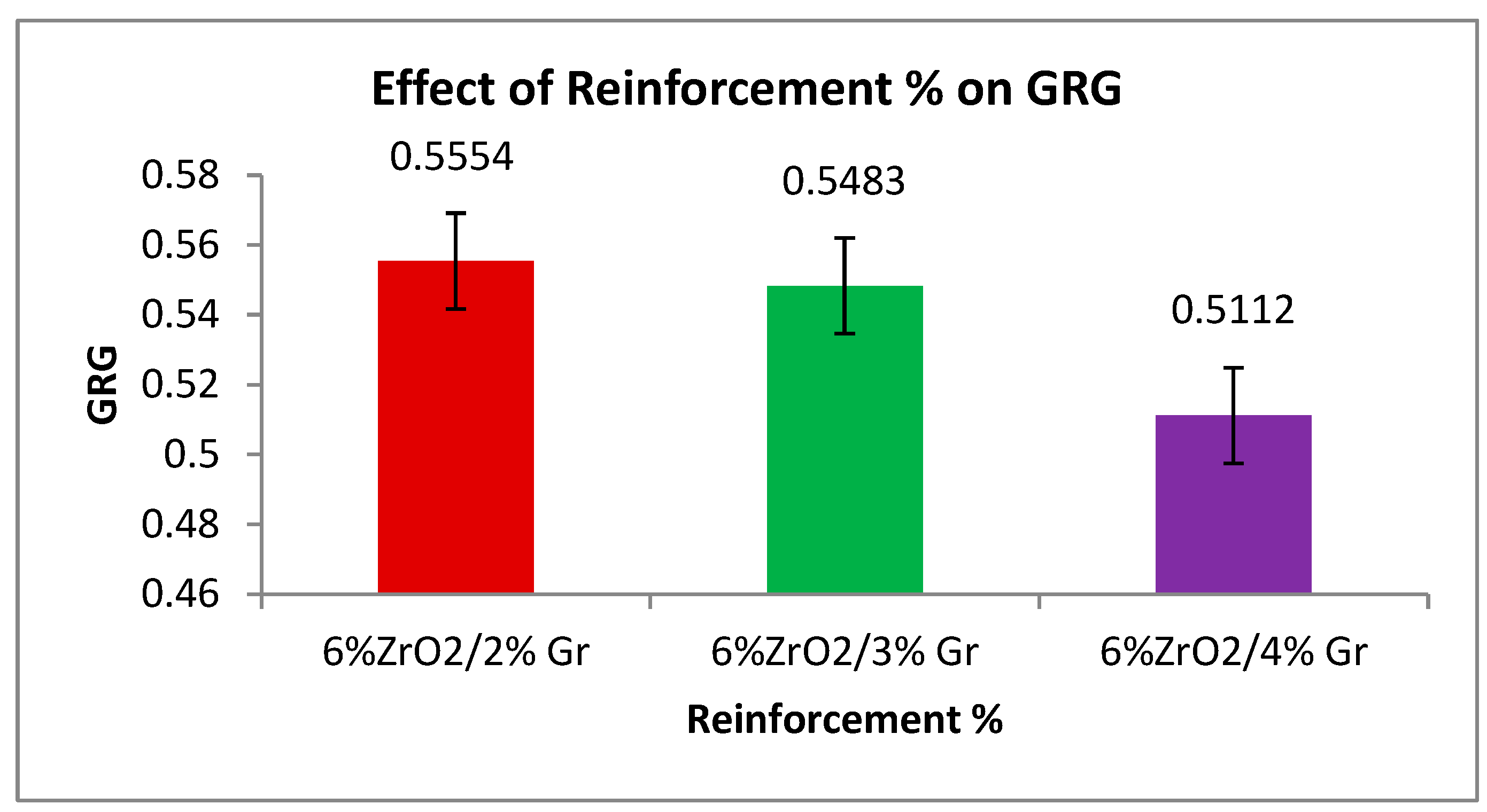

4.5.5. Effect of Reinforcement Percentage on GRG

4.6. Mathematical Models

5. Conclusions

- i.

- Wire EDM was carried out using L27 OA to trace out the paramount parameters for machining by adjusting the input parameters.

- ii.

- The findings were analysed using GRA to govern the maximum MRR, minimum SR, and Kw.

- iii.

- ANOVA was used to determine the significance of the machining variables on the standard characteristics and to assess the influence of the machining parameters.

- iv.

- A confirmation experiment was performed to acquire the best findings. The experimental findings and GRA show that the optimum process parameters for achieving the highest GRG are 6% ZrO2 with 2% graphite reinforcement, a wire feed of 6 m/min, a Ton of 110 µs, a Toff of 40 µs, and a GV of 20 V.

- v.

- Gap voltage (22.87%) has the greatest impact on the GRG according to ANOVA, subsequent to the interaction between the pulse on time and gap voltage (16.73%), pulse on time (15.28%), and pulse off time (14.42%).

- vi.

- The predicted value of the GRG is 0.679; however, the experimental GRG value is 0.672. The values are well-aligned between the expected and the experimental results. The error is only 3.29%, which is acceptable.

- vii.

- Mathematical models were created for each response using linear regression.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ujah, C.O.; Kallon, D.V.V. Trends in aluminium matrix composite development. Crystals 2022, 12, 1357. [Google Scholar] [CrossRef]

- Razzaq, A.M.; Majid, D.L.; Basheer, U.M.; Aljibori, H.S.S. Research summary on the processing, mechanical and tribological properties of aluminium matrix composites as effected by fly ash reinforcement. Crystals 2021, 11, 1212. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S.; Atreya, T.S.A.; Vignesh, V.; Subramanian, C. Aluminium metal matrix composites—A review. Rev. Adv. Mater. Sci. 2014, 38, 55–60. [Google Scholar]

- Prakash, J.U.; Jebarose Juliyana, S.; Salunkhe, S.; Gawade, S.R.; Nasr, E.S.A.; Kamrani, A.K. Mechanical Characterization and Microstructural Analysis of Stir-Cast Aluminium Matrix Composites (LM5/ZrO2). Crystals 2023, 13, 1220. [Google Scholar] [CrossRef]

- Bilal, A.; Jahan, M.P.; Talamona, D.; Perveen, A. Electro-discharge machining of ceramics: A review. Micromachines 2018, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Hemanth, J. Development and property evaluation of Aluminium alloy reinforced with nano-ZrO2 metal matrix composites (NMMCs). Mater. Sci. Eng. A 2009, 507, 110–113. [Google Scholar] [CrossRef]

- Sharma, P.; Khanduja, D.; Sharma, S. Dry sliding wear investigation of Al6082/Gr metal matrix composites by response surface methodology. J. Mater. Res. Technol. 2016, 5, 29–36. [Google Scholar] [CrossRef]

- Kumar, J.; Singh, D.; Kalsi, N.S.; Sharma, S.; Mia, M.; Singh, J.; Rahman, M.A.; Khan, A.M.; Rao, K.V. Investigation on the mechanical, tribological, morphological and machinability behavior of stir-casted Al/SiC/Mo reinforced MMCs. J. Mater. Res. Technol. 2021, 12, 930–946. [Google Scholar] [CrossRef]

- Singh, H.; Brar, G.S.; Kumar, H.; Aggarwal, V. A review on metal matrix composite for automobile applications. Mater. Today Proc. 2021, 43, 320–325. [Google Scholar] [CrossRef]

- Bhutta, M.R.; Gillani, F.; Zahid, T.; Bibi, S.; Ghafoor, U. Investigation of Hardness and Microanalysis of Sintered Aluminium-Based Supplemented Metal Matrix Machined Composites. Crystals 2023, 13, 1347. [Google Scholar] [CrossRef]

- Samal, P.; Vundavilli, P.R.; Meher, A.; Mahapatra, M.M. Recent progress in Aluminium metal matrix composites: A review on processing, mechanical and wear properties. J. Manuf. Process. 2020, 59, 131–152. [Google Scholar] [CrossRef]

- Gupta, K.; Gupta, M.K. Developments in nonconventional machining for sustainable production: A state-of-the-art review. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 4213–4232. [Google Scholar] [CrossRef]

- Thangaraj, M.; Annamalai, R.; Moiduddin, K.; Alkindi, M.; Ramalingam, S.; Alghamdi, O. Enhancing the surface quality of micro titanium alloy specimen in WEDM process by adopting TGRA-based optimization. Materials 2020, 13, 1440. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Zhang, J.; Ni, H.; Zhu, Y.; Wang, X.; Wan, X.; Chen, K. Optimization of AlSi10MgMn alloy heat treatment process based on orthogonal test and grey relational analysis. Crystals 2021, 11, 385. [Google Scholar] [CrossRef]

- Deng, J.; Yan, Q.; Lu, J.; Xiong, Q.; Pan, J. Optimisation of lapping process parameters for single-crystal 4H–SiC using orthogonal experiments and grey relational analysis. Micromachines 2021, 12, 910. [Google Scholar] [CrossRef] [PubMed]

- Jebarose, J.S.; UdayaPrakash, J.; Čep, R.; Karthik, K. Multi-Objective Optimization of Machining Parameters for Drilling LM5/ZrO2 Composites Using Grey Relational Analysis. Materials 2023, 16, 3615. [Google Scholar] [CrossRef] [PubMed]

- Bhoi, N.K.; Singh, H.; Pratap, S. Developments in the Aluminium metal matrix composites reinforced by micro/nano particles—A review. J. Compos. Mater. 2020, 54, 813–833. [Google Scholar] [CrossRef]

- Saravanan, R.; Anbuchezhiyan, G.; Mamidi, V.K.; Kumaran, P. Optimizing WEDM parameters on nano-SiC-Gr reinforced Aluminium composites using RSM. Adv. Mater. Sci. Eng. 2022, 2022, 1612539. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, Z.; Guo, J.; Ming, W.; Li, M.; Huang, Y. Modeling and optimization of medium-speed WEDM process parameters for machining SKD11. Mater. Manuf. Process. 2013, 28, 1124–1132. [Google Scholar] [CrossRef]

- Kumar, R.; Katyal, P.; Mandhania, S. Grey relational analysis based multiresponse optimization for WEDM of ZE41A magnesium alloy. Int. J. Lightweight Mater. Manuf. 2022, 5, 543–554. [Google Scholar] [CrossRef]

- Bagherian Azhiri, R.; Reza, T.; Mohammadhosein, G.B.; Zayd, L. Application of Taguchi, ANFIS and grey relational analysis for studying, modeling and optimization of wire EDM process while using gaseous media. Int. J. Adv. Manuf. Technol. 2014, 71, 279–295. [Google Scholar] [CrossRef]

- Martynenko, V.; MartínezKrahmer, D.; Napoles Alberro, A.; Cabo, A.; Pérez, D.; Zayas Figueras, E.E.; Gonzalez Rojas, H.A.; Sánchez Egea, A.J. Surface Damaging of Brass and Steel Pins when Sliding over Nitrided Samples Cut by Finishing and Roughing EDM Conditions. Materials 2020, 13, 3199. [Google Scholar] [CrossRef] [PubMed]

- Shanmugavel, R.; Chinthakndi, N.; Selvam, M.; Madasamy, N.; Shanmugakani, S.K.; Nair, A.; Prakash, C.; Buddhi, D.; Dixit, S. Al-Mg-MoS2 reinforced metal matrix composites: Machinability characteristics. Materials 2022, 15, 4548. [Google Scholar] [CrossRef] [PubMed]

- Sathish, T.; Mohanavel, V.; Ansari, K.; Saravanan, R.; Karthick, A.; Afzal, A.; Alamri, S.; Saleel, C.A. Synthesis and characterization of mechanical properties and wire cut EDM process parameters analysis in AZ61 magnesium alloy+ B4C+ SiC. Materials 2021, 14, 3689. [Google Scholar] [CrossRef] [PubMed]

- Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R.; Zhurin, A.V. Study of the EDM process of bimetallic materials using a composite electrode tool. Materials 2022, 15, 750. [Google Scholar] [CrossRef] [PubMed]

- Ramulu, M.; Spaulding, M. Drilling of hybrid titanium composite laminate (HTCL) with electrical discharge machining. Materials 2016, 9, 746. [Google Scholar] [CrossRef]

- Kosaraju, S.; BabuBobba, P.; Salkuti, S.R. Optimization and Microstructural Studies on the Machining of Inconel 600 in WEDM Using Untreated and Cryogenically Treated Zinc Electrodes. Materials 2023, 16, 3181. [Google Scholar] [CrossRef] [PubMed]

- Balamurugan, P.; Uthayakumar, M.; Pethuraj, M.; Mierzwiński, D.; Korniejenko, K.; Majid, M.S.A. Electric Discharge Machining on Stainless Steel Using a Blend of Copper and Fly Ash as the Electrode Material. Materials 2022, 15, 6735. [Google Scholar] [CrossRef]

- Zaman, U.K.U.; Khan, U.A.; Aziz, S.; Baqai, A.A.; Butt, S.U.; Hussain, D.; Siadat, A.; Jung, D.W. Optimization of Wire Electric Discharge Machining (WEDM) Process Parameters for AISI 1045 Medium Carbon Steel Using Taguchi Design of Experiments. Materials 2022, 15, 7846. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Nadykto, A.B.; Volosova, M.A.; Zelensky, A.A.; Pivkin, P.M. WEDM as a replacement for grinding in machining ceramic Al2O3-TiC cutting inserts. Metals 2021, 11, 882. [Google Scholar] [CrossRef]

- James, S.J.; Ganesan, M.; Santhamoorthy, P.; Kuppan, P. Development of hybrid aluminium metal matrix composite and study of property. Mater. Today Proc. 2018, 5, 13048–13054. [Google Scholar] [CrossRef]

- Urtekin, L.; Şahin, İ.B.; Yılan, F.; Kuloğlu, E.; Genç, A. Investigation and Optimization of Cutting Performance of High Chrome White Cast Iron by Wire Erosion. Arab. J. Sci. Eng. 2023, 1–12. [Google Scholar] [CrossRef]

- Arunadevi, M.; Prakash, C.P.S. Predictive analysis and multi objective optimization of wireEDM process using ANN. Mater. Today Proc. 2021, 46, 6012–6016. [Google Scholar] [CrossRef]

- Ramanan, G.; Dhas, J.E.R. Multi objective optimization of wire EDM machining parameters for AA7075-PAC composite using grey-fuzzy technique. Mater. Today Proc. 2018, 5, 8280–8289. [Google Scholar] [CrossRef]

- Shadab, M.; Singh, R.; Rai, R.N. Multi-objective Optimization of Wire Electrical Discharge Machining Process Parameters for Al5083/7% B _ 4 C B 4 C Composite Using Metaheuristic Techniques. Arab. J. Sci. Eng. 2019, 44, 591–601. [Google Scholar] [CrossRef]

- Kavimani, V.; Prakash, K.S.; Thankachan, T. Multi-objective optimization in WEDM process of graphene–SiC-magnesium composite through hybrid techniques. Measurement 2019, 145, 335–349. [Google Scholar] [CrossRef]

- Lok, Y.K.; Lee, T.C. Processing of advanced ceramics using the wire-cut EDM process. J. Mater. Process. Technol. 1997, 63, 839–843. [Google Scholar] [CrossRef]

- Pansare, M.P.; Bajaj, D.S.; Aher, V.S. Tribological Behavior of Ptfe Composite Material for Journal Bearing. Int. J. Innov. Eng. Res. Technol. 2015, 1–5. [Google Scholar]

- Jebarose Juliyana, S.; Udaya Prakash, J. Optimization of burr height in drilling of aluminium matrix composites (LM5/ZrO2) using Taguchi technique. Adv. Mater. Process. Technol. 2022, 8, 417–426. [Google Scholar] [CrossRef]

- Juliyana, S.J.; Prakash, J.U.; Sadhana, A.D.; Rubi, C.S. Multi-objective optimization of process parameters of wire EDM for machining of AMCs (LM5/ZrO2) using grey relational analysis. Mater. Today Proc. 2022, 52, 1494–1498. [Google Scholar] [CrossRef]

- Juliyana, S.J.; Prakash, J.U. Optimization of machining parameters for wire EDM of AMCs (LM5/ZrO2) using Taguchi technique. INCAS Bull. 2022, 14, 57–68. [Google Scholar] [CrossRef]

- Wei, Q.; Li, S.; Han, C.; Li, W.; Cheng, L.; Hao, L.; Shi, Y. Selective laser melting of stainless-steel/nano-hydroxyapatite composites for medical applications: Microstructure, element distribution, crack and mechanical properties. J. Mater. Process. Technol. 2015, 222, 444–453. [Google Scholar] [CrossRef]

- Juliyana, S.J.; Prakash, J.U.; Salunkhe, S.; Hussein, H.M.A.; Gawade, S.R. Mechanical Characterization and Microstructural Analysis of Hybrid Composites (LM5/ZrO2/Gr). Crystals 2022, 12, 1207. [Google Scholar] [CrossRef]

- Franco Jr, A.R.; Pintaúde, G.; Sinatora, A.; Pinedo, C.E.; Tschiptschin, A.P. The use of a Vickers indenter in depth sensing indentation for measuring elastic modulus and Vickers hardness. Mater. Res. 2004, 7, 483–491. [Google Scholar] [CrossRef]

- Zhang, X.; Naeem, M.; Baig, A.Q.; Zahid, M.A. Study of hardness of superhard crystals by topological indices. J. Chem. 2021, 2021, 9604106. [Google Scholar] [CrossRef]

- Gurupavan, H.R.; Devegowda, T.M.; Ravindra, H.V.; Ugrasen, G. Estimation of machining performances in WEDM of aluminium based metal matrix composite material using ANN. Mater. Today Proc. 2017, 4, 10035–10038. [Google Scholar] [CrossRef]

- Chen, Z.; Zhou, H.; Wu, C.; Zhang, G.; Yan, H. A new wire electrode for improving the machining characteristics of high-volume fraction SiCp/Al composite in WEDM. Materials 2022, 15, 4098. [Google Scholar] [CrossRef] [PubMed]

- Prakash, J.U.; Sivaprakasam, P.; Juliyana, S.J.; Ananth, S.; Rubi, C.S.; Sadhana, A.D. Multi-objective optimization using grey relational analysis for wire EDM of aluminium matrix composites. Mater. Today Proc. 2023, 72, 2395–2401. [Google Scholar] [CrossRef]

- Bellubbi, S.; Sathisha, N.; Mallick, B. Multi response optimization of ECDM process parameters for machining of microchannel in silica glass using Taguchi–GRA technique. Silicon 2022, 14, 4249–4263. [Google Scholar] [CrossRef]

- Sheth, M.; Gajjar, K.; Jain, A.; Shah, V.; Patel, H.; Chaudhari, R.; Vora, J. Multi-objective optimization of inconel 718 using Combined approach of taguchi—Grey relational analysis. In Advances in Mechanical Engineering: Select Proceedings of ICAME 2020; Springer: Singapore, 2021; pp. 229–235. [Google Scholar]

- Kumar, V.; Chakraborty, S. Analysis of the surface roughness characteristics of EDMed components using GRA method. In International Conference on Industrial and Manufacturing Systems (CIMS-2020) Optimization in Industrial and Manufacturing Systems and Applications; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 461–478. [Google Scholar]

- Çakıroğlu, R.; Günay, M. Comprehensive analysis of material removal rate, tool wear and surface roughness in electrical discharge turning of L2 tool steel. J. Mater. Res. Technol. 2020, 9, 7305–7317. [Google Scholar] [CrossRef]

- Udaya Prakash, J.; Ananth, S.; Jebarose Juliyana, S.; John Paul, P. Effect of wire EDM process parameters on machining of aluminium matrix composites (356/Fly Ash). In ICDMC 2019: Design, Materials, Cryogenics, and Constructions; Springer: Singapore, 2020; pp. 411–419. [Google Scholar]

- Soni, H.; Ramesh, M.R. Experimental investigation on effects of wire electro discharge machining of Ti50Ni45Co5 shape memory alloys. Silicon 2018, 10, 2483–2490. [Google Scholar] [CrossRef]

- Yan, H.; Kabongo, B.D.; Zhou, H.; Wu, C.; Chen, Z. Analysis and Optimization of the Machining Characteristics of High-Volume Content SiCp/Al Composite in Wire Electrical Discharge Machining. Crystals 2021, 11, 1342. [Google Scholar] [CrossRef]

- Prakash, J.U.; Rubi, C.S.; Rajkumar, C.; Juliyana, S.J. Multi-objective drilling parameter optimization of hybrid metal matrix composites using grey relational analysis. Mater. Today Proc. 2021, 39, 1345–1350. [Google Scholar] [CrossRef]

| Cu | Mg | Si | Mn | Fe | Pb | Zn | Al |

|---|---|---|---|---|---|---|---|

| 0.032 | 3.299 | 0.212 | 0.022 | 0.268 | 0.02 | 0.01 | Balance |

| Level | Pulse on Time Ton (µs) | Pulse off Time Toff (µs) | Gap Voltage GV (V) | Wire Feed WF (m/min) | Reinforcement % R % |

|---|---|---|---|---|---|

| 1 | 110 | 30 | 20 | 3 | 6% ZrO2 + 2%Gr |

| 2 | 115 | 40 | 30 | 6 | 6% ZrO2 + 3%Gr |

| 3 | 120 | 50 | 40 | 9 | 6% ZrO2 + 4%Gr |

| Ex. No | Pulse on Time (µs) | Pulse off Time (µs) | Gap Voltage (V) | Wire Feed (m/min) | Reinforcement wt % | GRC of MRR | GRC of SR | GRC of kerf | GRG | Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 110 | 30 | 20 | 3 | 2 | 0.418 | 0.767 | 0.491 | 0.559 | 10 |

| 2 | 110 | 30 | 30 | 6 | 3 | 0.386 | 0.763 | 0.373 | 0.507 | 18 |

| 3 | 110 | 30 | 40 | 9 | 4 | 0.354 | 0.387 | 0.412 | 0.384 | 27 |

| 4 | 110 | 40 | 20 | 6 | 3 | 0.417 | 0.694 | 0.7 | 0.604 | 9 |

| 5 | 110 | 40 | 30 | 9 | 4 | 0.369 | 1 | 0.509 | 0.626 | 5 |

| 6 | 110 | 40 | 40 | 3 | 2 | 0.343 | 0.921 | 0.583 | 0.616 | 7 |

| 7 | 110 | 50 | 20 | 9 | 4 | 0.394 | 0.755 | 0.7 | 0.616 | 8 |

| 8 | 110 | 50 | 30 | 3 | 2 | 0.38 | 0.506 | 1 | 0.629 | 3 |

| 9 | 110 | 50 | 40 | 6 | 3 | 0.333 | 0.916 | 0.718 | 0.656 | 2 |

| 10 | 115 | 30 | 20 | 3 | 2 | 0.544 | 0.603 | 0.491 | 0.546 | 11 |

| 11 | 115 | 30 | 30 | 6 | 3 | 0.462 | 0.678 | 0.424 | 0.521 | 15 |

| 12 | 115 | 30 | 40 | 9 | 4 | 0.426 | 0.357 | 0.5 | 0.428 | 26 |

| 13 | 115 | 40 | 20 | 6 | 3 | 0.597 | 0.59 | 0.424 | 0.537 | 12 |

| 14 | 115 | 40 | 30 | 9 | 4 | 0.445 | 0.614 | 0.424 | 0.494 | 20 |

| 15 | 115 | 40 | 40 | 3 | 2 | 0.396 | 0.726 | 0.424 | 0.515 | 17 |

| 16 | 115 | 50 | 20 | 9 | 4 | 0.535 | 0.605 | 0.412 | 0.517 | 16 |

| 17 | 115 | 50 | 30 | 3 | 2 | 0.47 | 0.503 | 0.437 | 0.47 | 23 |

| 18 | 115 | 50 | 40 | 6 | 3 | 0.386 | 0.758 | 0.424 | 0.523 | 14 |

| 19 | 120 | 30 | 20 | 3 | 2 | 0.804 | 0.541 | 0.509 | 0.618 | 6 |

| 20 | 120 | 30 | 30 | 6 | 3 | 0.622 | 0.473 | 0.364 | 0.486 | 21 |

| 21 | 120 | 30 | 40 | 9 | 4 | 0.496 | 0.42 | 0.389 | 0.435 | 24 |

| 22 | 120 | 40 | 20 | 6 | 3 | 1 | 0.637 | 0.4 | 0.679 | 1 |

| 23 | 120 | 40 | 30 | 9 | 4 | 0.578 | 0.496 | 0.373 | 0.482 | 22 |

| 24 | 120 | 40 | 40 | 3 | 2 | 0.458 | 0.701 | 0.424 | 0.528 | 13 |

| 25 | 120 | 50 | 20 | 9 | 4 | 0.814 | 0.66 | 0.412 | 0.629 | 4 |

| 26 | 120 | 50 | 30 | 3 | 2 | 0.639 | 0.333 | 0.333 | 0.435 | 25 |

| 27 | 120 | 50 | 40 | 6 | 3 | 0.447 | 0.625 | 0.412 | 0.495 | 19 |

| Level | Pulse on Time | Pulse off Time | Gap Voltage | Wire Feed | Reinforcement % |

|---|---|---|---|---|---|

| 1 | 0.5774 | 0.4982 | 0.5894 | 0.5462 | 0.5554 |

| 2 | 0.5057 | 0.5646 | 0.5167 | 0.5564 | 0.5483 |

| 3 | 0.5319 | 0.5522 | 0.5089 | 0.5123 | 0.5112 |

| Delta | 0.0718 | 0.0663 | 0.0806 | 0.0441 | 0.0442 |

| Rank | 2 | 3 | 1 | 5 | 4 |

| Source of Variation | DF | SS | MS | F | p | C % |

|---|---|---|---|---|---|---|

| Pulse on Time | 2 | 0.0237 | 0.0119 | 18.61 | 0.001 | 15.28 |

| Pulse off Time | 2 | 0.0224 | 0.0112 | 17.56 | 0.001 | 14.42 |

| Gap Voltage | 2 | 0.0355 | 0.0178 | 27.85 | 0 | 22.87 |

| Wire Feed | 2 | 0.0096 | 0.0048 | 7.52 | 0.015 | 6.18 |

| Reinforcement % | 2 | 0.0102 | 0.0051 | 7.96 | 0.013 | 6.53 |

| Ton * Toff | 4 | 0.0228 | 0.0057 | 8.95 | 0.005 | 14.70 |

| Ton * GV | 4 | 0.0260 | 0.0065 | 10.19 | 0.003 | 16.73 |

| Pooled Error | 8 | 0.0051 | 0.0006 | 3.29 | ||

| Total | 26 | 0.1554 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jebarose Juliyana, S.; Udaya Prakash, J.; Rubi, C.S.; Salunkhe, S.; Gawade, S.R.; Abouel Nasr, E.S.; Kamrani, A.K. Optimization of Wire EDM Process Parameters for Machining Hybrid Composites Using Grey Relational Analysis. Crystals 2023, 13, 1549. https://doi.org/10.3390/cryst13111549

Jebarose Juliyana S, Udaya Prakash J, Rubi CS, Salunkhe S, Gawade SR, Abouel Nasr ES, Kamrani AK. Optimization of Wire EDM Process Parameters for Machining Hybrid Composites Using Grey Relational Analysis. Crystals. 2023; 13(11):1549. https://doi.org/10.3390/cryst13111549

Chicago/Turabian StyleJebarose Juliyana, Sunder, Jayavelu Udaya Prakash, Charles Sarala Rubi, Sachin Salunkhe, Sharad Ramdas Gawade, Emad S. Abouel Nasr, and Ali K. Kamrani. 2023. "Optimization of Wire EDM Process Parameters for Machining Hybrid Composites Using Grey Relational Analysis" Crystals 13, no. 11: 1549. https://doi.org/10.3390/cryst13111549

APA StyleJebarose Juliyana, S., Udaya Prakash, J., Rubi, C. S., Salunkhe, S., Gawade, S. R., Abouel Nasr, E. S., & Kamrani, A. K. (2023). Optimization of Wire EDM Process Parameters for Machining Hybrid Composites Using Grey Relational Analysis. Crystals, 13(11), 1549. https://doi.org/10.3390/cryst13111549