Assessment of Joinability in Additively Manufactured Interlocking Structures

Abstract

:1. Introduction

2. Materials and Methods

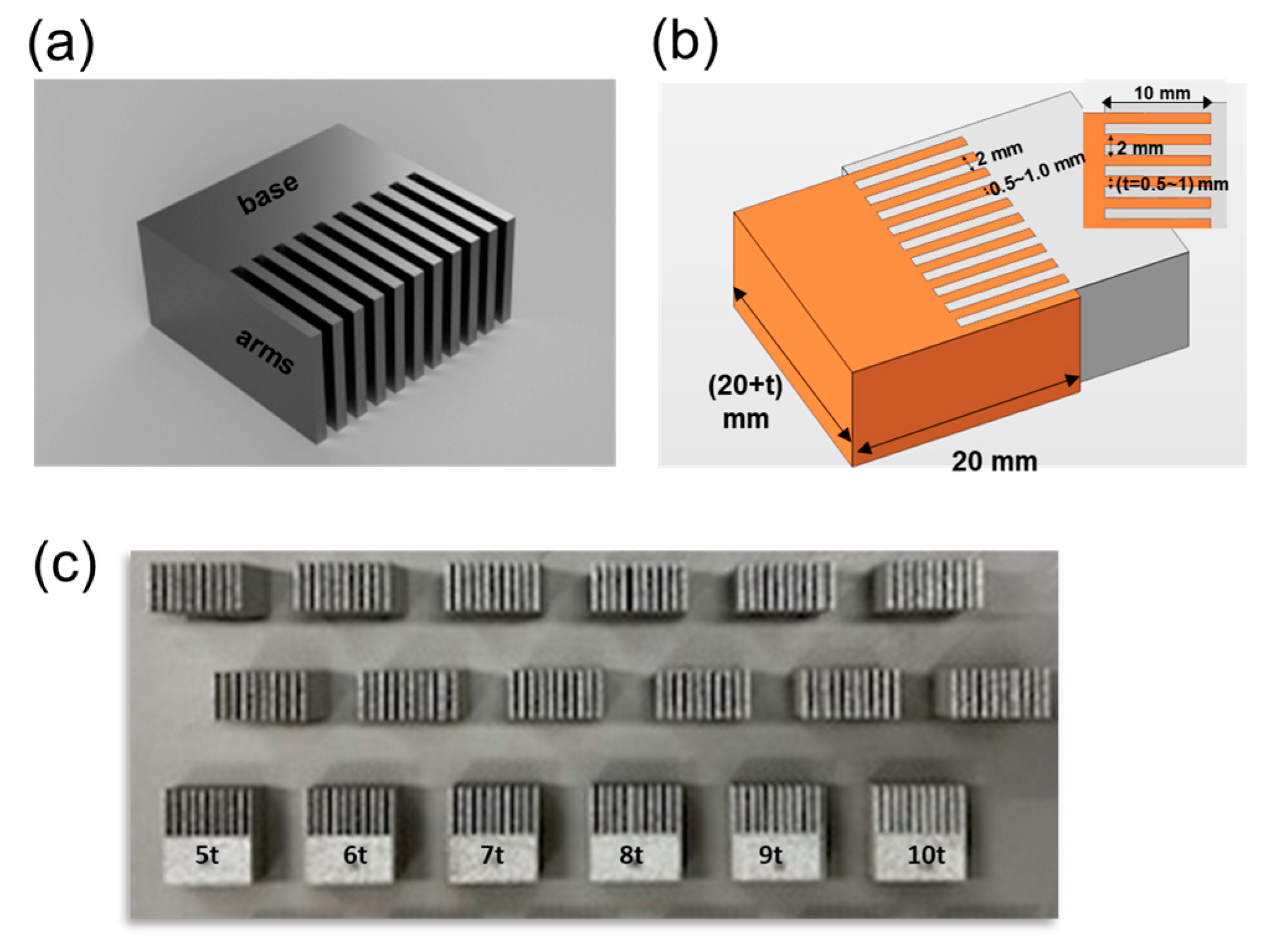

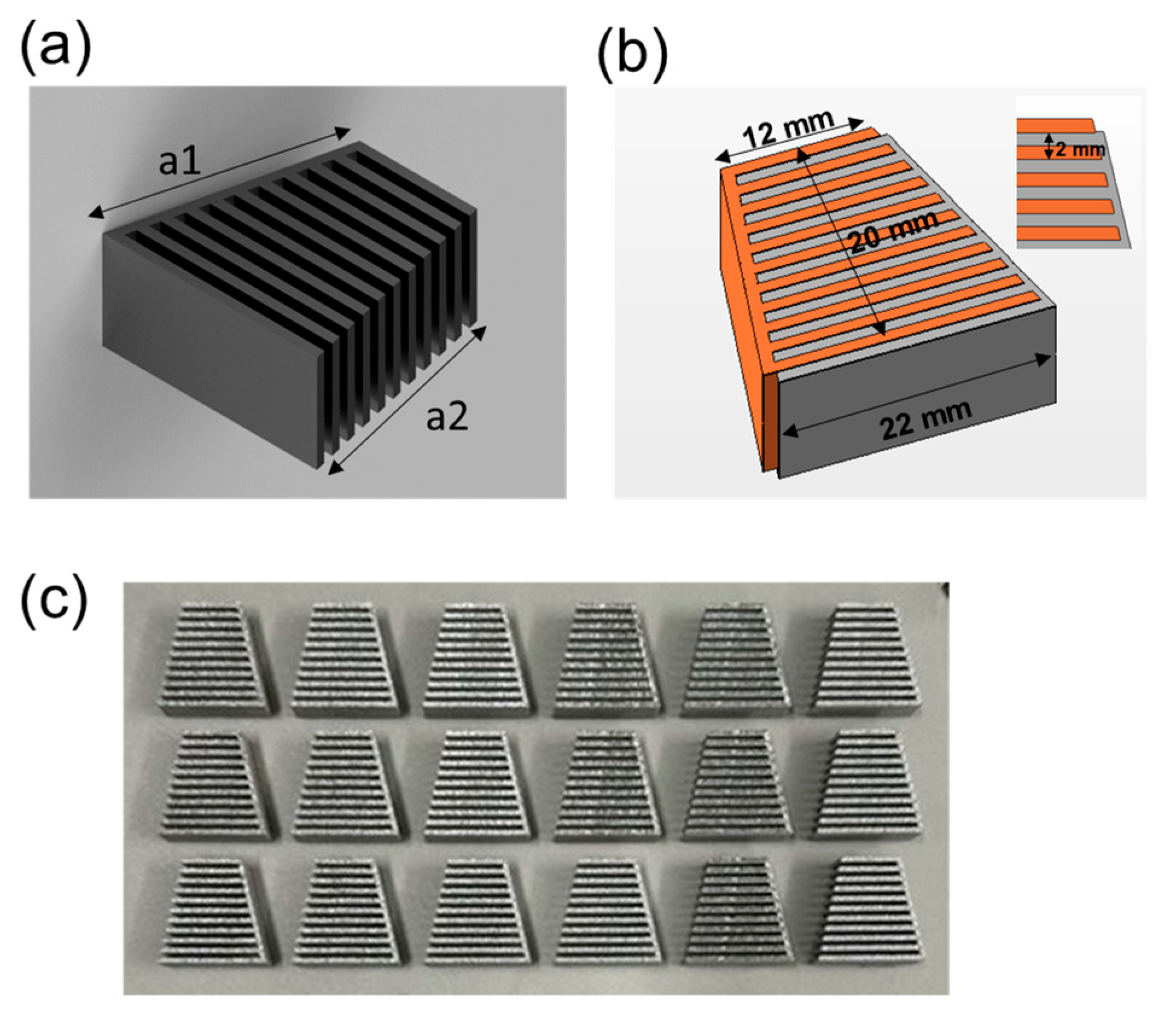

2.1. Design of Interlocking Structures

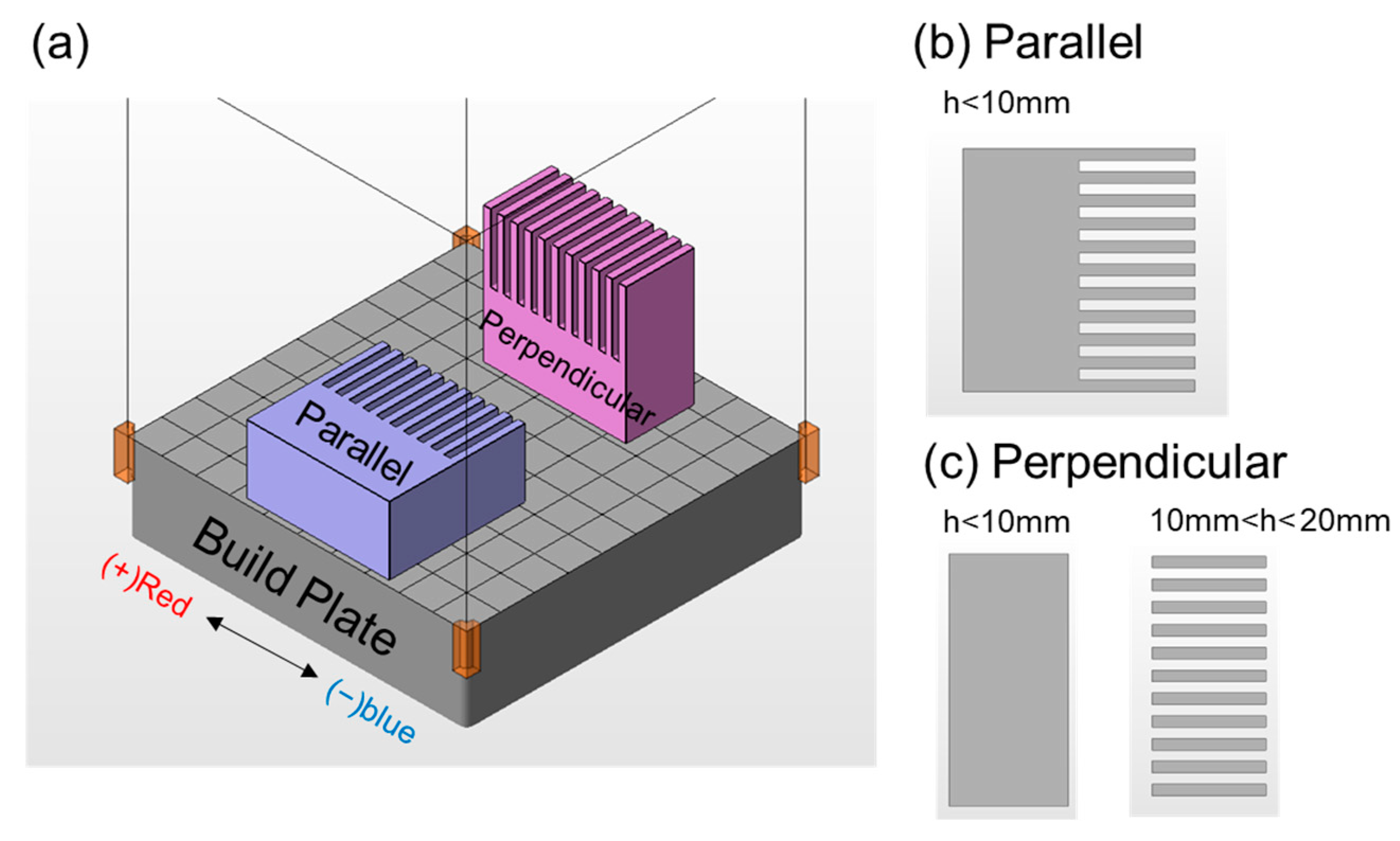

2.2. Additive Manufacturing of Interlocking Structures

2.3. Joinability Test and X-ray Computed Tomography (CT) Analysis

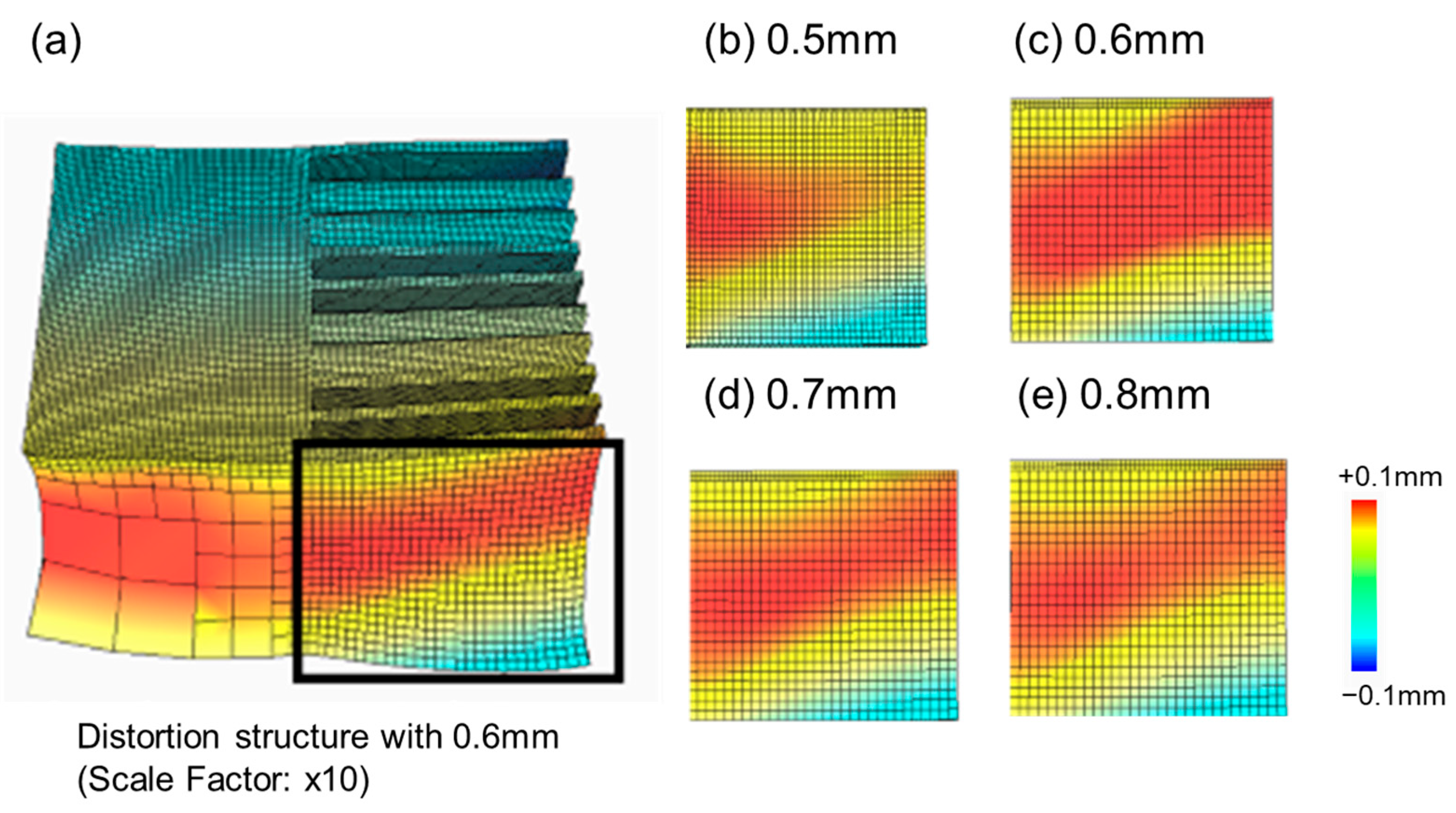

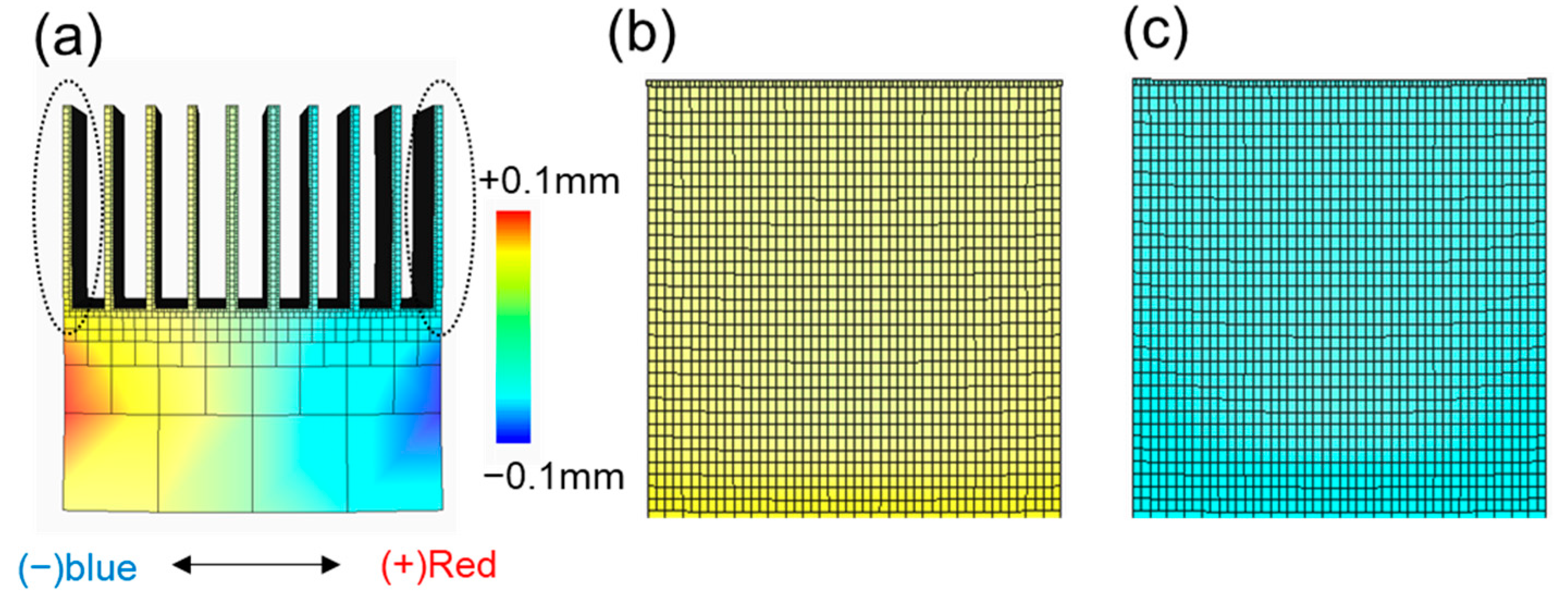

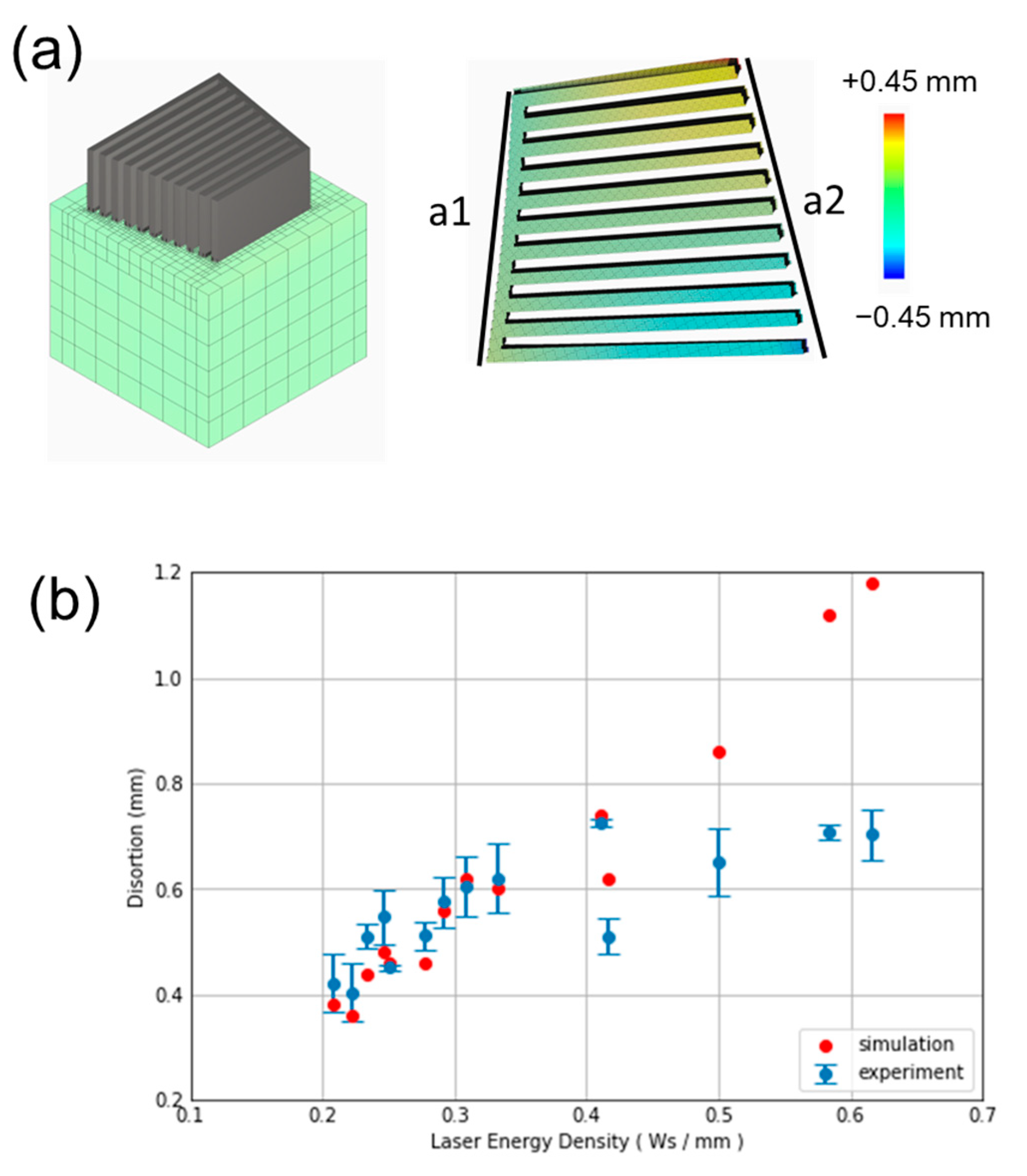

2.4. Simulation of the Distortion in Additive Manufacturing

3. Results

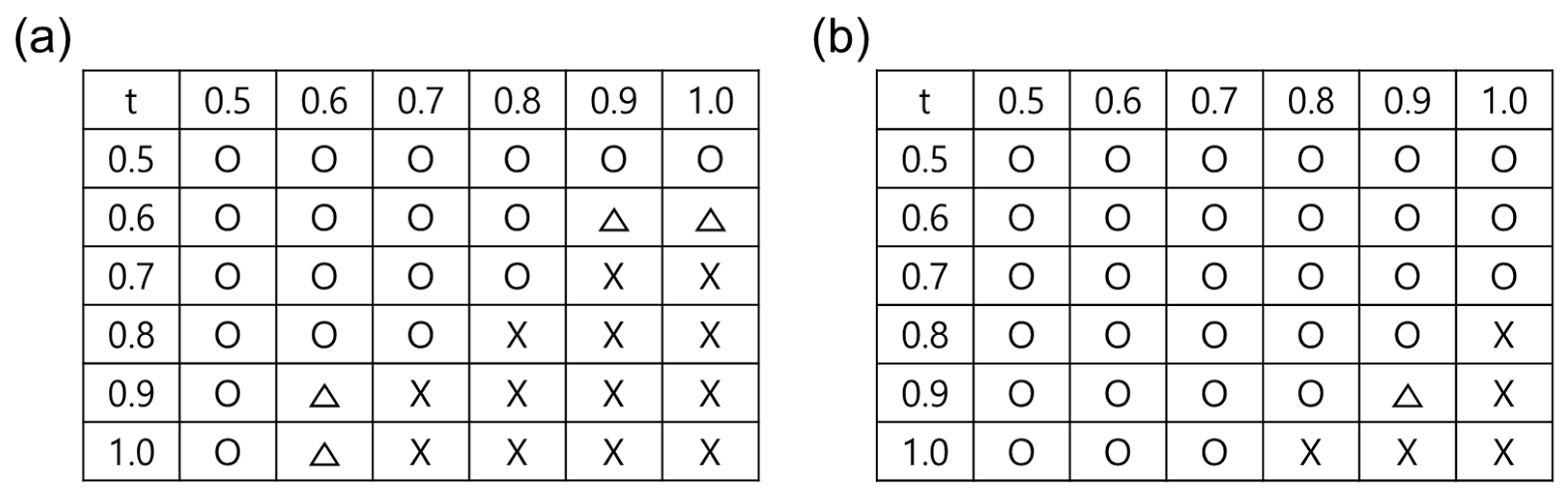

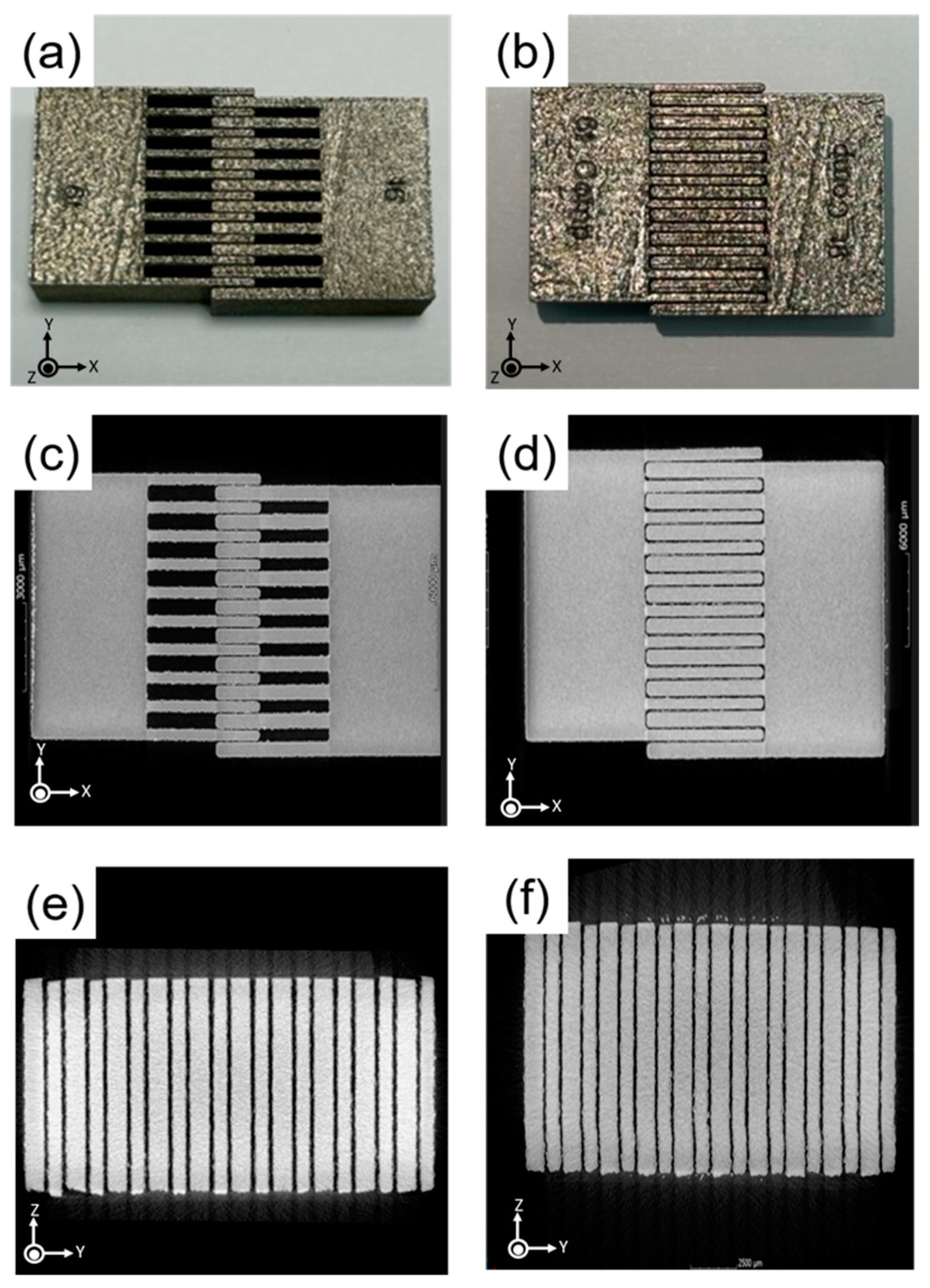

3.1. The Effect of Building Direction on Joinability of Interlocking Structures

3.2. Compensated Structure to Improve Joinability

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Lu, B.; Li, D.; Tian, X. Development trends in additive manufacturing and 3D printing. Engineering 2015, 1, 085–089. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar]

- DebRoy, T.; Wei, H.; Zuback, J.; Mukherjee, T.; Elmer, J.; Milewski, J.; Beese, A.M.; Wilson-Heid, A.d.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar]

- DebRoy, T.; Mukherjee, T.; Milewski, J.; Elmer, J.; Ribic, B.; Blecher, J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef]

- Madhavadas, V.; Srivastava, D.; Chadha, U.; Raj, S.A.; Sultan, M.T.H.; Shahar, F.S.; Shah, A.U.M. A review on metal additive manufacturing for intricately shaped aerospace components. CIRP J. Manuf. Sci. Technol. 2022, 39, 18–36. [Google Scholar]

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar]

- Tofail, S.A.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Ann. 2020, 69, 578–599. [Google Scholar]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The role of additive manufacturing in the era of industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Peralta Marino, G.; De la Pierre, S.; Salvo, M.; Díaz Lantada, A.; Ferraris, M. Modelling, additive layer manufacturing and testing of interlocking structures for joined components. Sci. Rep. 2022, 12, 2526. [Google Scholar] [CrossRef] [PubMed]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive manufacturing of ceramics: Issues, potentialities, and opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Song, P.; Fu, Z.; Liu, L.; Fu, C.-W. Printing 3D objects with interlocking parts. Comput. Aided Geom. Des. 2015, 35, 137–148. [Google Scholar] [CrossRef]

- Zareiyan, B.; Khoshnevis, B. Effects of interlocking on interlayer adhesion and strength of structures in 3D printing of concrete. Autom. Constr. 2017, 83, 212–221. [Google Scholar] [CrossRef]

- Li, Z.; Tsavdaridis, K.D. Limited-damage 3D-printed interlocking connection for timber volumetric structures: Experimental validation and computational modelling. J. Build. Eng. 2023, 63, 105373. [Google Scholar] [CrossRef]

- Mirkhalaf, M.; Barthelat, F. Design, 3D printing and testing of architectured materials with bistable interlocks. Extrem. Mech. Lett. 2017, 11, 1–7. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Tarraste, M.; Vaimann, T.; Rassõlkin, A.; Asad, B.; Shams Ghahfarokhi, P. AC magnetic loss reduction of SLM processed Fe-Si for additive manufacturing of electrical machines. Energies 2021, 14, 1241. [Google Scholar] [CrossRef]

- Isa, M.; Kadir, M.; Gomes, C.; Azis, N.; Izadi, M.; Alyozbaky, O. Analysis on magnetic flux density and core loss for hexagonal and butt-lap core joint transformers. In Proceedings of the 2016 IEEE 2nd Annual Southern Power Electronics Conference (SPEC), Auckland, New Zealand, 5–8 December 2016; pp. 1–4. [Google Scholar]

- Koo, B.; Jang, M.-S.; Nam, Y.G.; Yang, S.; Yu, J.; Park, Y.H.; Jeong, J.W. Structurally-layered soft magnetic Fe-Si components with surface insulation prepared by shell-shaping selective laser melting. Appl. Surf. Sci. 2021, 553, 149510. [Google Scholar] [CrossRef]

- Manninen, A.; Pippuri-Mäkeläinen, J.; Riipinen, T.; Lindroos, T.; Metsä-Kortelainen, S.; Antikainen, A. The Mitigation of Eddy-Current Losses in Ferromagnetic Samples Produced by Laser Powder Bed Fusion. IEEE Access 2022, 10, 115571–115582. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mhapsekar, K.; Anand, S. Part build orientation optimization and neural network-based geometry compensation for additive manufacturing process. J. Manuf. Sci. Eng. 2018, 140, 031009. [Google Scholar] [CrossRef]

- Hamilton, A.; Xu, Y.; Kartal, M.E.; Kumar, S.; Gadegaard, N.; Mulvihill, D.M. Optimisation of interlocking microstructured adhesive joints via finite element modelling, design of experiments and 3D printing. Int. J. Adhes. Adhes. 2023, 120, 103292. [Google Scholar] [CrossRef]

- Chaudhary, V.; Mantri, S.; Ramanujan, R.; Banerjee, R. Additive manufacturing of magnetic materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Li, S.; Yuan, S.; Zhu, J.; Wang, C.; Li, J.; Zhang, W. Additive manufacturing-driven design optimization: Building direction and structural topology. Addit. Manuf. 2020, 36, 101406. [Google Scholar] [CrossRef]

- Sanaei, N.; Fatemi, A.; Phan, N. Defect characteristics and analysis of their variability in metal L-PBF additive manufacturing. Mater. Des. 2019, 182, 108091. [Google Scholar] [CrossRef]

- Di Angelo, L.; Di Stefano, P.; Guardiani, E. Search for the optimal build direction in additive manufacturing technologies: A review. J. Manuf. Mater. Process. 2020, 4, 71. [Google Scholar] [CrossRef]

- Pal, D.; Patil, N.; Zeng, K.; Stucker, B. An integrated approach to additive manufacturing simulations using physics based, coupled multiscale process modeling. J. Manuf. Sci. Eng. 2014, 136, 061022. [Google Scholar] [CrossRef]

- Rashid, R.; Masood, S.H.; Ruan, D.; Palanisamy, S.; Rashid, R.R.; Brandt, M. Effect of scan strategy on density and metallurgical properties of 17-4PH parts printed by Selective Laser Melting (SLM). J. Mater. Process. Technol. 2017, 249, 502–511. [Google Scholar] [CrossRef]

- Zhang, Q.; Hu, Z.; Su, W.; Zhou, H.; Liu, C.; Yang, Y.; Qi, X. Microstructure and surface properties of 17-4PH stainless steel by ultrasonic surface rolling technology. Surf. Coat. Technol. 2017, 321, 64–73. [Google Scholar] [CrossRef]

- Giganto, S.; Martínez-Pellitero, S.; Barreiro, J.; Leo, P.; Castro-Sastre, M.Á. Impact of the laser scanning strategy on the quality of 17-4PH stainless steel parts manufactured by selective laser melting. J. Mater. Res. Technol. 2022, 20, 2734–2747. [Google Scholar] [CrossRef]

- Jhabvala, J.; Boillat, E.; Antignac, T.; Glardon, R. On the effect of scanning strategies in the selective laser melting process. Virtual Phys. Prototyp. 2010, 5, 99–109. [Google Scholar] [CrossRef]

- Afazov, S.; Okioga, A.; Holloway, A.; Denmark, W.; Triantaphyllou, A.; Smith, S.-A.; Bradley-Smith, L. A methodology for precision additive manufacturing through compensation. Precis. Eng. 2017, 50, 269–274. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. A comprehensive review of additive manufacturing in construction of electrical machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef]

- Wei, X.; Jin, M.-L.; Yang, H.; Wang, X.-X.; Long, Y.-Z.; Chen, Z. Advances in 3D printing of magnetic materials: Fabrication, properties, and their applications. J. Adv. Ceram. 2022, 11, 665–701. [Google Scholar] [CrossRef]

| Laser Power (W) | Laser Scan Speed (mm/s) | Hatch Distance (µm) | Laser Spot Size (µm) | Layer Thickness (µm) |

|---|---|---|---|---|

| 370 | 600 | 90 | 130 | 50 |

| 370 | 900 | 90 | 130 | 50 |

| 370 | 1200 | 90 | 130 | 50 |

| 370 | 1500 | 90 | 130 | 50 |

| 350 | 600 | 90 | 130 | 50 |

| 350 | 1200 | 90 | 130 | 50 |

| 350 | 1500 | 90 | 130 | 50 |

| 300 | 600 | 90 | 130 | 50 |

| 300 | 900 | 90 | 130 | 50 |

| 300 | 1200 | 90 | 130 | 50 |

| 250 | 600 | 90 | 130 | 50 |

| 250 | 900 | 90 | 130 | 50 |

| 250 | 1200 | 90 | 130 | 50 |

| 200 | 900 | 90 | 130 | 50 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-r.; Kim, E.-a.; Choi, J.P.; Ha, T.; Won, S.; Jeon, J.B.; Kwon, S.-h.; Lee, H.-s. Assessment of Joinability in Additively Manufactured Interlocking Structures. Crystals 2023, 13, 1575. https://doi.org/10.3390/cryst13111575

Kim Y-r, Kim E-a, Choi JP, Ha T, Won S, Jeon JB, Kwon S-h, Lee H-s. Assessment of Joinability in Additively Manufactured Interlocking Structures. Crystals. 2023; 13(11):1575. https://doi.org/10.3390/cryst13111575

Chicago/Turabian StyleKim, Ye-rim, Eun-ah Kim, Joon Phil Choi, Taeho Ha, Soonho Won, Jong Bae Jeon, Se-hun Kwon, and Hak-sung Lee. 2023. "Assessment of Joinability in Additively Manufactured Interlocking Structures" Crystals 13, no. 11: 1575. https://doi.org/10.3390/cryst13111575

APA StyleKim, Y.-r., Kim, E.-a., Choi, J. P., Ha, T., Won, S., Jeon, J. B., Kwon, S.-h., & Lee, H.-s. (2023). Assessment of Joinability in Additively Manufactured Interlocking Structures. Crystals, 13(11), 1575. https://doi.org/10.3390/cryst13111575