Biosynthesis Effect of Egg White on Formation and Characteristics of NiO/NiCo2O4 Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

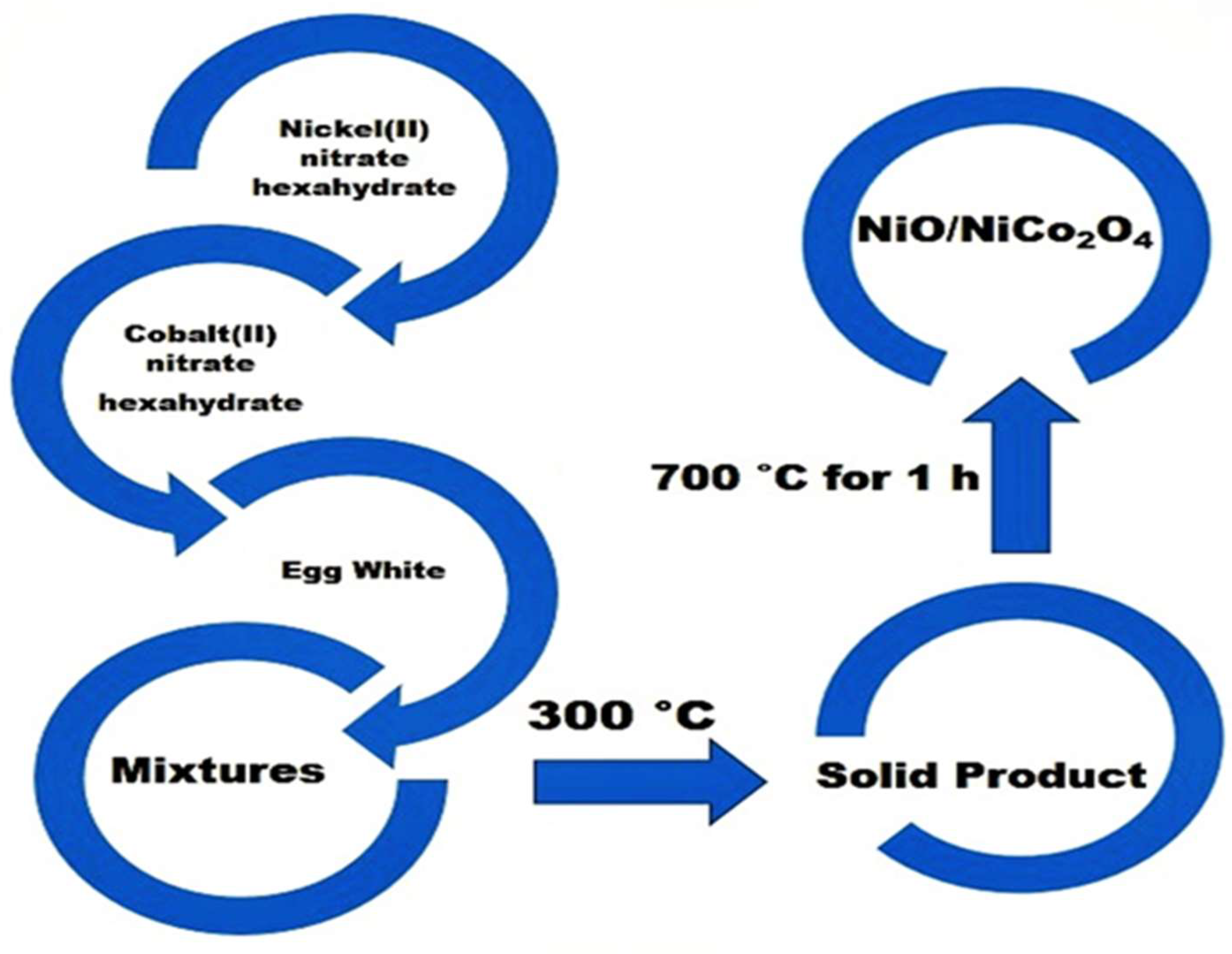

2.2. Preparation of Nanocomposite

2.3. Characterization of Nanocomposite

3. Results

3.1. XRD Study

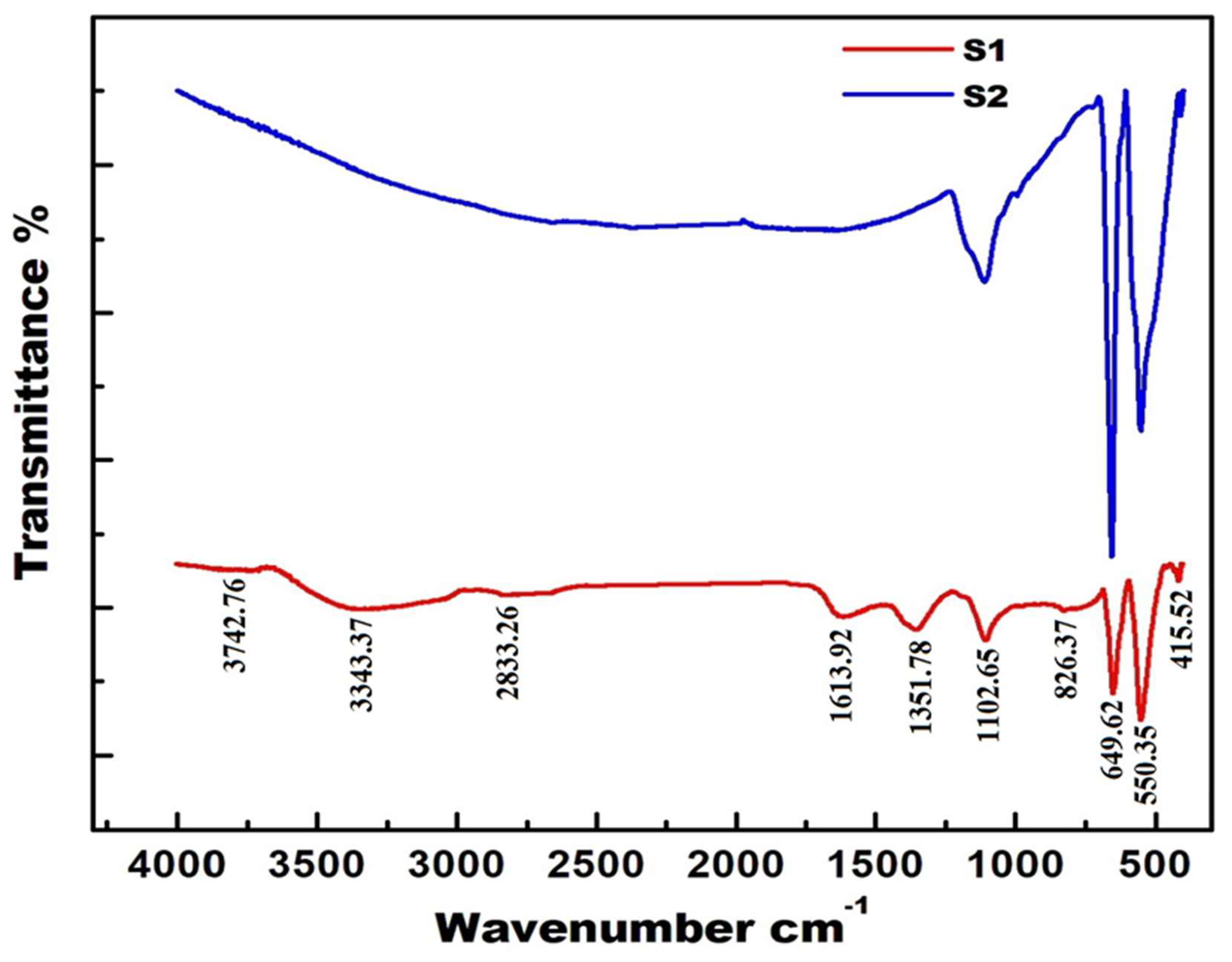

3.2. Fourier-Transform Infrared Spectroscopy (FTIR) Analysis

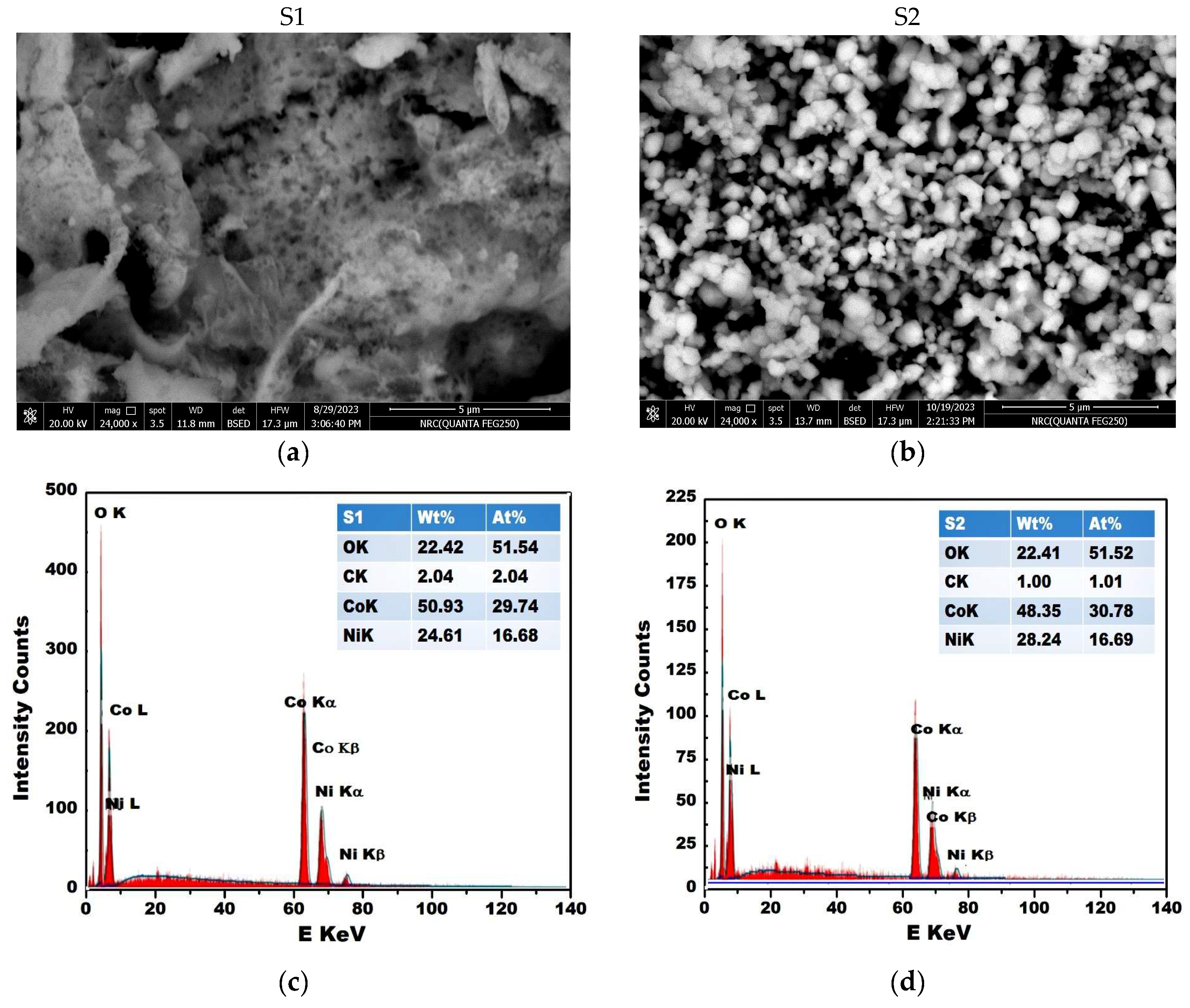

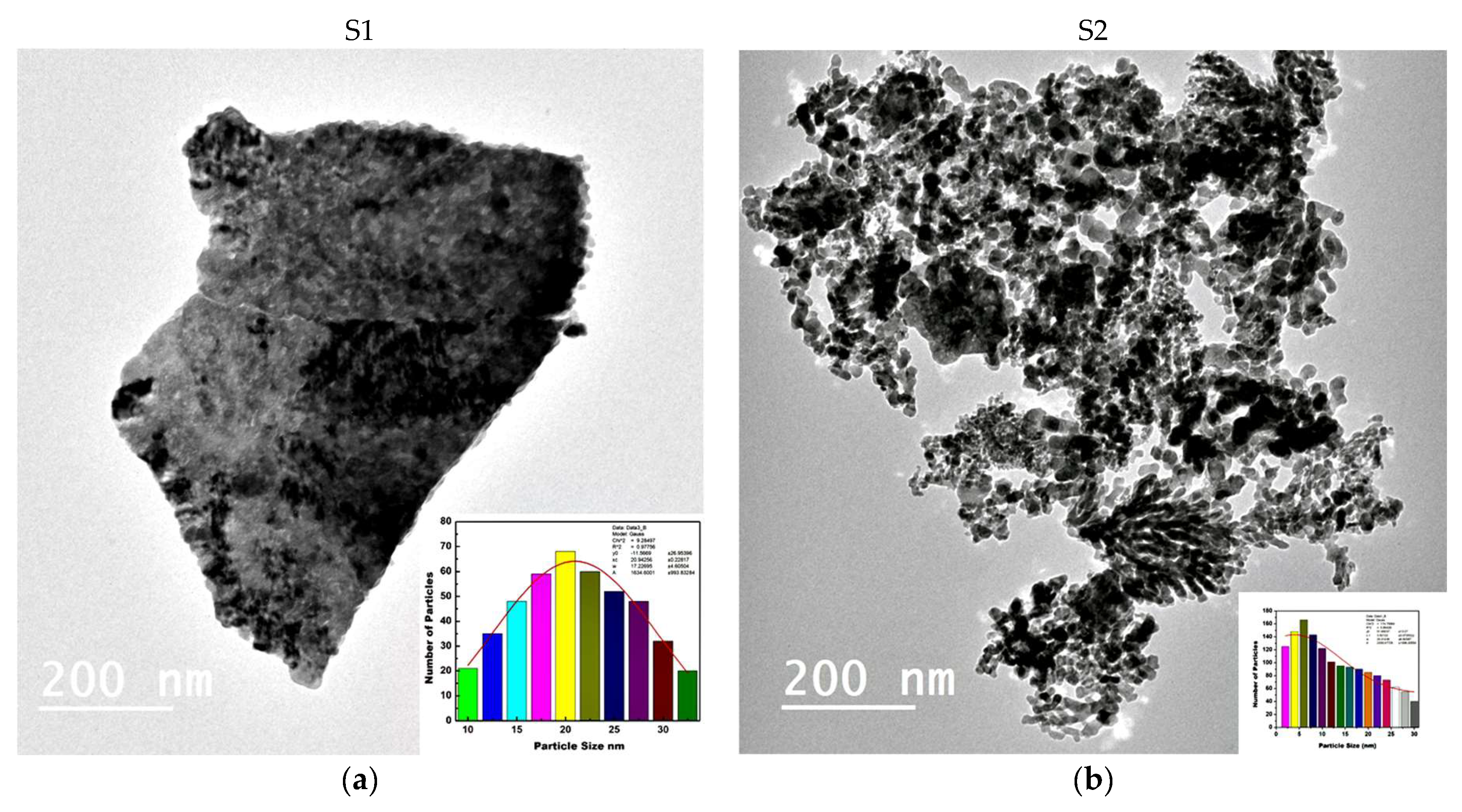

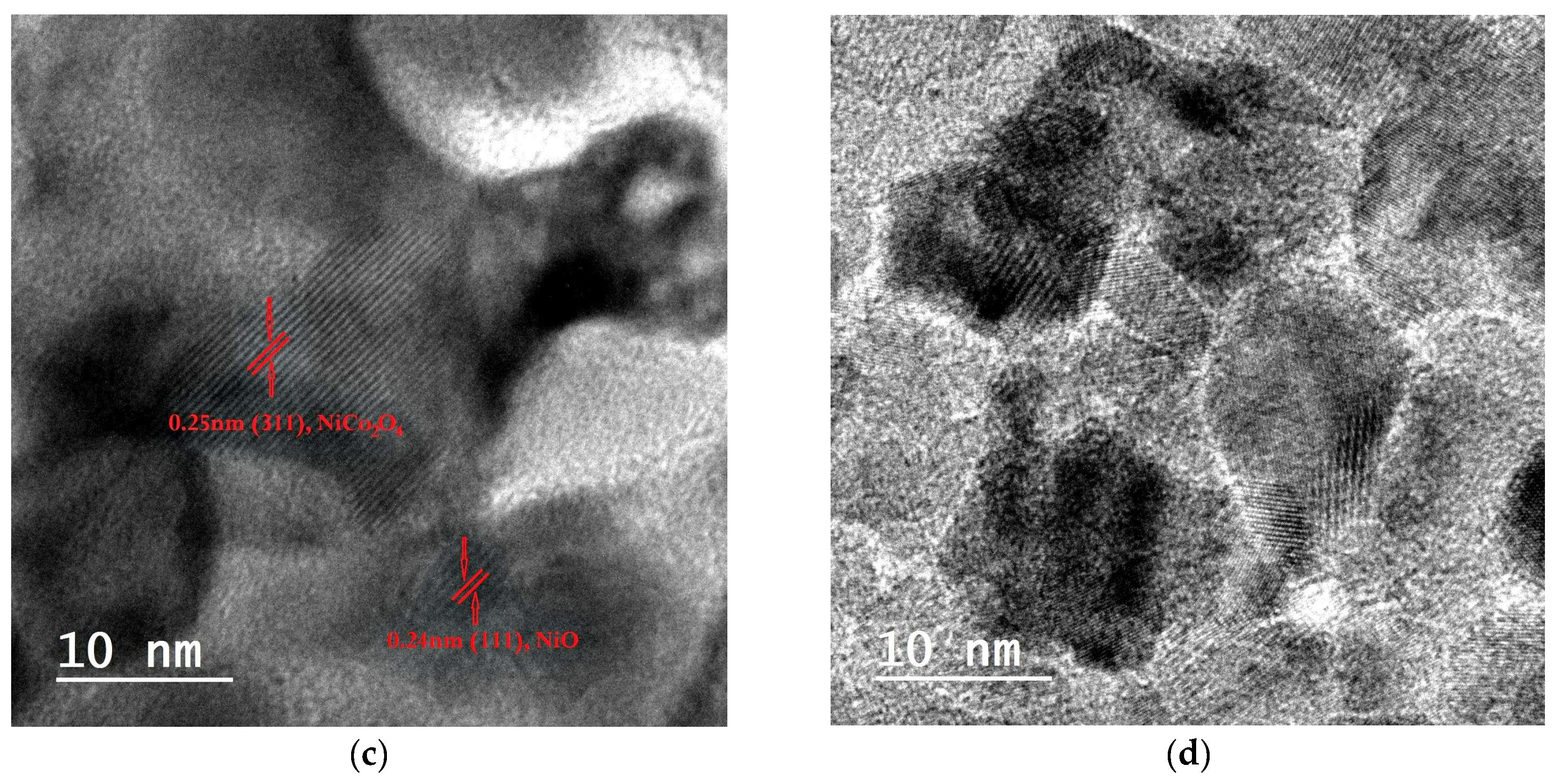

3.3. Morphological Characteristics of the Investigated Composite

3.4. Surface Properties of NiO/NiCo2O4 Nanocomposites

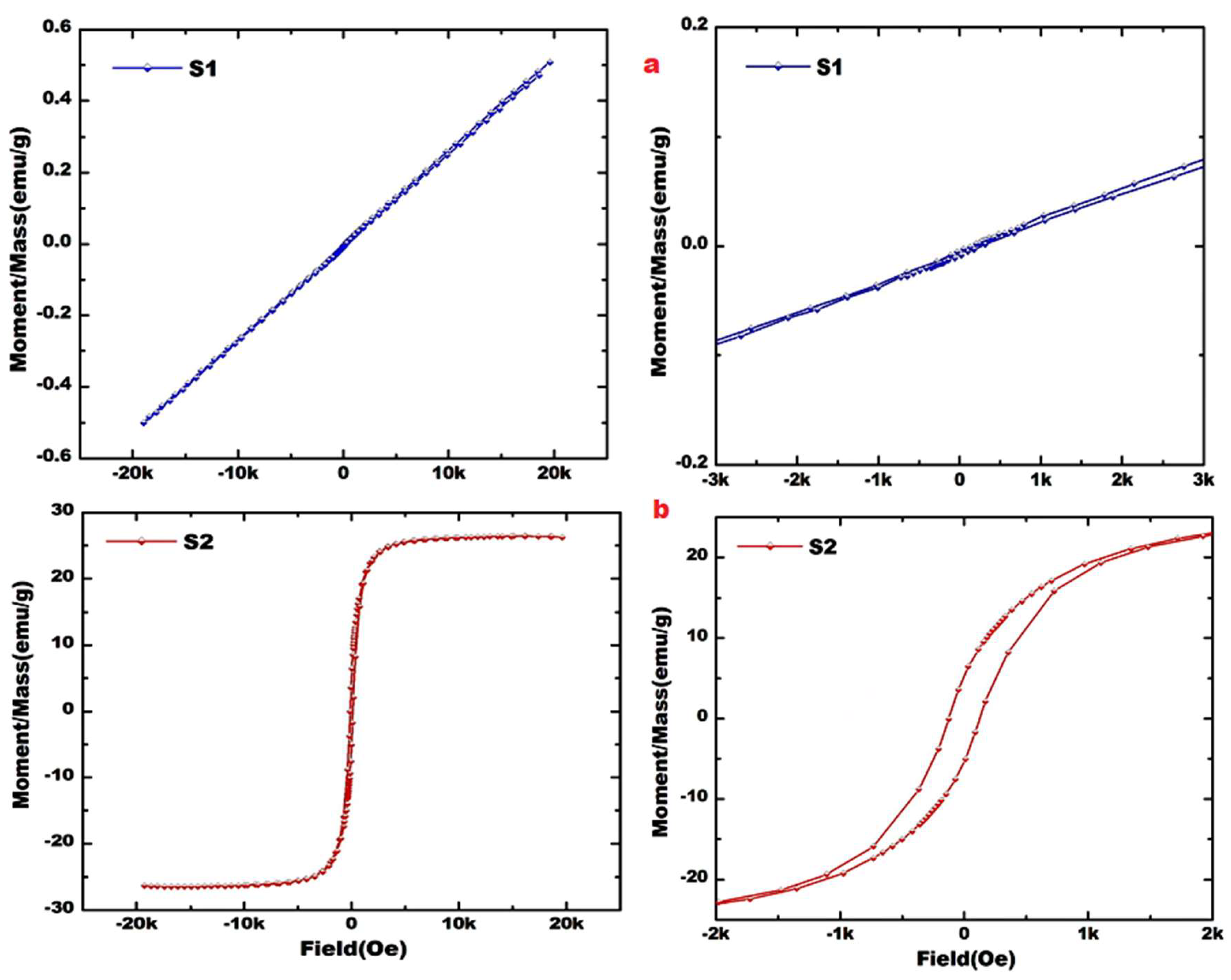

3.5. Magnetic Properties of NiO/NiCo2O4 Nanocomposites

4. Discussion

4.1. Formation of Porous Nickel Cobaltite

4.2. Cation Distribution

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, L.; Zhang, H.; Fang, L.; Mu, Y.; Wang, Y. Facile preparation of novel dandelion-like Fe-doped NiCo2O4 microspheres@ nanomeshes for excellent capacitive property in asymmetric supercapacitors. J. Power Sources 2016, 327, 135–144. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, E.; He, W.; Deng, X.; Huang, J.; Ding, M.; Wei, X.; Liu, X.; Xu, X. NiCo2O4-based supercapacitor nanomaterials. Nanomaterials 2017, 7, 41. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Pu, X.; Song, W.; Wu, Z.; Zhou, Z.; He, X.; Lu, F.; Jing, M.; Tang, B.; Ji, X. High capacity NiCo2O4 nanorods as electrode materials for supercapacitor. J. Alloys Compd. 2014, 617, 988–993. [Google Scholar] [CrossRef]

- Gao, G.; Wu, H.B.; Ding, S.; Liu, L.M.; Lou, X.W. Hierarchical NiCo2O4 nanosheets grown on Ni nanofoam as high-performance electrodes for supercapacitors. Small 2015, 11, 804–808. [Google Scholar] [CrossRef]

- Yang, M.; Chen, A.; Zhang, Y.; Le, L. Synthesis and characterization of Nano NiCo2O4 by microwave promoted precipitation method. IOP Conf. Ser. Mater. Sci. Eng. 2018, 397, 012087. [Google Scholar] [CrossRef]

- Wu, Z.; Zhu, Y.; Ji, X. NiCo2O4-based materials for electrochemical supercapacitors. J. Mater. Chem. A 2014, 2, 14759–14772. [Google Scholar] [CrossRef]

- Wang, N.; Sun, B.; Zhao, P.; Yao, M.; Hu, W.; Komarneni, S. Electrodeposition preparation of NiCo2O4 mesoporous film on ultrafine nickel wire for flexible asymmetric supercapacitors. J. Chem. Eng. 2018, 345, 31–38. [Google Scholar] [CrossRef]

- Xiao, Y.; Lei, Y.; Zheng, B.; Gu, L.; Wang, Y.; Xiao, D. Rapid microwave-assisted fabrication of 3D cauliflower-like NiCo2S4 architectures for asymmetric supercapacitors. RSC Adv. 2015, 5, 21604–21613. [Google Scholar] [CrossRef]

- Gao, S.; Liao, F.; Ma, S.; Zhu, L.; Shao, M. Network-like mesoporous NiCo2O4 grown on carbon cloth for high-performance pseudocapacitors. J. Mater. Chem. A 2015, 3, 16520–16527. [Google Scholar] [CrossRef]

- Li, S.; Yang, K.; Ye, P.; Jiang, H.; Zhang, Z.; Huang, Q.; Wang, L. Hierarchical interpenetrating rHGO-decorated NiCo2O4 nanowires architectures for high-performance supercapacitors. Appl. Surf. Sci. 2019, 473, 326–333. [Google Scholar] [CrossRef]

- Zhang, W.; Xin, W.; Hu, T.; Gong, Q.; Gao, T.; Zhou, G. One-step synthesis of NiCo2O4 nanorods and firework-shaped microspheres formed with necklace-like structure for supercapacitor materials. Ceram. Int. 2019, 45, 8406–8413. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, R.; Li, T.; Li, F.; Meng, L.; Yang, Z.; Wan, Y.; Luo, H. Conductive polypyrrole coated hollow NiCo2O4 microspheres as anode material with improved pseudocapacitive contribution and enhanced conductivity for lithium-ion batteries. ChemElectroChem 2019, 6, 690–699. [Google Scholar] [CrossRef]

- Fan, H.L.; Zhang, J.; Ju, W.; Liu, B.X.; Zhao, X.F.; Liu, X.C.; Yi, X.B. Growth of NiCo2O4 nanotubes@ MnO2 sheet core-shell arrays on 3D hierarchical porous carbon aerogels as superior electrodes for supercapacitors. Int. J. Nanomanuf. 2019, 15, 92–104. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Chen, R.; Ni, H. Direct synthesis of NiCo2O4 nanoneedles and MoS2 nanoflakes grown on 316L stainless steel meshes by two step hydrothermal method for HER. Acta Metall. Sin. 2018, 54, 1179–1186. [Google Scholar]

- Dai, J.; Zhao, R.; Xiang, J.; Wu, F.; Xin, L.; Zhang, Y.; Ma, S. Facile hydrothermal synthesis and their electrochemical performance of NiCo2O4 nanosheets. Sci. Adv. Mater. 2019, 11, 379–385. [Google Scholar] [CrossRef]

- Cheng, X.; Zhou, X.; Wang, S.; Liu, Z.; Liu, Q.; Zhang, Y.; Liu, Q.; Li, B. Fabrication of NiO/NiCo2O4 Mixtures as Excellent Microwave Absorbers. Nanoscale Res. Lett. 2019, 14, 155. [Google Scholar] [CrossRef]

- Amiri, M.; Javar, H.A.; Mahmoudi-Moghaddam, H. Facile Green Synthesis of NiO/NiCo2O4 Nanocomposite as an Efficient Electrochemical Platform for Determination of Dopamine. Electroanalysis 2021, 33, 1205–1214. [Google Scholar] [CrossRef]

- Mohamed, Z.; Zhang, G.; He, B.; Fan, Y. Heterostructure Necklace-like NiO-NiCo2O4 Hybrid with Superior Catalytic Capability as Electrocatalyst for Li-Oxygen Batteries. Eng. Sci. 2021, 17, 231–241. [Google Scholar]

- Zhu, C.M.; Wang, L.G.; Liu, F.C.; Kong, W.J. Exchange bias behaviors up to room temperature in NiCo2O4/NiO nanoparticle system. Ceram. Int. 2019, 45, 9878–9883. [Google Scholar] [CrossRef]

- Deraz, N. Construction of Mn0.5Mg0.5Fe2O4 Nano Particles. Egypt. J. Chem. 2018, 61, 531–538. [Google Scholar] [CrossRef]

- Abd-Elkader, O.H.; Deraz, N.M.; Aleya, L. Rapid Bio-Assisted Synthesis and Magnetic Behavior of Zinc Oxide/Carbon Nanoparticles. Crystals 2023, 13, 1081. [Google Scholar] [CrossRef]

- Cullity, B.D. Elements of X-ray Diffraction; Chapter 14; Addison-Wesley Publishing Co., Inc.: Boston, MA, USA, 1956. [Google Scholar]

- Ganachari, S.V.; Bhat, R.; Deshpande, R.; Venkataraman, A. Synthesis and characterization of nickel oxide nanoparticles by self-propagating low temperature combustion method. Recent Res. Sci. Technol. 2012, 4, 4. [Google Scholar]

- Waldron, R.D. Infrared spectra of ferrites. Phys. Rev. 1955, 99, 1727. [Google Scholar] [CrossRef]

- Shinde, V.R.; Mahadik, S.B.; Gujar, T.P.; Lokhande, C.D. Supercapacitive cobalt oxide (Co3O4) thin films by spray pyrolysis. Appl. Surf. Sci. 2006, 252, 7487–7492. [Google Scholar] [CrossRef]

- Rendale, M.K.; Mathad, S.N.; Puri, V. Thick films of magnesium zinc ferrite with lithium substitution: Structural characteristics. Int. J. Self-Propagating High-Temp. Synth. 2015, 24, 78–82. [Google Scholar] [CrossRef]

- Baldovino-Medrano, V.G.; Niño-Celis, V.; Isaacs Giraldo, R. Systematic Analysis of the Nitrogen Adsorption–Desorption Isotherms Recorded for a Series of Materials Based on Microporous–Mesoporous Amorphous Aluminosilicates Using Classical Methods. J. Chem. Eng. Data. 2023, 68, 2512–2528. [Google Scholar] [CrossRef]

- Mathad, S.N.; Jadhav, R.N.; Patil, N.D.; Puri, V. Structural and mechanical properties of Sr+2-doped bismuth manganite thick films. Int. J. Self-Propagating High-Temp. Synth. 2013, 22, 180–184. [Google Scholar] [CrossRef]

- Mathad, S.N.; Jadhav, R.N.; Phadtare, V.; Puri, V. Structural and mechanical properties of Sr-doped barium niobate thick films. Int. J. Self-Propagating High-Temp. Synth. 2014, 23, 145–150. [Google Scholar] [CrossRef]

- Standley, K.J. Oxide Magnetic Materials; Oxford at Clarendon Press: London, UK, 1962; p. 24. [Google Scholar]

- Rath, C.; Anand, S.; Das, R.P.; Sahu, K.K.; Kulkarni, S.D.; Date, S.K.; Mishra, N.C. Dependence on cation distribution of particle size, lattice parameter, and magnetic properties in nanosize Mn–Zn ferrite. J. Appl. Phys. 2002, 91, 2211–2215. [Google Scholar] [CrossRef]

- Sudalai Muthu, K.; Perumal, P. Synthesis and characterization of NiO Nanoparticles using egg white method. J. Mater. Sci. Mater. Electron. 2017, 28, 9612–9617. [Google Scholar] [CrossRef]

- Chang, C.; Meikle, T.G.; Su, Y.; Wang, X.; Dekiwadia, C.; Drummond, C.J.; Conn, C.E.; Yang, Y. Encapsulation in egg white protein nanoparticles protects antioxidant activity of curcumin. Food Chem. 2019, 280, 65–72. [Google Scholar] [CrossRef] [PubMed]

- Kargar, H.; Ghazavi, H.; Darroudi, M. Size-controlled and bio-directed synthesis of ceria nanopowders and their in vitro cytotoxicity effects. Ceram. Int. 2015, 41, 4123–4128. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Y.; Zhang, Y.; Xu, C.; Chen, H. Egg albumin-assisted hydrothermal synthesis of Co3O4 quasi-cubes as superior electrode material for supercapacitors with excellent performances. Nanoscale Res. Lett. 2019, 14, 340. [Google Scholar] [CrossRef] [PubMed]

- Abdulkhadar, M.; George, K.C. Study of laser Raman spectra of nanoparticles of AgI and HgI2. Solid State Commun. 1992, 84, 603–606. [Google Scholar] [CrossRef]

- Abdulkhadar, M.; Thomas, B. Raman scattering in nanoparticles of mercuric iodide. Mater. Res. Bull. 1995, 30, 1301–1308. [Google Scholar] [CrossRef]

- Vivekanand, V.; Ryden, P.; Horn, S.J.; Tapp, H.S.; Wellner, N.; Eijsink, V.G.; Waldron, K.W. Impact of steam explosion on biogas production from rape straw in relation to changes in chemical composition. Bioresour. Technol. 2012, 123, 608–615. [Google Scholar] [CrossRef]

- Ivanenko, I.; Voronova, A.; Astrelin, I.; Romanenko, Y. Structural and catalytic properties of Ni–Co spinel and its composites. Bull. Mater. Sci. 2019, 42, 172. [Google Scholar] [CrossRef]

- Mohammed, E.M.; Malini, K.A.; Kurian, P.; Anantharaman, M.R. Modification of dielectric and mechanical properties of rubber ferrite composites containing manganese zinc ferrite. Mater. Res. Bull. 2002, 37, 753–768. [Google Scholar] [CrossRef]

- Cabo, M.; Pellicer, E.; Rossinyol, E.; Estrader, M.; López-Ortega, A.; Nogués, J.; Castell, O.; Suriñach, S.; Baró, M.D. Synthesis of compositionally graded nanocast NiO/NiCo2O4/Co3O 4 mesoporous composites with tunable magnetic properties. J. Mater. Chem. 2010, 20, 7021–7028. [Google Scholar] [CrossRef]

- Cabo, M.; Pellicer, E.; Rossinyol, E.; Castell, O.; Surinach, S.; Baró, M.D. Mesoporous NiCo2O4 spinel: Influence of calcination temperature over phase purity and thermal stability. Cryst. Growth Des. 2009, 9, 4814–4821. [Google Scholar] [CrossRef]

- Knop, O.; Reid, K.I.; Sutarno; Nakagawa, Y. Chalkogenides of the transition elements. VI. X-Ray, neutron, and magnetic investigation of the spinels Co3O4, NiCo2O4, Co3S4, and NiCo2S4. Can. J. Chem. 1968, 46, 3463–3476. [Google Scholar] [CrossRef]

- Al-Senani, G.M.; Al-Fawzan, F.F.; Alshabanat, M.; Abd-Elkader, O.H.; Nasrallah, M.; Nasrallah, M. One pot synthesis, surface and magnetic properties of Ni-NiO@C composite. Crystals 2023, 13, 1497. [Google Scholar] [CrossRef]

- Al-Senani, G.M.; Deraz, N.M.; Abd-Elkader, O.H. Magnetic and characterization studies of CoO/Co3O4 nanocomposite. Processes 2020, 8, 844. [Google Scholar] [CrossRef]

| Properties | S1 | S2 | ||

|---|---|---|---|---|

| NiCo2O4 | NiO | NiCo2O4 | NiO | |

| Crystal structure | Cubic | Cubic | Cubic | Cubic |

| Lattice constant (a), nm | 0.8087 | 0.4181 | 0.8375 | 0.4082 |

| Unit cell volume (V) nm3 | 0.5289 | 0.0731 | 0.5874 | 0.0680 |

| Density, g/cm3 | 6.040 | 6.10 | 5.4385 | 6.56 |

| Dislocation density (δ) | 2.770 × 10−3 | 6.944 × 10−3 | 1.372 × 10−3 | 1.562 × 10−3 |

| Crystallite size (d), nm | 19 | 12 | 27 | 8 |

| Parameters | S1 | S2 |

|---|---|---|

| LA | 0.3502 | 0.3626 |

| LB | 0.2858 | 0.2956 |

| A–O | 0.1849 | 0.1914 |

| B–O | 0.2086 | 0.2161 |

| rA | 0.0244 | 0.0594 |

| rB | 0.0275 | 0.0841 |

| Samples | SBET (m2/g) | Vm (cc/g) | Vp (cc/g) | ȓ (nm) |

|---|---|---|---|---|

| S1 | 24 | 5.479 | 0.1303 | 21.85 |

| S2 | 18 | 4.136 | 0.0665 | 14.78 |

| Samples | Ms (emu/g) | Mr (emu/g) | Mr/Ms | Hc (Oe) | Ka (erg/cm3) |

|---|---|---|---|---|---|

| S1 | 0.504 | 0.0024 | 0.0048 | 61 | 31 |

| S2 | 21.27 | 6.45 | 0.303 | 126.29 | 2741 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Senani, G.M.; Al-Fawzan, F.F.; Alshabanat, M.; Abd-Elkader, O.H.; Nasrallah, M.; Nasrallah, M. Biosynthesis Effect of Egg White on Formation and Characteristics of NiO/NiCo2O4 Nanocomposites. Crystals 2023, 13, 1579. https://doi.org/10.3390/cryst13111579

Al-Senani GM, Al-Fawzan FF, Alshabanat M, Abd-Elkader OH, Nasrallah M, Nasrallah M. Biosynthesis Effect of Egg White on Formation and Characteristics of NiO/NiCo2O4 Nanocomposites. Crystals. 2023; 13(11):1579. https://doi.org/10.3390/cryst13111579

Chicago/Turabian StyleAl-Senani, Ghadah M., Foziah F. Al-Fawzan, Mashael Alshabanat, Omar H. Abd-Elkader, Mai Nasrallah, and Mohamed Nasrallah. 2023. "Biosynthesis Effect of Egg White on Formation and Characteristics of NiO/NiCo2O4 Nanocomposites" Crystals 13, no. 11: 1579. https://doi.org/10.3390/cryst13111579

APA StyleAl-Senani, G. M., Al-Fawzan, F. F., Alshabanat, M., Abd-Elkader, O. H., Nasrallah, M., & Nasrallah, M. (2023). Biosynthesis Effect of Egg White on Formation and Characteristics of NiO/NiCo2O4 Nanocomposites. Crystals, 13(11), 1579. https://doi.org/10.3390/cryst13111579