Solidification Segregation Behavior and Homogenization Process of a Difficult-to-Deform Superalloy Used at 850 °C

Abstract

:1. Introduction

2. Materials and Methods

3. Results

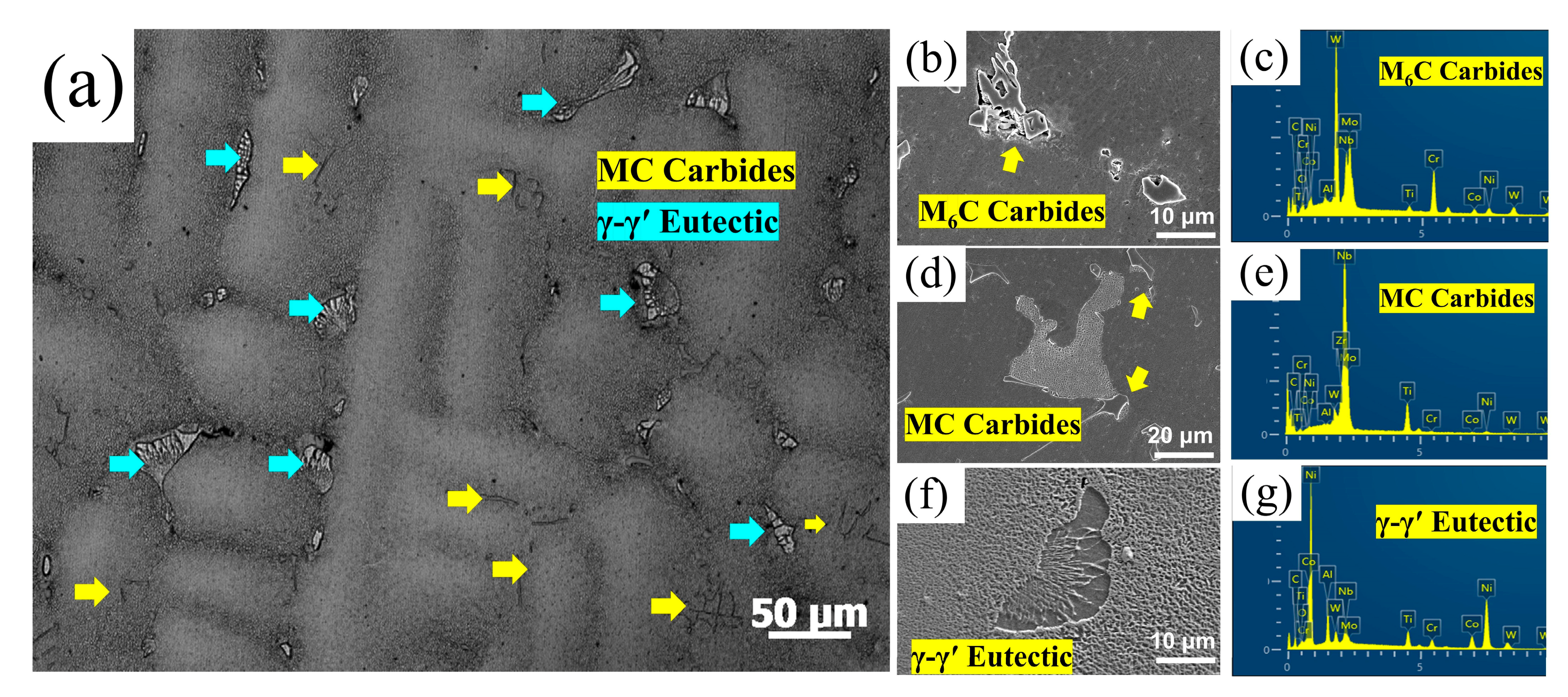

3.1. As-Cast Microstructure and Solidification Segregation Behavior of Alloy

3.2. Microstructure and Element Segregation of Alloys with Different C Contents

3.3. Effect of Homogenization Heat Treatment on Microstructure

3.3.1. Effect of Homogenization Heat Treatment Temperature on Microstructure

3.3.2. Effect of Homogenization Heat Treatment Time on Microstructure

4. Discussion

4.1. Pore Growth Mechanism

4.2. Homogenization Behavior of Alloys with Different C Contents

5. Conclusions

- The alloy displays a clear dendritic distribution in its as-cast microstructure. Among the interdendritic regions, elements such as Al, Ti, and Nb are dispersed, while W and Mo elements are distributed within the dendrites. Additionally, numerous γ-γ′ eutectic phases and MC carbides are precipitated among the interdendritic regions.

- An increase in C content leads to a reduction in the presence of γ-γ′ eutectic phases in the as-cast alloy. This reduction may have a favorable impact on the forging performance of the alloy.

- In the case of the alloy containing 0.1 wt% C, effective elimination of element segregation and γ-γ′ eutectic phases can be achieved through homogenization heat treatment at 1200 °C for 48 h.

- The time required for the homogenization heat treatment can be appropriately decreased with an increase in C content. Consequently, smaller and more uniformly distributed pores are observed, which can contribute to the improved forging characteristics of the alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Tan, Y.; Li, X.; You, X.; Zhao, J.; Li, M.; Bai, R.; Li, P. Microstructures and homogenization behavior of a nickel-based superalloy used for 850 ℃ turbine disc prepared by electron beam smelting layered solidification. J. Alloys Compd. 2023, 935, 168119. [Google Scholar] [CrossRef]

- Logunov, A.V.; Zavodov, S.A.; Danilov, D.V. The Challenges in Development of Nickel-Based Heat-Resistant Superalloys for Gas Turbine Disks and Creation of a New Superalloy with Increased Operational Characteristics. Mater. Today Proc. 2019, 11, 459–464. [Google Scholar] [CrossRef]

- Henderson, M.B.; Arrell, D.; Larsson, R.; Heobel, M.; Marchant, G. Nickel based superalloy welding practices for industrial gas turbine applications. Sci. Technol. Weld. Join. 2004, 9, 13–21. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, C.; Peng, Y.; Xia, X.; Li, J.; Ding, J.; Liu, C.; Chen, X.; Dong, J.; Liu, Y. Hot compression deformation behavior and processing maps of ATI 718Plus superalloy. J. Alloys Compd. 2020, 835, 155195. [Google Scholar] [CrossRef]

- Chang, L.; Jin, H.; Sun, W. Solidification behavior of Ni-base superalloy Udimet 720Li. J. Alloys Compd. 2015, 653, 266–270. [Google Scholar] [CrossRef]

- Yuan, Y.; Gu, Y.; Osada, T.; Zhong, Z.; Yokokawa, T.; Harada, H. Deformation mechanisms in a new disc superalloy at low and intermediate temperatures. Scr. Mater. 2012, 67, 137–140. [Google Scholar] [CrossRef]

- Xinxu, L.; Chonglin, J.; Yong, Z.; Shaomin, L.; Zhouhua, J. Segregation and homogenization for a new nickel-based superalloy. Vacuum 2020, 177, 109379. [Google Scholar] [CrossRef]

- Li, Y.; Dong, Y.; Jiang, Z.; Yao, K.; Du, S.; Liu, Y.; Hou, Z. Study on microsegregation and homogenization process of a novel nickel-based wrought superalloy. J. Mater. Res. Technol. 2022, 19, 3366–3379. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhang, R.; Cui, C.; Zhou, Y.; Sun, X. Effects of Homogenization Treatment on the Microsegregation of a Ni–Co Based Superalloy Produced by Directional Solidification. Acta Metall. Sin. 2021, 34, 943–954. [Google Scholar] [CrossRef]

- Semiatin, S.; Kramb, R.; Turner, R.; Zhang, F.; Antony, M. Analysis of the homogenization of a nickel-base superalloy. Scr. Mater. 2004, 51, 491–495. [Google Scholar] [CrossRef]

- Kramb, R.; Antony, M.; Semiatin, S. Homogenization of a nickel-base superalloy ingot material. Scr. Mater. 2006, 54, 1645–1649. [Google Scholar] [CrossRef]

- Wei, C.-N.; Bor, H.-Y.; Chang, L. The influence of carbon addition on carbide characteristics and mechanical properties of CM-681LC superalloy using fine-grain process. J. Alloys Compd. 2011, 509, 5708–5714. [Google Scholar] [CrossRef]

- Al-Jarba, K.; Fuchs, G. Effect of carbon additions on the as-cast microstructure and defect formation of a single crystal Ni-based superalloy. Mater. Sci. Eng. A 2004, 373, 255–267. [Google Scholar] [CrossRef]

- Jiang, H.; Xiang, X.; Dong, J. The morphology and characteristics evolution of MC carbide during homogenization in hard-to-deform superalloy GH4975. J. Alloys Compd. 2022, 929, 167086. [Google Scholar] [CrossRef]

- Sohrabi, M.J.; Mirzadeh, H. Interdiffusion coefficients of alloying elements in a typical Ni-based superalloy. Vacuum 2019, 169, 108875. [Google Scholar] [CrossRef]

- Schneider, M.C.; Gu, J.P.; Beckermann, C.; Boettinger, W.J.; Kattner, U.R. Modeling of micro- and macrosegregation and freckle formation in single-crystal nickel-base superalloy directional solidification. Met. Mater. Trans. A 1997, 28, 1517–1531. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Y.; Li, X.; Zhao, J.; You, X. Microsegregation and homogenization behavior of a Ni-Co based refractory superalloy for turbine discs. Mater. Charact. 2023, 196, 112598. [Google Scholar] [CrossRef]

- Karunaratne, M.; Cox, D.; Carter, P.; Reed, R. Modelling of the Microsegregation in CMSX-4 Superalloy and its Homogenisation During Heat Treatment. Superalloys 2000, 2000, 263–272. [Google Scholar] [CrossRef]

- Bokstein, B.; Epishin, A.; Link, T.; Esin, V.; Rodin, A.; Svetlov, I. Model for the porosity growth in single-crystal nickel-base superalloys during homogenization. Scr. Mater. 2007, 57, 801–804. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; De Vecchis, R.R.; Xiong, W. Evolution of Carbide Precipitates in Haynes® 282 Superalloy Processed by Wire Arc Additive Manufacturing. J. Mater. Process. Technol. 2022, 305, 117597. [Google Scholar] [CrossRef]

- Tin, S.; Pollock, T.M.; King, W.T. Carbon Additions and Grain Defect Formation in High Refractory Nickel-Base Single Crystal Superalloys. In Proceedings of the Superalloys 2000, Ninth International Symposium, TMS, Seven Springs, PA, USA, 17–21 September 2000; pp. 201–210. [Google Scholar] [CrossRef]

- Li, Q.; Xie, J.; Yu, J.; Shu, D.; Hou, G.; Sun, X.; Zhou, Y. Solidification behavior and segregation characteristics of high W-content cast Ni-Based superalloy K416B. J. Alloys Compd. 2021, 854, 156027. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, F.; Dong, X.; Zhang, L.; Shan, A. Thermodynamic study on equilibrium precipitation phases in a novel Ni-Co base superalloy. Acta Metall. Sin. 2010, 46, 334–339. [Google Scholar] [CrossRef]

- Xu, Y.; Jin, Q.; Xiao, X.; Cao, X.; Jia, G.; Zhu, Y.; Yin, H. Strengthening mechanisms of carbon in modified nickel-based superalloy Nimonic 80A. Mater. Sci. Eng. A 2011, 528, 4600–4607. [Google Scholar] [CrossRef]

- Lvov, G.; Levit, V.I.; Kaufman, M.J. Mechanism of Primary MC Carbide Decomposition in Ni-Base Superalloys. Metall. Mater. Trans. A 2004, 35, 1669–1679. [Google Scholar] [CrossRef]

- Qin, X.Z.; Guo, J.T.; Yuan, C.; Hou, J.S.; Ye, H.Q. Precipitation and Thermal Instability of M23C6 Carbide in Cast Ni-Base Superalloy K452. Mater. Lett. 2008, 62, 258–261. [Google Scholar] [CrossRef]

- Ebrahimian, M.; Rizi, M.S.; Hong, S.I.; Kim, J.H. Effects of Molybdenum on Hot Deformation Behavior and Microstructural Evolution of Fe40Mn40Co10Cr10C0.5 High Entropy Alloys. Sci. Technol. Adv. Mater. 2023, 24, 2186119. [Google Scholar] [CrossRef]

- Rizi, M.S.; Minouei, H.; Lee, B.J.; Pouraliakbar, H.; Toroghinejad, M.R.; Hong, S.I. Hierarchically activated deformation mechanisms to form ultra-fine grain microstructure in carbon containing FeMnCoCr twinning induced plasticity high entropy alloy. Mater. Sci. Eng. A 2021, 824, 141803. [Google Scholar] [CrossRef]

- Zhao, G.-D.; Zang, X.-M.; Sun, W.-R. Role of carbon in modifying solidification and microstructure of a Ni-based superalloy with high Al and Ti contents. J. Iron Steel Res. Int. 2021, 28, 98–110. [Google Scholar] [CrossRef]

- Wei, C.-N.; Bor, H.-Y.; Chang, L. The effects of carbon content on the microstructure and elevated temperature tensile strength of a nickel-base superalloy. Mater. Sci. Eng. A 2010, 527, 3741–3747. [Google Scholar] [CrossRef]

- Xu, H.; Zhang, Y.; Fu, H.; Xue, F.; Zhou, X.; Xie, J. Effects of boron or carbon on solidification behavior of Co-Ni-Al-W-based superalloys. J. Alloys Compd. 2022, 891, 161965. [Google Scholar] [CrossRef]

- Lukas, H.; Fries, S.G.; Sundman, B. Computational Thermodynamics; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar] [CrossRef]

- Wu, J.; Meng, J.; Zou, M.; Yao, L.; Wang, X.; Yang, Y.; Zhou, Y.; Sun, X. Effect of wall thickness on micropores and stress-rupture properties of a single-crystal nickel-based superalloy. Mater. Sci. Eng. A 2023, 872, 144941. [Google Scholar] [CrossRef]

- Huang, Z.; He, X.; Chen, K.; Wang, X. Solidification and segregation characteristics of Ni-based superalloy C700R-1 for ultra-supercritical steam turbine rotor. J. Alloys Compd. 2022, 912, 165107. [Google Scholar] [CrossRef]

- Campbell, C.; Boettinger, W.; Kattner, U. Development of a diffusion mobility database for Ni-base superalloys. Acta Mater. 2002, 50, 775–792. [Google Scholar] [CrossRef]

- Warnken, N.; Ma, D.; Drevermann, A.; Reed, R.; Fries, S.; Steinbach, I. Phase-field modelling of as-cast microstructure evolution in nickel-based superalloys. Acta Mater. 2009, 57, 5862–5875. [Google Scholar] [CrossRef]

- Gasson, P.C. The Superalloys: Fundamentals and Applications R. C. Reed Cambridge University Press, The Edinburgh Building, Shaftesbury Road, Cambridge, CB2 2RU, UK, 2006. 372pp. Illustrated. £80. ISBN 0-521-85904-2. Aeronaut. J. 2008, 112, 291. [Google Scholar] [CrossRef]

- Epishin, A.; Link, T.; Svetlov, I.L.; Nolze, G.; Neumann, R.S.; Lucas, H. Mechanism of porosity growth during homogenisation in single crystal nickel-based superalloys. Int. J. Mater. Res. 2013, 104, 776–782. [Google Scholar] [CrossRef]

- Anton, D.; Giamei, A. Porosity distribution and growth during homogenization in single crystals of a nickel-base superalloy. Mater. Sci. Eng. 1985, 76, 173–180. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Dong, J.; Lou, L. Effect of Solidification Condition and Carbon Content on the Morphology of MC Carbide in Directionally Solidified Nickel-base Superalloys. J. Mater. Sci. Technol. 2014, 30, 1296–1300. [Google Scholar] [CrossRef]

- Banaszek, G.; Stefanik, A. Theoretical and laboratory modelling of the closure of metallurgical defects during forming of a forging. J. Am. Acad. Dermatol. 2006, 177, 238–242. [Google Scholar] [CrossRef]

| C | Cr | Co | Al + Ti + Nb | W + Mo | B + Zr | Ni |

|---|---|---|---|---|---|---|

| 0.05 | 8 | 15–18 | 9–10 | 10–13 | 0.02–0.1 | Bal. |

| 0.1 | ||||||

| 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tai, W.; Zhang, R.; Cui, C.; Zhou, Z.; Zhou, Y.; Sun, X. Solidification Segregation Behavior and Homogenization Process of a Difficult-to-Deform Superalloy Used at 850 °C. Crystals 2023, 13, 1582. https://doi.org/10.3390/cryst13111582

Tai W, Zhang R, Cui C, Zhou Z, Zhou Y, Sun X. Solidification Segregation Behavior and Homogenization Process of a Difficult-to-Deform Superalloy Used at 850 °C. Crystals. 2023; 13(11):1582. https://doi.org/10.3390/cryst13111582

Chicago/Turabian StyleTai, Wenbin, Rui Zhang, Chuanyong Cui, Zijian Zhou, Yizhou Zhou, and Xiaofeng Sun. 2023. "Solidification Segregation Behavior and Homogenization Process of a Difficult-to-Deform Superalloy Used at 850 °C" Crystals 13, no. 11: 1582. https://doi.org/10.3390/cryst13111582