Self-Assembled La0.67Sr0.33MnO3:CeO2 Vertically Aligned Nanocomposite Thin Films on Flexible Mica

Abstract

:1. Introduction

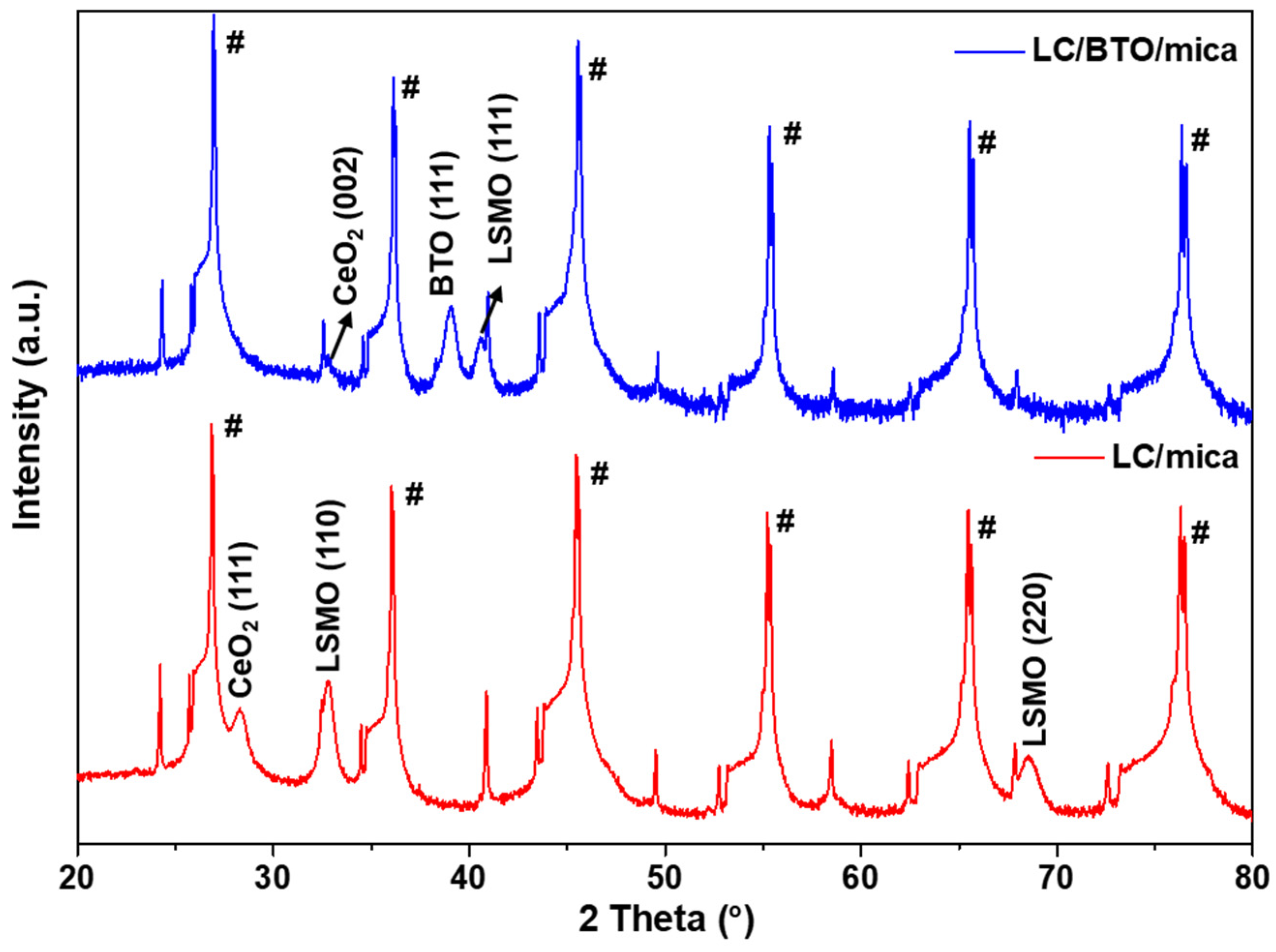

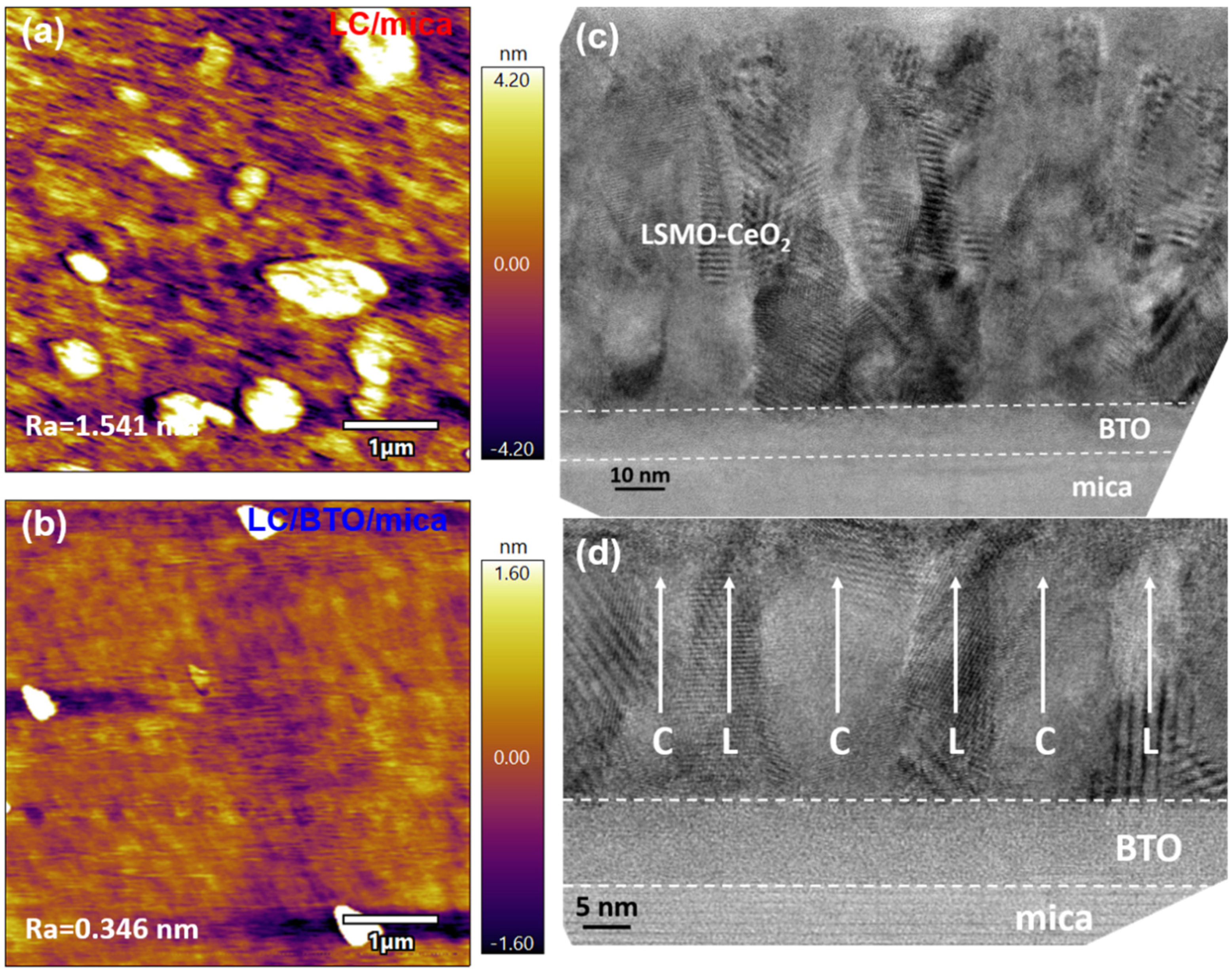

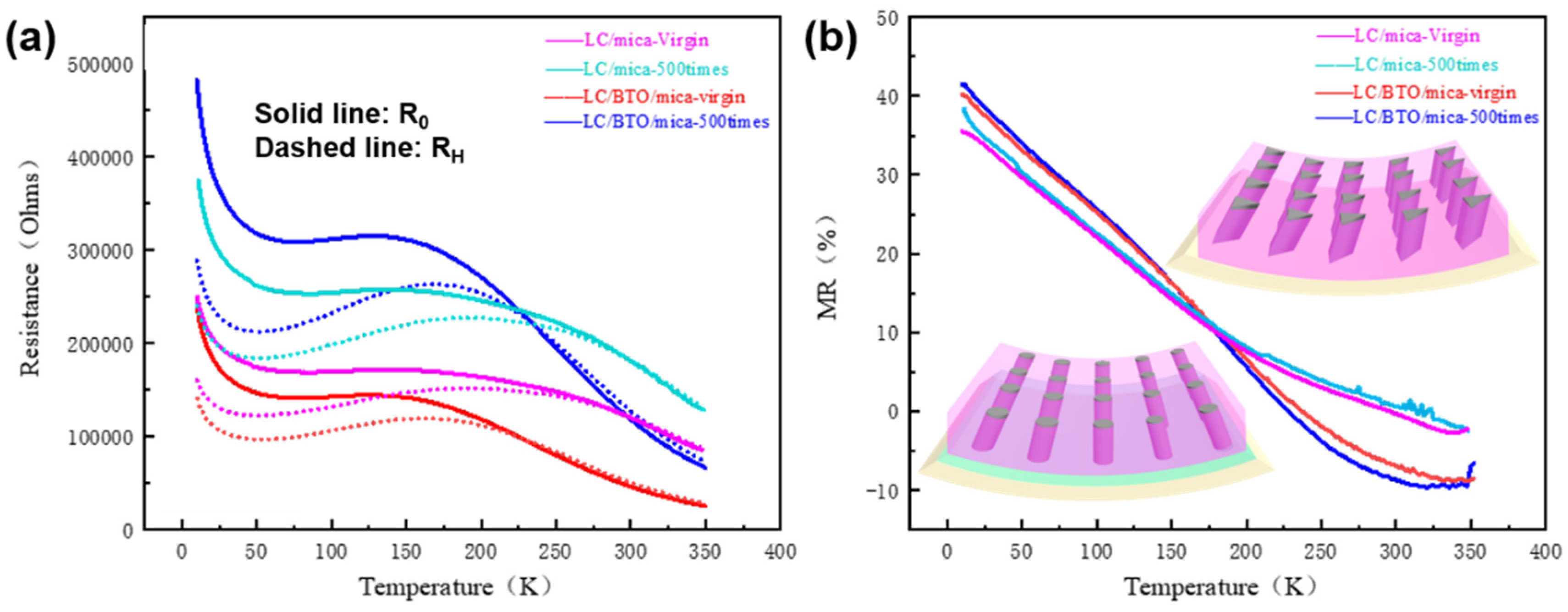

2. Results and Discussion

3. Conclusions

4. Experimental

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lorenz, M.; Rao, M.R.; Venkatesan, T.; Fortunato, E.; Barquinha, P.; Branquinho, R.; Salgueiro, D.; Martins, R.; Carlos, E.; Liu, A.; et al. The 2016 oxide electronic materials and oxide interfaces roadmap. J. Phys. D Appl. Phys. 2016, 49, 433001. [Google Scholar] [CrossRef]

- Huang, J.; MacManus-Driscoll, J.L.; Wang, H. New epitaxy paradigm in epitaxial self-assembled oxide vertically aligned nanocomposite thin films. J. Mater. Res. 2017, 32, 4054–4066. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Zerrer, P.; Wang, H.; Yang, H.; Yoon, J.; Fouchet, A.; Yu, R.; Blamire, M.G.; Jia, Q. Strain control and spontaneous phase ordering in vertical nanocomposite heteroepitaxial thin films. Nat. Mater. 2008, 7, 314–320. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Li, W.; Yang, H.; MacManus, J.L. Tailoring physical functionalities of complex oxides by vertically aligned nanocomposite thin-film design. MRS Bull. 2021, 46, 159–167. [Google Scholar] [CrossRef]

- Wang, J.; Neaton, J.B.; Zheng, H.; Nagarajan, V.; Ogale, S.B.; Liu, B.; Viehland, D.; Vaithyanathan, V.; Schlom, D.G.; Waghmare, U.V.; et al. Epitaxial BiFeO3 multiferroic thin film heterostructures. Science 2003, 299, 1719–1722. [Google Scholar] [CrossRef]

- Wang, N.; Luo, X.; Han, L.; Zhang, Z.; Zhang, R.; Olin, H.; Yang, Y. Structure, performance, and application of BiFeO3 nanomaterials. Nano-Micro Lett. 2020, 12, 81. [Google Scholar] [CrossRef] [PubMed]

- Kimura, T.; Goto, T.; Shintani, H.; Ishizaka, K.; Arima, T.; Tokura, Y. Magnetic control of ferroelectric polarization. Nature 2003, 426, 55–58. [Google Scholar] [CrossRef]

- Hu, N.; Lu, C.; Xia, Z.; Xiong, R.; Fang, P.; Shi, J.; Liu, J. Multiferroicity and magnetoelectric coupling in TbMnO3 thin films. ACS Appl. Mater. Interfaces 2015, 7, 26603–26607. [Google Scholar] [CrossRef]

- Zheng, H.; Wang, J.; Lofand, S.E.; Ma, Z.; Mohaddes-Ardabili, L.; Zhao, T.; Salamanca-Riba, L.; Shinde, S.R.; Ogale, S.B.; Bai, F.; et al. Multiferroic BaTiO3-CoFe2O4 nanostructures. Science 2004, 303, 661–663. [Google Scholar] [CrossRef]

- Wang, H.; Li, L.; Huang, J.; Gao, X.; Sun, X.; Wang, H. Multiferroic vertically aligned nanocomposite with CoFe2O4 nanocones embedded in layered Bi2WO6 matrix. Mater. Res. Lett. 2019, 7, 418–425. [Google Scholar] [CrossRef]

- Lee, O.; Harrington, S.A.; Kursumovic, A.; Defay, E.; Wang, H.; Bi, Z.; Tsai, C.; Yan, L.; Jia, Q.; MacManus-Driscoll, J.L. Extremely high tunability and low loss in nanoscaffold ferroelectric films. Nano Lett. 2012, 12, 4311–4317. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Zhang, D.; Liu, J.; Wang, H. Freestanding La0.7Sr0.3MnO3: NiO vertically aligned nanocomposite thin films for flexible perpendicular interfacial exchange coupling. Mater. Res. Lett. 2022, 10, 287–294. [Google Scholar] [CrossRef]

- Sun, X.; Huang, J.; Jian, J.; Fan, M.; Wang, H.; Li, Q.; MacManus-Driscoll, J.L.; Lu, P.; Zhang, X.; Wang, H. Three-dimensional strain engineering in epitaxial vertically aligned nanocomposite thin films with tunable magnetotransport properties. Mater. Horiz. 2018, 5, 536–544. [Google Scholar] [CrossRef]

- Ma, W.; Kim, J.; Tsvetkov, N.; Daio, T.; Kuru, Y.; Cai, Z.; Chen, Y.; Sasaki, K.; Tuller, H.L.; Yildiz, B. Vertically aligned nanocomposite La0.8Sr0.2CoO3/(La0.5Sr0.5)2CoO4 cathodes—Electronic structure, surface chemistry and oxygen reduction kinetics. J. Mater. Chem. A 2015, 3, 207–219. [Google Scholar] [CrossRef]

- Huang, J.; Wang, H.; Qi, Z.; Lu, P.; Zhang, D.; Zhang, B.; He, Z.; Wang, H. Multifunctional Metal–Oxide Nanocomposite Thin Film with Plasmonic Au Nanopillars Embedded in Magnetic La0.67Sr0.33MnO3 Matrix. Nano Lett. 2021, 21, 1032–1039. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Wang, X.; Hogan, N.; Wu, S.; Lu, P.; Fan, Z.; Dai, Y.; Zeng, B.; Starko-Bowes, R.; Jian, J.; et al. Nanoscale artificial plasmonic lattice in self-assembled vertically aligned nitride–metal hybrid metamaterials. Adv. Sci. 2018, 6, 1800416. [Google Scholar] [CrossRef]

- Huang, J.; Phuah, X.L.; McClintock, L.M.; Padmanabhan, P.; Vikrant, K.S.N.; Wang, H.; Zhang, D.; Wang, H.; Lu, P.; Gao, X.; et al. Core-shell metallic alloy nanopillars-in-dielectric hybrid metamaterials with magneto-plasmonic coupling. Mater. Today 2021, 51, 39–47. [Google Scholar] [CrossRef]

- Huang, J.; Gellatly, A.; Kauffmann, A.; Sun, X.; Wang, H. Exchange bias effect along vertical interfaces in La0.7Sr0.3MnO3: NiO vertically aligned nanocomposite thin films integrated on silicon substrates. Cryst. Growth Des. 2018, 18, 4388–4394. [Google Scholar] [CrossRef]

- Tian, H.; Wang, G.; Wang, F.; Jiang, C.; Huang, J. Si integration of La0.7Sr0.3MnO3: BiFeO3 nanocomposite thin films with strong exchange bias coupling. Appl. Phys. Lett. 2022, 121, 022403. [Google Scholar] [CrossRef]

- Zhang, W.; Chen, A.; Khatkhatay, F.; Tsai, C.F.; Su, Q.; Jiao, L.; Zhang, X.; Wang, H. Integration of self-assembled vertically aligned nanocomposite (La0. 7Sr0. 3MnO3) 1−x:(ZnO) x thin films on silicon substrates. ACS Appl. Mater. Interfaces 2013, 5, 3995–3999. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, H.; Wang, G.; Zhang, Y.; Huang, J. Flexible La0.67Sr0.33MnO3: ZnO Nanocomposite Thin Films Integrated on Mica. Front. Mater. 2022, 9, 913326. [Google Scholar] [CrossRef]

- Amrillah, T.; Bitla, Y.; Shin, K.; Yang, T.; Hsieh, Y.H.; Chiou, Y.Y.; Liu, H.J.; Do, T.H.; Su, D.; Chen, Y.C.; et al. Flexible multiferroic bulk heterojunction with giant magnetoelectric coupling via van der Waals epitaxy. ACS Nano 2017, 11, 6122–6130. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Wang, H.; Wang, X.; Gao, X.; Liu, J.; Wang, H. Exchange bias in a La0.67Sr0.33MnO3/NiO heterointerface integrated on a flexible mica substrate. ACS Appl. Mater. Interfaces 2020, 12, 39920–39925. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.J.; Wang, C.K.; Su, D.; Amrillah, T.; Hsieh, Y.H.; Wu, K.H.; Chen, Y.C.; Juang, J.Y.; Eng, L.M.; Jen, S.U.; et al. Flexible heteroepitaxy of CoFe2O4/muscovite bimorph with large magnetostriction. ACS Appl. Mater. Interfaces 2017, 9, 7297–7304. [Google Scholar] [CrossRef] [PubMed]

- Ye, L.; Zhang, D.; Lu, J.; Xu, S.; Xu, R.; Fan, J.; Tang, R.; Wang, H.; Guo, H.; Li, W.; et al. Epitaxial (110)-oriented La0.7Sr0.3MnO3 film directly on flexible mica substrate. J. Phys. D Appl. Phys. 2022, 55, 224002. [Google Scholar] [CrossRef]

- Li, C.I.; Lin, J.C.; Liu, H.J.; Chu, M.W.; Chen, H.W.; Ma, C.H.; Tsai, C.Y.; Huang, H.W.; Lin, H.J.; Liu, H.L.; et al. Van der Waal epitaxy of flexible and transparent VO2 film on muscovite. Chem. Mater. 2016, 28, 3914–3919. [Google Scholar] [CrossRef]

- Jiang, J.; Bitla, Y.; Huang, C.W.; Do, T.H.; Liu, H.J.; Hsieh, Y.H.; Ma, C.H.; Jang, C.Y.; Lai, Y.H.; Chiu, P.W.; et al. Flexible ferroelectric element based on van der Waals heteroepitaxy. Sci. Adv. 2017, 3, e1700121. [Google Scholar] [CrossRef]

- Liu, J.; Feng, Y.; Tang, R.; Zhao, R.; Gao, J.; Shi, D.; Yang, H. Flexible Electronics: Mechanically Tunable Magnetic Properties of Flexible SrRuO3 Epitaxial Thin Films on Mica Substrates. Adv. Electron. Mater. 2018, 4, 1700522. [Google Scholar] [CrossRef]

- Fan, M.; Zhang, W.; Khatkhatay, F.; Li, L.; Wang, H. Enhanced tunable magnetoresistance properties over a wide temperature range in epitaxial (La0.7Sr0.3MnO3)1−x:(CeO2)x nanocomposites. J. Appl. Phys. 2015, 118, 065302. [Google Scholar] [CrossRef]

- Sun, X.; Li, Q.; Huang, J.; Fan, M.; Rutherford, B.X.; Paldi, R.L.; Jian, J.; Zhang, X.; Wang, H. Strain-driven nanodumbbell structure and enhanced physical properties in hybrid vertically aligned nanocomposite thin films. Appl. Mater. Today 2019, 16, 204–212. [Google Scholar] [CrossRef]

- Fan, J.; Xie, Y.; Qian, F.; Ji, Y.; Hu, D.; Tang, R.; Liu, W.; Zhang, L.; Tong, W.; Ma, C.; et al. Isotropic magnetoresistance and enhancement of ferromagnetism through repetitious bending moments in flexible perovskite manganite thin film. J. Alloys Compd. 2019, 806, 753–760. [Google Scholar] [CrossRef]

- Skorodumova, N.V.; Baudin, M.; Hermansson, K. Surface properties of CeO2 from first principles. Phys. Rev. B 2004, 69, 075401. [Google Scholar] [CrossRef]

- Liu, Y.P.; Du, Y.S.; Zhang, M.; Yan, H.; Wang, Y.Y. Effect of internal strain on magnetic properties of La0.7Sr0.3MnO3 films. Vacuum 2007, 81, 826–829. [Google Scholar] [CrossRef]

- Praus, R.B.; Gross, G.M.; Razavi, F.S.; Habermeier, H.-U. Effects of strain on the properties of La0.67Ca0.33MnO3 thin films. J. Magn. Magn. Mater. 2000, 211, 41–46. [Google Scholar] [CrossRef]

- Mathews, M.; Postma, F.M.; Lodder, J.C.; Jansen, R.; Rijnders, G.; Blank, D.H.A. Step-induced uniaxial magnetic anisotropy of La:67Sr:33MnO3 thin films. Appl. Phys. Lett. 2005, 87, 242507. [Google Scholar] [CrossRef]

- Pardavi-Horvath, M. Coercivity of epitaxial magnetic garnet crystals. IEEE Trans. Magn. 1985, 21, 1694–1699. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, J.; Feng, J.; Zheng, X.; Yang, L.; Ge, C.; Jin, K.; Wang, Z.; Li, R. Synthesis of single-crystal La0.67Sr0.33MnO3 freestanding films with different crystal-orientation. APL Mater. 2020, 8, 051105. [Google Scholar] [CrossRef]

- Urushibara, A.; Moritomo, Y.; Arima, T.; Asamitsu, A.; Kido, G.; Tokura, Y. Insulator-metal transition and giant magnetoresistance in La1−x Srx MnO3. Phys. Rev. B 1995, 51, 14103. [Google Scholar] [CrossRef]

- Rivadulla, F.; Otero-Leal, M.; Espinosa, A.; de Andres, A.; Ramos, C.; Rivas, J.; Goodenough, J.B. Suppression of ferromagnetic double exchange by vibronic phase segregation. Phys. Rev. Lett. 2006, 96, 016402. [Google Scholar] [CrossRef]

- Rao, R.A.; Lavric, D.; Nath, T.K.; Eom, C.B.; Wu, L.; Tsui, F. Three-dimensional strain states and crystallographic domain structures of epitaxial colossal magnetoresistive La0.8Ca0.2MnO3 thin films. Appl. Phys. Lett. 1998, 73, 3294–3296. [Google Scholar] [CrossRef]

- Kang, B.S.; Wang, H.; MacManus-Driscoll, J.L.; Li, Y.; Jia, Q.; Mihut, I.; Betts, J.B. Low field magnetotransport properties of (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 nanocomposite films. Appl. Phys. Lett. 2006, 88, 192514. [Google Scholar] [CrossRef]

- Chen, A.; Bi, Z.; Hazariwala, H.; Zhang, X.; Su, Q.; Chen, L.; Jia, Q.; MacManus-Driscoll, J.L.; Wang, H. Microstructure, magnetic, and low-field magnetotransport properties of self-assembled (La0.7Sr0.3MnO3)0.5:(ZnO)0.5 vertically aligned nanocomposite thin films. Nanotechnology 2011, 22, 315712. [Google Scholar] [CrossRef]

- Xiong, C.; Zeng, Y.; Xiong, Y.; Zhang, J.; Pi, Y.; Zhang, L.; Xiong, J.; Cheng, X.; Wei, F.; Li, L. Low-field transport properties of (1−x)La0.7Ca0.2Sr0.1MnO3+x(ZnO) composites. Phys. B 2008, 403, 3266–3270. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, H.; Zhang, X.; Alodhayb, A.; Wang, F.; Jian, J.; Huang, J. Self-Assembled La0.67Sr0.33MnO3:CeO2 Vertically Aligned Nanocomposite Thin Films on Flexible Mica. Crystals 2023, 13, 1595. https://doi.org/10.3390/cryst13111595

Tian H, Zhang X, Alodhayb A, Wang F, Jian J, Huang J. Self-Assembled La0.67Sr0.33MnO3:CeO2 Vertically Aligned Nanocomposite Thin Films on Flexible Mica. Crystals. 2023; 13(11):1595. https://doi.org/10.3390/cryst13111595

Chicago/Turabian StyleTian, Hongxia, Xiong Zhang, Abdullah Alodhayb, Feng Wang, Jie Jian, and Jijie Huang. 2023. "Self-Assembled La0.67Sr0.33MnO3:CeO2 Vertically Aligned Nanocomposite Thin Films on Flexible Mica" Crystals 13, no. 11: 1595. https://doi.org/10.3390/cryst13111595

APA StyleTian, H., Zhang, X., Alodhayb, A., Wang, F., Jian, J., & Huang, J. (2023). Self-Assembled La0.67Sr0.33MnO3:CeO2 Vertically Aligned Nanocomposite Thin Films on Flexible Mica. Crystals, 13(11), 1595. https://doi.org/10.3390/cryst13111595