Pre-Recycling Material Analysis of NMC Lithium-Ion Battery Cells from Electric Vehicles

Abstract

:1. Introduction

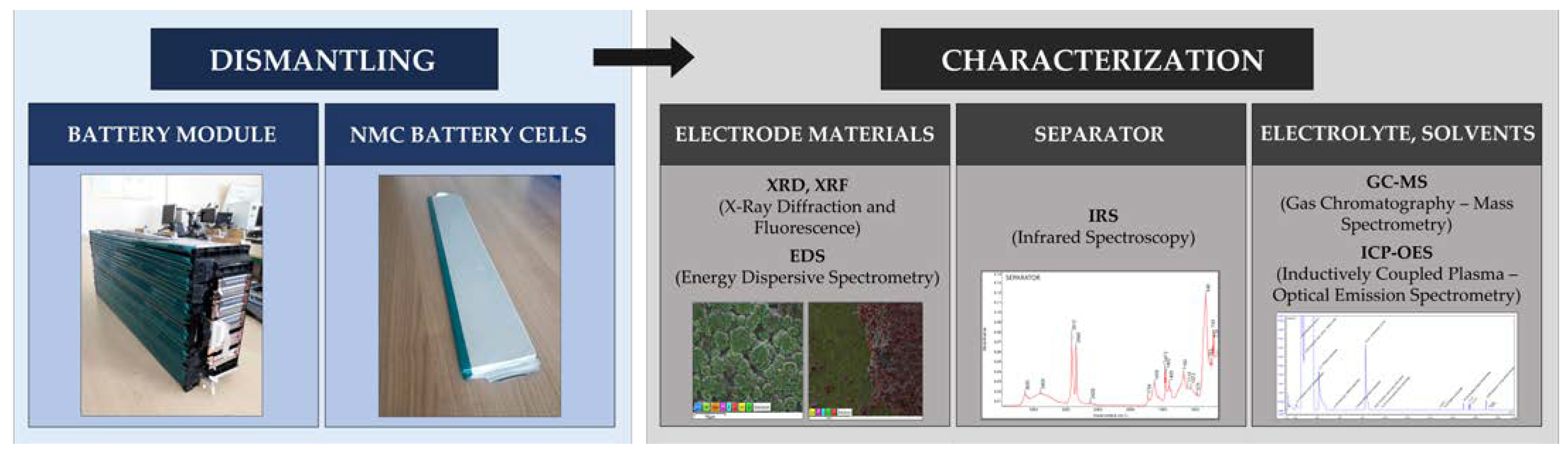

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Material Analysis

X-ray Diffraction and Fluorescence

Light and Electron Microscopy

Infrared Spectroscopy

Gas Chromatography—Mass Spectrometry

Inductively Coupled Plasma—Optical Emission Spectrometry

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Armand, M.; Axmann, P.; Bresser, D.; Copley, M.; Edström, K.; Ekberg, C.; Guyomard, D.; Lestriez, B.; Novák, P.; Petranikova, M.; et al. Lithium-ion batteries—Current state of the art and anticipated developments. J. Power Sources 2020, 479, 228708. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Ambrose, H.; Gershenson, D.; Gershenson, A.; Kammen, D. Driving rural energy access: A second-life application for electric-vehicle batteries. Environ. Res. Lett. 2014, 9, 094004. [Google Scholar] [CrossRef] [Green Version]

- Chen, W.; Liang, J.; Yang, Z.; Li, G. A Review of Lithium-Ion Battery for Electric Vehicle Applications and Beyond. Energy Procedia 2019, 158, 4363–4368. [Google Scholar] [CrossRef]

- Chen, T.; Jin, Y.; Lv, H.; Yang, A.; Liu, M.; Chen, B.; Xie, Y.; Chen, Q. Applications of Lithium-Ion Batteries in Grid-Scale Energy Storage Systems. Trans. Tianjin Univ. 2020, 26, 208–217. [Google Scholar] [CrossRef] [Green Version]

- Knap, V.; Kjelgaard Vestergaard, L.; Gismero, A.; Stroe, D.-I.; Knap, V.; Vestergaard, L.; Gismero, A. In Proceedings of the 71st International Astronautical Congress, Dubai, United Arab Emirates, 12–16 October 2020.

- Fallahifar, R.; Kalantar, M. Optimal planning of lithium ion battery energy storage for microgrid applications: Considering capacity degradation. J. Energy Storage 2023, 57, 106103. [Google Scholar] [CrossRef]

- González, I.; Calderón, A.J.; Folgado, F.J. IoT real time system for monitoring lithium-ion battery long-term operation in microgrids. J. Energy Storage 2022, 51, 104596. [Google Scholar] [CrossRef]

- Wei, Y.; Wang, S.; Han, X.; Lu, L.; Li, W.; Zhang, F.; Ouyang, M. Toward more realistic microgrid optimization: Experiment and high-efficient model of Li-ion battery degradation under dynamic conditions. eTransportation 2022, 14, 100200. [Google Scholar] [CrossRef]

- Tomaszewska, A.; Chu, Z.; Feng, X.; O’Kane, S.; Liu, X.; Chen, J.; Ji, C.; Endler, E.; Li, R.; Liu, L.; et al. Lithium-ion battery fast charging: A review. eTransportation 2019, 1, 100011. [Google Scholar] [CrossRef]

- Kim, T.; Song, W.; Son, D.-Y.; Ono, L.K.; Qi, Y. Lithium-ion batteries: Outlook on present, future, and hybridized technologies. J. Mater. Chem. A 2019, 7, 2942–2964. [Google Scholar] [CrossRef]

- Bonsu, N.O. Towards a circular and low-carbon economy: Insights from the transitioning to electric vehicles and net zero economy. J. Clean. Prod. 2020, 256, 120659. [Google Scholar] [CrossRef]

- Skeete, J.-P.; Wells, P.; Dong, X.; Heidrich, O.; Harper, G. Beyond the EVent horizon: Battery waste, recycling, and sustainability in the United Kingdom electric vehicle transition. Energy Res. Soc. Sci. 2020, 69, 101581. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, D.-C.; Lee, J.-J.; Kim, C.-W. Optimization of Lithium-Ion Battery Pouch Cell for Maximization of Energy Density while Preventing Internal Short Circuit Caused by Separator Failure under Crush Load. J. Electrochem. Soc. 2021, 168, 030536. [Google Scholar] [CrossRef]

- Löbberding, H.; Wessel, S.; Offermanns, C.; Kehrer, M.; Rother, J.; Heimes, H.; Kampker, A. From Cell to Battery System in BEVs: Analysis of System Packing Efficiency and Cell Types. World Electr. Veh. J. 2020, 11, 77. [Google Scholar] [CrossRef]

- Halimah, P.N.; Budiman, B.A.; Sambegoro, P.L. Mechanical properties of pouch battery constituents. AIP Conf. Proc. 2020, 2217, 030097. [Google Scholar] [CrossRef]

- Günter, F.J.; Wassiliadis, N. State of the Art of Lithium-Ion Pouch Cells in Automotive Applications: Cell Teardown and Characterization. J. Electrochem. Soc. 2022, 169, 030515. [Google Scholar] [CrossRef]

- Battery University Homepage. Available online: https://batteryuniversity.com/ (accessed on 5 December 2022).

- Sustainable Commodities and Supply Chain Solutions | Targray. Available online: https://www.targray.com/ (accessed on 5 December 2022).

- Chen, S.; Zhang, X.; Xia, M.; Wei, K.; Zhang, L.; Zhang, X.; Cui, Y.; Shu, J. Issues and challenges of layered lithium nickel cobalt manganese oxides for lithium-ion batteries. J. Electroanal. Chem. 2021, 895, 115412. [Google Scholar] [CrossRef]

- Xuan, W.; Otsuki, A.; Chagnes, A. Investigation of the leaching mechanism of NMC 811 (LiNi0.8Mn0.1Co0.1O2) by hydrochloric acid for recycling lithium ion battery cathodes. RSC Adv. 2019, 9, 38612–38618. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, Z.; Wang, Z.; Kim, G.T.; Yang, G.; Wang, H.; Wang, X.; Huang, Y.; Passerini, S.; Shen, Z. Enhancing the Electrochemical Performance of LiNi0.4Co0.2Mn0.4O2 by V2O5/LiV3O8 Coating. ACS Appl. Mater. Interfaces 2019, 11, 26994–27003. [Google Scholar] [CrossRef] [PubMed]

- Theivaprakasam, S.; Girard, G.; Howlett, P.; Forsyth, M.; Mitra, S.; MacFarlane, D. Passivation behaviour of aluminium current collector in ionic liquid alkyl carbonate (hybrid) electrolytes. Npj Mater. Degrad. 2018, 2, 13. [Google Scholar] [CrossRef] [Green Version]

- Holze, R. Anodes—Materials for negative electrodes in electrochemical energy technology. AIP Conf. Proc. 2014, 1597, 44–65. [Google Scholar] [CrossRef]

- Weber, C.J.; Geiger, S.; Falusi, S.; Roth, M. Material review of Li ion battery separators. AIP Conf. Proc. 2014, 1597, 66–81. [Google Scholar] [CrossRef] [Green Version]

- Liu, R.; Yuan, B.; Zhong, S.; Liu, J.; Dong, L.; Ji, Y.; Dong, Y.; Yang, C.; He, W. Poly(vinylidene fluoride) separators for next-generation lithium based batteries. Nano Sel. 2021, 2, 2308–2345. [Google Scholar] [CrossRef]

- Zackrisson, M.; Schellenberger, S. Toxicity of Lithium Ion Battery Chemicals—Overview with Focus on Recycling; Rise: Borås, Sweden, 2020. [Google Scholar]

- Balbuena, P.B. Electrolyte materials—Issues and challenges. AIP Conf. Proc. 2014, 1597, 82. [Google Scholar] [CrossRef]

- Elgowainy, A.; Burnham, A.; Wang, M.; Molburg, J.; Rousseau, A. Well-to-Wheels Energy Use and Greenhouse Gas Emissions Analysis of Plug-in Hybrid Electric Vehicles Energy Systems Division. Cent. Transp. Res. Energy Syst. Div. Argonne Natl. Lab. 2009, 2, 627–644. [Google Scholar]

- McLaren, J.; Miller, J.; O’Shaughnessy, E.; Wood, E.; Shapiro, E. CO2 emissions associated with electric vehicle charging: The impact of electricity generation mix, charging infrastructure availability and vehicle type. Electr. J. 2016, 29, 72–88. [Google Scholar] [CrossRef] [Green Version]

- Tang, Y.; Cockerill, T.T.; Pimm, A.J.; Yuan, X. Reducing the life cycl4e environmental impact of electric vehicles through emissions-responsive charging. iScience 2021, 24, 103499. [Google Scholar] [CrossRef]

- Xu, B.; Sharif, A.; Shahbaz, M.; Dong, K. Have electric vehicles effectively addressed CO2 emissions? Analysis of eight leading countries using quantile-on-quantile regression approach. Sustain. Prod. Consum. 2021, 27, 1205–1214. [Google Scholar] [CrossRef]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part II: Environmental and Economic Perspective. Energies 2022, 15, 7356. [Google Scholar] [CrossRef]

- Chen, M.; Ma, X.; Chen, B.; Arsenault, R.; Karlson, P.; Simon, N.; Wang, Y. Recycling End-of-Life Electric Vehicle Lithium-Ion Batteries. Joule 2019, 3, 2622–2646. [Google Scholar] [CrossRef]

- Forsgren, C. Lithium-Ion Batteries, How to Generate Value Out of End of Life Mobile Units. Miner. Met. Mater. Ser. 2019, 261–263. [Google Scholar] [CrossRef]

- MarketsandMarkets Preview: Lithium-ion Battery Recycling Market Global Forecast to 2030|MarketsandMarkets. Available online: https://www.marketsandmarkets.com/Market-Reports/lithium-ion-battery-recycling-market-153488928.html (accessed on 19 September 2021).

- Gu, S.; Zhang, L.; Fu, B.; Ahn, J.W.; Wang, X. Recycling of mixed lithium-ion battery cathode materials with spent lead-acid battery electrolyte with the assistance of thermodynamic simulations. J. Clean. Prod. 2020, 266, 121827. [Google Scholar] [CrossRef]

- Park, K.; Yu, J.; Coyle, J.; Dai, Q.; Frisco, S.; Zhou, M.; Burrell, A. Direct Cathode Recycling of End-Of-Life Li-Ion Batteries Enabled by Redox Mediation. ACS Sustain. Chem. Eng. 2021, 9, 8214–8221. [Google Scholar] [CrossRef]

- Natarajan, S.; Aravindan, V. Recycling Strategies for Spent Li-Ion Battery Mixed Cathodes. ACS Energy Lett. 2018, 3, 2101–2103. [Google Scholar] [CrossRef] [Green Version]

- Pražanová, A.; Knap, V.; Stroe, D.-I. Literature Review, Recycling of Lithium-Ion Batteries from Electric Vehicles, Part I: Recycling Technology. Energies 2022, 15, 1086. [Google Scholar] [CrossRef]

- Bae, H.; Kim, Y. Technologies of lithium recycling from waste lithium ion batteries: A review. Mater. Adv. 2021, 2, 3234–3250. [Google Scholar] [CrossRef]

- Kim, H.-J.; Krishna, T.; Zeb, K.; Rajangam, V.; Gopi, C.V.V.M.; Sambasivam, S.; Raghavendra, K.V.G.; Obaidat, I.M. A Comprehensive Review of Li-Ion Battery Materials and Their Recycling Techniques. Electronics 2020, 9, 1161. [Google Scholar] [CrossRef]

- Beaudet, A.; Larouche, F.; Amouzegar, K.; Bouchard, P.; Zaghib, K. Key Challenges and Opportunities for Recycling Electric Vehicle Battery Materials. Sustainability 2020, 12, 5837. [Google Scholar] [CrossRef]

- European Commission 2050 Long-Term Strategy. Available online: https://ec.europa.eu/clima/eu-action/climate-strategies-targets/2050-long-term-strategy_en (accessed on 3 May 2022).

- Pražanová, A.; Míka, M.H.; Knap, V. Lithium-ion battery module-to-cell: Disassembly and material analysis.J. Phys. Conf. Ser. 2022, 2382, 12002. [Google Scholar] [CrossRef]

- Meng, F.; Guo, H.; Wang, Z.; Yan, G.; Li, X. Modification by simultaneously γ-WO3/Li2WO4 composite coating and spinel-structure formation on Li[Li0.2Mn0.54Ni0.13Co0.13]O2 cathode via a simple wet process. J. Alloys Compd. 2019, 790, 421–432. [Google Scholar] [CrossRef]

- Gan, Z.; Hu, G.; Peng, Z.; Cao, Y.; Tong, H.; Du, K. Surface modification of LiNi0.8Co0.1Mn0.1O2 by WO3 as a cathode material for LIB. Appl. Surf. Sci. 2019, 481, 1228–1238. [Google Scholar] [CrossRef]

- Wang, Y.; Yin, C.; Song, Z.; Wang, Q.; Lan, Y.; Luo, J.; Bo, L.; Yue, Z.; Sun, F.; Li, X. Application of PVDF Organic Particles Coating on Polyethylene Separator for Lithium Ion Batteries. Materials 2019, 12, 3125. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Battery Cell Component | Material Composition | Material Thickness | Analysis Method |

|---|---|---|---|

| Cathode | Al foil | 15 μm | XRD, XRF, |

| LiNi0.6Mn0.2Co0.2O2 | 80 μm in one layer | EDS | |

| Anode | Cu foil | 60 μm | XRD, XRF, |

| carbon | 100 μm in one layer | EDS | |

| Separator | PE/PVDF | 25 μm | IR |

| Electrolyte | LiPF6 | - | ICP-OES |

| Solvents | Carbonates, FB | - | GC-MS |

| Element | Visually Pure Layer | Layer with Separator Residues | ||

|---|---|---|---|---|

| Weight (wt.%) | σ (wt.%) | Weight (wt.%) | σ (wt.%) | |

| Ni | 28.0 | 2.7 | 23.1 | 2.2 |

| O | 23.7 | 1.1 | 21.7 | 0.8 |

| F | 16.4 | 0.8 | 16.7 | 0.7 |

| C | 10.9 | 0.7 | 15.0 | 0.7 |

| Mn | 8.5 | 0.9 | 7.4 | 0.7 |

| Co | 7.3 | 1.6 | 7.8 | 1.3 |

| W | 3.8 | 0.5 | 1.5 | 0.3 |

| P | 1.3 | 0.2 | 0.6 | 0.1 |

| Al | - | 6.1 | 0.3 | |

| Element | Visually Pure Layer | Layer with Separator Residues | ||

|---|---|---|---|---|

| Weight (wt.%) | σ (wt.%) | Weight (wt.%) | σ (wt.%) | |

| C | 48.0 | 0.6 | 35.8 | 0.7 |

| Cu | 39.1 | 0.6 | 23.0 | 0.4 |

| O | 6.0 | 0.2 | 14.1 | 0.3 |

| F | 4.3 | 0.2 | 10.4 | 0.2 |

| P | 1.1 | 0.1 | 2.6 | 0.1 |

| Al | - | 12.9 | 0.1 | |

| Element | Separator | |

|---|---|---|

| Weight (wt.%) | σ (wt.%) | |

| F | 31.9 | 0.5 |

| C | 29.2 | 0.7 |

| O | 19.8 | 0.4 |

| Al | 15.7 | 0.3 |

| P | 3.5 | 0.2 |

| Concentration (mg/L) | Al | Co | Cu | Li | Mn | Ni | P |

|---|---|---|---|---|---|---|---|

| Blank | <LOQ | <LOQ | 1.6 | 0.1 | <LOQ | <LOQ | 1.7 |

| Cell opening (time: 0:00) | <LOQ | <LOQ | 2.0 | 12.5 | <LOQ | <LOQ | 764.8 |

| Cell disassembly (time: 0:30) | 2.5 | 0.1 | 18.8 | 110.5 | 0.3 | 0.4 | 4 316.8 |

| Cell crushing (time: 0:45) | 3.3 | 0.1 | 18.0 | 106.4 | 0.4 | 0.5 | 4 139.8 |

| Removal of solids (time: 1:00) | 8.6 | 0.2 | 17.6 | 133.1 | 0.8 | 1.1 | 4 501.1 |

| mg/one cell | 103.0 | 3.0 | 210.8 | 1 597.6 | 9.5 | 13.8 | 54 012.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pražanová, A.; Kočí, J.; Míka, M.H.; Pilnaj, D.; Plachý, Z.; Knap, V. Pre-Recycling Material Analysis of NMC Lithium-Ion Battery Cells from Electric Vehicles. Crystals 2023, 13, 214. https://doi.org/10.3390/cryst13020214

Pražanová A, Kočí J, Míka MH, Pilnaj D, Plachý Z, Knap V. Pre-Recycling Material Analysis of NMC Lithium-Ion Battery Cells from Electric Vehicles. Crystals. 2023; 13(2):214. https://doi.org/10.3390/cryst13020214

Chicago/Turabian StylePražanová, Anna, Jan Kočí, Martin Havlík Míka, Dominik Pilnaj, Zbyněk Plachý, and Vaclav Knap. 2023. "Pre-Recycling Material Analysis of NMC Lithium-Ion Battery Cells from Electric Vehicles" Crystals 13, no. 2: 214. https://doi.org/10.3390/cryst13020214

APA StylePražanová, A., Kočí, J., Míka, M. H., Pilnaj, D., Plachý, Z., & Knap, V. (2023). Pre-Recycling Material Analysis of NMC Lithium-Ion Battery Cells from Electric Vehicles. Crystals, 13(2), 214. https://doi.org/10.3390/cryst13020214