Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms

Abstract

:1. Introduction

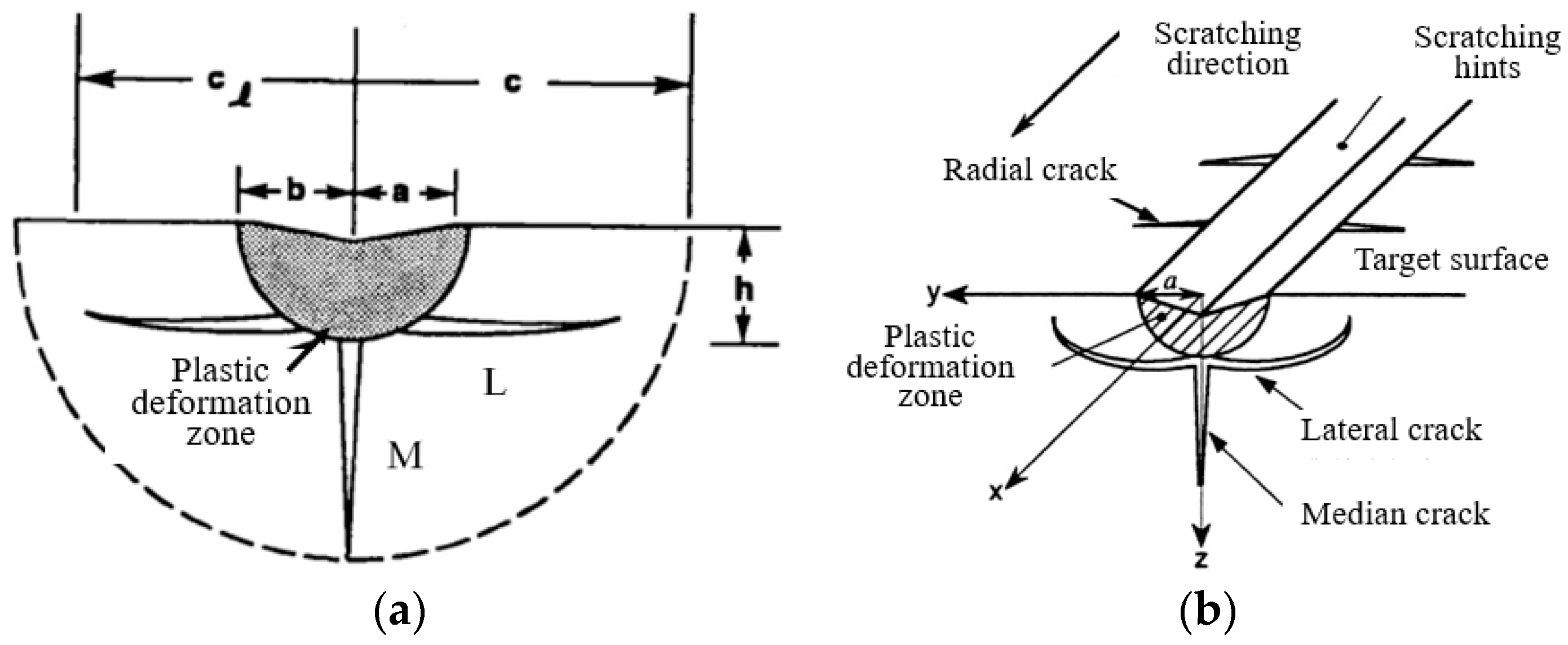

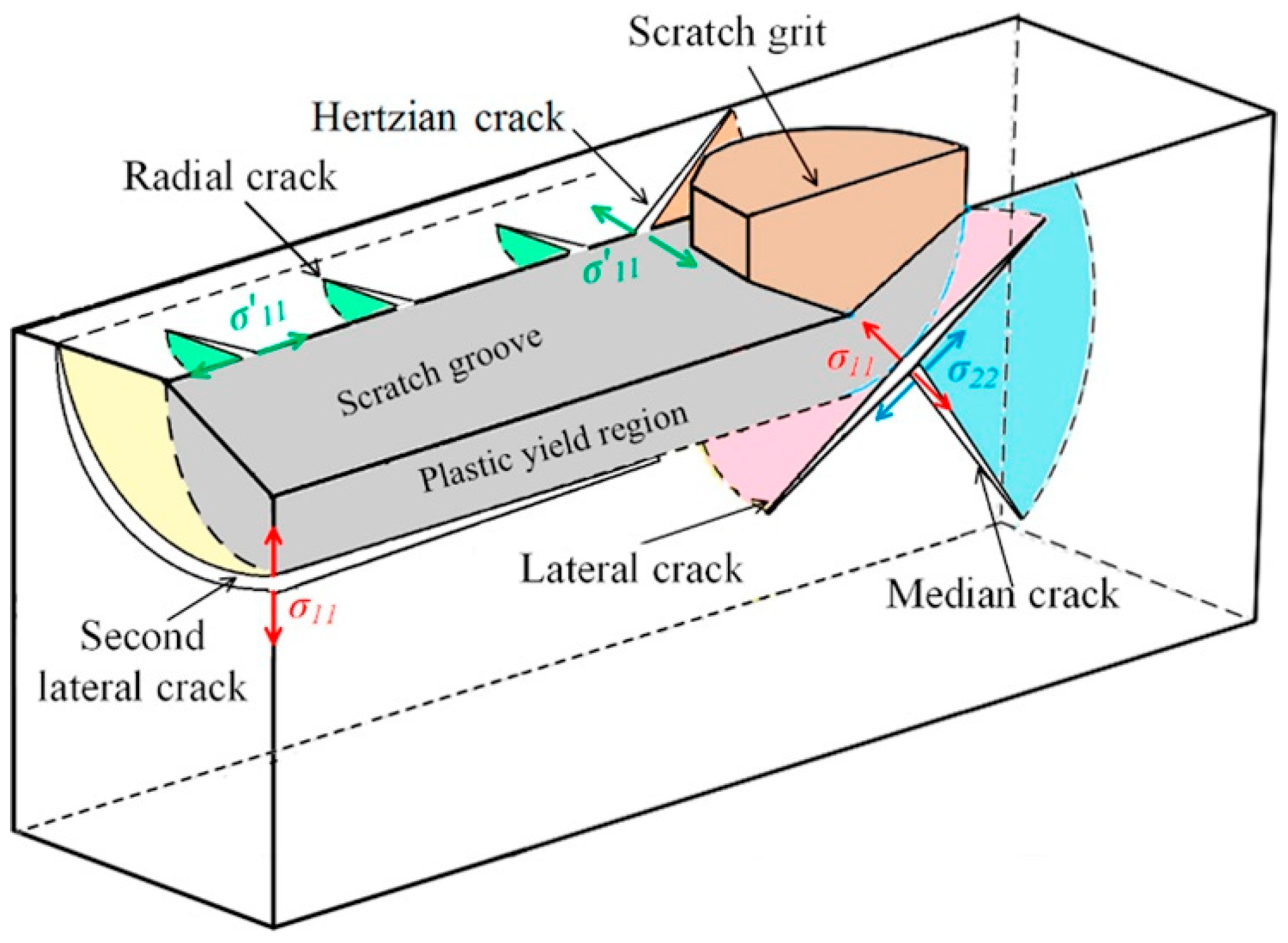

2. Abrasive Grinding and Scratching Mechanism of Hard Brittle Materials

3. Elastic Stress Field of Hard Brittle Materials by Single Abrasive Scratching

4. Effect of Strain Rate and Temperature on the Single Abrasive Scratching of Hard Brittle Materials

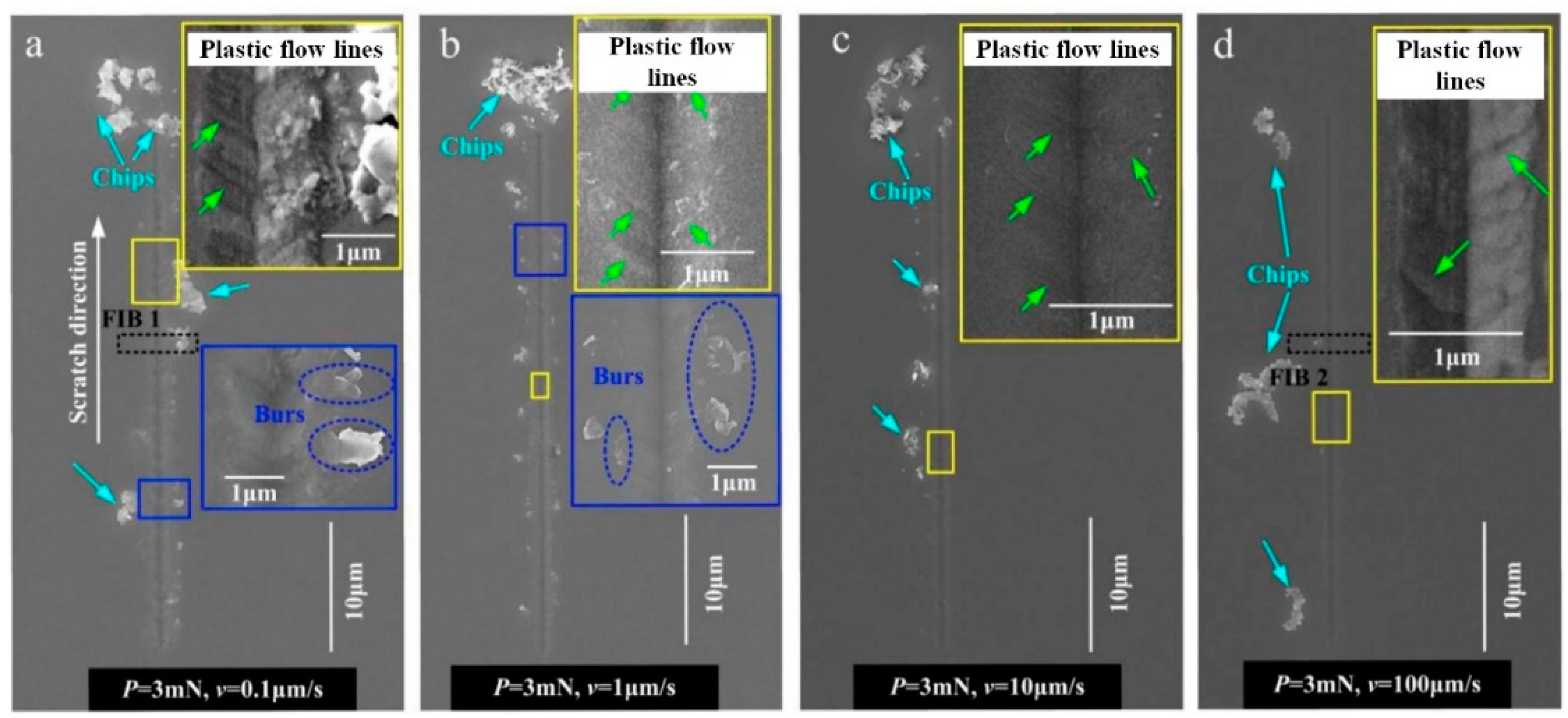

4.1. Strain Rate

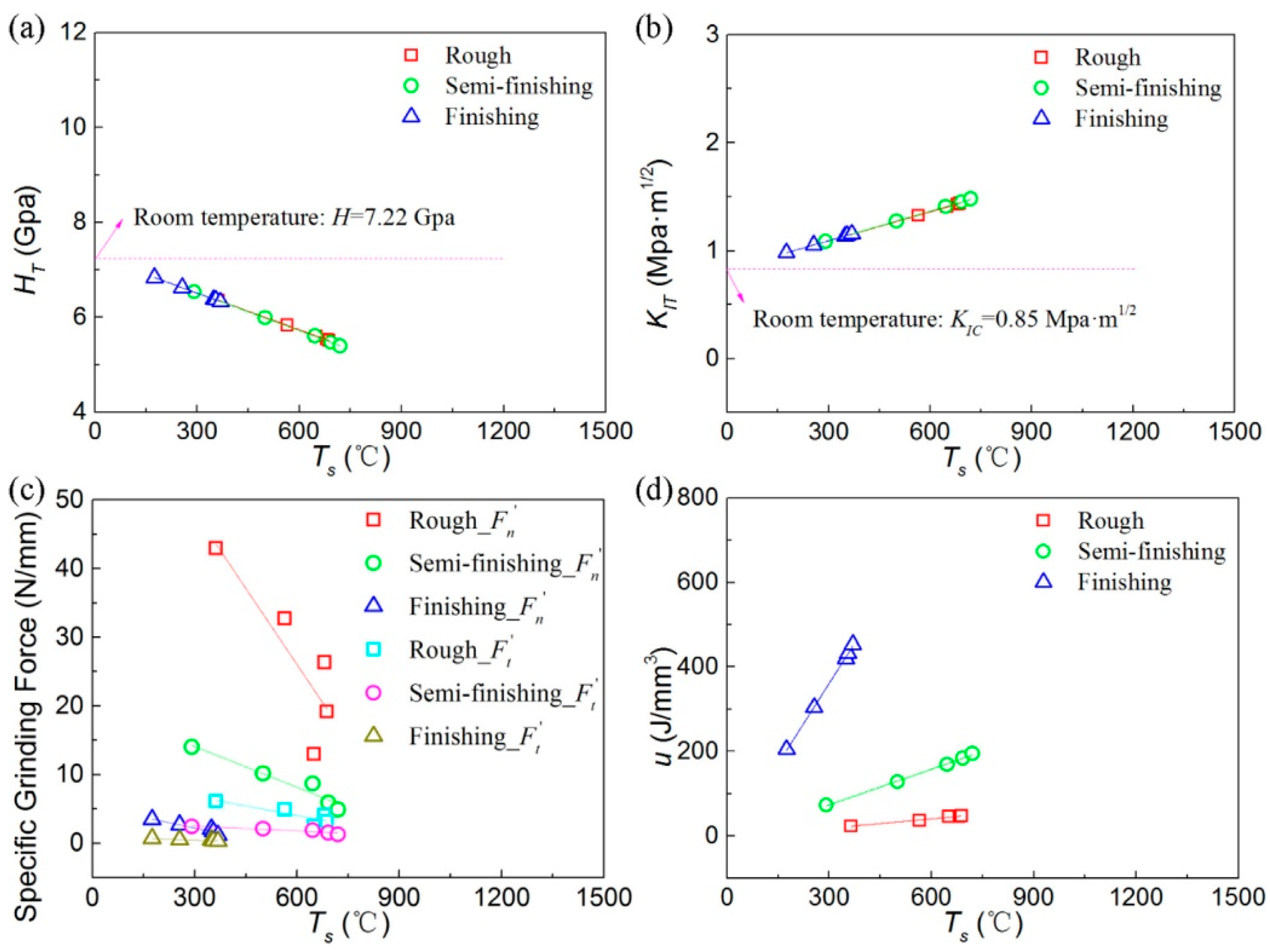

4.2. Temperature

5. Conclusions

- (1)

- In the calculation of the stress field model and principal stress–hardness ratio model for the single abrasive scratching of hard brittle materials, the abrasive was idealized as a sharp indenter and the force on the workpiece was treated as a point load. However, in actual single abrasive scratching, the contact between the abrasive and the workpiece is usually surface contact between the abrasive rake face and the workpiece surface. Further study is necessary to better understand the nature of this contact and improve the model accordingly.

- (2)

- This study considered the impact of grinding temperature on the abrasive grain–workpiece contact area. However, the grinding area temperature was not directly measured during the experiments, and the temperature calculation model was not verified, leading to potential inaccuracies in the subsurface damage model calculation. Further research should focus on verifying the temperature calculation model through experimentation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Piao, Y.; Meng, B.; Hu, Y.; Li, L.; Zhang, F. Phase transition and plastic deformation mechanisms induced by self-rotating grinding of GaN single crystals. Int. J. Mach. Tools Manuf. 2022, 172, 103827. [Google Scholar] [CrossRef]

- Evans, C.; Paul, E.; Dornfeld, D.; Lucca, D.; Byrne, G.; Tricard, M.; Klocke, F.; Dambon, O.; Mullany, B. Material removal mechanisms in lapping and polishing. CIRP Ann. 2003, 52, 611–633. [Google Scholar] [CrossRef]

- Li, C.; Hu, Y.; Zhang, F.; Geng, Y.; Meng, B. Molecular dynamics simulation of laser assisted grinding of GaN crystals. Int. J. Mech. Sci. 2023, 239, 107856. [Google Scholar] [CrossRef]

- Li, C.; Piao, Y.; Zhang, F.; Zhang, Y.; Hu, Y.; Wang, Y. Understand anisotropy dependence of damage evolution and material removal during nanoscratch of MgF2 single crystals. Int. J. Extrem. Manuf. 2023, 5, 015101. [Google Scholar] [CrossRef]

- Li, H.N.; Axinte, D. On a stochastically grain-discretised model for 2D/3D temperature mapping prediction in grinding. Int. J. Mach. Tools Manuf. 2017, 116, 60–76. [Google Scholar] [CrossRef]

- Qi, H.; Wang, Y.; Qi, Z.; Shi, L.; Fang, Z.; Zhang, L.; Riemer, O.; Karpuschewski, B. A Novel Grain-Based DEM Model for Evaluating Surface Integrity in Scratching of RB-SiC Ceramics. Materials 2022, 15, 8486. [Google Scholar] [CrossRef]

- Marshall, D.; Lawn, B.; Evans, A. Elastic/plastic indentation damage in ceramics: The lateral crack system. J. Am. Ceram. Soc. 1982, 65, 561–566. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marschall, D. Elastic/plastic indentation damage in ceramics: The median/radial crack system. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Shi, X.K.; Teng, L.; Li, Y.Q. The critical condition of ductile grinding of hard brittle materials. Aviat. Precis. Manuf. Technol. 1996, 4, 10–13. [Google Scholar]

- Zhang, W.; Subhash, G. An elastic–plastic-cracking model for finite element analysis of indentation cracking in brittle materials. Int. J. Solids Struct. 2001, 38, 5893–5913. [Google Scholar] [CrossRef]

- Muchtar, A.; Lim, L.C.; Lee, K.H. Finite element analysis of vickers indentation cracking processes in brittle solids using elements exhibiting cohesive post-failure behaviour. J. Mater. Sci. 2003, 38, 235–243. [Google Scholar] [CrossRef]

- Zhang, B.; Yoshioka, M.; Hira, S. Experimental observation and numerical analysis of cracking phenomena in adjoining Vickers indentations on glass surface—ScienceDirect. J. Mater. Process. Technol. 2008, 208, 171–178. [Google Scholar] [CrossRef]

- Ahn, Y.; Farris, T.; Chandrasekar, S. Sliding microindentation fracture of brittle materials: Role of elastic stress fields. Mech. Mater. 1998, 29, 143–152. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.; Xiao, H.; Chen, Z.; Qu, M.; Dai, H.; Jin, T. Effects of local strain rate and temperature on the workpiece subsurface damage in grinding of optical glass. Int. J. Mech. Sci. 2020, 182, 105737. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F.; Cai, Y.; Sun, J.; Liu, H. Material removal mode and friction behaviour of RB-SiC ceramics during scratching at elevated temperatures. J. Eur. Ceram. Soc. 2019, 39, 3534–3545. [Google Scholar] [CrossRef]

- Sellappan, P.; Rouxel, T.; Celarie, F.; Becker, E.; Houizot, P.; Conradt, R.J. Composition dependence of indentation deformation and indentation cracking in glass. Acta Mater. 2013, 61, 5949–5965. [Google Scholar] [CrossRef]

- Wang, W.; Yao, P.; Wang, J.; Huang, C.; Zhu, H.; Zou, B.; Liu, H.; Yan, J. Crack-free ductile mode grinding of fused silica under controllable dry grinding conditions. Int. J. Mach. Tools Manuf. 2016, 109, 126–136. [Google Scholar] [CrossRef]

- Meng, B.; Zhang, F.; Li, Z. Deformation and removal characteristics in nanoscratching of 6H-SiC with Berkovich indenter. Mater. Sci. Semicond. Process. 2015, 31, 160–165. [Google Scholar] [CrossRef]

- Bulsara, V.H.; Chandrasekar, S. Direct observation of contact damage around scratches in brittle solids. In Proceedings of the SPIE—The International Society for Optical Engineering, Orlando, FL, USA, 20–25 April 1997; Volume 3060. [Google Scholar]

- Li, K.; Shapiro, Y.; Li, J.C.M. Scratch tests of soda-lime glass. Acta Mater. 1998, 46, 5569–5578. [Google Scholar] [CrossRef]

- Nakamura, M.; Sumomogi, T.; Endo, T. Evaluation of surface and subsurface cracks on nano-scale machined brittle materials by scanning force microscope and scanning laser microscope. Surf. Coat. Technol. 2003, 169, 743–747. [Google Scholar] [CrossRef]

- Yoshino, M.; Ogawa, Y.; Aravindan, S. Machining of hard-brittle materials by a single point tool under external hydrostatic pressure. J. Manuf. Sci. Eng. 2005, 127, 837–845. [Google Scholar] [CrossRef]

- Gu, W.; Yao, Z.; Liang, X. Material removal of optical glass BK7 during single and double scratch tests. Wear 2011, 270, 241–246. [Google Scholar] [CrossRef]

- Qiu, Z.; Liu, C.; Wang, H.; Yang, X.; Fang, F.; Tang, J. Crack propagation and the material removal mechanism of glass–ceramics by the scratch test. J. Mech. Behav. Biomed. Mater. 2016, 64, 75–85. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Wan, Z.; Wang, W.; Ding, X.; Tang, Y. Crack behaviors of optical glass BK7 during scratch tests under different tool apex angles. Wear 2019, 430–431, 299–308. [Google Scholar] [CrossRef]

- Ji, R.Q.; Qi, Z.J.; Chen, J.C.; Zhang, L.; Lin, K.F.; Lu, S.S.; Li, Y.B. Numerical and experimental investigation on the abrasive flow machining of artificial knee joint surface. Crystals 2023, 13, 430. [Google Scholar]

- Wang, W. High Efficiency Controllable Precision Grinding Mechanisms of Fused Silica. Ph.D. Thesis, Shandong University, Jinan, China, 2017. [Google Scholar]

- Lawn, B.; Swain, M. Microfracture beneath point indentations in brittle solids. J. Mater. Sci. 1975, 10, 113–122. [Google Scholar] [CrossRef]

- Yoffe, E. Elastic stress fields caused by indenting brittle materials. Philos. Mag. A 1982, 46, 617–628. [Google Scholar] [CrossRef]

- Cook, R.F.; Pharr, G.M. Direct observation and analysis of indentation cracking in glasses and ceramics. J. Am. Ceram. Soc. 1990, 73, 787–817. [Google Scholar] [CrossRef]

- Lin, B. Theoretical and Experimental Studies on the Ultra-precision Grinding of Engineering Ceramics. Doctoral Thesis, Tianjin University, Tianjin, China, 1999. [Google Scholar]

- Jing, X.; Maiti, S.; Subhash, G. A new analytical model for estimation of scratch-induced damage in brittle solids. J. Am. Ceram. Soc. 2007, 90, 885–892. [Google Scholar] [CrossRef]

- Yang, X.; Qiu, Z.; Li, X. Investigation of scratching sequence influence on material removal mechanism of glass-ceramics by the multiple scratch tests. Ceram. Int. 2019, 45, 861–873. [Google Scholar] [CrossRef]

- Yang, X.; Qiu, Z.; Wang, Y. Investigation of material flow behaviour and chip formation mechanism during grinding of glass-ceramics by nanoscratch. Ceram. Int. 2019, 45, 15954–15963. [Google Scholar] [CrossRef]

- Yuan, H.Y.; Yang, W.B.; Zhang, L.; Hong, T. Model development of stress intensity factor on 7057T6 aluminum alloy using extended finite element method. Coatings 2023, 13, 581. [Google Scholar]

- Xie, X.D.; Zhang, L.; Zhu, L.L.; Li, Y.B.; Hong, T.; Yang, W.B.; Shan, X.H. State of the art and perspectives on surface strengthening process and associated mechanisms by shot peening. Coatings 2023, 13. [Google Scholar]

- Qi, H.; Shi, L.; Teng, Q.; Hong, T.; Tangwarodomnukun, V.; Liu, G.; Li, H.N. Subsurface damage evaluation in the single abrasive scratching of BK7 glass by considering coupling effect of strain rate and temperature. Ceram. Int. 2021, 48, 8661–8670. [Google Scholar] [CrossRef]

- Shi, H.; Liu, G.; Yang, G.; Bi, Q.; Zhao, Y.; Wang, B.; Sun, X.; Liu, X.; Qi, H.; Xu, W.; et al. Analytical modelling of edge chipping in scratch of soda-lime glass considering strain-rate hardening effect. Ceram. Int. 2021, 47, 26552–26566. [Google Scholar] [CrossRef]

- Hu, W.; Teng, Q.; Hong, T.; Saetang, V.; Qi, H. Stress field modeling of single-abrasive scratching of BK7 glass for surface integrity evaluation. Ceram. Int. 2021, 48, 12819–12828. [Google Scholar] [CrossRef]

- Gauthier, C.; Schirrer, R. Time and temperature dependence of the scratch properties of poly (methylmethacrylate) surfaces. J. Mater. Sci. 2000, 35, 2121–2130. [Google Scholar] [CrossRef]

- Wasmer, K.; Parlinska-Wojtan, M.; Gassilloud, R.; Pouvreau, C.; Tharian, J.; Micher, J. Plastic deformation modes of gallium arsenide in nanoindentation and nanoscratching. Appl. Phys. Lett. 2007, 90, 031902. [Google Scholar] [CrossRef]

- Haasen, P. Zur plastischen Verformung von Germanium und InSb. Z. Phys. 1962, 167, 461–467. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, J. Strain rate effect on the ductile brittle transition in grinding hot pressed SiC ceramics. Micromachines 2020, 11, 545. [Google Scholar] [CrossRef]

- Zhao, H.H.; Cai, G.Q. Model establishment and mechanism research of chip-formation due to shock under ultra-high speed grinding. China Mech. Eng. 2004, 12, 1038–1041. [Google Scholar]

- Feng, P.F.; Zhang, C.L.; Wu, Z.J.; Zhang, J.F. Effect of scratch velocity on deformation features of C-plane Sapphire during nanoscratching. J. Mech. Eng. 2013, 59, 367–374. [Google Scholar] [CrossRef]

- Li, B.; Ni, J.; Yang, J.; Liang, S.Y. Study on high-speed grinding mechanisms for quality and process efficiency. Int. J. Adv. Manuf. Technol. 2013, 70, 813–819. [Google Scholar] [CrossRef]

- Mukaiyama, K.; Ozaki, M.; Wada, T. Study on ductile-brittle transition of single crystal silicon by a scratching test using a single diamond tool. In Proceedings of the 2017 8th International Conference on Mechanical and Aerospace Engineering (ICMAE), Prague, Czech Republic, 22–25 July 2017. [Google Scholar]

- Yang, X.; Qiu, Z.; Lu, C.; Li, X.; Tang, J. Modelling the strain rate sensitivity on the subsurface damages of scratched glass ceramics. Ceram. Int. 2017, 43, 12930–12938. [Google Scholar] [CrossRef]

- Li, C.; Zhang, F.; Piao, Y. Strain-rate dependence of surface/subsurface deformation mechanisms during nanoscratching tests of GGG single crystal. Ceram. Int. 2019, 45, 15015–15024. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, B. Material embrittlement in high strain-rate loading. Int. J. Extrem. Manuf. 2019, 1, 022003. [Google Scholar] [CrossRef]

- Qi, H.; Xing, W.; Tan, W.; Lin, H.; Guo, H.J.; Chen, M.Z.; Tang, H.P. Effect of the sintering process on mechanical behaviors of Zirconia ceramics by NanoParticle Jetting. Ceram. Int. 2023. Submitted for Publication. [Google Scholar]

- Ji, P.J.; Zhang, J.J.; Xie, X.D.; Ying, R.M.; Zhang, L. Review on Wear Characteristics of Artificial Hip Joint and Associated Physical Training. Front. Mater. 2023, 10. [Google Scholar]

- Jaeger, J.C. Moving sources of heat and the temperature of sliding contacts. J. Proc. R. Soc. 1942, 76, 203. [Google Scholar]

- Hahn, R.S. On the nature of the grinding process. In Proceedings of the 3rd International Machine Tool Design & Research Conference, Manchester, UK, 18–20 September 1962; pp. 129–154. [Google Scholar]

- Guo, C.; Malkin, S. Analysis of energy partition in grinding. J. Eng. Ind. 1995, 117, 55–61. [Google Scholar] [CrossRef]

- Rowe, W.B.; Jin, T. Temperatures in high efficiency deep grinding. CIRP Ann. 2001, 50, 205–208. [Google Scholar] [CrossRef]

- Jin, T.; Cai, G. Analytical thermal models of oblique moving heat source for deep grinding and cutting. J. Manuf. Sci. Eng. 2001, 123, 185–190. [Google Scholar] [CrossRef]

- Desruisseaux, N.R.; Zerkle, R.D. Temperature in semi-infinite and cylindrical bodies subjected to moving heat sources and surface cooling. J. Heat Transf. 1970, 92, 456–464. [Google Scholar] [CrossRef]

- Malkin, S.; Cook, N.H. The wear of grinding wheels: Part 2—Fracture wear. J. Eng. Ind. 1971, 93, 1129–1133. [Google Scholar] [CrossRef]

- Guo, C.; Malkin, S. Analytical and experimental investigation of burnout in creep-feed grinding. CIRP Ann. 1994, 43, 283–286. [Google Scholar] [CrossRef]

- Hou, Z.B.; Komanduri, R. On the mechanics of the grinding process, Part III-thermal analysis of the abrasive cut-off operation. Int. J. Mach. Tools Manuf. 2004, 44, 271–289. [Google Scholar] [CrossRef]

- Rowe, W.B. Principles of Modern Grinding Technology, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Michel, M.; Mikowski, A.; Lepienski, C.; Foerster, C.; Serbena, F. High temperature microhardness of soda-lime glass. J. Non-Cryst. Solids 2004, 348, 131–138. [Google Scholar] [CrossRef]

- Michel, M.D.; Serbena, F.C.; Lepienski, C.M. Effect of temperature on hardness and indentation cracking of fused silica. J. Non-Cryst. Solids 2006, 352, 3550–3555. [Google Scholar] [CrossRef]

- Rao, X.; Zhang, F.; Luo, X.; Ding, F. Characterization of hardness, elastic modulus and fracture toughness of RB-SiC ceramics at elevated temperature by Vickers test. Mater. Sci. Eng. A 2019, 744, 426–435. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, F.; Luo, X.; Chang, W.; Cai, Y.; Zhong, W.; Ding, F. Material removal mechanism of laser-assisted grinding of RB-SiC ceramics and process optimization. J. Eur. Ceram. Soc. 2019, 39, 705–717. [Google Scholar] [CrossRef]

- Niu, Y.; Zhao, D.; Wang, S.; Li, S.; Wang, Z.; Zhao, H. Investigations on thermal effects on scratch behavior of monocrystalline silicon via molecular dynamics simulation. Mater. Today Commun. 2021, 26, 102042. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, Z.; Qi, Z.; Cai, D.; Cheng, Z.; Qi, H. CFD-based study of the abrasive flow characteristics within constrained flow passage in polishing of complex titanium alloy surfaces. Powder Technol. 2018, 333, 209–218. [Google Scholar] [CrossRef]

- Qi, H.; Fan, J.; Wang, J.; Li, H. Impact erosion by high velocity micro-particles on a quartz crystal. Tribol. Int. 2015, 82, 200–210. [Google Scholar] [CrossRef]

- Qi, H.; Fan, J.; Wang, J.; Li, H. On the erosion process on quartz crystals by the impact of multiple high-velocity micro-particles. Tribol. Int. 2016, 95, 462–474. [Google Scholar] [CrossRef]

- Qi, H.; Qin, S.; Cheng, Z.; Teng, Q.; Hong, T.; Xie, Y. Towards understanding performance enhancing mechanism of micro-holes on K9 glasses using ultrasonic vibration-assisted abrasive slurry jet. J. Manuf. Process. 2021, 64, 585–593. [Google Scholar] [CrossRef]

- Qi, H.; Cheng, Z.; Cai, D.; Yin, L.; Wang, Z.; Wen, D. Experimental study on the improvement of surface integrity of tungsten steel using acoustic levitation polishing. J. Mater. Process. Technol. 2018, 259, 361–367. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Wang, Z.; Ni, P.C.; Wang, D.J.; Guo, S.H.; Chen, Z.Z. Experimental and numerical study on regulation of cutting temperature during the circular sawing of 45 steel. Coatings 2023, 13. [Google Scholar]

- Chen, Z.; Wen, D.; Lu, J.; Yang, J.; Qi, H. Surface quality improvement by using a novel driving system design in single-side planetary abrasive lapping. Materials 2022, 14, 1691. [Google Scholar] [CrossRef]

- Wu, B.; Li, D.R.; Zhou, Y.; Zhu, D.; Zhao, Y.P.; Qiao, Z.K.; Chen, B.; Wang, X.L.; Lin, Q. Construction of a calibration field of absolute gravity in a cave using the Cold Atom Gravimeter. Sensors 2023, 23. [Google Scholar]

- Qi, H.; Qin, S.; Cheng, Z.; Zou, Y.; Cai, D.; Wen, D. DEM and experimental study on the ultrasonic vibration-assisted abrasive finishing of WC-8Co cemented carbide cutting edge. Powder Technol. 2021, 378, 716–723. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, H.; Chen, M.; Qi, Z.; Teng, Q.; Qi, H.; Zhang, L.; Shan, X. Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms. Crystals 2023, 13, 428. https://doi.org/10.3390/cryst13030428

Qian H, Chen M, Qi Z, Teng Q, Qi H, Zhang L, Shan X. Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms. Crystals. 2023; 13(3):428. https://doi.org/10.3390/cryst13030428

Chicago/Turabian StyleQian, Huina, Mengkai Chen, Zijian Qi, Qi Teng, Huan Qi, Li Zhang, and Xiaohang Shan. 2023. "Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms" Crystals 13, no. 3: 428. https://doi.org/10.3390/cryst13030428

APA StyleQian, H., Chen, M., Qi, Z., Teng, Q., Qi, H., Zhang, L., & Shan, X. (2023). Review on Research and Development of Abrasive Scratching of Hard Brittle Materials and Its Underlying Mechanisms. Crystals, 13(3), 428. https://doi.org/10.3390/cryst13030428