Study on Thermal Conductivity and Mechanical Properties of Cyclotriphosphazene Resin-Forced Epoxy Resin Composites

Abstract

1. Introduction

2. Simulation Techniques and Experimentation

- -

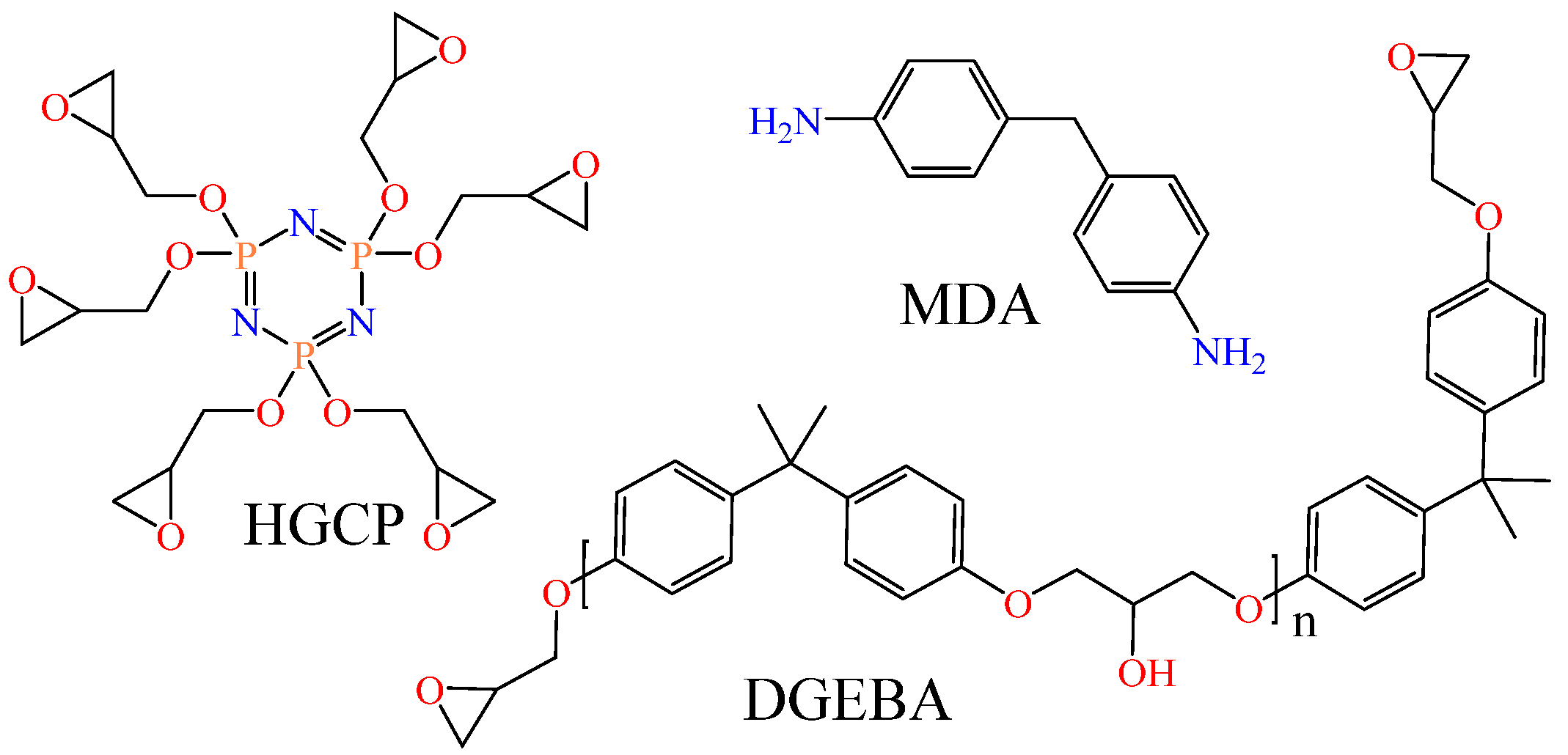

- The samples were prepared by mixing stoichiometric amounts of MDA and epoxy resins HGCP, DGEBA and their blend.

- -

- The samples thus prepared underwent the cycle of heating: one night at 70 °C, three hours at l00 °C, two hours at 120 °C, one hour at 140 °C and 30 min at 150 °C.

- M: Molar mass of the DGEBA (M = 340 g/mol).

- f: Functionality of the DGEBA (f = 2).

- M: Molar mass of the HGCP (M = 573 g/mol).

- f: Functionality of the HGCP (f = 6).

- M: Molar mass of the hardener used.

- f: Functionality of the hardener.

3. Results and Discussion

3.1. Analysis of Glass Transition Temperature

| Samples | Tg Values (K) | ||

|---|---|---|---|

| Theoretical Values | Experimental Values | Ref | |

| DGEBA@MDA | 389.30 | 368.00 | [24] |

| 431.55 | [12] | ||

| 425.00 | [40] | ||

| 429.15 | [41] | ||

| 428.15 | [42] | ||

| 405.85 | [43] | ||

| HGCP@MDA | 365.90 | 350.00 | [24] |

| DGEBA@HGCP@MDA | 310.50 | 366.00 | [24] |

3.2. Thermal Conductivity

Theory for Calculation Details of Thermal Conductivity

3.3. Technical Features

4. Conclusions

- -

- The Tg values of DGEBA@MDA and HGCP@MDA are 389.3 K and 365.9 K, respectively, which far exceeded those of DGEBA@HGCP@MDA (310.5 K), demonstrating a strong heat resistance of HGCP thermosets. The early breakdown of DGEBA was produced by the introduction of HGCP, and the Tg of DGEBA was somewhat lowered.

- -

- HGCP@MDA’s thermal conductivity improves by 162% (0.301005 W/m·K), whereas DGEBA@HGCP@MDA’s thermal conductivity increases by 116.04% (0.215284 W/m·K).

- -

- Young’s modulus for DGEBA@HGCP@MDA is 5.4902 GPa, which rose by 103% compared to HGCP@MDA (5.3074 Gpa) and by 114.28% versus pure DGEBA@MDA (4.804 Gpa). The DGEBA-based epoxy materials’ mechanical characteristics were improved when HGCP was included. By improving the compatibility of the cyclophosphazene with the organic matrix, the complexation of cyclophosphazene enabled enhanced dispersion. Shear modulus, Bulk modulus, Young’s modulus, and Poisson’s ratio all significantly improved when HGCP was included in the DGEBA resin.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DGEBA | Bisphenol A diglycidyl ether |

| MDA | 4,4′-Methylene dianiline |

| HGCP | Hexaglycidyl cyclotriphosphazene |

| COMPASS | Condensed-phase optimized molecular potentials for atomistic simulation |

| Studies | |

| MSD | Mean square displacement |

| PCFF | Polymer consistent force-field |

| BNNS | Boron nitride nanosheets |

| MD | Molecular dynamics |

| MTHPA | Methyl tetrahydrophthalic anhydride |

| SWCNT | Single-walled carbon nanotubes |

| CNB | Carbon nanobud |

| NPT | Constant-temperature, constant-pressure ensemble |

| NVT | Constant-temperature, constant-volume ensemble |

| EEW | Epoxy Equivalent Weight |

| AHEW | Amine hydrogen equivalent weights |

| M | Molar mass |

| f | Functionality |

| PHR | Parts per Hundered of Resin |

| Wt | Total Weight |

| EP | Epoxy resins |

References

- Zhao, W.; Zhao, W.; Huang, Z.; Liu, G.; Wu, B. Tribological performances of epoxy resin composite coatings using hexagonal boron nitride and cubic boron nitride nanoparticles as additives. Chem. Phys. Lett. 2019, 732, 136646. [Google Scholar] [CrossRef]

- Dagdag, O.; Berisha, A.; Safi, Z.; Hamed, O.; Jodeh, S.; Verma, C.; Ebenso, E.E.; El Harfi, A. DGEBA-polyaminoamide as effective anti-corrosive material for 15CDV6 steel in NaCl medium: Computational and experimental studies. J. Appl. Polym. Sci. 2020, 137, 48402. [Google Scholar] [CrossRef]

- Dagdag, O.; Berisha, A.; Safi, Z.; Dagdag, S.; Berrani, M.; Jodeh, S.; Verma, C.; Ebenso, E.E.; Wazzan, N.; El Harfi, A. Highly durable macromolecular epoxy resin as anticorrosive coating material for carbon steel in 3% NaCl: Computational supported experimental studies. J. Appl. Polym. Sci. 2020, 137, 49003. [Google Scholar] [CrossRef]

- Dagdag, O.; Hanbali, G.; Khalaf, B.; Jodeh, S.; El Harfi, A.; Deghles, A. Dual Component Polymeric Epoxy-Polyaminoamide Based Zinc Phosphate Anticorrosive Formulation for 15CDV6 Steel. Coatings 2019, 9, 463. [Google Scholar] [CrossRef]

- Cheng, J.; Li, J.; Zhang, J. Curing behavior and thermal properties of trifunctional epoxy resin cured by 4, 4′-diaminodiphenyl sulfone. Express Polym. Lett. 2009, 3, 501–509. [Google Scholar] [CrossRef]

- Dagdag, O.; Essamri, A.; El Gana, L.; El Bouchti, M.; Hamed, O.; Cherkaoui, O.; Jodeh, S.; El Harfi, A. Synthesis, characterization and rheological properties of epoxy monomers derived from bifunctional aromatic amines. Polym. Bull. 2019, 76, 4399–4413. [Google Scholar] [CrossRef]

- Gu, L.; Qiu, C.; Qiu, J.; Yao, Y.; Sakai, E.; Yang, L. Preparation and Characterization of DOPO-Functionalized MWCNT and Its High Flame-Retardant Performance in Epoxy Nanocomposites. Polymers 2020, 12, 613. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Cai, Z. Flame-Retardant Performance of Transparent and Tensile-Strength-Enhanced Epoxy Resins. Polymers 2020, 12, 317. [Google Scholar] [CrossRef]

- Dagdag, O.; El Harfi, A.; El Gana, L.; Hlimi, Z.; Erramli, H.; Hamed, O.; Jodeh, S. The role of zinc phosphate pigment in the anticorrosion properties of bisphenol A diglycidyl ether-polyaminoamide coating for aluminum alloy AA2024-T3. J. Bio-Tribo-Corros. 2019, 5, 7. [Google Scholar] [CrossRef]

- Dagdag, O.; El Gouri, M.; El Mansouri, A.; Outzourhit, A.; El Harfi, A.; Cherkaoui, O.; El Bachiri, A.; Hamed, O.; Jodeh, S.; Hanbali, G.; et al. Rheological and Electrical Study of a Composite Material Based on an Epoxy Polymer Containing Cyclotriphosphazene. Polymers 2020, 12, 921. [Google Scholar] [CrossRef]

- El Gouri, M.; El-Harfi, A. Modifications chimiques de l’hexachlorocyclotriphosphazène-Préparation de retardateurs de flame et de matériaux polymères ignifuges écologiques (Chemical modification of hexachlorocyclotriphosphazene-Preparation of flame retardants and ecological flame retardant polymers). J. Mater. Environ. Sci. 2012, 3, 17–33. [Google Scholar]

- Liang, W.J.; Zhao, B.; Zhang, C.Y.; Jian, R.K.; Liu, D.Y.; Liu, Y.Q. Enhanced flame retardancy of DGEBA epoxy resin with a novel bisphenol-A bridged cyclotriphosphazene. Polym. Degrad. Stab. 2017, 144, 292–303. [Google Scholar] [CrossRef]

- Yarovsky, I.; Evans, E. Computer simulation of structure and properties of crosslinked polymers: Application to epoxy resins. Polymer 2002, 43, 963–969. [Google Scholar] [CrossRef]

- Wu, C.; Xu, W. Atomistic molecular modelling of crosslinked epoxy resin. Polymer 2006, 47, 6004–6009. [Google Scholar] [CrossRef]

- Jeyranpour, F.; Alahyarizadeh, G.; Arab, B. Comparative investigation of thermal and mechanical properties of cross-linked epoxy polymers with different curing agents by molecular dynamics simulation. J. Mol. Graph. Model. 2015, 62, 157–164. [Google Scholar] [CrossRef]

- Fan, H.B.; Yuen, M.M. Material properties of the cross-linked epoxy resin compound predicted by molecular dynamics simulation. Polymer 2007, 48, 2174–2178. [Google Scholar] [CrossRef]

- Yang, S.; Qu, J. Computing thermomechanical properties of crosslinked epoxy by molecular dynamic simulations. Polymer 2012, 53, 4806–4817. [Google Scholar] [CrossRef]

- Li, C.; Browning, A.R.; Christensen, S.; Strachan, A. Atomistic simulations on multilayer graphene reinforced epoxy composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1293–1300. [Google Scholar] [CrossRef]

- Hadden, C.; Jensen, B.; Bandyopadhyay, A.; Odegard, G.; Koo, A.; Liang, R. Molecular modeling of EPON-862/graphite composites: Interfacial characteristics for multiple crosslink densities. Compos. Sci. Technol. 2013, 76, 92–99. [Google Scholar] [CrossRef]

- Zhang, W.; Li, H.; Gao, L.; Zhang, Q.; Zhong, W.; Sui, G.; Yang, X. Molecular simulation and experimental analysis on thermal and mechanical properties of carbon nanotube/epoxy resin composites with different curing agents at high-low temperature. Polym. Compos. 2018, 39, E945–E954. [Google Scholar] [CrossRef]

- Liu, Z.; Li, J.; Zhou, C.; Zhu, W. A molecular dynamics study on thermal and rheological properties of BNNS-epoxy nanocomposites. Int. J. Heat Mass Transf. 2018, 126, 353–362. [Google Scholar] [CrossRef]

- Yang, X.; Wan, Y.; Wang, X.; Fu, Y.; Huang, Z.; Xie, Q. Molecular dynamics studies of the mechanical behaviors and thermal conductivity of the DGEBA/MTHPA/CNB composites. Compos. Part B Eng. 2019, 164, 659–666. [Google Scholar] [CrossRef]

- El Gouri, M.; El Bachiri, A.; Hegazi, S.E.; Rafik, M.; El Harfi, A. Thermal degradation of a reactive flame retardant based on cyclotriphosphazene and its blend with DGEBA epoxy resin. Polym. Degrad. Stab. 2009, 94, 2101–2106. [Google Scholar] [CrossRef]

- Dagdag, O.; El Gouri, M.; Safi, Z.S.; Wazzan, N.; Safi, S.K.; Jodeh, S.; Hamed, O.; Haldhar, R.; Verma, C.; Ebenso, E.E. Flame retardancy of an intumescent epoxy resin containing cyclotriphosphazene: Experimental, computational and statistical studies. Iran. Polym. J. 2021, 30, 1169–1179. [Google Scholar] [CrossRef]

- Dagdag, O.; Bachiri, A.E.; Hamed, O.; Haldhar, R.; Verma, C.; Ebenso, E.; Gouri, M.E. Dendrimeric epoxy resins based on hexachlorocyclotriphosphazene as a reactive flame retardant polymeric materials: A review. J. Inorg. Organomet. Polym. Mater. 2021, 31, 3240–3261. [Google Scholar] [CrossRef]

- El Gouri, M.; El Bachiri, A.; Hegazi, S.E.; Ziraoui, R.; Rafik, M.; El Harfi, A. A phosphazene compound multipurpose application-Composite material precursor and reactive flame retardant for epoxy resin materials. J. Mater. Environ. Sci. 2011, 2, 319–334. [Google Scholar]

- Levan, Q. Thèse de Docteur-Ingénieur; INP: Toulouse, France, 1981. [Google Scholar]

- Dagdag, O.; Hsissou, R.; Berisha, A.; Erramli, H.; Hamed, O.; Jodeh, S.; El Harfi, A. Polymeric-based epoxy cured with a polyaminoamide as an anticorrosive coating for aluminum 2024-T3 surface: Experimental studies supported by computational modeling. J. Bio-Tribo-Corros. 2019, 5, 58. [Google Scholar] [CrossRef]

- Dagdag, O.; Hamed, O.; Erramli, H.; El Harfi, A. Anticorrosive performance approach combining an epoxy polyaminoamide–zinc phosphate coatings applied on sulfo-tartaric anodized aluminum alloy 5086. J. Bio-Tribo-Corros. 2018, 4, 52. [Google Scholar] [CrossRef]

- Dagdag, O.; El Bouchti, M.; Cherkaoui, O.; Hamed, O.; El Gouri, M.; Dagdag, S.; El Harfi, A. A study on thermal and rheological cure characterization of a sulfur-containing epoxy resin. J. Chem. Technol. Metall. 2019, 54, 881–888. [Google Scholar]

- Tang, Y.; Tang, C.; Hu, D.; Gui, Y. Effect of aminosilane coupling agents with different chain lengths on thermo-mechanical properties of cross-linked epoxy resin. Nanomaterials 2018, 8, 951. [Google Scholar] [CrossRef] [PubMed]

- Hsissou, R.; Dagdag, O.; Abbout, S.; Benhiba, F.; Berradi, M.; El Bouchti, M.; Berisha, A.; Hajjaji, N.; Elharfi, A. Novel derivative epoxy resin TGETET as a corrosion inhibition of E24 carbon steel in 1.0 M HCl solution. Experimental and computational (DFT and MD simulations) methods. J. Mol. Liq. 2019, 284, 182–192. [Google Scholar] [CrossRef]

- Dagdag, O.; Hsissou, R.; El Harfi, A.; Berisha, A.; Safi, Z.; Verma, C.; Ebenso, E.; Touhami, M.E.; El Gouri, M. Fabrication of polymer based epoxy resin as effective anti-corrosive coating for steel: Computational modeling reinforced experimental studies. Surf. Interfaces 2020, 18, 100454. [Google Scholar] [CrossRef]

- Sharma, S.; Kumar, P.; Chandra, R.; Singh, S.P.; Mandal, A.; Dondapati, R.S. Overview of BIOVIA Materials Studio, LAMMPS, and GROMACS; Molecular Dynamics Simulation of Nanocomposites Using BIOVIA Materials Studio, LAMMPS and GROMACS; Elsevier: Amsterdam, The Netherlands, 2019; pp. 39–100. [Google Scholar]

- El Gouri, M.; El Mansouri, A.; El Gouri, R.; Hadik, N.; Cherkaoui, O.; Outzourhit, A.; El Harfi, A. Physical behaviour of epoxy resin material flame retarded with a reactive flame retardant based on cyclophosphazene. J. Mater. Environ. Sci. 2014, 5, 400–407. [Google Scholar]

- Fan, J.; Anastassiou, A.; Macosko, C.W.; Tadmor, E.B. Molecular dynamics predictions of thermomechanical properties of an epoxy thermosetting polymer. Polymer 2020, 196, 122477. [Google Scholar] [CrossRef]

- Pan, M.; Zhang, C.; Zhai, X.; Qu, L.; Mu, J. Effect of hexaphenoxycyclotriphosphazene combined with octapropylglycidylether polyhedral oligomeric silsesquioxane on thermal stability and flame retardancy of epoxy resin. High Perform. Polym. 2014, 26, 744–752. [Google Scholar] [CrossRef]

- Zang, L.; Wagner, S.; Ciesielski, M.; Mueller, P.; Döring, M. Novel star-shaped and hyperbranched phosphorus-containing flame retardants in epoxy resins. Polym. Adv. Technol. 2011, 22, 1182–1191. [Google Scholar] [CrossRef]

- Ciesielski, M.; Schäfer, A.; Döring, M. Novel efficient DOPO-based flame-retardants for PWB relevant epoxy resins with high glass transition temperatures. Polym. Adv. Technol. 2008, 19, 507–515. [Google Scholar] [CrossRef]

- Nabipour, H.; Wang, X.; Rahman, M.Z.; Song, L.; Hu, Y. Improvement of the flame retardant and thermomechanical properties of epoxy resins by a vanillin-derived cyclotriphosphazene-cored triazole compound. Polym. Degrad. Stab. 2022, 204, 110088. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, G.; Yang, S.; Yang, L.; Cao, J.; Yang, K. The synthesis, curing kinetics, thermal properties and flame rertardancy of cyclotriphosphazene-containing multifunctional epoxy resin. Thermochim. Acta 2019, 680, 178348. [Google Scholar] [CrossRef]

- Xu, G.-R.; Xu, M.-J.; Li, B. Synthesis and characterization of a novel epoxy resin based on cyclotriphosphazene and its thermal degradation and flammability performance. Polym. Degrad. Stab. 2014, 109, 240–248. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X. Synthesis, characterization, thermal properties and flame retardancy of a novel nonflammable phosphazene-based epoxy resin. Polym. Degrad. Stab. 2009, 94, 617–624. [Google Scholar] [CrossRef]

- Su, C.-H.; Chen, H.-L.; Ju, S.-P.; Liao, B.-Y.; Pan, C.-T. Thermal conductivity and stability for ultrathin SiO2 nanowires: Insight from molecular dynamics simulation. Mater. Res. Express 2019, 6, 105073. [Google Scholar] [CrossRef]

- Huang, Z.; Huang, C.; Wu, D.; Rao, Z. Influence of chemical bonding on thermal contact resistance at silica interface: A molecular dynamics simulation. Comput. Mater. Sci. 2018, 149, 316–323. [Google Scholar] [CrossRef]

- Jin, W.; Yuan, L.; Liang, G.; Gu, A. Multifunctional cyclotriphosphazene/hexagonal boron nitride hybrids and their flame retarding bismaleimide resins with high thermal conductivity and thermal stability. ACS Appl. Mater. Interfaces 2014, 6, 14931–14944. [Google Scholar] [CrossRef] [PubMed]

- Allcock, H.R.; Taylor, J.P. Phosphorylation of phosphazenes and its effects on thermal properties and fire retardant behavior. Polym. Eng. Sci. 2000, 40, 1177–1189. [Google Scholar] [CrossRef]

- Dieck, E.J.; Quinn, R.L. Low Smoke Polyphosphazene Compositions. U.S. Patent No 4,083,820, 11 April 1978. [Google Scholar]

- Zhu, M.; Li, J.; Chen, J.; Song, H.; Zhang, H. Improving thermal conductivity of epoxy resin by filling boron nitride nanomaterials: A molecular dynamics investigation. Comput. Mater. Sci. 2019, 164, 108–115. [Google Scholar] [CrossRef]

- Aghadavoudi, F.; Golestanian, H.; Tadi Beni, Y. Investigating the effects of resin crosslinking ratio on mechanical properties of epoxy-based nanocomposites using molecular dynamics. Polym. Compos. 2017, 38, E433–E442. [Google Scholar] [CrossRef]

| Samples | % DGEBA per 100 g of Blend | % HGCP per 100 g of Blend | Parts of MDA to Thermoset 100 g of (DGEBA/HGCP) Blend (g) |

|---|---|---|---|

| 1 | 100 | 0 | 29.15 |

| 2 | 0 | 100 | 51.89 |

| 3 | 95 | 5 | 29.73 |

| 4 | 90 | 10 | 31.22 |

| 5 | 85 | 15 | 31.56 |

| 6 | 80 | 20 | 33.70 |

| Parameter | DGEBA@MDA | HGCP@MDA | DGEBA@HGCP@MDA | |||

|---|---|---|---|---|---|---|

| Ensemble | NPT | NVT | NPT | NVT | NPT | NVT |

| Temperature | 298.00 K | |||||

| Control method | Nose | Nose | Nose | Nose | Random | Nose |

| Q ratio | 0.01 | |||||

| Pressure | 0.10 GPa | |||||

| Control method | Berendsen | |||||

| Decay constant | 0.10 ps | |||||

| Time step | 1.00 fs | |||||

| Number of steps | 200,000 | 500,000 | 200,000 | 500,000 | 200,000 | 500,000 |

| Duration | 200 ps | 500 ps | 200 ps | 500 ps | 200 ps | 500 ps |

| Initial velocities | Random | |||||

| Setting | Values | ||

|---|---|---|---|

| DGEBA@MDA | HGCP@MDA | DGEBA@HGCP@MDA | |

| Thermal conductivity (W/m·K) | 0.185524 | 0.301005 | 0.215284 |

| Energy Flux (GW/m2) | 21.92603 | 18.75423 | 13.34884 |

| Temperature gradient (GK/m) | 118.1842 | 62.30541 | 62.00563 |

| Mechanical Properties | DGEBA@MDA | HGCP@MDA | DGEBA@HGCP@MDA |

|---|---|---|---|

| Young’s modulus (GPa) | 4.804 ± 0.005 | 5.3074 ± 0.005 | 5.4902 ± 0.005 |

| Bulk modulus (GPa) | 3.6645 ± 0.005 | 4.4894 ± 0.005 | 6.0021 ± 0.005 |

| Shear modulus (GPa) | 1.8745 ± 0.005 | 2.0367 ± 0.005 | 2.0371 ± 0.005 |

| Poisson’s ratio (GPa) | 0.2815 ± 0.005 | 0.3030 ± 0.005 | 0.3475 ± 0.005 |

| Compressibility (1/TPa) | 243.9626 ± 0.005 | 210.1934 ± 0.005 | 172.0031 ± 0.005 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dagdag, O.; El Gana, L.; Haldhar, R.; Berisha, A.; Kim, S.-C.; Berdimurodov, E.; Hamed, O.; Jodeh, S.; Akpan, E.D.; Ebenso, E.E. Study on Thermal Conductivity and Mechanical Properties of Cyclotriphosphazene Resin-Forced Epoxy Resin Composites. Crystals 2023, 13, 478. https://doi.org/10.3390/cryst13030478

Dagdag O, El Gana L, Haldhar R, Berisha A, Kim S-C, Berdimurodov E, Hamed O, Jodeh S, Akpan ED, Ebenso EE. Study on Thermal Conductivity and Mechanical Properties of Cyclotriphosphazene Resin-Forced Epoxy Resin Composites. Crystals. 2023; 13(3):478. https://doi.org/10.3390/cryst13030478

Chicago/Turabian StyleDagdag, Omar, Lahoucine El Gana, Rajesh Haldhar, Avni Berisha, Seong-Cheol Kim, Elyor Berdimurodov, Othman Hamed, Shehdeh Jodeh, Ekemini Daniel Akpan, and Eno Effiong Ebenso. 2023. "Study on Thermal Conductivity and Mechanical Properties of Cyclotriphosphazene Resin-Forced Epoxy Resin Composites" Crystals 13, no. 3: 478. https://doi.org/10.3390/cryst13030478

APA StyleDagdag, O., El Gana, L., Haldhar, R., Berisha, A., Kim, S.-C., Berdimurodov, E., Hamed, O., Jodeh, S., Akpan, E. D., & Ebenso, E. E. (2023). Study on Thermal Conductivity and Mechanical Properties of Cyclotriphosphazene Resin-Forced Epoxy Resin Composites. Crystals, 13(3), 478. https://doi.org/10.3390/cryst13030478