Hydrogen Embrittlement Failure Behavior of Fatigue-Damaged Welded TC4 Alloy Joints

Abstract

:1. Introduction

2. Material and Methods

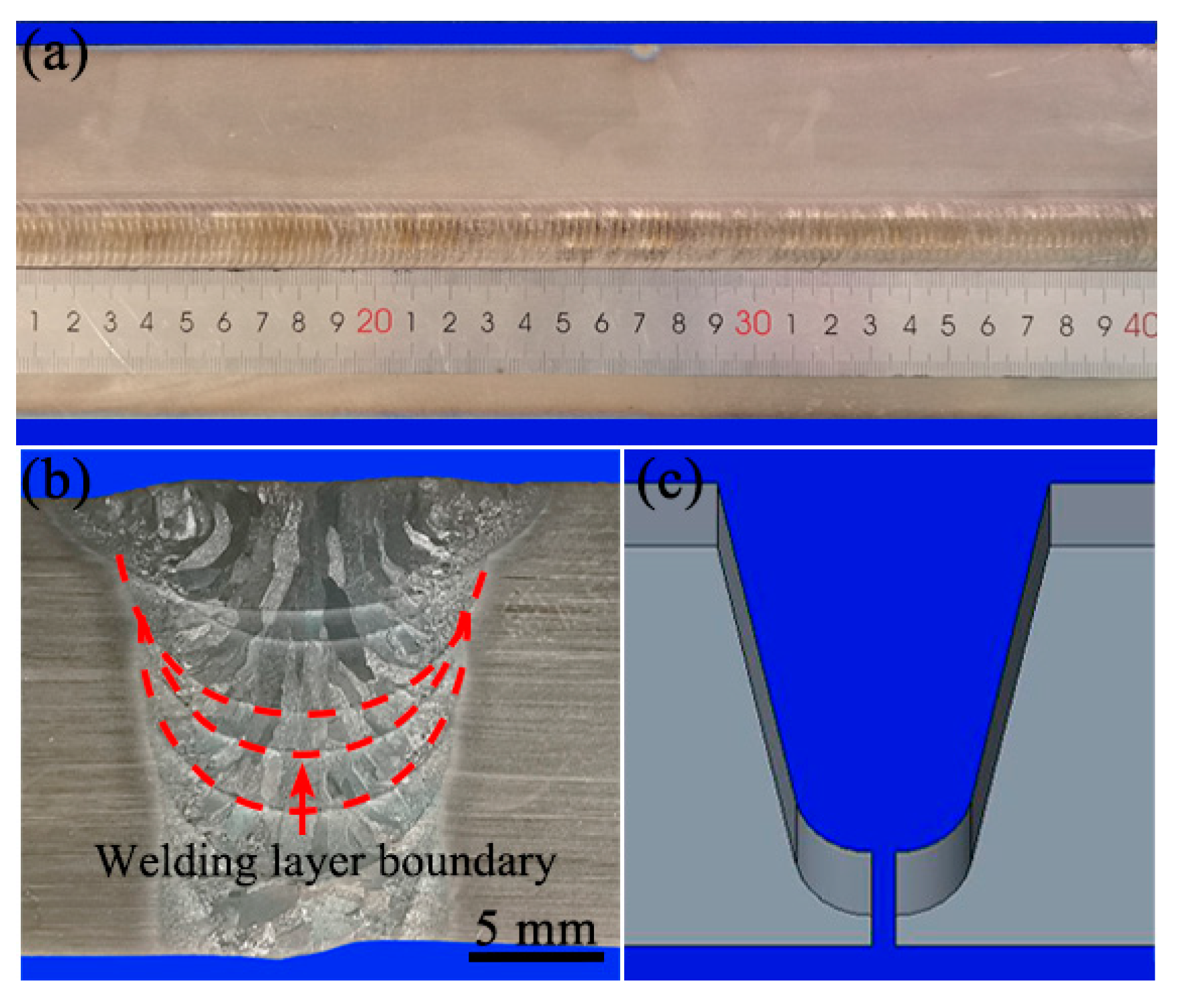

2.1. Test Material and Welded Joint Preparation

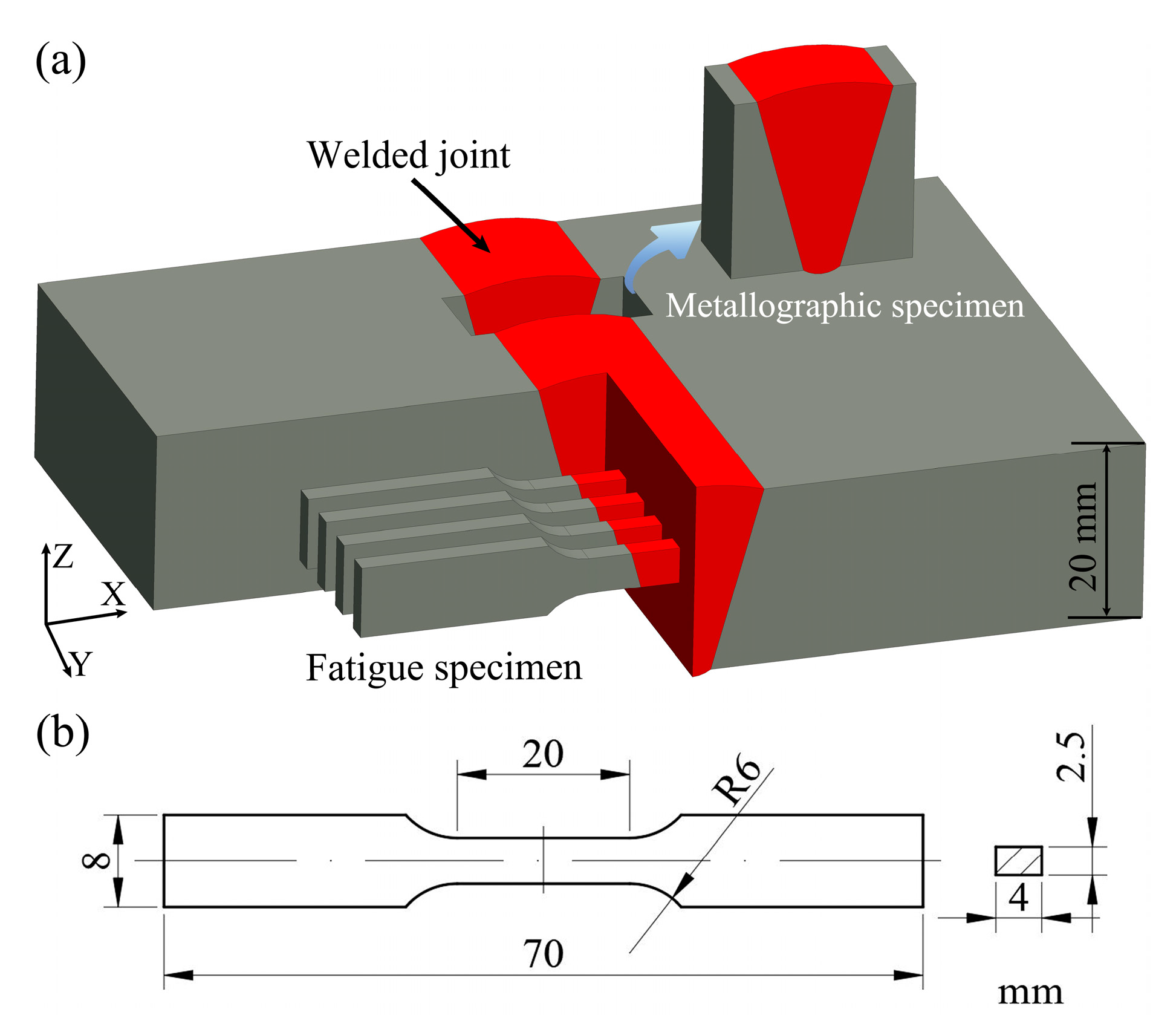

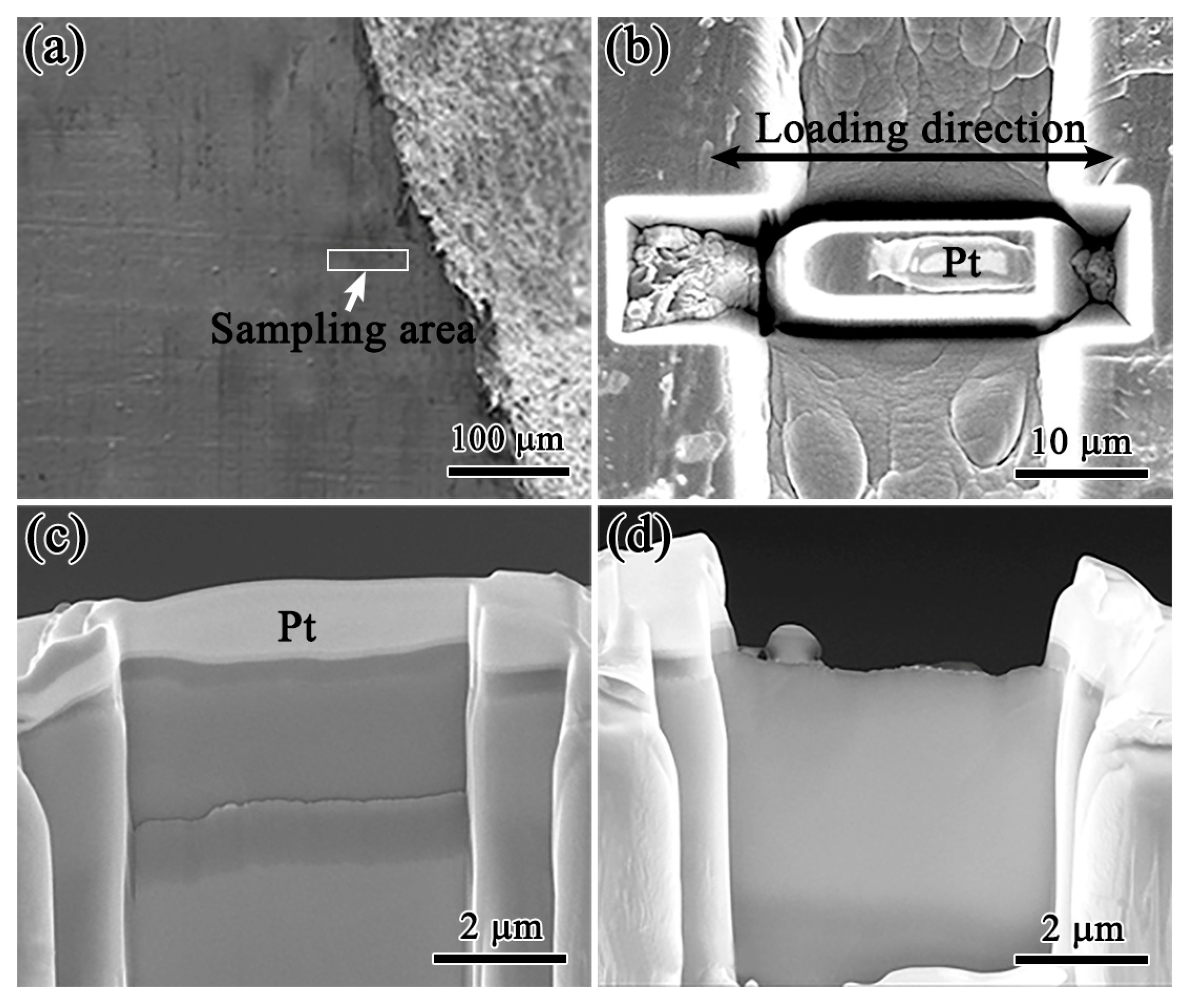

2.2. Sample Design and Preparation

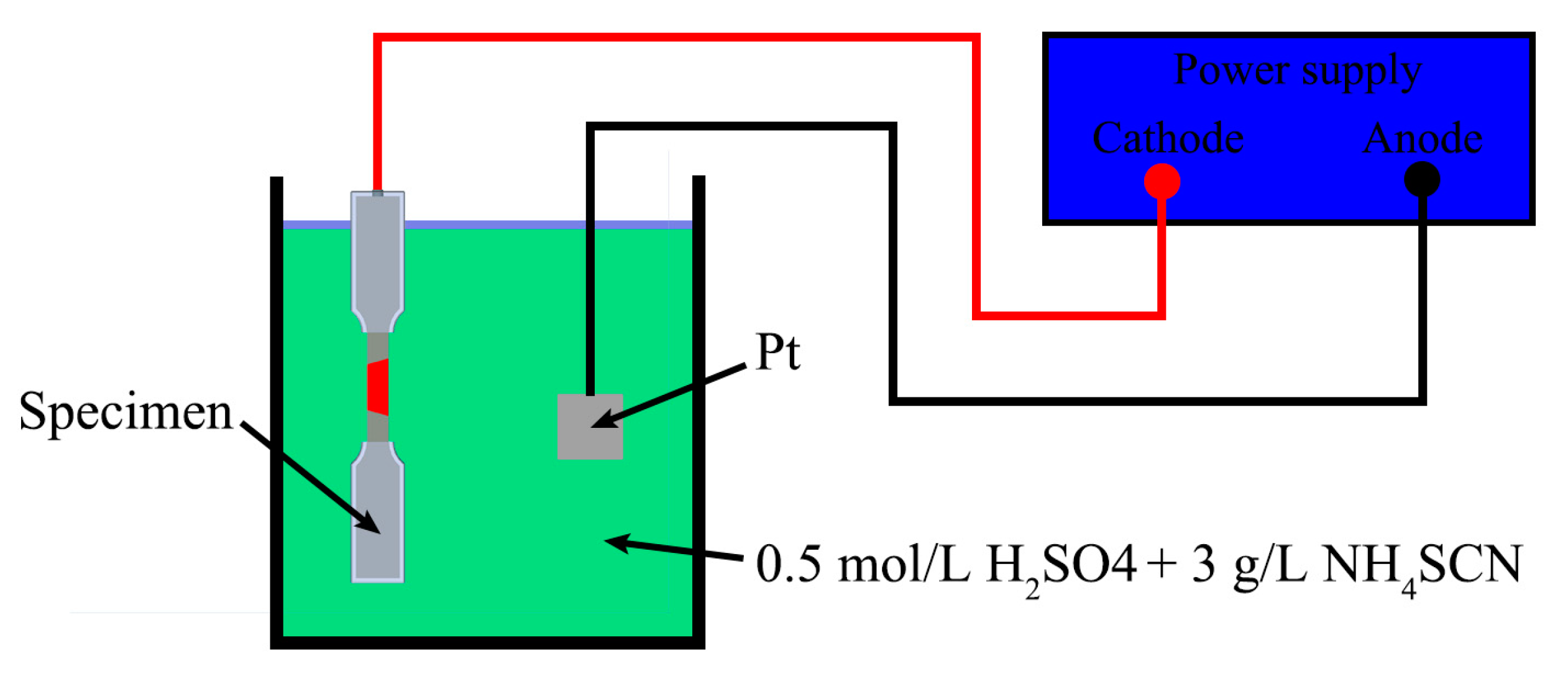

2.3. Cathodic Hydrogen Charging and Tensile Tests

2.4. Microstructural Characterization and Fracture Surface Analysis

3. Results

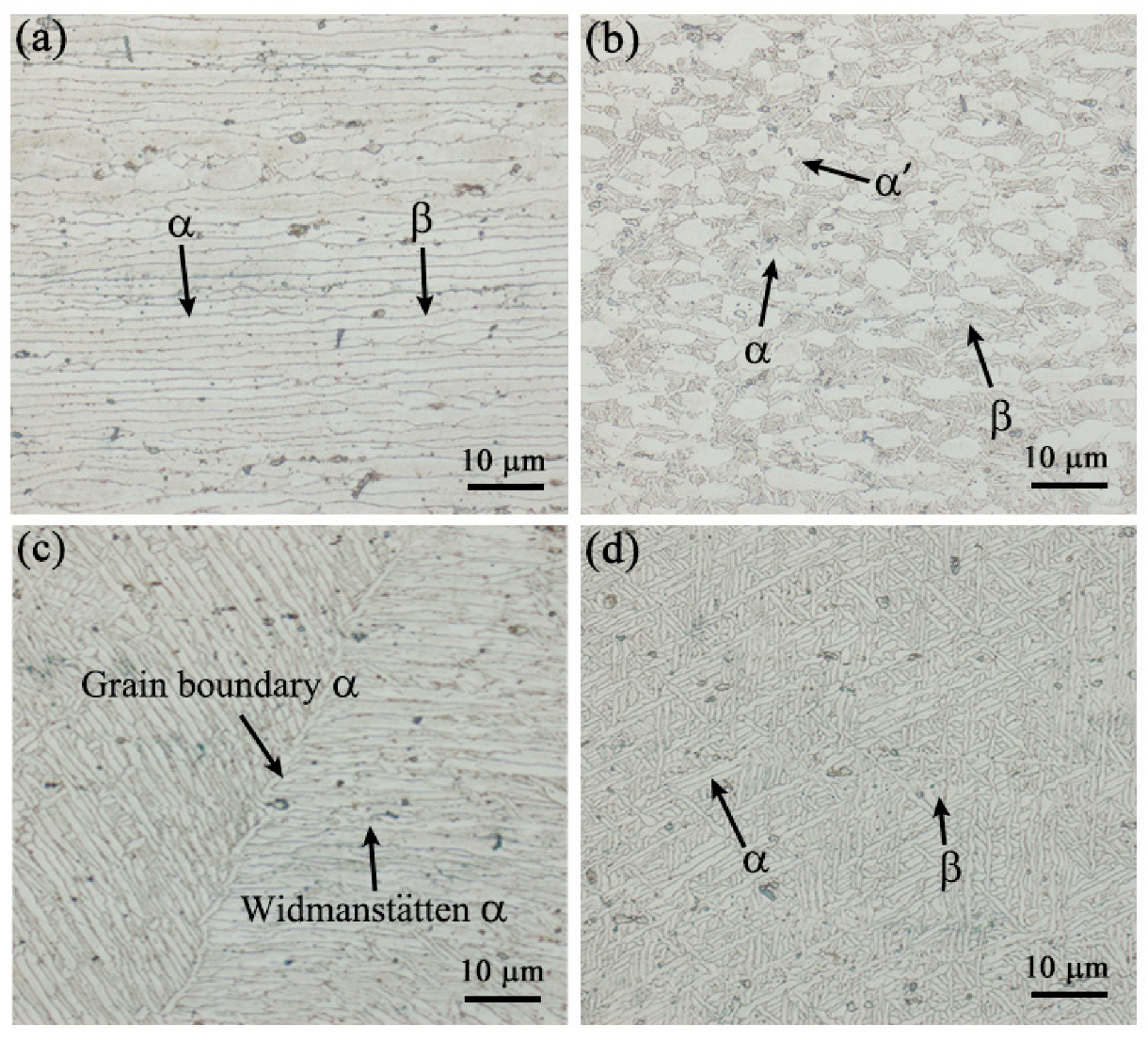

3.1. Microstructural Analysis

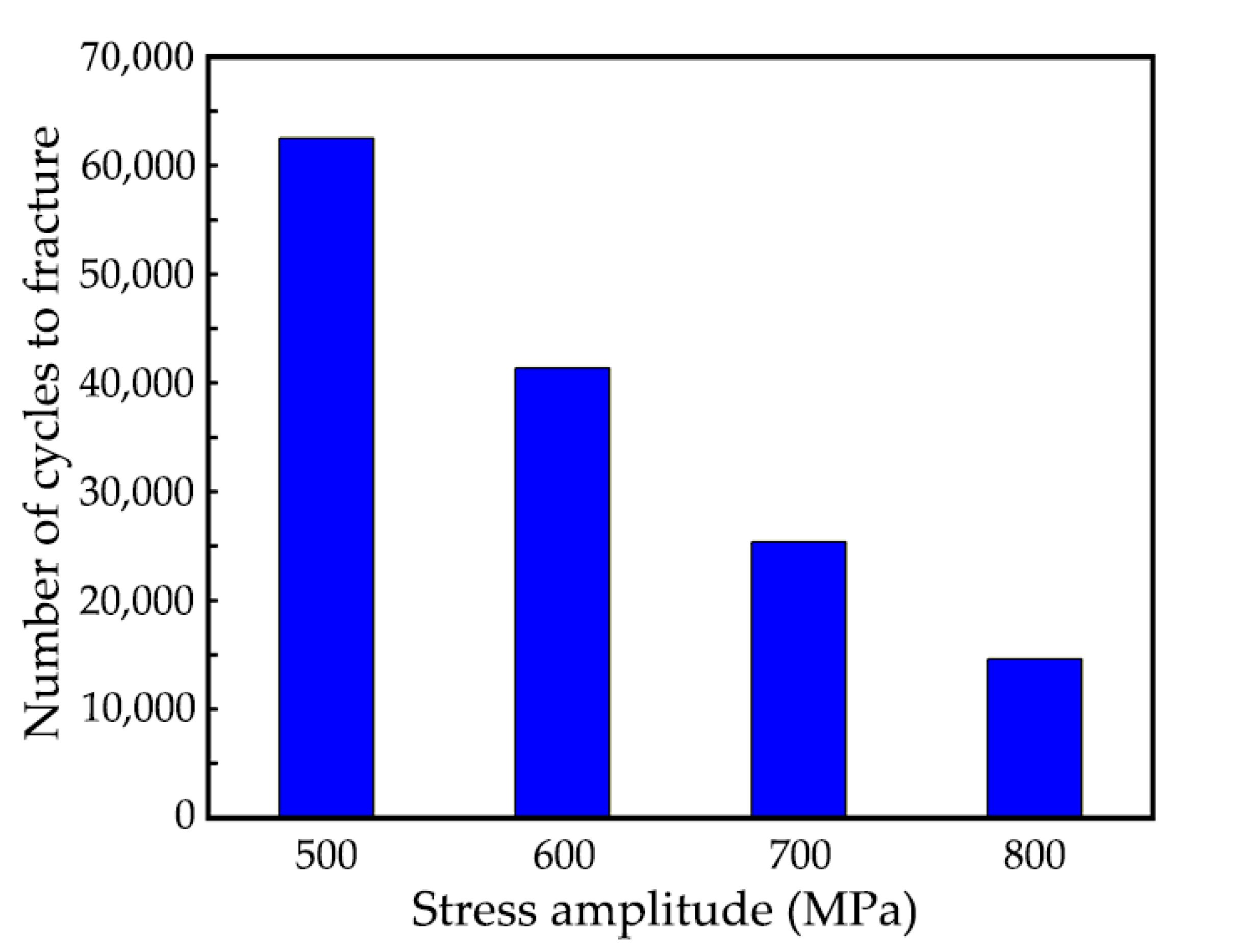

3.2. Mechanical Properties

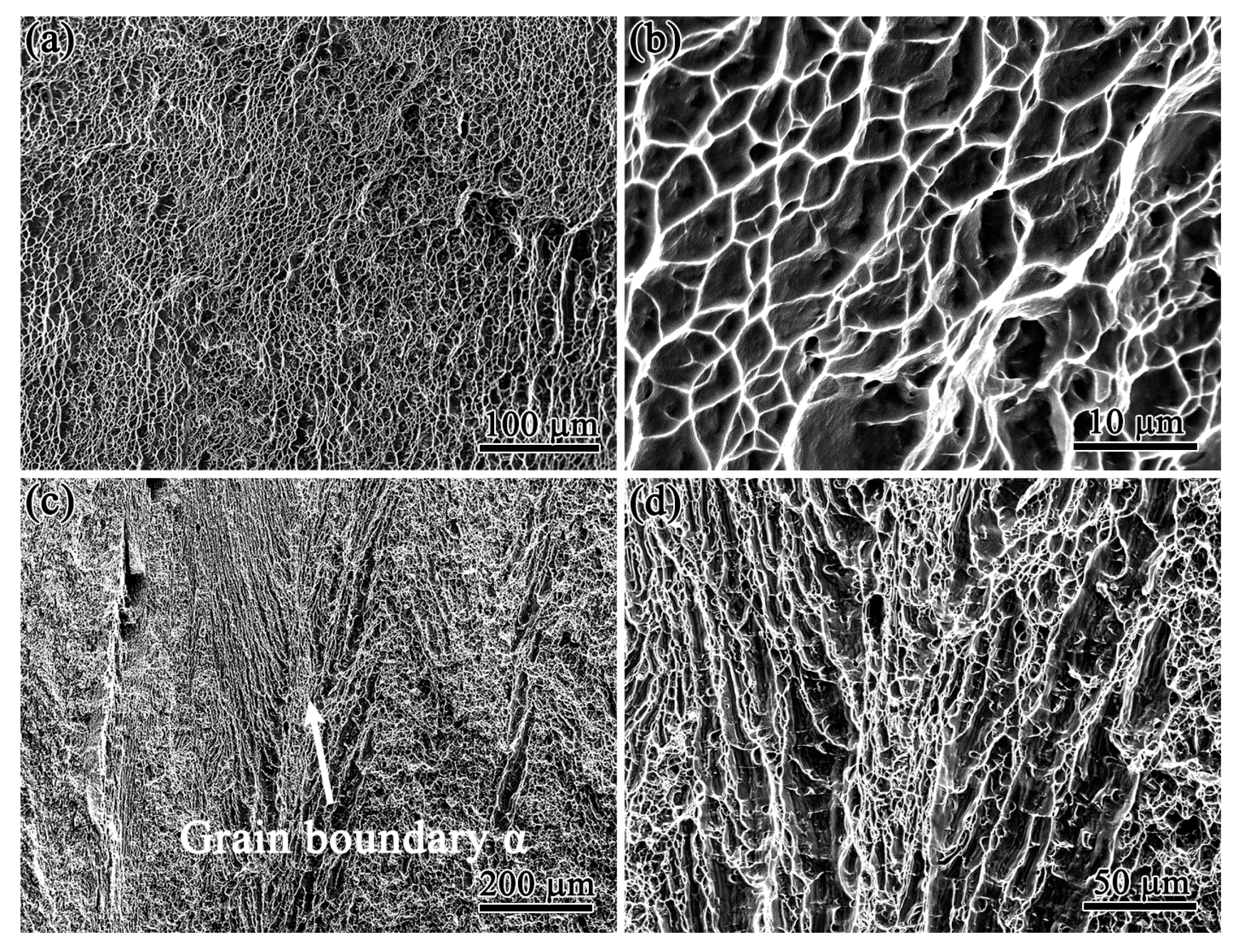

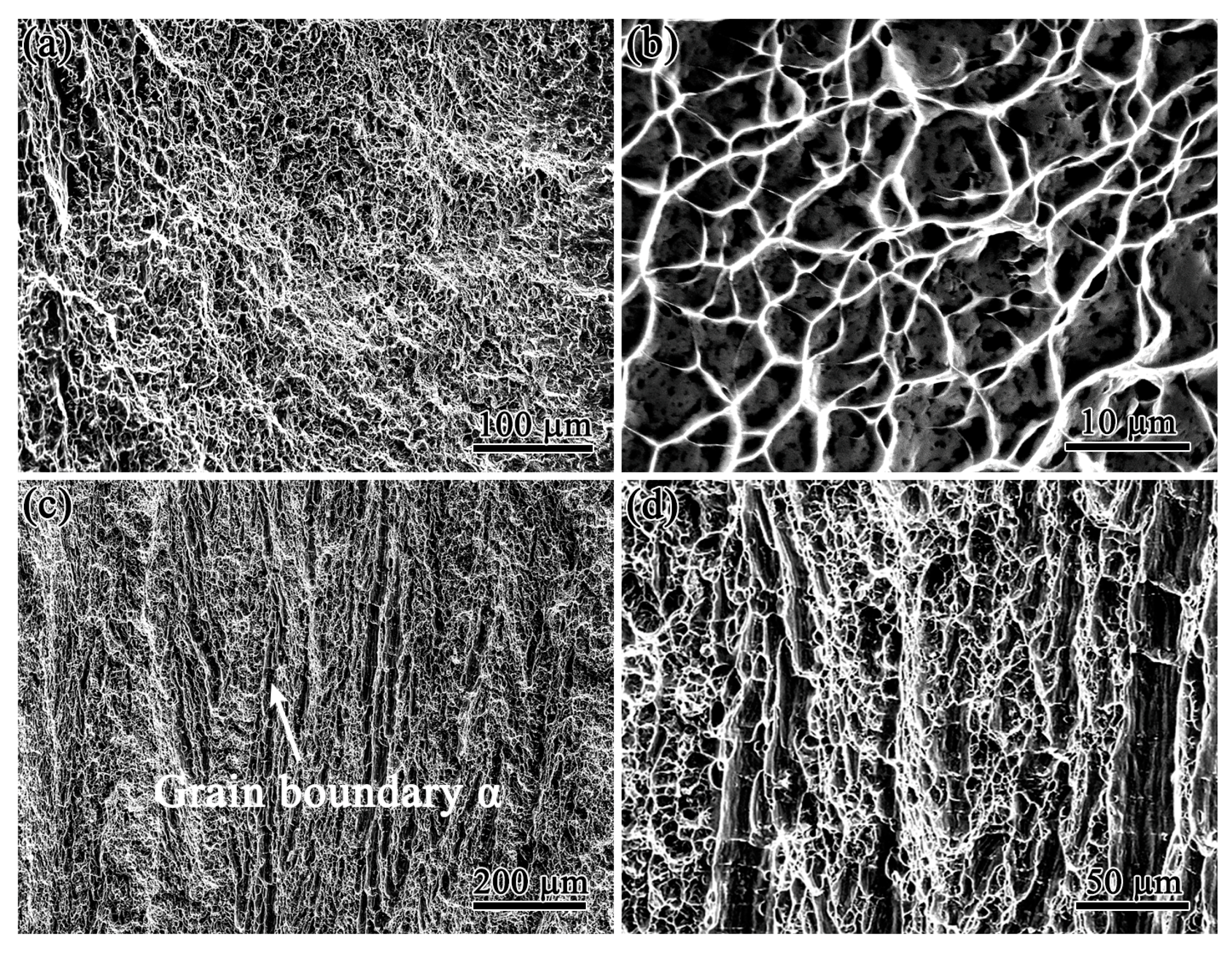

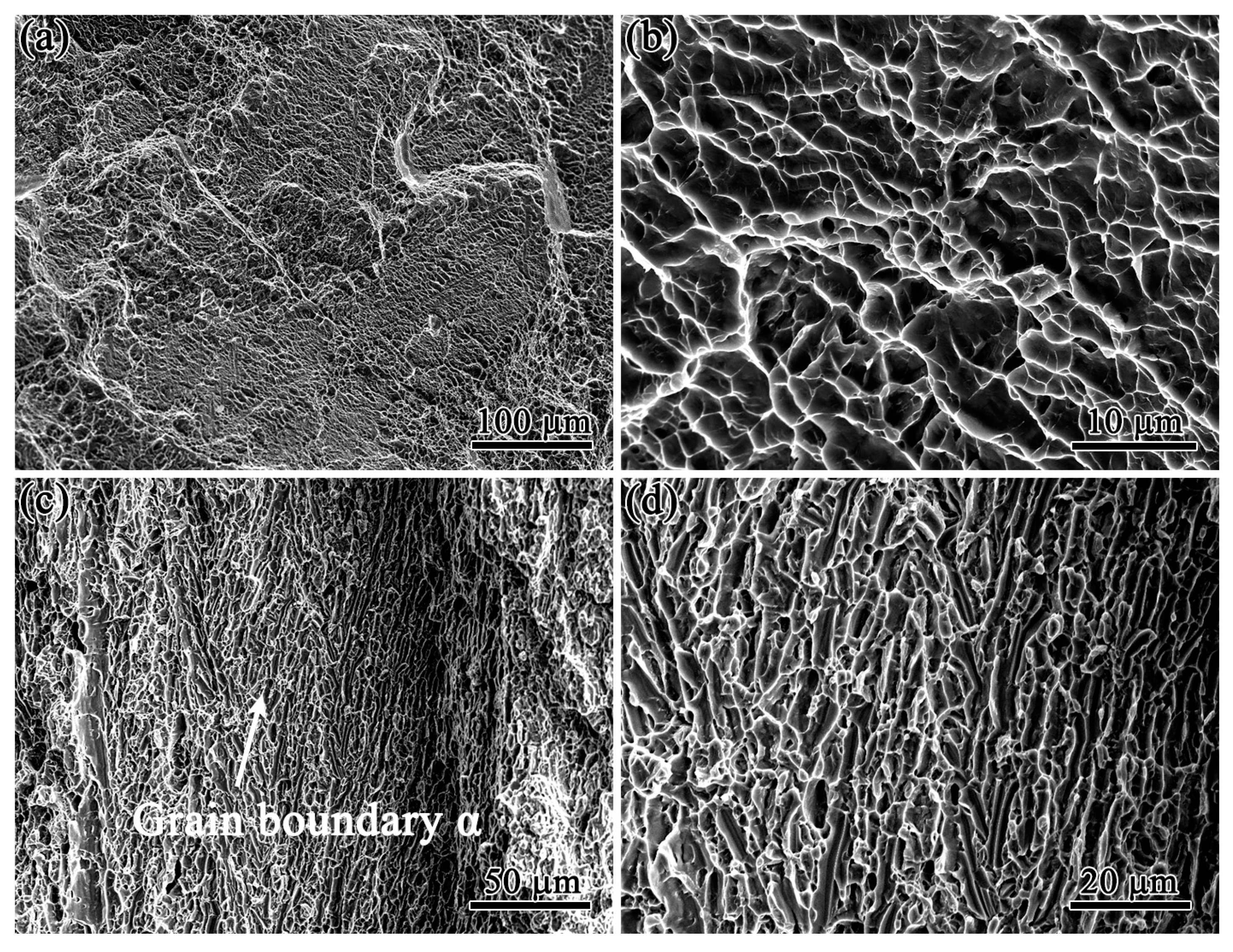

3.3. Fracture Analysis

3.4. Microstructures

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Banerjee, D.; Williams, J.C. Perspectives on titanium science and technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- Wang, X.-Q.; Zhang, Y.-S.; Han, W.-Z. Design of high strength and wear-resistance β-Ti alloy via oxygen-charging. Acta Mater. 2022, 227, 117686. [Google Scholar] [CrossRef]

- Hoar, E.; Sahoo, S.; Mahdavi, M.; Liang, S.; Roy, S.; Garmestani, H. Statistical modeling of microstructure evolution in a Ti-6Al-4V alloy during isothermal compression. Acta Mater. 2021, 210, 116827. [Google Scholar] [CrossRef]

- Hardie, D.; Charles, E.A.; Lopez, A.H. Hydrogen embrittlement of high strength pipeline steels. Corros. Sci. 2006, 48, 4378–4385. [Google Scholar] [CrossRef]

- Bouledroua, O.; Hafsi, Z.; Djukic, M.B.; Elaoud, S. The synergistic effects of hydrogen embrittlement and transient gas flow conditions on integrity assessment of a precracked steel pipeline. Int. J. Hydrogen Energy 2020, 45, 18010–18020. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B.; Ngo, T.D. Influence of hydrogen-enhanced plasticity and decohesion mechanisms of hydrogen embrittlement on the fracture resistance of steel. Eng. Fail. Anal. 2021, 123, 105312. [Google Scholar] [CrossRef]

- Nagao, A.; Smith, C.D.; Dadfarnia, M.; Sofronis, P.; Robertson, I.M. The role of hydrogen in hydrogen embrittlement fracture of lath martensitic steel. Acta Mater. 2012, 60, 5182–5189. [Google Scholar] [CrossRef]

- Kholtobina, A.S.; Ecker, W.; Pippan, R.; Razumovskiy, V.I. Effect of Alloying Elements on Hydrogen enhanced decohesion in bcc iron. Comput. Mater. Sci. 2021, 188, 110215. [Google Scholar] [CrossRef]

- Nagumo, M.; Takai, K. The Predominant role of strain-induced vacancies in hydrogen embrittlement of steels: Overview. Acta Mater. 2019, 165, 722–733. [Google Scholar] [CrossRef]

- Takai, K.; Shoda, H.; Suzuki, H.; Nagumo, M. Lattice defects dominating hydrogen-related failure of metals. Acta Mater. 2008, 56, 5158–5167. [Google Scholar] [CrossRef]

- Liang, S.; Huang, M.; Zhao, L.; Zhu, Y.; Li, Z. Effect of multiple hydrogen embrittlement mechanisms on crack propagation behavior of FCC metals: Competition vs. Synergy. Int. J. Plast. 2021, 143, 103023. [Google Scholar] [CrossRef]

- Li, G.; Chandra, S.; Rahman Rashid, R.A.; Palanisamy, S.; Ding, S. Machinability of additively manufactured titanium alloys: A Comprehensive Review. J. Manuf. Process. 2022, 75, 72–99. [Google Scholar] [CrossRef]

- Echlin, M.P.; Stinville, J.C.; Miller, V.M.; Lenthe, W.C.; Pollock, T.M. Incipient slip and long range plastic strain localization in microtextured Ti-6Al-4V titanium. Acta Mater. 2016, 114, 164–175. [Google Scholar] [CrossRef] [Green Version]

- Alabort, E.; Kontis, P.; Barba, D.; Dragnevski, K.; Reed, R.C. On the mechanisms of superplasticity in Ti–6Al–4V. Acta Mater. 2016, 105, 449–463. [Google Scholar] [CrossRef] [Green Version]

- Panwisawas, C.; Perumal, B.; Ward, R.M.; Turner, N.; Turner, R.P.; Brooks, J.W.; Basoalto, H.C. Keyhole formation and thermal fluid flow-induced porosity during laser fusion welding in titanium alloys: Experimental and modelling. Acta Mater. 2017, 126, 251–263. [Google Scholar] [CrossRef] [Green Version]

- Świerczyńska, A.; Fydrych, D.; Landowski, M.; Rogalski, G.; Łabanowski, J. Hydrogen embrittlement of X2CrNiMoCuN25-6-3 super duplex stainless steel welded joints under cathodic protection. Constr. Build. Mater. 2020, 238, 117697. [Google Scholar] [CrossRef]

- Świerczyńska, A.; Łabanowski, J.; Michalska, J.; Fydrych, D. Corrosion behavior of hydrogen charged super duplex stainless steel welded joints. Mater. Corros. 2017, 68, 1037–1045. [Google Scholar] [CrossRef]

- Balyts’kyi, O.I.; Kostyuk, I.F. Strength of Welded Joints of Cr–Mn Steels with Elevated Content of Nitrogen in Hydrogen-Containing Media. Mater. Sci. 2009, 45, 97–107. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, S.; Lecomte, J.-S.; Schuman, C.; Peltier, L.; Shen, X.; Song, W. Crystallographic orientation dependence of hydride precipitation in commercial pure titanium. Acta Mater. 2020, 183, 329–339. [Google Scholar] [CrossRef]

- Sinha, V.; Schwarz, R.B.; Mills, M.J.; Williams, J.C. Influence of hydrogen on dwell-fatigue response of near-alpha titanium alloys. Acta Mater. 2020, 188, 315–327. [Google Scholar] [CrossRef]

- Ren, D.; Jiang, Y.; Hu, X.; Zhang, X.; Xiang, X.; Huang, K.; Ling, H. Investigation of tensile and high cycle fatigue failure behavior on a TIG welded titanium alloy. Intermetallics 2021, 132, 107115. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, Z.; Du, C.; Sun, M.; Li, X. Effects of cathodic polarization on corrosion fatigue life of E690 steel in simulated seawater. Int. J. Fatigue 2018, 110, 105–114. [Google Scholar] [CrossRef]

- Zhao, T.; Liu, Z.; Du, C.; Dai, C.; Li, X.; Zhang, B. Corrosion fatigue crack initiation and initial propagation mechanism of E690 steel in simulated seawater. Mater. Sci. Eng. A 2017, 708, 181–192. [Google Scholar] [CrossRef]

- Alvaro, A.; Olden, V.; Akselsen, O.M. 3D Cohesive modelling of hydrogen embrittlement in the heat affected zone of an X70 pipeline steel. Int. J. Hydrogen Energy 2013, 38, 7539–7549. [Google Scholar] [CrossRef]

- Gaddam, R.; Pederson, R.; Hörnqvist, M.; Antti, M.-L. Influence of hydrogen environment on fatigue crack growth in forged Ti-6Al-4V: Fractographic analysis. IOP Conf. Ser. Mater. Sci. Eng. 2013, 48, 012010. [Google Scholar] [CrossRef] [Green Version]

- Murakami, Y.; Matsunaga, H. The effect of hydrogen on fatigue properties of steels used for fuel cell system. Int. J. Fatigue 2006, 28, 1509–1520. [Google Scholar] [CrossRef]

- Tao, J.; Hu, S.; Ji, L. Effect of trace solute hydrogen on the fatigue life of electron beam welded Ti-6Al-4V alloy joints. Mater. Sci. Eng. A 2017, 684, 542–551. [Google Scholar] [CrossRef]

- Flis, J.; Ashok, S.; Stoloff, N.S.; Duquette, D.J. Hydrogen embrittlement of amorphous alloys based on iron and nickel. Acta Metall. 1987, 35, 2071–2079. [Google Scholar] [CrossRef]

- Zhao, Y.; Seok, M.-Y.; Choi, I.-C.; Lee, Y.-H.; Park, S.-J.; Ramamurty, U.; Suh, J.-Y.; Jang, J. The role of hydrogen in hardening/softening steel: Influence of the charging process. Scr. Mater. 2015, 107, 46–49. [Google Scholar] [CrossRef]

- Miresmaeili, R.; Liu, L.; Kanayama, H. A Possible Explanation for the contradictory results of hydrogen effects on macroscopic deformation. Int. J. Press. Vessel. Pip. 2012, 99–100, 34–43. [Google Scholar] [CrossRef]

- Li, S.; Li, Y.; Lo, Y.-C.; Neeraj, T.; Srinivasan, R.; Ding, X.; Sun, J.; Qi, L.; Gumbsch, P.; Li, J. The interaction of dislocations and hydrogen-vacancy complexes and its importance for deformation-induced proto nano-voids formation in α-Fe. Int. J. Plast. 2015, 74, 175–191. [Google Scholar] [CrossRef]

- Sirois, E.; Birnbaum, H.K. Effects of hydrogen and carbon on thermally activated deformation in nickel. Acta Metall. Mater. 1992, 40, 1377–1385. [Google Scholar] [CrossRef]

- Robertson, I.M.; Sofronis, P.; Nagao, A.; Martin, M.L.; Wang, S.; Gross, D.W.; Nygren, K.E. Hydrogen embrittlement understood. Metall. Mater. Trans. A 2015, 46, 2323–2341. [Google Scholar] [CrossRef] [Green Version]

- Ohaeri, E.; Eduok, U.; Szpunar, J. Relationship between microstructural features in pipeline steel and hydrogen assisted degradation. Eng. Fail. Anal. 2019, 96, 496–507. [Google Scholar] [CrossRef]

- Metalnikov, P.; Eliezer, D.; Ben-Hamu, G. Hydrogen trapping in additive manufactured Ti–6Al–4V alloy. Mater. Sci. Eng. A 2021, 811, 141050. [Google Scholar] [CrossRef]

- Kong, D.; Zhao, D.; Zhu, G.; Ni, X.; Zhang, L.; Wu, W.; Man, C.; Zhou, Y.; Dong, C.; Sun, B. Heat treatment effects on the hydrogen embrittlement of Ti6Al4V fabricated by laser beam powder bed fusion. Addit. Manuf. 2022, 50, 102580. [Google Scholar] [CrossRef]

- Benmessaoud, F.; Cheikh, M.; Velay, V.; Vidal, V.; Matsumoto, H. Role of grain size and crystallographic texture on tensile behavior induced by sliding mechanism in Ti-6Al-4V alloy. Mater. Sci. Eng. A 2020, 774, 138835. [Google Scholar] [CrossRef]

- Kim, J.; Plancher, E.; Tasan, C.C. Hydrogenation-induced lattice expansion and its effects on hydrogen diffusion and damage in Ti–6Al–4V. Acta Mater. 2020, 188, 686–696. [Google Scholar] [CrossRef]

- Takasawa, K.; Ikeda, R.; Ishikawa, N.; Ishigaki, R. Effects of grain size and dislocation density on the susceptibility to high-pressure hydrogen environment embrittlement of high-strength low-alloy steels. Int. J. Hydrogen Energy 2012, 37, 2669–2675. [Google Scholar] [CrossRef]

- Kappes, M.; Iannuzzi, M.; Carranza, R.M. Hydrogen embrittlement of magnesium and magnesium alloys: A Review. J. Electrochem. Soc. 2013, 160, C168–C178. [Google Scholar] [CrossRef]

- Laptev, R.; Kudiiarov, V.; Pushilina, N. Hydrogen influence on defect structure and mechanical properties of EBM Ti-6Al-4V. Mater. Today Proc. 2019, 19, 2084–2088. [Google Scholar] [CrossRef]

- Martin, M.L.; Somerday, B.P.; Ritchie, R.O.; Sofronis, P.; Robertson, I.M. Hydrogen-induced intergranular failure in nickel revisited. Acta Mater. 2012, 60, 2739–2745. [Google Scholar] [CrossRef]

- Dwivedi, S.K.; Vishwakarma, M. Hydrogen embrittlement in different materials: A review. Int. J. Hydrogen Energy 2018, 43, 21603–21616. [Google Scholar] [CrossRef]

- Djukic, M.B.; Bakic, G.M.; Sijacki Zeravcic, V.; Sedmak, A.; Rajicic, B. The synergistic action and interplay of hydrogen embrittlement mechanisms in steels and iron: Localized plasticity and decohesion. Eng. Fract. Mech. 2019, 216, 106528. [Google Scholar] [CrossRef]

| Ti | Al | V | Fe | C | N | H | O |

|---|---|---|---|---|---|---|---|

| Bal. | 6.25 | 4.05 | 0.20 | 0.01 | 0.01 | 0.001 | 0.12 |

| Sample | Tensile Strength (MPa) | Yield Strength (MPa) |

|---|---|---|

| Welded joint | 1063.4 | 944.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, X.; Shi, Y.; Zhang, W.; Volodymyr, K. Hydrogen Embrittlement Failure Behavior of Fatigue-Damaged Welded TC4 Alloy Joints. Crystals 2023, 13, 512. https://doi.org/10.3390/cryst13030512

Feng X, Shi Y, Zhang W, Volodymyr K. Hydrogen Embrittlement Failure Behavior of Fatigue-Damaged Welded TC4 Alloy Joints. Crystals. 2023; 13(3):512. https://doi.org/10.3390/cryst13030512

Chicago/Turabian StyleFeng, Xudong, Yu Shi, Wenzhu Zhang, and Korzhyk Volodymyr. 2023. "Hydrogen Embrittlement Failure Behavior of Fatigue-Damaged Welded TC4 Alloy Joints" Crystals 13, no. 3: 512. https://doi.org/10.3390/cryst13030512

APA StyleFeng, X., Shi, Y., Zhang, W., & Volodymyr, K. (2023). Hydrogen Embrittlement Failure Behavior of Fatigue-Damaged Welded TC4 Alloy Joints. Crystals, 13(3), 512. https://doi.org/10.3390/cryst13030512