Production of LM28 Tubes by Mechanical Alloying and Using Friction Stir Extrusion

Abstract

:1. Introduction

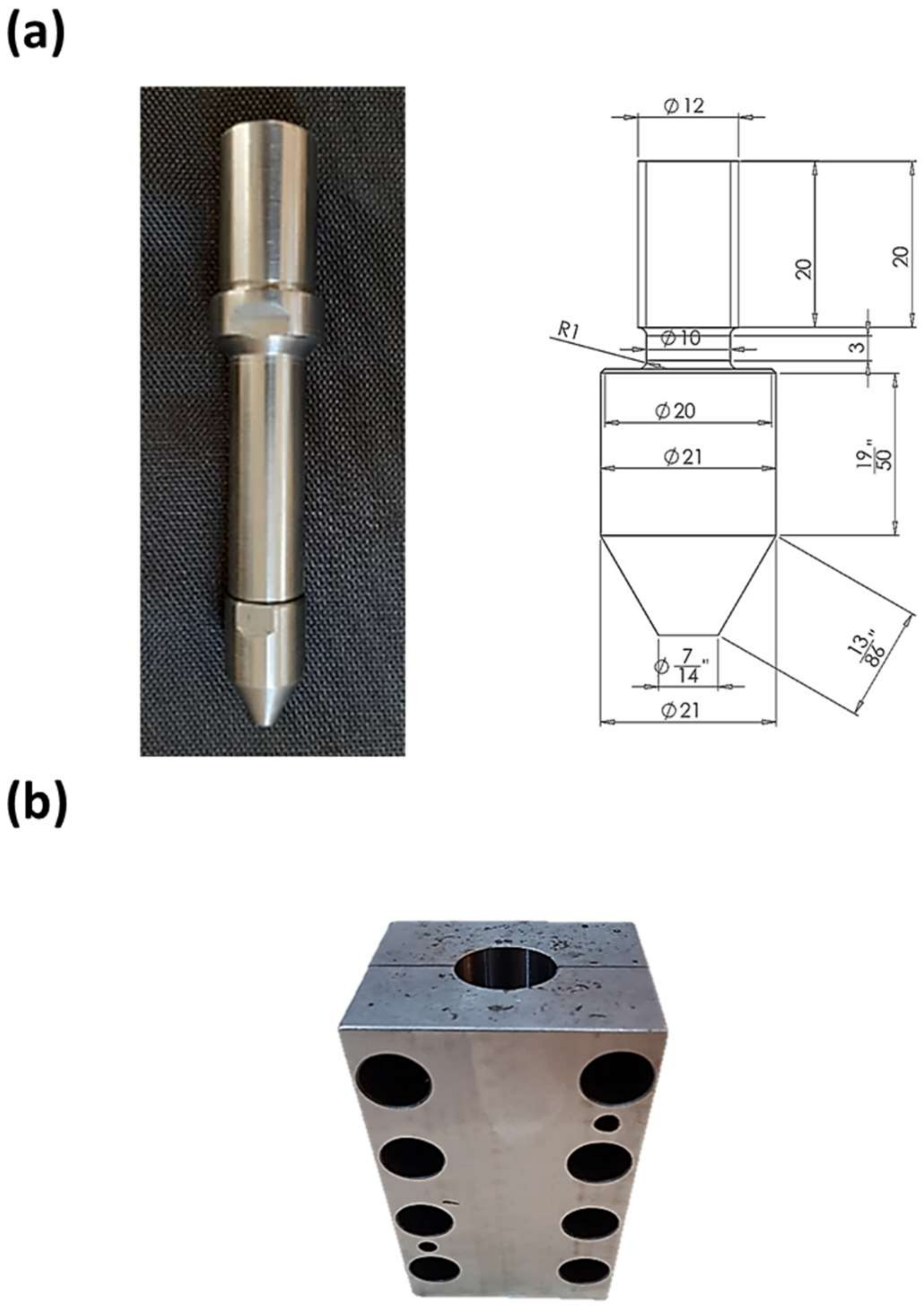

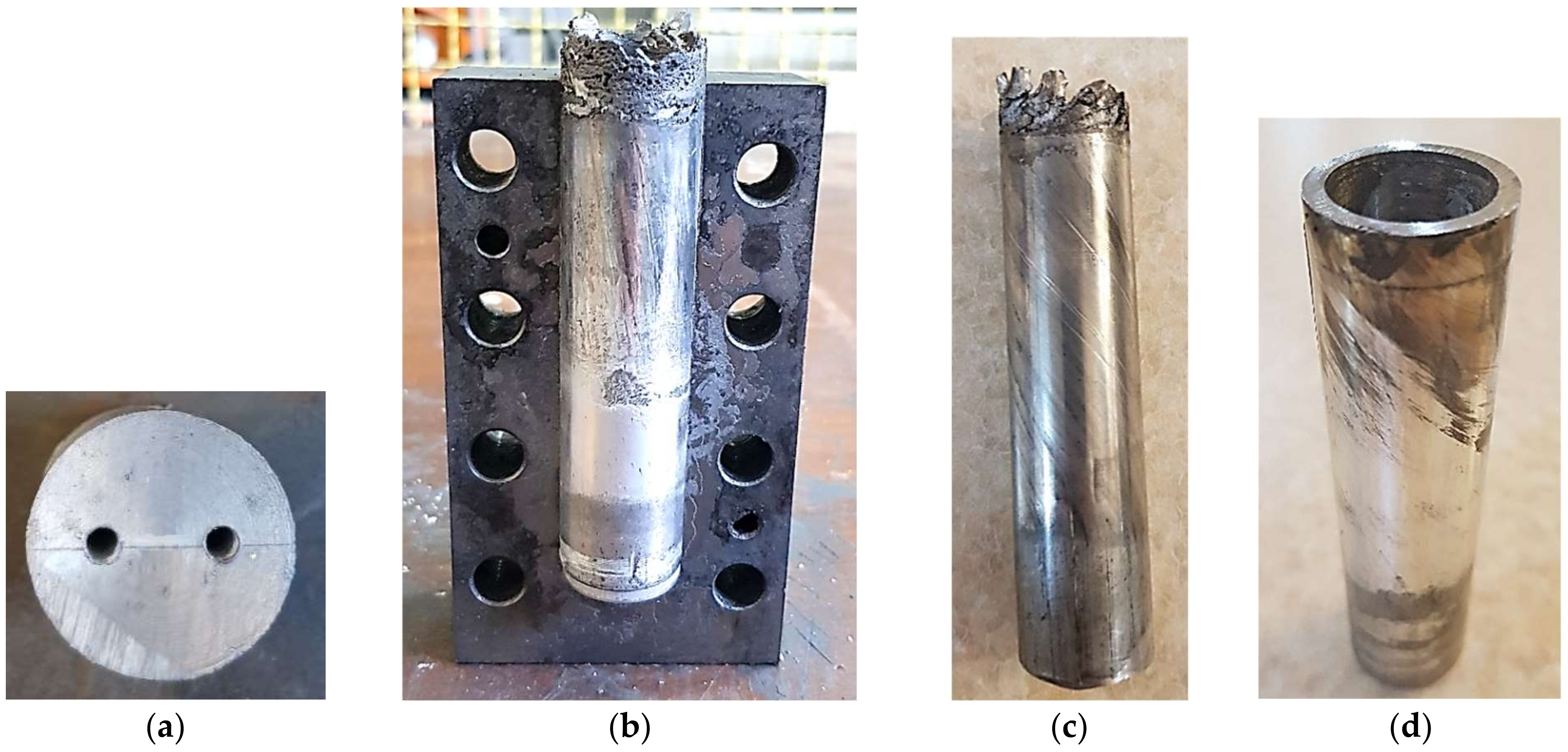

2. Experimental Procedure

- The head, the more critical part, is in contact with the under-processing material, and its temperature will rise to 700–800 °C. Thus, it should be strict, rigid, and wear-resistant at high temperatures.

- The holder, which is connected to the rotating spindle of a milling machine and will experience lower temperatures and can be made of cheaper steel.

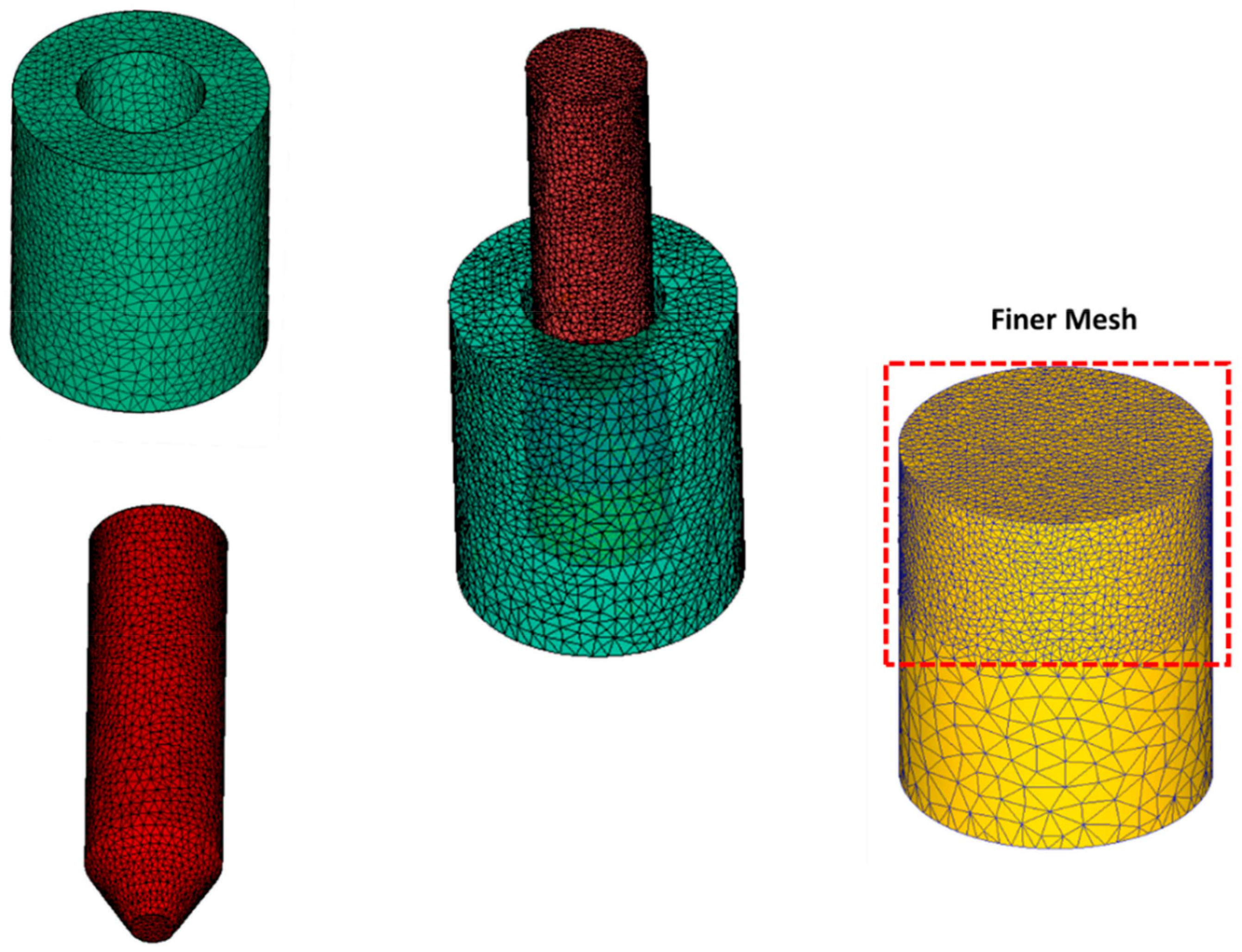

3. Simulation Details

4. Results and Discussions

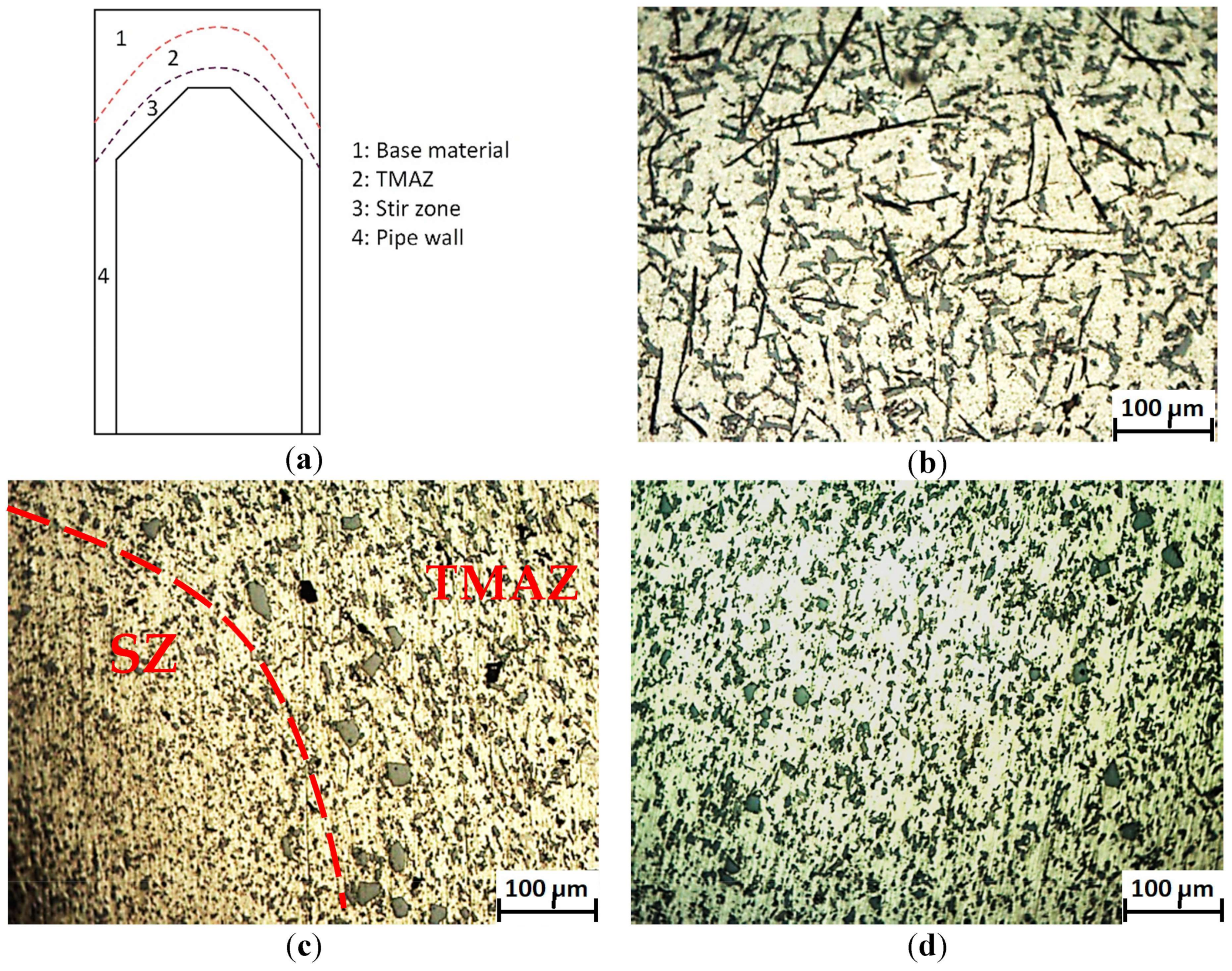

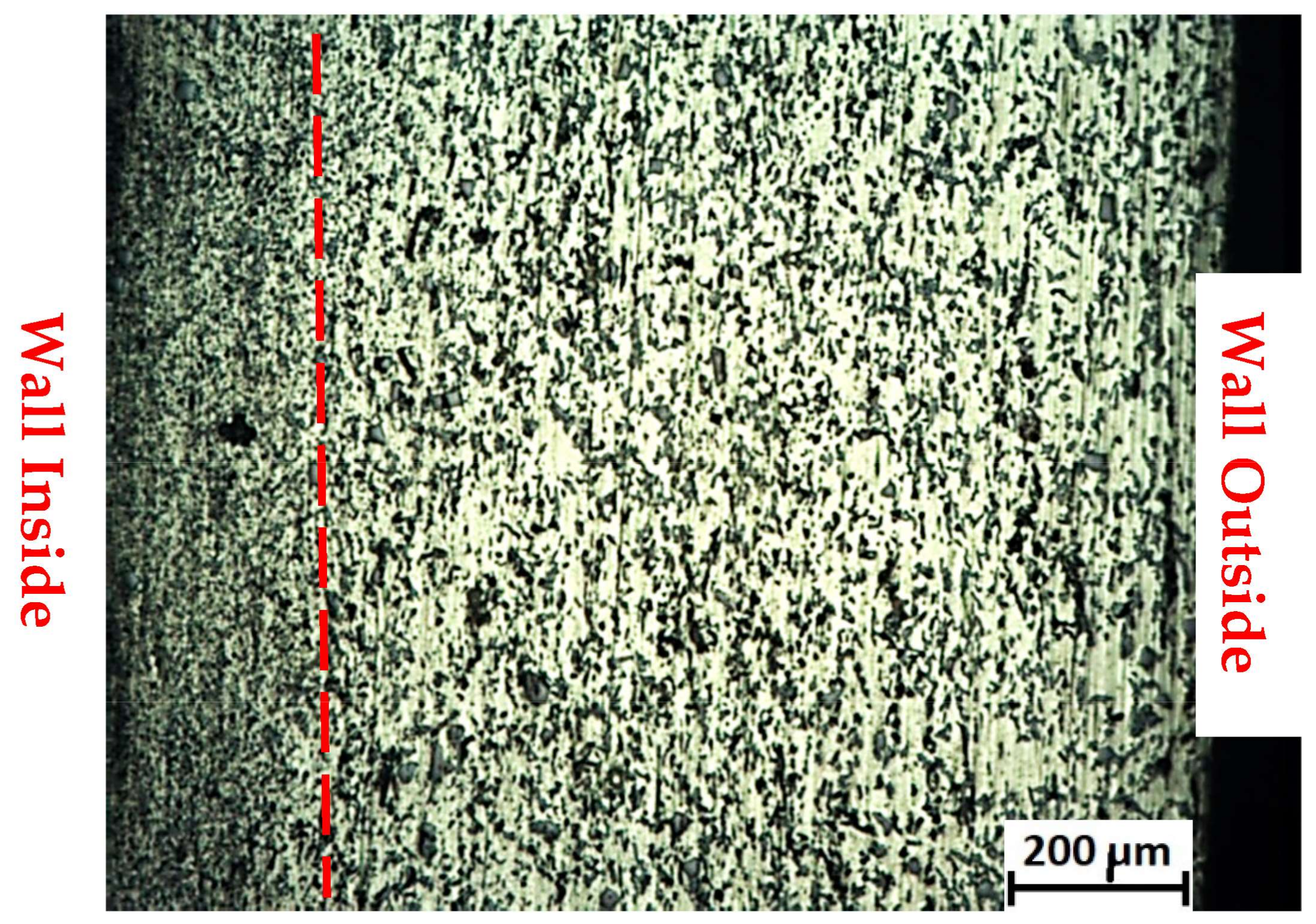

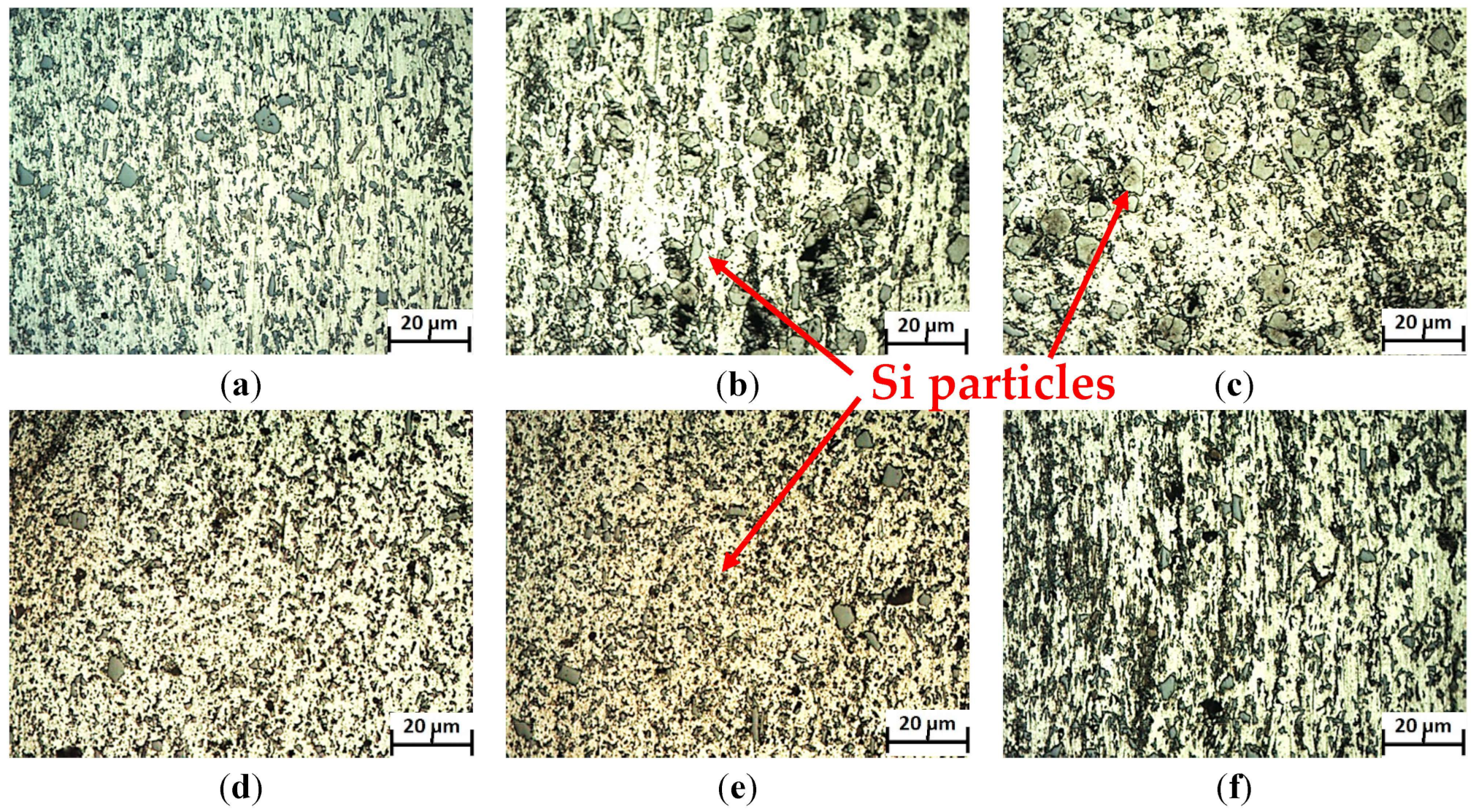

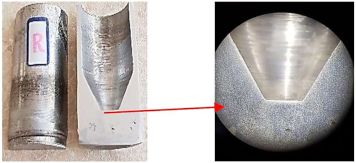

4.1. Macro- and Micro-Structural Properties

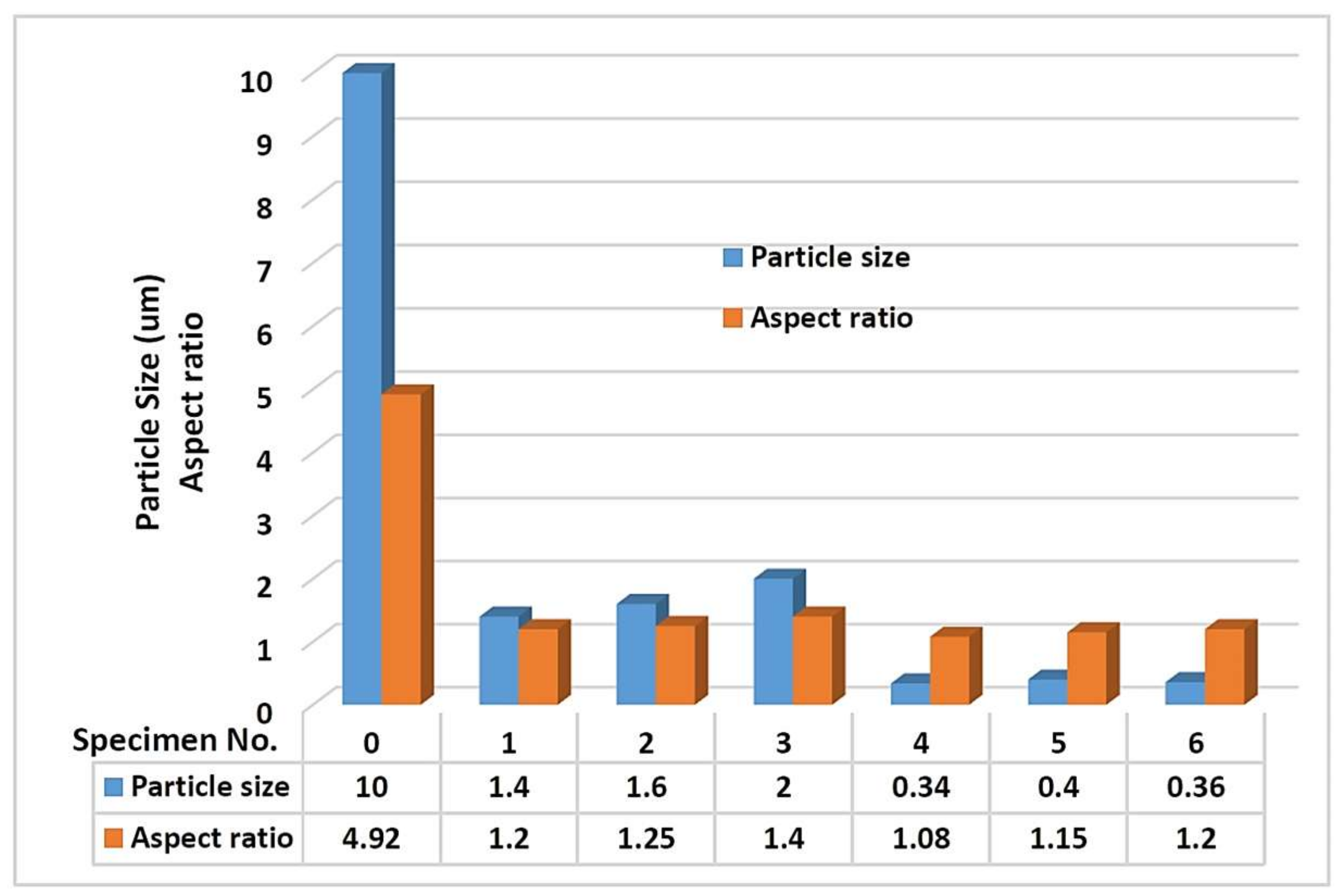

- The first one is that the level of particle distribution uniformity becomes worse as the advancing speed rises for both alloyed and non-alloyed samples. Indeed, an increase in the advancing speed reduces the time in which the rotating tool sweeps the material by rotational movement in a constant length of pipe production. Therefore, the strain amount applied to the material decreases (as will be discussed in Figure 12), leading to worse distribution of alloying particles in the metal matrix. This weakened strain will result in a lower breakage and larger size of Si precipitates. The average size of Si precipitates in the Al matrix is shown in Figure 10. For instance, in the sample produced without alloying particles, the Si particle size increases from 1.4 µm for the sample with an advancing speed of 25 mm/min to 2 µm for the sample with an advancing speed of 40 mm/min.

- The addition of finer alloying elements in samples 4–6 reduced the average precipitate size drastically, and there is also no sign of large precipitates compared to the equivalent non-alloyed samples (for instance, compare Figure 9c,f). Adding finer alloying particles seems to have led to more breakage of primary precipitates during the FSE process.

4.2. Mechanical Properties of the Tubes

4.3. Hardness and Wear Properties

5. Conclusions

- At a constant rotational speed, the quality of the outer surface of the tube improves due to the increase in extrusion pressure as the advancing speed increases.

- The optical microscopy considerations reveal that in the stirring zone, the extended precipitates undergo severe breakage and become very fine in an almost circular shape. The size of silicon particles in LM13 decreased from 10 to almost 1.6 µm on average just by applying the FSE process. The addition of alloying elements for transforming LM13 to LM28 led to more breakage of the precipitates over the process, and since their primary size is around 200 nm, the average Si size dropped below 0.4 µm for the LM28 samples.

- The compression test results show that the FSE process improves the compression strength of as-cast LM13, depending on the process parameters, from almost 19 to 63%. Increasing the advancing speed improves the compressive strength of FSE pipes through the more severe forging force during the process. Additionally, the alloyed FSE specimens (LM28 samples) have higher compressive strength than the non-alloyed ones (LM13) and show an average of 17% improvement in strength.

- The wear resistance of as-cast LM13 alloy can be improved by an average of 18% by applying the FSE process. Furthermore, an extra improvement of 20% (on average) on the wear resistance can be achieved by the addition of alloying elements and transforming to LM28.

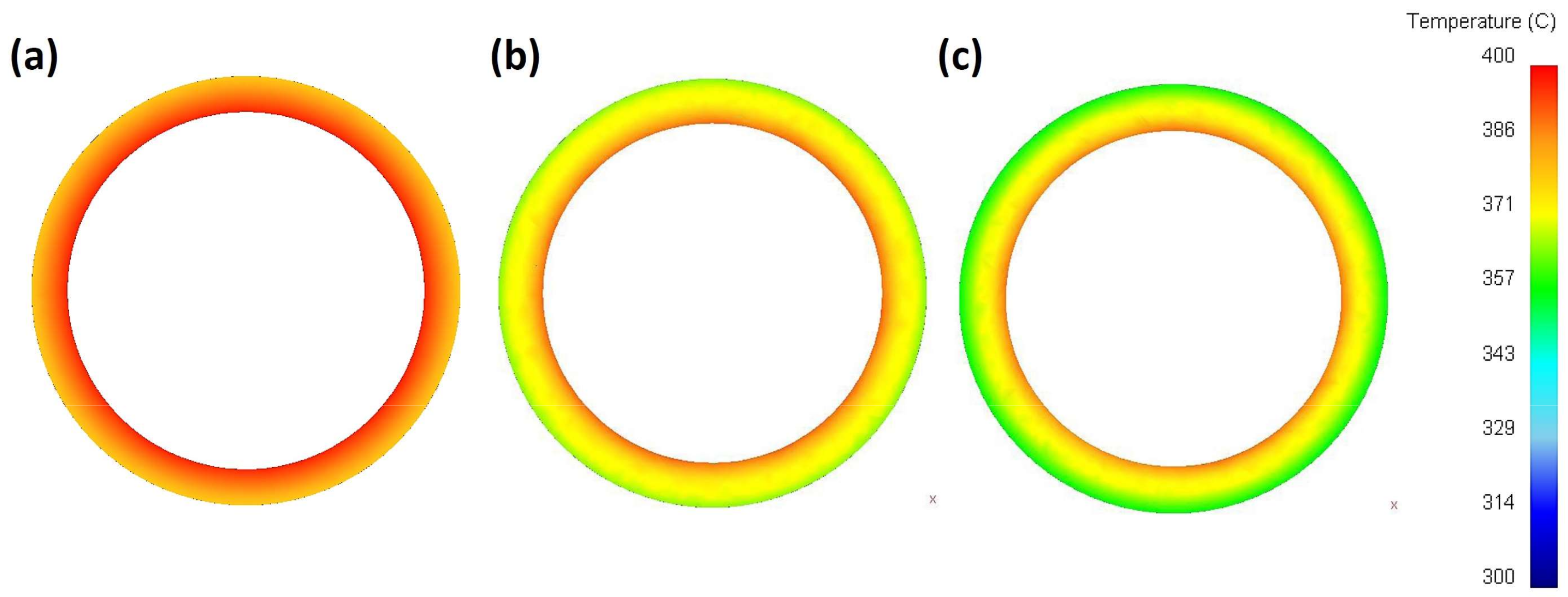

- During FSE the temperature of the under-process material rises due to the frictional heat and plastic deformation. The maximum temperature occurs in the stir zone and inside the wall thickness where the tube and the rotating tool are in contact. Reducing the advancing speed from 40 to 25 mm/min increases this maximum temperature from 350 to 400 °C.

- Similar results have been found for the strain distribution, as the maximum strain occurs in the inside wall of the tube and its value increases as the advancing speed decreases. This is because, at a lower advancing speed, the material under process experiences more movement over a constant period.

- Because of the greater strain on the inner wall of the pipe, the precipitates are much finer at approximately 1/5 of the inner wall thickness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rafieazad, M.; Mohammadi, M.; Gerlich, A.; Nasiri, A. Enhancing the corrosion properties of additively manufactured AlSi10Mg using friction stir processing. Corros. Sci. 2021, 178, 109073. [Google Scholar] [CrossRef]

- Mehrian, S.S.M.; Rahsepar, M.; Khodabakhshi, F.; Gerlich, A.P. Effects of friction stir processing on the microstructure, mechanical and corrosion behaviors of an aluminum-magnesium alloy. Surf. Coat. Technol. 2021, 405, 126647. [Google Scholar] [CrossRef]

- Pietras, D.; Sadowski, T.; Boniecki, M.; Postek, E. Experimental Testing of Al-Si12/SiC Interpenetrating Composites (IPC) in Uniaxial Tension and Compression. Arch. Metall. Mater. 2023, 68, 145–154. [Google Scholar] [CrossRef]

- Ajay Kumar, P.; Madhu, H.C.; Pariyar, A.; Perugu, C.S.; Kailas, S.V.; Garg, U.; Rohatgi, P. Friction stir processing of squeeze cast A356 with surface compacted graphene nanoplatelets (GNPs) for the synthesis of metal matrix composites. Mater. Sci. Eng. A 2020, 769, 138517. [Google Scholar] [CrossRef]

- Ma, L.; Zhou, C.; Shi, Y.; Cui, Q.; Ji, S.; Yang, K. Grain-Refinement and Mechanical Properties Optimisation of A356 Casting Al by Ultrasonic-Assisted Friction Stir Processing. Met. Mater. Int. 2021, 27, 5374–5388. [Google Scholar] [CrossRef]

- Ahmadkhaniha, D.; Asadi, P. 9—Mechanical alloying by friction stir processing. In Advances in Friction-Stir Welding and Processing; Givi, M.K.B., Asadi, P., Eds.; Woodhead Publishing: London, UK, 2014; pp. 387–425. [Google Scholar] [CrossRef]

- Choudhary, C.; Sahoo, K.L.; Mandal, D. Microstructure and mechanical properties of Al-Si alloys processed by strain induced melt activation. Mater. Today Proc. 2018, 5, 27107–27111. [Google Scholar] [CrossRef]

- Akbari, M.; Shojaeefard, M.H.; Asadi, P.; Khalkhali, A. Wear and mechanical properties of surface hybrid metal matrix composites on Al–Si aluminum alloys fabricated by friction stir processing. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2017, 233, 790–799. [Google Scholar] [CrossRef]

- Jahani, A.; Jamshidi Aval, H.; Rajabi, M.; Jamaati, R. Microstructures and properties of copper matrix composite wires reinforced with Ti2SnC particles. Mater. Sci. Technol. 2023, 1–17. [Google Scholar] [CrossRef]

- Amini, A.; Asadi, P.; Zolghadr, P. Friction stir welding applications in industry. In Advances in Friction-Stir Welding and Processing; Woodhead Publishing: London, UK, 2014; pp. 671–722. [Google Scholar] [CrossRef]

- Asadi, P.; Aliha, M.R.M.; Akbari, M.; Imani, D.M.; Berto, F. Multivariate optimization of mechanical and microstructural properties of welded joints by FSW method. Eng. Fail. Anal. 2022, 140, 106528. [Google Scholar] [CrossRef]

- Sharifzadeh, M.; Ansari, M.A.; Narvan, M.; Behnagh, R.A.; Araee, A.; Besharati Givi, M.K. Evaluation of wear and corrosion resistance of pure Mg wire produced by friction stir extrusion. Trans. Nonferrous Met. Soc. China 2015, 25, 1847–1855. [Google Scholar] [CrossRef]

- Tahmasbi, K.; Mahmoodi, M. Evaluation of microstructure and mechanical properties of aluminum AA7022 produced by friction stir extrusion. J. Manuf. Process. 2018, 32, 151–159. [Google Scholar] [CrossRef]

- Ingarao, G.; Baffari, D.; Reynolds, A.P.; Fratini, L.; Masnata, A. Friction stir extrusion to recycle aluminum alloys scraps: Energy efficiency characterization. J. Manuf. Process. 2019, 43, 63–69. [Google Scholar] [CrossRef]

- Milner, J.L.; Abu-Farha, F. Microstructural Evolution and Its Relationship to the Mechanical Properties of Mg AZ31B Friction Stir Back Extruded Tubes. In Magnesium Technology 2014; Alderman, M., Manuel, M.V., Hort, N., Neelameggham, N.R., Eds.; Springer International Publishing: Cham, Switzerland, 2016; pp. 263–268. [Google Scholar] [CrossRef]

- Ramesh, S.; Lakshminarayanan, A.K.; Raghavan, Y.; Harathi, Y. Fabrication and Numerical Analysis of Friction Stir Back Extruded Lightweight Magnesium Alloy Heat Pipes. Mater. Sci. Forum 2020, 979, 129–134. [Google Scholar] [CrossRef]

- Asadi, P.; Akbari, M. Numerical modeling and experimental investigation of brass wire forming by friction stir back extrusion. Int. J. Adv. Manuf. Technol. 2021, 116, 3231–3245. [Google Scholar] [CrossRef]

- Asadi, P.; Akbari, M.; Kohantorabi, O.; Peyghami, M.; Aliha, M.R.M.; Salehi, S.M.; Asiabaraki, H.R.; Berto, F. Characterization of the Influence of Rotational and Traverse Speeds on the Mechanical and Microstructural Properties of Wires Produced By the FSBE Method. Strength Mater. 2022, 54, 318–330. [Google Scholar] [CrossRef]

- Akbari, M.; Asadi, P. Dissimilar friction stir lap welding of aluminum to brass: Modeling of material mixing using coupled Eulerian–Lagrangian method with experimental verifications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 1117–1128. [Google Scholar] [CrossRef]

- Hangai, Y.; Nakano, Y.; Utsunomiya, T.; Kuwazuru, O.; Yoshikawa, N. Drop Weight Impact Behavior of Al-Si-Cu Alloy Foam-Filled Thin-Walled Steel Pipe Fabricated by Friction Stir Back Extrusion. J. Mater. Eng. Perform. 2016, 26, 894–900. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, C.Y.; Ge, Z.J. Optimizing the mechanical properties of Al–Si alloys through friction stir processing and rolling. Mater. Sci. Eng. A 2021, 804, 140786. [Google Scholar] [CrossRef]

- Al-Buainain, M.; Shunmugasamy, V.C.; Usman, C.A.; Mansoor, B. Influence of Microstructure on the Mechanical and Corrosion Response of a Friction Stir-Extruded WE43 Magnesium Rod. Metals 2023, 13, 191. [Google Scholar] [CrossRef]

- Wojcicka, A.; Mroczka, K.; Morgiel, J. Modification of Mechanical Properties of Aluminum Alloy Rods via Friction-Extrusion Method. Materials 2020, 13, 5224. [Google Scholar] [CrossRef]

- Zolghadr, P.; Akbari, M.; Asadi, P. Formation of thermo-mechanically affected zone in friction stir welding. Mater. Res. Express 2019, 6, 086558. [Google Scholar] [CrossRef]

- Hohe, J.; Becker, W. Effective stress-strain relations for two-dimensional cellular sandwich cores: Homogenization, material models, and properties. Appl. Mech. Rev. 2002, 55, 61–87. [Google Scholar] [CrossRef]

- Estrin, Y.; Molotnikov, A.; Davies, C.; Lapovok, R. Strain gradient plasticity modelling of high-pressure torsion. J. Mech. Phys. Solids 2008, 56, 1186–1202. [Google Scholar] [CrossRef]

- Ivanisenko, Y.; Kulagin, R.; Fedorov, V.; Mazilkin, A.; Scherer, T.; Baretzky, B.; Hahn, H. High Pressure Torsion Extrusion as a new severe plastic deformation process. Mater. Sci. Eng. A 2016, 664, 247–256. [Google Scholar] [CrossRef]

- Tayebi, P.; Fazli, A.; Asadi, P.; Soltanpour, M. Formability study and metallurgical properties analysis of FSWed AA 6061 blank by the SPIF process. SN Appl. Sci. 2021, 3, 367. [Google Scholar] [CrossRef]

- Hamilton, C.; Kopyściański, M.; Węglowska, A.; Dymek, S.; Pietras, A. A Numerical Simulation for Dissimilar Aluminum Alloys Joined by Friction Stir Welding. Met. Mat. Trans. A 2016, 47, 4519–4529. [Google Scholar] [CrossRef]

- Hamilton, C.; Kopyściański, M.; Senkov, O.; Dymek, S. A Coupled Thermal/Material Flow Model of Friction Stir Welding Applied to Sc-Modified Aluminum Alloys. Met. Mat. Trans. A 2012, 44, 1730–1740. [Google Scholar] [CrossRef]

- Hemanth, J.; Arasukumar, K. Microstructure, Mechanical Properties (Strength and Hardness) and Wear Behavior of Chilled Aluminum Alloy (LM-13) Reinforced with Titanium Carbide (TiC) Metal Matrix Composites. J. Mater. Sci. Chem. Eng. 2019, 7, 55–66. [Google Scholar] [CrossRef]

- Rajamanickam, A.K.; Uvaraja, V.C. Assessment of mechanical properties of LM13 aluminum alloy hybrid metal matrix composites. Mater. Res. Express 2022, 9, 075001. [Google Scholar] [CrossRef]

| Element | Al | Si | Fe | Cu | Mn | Mg |

|---|---|---|---|---|---|---|

| % wt. | - | 12.93 | 0.9 | 0.9 | 0.11 | 1.05 |

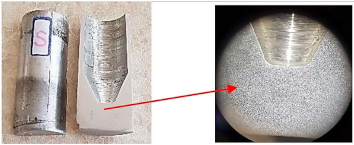

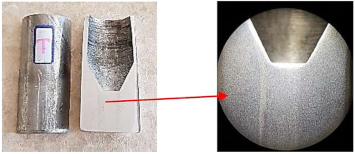

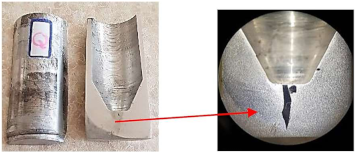

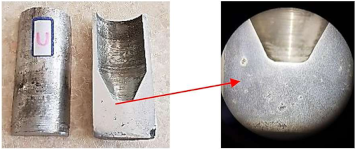

| Advancing Speed (mm/min) | Alloyed or Not | Sample Appearance | Macroscopic Structure | Sample No. |

|---|---|---|---|---|

| 25 | - |  | 1 | |

| alloyed |  | 4 | ||

| 31.5 | - |  | 2 | |

| alloyed |  | 5 | ||

| 40 | - |  | 3 | |

| alloyed |  | 6 | ||

| Sample No. | Base Metal | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| Max. compression stress (MPa) | 85 | 101 | 125.8 | 138.7 | 119.2 | 143.8 | 158.2 |

| Strain at max. compression stress | 7.7 | 9.7 | 9.5 | 14 | 8.4 | 14.5 | 16.5 |

| Sample No. | Base Metal | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|---|

| Average hardness (HV) | 72 | 83 | 81 | 77 | 89 | 86 | 83 |

| Dry wear rate (10−5 mm3/Nm) | 9.366 | 7.024 | 7.660 | 8.107 | 4.832 | 5.731 | 5.927 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Asadi, P.; Akbari, M.; Talebi, M.; Peyghami, M.; Sadowski, T.; Aliha, M.R.M. Production of LM28 Tubes by Mechanical Alloying and Using Friction Stir Extrusion. Crystals 2023, 13, 814. https://doi.org/10.3390/cryst13050814

Asadi P, Akbari M, Talebi M, Peyghami M, Sadowski T, Aliha MRM. Production of LM28 Tubes by Mechanical Alloying and Using Friction Stir Extrusion. Crystals. 2023; 13(5):814. https://doi.org/10.3390/cryst13050814

Chicago/Turabian StyleAsadi, Parviz, Mostafa Akbari, Mahyar Talebi, Maryam Peyghami, Tomasz Sadowski, and Mohammad Reza Mohammad Aliha. 2023. "Production of LM28 Tubes by Mechanical Alloying and Using Friction Stir Extrusion" Crystals 13, no. 5: 814. https://doi.org/10.3390/cryst13050814

APA StyleAsadi, P., Akbari, M., Talebi, M., Peyghami, M., Sadowski, T., & Aliha, M. R. M. (2023). Production of LM28 Tubes by Mechanical Alloying and Using Friction Stir Extrusion. Crystals, 13(5), 814. https://doi.org/10.3390/cryst13050814