Atomic-Scale Imaging of Organic-Inorganic Hybrid Perovskite Using Transmission Electron Microscope

Abstract

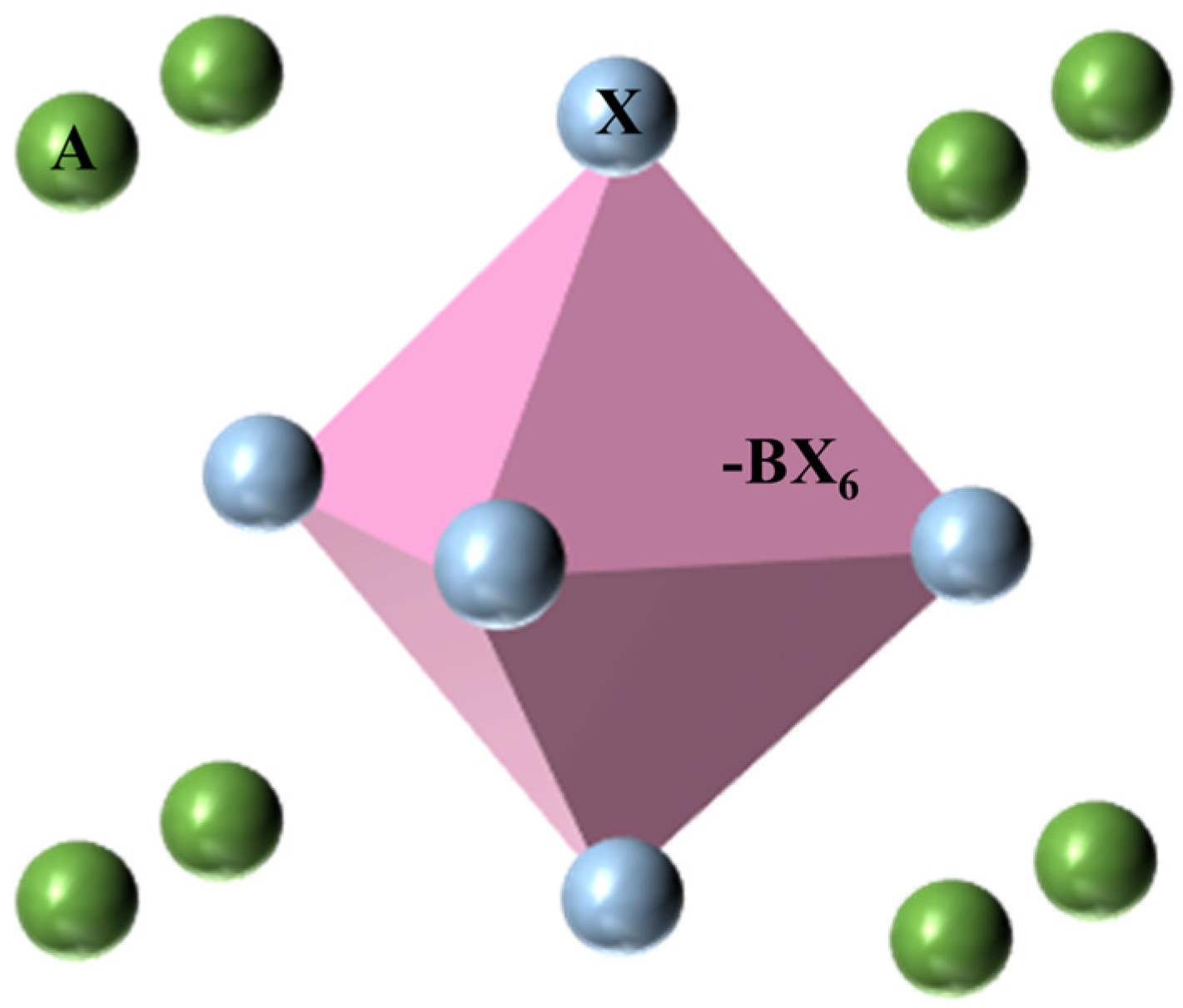

:1. Introduction

2. The Actuality of Atomic-Resolution Imaging of OIHPs Using Transmission Electron Microscopy

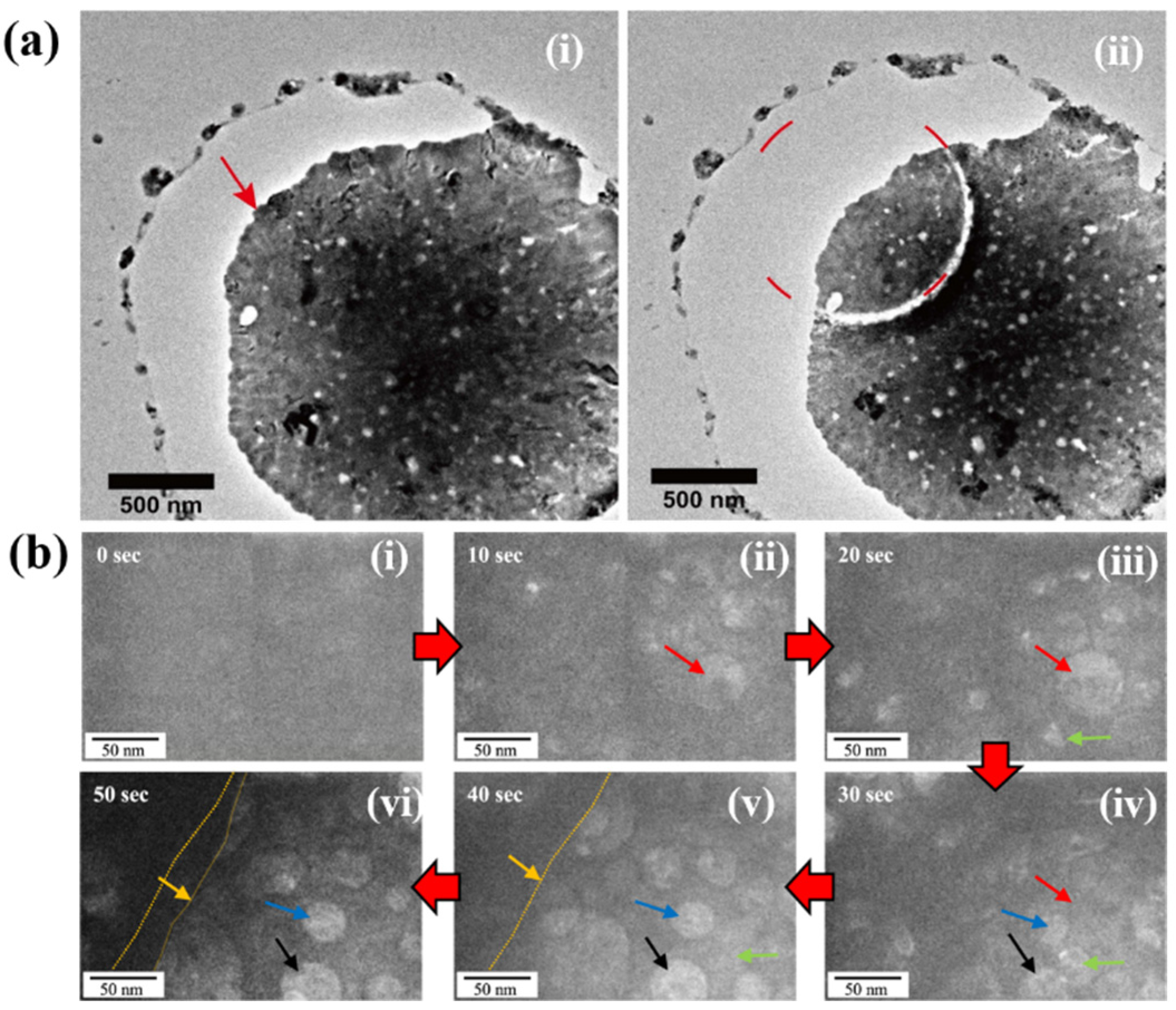

2.1. Application Status of TEM in OIHPs

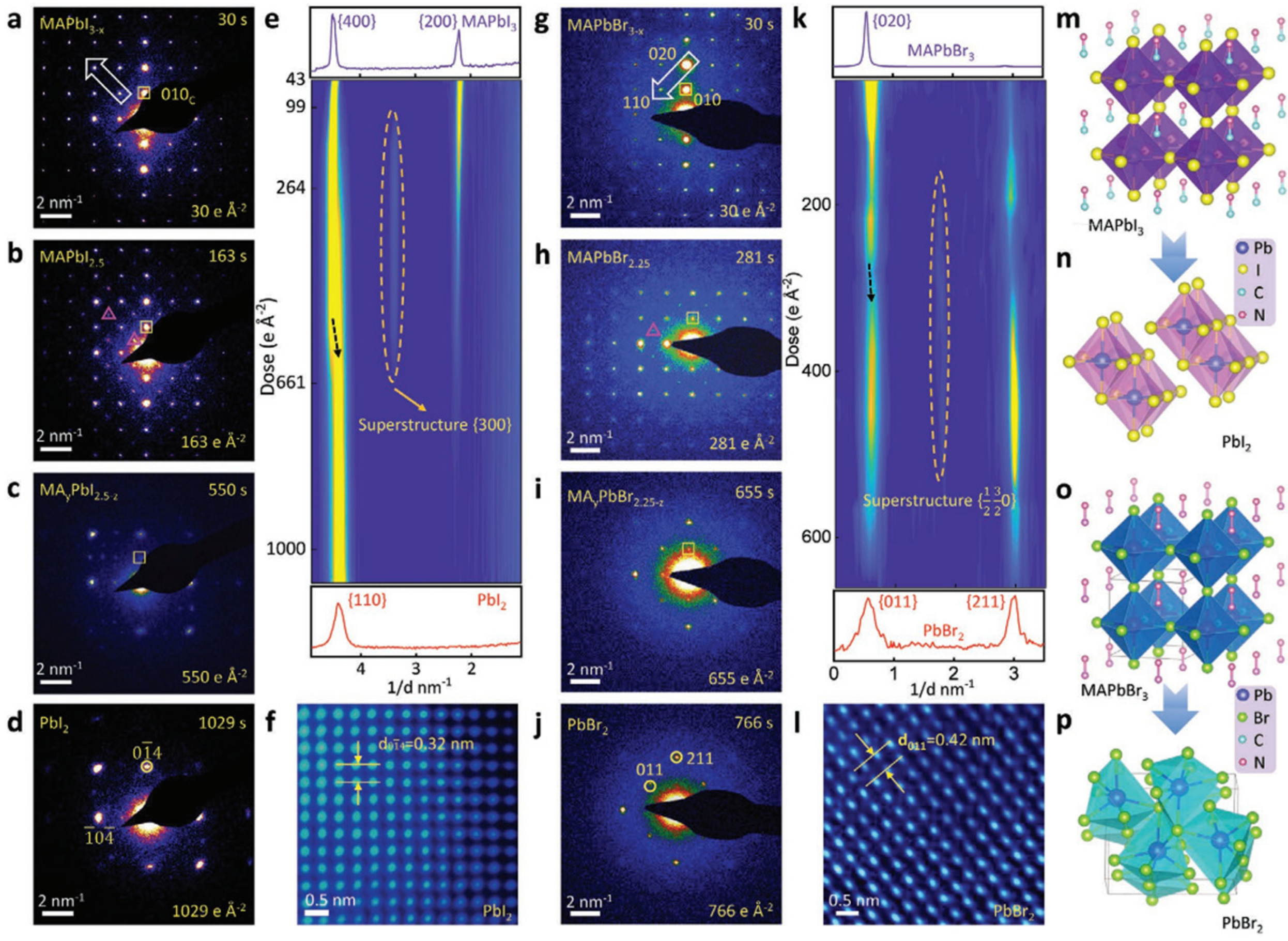

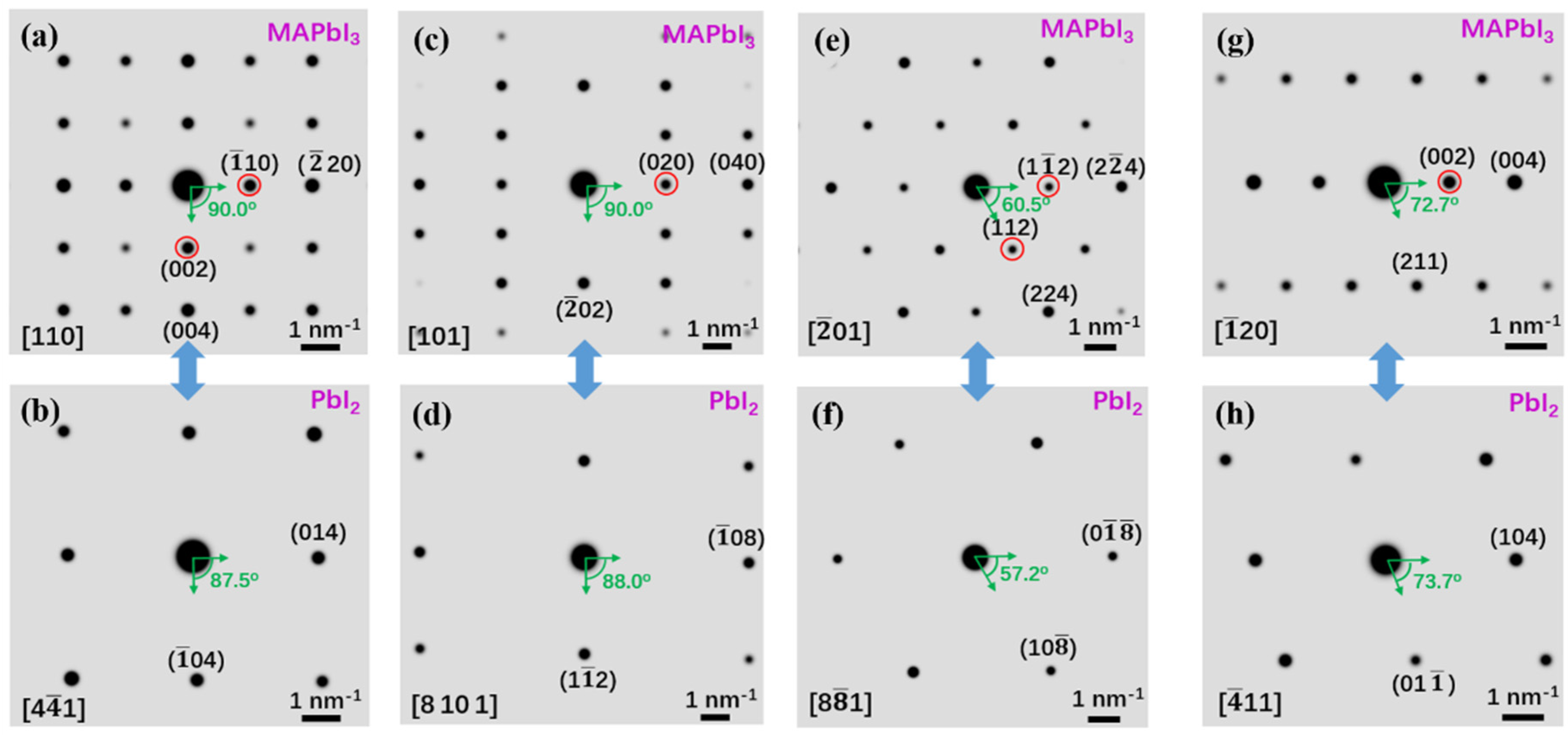

2.2. Main Issues of TEM in Characterizating OIHPs

2.3. Strategies to Improve the Compability of TEM in OIHPs

2.3.1. Sample Protection

2.3.2. Low-Temperature-Based Technologies

3. Summary and Outlook

Funding

Data Availability Statement

Conflicts of Interest

References

- Manser, J.S.; Christians, J.A.; Kamat, P.V. Intriguing Optoelectronic Properties of Metal Halide Perovskites. Chem. Rev. 2016, 116, 12956–13008. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, M.; Li, Z.; Yang, X.; Zhu, R. Challenges and Perspectives toward Future Wide-Bandgap Mixed-Halide Perovskite Photovoltaics. Adv. Energy Mater. 2023, 13, 2203911. [Google Scholar] [CrossRef]

- Xu, F.; Li, Y.; Liu, N.; Han, Y.; Zou, M.; Song, T. 1D Perovskitoid as Absorbing Material for Stable Solar Cells. Crystals 2021, 11, 241. [Google Scholar] [CrossRef]

- Shi, D.; Adinolfi, V.; Comin, R.; Yuan, M.J.; Alarousu, E.; Buin, A.; Chen, Y.; Hoogland, S.; Rothenberger, A.; Katsiev, K.; et al. Low trap-state density and long carrier diffusion in organolead trihalide perovskite single crystals. Science 2015, 347, 519–522. [Google Scholar] [CrossRef] [Green Version]

- Dong, Q.F.; Fang, Y.J.; Shao, Y.C.; Mulligan, P.; Qiu, J.; Cao, L.; Huang, J.S. Electron-hole diffusion lengths >175 μm in solution-grown CH3NH3PbI3 single crystals. Science 2015, 347, 967–970. [Google Scholar] [CrossRef] [Green Version]

- Wang, R.T.; Zhang, Y.; Wu, X.; Zhang, W.; Chi, L.; Xu, F. Stable FAPbI3 hydrate structure by kinetics negotiation for solar cells. Sustain. Energy Fuels 2023, 7, 1974–1980. [Google Scholar] [CrossRef]

- Xu, A.F.; Liu, N.; Xie, F.; Song, T.; Ma, Y.; Zhang, P.; Bai, Y.; Li, Y.; Chen, Q.; Xu, G. Promoting thermodynamic and kinetic stabilities of FA-based perovskite by an in situ bilayer structure. Nano Lett. 2020, 20, 3864–3871. [Google Scholar] [CrossRef]

- Zhu, Y.F.; Liu, Y.F.; Ai, Q.; Gao, G.H.; Yuan, L.; Fang, Q.Y.; Tian, X.Y.; Zhang, X.; Egap, E.; Ajayan, P.M.; et al. In situ synthesis of lead-free halide perovskite-COF nanocomposites as photocatalysts for photoinduced polymerization in both organic and aqueous phases. ACS Mater. Lett. 2022, 4, 464–471. [Google Scholar] [CrossRef]

- Leyden, M.R.; Meng, L.Q.; Jiang, Y.; Ono, L.K.; Qiu, L.B.; Juarez-Perez, E.J.; Qin, C.J.; Adachi, C.; Qi, Y.B. Methylammonium lead bromide perovskite light-emitting diodes by chemical vapor deposition. J. Phys. Chem. Lett. 2017, 8, 3193–3198. [Google Scholar] [CrossRef] [Green Version]

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef] [PubMed]

- Interactive Best Research-Cell Efficiency Chart. Available online: http://www.nrel.gov/pv/interactive-cell-effciency.html (accessed on 1 June 2023).

- Domanski, K.; Alharbi, E.A.; Hagfeldt, A.; Grätzel, M.; Tress, W. Systematic investigation of the impact of operation conditions on the degradation behaviour of perovskite solar cells. Nat. Energy 2018, 3, 61–67. [Google Scholar] [CrossRef]

- Song, K.P.; Liu, L.M.; Zhang, D.L.; Hautzinger, M.P.; Jin, S.; Han, Y. Atomic-Resolution Imaging of Halide Perovskites Using Electron Microscopy. Adv. Energy Mater. 2020, 10, 1904006. [Google Scholar] [CrossRef]

- Jia, C.L.; Lentzen, M.; Urban, K. Atomic-Resolution Imaging of Oxygen in Perovskite Ceramics. Science 2003, 299, 870–873. [Google Scholar] [CrossRef] [Green Version]

- Krivanek, O.L.; Chisholm, M.F.; Nicolosi, V.; Pennycook, T.J.; Corbin, G.J.; Dellby, N.D.; Murfitt, M.F.; Own, C.S.; Szilagyi, Z.S.; Oxley, M.P.; et al. Atom-by-atom structural and chemical analysis by annular dark-field electron microscopy. Nature 2010, 464, 571–574. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Egerton, R.F. Outrun radiation damage with electrons? Adv. Struct. Chem. Imag. 2015, 1, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Egerton, R.F. Control of radiation damage in the TEM. Ultramicroscopy 2013, 127, 100–108. [Google Scholar] [CrossRef]

- Egerton, R.F.; Qian, H. Exploiting the Dose-Rate Dependence of Radiolysis-a Future for Cryo -STEM? Microsc. Microanal. 2019, 25, 992–993. [Google Scholar] [CrossRef] [Green Version]

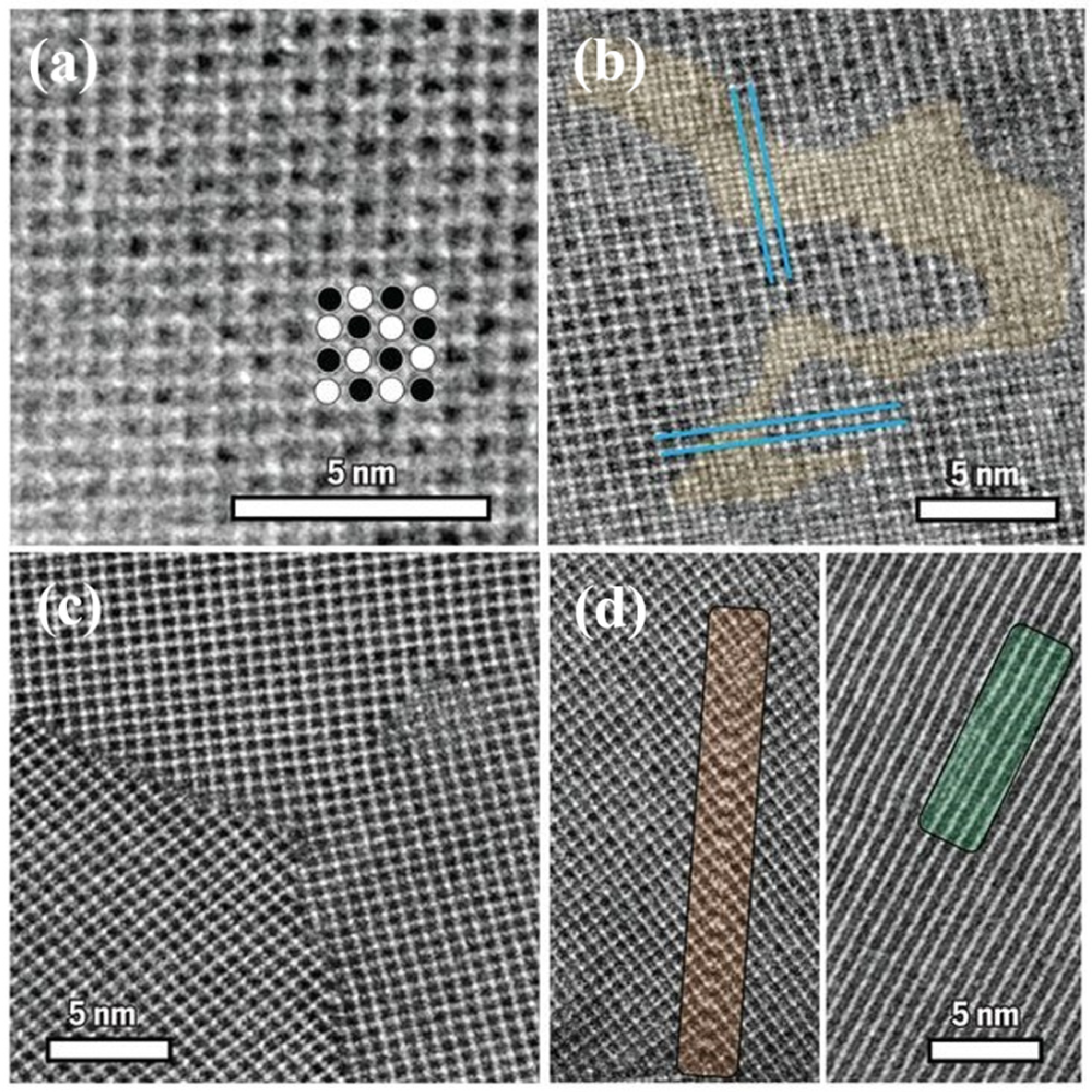

- Rothmann, M.U.; Li, W.; Zhu, Y.; Bach, U.; Spiccia, L.; Etheridge, J.; Cheng, Y.B. Direct observation of intrinsic twin domains in tetragonal CH3NH3PbI3. Nat. Commun. 2017, 8, 14547. [Google Scholar] [CrossRef] [Green Version]

- Milosavljević, A.R.; Huang, W.X.; Sadhu, S.; Ptasinska, S. Low-Energy Electron-Induced Transformations in Organolead Halide Perovskite. Angew. Chem. Int. Ed. 2016, 128, 10237–10241. [Google Scholar] [CrossRef]

- Dang, Z.Y.; Shamsi, J.; Palazon, F.; Imran, M.; Akkerman, Q.A.; Park, S.; Bertoni, G.; Prato, M.; Brescia, R.; Manna, L. In Situ Transmission Electron Microscopy Study of Electron Beam-Induced Transformations in Colloidal Cesium Lead Halide Perovskite Nanocrystals. ACS Nano 2017, 11, 2124–2132. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Sun, Y.B.; Jiang Y, S. Structure and photocatalytic property of perovskite and perovskite-related compounds. Mater. Chem. Phys. 2006, 96, 234–239. [Google Scholar] [CrossRef]

- Aguiar, J.A.; Alkurd, N.R.; Wozny, S.; Patel, M.K.; Yang, M.J.; Zhou, W.L.; Aljassim, M.; Holesinger, T.G.; Zhu, K.; Berry, J.J. In situ investigation of halide incorporation into perovskite solar cells. MRS Commun. 2017, 7, 575–582. [Google Scholar] [CrossRef]

- Aguiar, J.A.; Wozny, S.; Alkurd, N.R.; Yang, M.J.; Kovarik, L.; Holesinger, T.G.; Al-Jassim, M.; Zhu, K.; Zhou, W.L.; Berry, J.J. Effect of Water Vapor, Temperature, and Rapid Annealing on Formamidinium Lead Triiodide Perovskite Crystallization. ACS Energy Lett. 2016, 1, 155–161. [Google Scholar] [CrossRef]

- Chen, X.Y.; Wang, Z.W. Investigating chemical and structural instabilities of lead halide perovskite induced by electron beam irradiation. Micron 2019, 116, 73–79. [Google Scholar] [CrossRef] [PubMed]

- Kim, T.W.; Kondo, T. Direction-selective electron beam damage to CH3NH3PbI3 based on crystallographic anisotropy. Appl. Phys. Express 2020, 13, 091001. [Google Scholar] [CrossRef]

- Wu, X.X.; Tan, L.Z.; Shen, X.Z.; Hu, T.; Miyata, K.; Trinh, M.T.; Li, R.K.; Coffee, R.; Liu, S.; Egger, D.A.; et al. Light-induced picosecond rotational disordering of the inorganic sublattice in hybrid perovskites. Sci. Adv. 2017, 3, e1602388. [Google Scholar] [CrossRef] [Green Version]

- Bryant, D.; Aristidou, N.; Pont, S.; Sanchez-Molina, I.; Chotchunangatchaval, T.; Wheeler, S.; Durrant, J.R.; Haque, S.A. Light and oxygen induced degradation limits the operational stability of methylammonium lead triiodide perovskite solar cells. Energy Environ. Sci. 2016, 9, 1655–1660. [Google Scholar] [CrossRef] [Green Version]

- Berhe, T.A.; Su, W.N.; Chen, C.H.; Pan, C.J.; Cheng, J.H.; Chen, H.M.; Tsai, M.C.; Chen, L.Y.; Dubale, A.A.; Hwang, B.J. Organometal halide perovskite solar cells: Degradation and stability. Energy Environ. Sci. 2016, 9, 323–356. [Google Scholar] [CrossRef]

- Chen, S.L.; Zhang, Y.; Zhang, X.W.; Zhao, Z.W.; Su, X.; Hua, Z.; Zhang, J.M.; Cao, J.; Feng, J.C.; Wang, X.; et al. General Decomposition Pathway of Organic–Inorganic Hybrid Perovskites through an Intermediate Superstructure and Its Suppression Mechanism. Adv. Mater. 2020, 32, 2001107. [Google Scholar] [CrossRef]

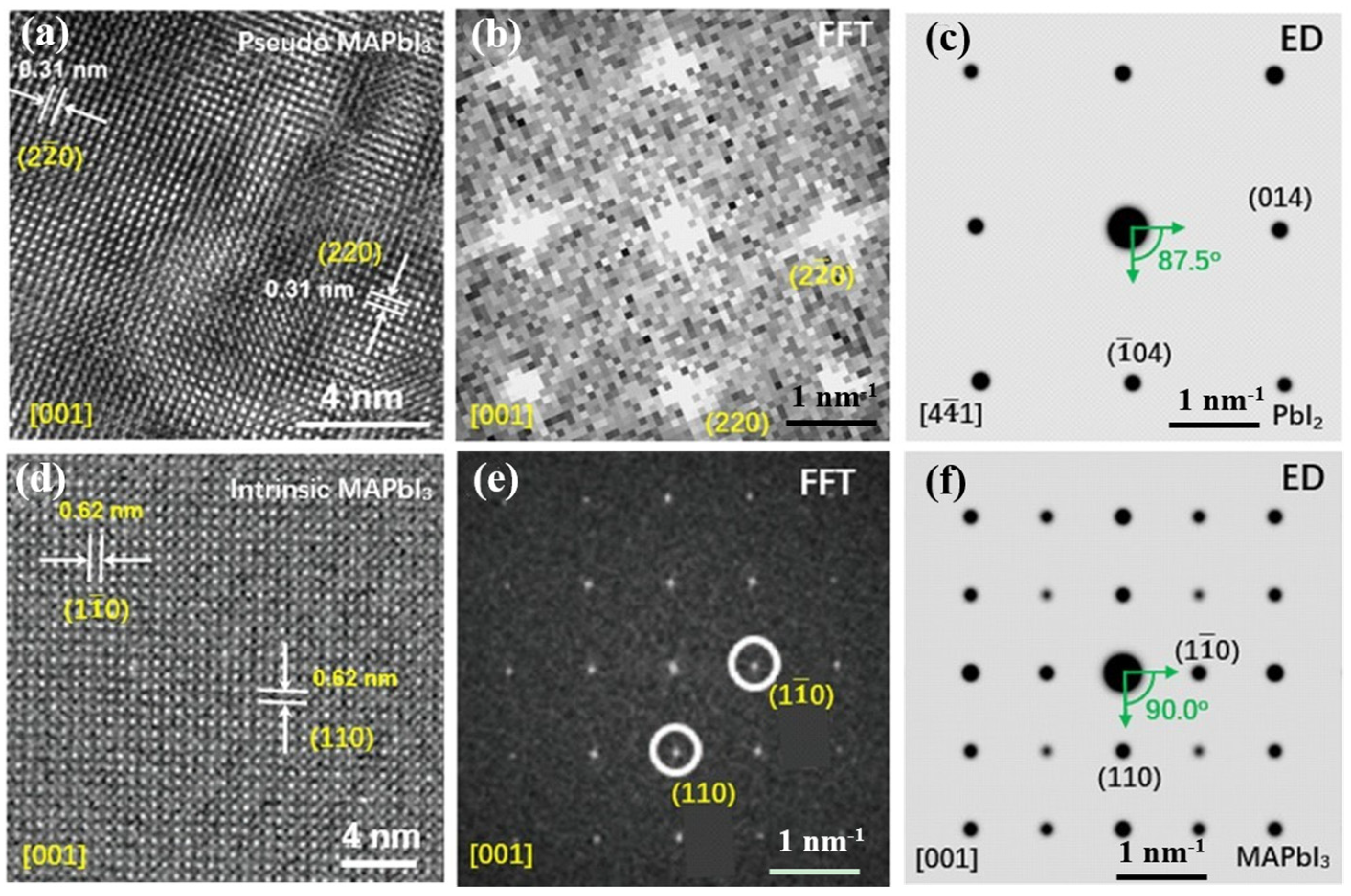

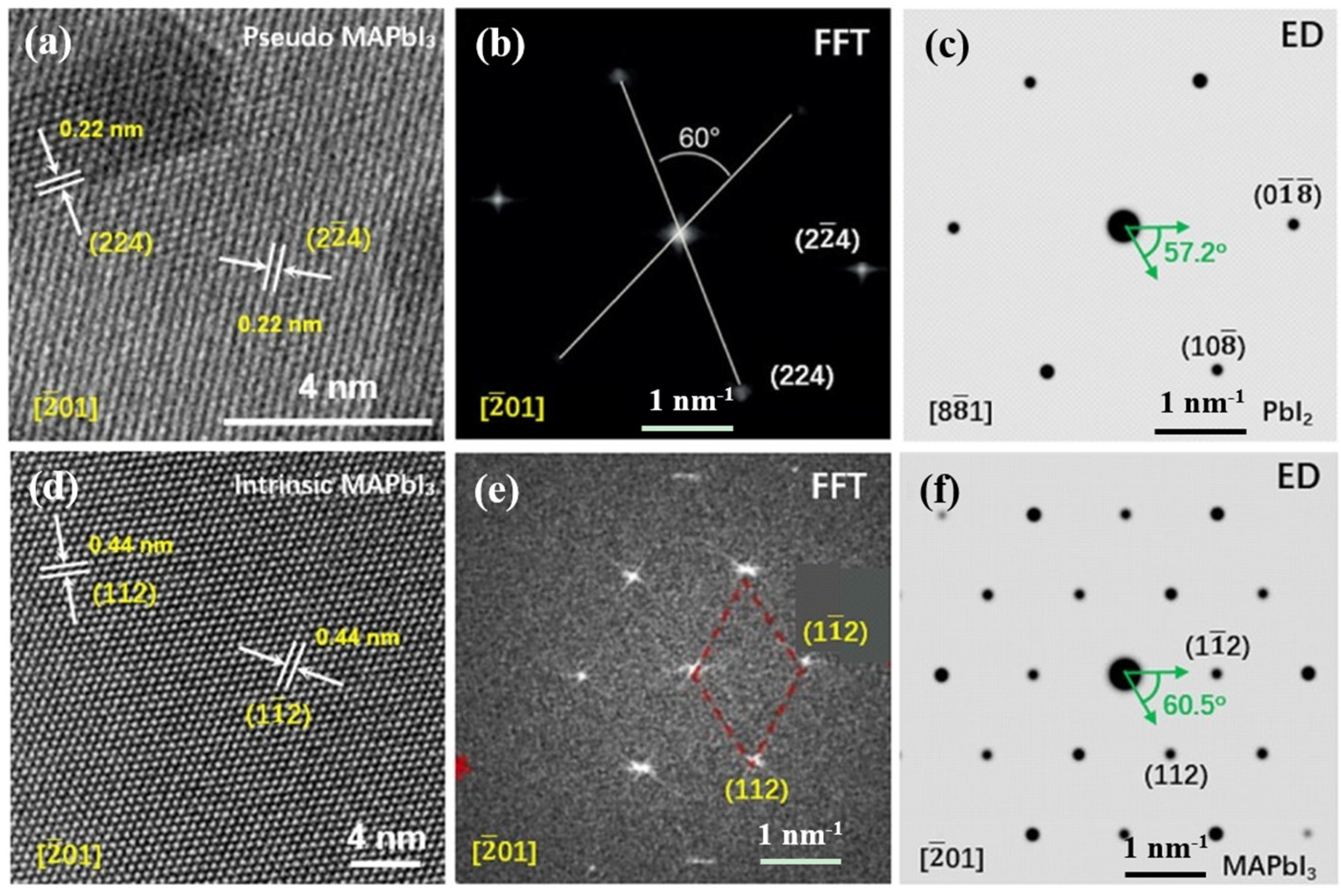

- Chen, S.L.; Zhang, Y.; Zhao, J.J.; Mi, Z.; Zhang, J.M.; Cao, J.; Feng, J.C.; Zhang, G.L.; Qi, J.L.; Li, J.Y.; et al. Transmission electron microscopy of organic-inorganic hybrid perovskites: Myths and truths. Sci. Bull. 2020, 65, 1643–1649. [Google Scholar] [CrossRef]

- Li, Y.B.; Zhou, W.J.; Li, Y.Z.; Huang, W.X.; Zhang, Z.W.; Chen, G.X.; Wang, H.S.; Wu, G.H.; Rolston, N.; Vila, R.; et al. Unravelling Degradation Mechanisms and Atomic Structure of Organic-Inorganic Halide Perovskites by Cryo-EM. Joule 2019, 3, 2854–2866. [Google Scholar] [CrossRef]

- Chen, S.L.; Zhang, X.W.; Zhao, J.J.; Zhang, Y.; Kong, G.L.; Li, Q.; Li, N.; Yu, Y.; Xu, N.G.; Zhang, J.M.; et al. Atomic scale insights into structure instability and decomposition pathway of methylammonium lead iodide perovskite. Nat. Commun. 2018, 9, 4807. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Deng, Y.H. Common Phase and Structure Misidentifications in High-Resolution TEM Characterization of Perovskite Materials. Condens. Matter 2020, 6, 1. [Google Scholar] [CrossRef]

- Zhu, H.M.; Fu, Y.P.; Meng, F.; Wu, X.X.; Gong, Z.Z.; Ding, Q.; Gustafsson, M.V.; Trinh, M.T.; Jin, S.; Zhu, X.Y. Lead halide perovskite nanowire lasers with low lasing thresholds and high quality factors. Nat. Mater. 2015, 14, 636–642. [Google Scholar] [CrossRef] [PubMed]

- Fan, Z.; Xiao, H.; Wang, Y.L.; Zhao, Z.P.; Lin, Z.Y.; Cheng, H.C.; Lee, S.J.; Wang, G.M.; Feng, Z.Y.; Goddard, W.A.; et al. Layer-by-Layer Degradation of Methylammonium Lead Tri-iodide Perovskite Microplates. Joule 2017, 1, 548–562. [Google Scholar] [CrossRef] [Green Version]

- Divitini, G.; Cacovich, S.; Matteocci, F.; Cina, L.; Carlo, A.D.; Midgley, P.; Ducati, C. In situ observation of heat-induced degradation of perovskite solar cells. Nat. Energy 2016, 1, 15012. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.J.; Zhou, Y.Y.; Zeng, Y.N.; Jiang, C.S.; Padture, N.P.; Zhu, K. Square-Centimeter Solution-Processed Planar CH3NH3PbI3 Perovskite Solar Cells with Efficiency Exceeding 15%. Adv. Mater. 2015, 27, 6363–6370. [Google Scholar] [CrossRef]

- Zhou, Y.Y.; Vasiliev, A.L.; Wu, W.W.; Yang, M.J.; Pang, S.P.; Zhu, K.; Padture, N.P. Crystal Morphologies of Organolead Trihalide in Mesoscopic/Planar Perovskite Solar Cells. J. Phys. Chem. Lett. S 2015, 6, 2292–2297. [Google Scholar] [CrossRef]

- Xiao, M.D.; Huang, F.Z.; Huang, W.C.; Dkhissi, Y.; Zhu, Y.; Etheridge, J.; Gray-Weale, A.; Bach, U.; Cheng, Y.B.; Spiccia, L. A Fast Deposition-Crystallization Procedure for Highly Efficient Lead Iodide Perovskite Thin-Film Solar Cells. Angew. Chem. Int. Ed. 2014, 53, 9898–9903. [Google Scholar] [CrossRef]

- Kollek, T.; Gruber, D.; Gehring, J.; Zimmermann, E.; Schmidt-Mende, L.; Polarz, S. Porous and Shape-Anisotropic Single Crystals of the Semiconductor Perovskite CH3NH3PbI3 from a Single-Source Precursor. Angew. Chem. Int. Ed. 2015, 54, 1341–1346. [Google Scholar] [CrossRef]

- Li, D.H.; Wang, G.M.; Cheng, H.C.; Chen, C.Y.; Wu, H.; Liu, Y.; Huang, Y.; Duan, X.F. Size-dependent phase transition in methylammonium lead iodide perovskite microplate crystals. Nat. Commun. 2016, 7, 11330. [Google Scholar] [CrossRef]

- Zhang, X.W.; Yang, Z.Q.; Li, J.Z.; Deng, Y.H.; Hou, Y.M.; Mao, Y.F.; Lu, J.; Ma, R.M. Directly imaging the structure–property correlation of perovskites in crystalline microwires. J. Mater. Chem. A 2019, 7, 13305–13314. [Google Scholar] [CrossRef]

- Deng, Y.H.; Nest, L.G. Analysis of misidentifications in TEM characterization of organic-inorganic hybrid perovskite material. J. Microsc. 2021, 282, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.M.; Gui, Z.G.; Wang, Q.; Meng, F.X.; Feng, S.H.; Han, B.; Wang, P.Y.; Huang, L.; Wang, H.L.; Gu, M. Direct atomic scale characterization of the surface structure and planar defects in the organic-inorganic hybrid CH3NH3PbI3 by Cryo-TEM. Nano Energy 2020, 73, 104820. [Google Scholar] [CrossRef]

- Rothmann, M.U.; Li, W.; Zhu, Y.; Liu, A.; Ku, Z.L.; Bach, U.; Etheridge, J.; Cheng, Y.B. Structural and Chemical Changes to CH3NH3PbI3 Induced by Electron and Gallium Ion Beams. Adv. Mater. 2018, 30, 1800629. [Google Scholar] [CrossRef]

- Spence, J.C.H. High-Resolution Electron Microscopy; Oxford University Press: Oxford, UK, 2013. [Google Scholar]

- Wu, X.M.; Ke, X.X.; Sui, M.L. Recent progress on advanced transmission electron microscopy characterization for halide perovskite semiconductors. J. Semicond. 2022, 43, 041106. [Google Scholar] [CrossRef]

- Cai, Z.H.; Wu, Y.N.; Chen, S.Y. Energy-dependent knock-on damage of organic-inorganic hybrid perovskites under electron beam irradiation: First-principles insights. Appl. Phys. Lett. 2021, 119, 123901. [Google Scholar] [CrossRef]

- Chen, Z.X.; Ke, X.X.; Zhu, L.J.; Zhu, C.; Chen, Q.; Sui, M.L. Electron microscopy of organic-inorganic hybrid perovskite solar cell materials: Degradation mechanism study and imaging condition optimization. J. Chin. Electron. Microsc. Soc. 2019, 38, 15. [Google Scholar]

- Rothmann, M.U.; Kim, J.S.; Borchert, J.; Lohmann, K.B.; O’Leary, C.M.; Sheader, A.A.; Clark, L.; Snaith, H.J.; Johnston, M.B.; Nellist, P.D.; et al. Atomic-scale microstructure of metal halide perovskite. Science 2020, 370, eabb5940. [Google Scholar] [CrossRef]

- Egerton, R.F. Radiation damage to organic and inorganic specimens in the TEM. Micron 2019, 119, 72–87. [Google Scholar] [CrossRef]

- Li, Y.Z.; Li, Y.B.; Pei, A.; Yan, K.; Sun, Y.M.; Wu, C.L.; Joubert, L.M.; Chin, R.; Koh, A.L.; Yu, Y.; et al. Atomic structure of sensitive battery materials and Interfaces revealed by cryo-electron microscopy. Science 2017, 358, 506–510. [Google Scholar] [CrossRef] [Green Version]

- Wiktor, C.; Turner, S.; Zacher, D.; Fischer, R.A.; Tendeloo, G.V. Imaging of intact MOF-5 nanocrystals by advanced TEM at liquid nitrogen temperature. Micropor. Mesopor. Mat. 2012, 162, 131–135. [Google Scholar] [CrossRef]

- Zachman, M.J.; Tu, Z.Y.; Choudhury, S.; Archer, L.A.; Kourkoutis, L.F. Cryo-STEM mapping of solid-liquid interfaces and dendrites in lithium-metal batteries. Nature 2018, 560, 345–349. [Google Scholar] [CrossRef]

- Wang, X.F.; Zhang, M.H.; Alvarado, J.; Wang, S.; Sina, M.; Lu, B.Y.; Bouwer, J.; Xu, W.; Xiao, J.; Zhang, J.G.; et al. New Insights on the Structure of Electrochemically Deposited Lithium Metal and Its Solid Electrolyte Interphases via Cryogenic TEM. Nano Lett. 2017, 17, 7606–7612. [Google Scholar] [CrossRef]

- Li, Y.Z.; Huang, W.; Li, Y.B.; Pei, A.; Boyle, D.T.; Yi, C. Correlating Structure and Function of Battery Interphases at Atomic Resolution Using Cryoelectron Microscopy. Joule 2018, 2, 2167–2177. [Google Scholar] [CrossRef] [Green Version]

- Meents, A.; Gutmann, S.; Wagner, A.; Schulze-Briese, C. Origin and temperature dependence of radiation damage in biological samples at cryogenic temperatures. Proc. Natl. Acad. Sci. USA 2010, 107, 1094–1099. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shi, L.X.; Wang, J.; Zhou, L.; Chen, Y.L.; Yan, J.; Dai, C.N. Facile in-situ preparation of MAPbBr3@UiO-66 composites for information encryption and decryption. J. Solid State Chem. 2019, 282, 121062. [Google Scholar] [CrossRef]

- Herzing, A.A.; Delongchamp, D.M. Cold Microscopy Solves Hot Problems in Energy Research. Matter 2019, 1, 1104–1118. [Google Scholar] [CrossRef]

- Cao, D.H.; Stoumpos, C.C.; Malliakas, C.D.; Katz, M.J.; Farha, O.K.; Hupp, J.T.; Kanatzidis, M.G. Remnant PbI2, an unforeseen necessity in high-efficiency hybrid perovskite-based solar cells? APL Mater. 2014, 2, 091101. [Google Scholar] [CrossRef] [Green Version]

- Hsu, H.Y.; Du, M.S.; Zhao, J.; Yu, E.T.; Bard, A.J. Optimization of PbI2/MAPbI3 Perovskite Composites by Scanning Electrochemical Microscopy. J. Phys. Chem. C 2016, 120, 19890–19895. [Google Scholar] [CrossRef]

- Kim, Y.C.; Jeon, N.J.; Noh, J.H.; Yang, W.S.; Seo, J.; Yun, J.S.; Ho-Baillie, A.; Huang, S.J.; Green, M.A.; Seidel, J.; et al. Beneficial Effects of PbI2 Incorporated in Organo-Lead Halide Perovskite Solar Cells. Adv. Energy Mater. 2016, 6, 1502104. [Google Scholar] [CrossRef]

- Zhang, D.L.; Zhu, Y.H.; Liu, L.M.; Ying, X.R.; Hsiung, C.E.; Sougrat, R.; Li, K.; Han, Y. Atomic-resolution transmission electron microscopy of electron beam–sensitive crystalline materials. Science 2018, 359, 675–679. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yuan, B.; Yu, Y. High-resolution transmission electron microscopy of beam-sensitive halide perovskites. Chem 2022, 8, 327–339. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bao, L.; Gao, P.; Song, T.; Xu, F.; Li, Z.; Xu, G. Atomic-Scale Imaging of Organic-Inorganic Hybrid Perovskite Using Transmission Electron Microscope. Crystals 2023, 13, 973. https://doi.org/10.3390/cryst13060973

Bao L, Gao P, Song T, Xu F, Li Z, Xu G. Atomic-Scale Imaging of Organic-Inorganic Hybrid Perovskite Using Transmission Electron Microscope. Crystals. 2023; 13(6):973. https://doi.org/10.3390/cryst13060973

Chicago/Turabian StyleBao, Lixia, Peifeng Gao, Tinglu Song, Fan Xu, Zikun Li, and Gu Xu. 2023. "Atomic-Scale Imaging of Organic-Inorganic Hybrid Perovskite Using Transmission Electron Microscope" Crystals 13, no. 6: 973. https://doi.org/10.3390/cryst13060973

APA StyleBao, L., Gao, P., Song, T., Xu, F., Li, Z., & Xu, G. (2023). Atomic-Scale Imaging of Organic-Inorganic Hybrid Perovskite Using Transmission Electron Microscope. Crystals, 13(6), 973. https://doi.org/10.3390/cryst13060973