A Study on the Effects of Liquid Phase Formation Temperature and the Content of Sintering Aids on the Sintering of Silicon Nitride Ceramics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Characterization Methods

3. Results and Discussion

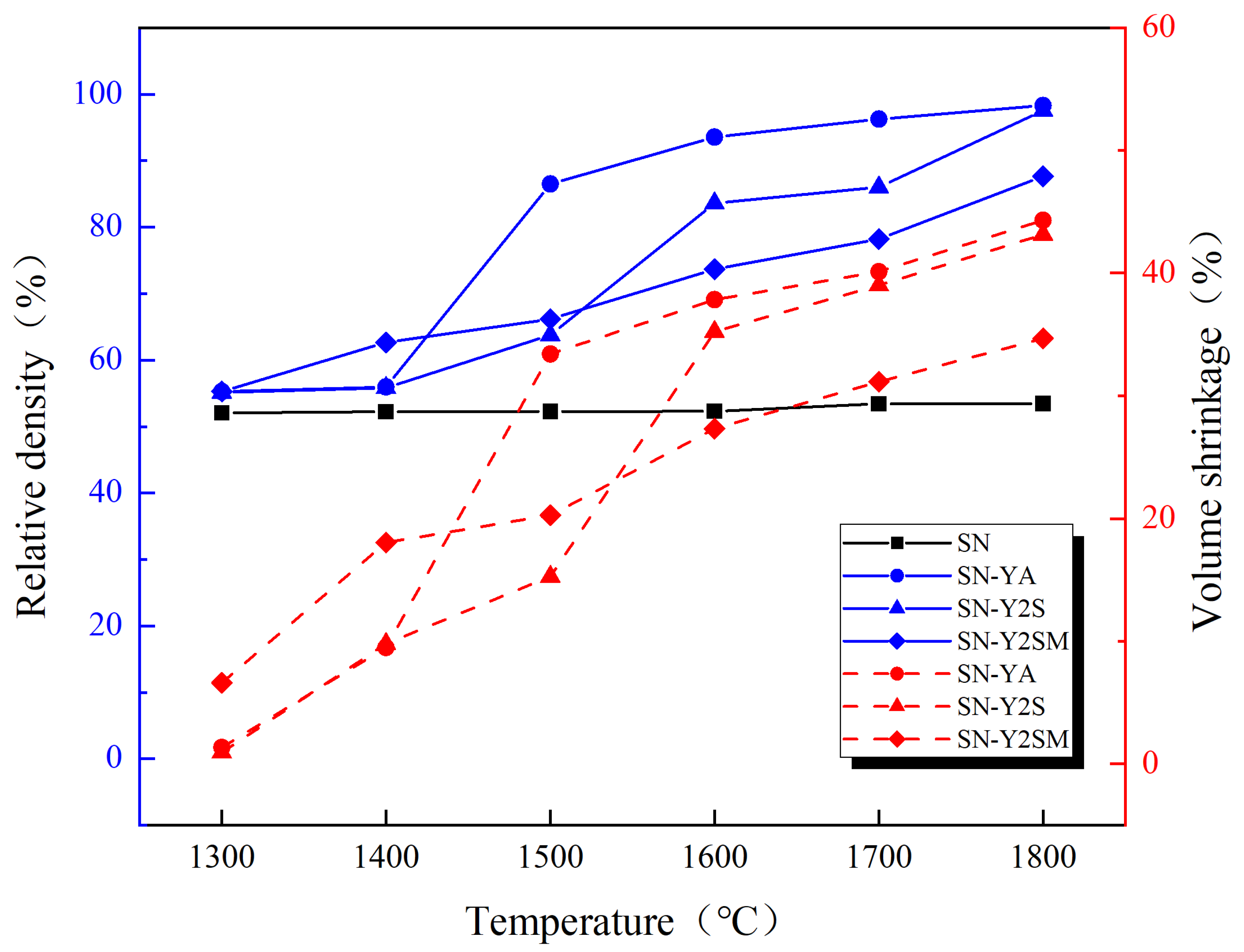

3.1. The Effects of Liquid Phase Formation Temperature

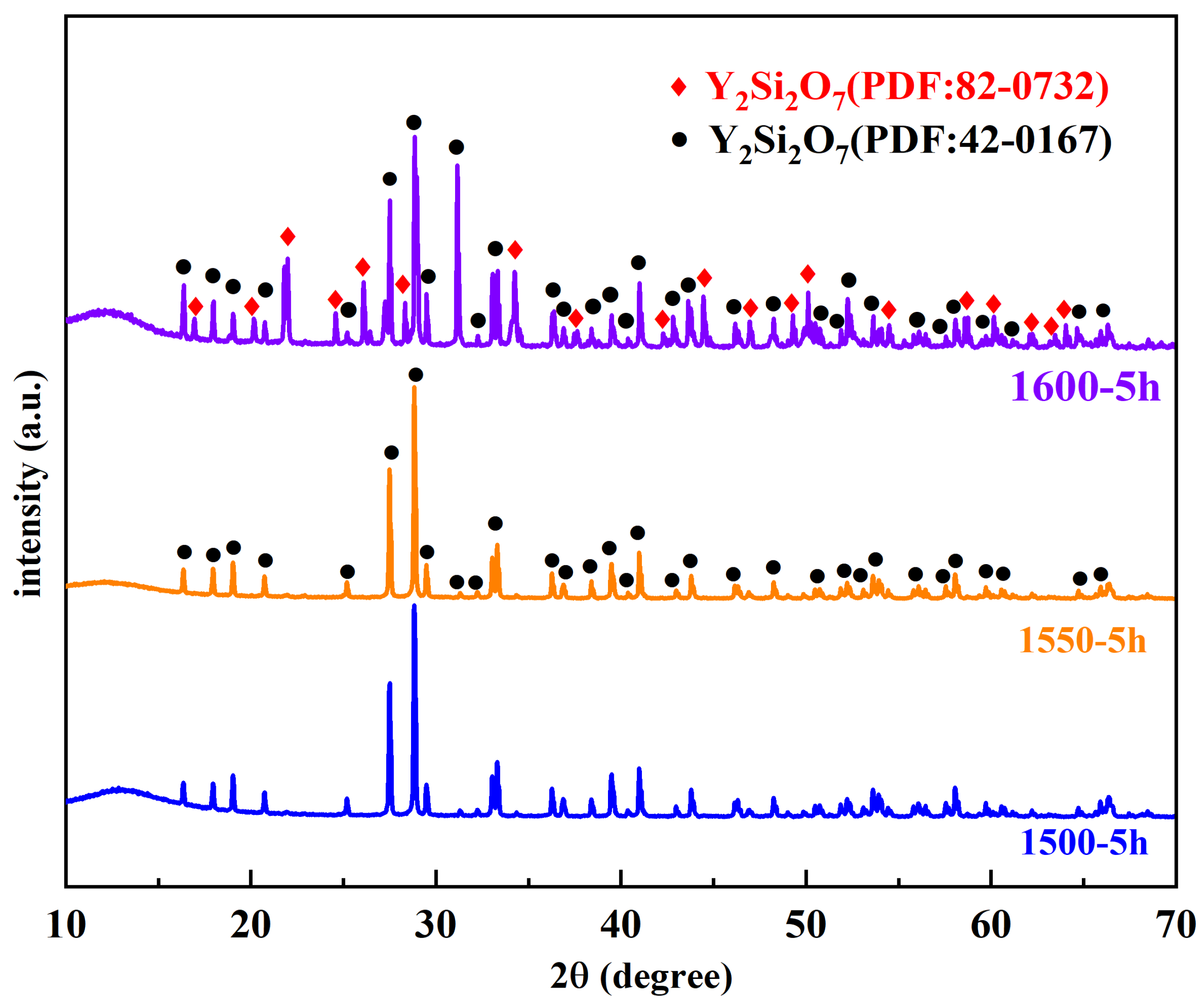

3.2. The Impact of Liquid Phase Formation Temperature on Phase Transformation

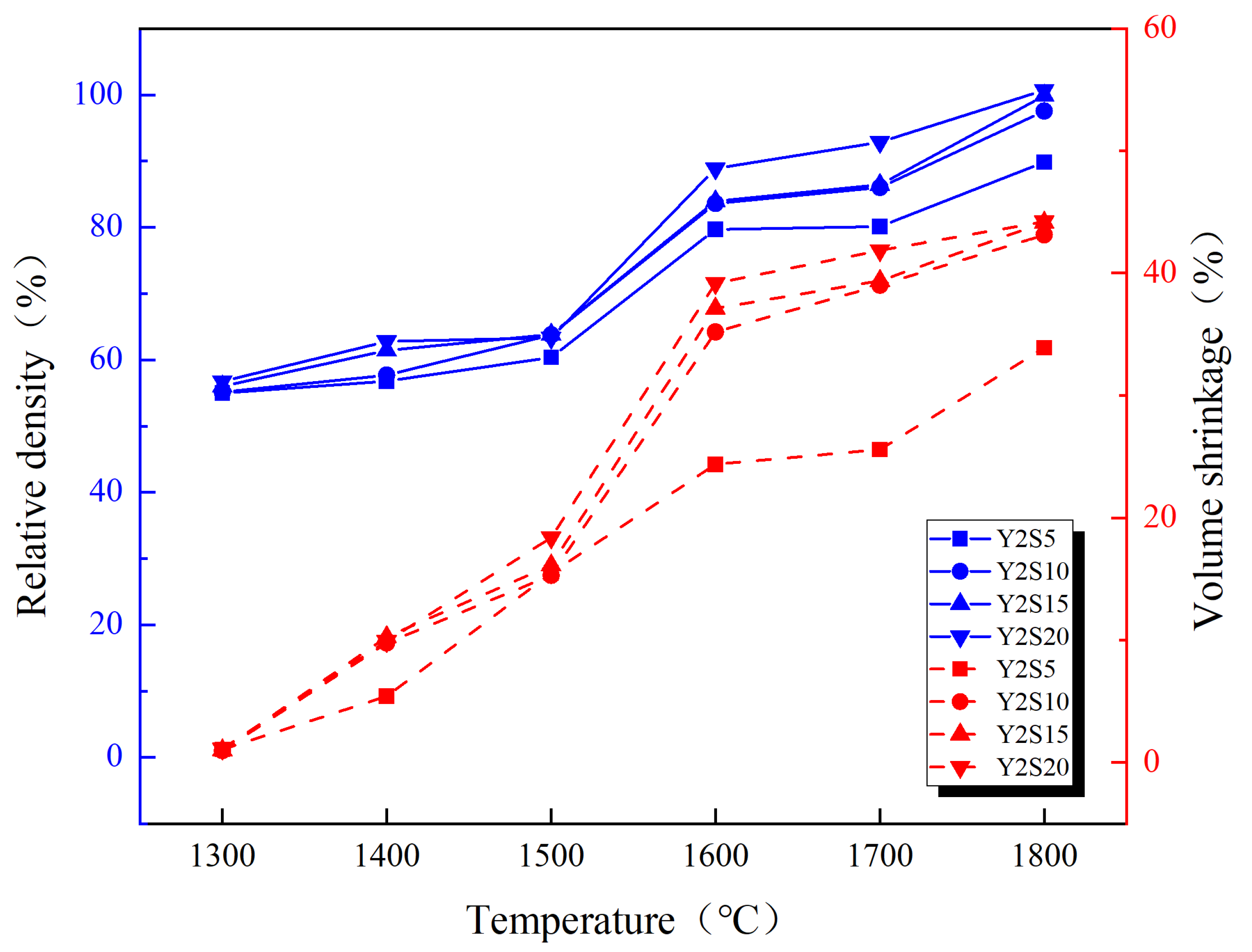

3.3. The Effect of Additive Content on Sintered Density and Shrinkage

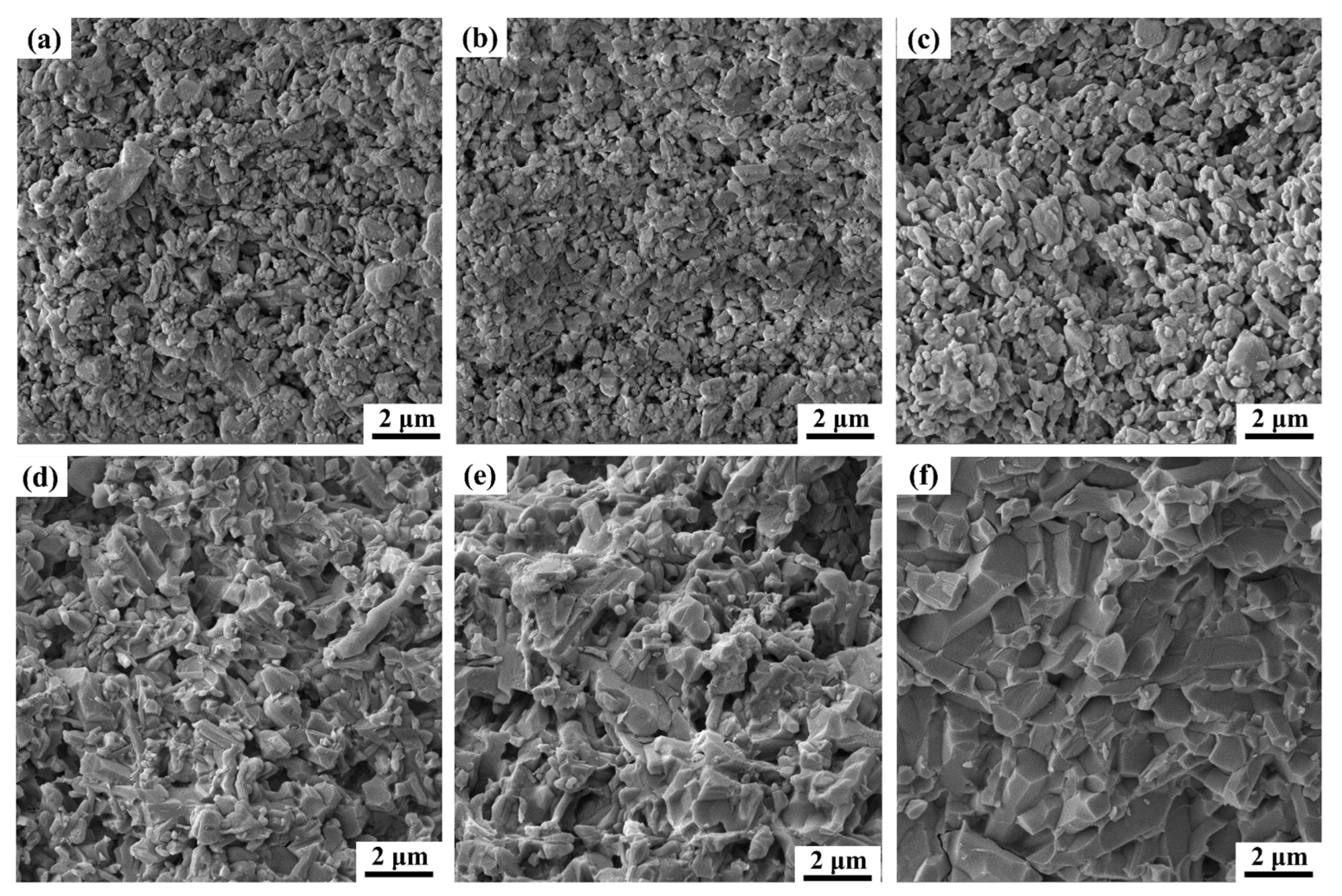

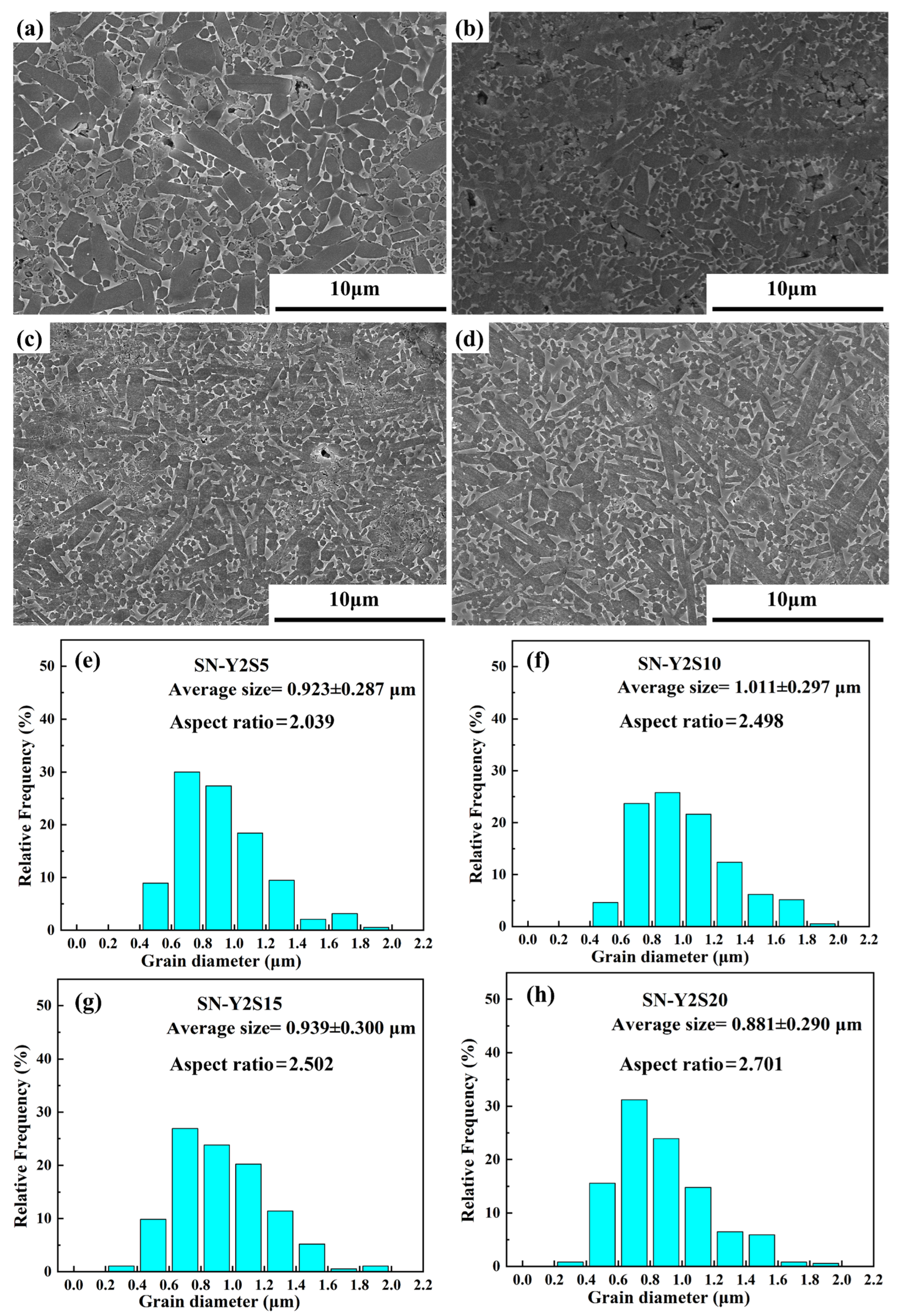

3.4. The Effect of Additive Content on Grain Size

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bocanegra-Bernal, M.; Matovic, B. Mechanical properties of silicon nitride-based ceramics and its use in structural applications at high temperatures. Mater. Sci. Eng. A 2010, 527, 1314–1338. [Google Scholar] [CrossRef]

- Zhou, Y.; Hyuga, H.; Kusano, D.; Yoshizawa, Y.-I.; Ohji, T.; Hirao, K. Development of high-thermal-conductivity silicon nitride ceramics. J. Asian Ceram. Soc. 2015, 3, 221–229. [Google Scholar] [CrossRef] [Green Version]

- Dong, X.; Wu, J.; Yu, H.; Zhou, Q.; Wang, W.; Zhang, X.; Zhang, L.; Li, L.; He, R. Additive manufacturing of silicon nitride ceramics: A review of advances and perspectives. Int. J. Appl. Ceram. Technol. 2022, 19, 2929–2949. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, Y.; Gong, H.; Nie, L.; Zhao, L. Effects of sintering aids on mechanical and dielectric properties of Si3N4 ceramics. Mater. Res. Innov. 2010, 14, 338–341. [Google Scholar] [CrossRef]

- Batha, H.D.; Whitney, E.D. Kinetics and mechanism of the thermal decomposition of Si3N4. J. Am. Ceram. Soc. 1973, 56, 365–369. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, J.-D.; Suh, J. Microstructural variations and machining characteristics of silicon nitride ceramics from increasing the temperature in laser assisted machining. Int. J. Precis. Eng. Manuf. 2014, 15, 1269–1274. [Google Scholar] [CrossRef]

- Tatami, J.; Hiratsuka, D.; Okada, S.; Komeya, K.; Wakihara, T. Analysis of sintering behavior of silicon nitride based on master sintering curve theory of liquid phase sintering. J. Ceram. Soc. Jpn. 2016, 124, 375–380. [Google Scholar] [CrossRef] [Green Version]

- Liu, W.; Tong, W.; Lu, X.; Wu, S. Effects of different types of rare earth oxide additives on the properties of silicon nitride ceramic substrates. Ceram. Int. 2019, 45, 12436–12442. [Google Scholar] [CrossRef]

- Han, W.; Li, Y.; Chen, G.; Yang, Q. Effect of sintering additive composition on microstructure and mechanical properties of silicon nitride. Mater. Sci. Eng. A 2017, 700, 19–24. [Google Scholar] [CrossRef]

- Gomez, E.; Echeberria, J.; Iturriza, I.; Castro, F. Liquid phase sintering of SiC with additions of Y2O3, Al2O3 and SiO2. J. Eur. Ceram. Soc. 2004, 24, 2895–2903. [Google Scholar] [CrossRef]

- Luo, C.; Zhang, Y.; Deng, T. Pressureless sintering of high performance silicon nitride ceramics at 1620 °C. Ceram. Int. 2021, 47, 29371–29378. [Google Scholar] [CrossRef]

- Tatli, Z.; Thompson, D.P. Low temperature densification of silicon nitride using Li2O-based surface coatings. Ceram. Int. 2012, 38, 15–21. [Google Scholar] [CrossRef]

- Perera, D.S.; Mitchell, D.R.G.; Leung, S. High aspect ratio β-Si3N4 grain growth. J. Eur. Ceram. Soc. 2000, 20, 789–794. [Google Scholar] [CrossRef]

- Li, Y.; Kim, H.N.; Wu, H.; Kim, M.J.; Kim, H.D. Microstructure and thermal conductivity of gas-pressure-sintered Si3N4 ceramic: The effects of Y2O3 additive content. J. Eur. Ceram. Soc. 2020, 41, 274–283. [Google Scholar] [CrossRef]

- Yamamoto, H.; Akiyama, K.; Murakami, Y. Densification behaviors and high-temperature characteristics of Si3N4 sintered bodies using Al2O3–Yb2O3 additives. J. Eur. Ceram. Soc. 2006, 26, 1059–1067. [Google Scholar] [CrossRef]

- Yin, X.; Li, X.; Zhang, L.; Cheng, L.; Liu, Y.; Pan, T. Microstructure and mechanical properties of Lu2O3-doped porous silicon nitride ceramics using phenolic resin as pore-forming agent. Int. J. Appl. Ceram. Technol. 2010, 7, 391–398. [Google Scholar] [CrossRef]

- Dressler, W.; Riedel, R. Progress in silicon-based non-oxide structural ceramics. Int. J. Refract. Met. Hard Mater. 1997, 15, 13–47. [Google Scholar] [CrossRef]

- Meng, Q.; Zhao, Z.; Sun, Y.; Li, X.; Ji, H. Low temperature pressureless sintering of dense silicon nitride using BaO-Al2O3-SiO2 glass as sintering aid. Ceram. Int. 2017, 43, 10123–10129. [Google Scholar] [CrossRef]

- Liu, X.-J.; Huang, Z.-Y.; Ge, Q.-M.; Sun, X.-W.; Huang, L.-P. Microstructure and mechanical properties of silicon nitride ceramics prepared by pressureless sintering with MgO–Al2O3–SiO2 as sintering additive. J. Eur. Ceram. Soc. 2005, 25, 3353–3359. [Google Scholar] [CrossRef]

- Joshi, P.N.; McCauley, R.A. Metal-organic Surfactants as Sintering Aids for Silicon Nitride in an Aqueous Medium. J. Am. Ceram. Soc. 1994, 77, 2926–2934. [Google Scholar] [CrossRef]

- Kingery, W.D. Densification during Sintering in the Presence of a Liquid Phase. I. Theory. J. Appl. Phys. 2004, 30, 301–306. [Google Scholar] [CrossRef]

- Rahaman, M.N. Ceramic Processing and Sintering; CRC Press: Boca Raton, FL, USA, 2017; Volume 1. [Google Scholar]

- Pyzik, A.J.; Beaman, D.R. Microstructure and properties of self-reinforced silicon nitride. J. Am. Ceram. Soc. 1993, 76, 2737–2744. [Google Scholar] [CrossRef]

- Satet, R.L.; Hoffmann, M.J. Influence of the rare-earth element on the mechanical properties of RE-Mg-bearing silicon nitride. J. Am. Ceram. Soc. 2005, 88, 2485–2490. [Google Scholar] [CrossRef]

- Satet, R.L.; Hoffmann, M.J.; Cannon, R.M. Experimental evidence of the impact of rare-earth elements on particle growth and mechanical behaviour of silicon nitride. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2006, 422, 66–76. [Google Scholar] [CrossRef]

- Becher, P.F.; Painter, G.S.; Shibata, N.; Waters, S.B.; Lin, H.-T. Effects of rare-earth (RE) intergranular adsorption on the phase transformation, microstructure evolution, and mechanical properties in silicon nitride with RE2O3 + MgO additives: RE=La, Gd, and Lu. J. Am. Ceram. Soc. 2008, 91, 2328–2336. [Google Scholar] [CrossRef]

- Jordache, M.K.; Du, H. Oxidation behavior of silicon nitride sintered with Lu2O3 additive. J. Mater. Sci. 2006, 41, 7040–7044. [Google Scholar] [CrossRef]

- Matovic, B.; Rixecker, G.; Aldinger, F. Pressureless sintering of silicon nitride with lithia and yttria. J. Eur. Ceram. Soc. 2004, 24, 3395–3398. [Google Scholar] [CrossRef]

- Huang, Z.K.; Tien, T.Y. Solid–Liquid Reaction in the System Si3N4–Y3Al5O12–Y2Si2O7 under 1 MPa of Nitrogen. J. Am. Ceram. Soc. 1994, 77, 2763–2766. [Google Scholar] [CrossRef] [Green Version]

- Murakami, Y.; Yamamoto, H. Phase equilibria in Al2O3-Y2O3-SiO2 system and phase separation and crystallization behavior of glass. J. Ceram. Soc. Jpn. 1991, 99, 215–221. [Google Scholar] [CrossRef]

- Wang, M.; Zheng, Q.; Chen, A.; Li, Y.; Zhang, X.; Zhang, D.; Jin, S.; Xiong, D.; Deng, W. Crystallization, thermal expansion and hardness of Y2O3–Al2O3–SiO2 glasses. Ceram. Int. 2021, 47, 25059–25066. [Google Scholar] [CrossRef]

- Gazzara, C.P.; Messier, D.R. Determination of phase content of Si3N4 by X-ray diffration analysis. Am. Ceram. Soc. Bull. 1977, 56, 777–780. [Google Scholar]

- Miranzo, P.; González-Julián, J.; Osendi, M.I.; Belmonte, M. Enhanced particle rearrangement during liquid phase spark plasma sintering of silicon nitride-based ceramics. Ceram. Int. 2011, 37, 159–166. [Google Scholar] [CrossRef]

- Jiang, Q.G.; Liu, W.Y.; Zhu, Z.Y.; Liu, J.; Wu, H.D.; Guo, W.M.; Wu, S.H. Fabrication of fine-grained α/β Si3N4 by Hot Pressing Flowing Sintering at 1550 °C. Ceram. Int. 2019, 45, 13958–13963. [Google Scholar] [CrossRef]

- Matovic, B.; Rixecker, G.; Boskovic, S.; Aldinger, F. Effect of LiYO2 addition on sintering behavior and indentation properties of silicon nitride ceramics. Int. J. Mater. Res. 2006, 97, 1268–1272. [Google Scholar] [CrossRef]

- Streitenberger, P.; Zöllner, D. The envelope of size distributions in Ostwald ripening and grain growth. Acta Mater. 2015, 88, 334–345. [Google Scholar] [CrossRef]

- Wang, W.; Yao, D.; Chen, H.; Xia, Y.; Zuo, K.; Yin, J.; Liang, H.; Zeng, Y.-P. ZrSi2-MgO as novel additives for high thermal conductivity of beta-Si3N4 ceramics. J. Am. Ceram. Soc. 2020, 103, 2090–2100. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon nitride: The engineering material of the future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Honma, T.; Ukyo, Y. Sintering Process of Si3N4 with Y2O3 and Al2O3 as Sintering Additives. J. Mater. Sci. Lett. 1999, 18, 735–737. [Google Scholar] [CrossRef]

- Hu, F.; Zhao, L.; Xie, Z.P. Silicon Nitride Ceramics with High Thermal Conductivity and Excellent Mechanical Properties Fabricated with MgF2 Sintering Aid and Post-Sintering Heat Treatment. J. Ceram. Sci. Technol. 2016, 7, 423–428. [Google Scholar] [CrossRef]

- Lee, C.J.; Chae, J.I.; Kim, D.J. Effect of β-Si3N4 starting powder size on elongated grain growth in β-Si3N4 ceramics. J. Eur. Ceram. Soc. 2000, 20, 2667–2671. [Google Scholar] [CrossRef]

- Romaniv, O.M.; Vasyliv, B.D. Some features of formation of the structural strength of ceramic materials. Mater. Sci. 1998, 34, 149–161. [Google Scholar] [CrossRef]

| Sample | Fraction (wt.%) | ||||

|---|---|---|---|---|---|

| Si3N4 | Y2O3 | Al2O3 | Y2S | MUL | |

| SN | 100 | - | - | - | - |

| SN-YA | 90 | 5 | 5 | - | - |

| SN-Y2S | 90 | - | - | 10 | - |

| SN-Y2SM | 90 | - | - | 5 | 5 |

| Y2S5 | 95 | - | - | 5 | - |

| Y2S10 | 90 | - | - | 10 | - |

| Y2S15 | 85 | - | - | 15 | - |

| Y2S20 | 80 | - | - | 20 | - |

| Sample | β-Si3N4 Phase Content (%) | |||||

|---|---|---|---|---|---|---|

| 1300 °C | 1400 °C | 1500 °C | 1600 °C | 1700 °C | 1800 °C | |

| SN-YA | 4.59 | 4.07 | 6.50 | 58.74 | 99.06 | 99.00 |

| SN-Y2S | 4.95 | 4.50 | 6.28 | 57.60 | 99.30 | 99.79 |

| SN-Y2SM | 4.62 | 4.73 | 6.62 | 55.62 | 99.34 | 99.45 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Huang, N.; Lu, D.; Sheng, P.; Zou, W. A Study on the Effects of Liquid Phase Formation Temperature and the Content of Sintering Aids on the Sintering of Silicon Nitride Ceramics. Crystals 2023, 13, 1099. https://doi.org/10.3390/cryst13071099

He L, Huang N, Lu D, Sheng P, Zou W. A Study on the Effects of Liquid Phase Formation Temperature and the Content of Sintering Aids on the Sintering of Silicon Nitride Ceramics. Crystals. 2023; 13(7):1099. https://doi.org/10.3390/cryst13071099

Chicago/Turabian StyleHe, Li, Niansheng Huang, Donglin Lu, Pengfei Sheng, and Wenjing Zou. 2023. "A Study on the Effects of Liquid Phase Formation Temperature and the Content of Sintering Aids on the Sintering of Silicon Nitride Ceramics" Crystals 13, no. 7: 1099. https://doi.org/10.3390/cryst13071099

APA StyleHe, L., Huang, N., Lu, D., Sheng, P., & Zou, W. (2023). A Study on the Effects of Liquid Phase Formation Temperature and the Content of Sintering Aids on the Sintering of Silicon Nitride Ceramics. Crystals, 13(7), 1099. https://doi.org/10.3390/cryst13071099