Simulations and Experiments on the Microstructure and Property Evolution of In Situ TiC+Al3Ti-Reinforced Aluminum Coatings on AZ91D Magnesium Alloy

Abstract

:1. Introduction

2. Simulation

2.1. Simulation of Coatings with Different (Ti+B4C) Contents

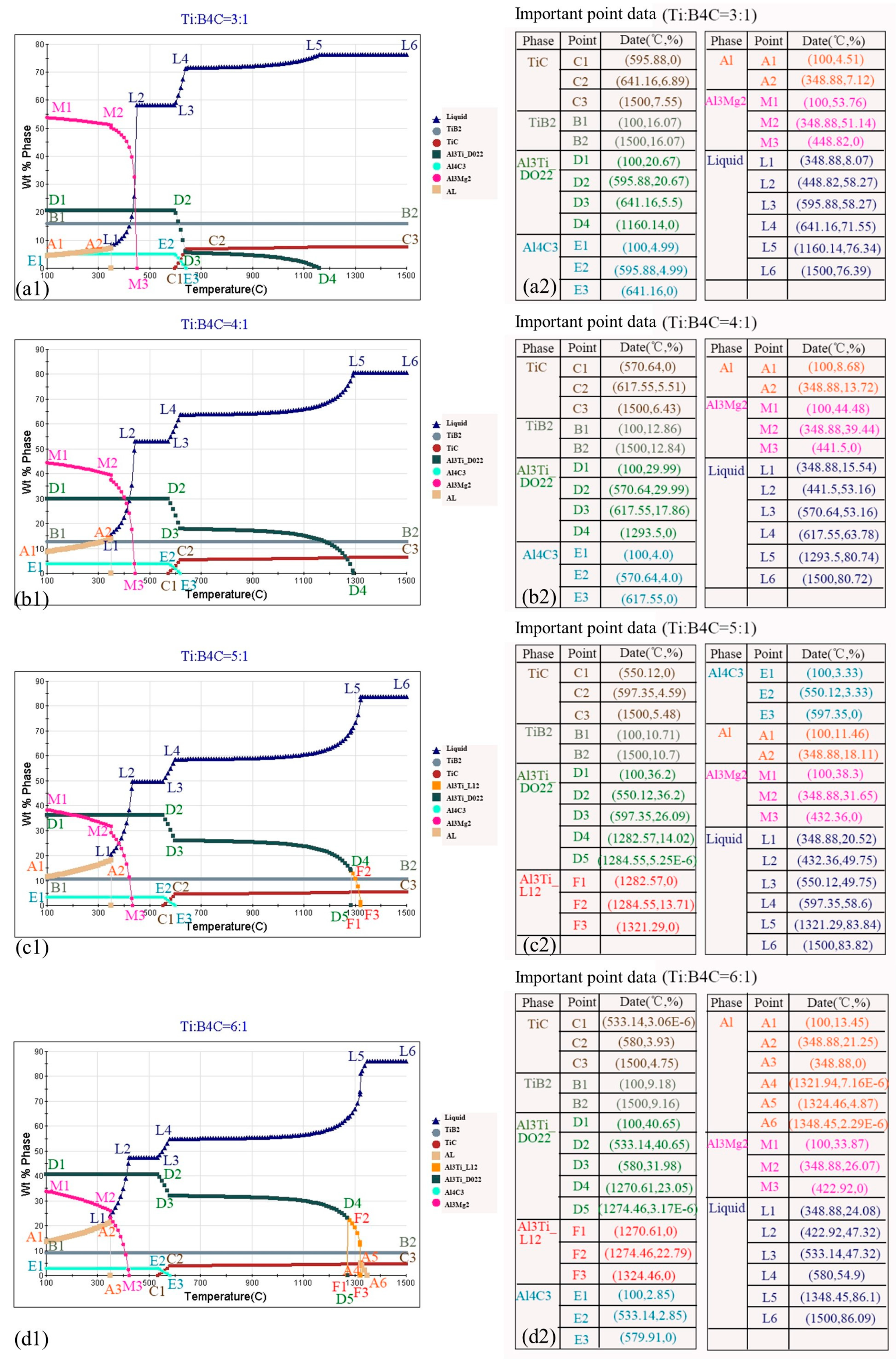

2.2. Simulation of Coatings with Different Ratios of Ti to B4C

2.3. Simulation of Coatings with Consideration of Mg Dilution

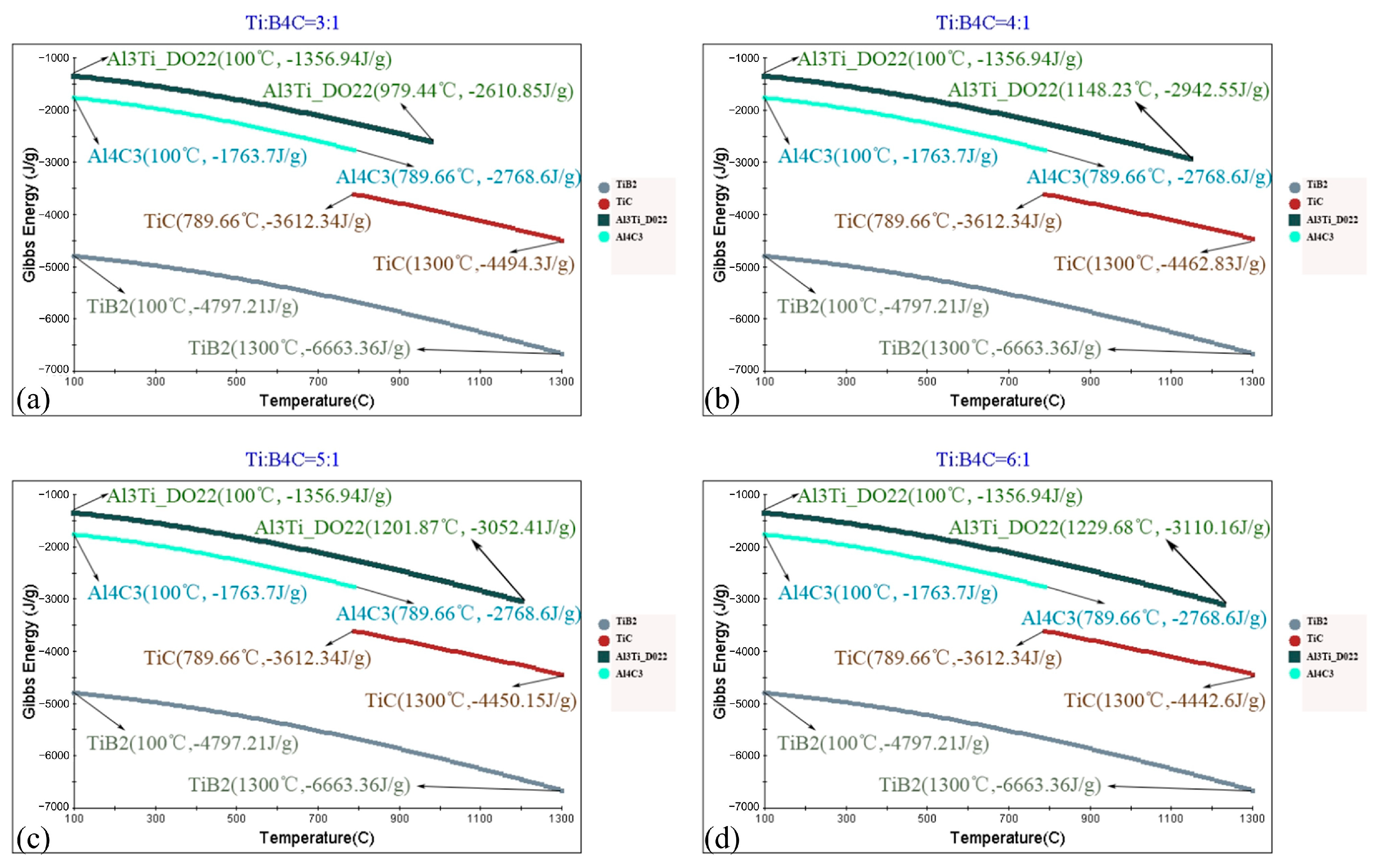

2.4. Thermodynamic Simulation

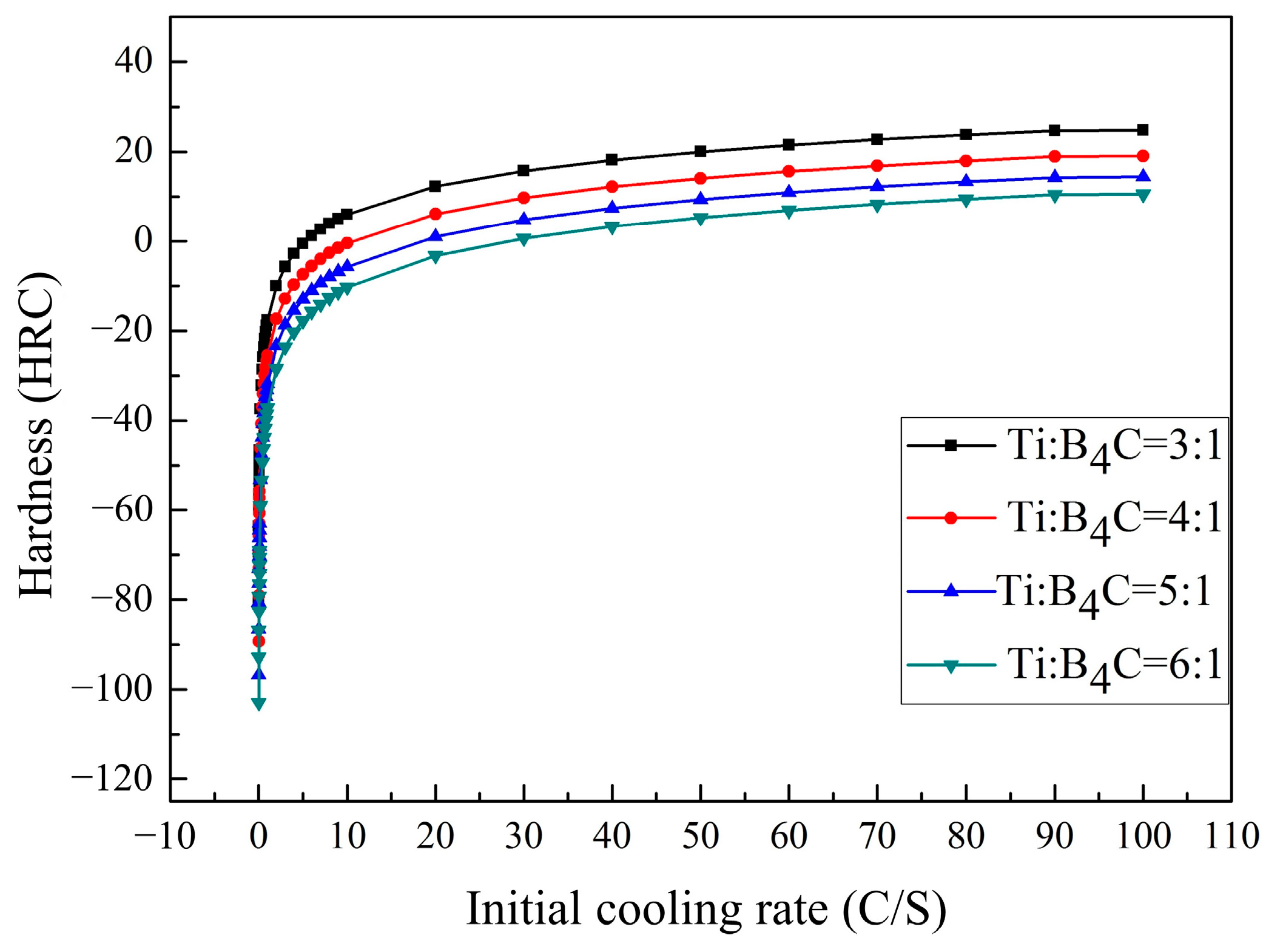

2.5. Simulation of Coating Hardness

3. Experiments

3.1. Materials and Methods

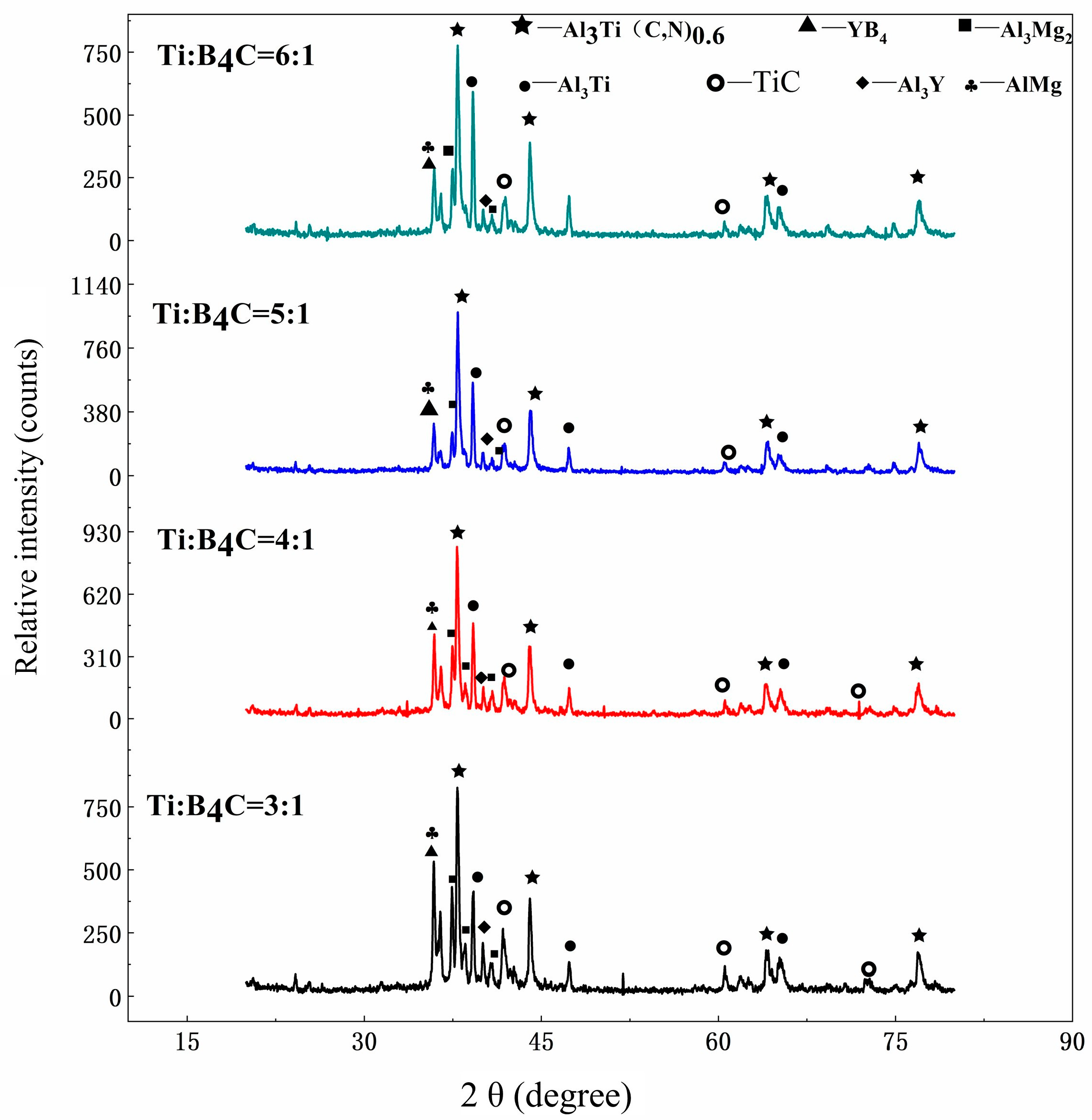

3.2. Phase Analysis

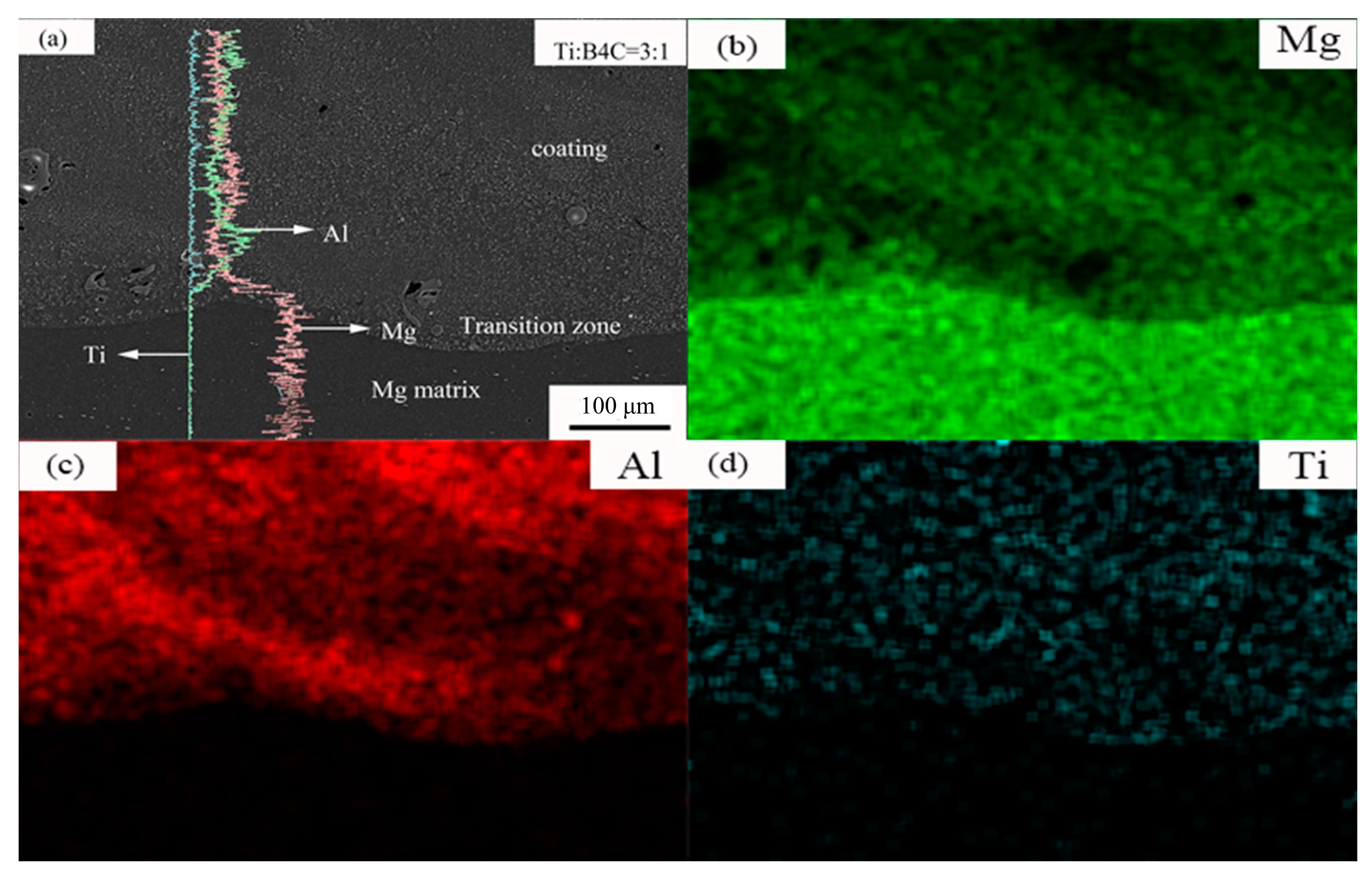

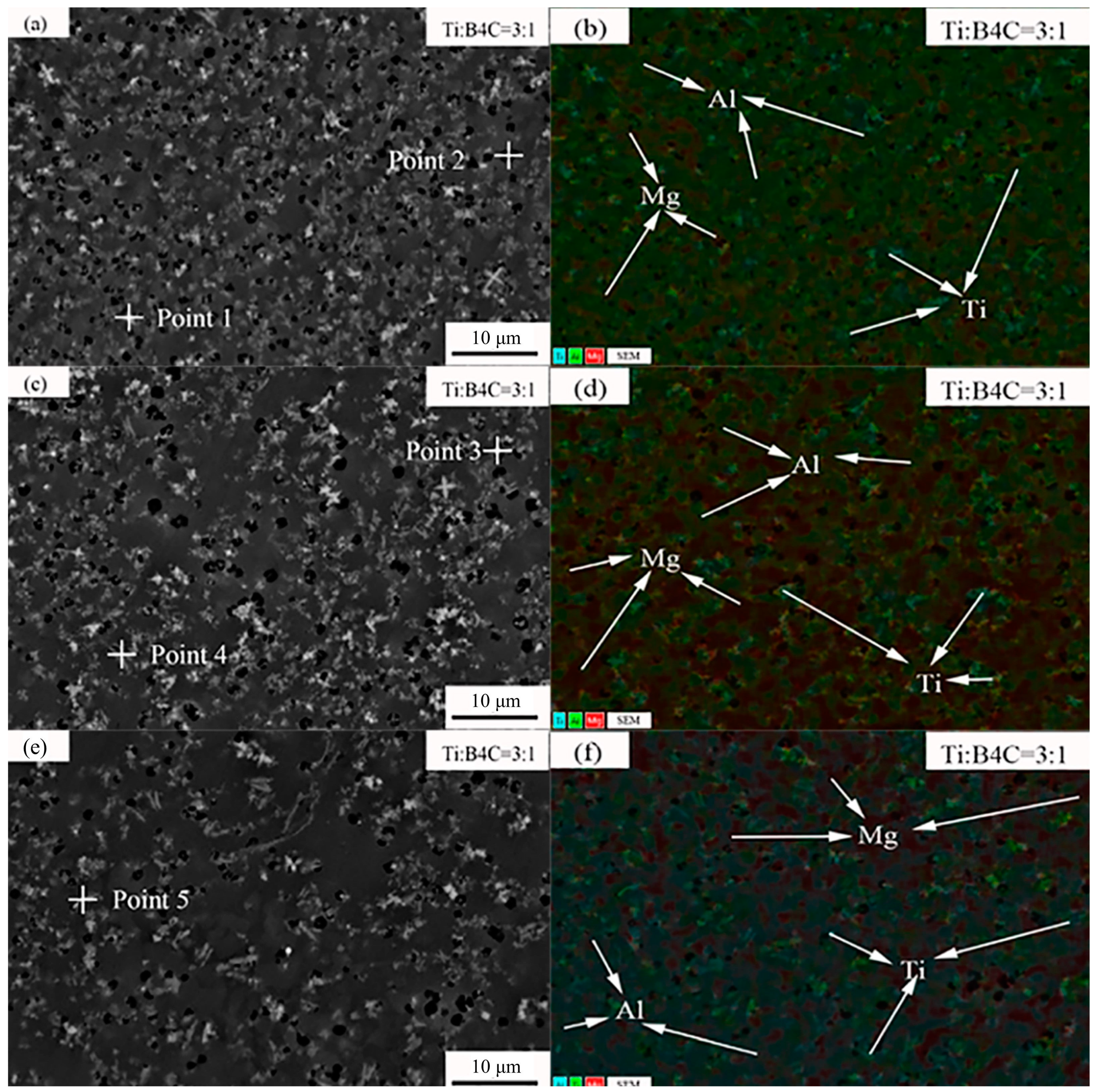

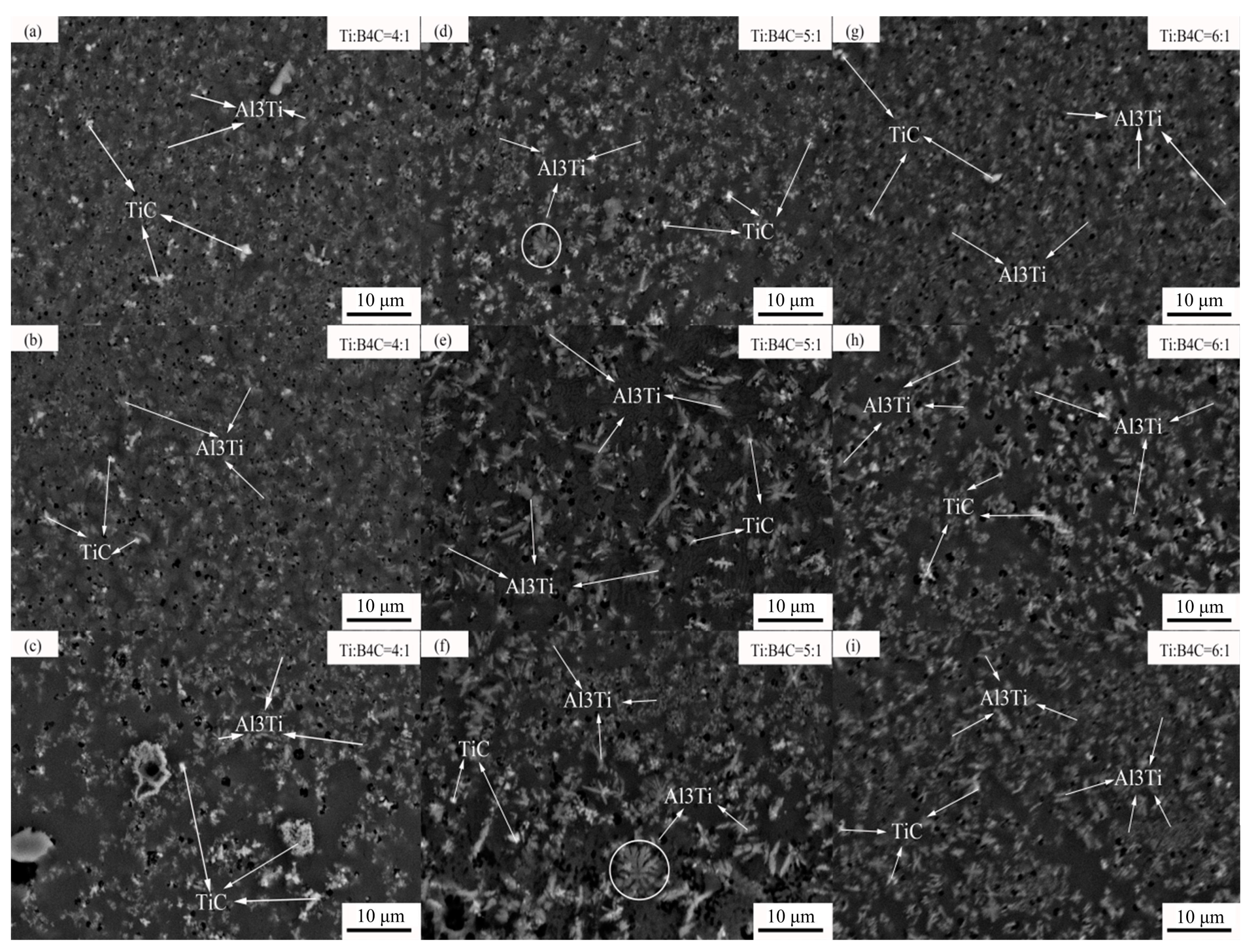

3.3. Microstructure

4. Coating Performance Test

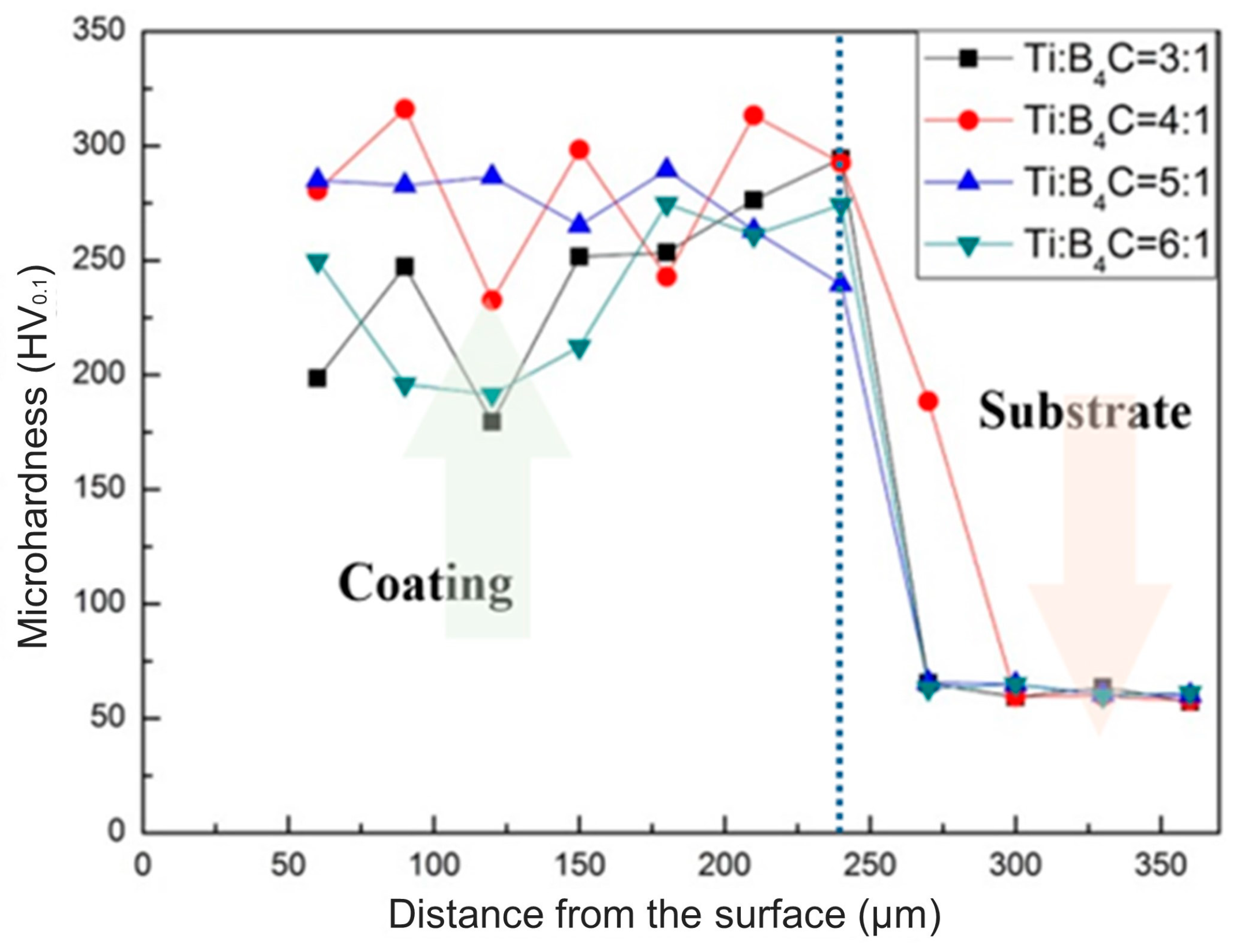

4.1. Micro-Hardness

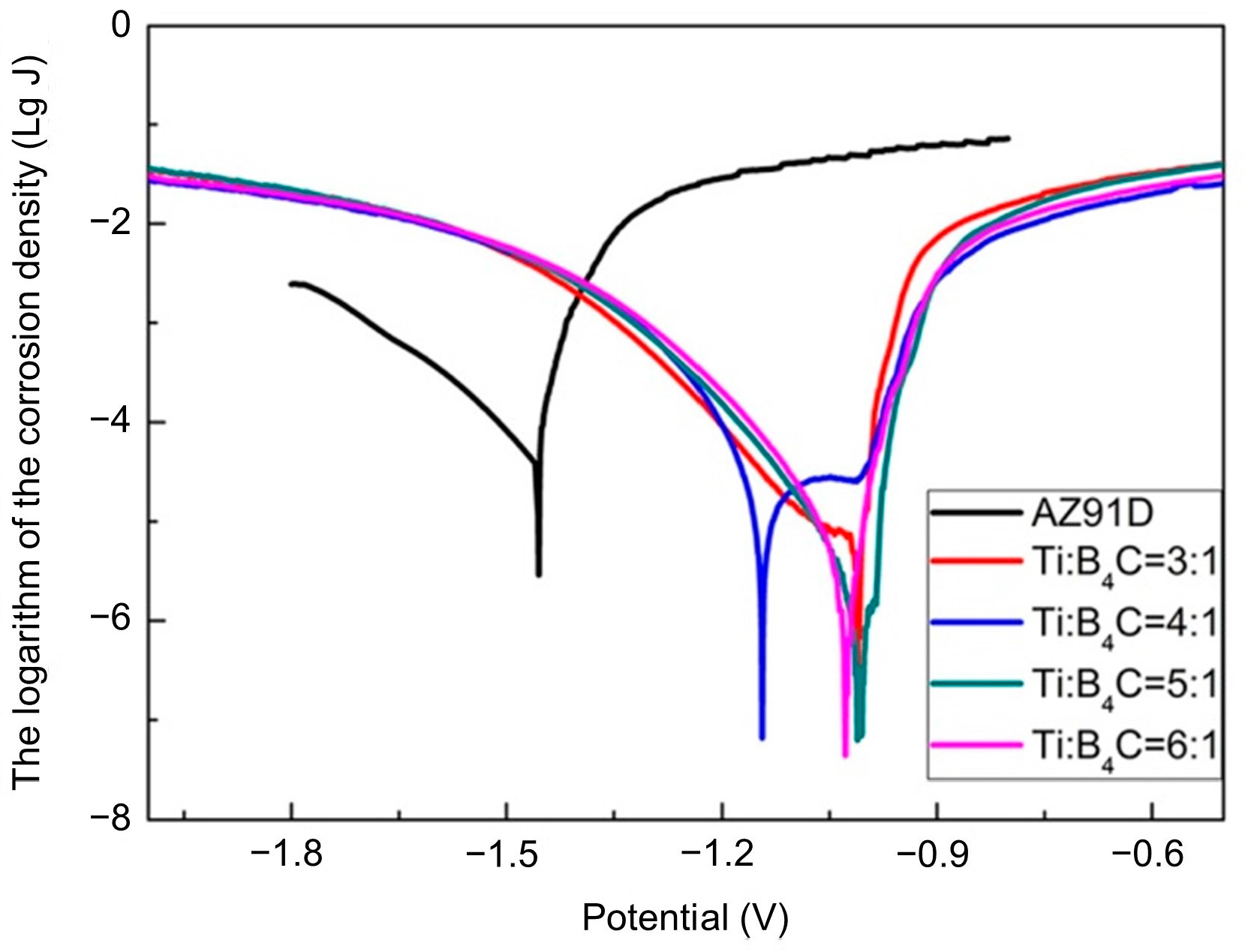

4.2. Corrosion

5. Conclusions

- (1)

- According to the simulation results, TiB2, TiC, Al3Ti_DO22, Al4C3 and Al were formed in the laser-cladded coating while Al, TiB2, TiC, Al3Ti_DO22, Al4C3, and Al3Mg2 were formed in the transition zone between the coating and the base metal. Al3Ti_L12 was formed in the transition zone when the ratio of Ti to B4C was 5:1 or 6:1. With an increase in the ratio of Ti to B4C, the content of Al3Ti gradually increased. In contrast, the content of TiC gradually decreased.

- (2)

- An Al–TiC coating was successfully prepared via laser cladding on AZ91D magnesium alloy. A TiC ceramic phase was generated in situ during laser cladding. AlTi3(C, N)0.6, AlMg, Al3Mg2, Al3Ti, TiC, and Al3Y were found in the coating. When the ratio of Ti to B4C was 5:1, the coating had the best performance.

- (3)

- The hardness of the coating was much higher than that of the AZ91D magnesium alloy substrate. According to the simulation results, the hard phase was generated during the laser cladding process, which greatly improved the performance of the coating. When the ratio of Ti to B4C was 5:1, the coating had the highest average hardness (273 HV), which is about 4.6 times higher than that of the magnesium alloy substrate.

- (4)

- The corrosion resistance of the laser-treated coating was better than that of the substrate. When the ratio of Ti to B4C was 5:1, the corrosion potential of the coating was −1.012 V, which is higher than that of the substrate (−1.455 V). The corrosion current density of the coating was 2.501 × 10−6, which is two orders lower than that of AZ91D magnesium alloy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Riquelme, A.; Rodrigo, P. An Introduction on the Laser Cladding Coatings on Magnesium Alloys. Metals 2021, 11, 1993. [Google Scholar] [CrossRef]

- Istrate, B.; Munteanu, C.; Antoniac, I.V.; Lupescu, S.C. Current Research Studies of Mg-Ca-Zn Biodegradable Alloys Used as Orthopedic Implants-Review. Crystals 2022, 12, 1468. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Guo, J.; Xu, G.D.; Li, Z.Y.; Wei, S.Z. Effect of Nd2O3 on microstructure, corrosion and wear properties of laser cladding Zr-based amorphous composite coatings on AZ91D magnesium alloy. Appl. Surf. Sci. 2023, 611, 155587. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Li, Z.Y.; Liu, S.Y.; Wei, S.Z. Al-WC composite coating on AZ91D Mg alloy by low power pulsed laser cladding. Kov. Mater. 2020, 58, 169–179. [Google Scholar] [CrossRef]

- Ren, Z.Q.; Zhao, Y.; Han, G.F.; Wang, W.Y.; Zhou, K.B.; He, T.P.; Sun, Y. Laser-Arc Hybrid Cladding of Al-Mg Alloy Coating on AZ80 Mg Alloy: Effect of Laser Beam Oscillations Amplitude. Materials 2022, 15, 7272. [Google Scholar] [CrossRef]

- Zhang, Y.Q.; Jin, K.; Li, Z.Y.; Wei, S.Z.; Guo, J. Microstructures, Wear and Corrosion Behaviors of Laser Cladding In Situ Synthetic Al3Ti/AlNi/AlNi3/MgNi2 Composite Coatings on Magnesium Alloy using Al as Middle Layer. J. Mater. Eng. Perform. 2022, 32, 4216–4228. [Google Scholar] [CrossRef]

- Yao, H.; Li, Z.Y.; Zhang, Y.Q.; Wei, S.Z.; Xu, G.D.; Yan, S.; Ren, J.L. Study on laser cladding system of the high-entropy alloy layer on the AZ91D magnesium. J. Laser Appl. 2022, 34, 032007. [Google Scholar] [CrossRef]

- Li, N.; Wang, Q.; Dong, F.; Liu, X.; Han, P.; Han, Y. Research Progress of Coating Preparation on Light Alloys in Aviation Field: A Review. Materials 2022, 15, 8535. [Google Scholar] [CrossRef]

- Wan, X.F.; Tian, C.; Li, Y.; Zhou, J.L.; Qian, S.Q.; Su, L.H.; Wang, L. Effect of Y2O3 Addition on Microstructure and Properties of Laser Cladded Al-Si Coatings on AZ91D Magnesium Alloy. Materials 2023, 16, 338. [Google Scholar] [CrossRef]

- Jiang, L.P.; Cui, X.F.; Jin, G.; Tian, H.L.; Tian, Z.M.; Zhang, X.R.; Wan, S.M. Synthesis and microstructure, properties characterization of Ni-Ti-Cu/Cu-Al functionally graded coating on Mg-Li alloy by laser cladding. Appl. Surf. Sci. 2022, 575, 151645. [Google Scholar] [CrossRef]

- Qi, Z.W.; Chen, C.Y.; Wang, C.Y.; Zhou, Z.K.; Zhou, J.; Long, Y. Effect of different laser wavelengths on laser cladding of pure copper. Surf. Coat. Technol. 2023, 454, 129181. [Google Scholar] [CrossRef]

- Baltatu, M.S.; Sandu, A.V.; Nabialek, M.; Vizureanu, P.; Ciobanu, G. Biomimetic Deposition of Hydroxyapatite Layer on Titanium Alloys. Micromachines 2021, 12, 1447. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.Y.; Gao, S.Y.; Zhao, W. Laser cladding of Mg-Zn-Y-Zr alloy using Al with different ratios of micro- and nano-SiC powder. J. Mater. Sci. 2020, 55, 13270–13293. [Google Scholar] [CrossRef]

- Yue, T.M.; Su, Y.P. Laser cladding of SiC reinforced Zr65Al7.5Ni10Cu17.5 amorphous coating on magnesium substrate. Appl. Surf. Sci. 2008, 255, 1692–1698. [Google Scholar] [CrossRef]

- Carcel, B.; Sampedro, J.; Ruescas, A.; Toneu, X. Corrosion and wear resistance improvement of magnesium alloys by laser cladding with Al-Si. Phys. Procedia 2011, 12, 353–363. [Google Scholar] [CrossRef] [Green Version]

- Muvvala, G.; Karmakar, D.P.; Nath, A.K. In-process detection of microstructural changes in laser cladding of in-situ Inconel 718/TiC metal matrix composite coating. J. Alloys Compd. 2018, 740, 545–558. [Google Scholar] [CrossRef]

- Liu, Y.H.; Ding, J.Q.; Qu, W.C.; Su, Y.; Yu, Z.S. Microstructure Evolution of TiC Particles In Situ, Synthesized by Laser Cladding. Materials 2017, 10, 281. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.G.; Chen, C.Z.; Ma, J.; Zhang, G. In situ synthesis of hydroxyapatite coating by laser cladding. Colloids Surf. B Biointerfaces 2008, 66, 155–162. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Li, G.J. Effect of Y2O3 on the sliding wear resistance of TiB/TiC-reinforced composite coatings fabricated by laser cladding. Wear 2014, 310, 72–82. [Google Scholar] [CrossRef]

- Li, Q.T.; Lei, Y.P.; Fu, H.G. Laser cladding in-situ NbC particle reinforced Fe-based composite coatings with rare earth oxide addition. Surf. Coat. Technol. 2014, 239, 102–107. [Google Scholar] [CrossRef]

- Savalani, M.M.; Ng, C.C.; Li, Q.H.; Man, H.C. In situ formation of titanium carbide using titanium and carbon-nanotube powders by laser cladding. Appl. Surf. Sci. 2012, 258, 3173–3177. [Google Scholar] [CrossRef]

- Pu, Y.; Guo, B.; Zhou, J.; Zhang, S.; Zhou, H.; Chen, J. Microstructure and tribological properties of in situ synthesized TiC, TiN, and SiC reinforced Ti3Al intermetallic matrix composite coatings on pure Ti by laser cladding. Appl. Surf. Sci. 2008, 255, 2697–2703. [Google Scholar] [CrossRef]

- Yang, L.; Li, Z.; Zhang, Y.; Wei, S.; Liu, F. Al-TiC in situ composite coating fabricated by low power pulsed laser cladding on AZ91D magnesium alloy. Appl. Surf. Sci. 2018, 435, 1187–1198. [Google Scholar] [CrossRef]

- Prasanthi, T.N.; Sudha, R.C.; Saroja, S. Explosive cladding and post-weld heat treatment of mild steel and titanium. Mater. Des. 2016, 93, 180–193. [Google Scholar] [CrossRef]

- Rai, A.K.; Trpathy, H.; Hajra, R.N.; Raju, S.; Saroja, S. Thermophysical properties of Ni based super alloy 617. J. Alloys Compd. 2016, 698, 442–450. [Google Scholar] [CrossRef]

- Park, J.; Lee, S.; Kang, S.; Jeon, J.; Lee, S.H.; Kim, H.K.; Choi, H. Complex effects of alloy composition and porosity on the phase transformations and mechanical properties of powder metallurgy steels. Powder Technol. 2015, 284, 459–466. [Google Scholar] [CrossRef]

- Shim, J.-H.; Hwang, B.; Lee, M.-G.; Lee, J. “Invited Paper” Computer-aided alloy designs of grade 600 MPa reinforced steel bars for seismic safety based on thermodynamic and kinetic calculations: Overview. Calphad 2018, 62, 67–74. [Google Scholar] [CrossRef]

| Chemical Composition | Mg | Al | Zn | Mn | Si | Be | Others |

|---|---|---|---|---|---|---|---|

| Relative amount (%) | 89.97 | 8.99 | 0.71 | 0.25 | 0.048 | 0.0071 | ≤0.002 |

| The Parameters | Value |

|---|---|

| Velocity (mm/min) | 150 |

| Pulse width (ms) | 4 |

| Current (A) | 120 |

| Frequency (HZ) | 18 |

| Overlap rate (%) | 50 |

| Point | Mg | Al | Ti | C | Si | O |

|---|---|---|---|---|---|---|

| 1 | 18.3 | 28.3 | 23.2 | 30.2 | - | - |

| 2 | 32.2 | 59.9 | 5.7 | - | 2.1 | - |

| 3 | 24.8 | 21.6 | 24.1 | 28.5 | - | - |

| 4 | 29.6 | 23.3 | 15.1 | 26.1 | 0.5 | 5.4 |

| 5 | 37.5 | 51.8 | 9.5 | - | 1.3 | - |

| Specimen Group | Corrosion Potential (V) | Corrosion Current Density (A/cm2) |

|---|---|---|

| AZ91D | −1.455 | 1.444 × 10−4 |

| Ti:B4C = 3:1 | −1.011 | 1.785203 × 10−4 |

| Ti:B4C = 4:1 | −1.145 | 2.389 × 10−5 |

| Ti:B4C = 5:1 | −1.012 | 2.501 × 10−6 |

| Ti:B4C = 6:1 | −1.028 | 4.596 × 10−6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, L.; Li, Z.; Li, B.; Zhang, Y.; Wei, S.; Jia, Y. Simulations and Experiments on the Microstructure and Property Evolution of In Situ TiC+Al3Ti-Reinforced Aluminum Coatings on AZ91D Magnesium Alloy. Crystals 2023, 13, 1151. https://doi.org/10.3390/cryst13071151

Yang L, Li Z, Li B, Zhang Y, Wei S, Jia Y. Simulations and Experiments on the Microstructure and Property Evolution of In Situ TiC+Al3Ti-Reinforced Aluminum Coatings on AZ91D Magnesium Alloy. Crystals. 2023; 13(7):1151. https://doi.org/10.3390/cryst13071151

Chicago/Turabian StyleYang, Liuqing, Zhiyong Li, Boqiong Li, Yingqiao Zhang, Shouzheng Wei, and Yanlong Jia. 2023. "Simulations and Experiments on the Microstructure and Property Evolution of In Situ TiC+Al3Ti-Reinforced Aluminum Coatings on AZ91D Magnesium Alloy" Crystals 13, no. 7: 1151. https://doi.org/10.3390/cryst13071151