Effect of Ultrasonic Vibration on Tensile Mechanical Properties of Mg-Zn-Y Alloy

Abstract

:1. Introduction

2. Experimental Procedures

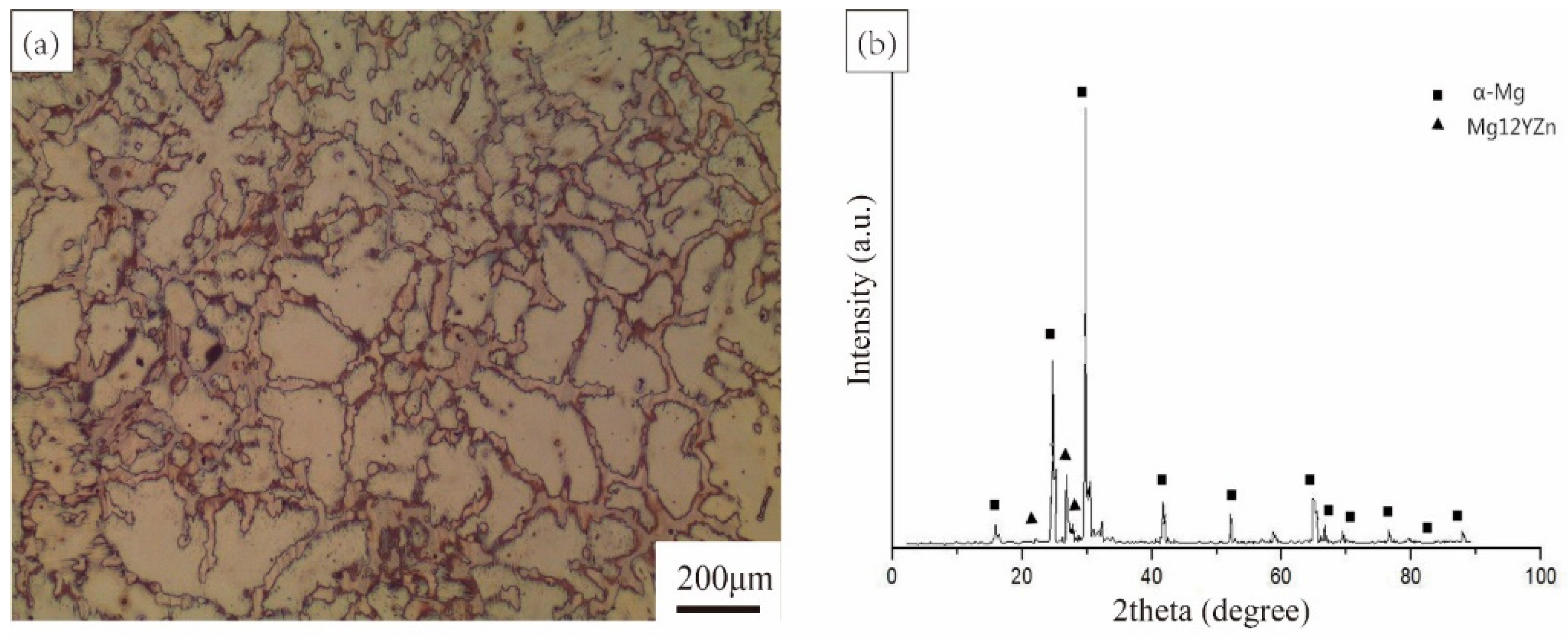

2.1. Specimen Preparation

2.2. Experimental Setup

3. Results and Discussion

3.1. Effect of the Ultrasonic Vibration on Flow Stress

3.2. Effects of Ultrasonic Vibration on Microstructure

3.2.1. Microstructure

3.2.2. Dislocation Structure

3.2.3. Fracture Morphology

4. Discussion

4.1. Johnson–Cook Model of Mg98.5Zn0.5Y1 Alloy without Vibration

4.2. Johnson–Cook Model of Mg98.5Zn0.5Y1 Alloy with Vibration

4.3. Verification of the Constitutive Equations

5. Finite Element Simulation

5.1. Effect of Ultrasonic Vibration on Stress-Strain Distribution during the Tensile Process

5.2. Effect of Ultrasonic Vibration on Material Flow Behavior

6. Conclusions

- (1)

- In the ultrasonic vibration stretching process, both the amplitude and frequency of vibration affected the flow behavior of Mg98.5Zn0.5Y1 alloy during the stretching process. The acoustic softening effect caused by ultrasonic vibration is gradually obvious with the increase of amplitude. A comparison of the stress-strain curves at various frequencies and amplitudes leads to the conclusion that amplitude has a more significant effect on the flow stresses of Mg98.5Zn0.5Y1 alloy when compared to vibration frequency.

- (2)

- A hybrid constitutive model coupling the frequency and amplitude of ultrasonic vibration is developed based on the modified Johnson Cook model. Comparing to the measured stress, it is evident that the proposed Johnson-Cook model aligns well with the experimental data, exhibiting a maximum error in the flow stress estimate of only 2.62. That indicates the proposed JC model is very suitable for the flow behavior prediction of Mg98.5Zn0.5Y1 alloy with and without UV.

- (3)

- The finite element analysis results show that ultrasonic vibration has a great influence on the stress-strain distribution in the stretching process. There is great potential in applying vibration-assisted ultrasonic vibration methods to the thermal processing of magnesium alloys. Examples of such applications include vibration-assisted additive manufacturing and vibration-assisted stamping. It can effectively improve the formability of magnesium alloy and improve the quality of formed parts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Song, J.; She, J.; Chen, D.; Pan, F. Latest research advances on magnesium and magnesium alloys worldwide. J. Magnes. Alloys 2020, 8, 1–41. [Google Scholar] [CrossRef]

- Yin, Z.; Qi, W.; Zeng, R.; Chen, X.; Gu, C.; Guan, S.; Zheng, Y. Advances in coatings on biodegradable magnesium alloys. J. Magnes. Alloys 2020, 8, 42–65. [Google Scholar] [CrossRef]

- Doege, E.; Dröder, K. Sheet metal forming of magnesium wrought alloys -formability and process technology. J. Mater. Process. Technol. 2001, 115, 14–19. [Google Scholar] [CrossRef]

- Wang, L.; Qiao, Q.; Liu, Y.; Song, X. Formability of AZ31 Mg alloy sheets within medium temperatures. J. Magnes. Alloys 2013, 1, 312–317. [Google Scholar] [CrossRef]

- Liu, N.; Lai, Z.; Cao, Q.; Han, X.; Huang, Y.; Li, X.; Chen, M.; Li, L. Effects of air on metallic sheet deformation by electromagnetic forming. Int. J. Adv. Manuf. Technol. 2019, 103, 311–324. [Google Scholar] [CrossRef]

- Fauzi, E.R.I.; Jamil, M.S.C.; Samad, Z.; Sheikh, M.A.; Najib, A.M. Influence of non-conventional beam profile on edge effects in laser forming of AISI 304 stainless steel plate. Int. J. Adv. Manuf. Technol. 2019, 104, 1593–1601. [Google Scholar] [CrossRef]

- Langenecker, B.; Frandsen, W.; Kennedy, A. Effects of ultrasound on deformation characteristics of structural metals Part 2. Acoustic heating and zone melting. Tech. Prog. Rep. 1965, 371, 14. [Google Scholar]

- Wen, T.; Wei, L.; Chen, X.; Pei, C. Effects of ultrasonic vibration on plastic deformation of AZ31 during the tensile process. Int. Miner. Metal. Mater. 2011, 18, 70–76. [Google Scholar] [CrossRef]

- Hung, J.; Hung, C. The influence of ultrasonic-vibration on hot upsetting of aluminum alloy. Ultrasonics 2005, 43, 692–698. [Google Scholar] [CrossRef]

- Siegert, K.; Ulmer, J. Superimposing ultrasonic waves on the dies in tube and wire drawing. J. Eng. Mater. Technol. 2001, 123, 517–523. [Google Scholar] [CrossRef]

- Mousavi, S.A.A.A.; Feizi, H.; Madoliat, R. Investigations on the effects of ultrasonic vibrations in the extrusion process. J. Mater. Process. Technol. 2007, 187–188, 657–661. [Google Scholar] [CrossRef]

- Aziz, S.A.; Lucas, M. Characterising the acoustoplastic effect in an ultrasonically assisted metal forming process. IOP Conf. Ser. Mater. Sci. Eng. 2012, 42, 12014–12017. [Google Scholar] [CrossRef]

- Cao, M.; Li, J.; Yuan, Y.; Zhao, C. Flexible die drawing of magnesium alloy sheet by superimposing ultrasonic vibration. Trans. Nonferrous Met. Soc. China 2017, 27, 163–171. [Google Scholar] [CrossRef]

- Bagherzadeh, S.; Abrinia, K.; Han, Q. Ultrasonic assisted equal channel angular extrusion (UAE) as a novel hybrid method for continuous production of ultra-fine grained metals. Mater. Lett. 2016, 169, 90–94. [Google Scholar] [CrossRef]

- Liao, J.; Zhang, L.; Xiang, H.; Xue, X. Mechanical behavior and microstructure evolution of AZ31 magnesium alloy sheet in an ultrasonic vibration-assisted hot tensile test. J. Alloys Compd. 2022, 895, 162575. [Google Scholar] [CrossRef]

- Yao, Z.; Kim, G.; Faidley, L.; Zou, Q.; Mei, D.; Chen, Z. Effects of superimposed high-frequency vibration on deformation of aluminum in micro/meso-scale upsetting. J. Mater. Process. Technol. 2012, 212, 640–646. [Google Scholar] [CrossRef]

- Hu, J.; Shimizu, T.; Yang, M. Investigation on dynamic impact effect of ultrasonic-assisted compression test. Mater. Sci. For. 2018, 920, 102–107. [Google Scholar] [CrossRef]

- Storck, H.; Littmann, W.; Wallaschek, J.; Mracek, M. The effect of friction reduction in presence of ultrasonic vibrations and its relevance to travelling wave ultrasonic motors. Ultrasonics 2002, 40, 379–383. [Google Scholar] [CrossRef]

- Yao, Z.; Kim, G.; Wang, Z.; Faidley, L.; Zou, Q.; Mei, D.; Chen, Z. Acoustic softening and residual hardening in aluminum: Modeling and experiments. Int. J. Plast. 2012, 39, 75–87. [Google Scholar] [CrossRef]

- Prabhakar, A.; Verma, G.C.; Krishnasamy, H.; Pandey, P.M.; Lee, M.G.; Suwas, S. Dislocation density based constitutive model for ultrasonic assisted deformation. Mech. Res. Commun. 2017, 85, 76–80. [Google Scholar] [CrossRef]

- Sedaghat, H.; Xu, W.; Zhang, L. Ultrasonic vibration-assisted metal forming: Constitutive modelling of acoustoplasticity and applications. J. Mater. Process. Technol. 2019, 265, 122–129. [Google Scholar] [CrossRef]

- Meng, B.; Cao, B.N.; Wan, M.; Wang, C.J.; Shan, D.B. Constitutive behavior and microstructural evolution in ultrasonic vibration assisted deformation of ultrathin superalloy sheet. Int. J. Mech. Sci. 2019, 157–158, 609–618. [Google Scholar] [CrossRef]

- Lin, J.; Li, J.; Liu, T.; Xie, Z.; Zhu, L.; Wang, Y.; Guan, Y. Investigation on ultrasonic vibration effects on plastic flow behavior of pure titanium: Constitutive modeling. J. Mater. Res. Technol. 2020, 9, 4978–4993. [Google Scholar] [CrossRef]

- Cao, M.Y.; Hu, H.; Jia, X.D.; Tian, S.J.; Zhao, C.C.; Han, X.B. Mechanism of ultrasonic vibration assisted upsetting of 6061 aluminum alloy. J. Manuf. Process. 2020, 59, 690–697. [Google Scholar] [CrossRef]

- Langenecker, B. Effects of ultrasound on deformation characteristics of Metals. IEEE Trans. Sonics Ultrason. 1966, 13, 1–8. [Google Scholar] [CrossRef]

- Liu, P.; Wang, R.; Liu, X.; Ren, R. Effect of surface ultrasonic rolling on evolution of surface microstructure of EA4T axle steel. J. Mater. Eng. Perform. 2021, 30, 1270–1279. [Google Scholar] [CrossRef]

- Zhou, H.; Cui, H.; Qin, Q.; Wang, H.; Shen, Y. A comparative study of mechanical and microstructural characteristics of aluminium and titanium undergoing ultrasonic assisted compression testing. Mater. Sci. Eng. A 2017, 682, 376–388. [Google Scholar] [CrossRef]

- Kamaya, M. Assessment of local deformation using EBSD: Quantification of local damage at grain boundaries. Mater. Charact. 2012, 66, 56–67. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, C.; Bi, R. Acoustic residual softening and microstructure evolution of T2 copper foil in ultrasonic vibration assisted micro-tension. Mater. Sci. Eng. A 2022, 841, 143044. [Google Scholar] [CrossRef]

- Wang, X.; Wang, C.; Liu, Y.; Liu, C.; Wang, Z.; Guo, B.; Shan, D. An energy based modeling for the acoustic softening effect on the Hall-Petch behavior of pure titanium in ultrasonic vibration assisted micro-tension. Int. J. Plast. 2021, 136, 102879. [Google Scholar] [CrossRef]

- Meng, D.A.; Zhao, X.; Li, J.; Zhao, S.; Han, Q. Mechanical behavior and microstructure of low-carbon steel undergoing low-frequency vibration-assisted tensile deformation. J. Mater. Res. 2017, 32, 3885–3893. [Google Scholar] [CrossRef]

- Deng, T.; Liu, H. A Study of Mechanical Characteristics and Microstructural Evolution of Copper-Nickel Alloy Sheet Undergoing Ultrasonic Vibration Assisted Uniaxial Tension. Mater. Sci. Eng. A 2023, 885, 145608. [Google Scholar] [CrossRef]

- Rusinko, A. Analytical description of ultrasonic hardening and softening. Ultrasonics 2011, 51, 709–714. [Google Scholar] [CrossRef] [PubMed]

- Siddiq, A.; El Sayed, T. Ultrasonic-assisted manufacturing processes: Variational model and numerical simulations. Ultrasonics 2012, 52, 521–529. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Eng. Fract. Mech. 1983, 21, 541–548. [Google Scholar]

- Frederick, J.R. Ultrasonic Engineering; Wiley: New York, NY, USA, 1965; p. 362. [Google Scholar]

- Pierce, A.D. Basic Linear Acoustics. In Springer Handbook of Acoustics; Thomas, D.R., Ed.; Springer: New York, NY, USA, 2014; pp. 29–115. [Google Scholar]

| Nominal Alloy | Actual Composition (at %) | |||

|---|---|---|---|---|

| Mg98.5Zn0.5Y1 | Mg | Zn | Y | Y/Zn |

| 98.5 | 0.5 | 1 | 2 | |

| Category | Frequency/kHz | Amplitude/μm | Strain Rate/s−1 |

|---|---|---|---|

| Tensile test | No vibration | ———— | 0.001 |

| 0.01 | |||

| 0.1 | |||

| 1 | |||

| 20 kHz/25 kHz/30 kHz | 3 μm/5 μm/7 μm | 0.001 | |

| 0.01 | |||

| 0.1 | |||

| 1 |

| Frequency | Amplitude | Initial Strain Rate/s−1 | |||

|---|---|---|---|---|---|

| 0.001 | 0.01 | 0.1 | 1 | ||

| No vibration | —— | 131.96 | 145.15 | 152.16 | 165.98 |

| 20 kHz | 3 μm | 126.78 | 137.77 | 147.55 | 161.40 |

| 5 μm | 119.33 | 131.78 | 142.80 | 151.81 | |

| 7 μm | 107.56 | 119.37 | 127.68 | 139.89 | |

| 25 kHz | 3 μm | 125.97 | 134.67 | 146.35 | 159.78 |

| 5 μm | 116.01 | 128.35 | 139.89 | 149.22 | |

| 7 μm | 105.46 | 116.67 | 124.87 | 135.67 | |

| 30 kHz | 3 μm | 123.63 | 132.41 | 145.76 | 157.91 |

| 5 μm | 115.33 | 125.31 | 137.24 | 147.82 | |

| 7 μm | 105.23 | 115.62 | 123.02 | 133.56 | |

| Amplitude/μm | A/MPa | B1/MPa | B2/MPa | B3/MPa | C |

|---|---|---|---|---|---|

| 0 | 110.18 | 521.72 | −1659.45 | 1561.44 | 0.0287 |

| 3 | 113.98 | 624.06 | −1764.68 | 2304.7 | 0.0296 |

| 5 | 70.22 | 817.34 | −2957.88 | 3085.99 | 0.0338 |

| 7 | 60.34 | 736.83 | −2587.12 | 2721.06 | 0.0362 |

| Amplitude/μm | A/MPa | B1/MPa | B2/MPa | B3/MPa | C |

|---|---|---|---|---|---|

| 0 | 110.18 | 521.72 | −1659.45 | 1561.44 | 0.0287 |

| 3 | 99.94 | 483.64 | −1411.37 | 1100.37 | 0.0302 |

| 5 | 71.04 | 756.17 | −2661.68 | 2678.3 | 0.0337 |

| 7 | 54.51 | 805.57 | −2931.22 | 3209.02 | 0.0371 |

| Amplitude/μm | A/MPa | B1/MPa | B2/MPa | B3/MPa | C |

|---|---|---|---|---|---|

| 0 | 124.43 | 160.91 | −778.08 | 730.22 | 0.082 |

| 3 | 87.35 | 651.5 | −2209.28 | 2576.18 | 0.031 |

| 5 | 69.99 | 739.15 | −2591.32 | 2611.52 | 0.0343 |

| 7 | 59.29 | 691.36 | −2414.21 | 2437.48 | 0.0384 |

| f/kHz | K1 | K2 | K3 | K4 | K5 | H | L1 | L2 | L3 | L4 | L5 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 20 | −0.02 | 0.07 | 0.10 | 0.12 | 0.04 | 0.02 | 0.97 | 1.03 | 0.97 | 1.08 | 0.97 |

| 25 | −0.03 | 0.08 | 0.11 | 0.14 | 0.04 | 0.03 | 0.98 | 1.00 | 0.97 | 1.05 | 0.97 |

| 30 | 0.008 | 0.05 | 0.07 | 0.08 | 0.04 | 0.07 | 0.99 | 1.05 | 1.07 | 1.17 | 0.97 |

| A0/Av | B1v/B1 | B2v/B2 | B3v/B3 | ||||

|---|---|---|---|---|---|---|---|

| D1 | 1.8 × 10−5 | E1 | 0.07 | G1 | 0.1 | I1 | 0.12 |

| D2 | 0.083 | E2 | −0.005 | G2 | −0.001 | I2 | −0.007 |

| D3 D4 | −0.004 1.03 | E3 | 1.14 | G3 | 1.04 | I3 | 1.29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, W.; Xu, Z.; Xiong, F.; Yang, H.; Guo, X.; San, H. Effect of Ultrasonic Vibration on Tensile Mechanical Properties of Mg-Zn-Y Alloy. Crystals 2024, 14, 39. https://doi.org/10.3390/cryst14010039

Yang W, Xu Z, Xiong F, Yang H, Guo X, San H. Effect of Ultrasonic Vibration on Tensile Mechanical Properties of Mg-Zn-Y Alloy. Crystals. 2024; 14(1):39. https://doi.org/10.3390/cryst14010039

Chicago/Turabian StyleYang, Wenju, Zhichao Xu, Feng Xiong, Haolun Yang, Xuefeng Guo, and Hongshan San. 2024. "Effect of Ultrasonic Vibration on Tensile Mechanical Properties of Mg-Zn-Y Alloy" Crystals 14, no. 1: 39. https://doi.org/10.3390/cryst14010039

APA StyleYang, W., Xu, Z., Xiong, F., Yang, H., Guo, X., & San, H. (2024). Effect of Ultrasonic Vibration on Tensile Mechanical Properties of Mg-Zn-Y Alloy. Crystals, 14(1), 39. https://doi.org/10.3390/cryst14010039