Biaxial Very High Cycle Fatigue Testing and Failure Mechanism of Welded Joints in Structural Steel Q345

Abstract

:1. Introduction

2. Experimental Setup

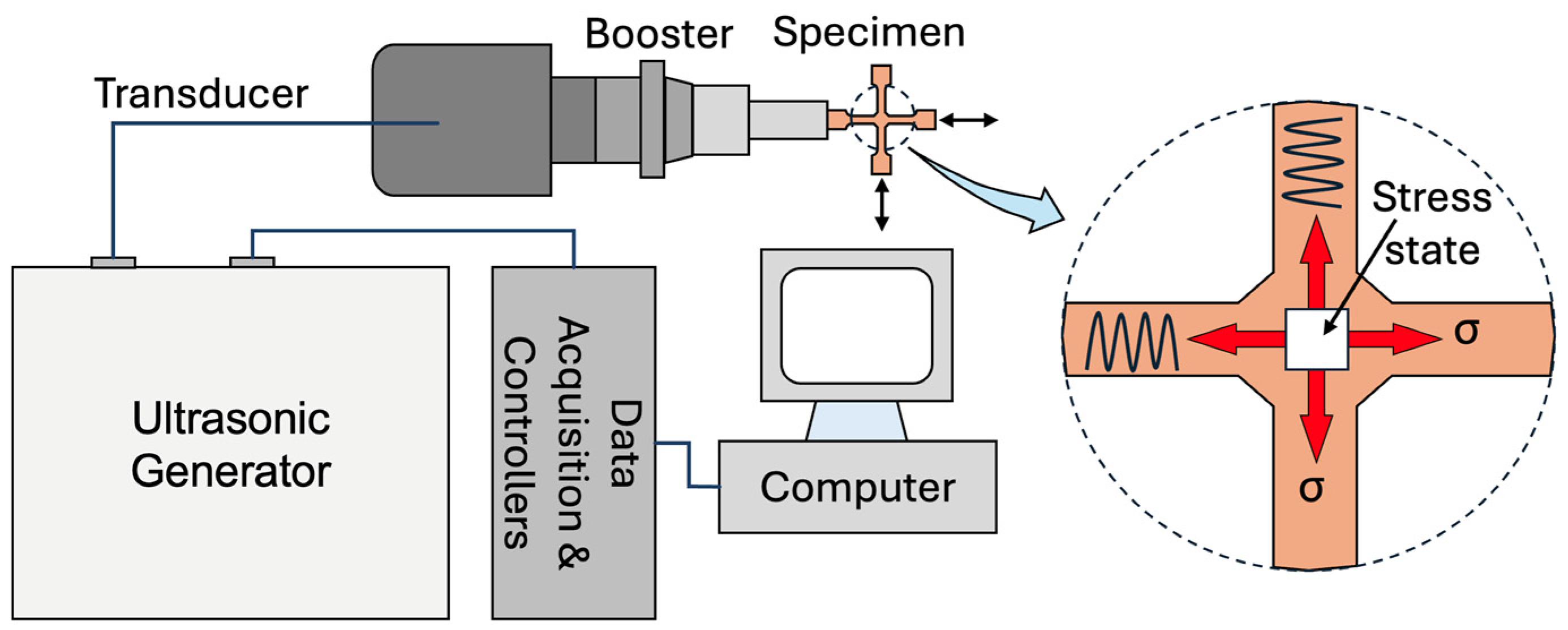

2.1. Ultrasonic Fatigue Testing

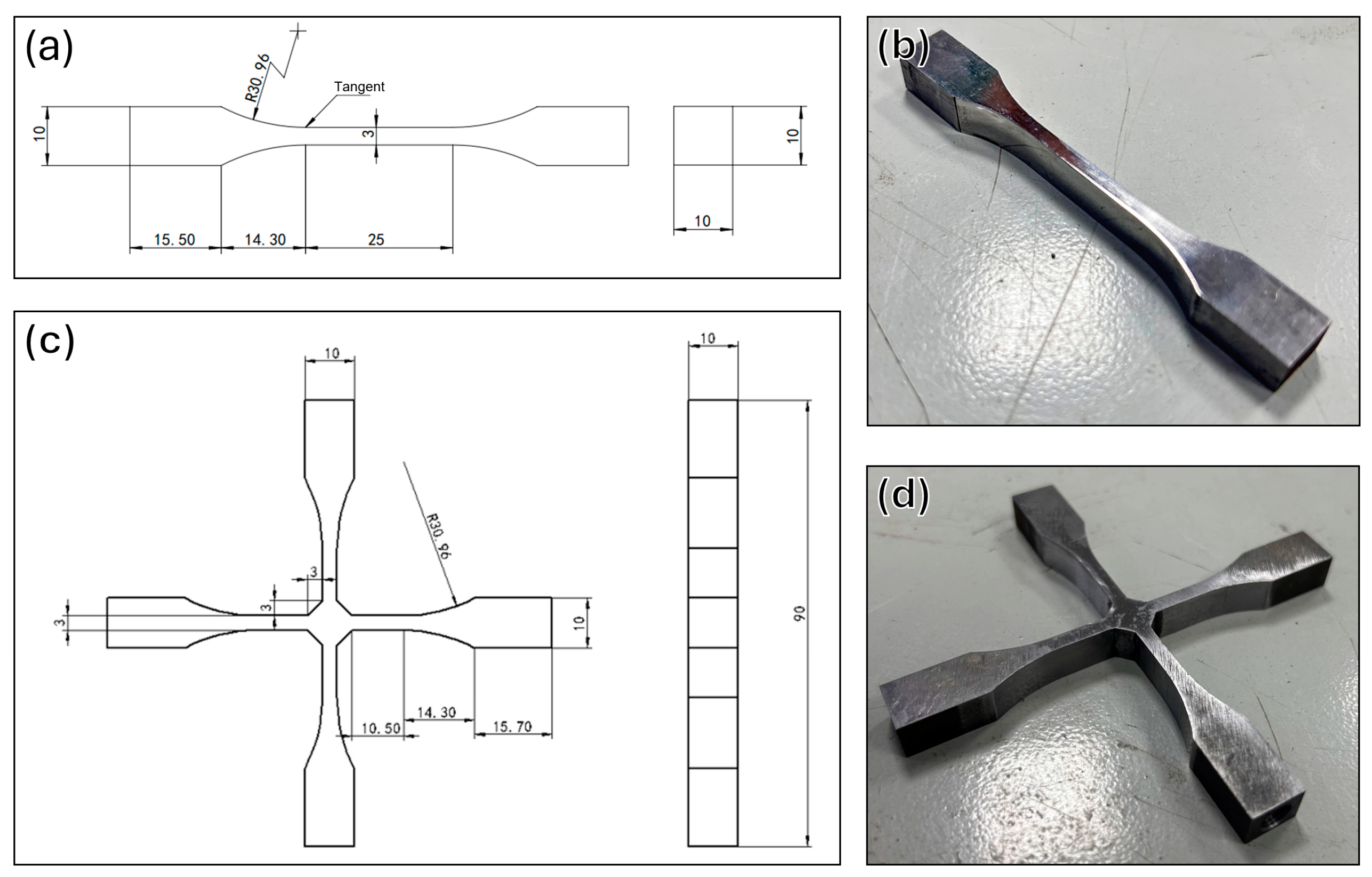

2.2. Uniaxial and Biaxial Ultrasonic Fatigue Specimens

2.3. Fatigue Testing and Failure Analysis

3. Results and Discussions

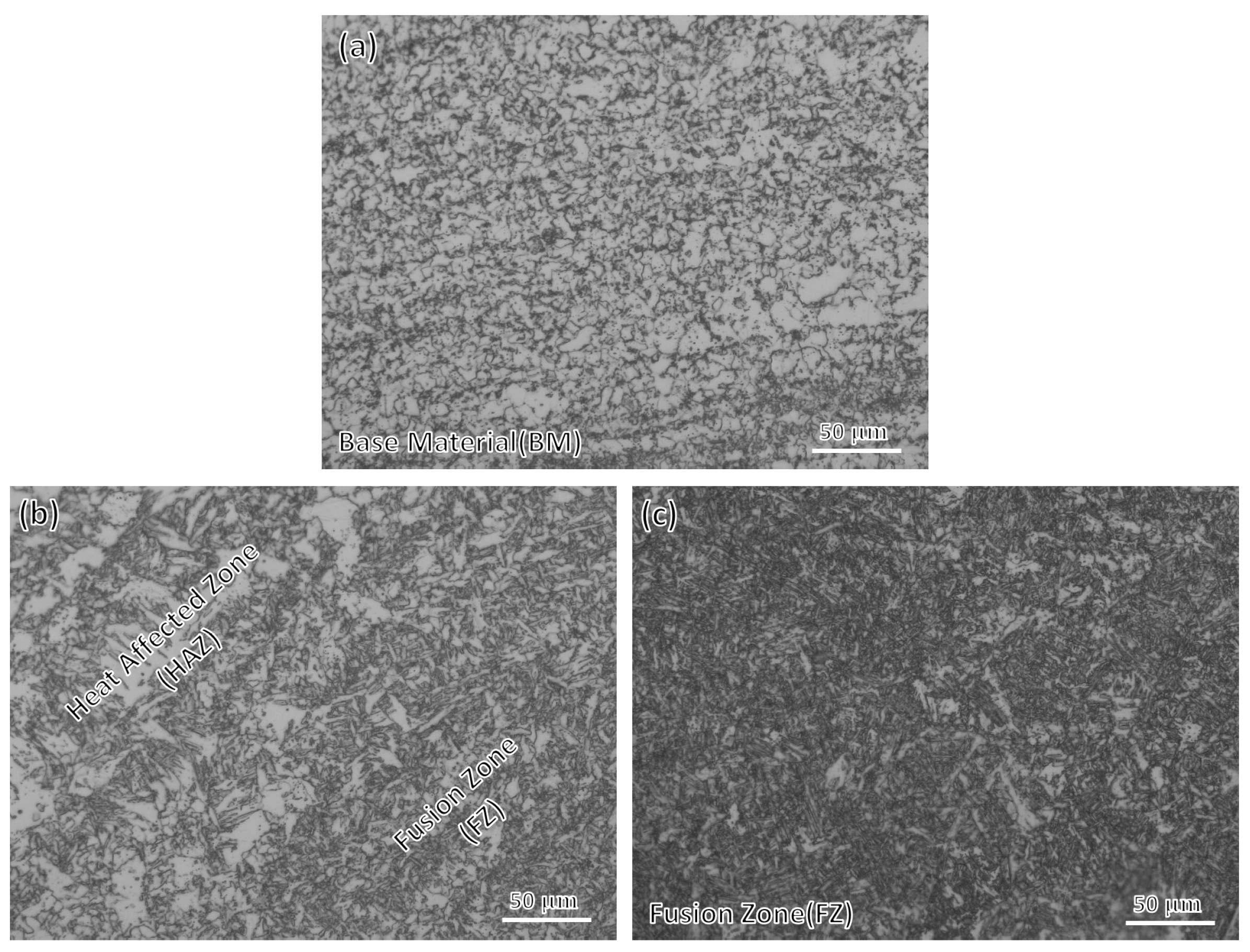

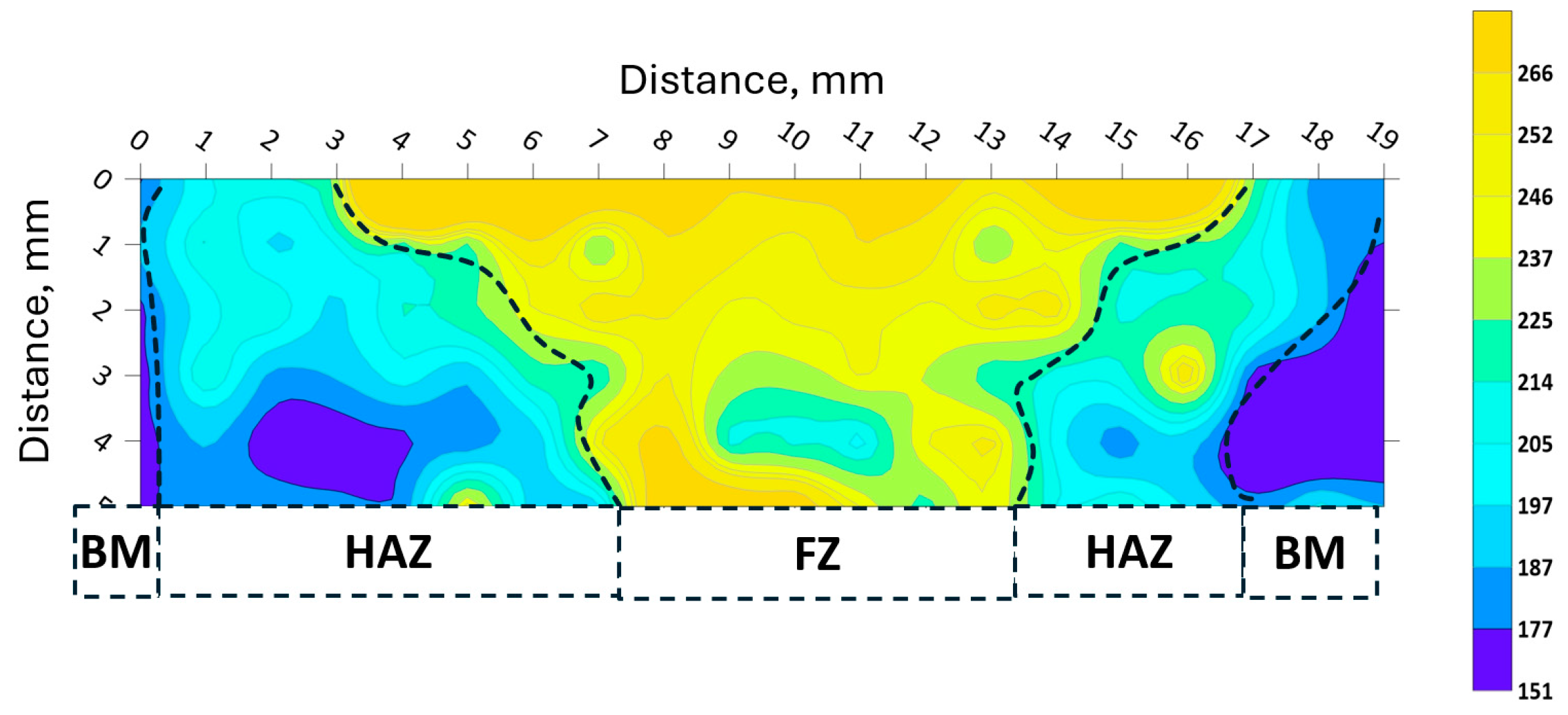

3.1. Microstructure and Hardness of the Welded Joint

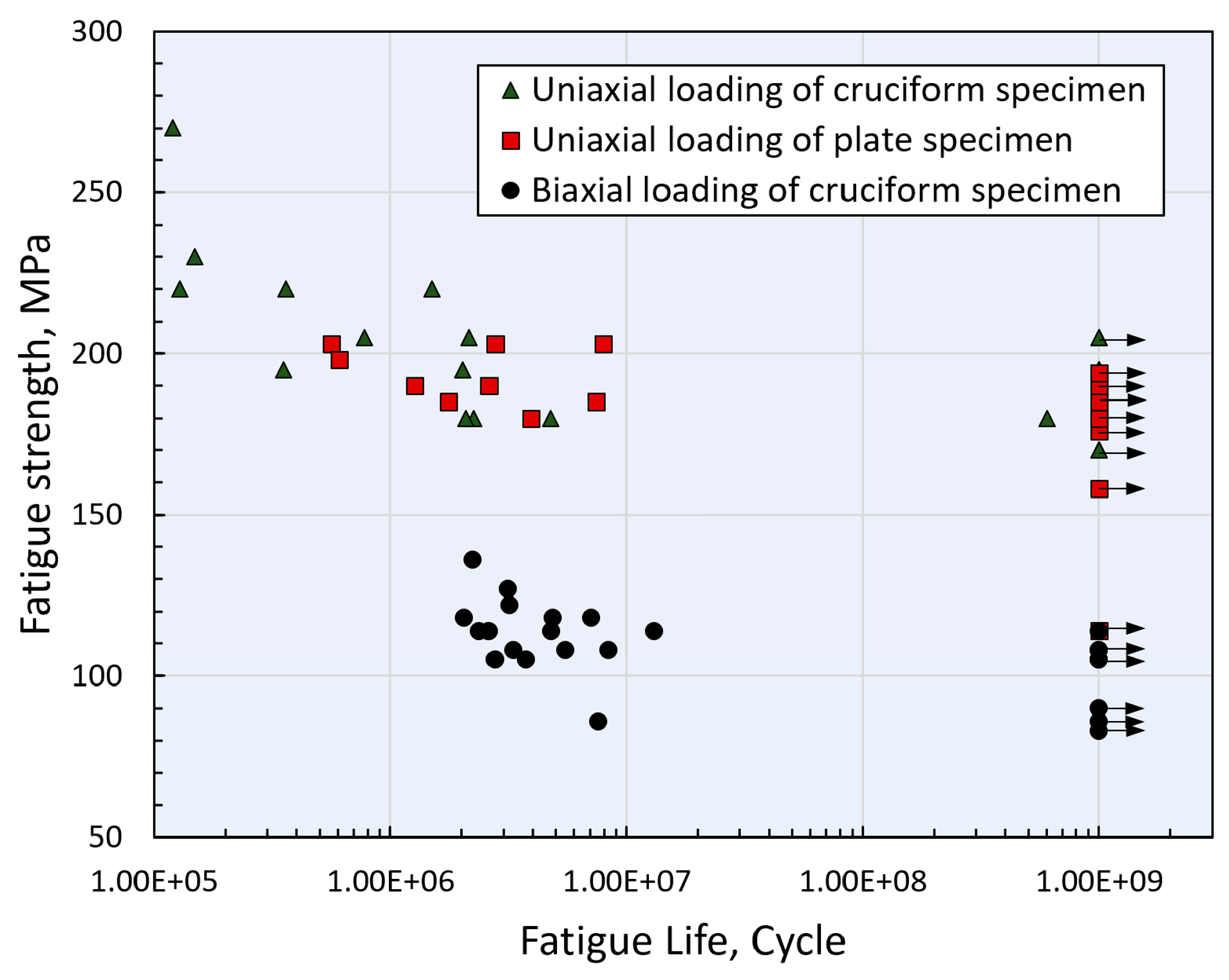

3.2. Fatigue Testing Results

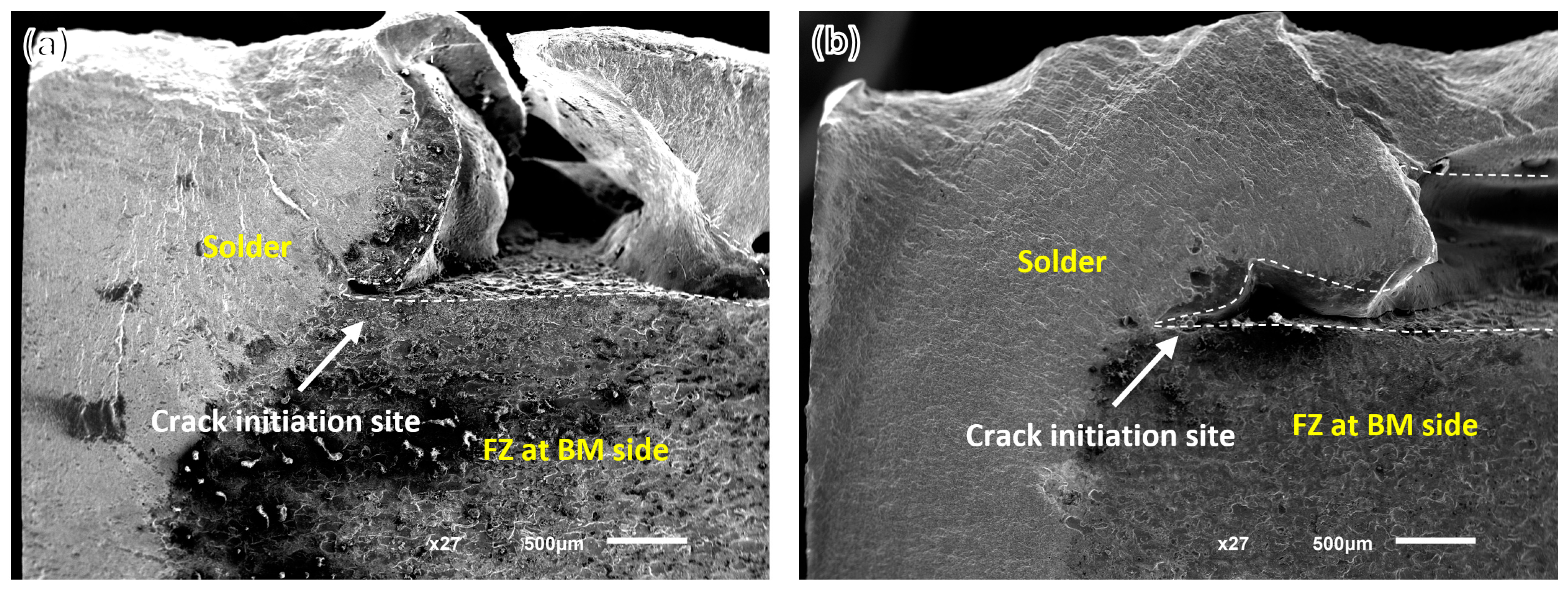

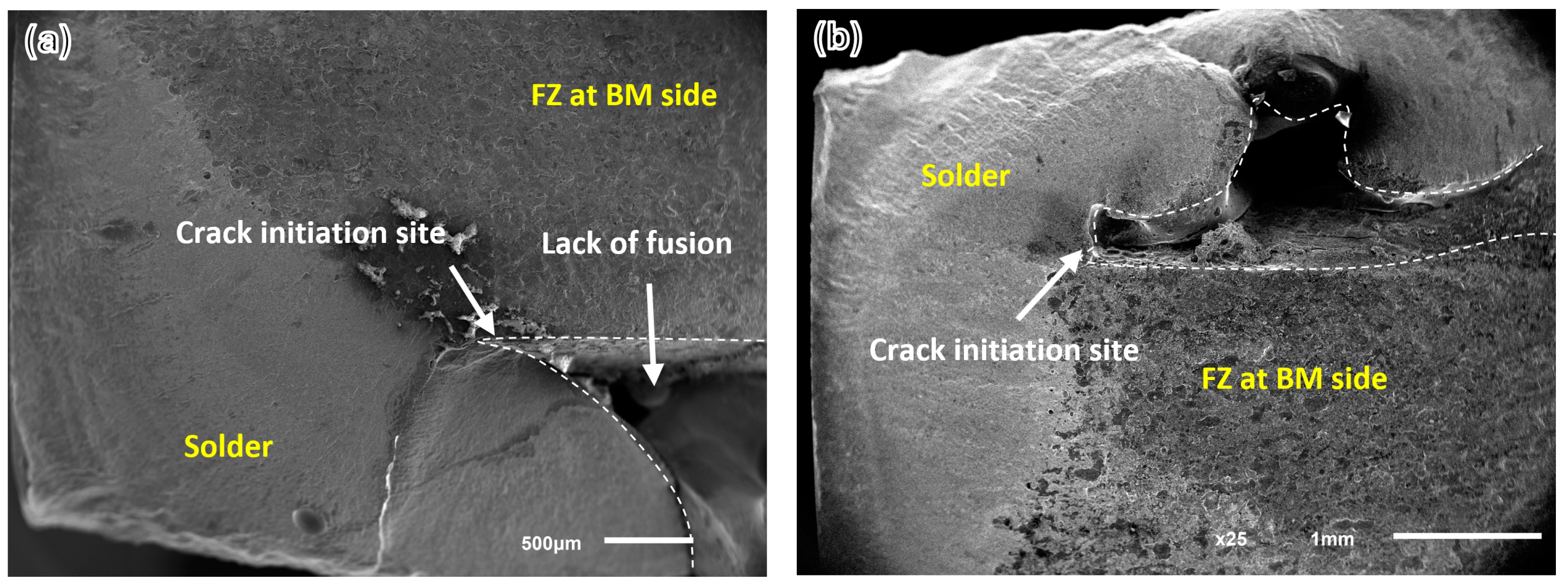

3.3. Fracture Analysis and Discussion

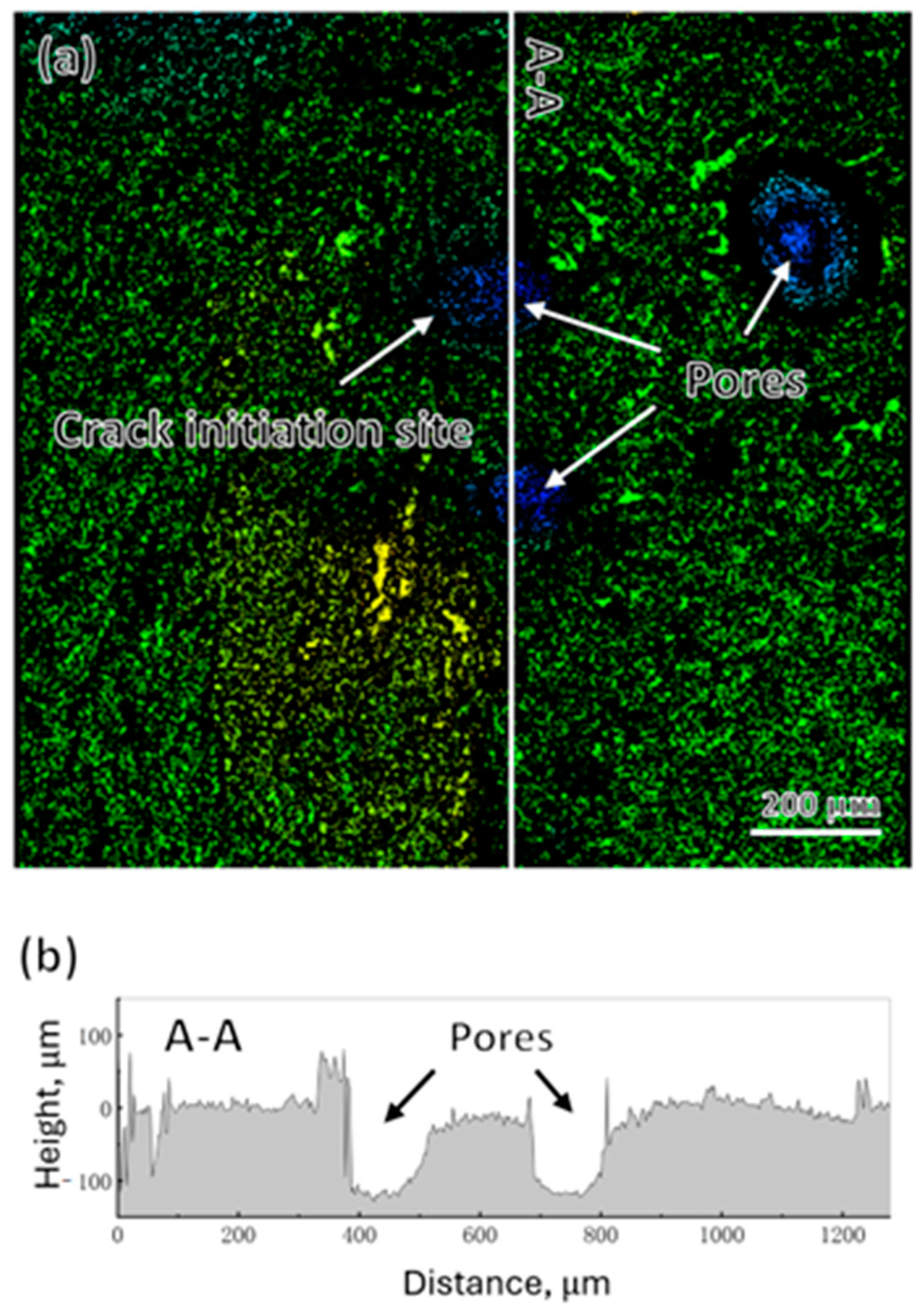

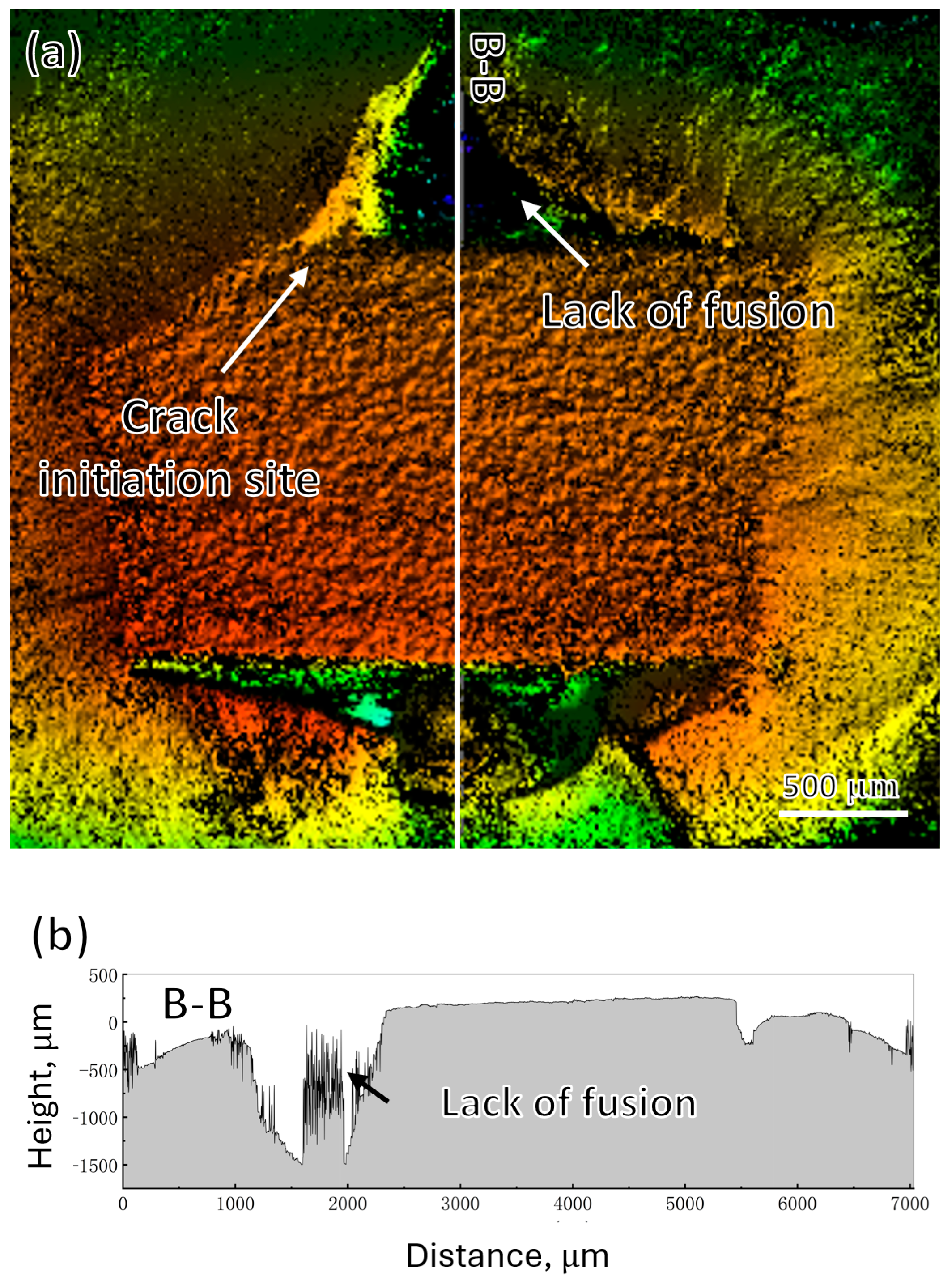

3.4. Three-Dimensional Topography of the Fracture Surface

3.5. Crystal Orientation Analysis of Materials near Pore

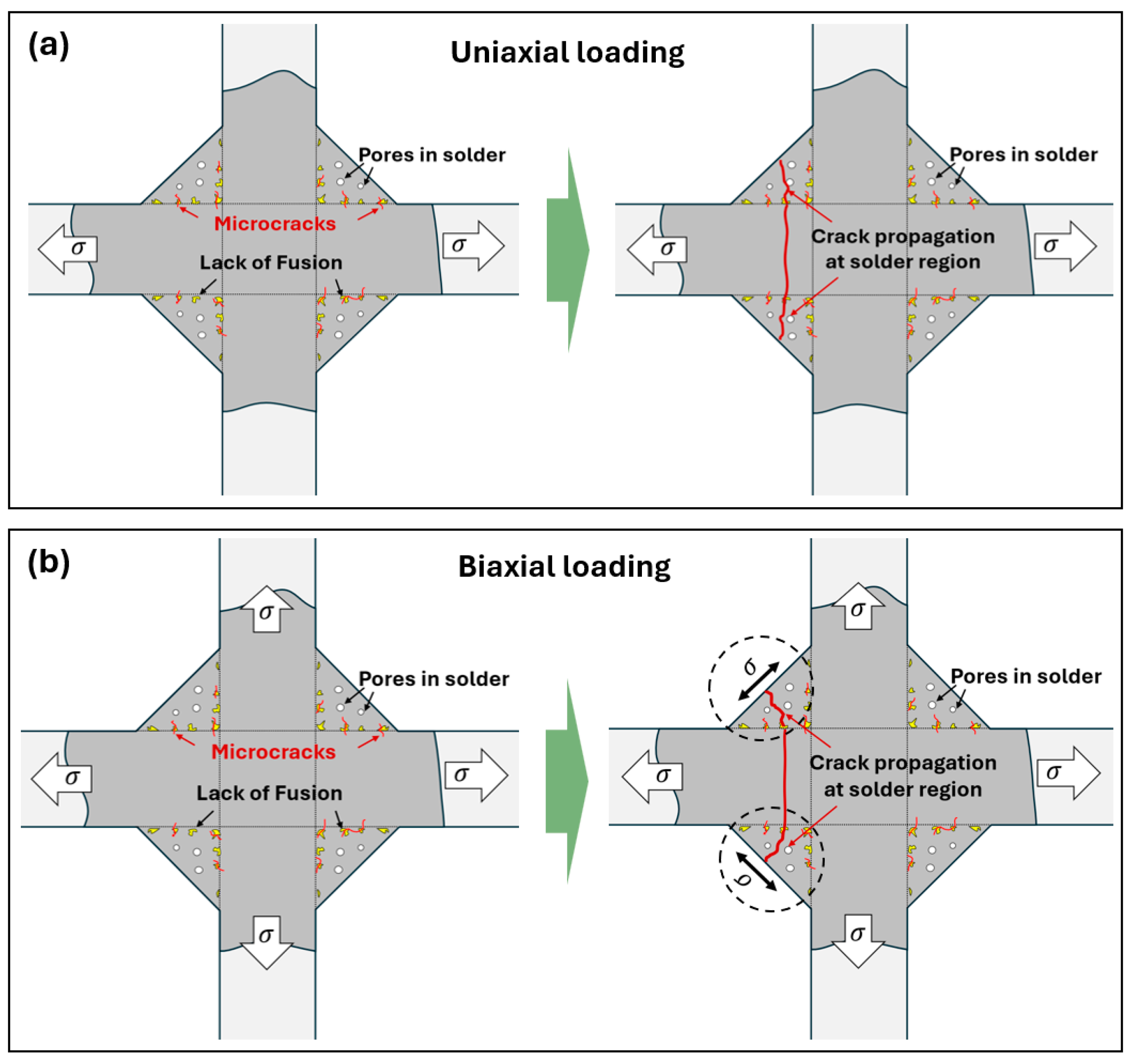

3.6. Discussion on Fatigue Failure Mechanism

4. Conclusions

- (1)

- Fatigue testing of cruciform specimens under biaxial loading revealed a fatigue strength of only 80 MPa, which is significantly lower than that under uniaxial loading conditions (180 MPa);

- (2)

- Fatigue cracks in plate specimens primarily originated from surface porosity, whereas fatigue cracks in cruciform welded joint specimens predominantly initiated from a lack of fusion defects;

- (3)

- There are many band-like textured regions near the defects in the fusion zone, and fatigue cracks are more likely to initiate from these textured zones;

- (4)

- Welding processes, the size and shape of defects, and the stress state significantly affect the distribution of defects and the degree of stress concentration. These factors collectively influence the initiation and propagation of fatigue cracks and ultimately determine the fatigue strength and life of the welded joints.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Phillips, D.H. Welding Engineering: An Introduction; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Radaj, D.; Sonsino, C.; Fricke, W. Recent developments in local concepts of fatigue assessment of welded joints. Int. J. Fatigue 2009, 31, 2–11. [Google Scholar] [CrossRef]

- Braun, M.; Wang, X. A review of fatigue test data on weld toe grinding and weld profiling. Int. J. Fatigue 2021, 145, 106073. [Google Scholar] [CrossRef]

- England, A.; Toumpis, A.; Gorash, Y. Very high cycle fatigue of welds: A review. Metals 2023, 13, 1860. [Google Scholar] [CrossRef]

- Daniel, T.; Smaga, M.; Beck, T.; Schopf, T.; Stumpfrock, L.; Weihe, S.; Rudolph, J. Investigation of the very high cycle fatigue (VHCF) behavior of austenitic stainless steels and their welds for reactor internals at ambient temperature and 300 C. In Proceedings of the Pressure Vessels and Piping Conference, 2020, Online, 3 August 2020; American Society of Mechanical Engineers: Houston, TX, USA, 2020. [Google Scholar]

- Da Silva, R.R.; Caloba, L.P.; Siqueira, M.H.S.; Rebello, J.M.A. Pattern recognition of weld defects detected by radiographic test. NDT E Int. 2004, 37, 461–470. [Google Scholar] [CrossRef]

- Zhan, R.; Wang, D.; Ren, Z.; Deng, C.; Xu, X.; Liang, H. Evolution of Welding Residual Stresses Involving the Cutting Process and Its Effect on Fatigue Performance. Int. J. Press. Vessel. Pip. 2022, 197, 104636. [Google Scholar] [CrossRef]

- Zerbst, U.; Ainsworth, R.A.; Beier, H.T.; Pisarski, H.; Zhang, Z.L.; Nikbin, K.; Nitschke-Pagel, T.; Münstermann, S.; Kucharczyk, P.; Klingbeil, D. Review on Fracture and Crack Propagation in Weldments—A Fracture Mechanics Perspective. Eng. Fract. Mech. 2014, 132, 200–276. [Google Scholar] [CrossRef]

- Tsutsumi, S.; Fincato, R.; Luo, P.; Sano, M.; Umeda, T.; Kinoshita, T.; Tagawa, T. Effects of Weld Geometry and HAZ Property on Low-Cycle Fatigue Behavior of Welded Joint. Int. J. Fatigue 2022, 156, 106683. [Google Scholar] [CrossRef]

- Ren, X.; Xu, X.; Jiang, C.; Huang, Z.; He, X. Strain distribution and fatigue life estimation for steel plate weld joint low cycle fatigue based on DIC. Opt. Lasers Eng. 2020, 124, 105839. [Google Scholar] [CrossRef]

- Dai, Y.; Liu, C.; Zhan, M.; Wang, X.; He, C.; Wang, Q. Heterogeneous deformation of friction stir welded aluminum alloy 6061 in tension and high cycle fatigue. Int. J. Struct. Integr. 2022, 13, 813–828. [Google Scholar] [CrossRef]

- He, C.; Huang, C.; Liu, Y.; Wang, Q. Fatigue damage evaluation of low-alloy steel welded joints in fusion zone and heat affected zone based on frequency response changes in gigacycle fatigue. Int. J. Fatigue 2014, 61, 297–303. [Google Scholar] [CrossRef]

- He, C.; Huang, C.; Liu, Y.; Li, J.; Wang, Q. Effects of mechanical heterogeneity on the tensile and fatigue behaviours in a laser-arc hybrid welded aluminium alloy joint. Mater. Des. (1980–2015) 2015, 65, 289–296. [Google Scholar] [CrossRef]

- Ma, M.; Lai, R.; Qin, J.; Wang, B.; Liu, H.; Yi, D. Effect of Weld Reinforcement on Tensile and Fatigue Properties of 5083 Aluminum Metal Inert Gas (MIG) Welded Joint: Experiments and Numerical Simulations. Int. J. Fatigue 2021, 144, 106046. [Google Scholar] [CrossRef]

- Yin, D.; Wang, D.; Jing, H.; Huo, L. The effects of ultrasonic peening treatment on the ultra-long life fatigue behavior of welded joints. Mater. Des. 2010, 31, 3299–3307. [Google Scholar] [CrossRef]

- Zhu, M.-L.; Xuan, F.-Z. Failure mechanisms and fatigue strength assessment of a low strength Cr−Ni−Mo−V steel welded joint: Coupled frequency and size effects. Mech. Mater. 2016, 100, 198–208. [Google Scholar] [CrossRef]

- Zhu, M.-L.; Xuan, F.-Z.; Du, Y.-N.; Tu, S.-T. Very high cycle fatigue behavior of a low strength welded joint at moderate temperature. Int. J. Fatigue 2012, 40, 74–83. [Google Scholar] [CrossRef]

- Cremer, M.; Zimmermann, M.; Christ, H.-J. High-frequency cyclic testing of welded aluminium alloy joints in the region of very high cycle fatigue (VHCF). Int. J. Fatigue 2013, 57, 120–130. [Google Scholar] [CrossRef]

- Cremer, M.; Kolyshkin, A.; Zimmermann, M.; Christ, H.J. Influence of process-related defects on the fatigue behaviour of welded aluminium joints at very high cycles. Adv. Mater. Res. 2014, 891, 1476–1481. [Google Scholar] [CrossRef]

- Mayer, H. Recent developments in ultrasonic fatigue. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 3–29. [Google Scholar] [CrossRef]

- Ilie, P.; Lesperance, X.; Ince, A. Development of an ultrasonic fatigue testing system for gigacycle fatigue. Mater. Des. Process. Commun. 2020, 2, e120. [Google Scholar] [CrossRef]

- Bharat, V. Nanoindentation hardness measurements using atomic force microscopy. Appl. Phys. Lett. 1994, 64, 1653–1655. [Google Scholar]

- Xue, T.C. Design of Ultrasonic Fatigue Specimen. Acta Aeronaut. 2004, 25, 425–428. [Google Scholar]

- Peng, B.; Zhang, M.; Ye, D. DIC/DSI based studies on the local mechanical behaviors of HR3C/T92 dissimilar welded joint during plastic deformation. Mater. Sci. Eng. A 2022, 857, 144073. [Google Scholar] [CrossRef]

- Invernizzi, S.; Montagnoli, F.; Carpinteri, A. Experimental evidence of specimen-size effects on EN-AW6082 aluminum alloy in VHCF regime. Appl. Sci. 2021, 11, 4272. [Google Scholar] [CrossRef]

- Xu, L.; Wang, Q.; Zhou, M. Micro-crack initiation and propagation in a high strength aluminum alloy during very high cycle fatigue. Mater. Sci. Eng. A 2018, 715, 404–413. [Google Scholar] [CrossRef]

- Nikitin, A.; Palin-Luc, T.; Shanyavskiy, A. Crack initiation in VHCF regime on forged titanium alloy under tensile and torsion loading modes. Int. J. Fatigue 2016, 93, 318–325. [Google Scholar] [CrossRef]

- Xu, W.; Chen, X.; Gao, Z.; Li, Y.; He, Y.; Tao, C. Fatigue behaviors of a titanium alloy in the VHCF regime based on a vibration-based bending fatigue test. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 2549–2562. [Google Scholar] [CrossRef]

- Nie, B.; Chen, D.; Zhao, Z.; Zhang, J.; Meng, Y.; Gao, G. Notch effect on the fatigue behavior of a TC21 titanium alloy in very high cycle regime. Appl. Sci. 2018, 8, 1614. [Google Scholar] [CrossRef]

- Xu, K.; Feng, M.; Qiu, X. Distinguishing welding defects from the stress concentration zone using metal magnetic memory field parameters. Trans. Indian Inst. Met. 2019, 72, 343–351. [Google Scholar]

- Afroz, L.; Inverarity, S.B.; Qian, M.; Easton, M.; Das, R. Analysing the effect of defects on stress concentration and fatigue life of L-PBF AlSi10Mg alloy using finite element modelling. Prog. Addit. Manuf. 2023, 9, 341–359. [Google Scholar] [CrossRef]

- He, C.; Wu, Y.; Peng, L.; Su, N.; Chen, Q.; Yuan, S.; Liu, Y.; Wang, Q. Effect of microstructure on small fatigue crack initiation and early propagation behavior in Mg-10Gd-3Y-0.3 Zr alloy. Int. J. Fatigue 2019, 119, 311–319. [Google Scholar]

- Li, X.; He, C.; Wang, X.; Chen, Y.; Wang, C.; Zhang, H.; Li, L.; Liu, Y.; Wang, Q. Effects of microstructure on crack initiation in super martensitic stainless steel under very-high-cycle fatigue at elevated temperature. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 1060–1077. [Google Scholar] [CrossRef]

- Li, X.; Dai, Y.; Wang, X.; Liu, Y.; Chen, Y.; Wang, C.; Zhang, H.; Li, L.; Liu, H.; He, C.; et al. Effects of local microstructure on crack initiation in super martensitic stainless steel under very-high-cycle fatigue. Int. J. Fatigue 2022, 163, 107019. [Google Scholar] [CrossRef]

- Szczepanski, C.; Jha, S.; Larsen, J.; Jones, J. Microstructural influences on very-high-cycle fatigue-crack initiation in Ti-6246. Metall. Mater. Trans. A 2008, 39, 2841–2851. [Google Scholar] [CrossRef]

- Benoit, M.J.; Mazur, M.; Easton, M.A.; Brandt, M. Effect of alloy composition and laser powder bed fusion parameters on the defect formation and mechanical properties of Inconel 625. Int. J. Adv. Manuf. Technol. 2021, 114, 915–927. [Google Scholar] [CrossRef]

- Wu, Z.; Wu, S.; Gao, X.; Lin, Y.; Xue, Y.; Withers, P.J. The role of internal defects on anisotropic tensile failure of L-PBF AlSi10Mg alloys. Sci. Rep. 2023, 13, 14681. [Google Scholar] [CrossRef]

- Liu, F.; He, C.; Chen, Y.; Zhang, H.; Wang, Q.; Liu, Y. Effects of defects on tensile and fatigue behaviors of selective laser melted titanium alloy in very high cycle regime. Int. J. Fatigue 2020, 140, 105795. [Google Scholar] [CrossRef]

- He, C.; Cui, S.; Liu, Y.; Wang, Q. Effect of pore on super long fatigue life of aluminium alloywelded joint. Trans. China Weld. Inst. 2014, 35, 18–22. [Google Scholar]

- Reiss, E.L.; Locke, S. On the theory of plane stress. Q. Appl. Math. 1961, 19, 195–203. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, B.; Li, Y.; Yi, W.; Shi, S.; Dai, Y.; Liu, C.; Ren, M.; He, C. Biaxial Very High Cycle Fatigue Testing and Failure Mechanism of Welded Joints in Structural Steel Q345. Crystals 2024, 14, 850. https://doi.org/10.3390/cryst14100850

Xue B, Li Y, Yi W, Shi S, Dai Y, Liu C, Ren M, He C. Biaxial Very High Cycle Fatigue Testing and Failure Mechanism of Welded Joints in Structural Steel Q345. Crystals. 2024; 14(10):850. https://doi.org/10.3390/cryst14100850

Chicago/Turabian StyleXue, Bing, Yongbo Li, Wanshuang Yi, Shoucheng Shi, Yajun Dai, Chang Liu, Maojia Ren, and Chao He. 2024. "Biaxial Very High Cycle Fatigue Testing and Failure Mechanism of Welded Joints in Structural Steel Q345" Crystals 14, no. 10: 850. https://doi.org/10.3390/cryst14100850

APA StyleXue, B., Li, Y., Yi, W., Shi, S., Dai, Y., Liu, C., Ren, M., & He, C. (2024). Biaxial Very High Cycle Fatigue Testing and Failure Mechanism of Welded Joints in Structural Steel Q345. Crystals, 14(10), 850. https://doi.org/10.3390/cryst14100850