Texture Intensity in Grain-Oriented Steel in the Main Stages of the Production Cycle

Abstract

1. Introduction

2. Materials and Methods

2.1. X-ray Diffraction

2.2. Magnetic Barkhausen Noise (MBN)

3. Results and Discussion

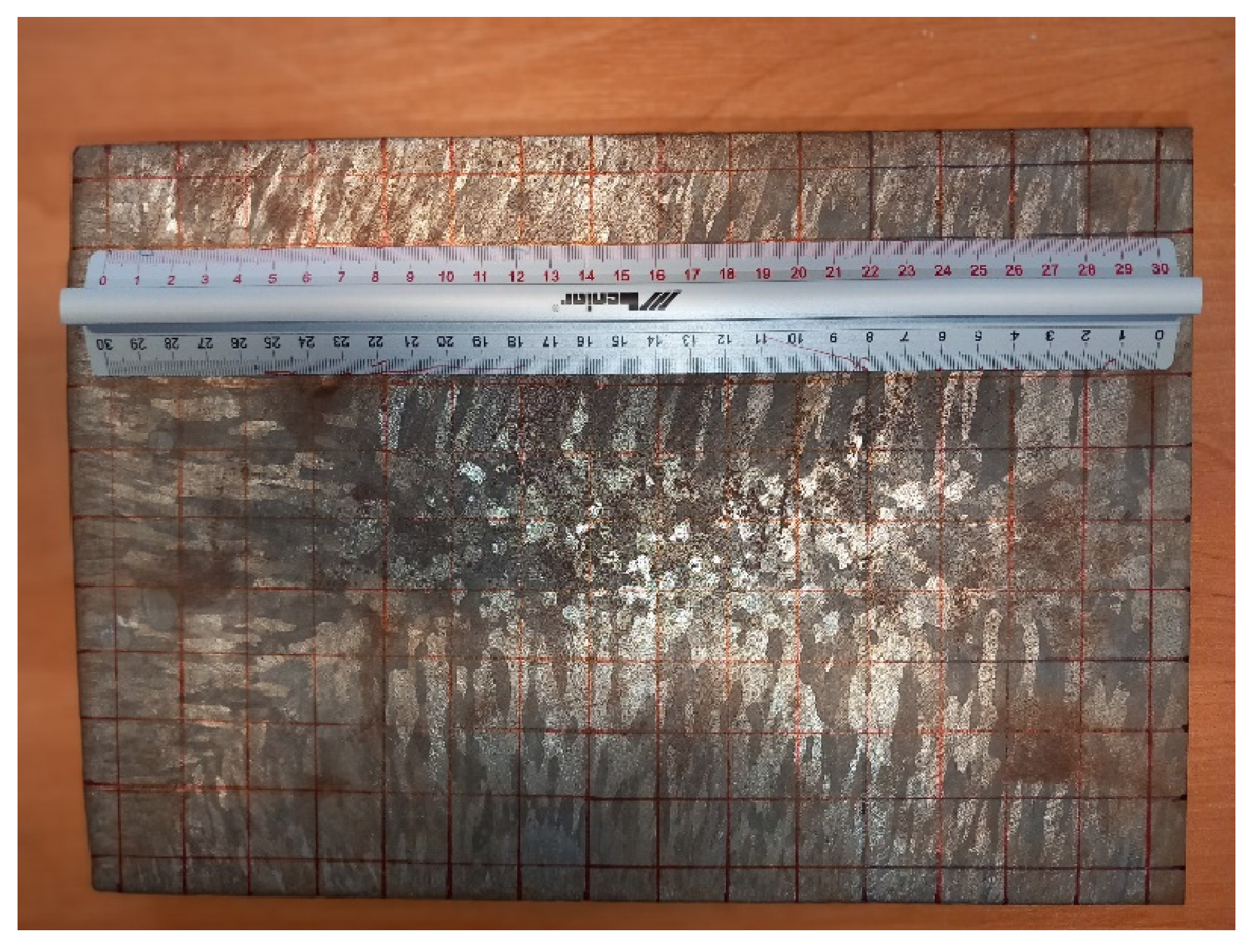

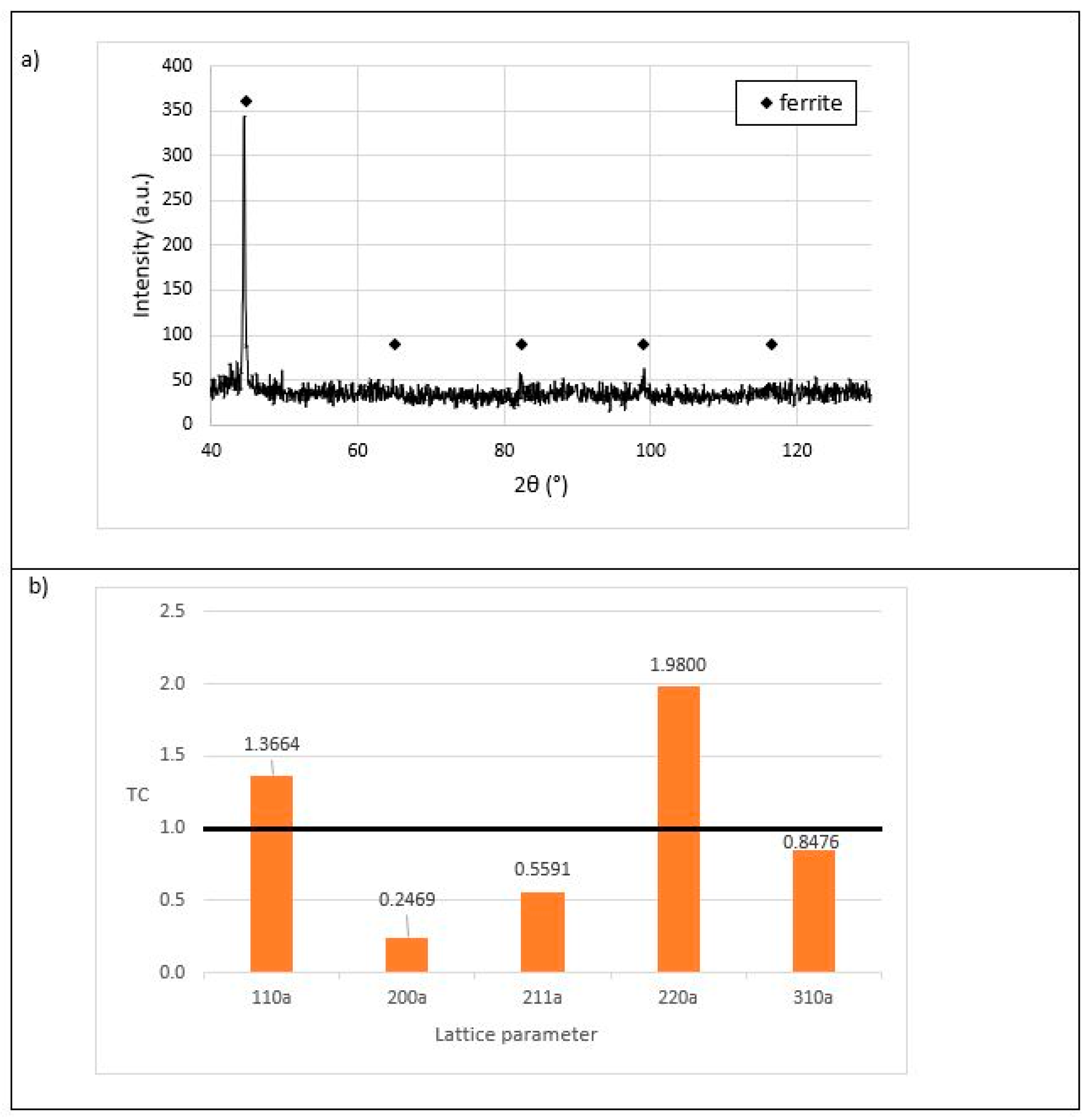

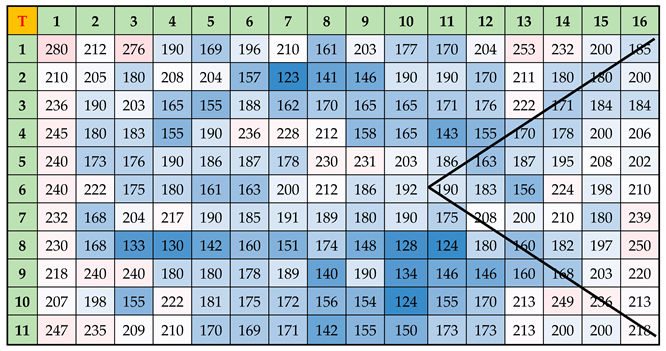

3.1. Analysis of Macrostructure, Texture and Magnetic Properties of the Slab Obtained after Continuous Casting Process

- FCZ—frozen crystal zone,

- SCCZ—small columnar crystal zone,

- LCCZ—large columnar crystal zone,

- ECZ—equiaxed crystal zone.

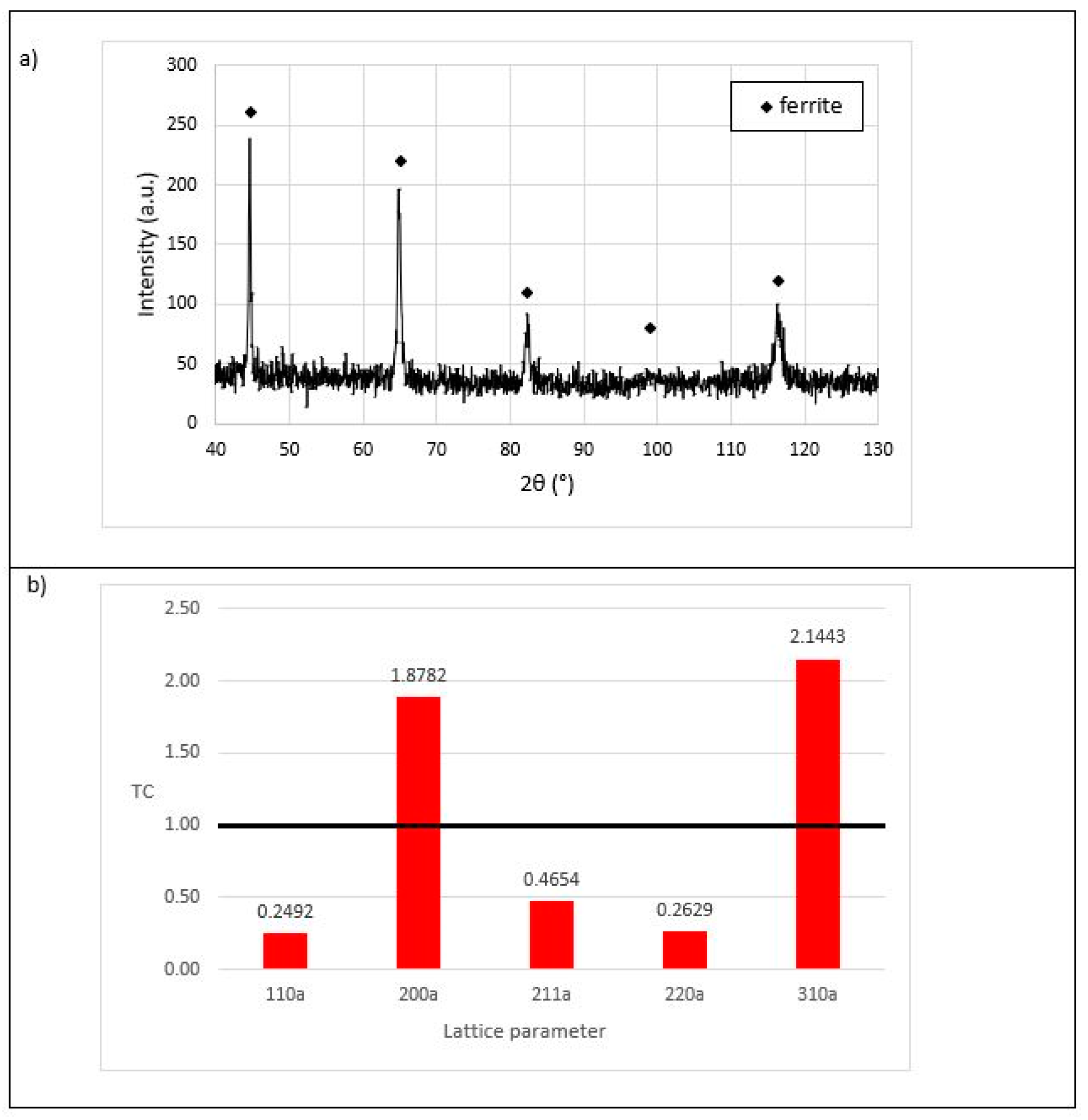

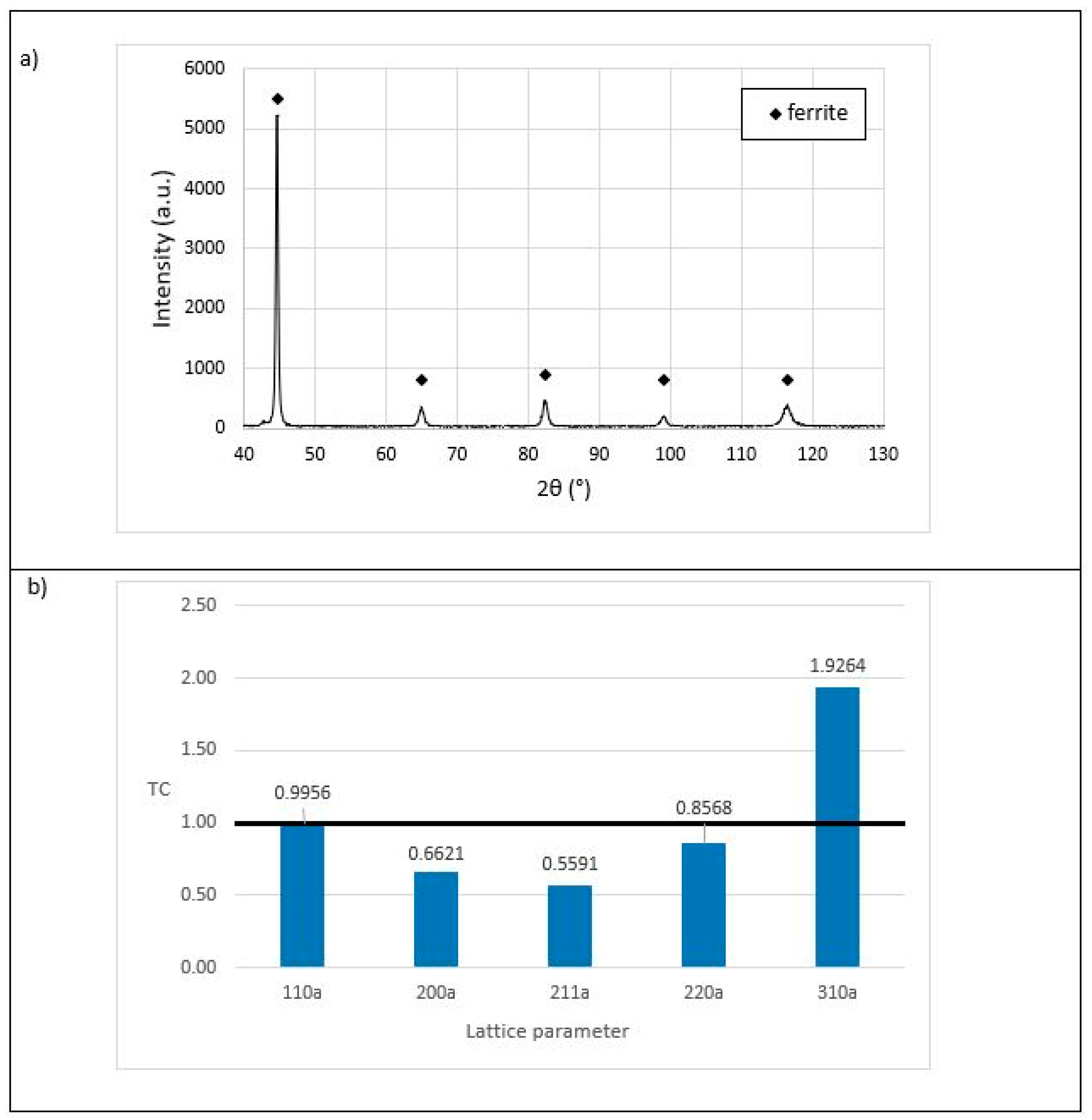

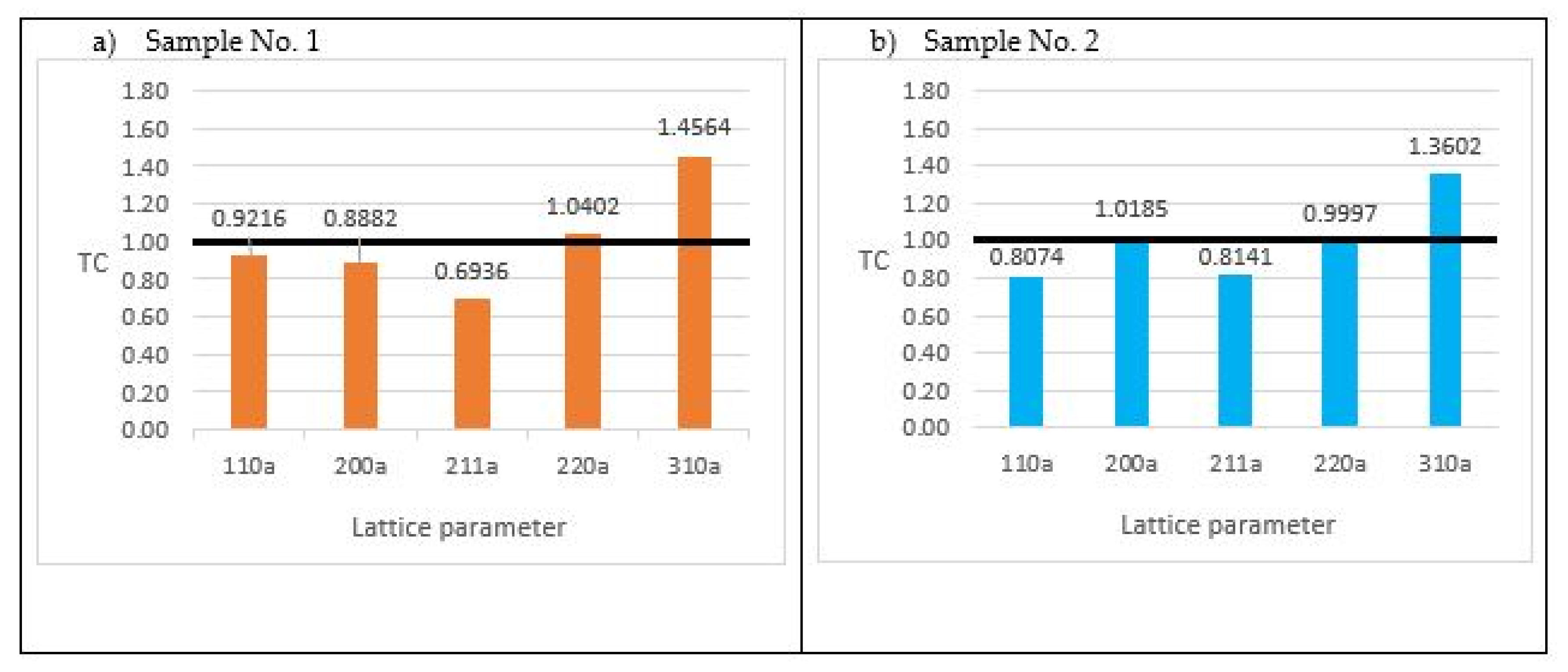

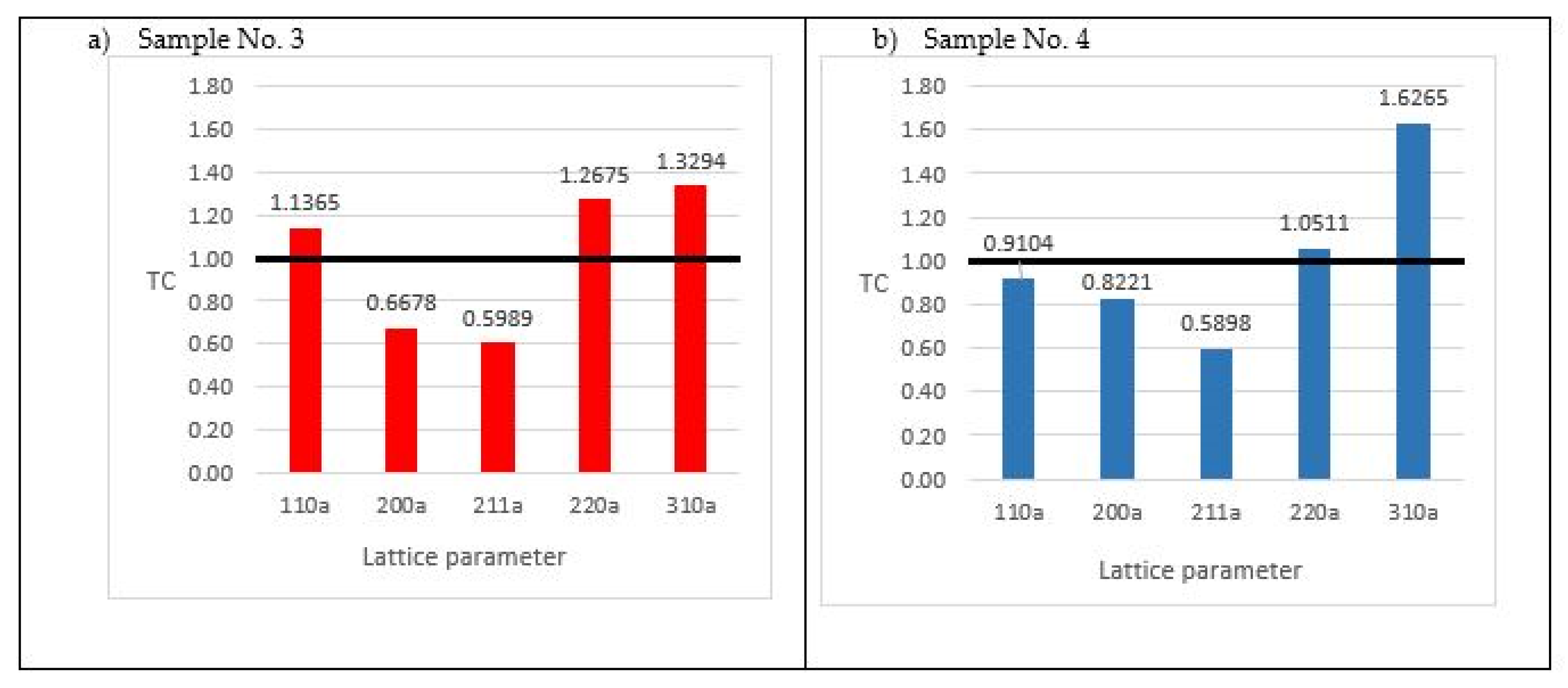

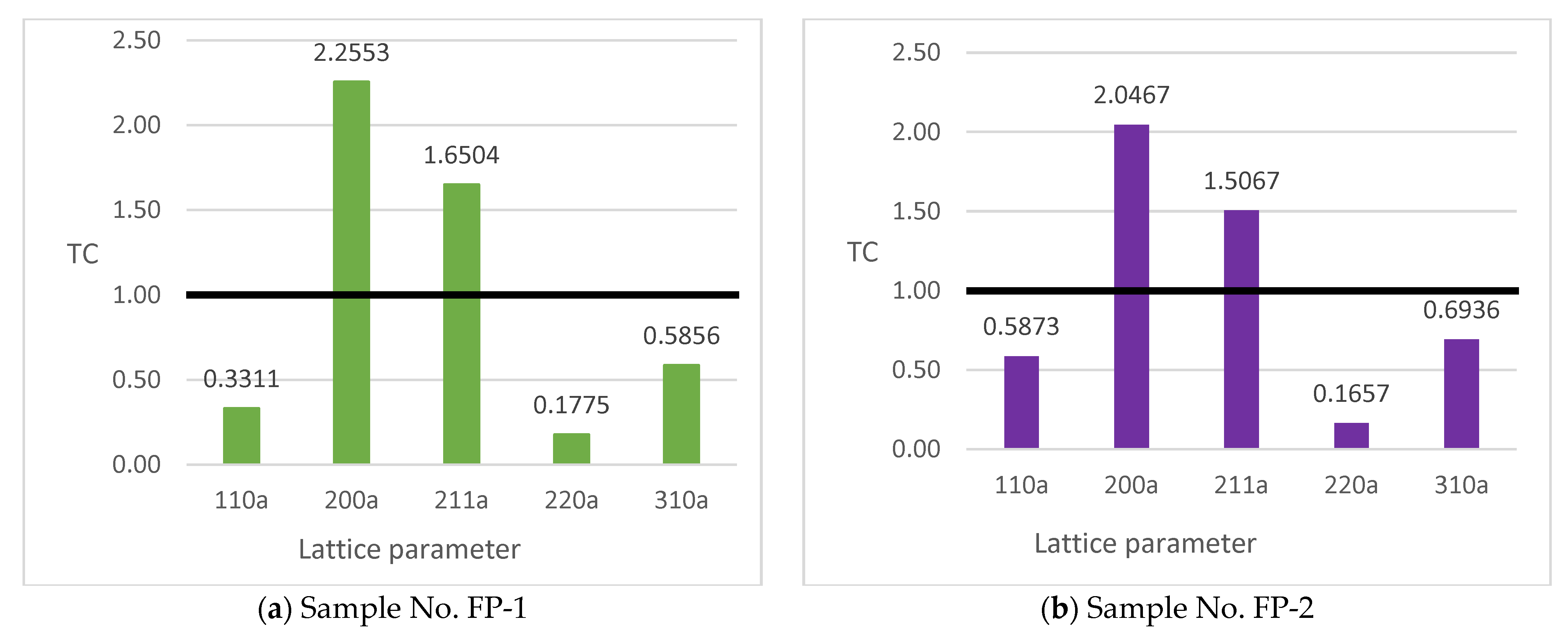

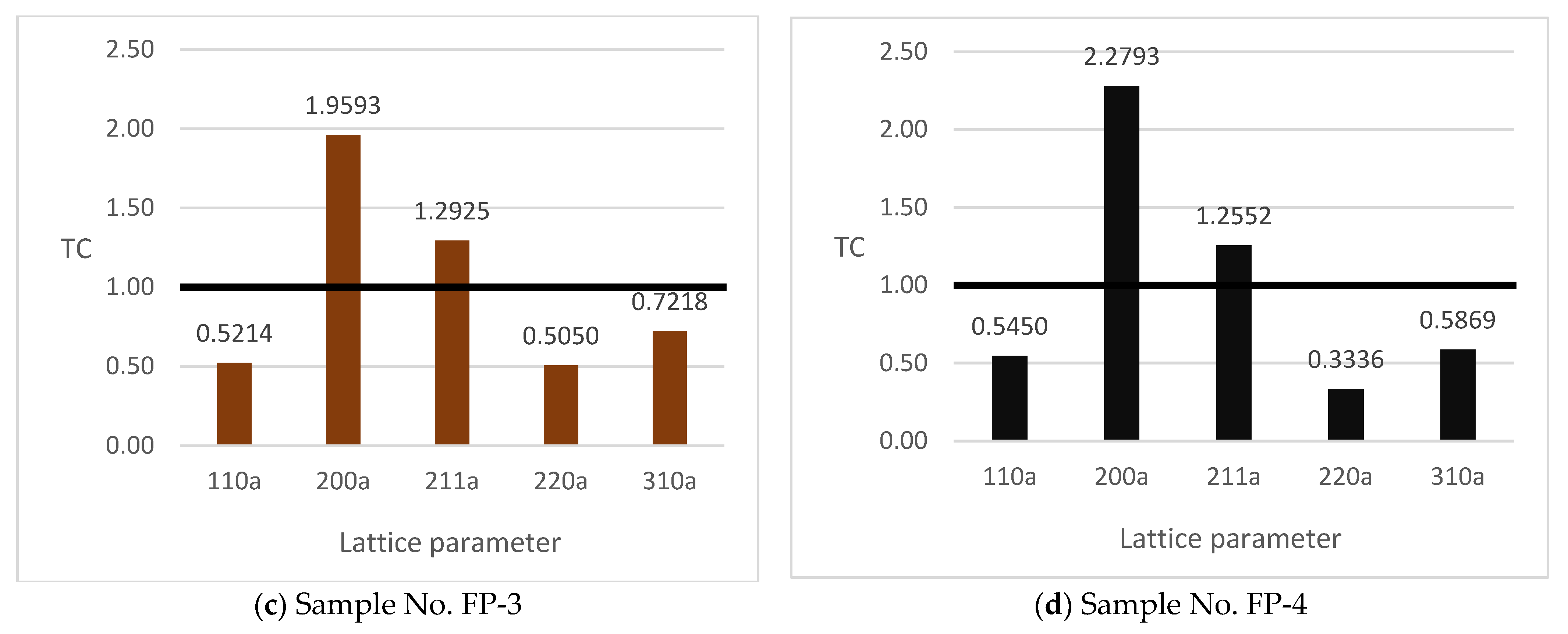

3.2. Analysis of Texture after Hot Rolling Process and Final Production of GOES

4. Conclusions

- The structure of the slab after the continuous casting process is composed of zones of frozen crystals, columnar crystals and equiaxed crystals in the center of the slab. The macrostructure of the slab at the side edges is devoid of an equiaxed crystals area. The crystallographic texture of the slab is strongest in the area of columnar crystals, while it is much weaker in the area of equiaxial crystals.

- The anisotropy of the magnetic properties is particularly high in the columnar crystal region of the slab structure, while in the region of the equiaxial crystals and the side edges of the slab, the magnetic properties should be considered largely isotropic.

- The hot-rolling process caused a strong weakening of the material’s crystallographic texture.

- The process of the production of grain-oriented electrical steel resulted in a very strong texturing coefficient, corresponding to the crystallographic directions and planes for the Goss texture.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Wang, X.; Yang, P.; Ma, J. Different formation mechanisms of {210}<001> orientation in η fiber texture of ultra-thin grain-oriented silicon steel using quasi-in-situ analysis method. Mater. Chem. Phys. 2022, 278, 125726. [Google Scholar] [CrossRef]

- Fang, F.; Zhang, Y.; Lu, X.; Wang, Y.; Cao, G.; Yuan, C.; Xu, Y.; Wang, G.; Mistra, R.D.K. Inhibitor induced secondary recrystallization in thin-gauge grain oriented silicon steel with high permeability. Mater. Des. 2016, 105, 398–403. [Google Scholar] [CrossRef]

- Zhu, C.; Liu, Y.; Xiao, Y.; Yan, W.; Li, G. A New Review on Inclusion and Precipitate Control in Grain-Oriented Silicon Steels. Miner. Met. Mater. Soc. 2022, 74, 3141–3161. [Google Scholar] [CrossRef]

- Huh, Y.; Jung Hong, J.; Soo Han, M.; Kang, S. Formation mechanism and microstructure of a forsterite film in grain-oriented electrical steel. Thin Solid Film. 2022, 752, 139258. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.; Zhang, Y.; Xie, S.; Yu, Y. On abnormal growth of {210}<0 01> grain in grain-oriented silicon steel. Mater. Res. Bull. 2015, 69, 138–141. [Google Scholar] [CrossRef]

- Zhou, M.; Zhang, X. Regulating the recrystallized grain to induce strong cube texture in oriented silicon steel. J. Mater. Sci. Technol. 2022, 96, 126–139. [Google Scholar] [CrossRef]

- Birosca, S.; Nadoum, A.; Hawezy, D.; Robinson, F.; Kockelmann, W. Mechanistic approach of Goss abnormal grain growth in electrical steel: Theory and argument. Acta Mater. 2020, 185, 370–381. [Google Scholar] [CrossRef]

- Kumar Gupta, V.; Kumar Jha, P.; Kumar Jain, P. A novel approach to predict the inclusion removal in a billet caster mold with the use of electromagnetic stirrer. J. Manuf. Process. 2022, 83, 27–39. [Google Scholar] [CrossRef]

- Fang, F.; Yang, J.; Zhang, Y.; Wang, Y.; Zhang, X.; Yuan, G.; Misra, R.D.K.; Wang, G. Microstructure and magnetic properties of ultra-thin grain-oriented silicon steel: Conventional process versus strip casting. J. Magn. Magn. Mater. 2021, 535, 168087. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Y.B.; Zhang, Y.X.; Fang, F.; Lu, X.; Liu, H.T.; Wang, G.D. Development of microstructure and texture in strip casting grain oriented silicon steel. J. Magn. Magn. Mater. 2015, 379, 161–166. [Google Scholar] [CrossRef]

- Vipul, J.; Pranabananda, M.; Sudipta, P.; Abhijit, G. Origin of Goss texture in grain oriented electrical steel: Role of shear bands. Materialia 2022, 22, 101398. [Google Scholar] [CrossRef]

- Wang, Y.P.; An, L.Z.; Song, H.Y.; Wang, G.D.; Liu, H.T. Dependence of recrystallization behavior on initial Goss orientation in ultrathin grain-oriented silicon steels. J. Magn. Magn. Mater. 2020, 499, 166290. [Google Scholar] [CrossRef]

- Mishra, S.; Kumar, V. Co-precipitation of copper-manganese sulphide in Fe-3%Si steel. Mater. Sci. Eng. 1995, B32, 177–184. [Google Scholar] [CrossRef]

- Imafaku, M.; Suzuki, H.; Akita, K.; Iwata, K.; Fujikura, M. Effects of laser irradiation on iron loss reduction for Fe–3%Si grain-oriented silicon steel. Acta Mater. 2005, 54, 939–945. [Google Scholar] [CrossRef]

- Jahangiri, M.R.; Bayani, H.; Ardestani, M.; Mehdizadeh, M. Core loss reduction in grain oriented silicon steel sheets by two-sided laser scribing in the presence of a magnetic field. J. Alloys Compd. 2021, 891, 162080. [Google Scholar] [CrossRef]

- Li, H.; Frng, Y.; Song, M.; Liang, J.L.; Cang, D. Effect of normalizing cooling process on microstructure and precipitates in low-temperature silicon steel. Trans. Nonferrous Met. Soc. China 2014, 24, 770–776. [Google Scholar] [CrossRef]

- Alcantara, F.L.; Barbosa, R.; Cunha, M.A. Study of Aluminum Nitride Precipitation in Fe-3%Si Steel. Mater. Res. 2013, 16, 1039–1044. [Google Scholar] [CrossRef]

- Calvillo, P.R.; Salazar, N.; Schneider, J.; Houbaert, Y. Microstructure Characterization by EBSD of Hot Rolled High-Silicon Steel. In Defect and Diffusion Forum; Trans Tech Publications Ltd.: Bach, Switzerland, 2008; Volume 273, pp. 69–74. [Google Scholar] [CrossRef]

- Park, J.Y.; Oh, K.H.; Ra, H.Y. Microstructure and crystallographic texture of strip-cast 4.3wt%Si Steel sheet. Scr. Mater. 1999, 40, 881–885. [Google Scholar] [CrossRef]

- Song, H.Y.; Liu, H.T.; Lu, H.H.; Li, H.Z.; Liu, W.Q.; Zhang, Z.M. Effect of hot rolling reduction on microstructure, texture and ductility of strip-cast grain-oriented silicon steel with different solidification structures. Mater. Sci. Eng. A 2014, 606, 260–269. [Google Scholar] [CrossRef]

- Zaveryukha, A.; Davis, C. An investigation into the cause of inhomogeneous distributions of aluminium nitrides in silicon steels. Mater. Sci. Eng. 2003, A345, 23–27. [Google Scholar] [CrossRef]

- Han, C.H.; Kwon, S.J. Effect of Nitrogen on the size and Distribution of ALN precipitates in 3% Silicon Steel. Scr. Mater. 1996, 34, 543–549. [Google Scholar] [CrossRef]

- Hauk, V. Structural and Residual Stress Analysis by Nondestructive Methods: Evaluation-Application-Assessment; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Wagner, J.N.; Hofmann, M.; Wimpory, R.; Krempaszky, C.; Stockinger, M. Microstructure and temperature dependence of intergranular strains on diffractometric macroscopic residual stress analysis. Mater. Sci. Eng. A 2014, 618, 271–279. [Google Scholar] [CrossRef]

- Stylianou, R.; Tkadles, M.; Schalk, N.; Penoy, M.; Czettl, C. Effects of reference materials on texture coefficients determined for a CVD α-Al2O3 coating. Surf. Coat. Technol. 2019, 359, 314–322. [Google Scholar] [CrossRef]

- Neslušan, M.; Minárik, P.; Čep, R.; Ondruš, J.; Pitoňák, M.; Zgútová, K. Measurement of bearing capacity of steel road barrier flange via Barkhausen noise emission. Eng. Fail. Anal. 2024, 156, 107804. [Google Scholar] [CrossRef]

- Dong, H.; Liu, X.; Song, Y.; Wang, B.; Chen, S.; He, C. Quantitative evaluation of residual stress and surface hardness in deep drawn parts based on magnetic Barkhausen noise technology. Measurement 2021, 168, 108473. [Google Scholar] [CrossRef]

- Pacyna, J.; Kokosza, A. Residual Stress Measurement in Steel Mill Rolls Using Magnetic Barkhausen Noise Analysis. J. Nondestruct. Test. Ultrason. 1999, 4, 8. [Google Scholar]

- Tavakoli, R.; Pourfathi, A. Thermal optimization of secondary cooling systems in the continuous steel casting process. Int. J. Therm. Sci. 2023, 183, 107860. [Google Scholar] [CrossRef]

- Shao, Y.Y.; Yang, P.; Fu, Y.J.; Mao, W.M. Texture evolution of columnar grains in electrical steel During Hot rolling. J. Iron Steel Res. Int. 2013, 20, 99–106. [Google Scholar] [CrossRef]

- Nadoum, A.; Robinson, F.; Birosca, S. On the correlation between magnetic domain and crystallographic grain orientation in grain oriented electrical steels. J. Magn. Magn. Mater. 2020, 494, 165772. [Google Scholar] [CrossRef]

- Szewczyk, R.; Nowicki, M.; Ostaszewska-Liżewska, A.; Bieńkowski, A.; Nowak, P.; Malinem, M. Accuracy of frame-shaped samples based measurements of magnetoelastic characteristics of soft magnetic materials. Measurement 2020, 162, 107899. [Google Scholar] [CrossRef]

- Zhang, N.; Yang, P.; Mao, W. {001}〈120〉−{113}〈361〉 recrystallization textures induced by initial {001} grains and related microstructure evolution in heavily rolled electrical steel. Mater. Charact. 2016, 119, 225–231. [Google Scholar] [CrossRef]

- Du, Y.; O’Malley, R.; Buchely, M. Review of Magnetic Properties and Texture Evolution in Non-Oriented Electrical Steels. Appl. Sci. 2023, 13, 6097. [Google Scholar] [CrossRef]

- Ścibisz, K.; Kaźmierski, T.; Krawczyk, J. A Roll’s wear during hot rolling of high-silicon steel and its impact on the quality of a strip’s profile. Tribologia 2023, 3, 95–102. [Google Scholar] [CrossRef]

- Lu, X.; Xu, Y.; Fang, F.; Zhang, Y.; Jiao, H.; Cao, G.; Li, C.; Yuan, G.; Wang, G. Microstructure, texture and precipitate of grain-oriented 4.5 wt %Si steel by strip casting. J. Magn. Magn. Mater. 2016, 404, 230–237. [Google Scholar] [CrossRef]

- Ramanathan, S. Study of Dislocations from Continuous Flattening Anneal and Its Effect on Magnetic Properties of Grain Oriented Electrical Steel; Cardiff University: Cardiff, UK, 2013. [Google Scholar]

- Wodzyński, A.; Suliga, M.; Chwastek, K. Grain-oriented steels for use in electrical engineering—Chosen issues. Pr. Inst. Elektrotechniki 2014, 267, 159–173. [Google Scholar]

- Wang, Y.; Xu, Y.B.; Zhang, Y.X.; Fang, F.; Lu, X.; Mistra, R.D.K.; Wang, G.D. Effect of annealing after strip casting on texture development in grain oriented silicon steel produced by twin roll casting. Mater. Charact. 2015, 107, 79–84. [Google Scholar] [CrossRef]

| Elements | C | Mn | Si | S | Cu | Fe |

|---|---|---|---|---|---|---|

| Nominal content | 0.028–0.040 | 0.22–0.30 | 3.00–3.25 | max. 0.007 | 0.048–0.55 | bal. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krawczyk, J.; Ścibisz, K.; Goły, M.; Śleboda, T. Texture Intensity in Grain-Oriented Steel in the Main Stages of the Production Cycle. Crystals 2024, 14, 107. https://doi.org/10.3390/cryst14020107

Krawczyk J, Ścibisz K, Goły M, Śleboda T. Texture Intensity in Grain-Oriented Steel in the Main Stages of the Production Cycle. Crystals. 2024; 14(2):107. https://doi.org/10.3390/cryst14020107

Chicago/Turabian StyleKrawczyk, Janusz, Kamila Ścibisz, Marcin Goły, and Tomasz Śleboda. 2024. "Texture Intensity in Grain-Oriented Steel in the Main Stages of the Production Cycle" Crystals 14, no. 2: 107. https://doi.org/10.3390/cryst14020107

APA StyleKrawczyk, J., Ścibisz, K., Goły, M., & Śleboda, T. (2024). Texture Intensity in Grain-Oriented Steel in the Main Stages of the Production Cycle. Crystals, 14(2), 107. https://doi.org/10.3390/cryst14020107