Influence of Spatter on Porosity, Microstructure, and Corrosion of Additively Manufactured Stainless Steel Printed Using Different Island Size

Abstract

1. Introduction

2. Experimental

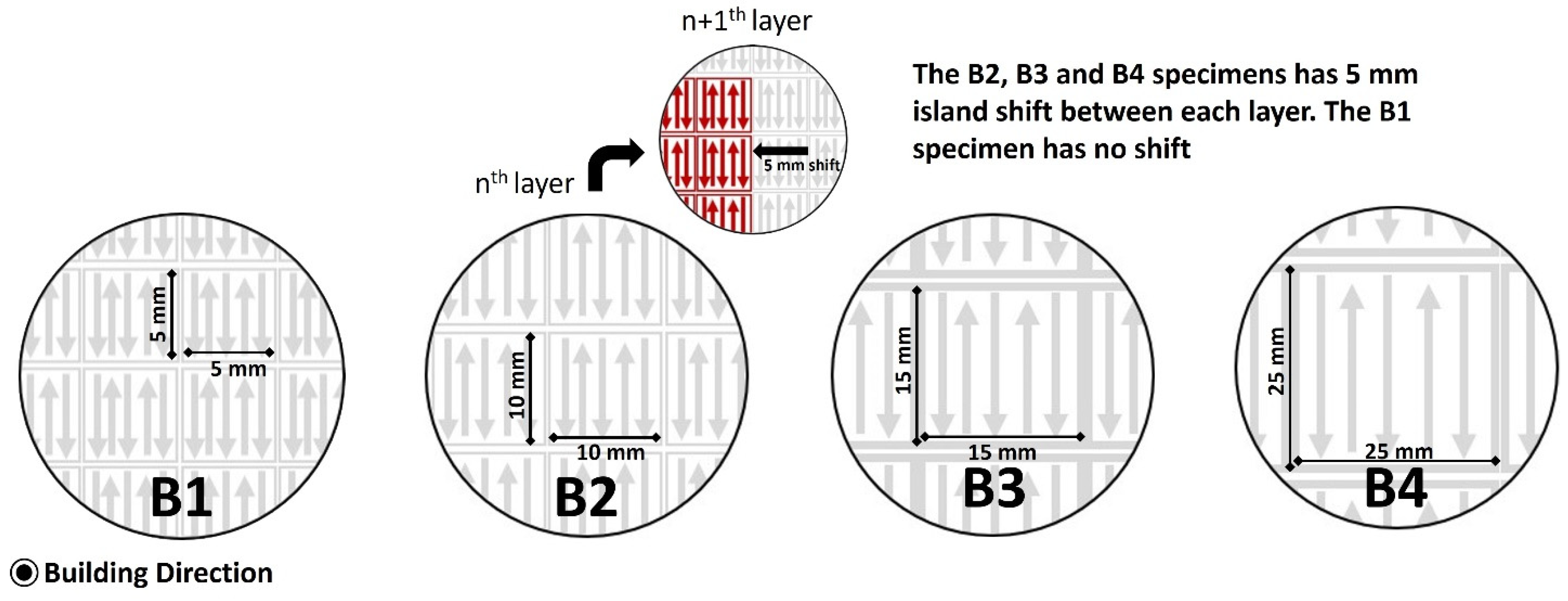

2.1. Materials and Laser—Powder Bed Fusion

2.2. Characterization

2.3. Electrochemical Testing

2.4. Microhardness

3. Results and Discussion

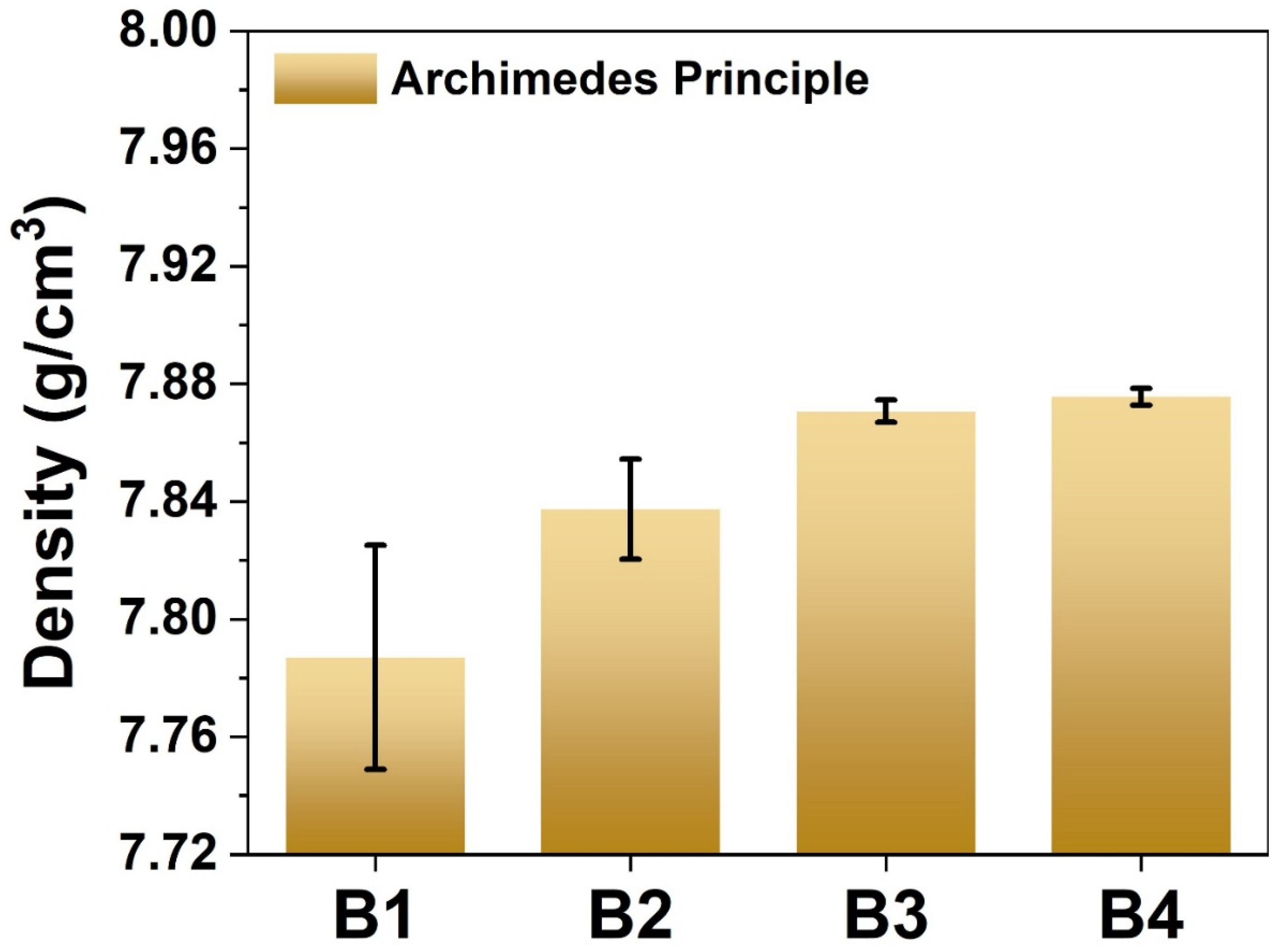

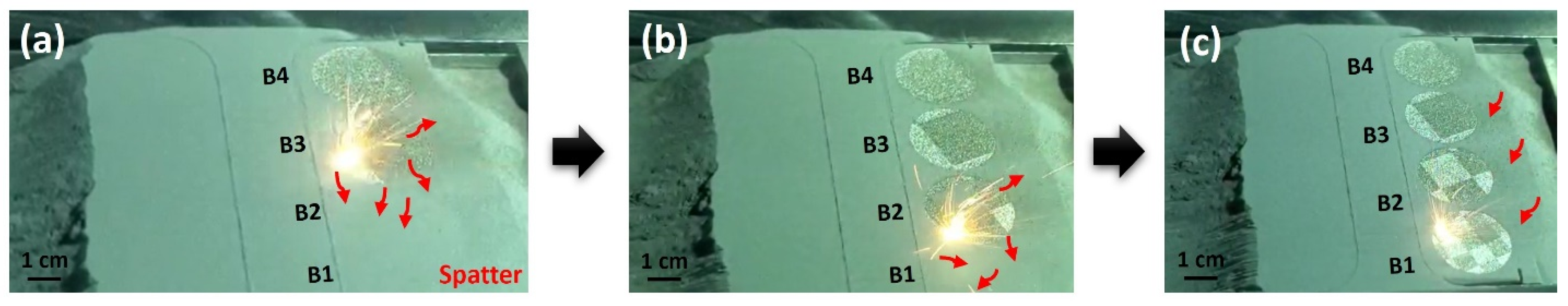

3.1. Density of LPBF Specimens

3.2. Microstructure of LPBF Specimens

3.3. Properties of LPBF Specimens

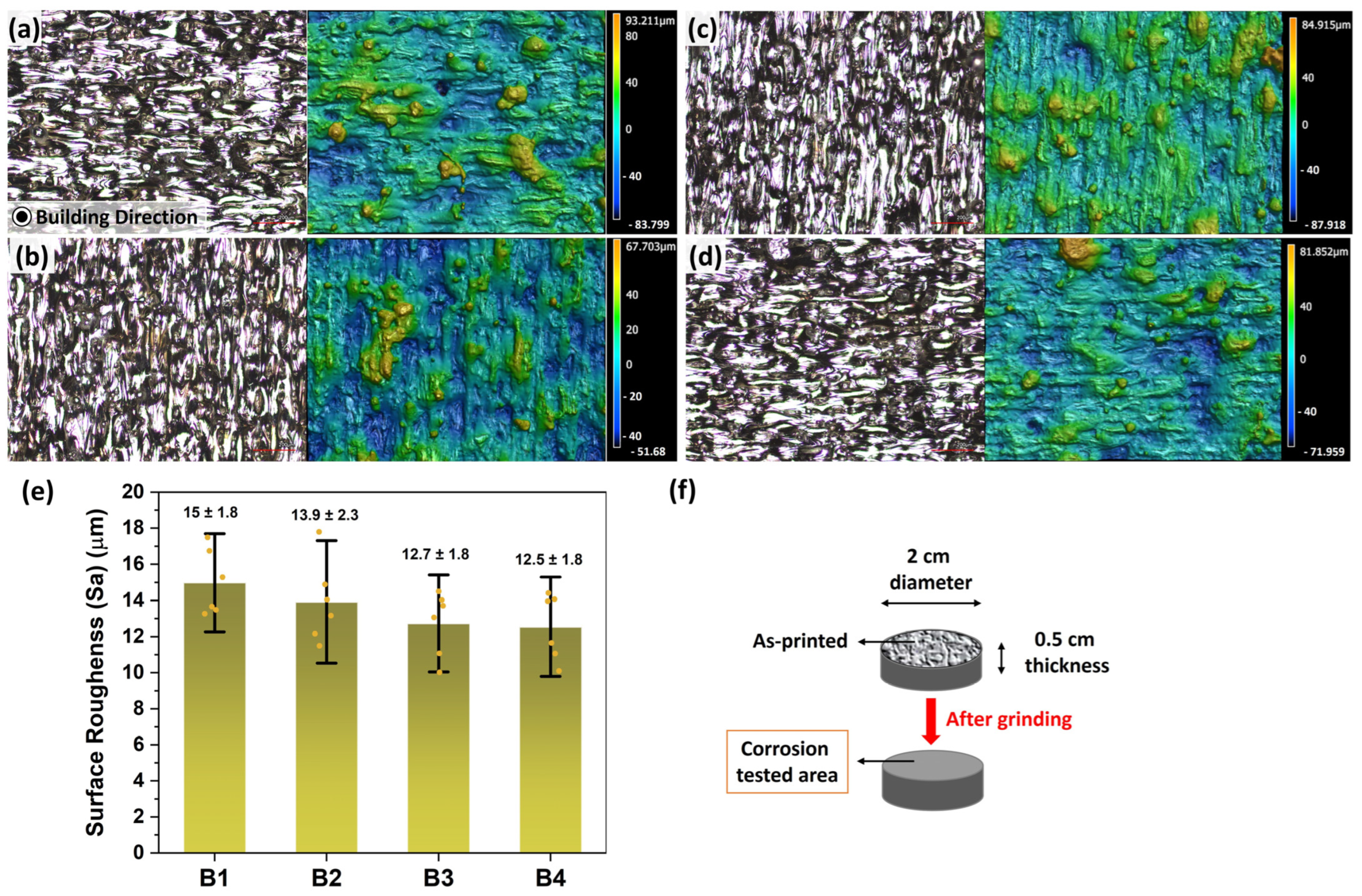

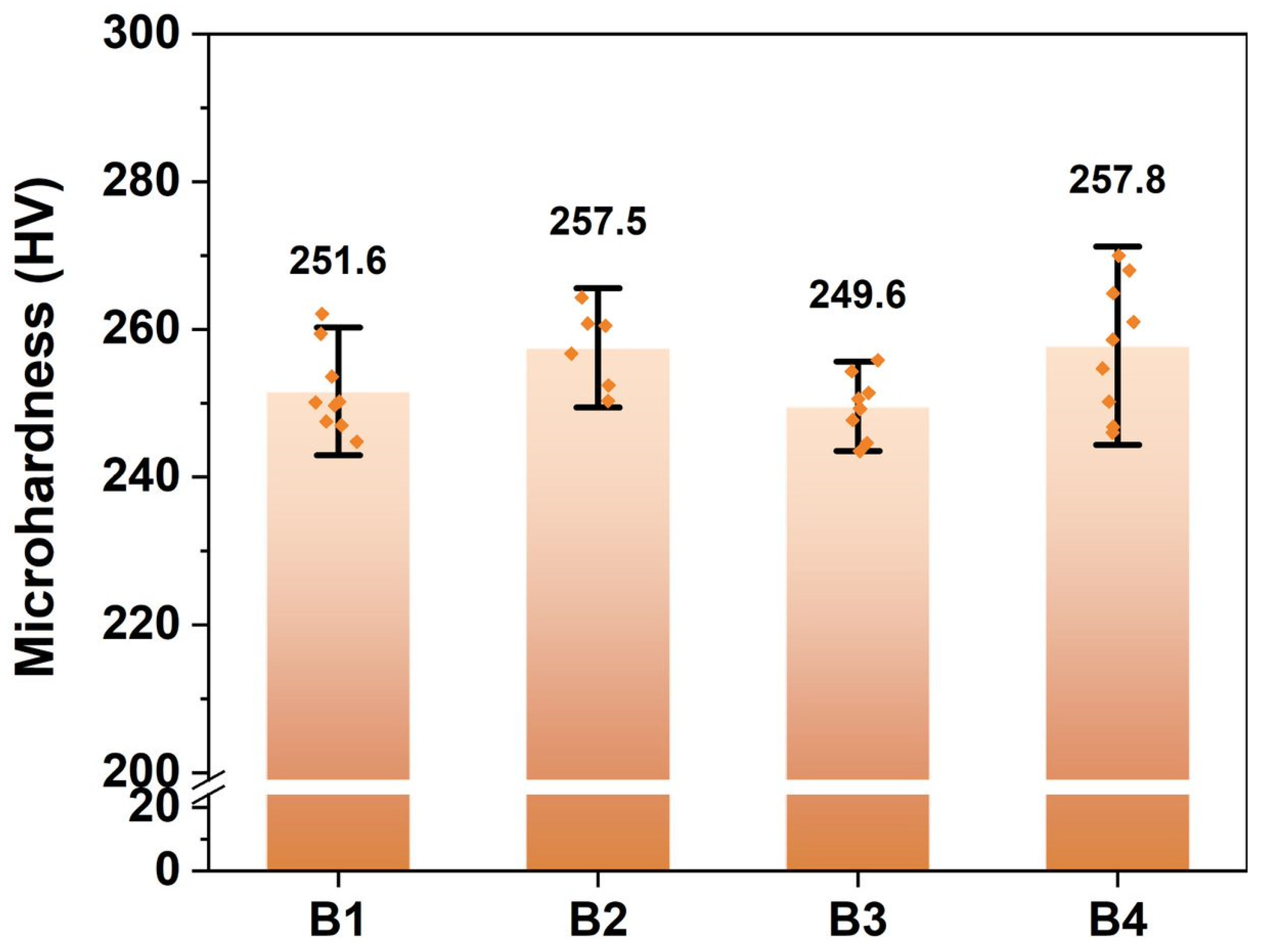

3.3.1. Surface Roughness and Microhardness

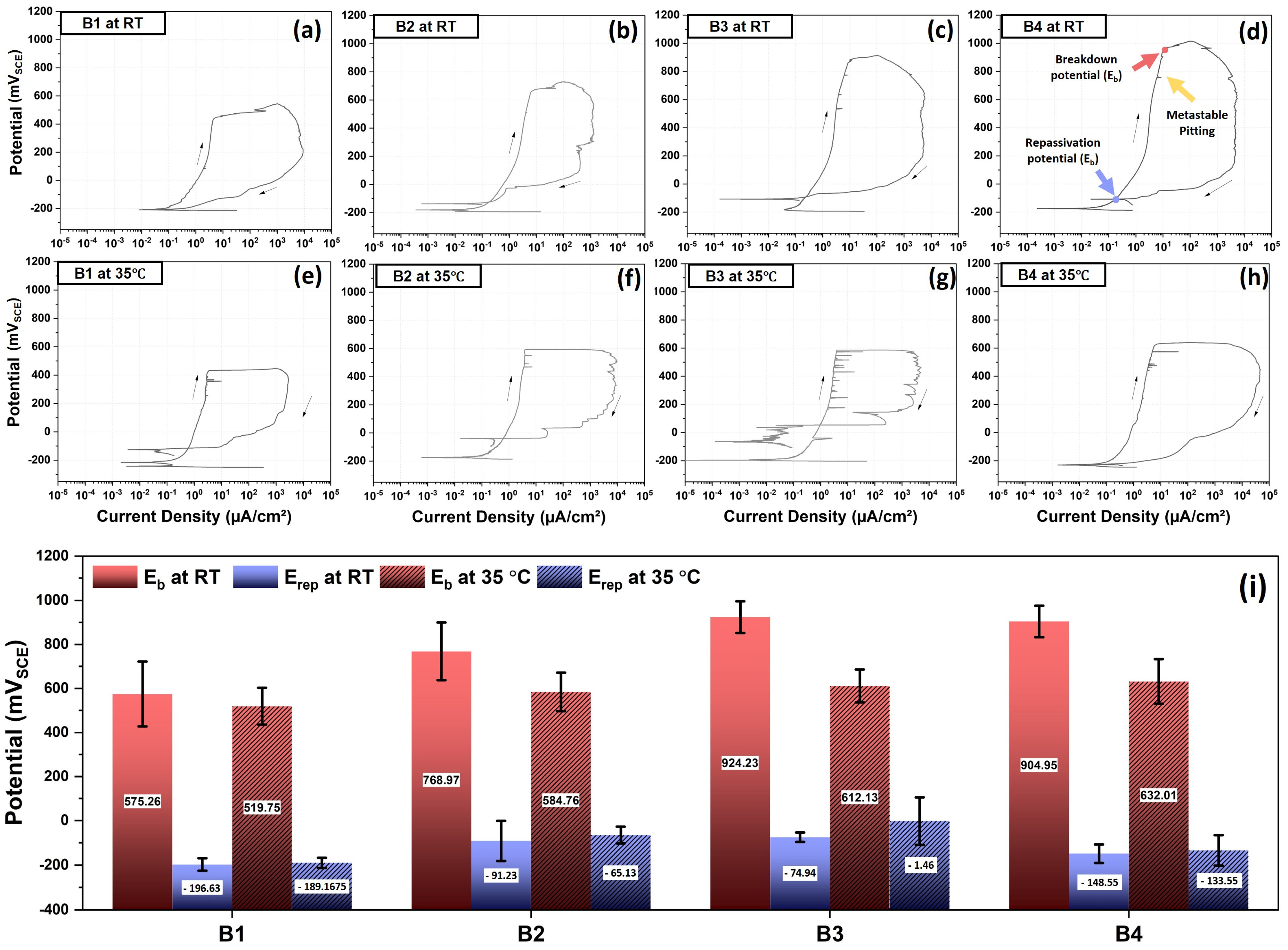

3.3.2. Corrosion Performance

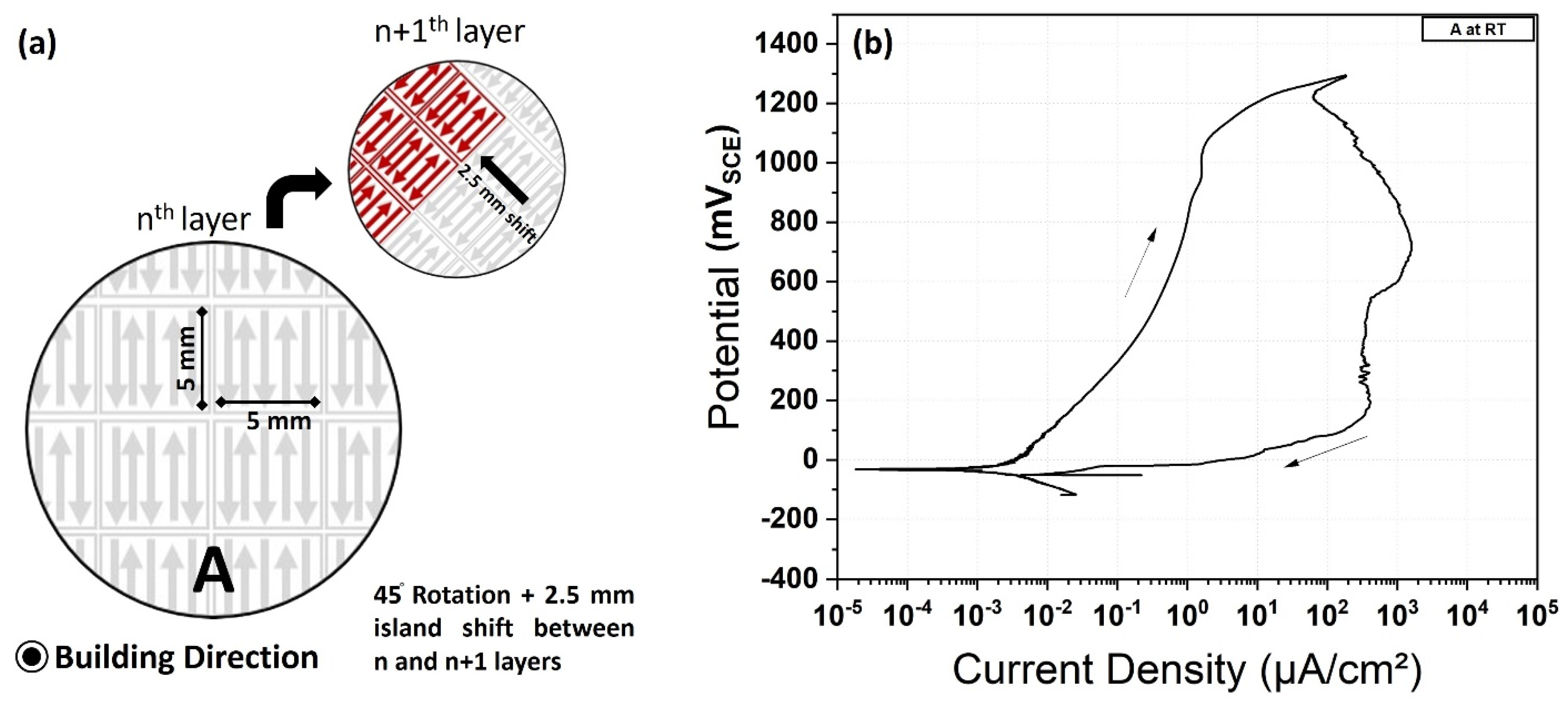

3.4. Enhanced Corrosion Resistance with Revised LPBF Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rajaguru, K.; Karthikeyan, T.; Vijayan, V. Additive manufacturing—State of art. Mater. Today Proc. 2020, 21, 628–633. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Singh, R.; Gupta, A.; Tripathi, O.; Srivastava, S.; Singh, B.; Awasthi, A.; Rajput, S.; Sonia, P.; Singhal, P.; Saxena, K.K. Powder bed fusion process in additive manufacturing: An overview. Mater. Today Proc. 2020, 26, 3058–3070. [Google Scholar] [CrossRef]

- Vukkum, V.; Gupta, R. Review on corrosion performance of laser powder-bed fusion printed 316L stainless steel: Effect of processing parameters, manufacturing defects, post-processing, feedstock, and microstructure. Mater. Des. 2022, 221, 110874. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Ray, T.; Karmakar, A.; Das, S. Microstructure–Texture–Mechanical Property Correlation in Laser-Welded Dual-Phase and Interstitial-Free Steel Blanks. J. Mater. Eng. Perform. 2023, 33, 318–329. [Google Scholar] [CrossRef]

- Anatoliy, P.; Vadim, S. Metal Powder Additive Manufacturing. In New Trends 3D Print; InTech: Houston, TX, USA, 2016. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Pidge, P.A.; Kumar, H. Additive manufacturing: A review on 3 D printing of metals and study of residual stress, buckling load capacity of strut members. Mater. Today Proc. 2019, 21, 1689–1694. [Google Scholar] [CrossRef]

- Ozdemir, F.; Christudasjustus, J.; Vukkum, V.B.; Okuyucu, H.; Gupta, R.K. Need of an Inert Atmosphere for High-Energy Ball Milling of Al Alloys. J. Mater. Eng. Perform. 2022, 32, 3007–3013. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Christudasjustus, J.; Ansell, T.Y.; Nieto, A.; Gupta, R.K. Influence of carbon nanotubes on microstructure and corrosion performance of additively manufactured 316L stainless steel. Corros. Sci. 2023, 224, 111494. [Google Scholar] [CrossRef]

- Vukkum, V.B.; A Darwish, A.; Christudasjustus, J.; Storck, S.; Gupta, R.K. Corrosion Performance of Additively Manufactured 316L Stainless Steel Produced By Feedstock Modification. ECS Meet. Abstr. 2022, MA2022-01, 1013. [Google Scholar] [CrossRef]

- Vukkum, V.; Ozdemir, F.; Storck, S.; Gupta, R. Corrosion performance of feedstock modified—Additively manufactured stainless steel. Corros. Sci. 2022, 209, 110724. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Christudasjustus, J.; Darwish, A.A.; Storck, S.M.; Gupta, R.K. Enhanced corrosion resistance of additively manufactured stainless steel by modification of feedstock. npj Mater. Degrad. 2022, 6, 2. [Google Scholar] [CrossRef]

- Santa-Aho, S.; Kiviluoma, M.; Jokiaho, T.; Gundgire, T.; Honkanen, M.; Lindgren, M.; Vippola, M. Additive Manufactured 316L Stainless-Steel Samples: Microstructure, Residual Stress and Corrosion Characteristics after Post-Processing. Metals 2021, 11, 182. [Google Scholar] [CrossRef]

- Chen, L.; Richter, B.; Zhang, X.; Ren, X.; Pfefferkorn, F.E. Modification of surface characteristics and electrochemical corrosion behavior of laser powder bed fused stainless-steel 316L after laser polishing. Addit. Manuf. 2020, 32, 101013. [Google Scholar] [CrossRef]

- Nieto, A.; Vukkum, V.B.; Jalagam, P.; Nema, K.; Budan, J.; Gupta, R.K.; Ansell, T.Y. 3D printed carbon nanotube reinforced stainless steel via selective laser melting. MRS Commun. 2022, 12, 578–584. [Google Scholar] [CrossRef]

- Vukkum, V.B.; Delvecchio, E.; Christudasjustus, J.; Storck, S.; Gupta, R.K. Intergranular Corrosion of Feedstock Modified—Additively Manufactured Stainless Steel After Sensitization. Corrosion 2023, 79, 624–636. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef]

- Minasyan, T.; Hussainova, I. Laser Powder-Bed Fusion of Ceramic Particulate Reinforced Aluminum Alloys: A Review. Materials 2022, 15, 2467. [Google Scholar] [CrossRef]

- Jadhav, S.D.; Goossens, L.R.; Kinds, Y.; Van Hooreweder, B.; Vanmeensel, K. Laser-based powder bed fusion additive manufacturing of pure copper. Addit. Manuf. 2021, 42, 101990. [Google Scholar] [CrossRef]

- Godec, M.; Donik, Č.; Kocijan, A.; Podgornik, B.; Balantič, D.S. Effect of post-treated low-temperature plasma nitriding on the wear and corrosion resistance of 316L stainless steel manufactured by laser powder-bed fusion. Addit. Manuf. 2020, 32, 101000. [Google Scholar] [CrossRef]

- Qu, S.; Ding, J.; Fu, J.; Fu, M.; Zhang, B.; Song, X. High-precision laser powder bed fusion processing of pure copper. Addit. Manuf. 2021, 48, 102417. [Google Scholar] [CrossRef]

- Depboylu, F.N.; Yasa, E.; Poyraz, Ö.; Minguella-Canela, J.; Korkusuz, F.; López, M.A.d.L.S. Titanium based bone implants production using laser powder bed fusion technology. J. Mater. Res. Technol. 2022, 17, 1408–1426. [Google Scholar] [CrossRef]

- Liu, J.; Wen, P. Metal vaporization and its influence during laser powder bed fusion process. Mater. Des. 2022, 215, 110505. [Google Scholar] [CrossRef]

- Walker, J.; Middendorf, J.R.; Lesko, C.C.; Gockel, J. Multi-material laser powder bed fusion additive manufacturing in 3-dimensions. Manuf. Lett. 2022, 31, 74–77. [Google Scholar] [CrossRef]

- Li, R.; Liu, J.; Shi, Y.; Du, M.; Xie, Z. 316L Stainless Steel with Gradient Porosity Fabricated by Selective Laser Melting. J. Mater. Eng. Perform. 2010, 19, 666–671. [Google Scholar] [CrossRef]

- Sun, Z.J.; Tan, X.P.; Tor, S.B.; Yeong, W.Y. Selective laser melting of stainless steel 316L with low porosity and high build rates. Mater. Des. 2016, 104, 197–204. [Google Scholar] [CrossRef]

- Wang, G.; Liu, Q.; Rao, H.; Liu, H.; Qiu, C. Influence of porosity and microstructure on mechanical and corrosion properties of a selectively laser melted stainless steel. J. Alloys Compd. 2020, 831, 154815. [Google Scholar] [CrossRef]

- Sola, A.; Nouri, A. Microstructural porosity in additive manufacturing: The formation and detection of pores in metal parts fabricated by powder bed fusion. J. Adv. Manuf. Process. 2019, 1, e10021. [Google Scholar] [CrossRef]

- Liu, M.; Zhu, J.-N.; Popovich, V.; Borisov, E.; Mol, J.; Gonzalez-Garcia, Y. Passive film formation and corrosion resistance of laser-powder bed fusion fabricated NiTi shape memory alloys. J. Mater. Res. Technol. 2023, 23, 2991–3006. [Google Scholar] [CrossRef]

- Oliveira, J.P.; LaLonde, A.D.; Ma, J. Processing parameters in laser powder bed fusion metal additive manufacturing. Mater. Des. 2020, 193, 108762. [Google Scholar] [CrossRef]

- Tucho, W.M.; Lysne, V.H.; Austbø, H.; Sjolyst-Kverneland, A.; Hansen, V. Investigation of effects of process parameters on microstructure and hardness of SLM manufactured SS316L. J. Alloys Compd. 2018, 740, 910–925. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Liu, E.; Tor, S.B. Process parameter optimization and mechanical properties for additively manufactured stainless steel 316L parts by selective electron beam melting. Mater. Des. 2018, 147, 157–166. [Google Scholar] [CrossRef]

- Kurzynowski, T.; Gruber, K.; Stopyra, W.; Kuźnicka, B.; Chlebus, E. Correlation between process parameters, microstructure and properties of 316 L stainless steel processed by selective laser melting. Mater. Sci. Eng. A 2018, 718, 64–73. [Google Scholar] [CrossRef]

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A critical review of powder-based additive manufacturing of ferrous alloys: Process parameters, microstructure and mechanical properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Eliasu, A.; Czekanski, A.; Boakye-Yiadom, S. Effect of laser powder bed fusion parameters on the microstructural evolution and hardness of 316L stainless steel. Int. J. Adv. Manuf. Technol. 2021, 113, 2651–2669. [Google Scholar] [CrossRef]

- Dursun, G.; Ibekwe, S.; Li, G.; Mensah, P.; Joshi, G.; Jerro, D. Influence of laser processing parameters on the surface characteristics of 316L stainless steel manufactured by selective laser melting. Mater. Today Proc. 2020, 26, 387–393. [Google Scholar] [CrossRef]

- Liverani, E.; Toschi, S.; Ceschini, L.; Fortunato, A. Effect of selective laser melting (SLM) process parameters on microstructure and mechanical properties of 316L austenitic stainless steel. J. Am. Acad. Dermatol. 2017, 249, 255–263. [Google Scholar] [CrossRef]

- Ni, X.; Kong, D.; Wu, W.; Zhang, L.; Dong, C.; He, B.; Lu, L.; Wu, K.; Zhu, D. Corrosion Behavior of 316L Stainless Steel Fabricated by Selective Laser Melting Under Different Scanning Speeds. J. Mater. Eng. Perform. 2018, 27, 3667–3677. [Google Scholar] [CrossRef]

- Puichaud, A.-H.; Flament, C.; Chniouel, A.; Lomello, F.; Rouesne, E.; Giroux, P.-F.; Maskrot, H.; Schuster, F.; Béchade, J.-L. Microstructure and mechanical properties relationship of additively manufactured 316L stainless steel by selective laser melting. EPJ Nucl. Sci. Technol. 2019, 5, 23. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, Y.; Mai, S.; Wang, D.; Song, C. Investigation into spatter behavior during selective laser melting of AISI 316L stainless steel powder. Mater. Des. 2015, 87, 797–806. [Google Scholar] [CrossRef]

- Khairallah, S.A.; Anderson, A.T.; Rubenchik, A.; King, W.E. Laser powder-bed fusion additive manufacturing: Physics of complex melt flow and formation mechanisms of pores, spatter, and denudation zones. Acta Mater. 2016, 108, 36–45. [Google Scholar] [CrossRef]

- Simonelli, M.; Tuck, C.; Aboulkhair, N.T.; Maskery, I.; Ashcroft, I.; Wildman, R.D.; Hague, R. A Study on the Laser Spatter and the Oxidation Reactions During Selective Laser Melting of 316L Stainless Steel, Al-Si10-Mg, and Ti-6Al-4V. Met. Mater. Trans. A 2015, 46, 3842–3851. [Google Scholar] [CrossRef]

- Ahmed, N.; Barsoum, I.; Haidemenopoulos, G.; Abu Al-Rub, R. Process parameter selection and optimization of laser powder bed fusion for 316L stainless steel: A review. J. Manuf. Process. 2022, 75, 415–434. [Google Scholar] [CrossRef]

- Salman, O.; Brenne, F.; Niendorf, T.; Eckert, J.; Prashanth, K.; He, T.; Scudino, S. Impact of the scanning strategy on the mechanical behavior of 316L steel synthesized by selective laser melting. J. Manuf. Process. 2019, 45, 255–261. [Google Scholar] [CrossRef]

- Jia, H.; Sun, H.; Wang, H.; Wu, Y.; Wang, H. Scanning strategy in selective laser melting (SLM): A review. Int. J. Adv. Manuf. Technol. 2021, 113, 2413–2435. [Google Scholar] [CrossRef]

- Song, Y.; Sun, Q.; Guo, K.; Wang, X.; Liu, J.; Sun, J. Effect of scanning strategies on the microstructure and mechanical behavior of 316L stainless steel fabricated by selective laser melting. Mater. Sci. Eng. A 2020, 793, 139879. [Google Scholar] [CrossRef]

- Marattukalam, J.J.; Karlsson, D.; Pacheco, V.; Beran, P.; Wiklund, U.; Jansson, U.; Hjörvarsson, B.; Sahlberg, M. The effect of laser scanning strategies on texture, mechanical properties, and site-specific grain orientation in selective laser melted 316L SS. Mater. Des. 2020, 193, 108852. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of laser power and scanning strategy on residual stress distribution in additively manufactured 316L steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Lu, Y.; Wu, S.; Gan, Y.; Huang, T.; Yang, C.; Junjie, L.; Lin, J. Study on the microstructure, mechanical property and residual stress of SLM Inconel-718 alloy manufactured by differing island scanning strategy. Opt. Laser Technol. 2015, 75, 197–206. [Google Scholar] [CrossRef]

- Larimian, T.; Kannan, M.; Grzesiak, D.; AlMangour, B.; Borkar, T. Effect of energy density and scanning strategy on densification, microstructure and mechanical properties of 316L stainless steel processed via selective laser melting. Mater. Sci. Eng. A 2020, 770, 138455. [Google Scholar] [CrossRef]

- Roirand, H.; Malard, B.; Hor, A.; Saintier, N. Effect of laser scan pattern in laser powder bed fusion process: The case of 316L stainless steel. Procedia Struct. Integr. 2021, 38, 149–158. [Google Scholar] [CrossRef]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Met. Mater. Trans. A 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Zhang, H.; Vallabh, C.K.P.; Zhao, X. Influence of spattering on in-process layer surface roughness during laser powder bed fusion. J. Manuf. Process. 2023, 104, 289–306. [Google Scholar] [CrossRef]

- Young, Z.A.; Guo, Q.; Parab, N.D.; Zhao, C.; Qu, M.; Escano, L.I.; Fezzaa, K.; Everhart, W.; Sun, T.; Chen, L. Types of spatter and their features and formation mechanisms in laser powder bed fusion additive manufacturing process. Addit. Manuf. 2020, 36, 101438. [Google Scholar] [CrossRef]

- Wang, Y.; Guo, W.; Xie, Y.; Li, H.; Zeng, C.; Xu, M.; Zhang, H. In-situ monitoring plume, spattering behavior and revealing their relationship with melt flow in laser powder bed fusion of nickel-based superalloy. J. Mater. Sci. Technol. 2024, 177, 44–58. [Google Scholar] [CrossRef]

- Pinto, F.; Filho, I.S.; Sandim, M.; Sandim, H. Defects in parts manufactured by selective laser melting caused by δ-ferrite in reused 316L steel powder feedstock. Addit. Manuf. 2020, 31, 100979. [Google Scholar] [CrossRef]

- Lu, C.; Zhang, R.; Wei, X.; Xiao, M.; Yin, Y.; Qu, Y.; Li, H.; Liu, P.; Qiu, X.; Guo, T. An investigation on the oxidation behavior of spatters generated during the laser powder bed fusion of 316L stainless steel. Appl. Surf. Sci. 2022, 586, 152796. [Google Scholar] [CrossRef]

| Element | Cr | Ni | Mo | Mn | Si | C | N | Cu | S | P | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 18 | 13.57 | 2.66 | 1.56 | 0.26 | 0.005 | 0.07 | 0.01 | <0.005 | 0.012 | Balance |

| LPBF Specimens | |||||

|---|---|---|---|---|---|

| B1 | B2 | B3 | B4 | A | |

| Laser power | 90 W | 90 W | 90 W | 90 W | 90 W |

| Laser scanning speed | 1500 mm/s | 1500 mm/s | 1500 mm/s | 1500 mm/s | 1500 mm/s |

| Layer thickness | 0.015 mm | 0.015 mm | 0.015 mm | 0.015 mm | 0.015 mm |

| Hatch spacing | 0.08 mm | 0.08 mm | 0.08 mm | 0.08 mm | 0.08 mm |

| Laser scanning strategy (Island pattern) | No shift | 5 mm shift | 5 mm shift | 5 mm shift | 2.5 mm shift, 45° rotation |

| Island size | 5 × 5 mm (No Shift) | 10 × 10 mm | 15 × 15 mm | 25 × 25 mm | 5 × 5 mm |

| Porosity | 2.85% | 1.44% | 1.43% | 0.86% | 0.34% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vukkum, V.B.; Sanborn, T.; Shepherd, J.; Saptarshi, S.; Basu, R.; Horn, T.; Gupta, R.K. Influence of Spatter on Porosity, Microstructure, and Corrosion of Additively Manufactured Stainless Steel Printed Using Different Island Size. Crystals 2024, 14, 328. https://doi.org/10.3390/cryst14040328

Vukkum VB, Sanborn T, Shepherd J, Saptarshi S, Basu R, Horn T, Gupta RK. Influence of Spatter on Porosity, Microstructure, and Corrosion of Additively Manufactured Stainless Steel Printed Using Different Island Size. Crystals. 2024; 14(4):328. https://doi.org/10.3390/cryst14040328

Chicago/Turabian StyleVukkum, Venkata Bhuvaneswari, Taylor Sanborn, John Shepherd, Sourabh Saptarshi, Rakesh Basu, Timothy Horn, and Rajeev Kumar Gupta. 2024. "Influence of Spatter on Porosity, Microstructure, and Corrosion of Additively Manufactured Stainless Steel Printed Using Different Island Size" Crystals 14, no. 4: 328. https://doi.org/10.3390/cryst14040328

APA StyleVukkum, V. B., Sanborn, T., Shepherd, J., Saptarshi, S., Basu, R., Horn, T., & Gupta, R. K. (2024). Influence of Spatter on Porosity, Microstructure, and Corrosion of Additively Manufactured Stainless Steel Printed Using Different Island Size. Crystals, 14(4), 328. https://doi.org/10.3390/cryst14040328