Influence of Powder Size on Pore Characteristics and Intermetallic Phase Kinetics in Porous Ti-Al Alloys †

Abstract

:1. Introduction

2. Materials and Methods

3. Results

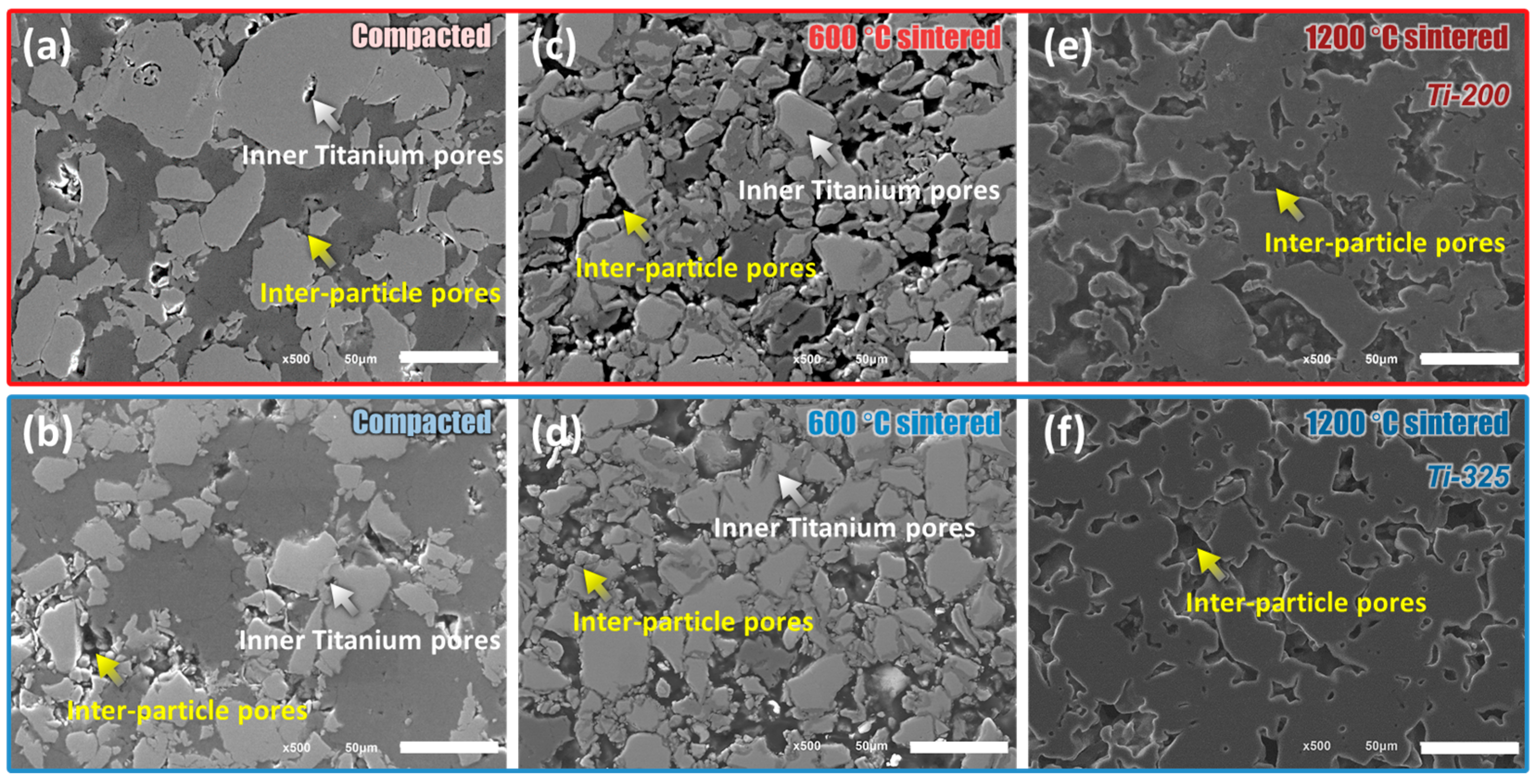

3.1. Effect of Powder Size on Microstructure and Bulk Volume

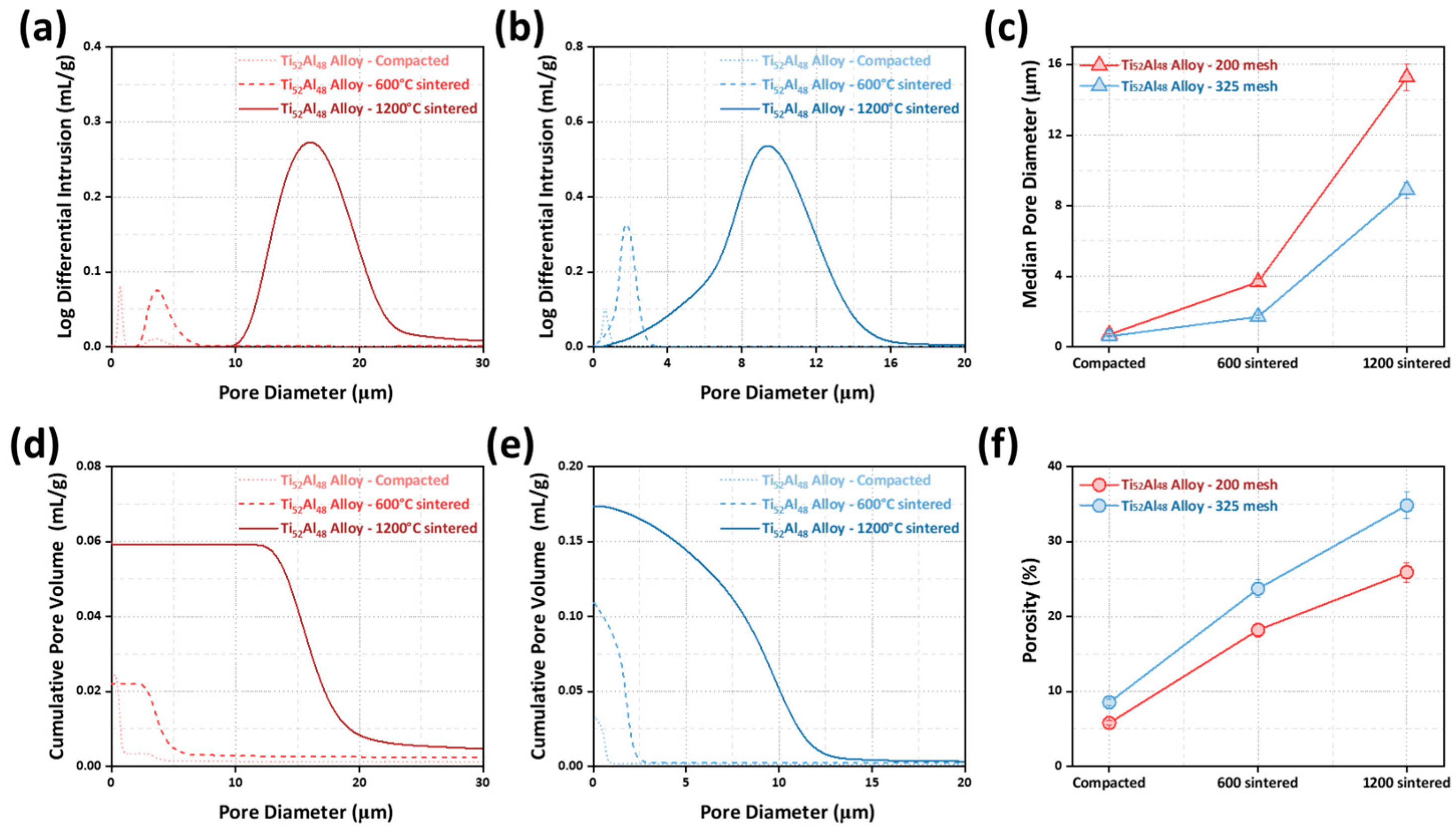

3.2. Effect of Powder Size on Pore Size and Porosity

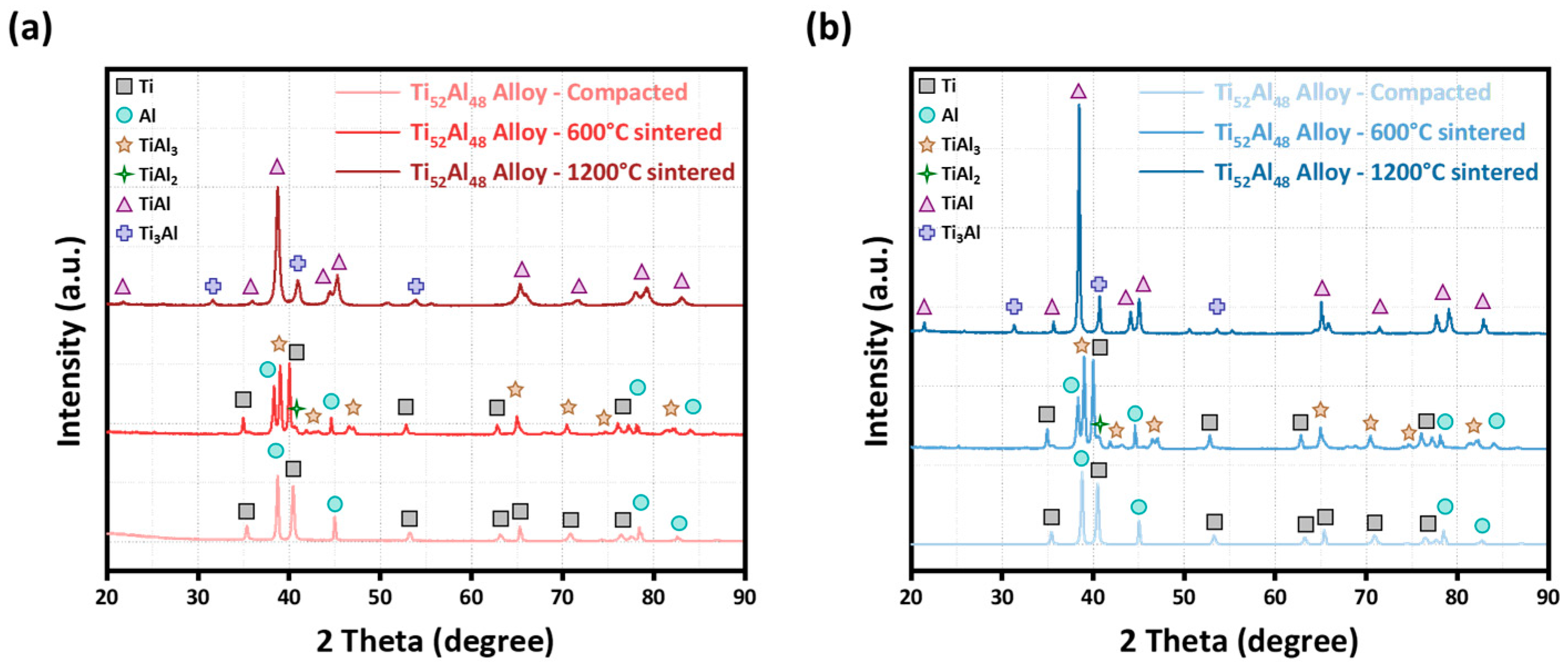

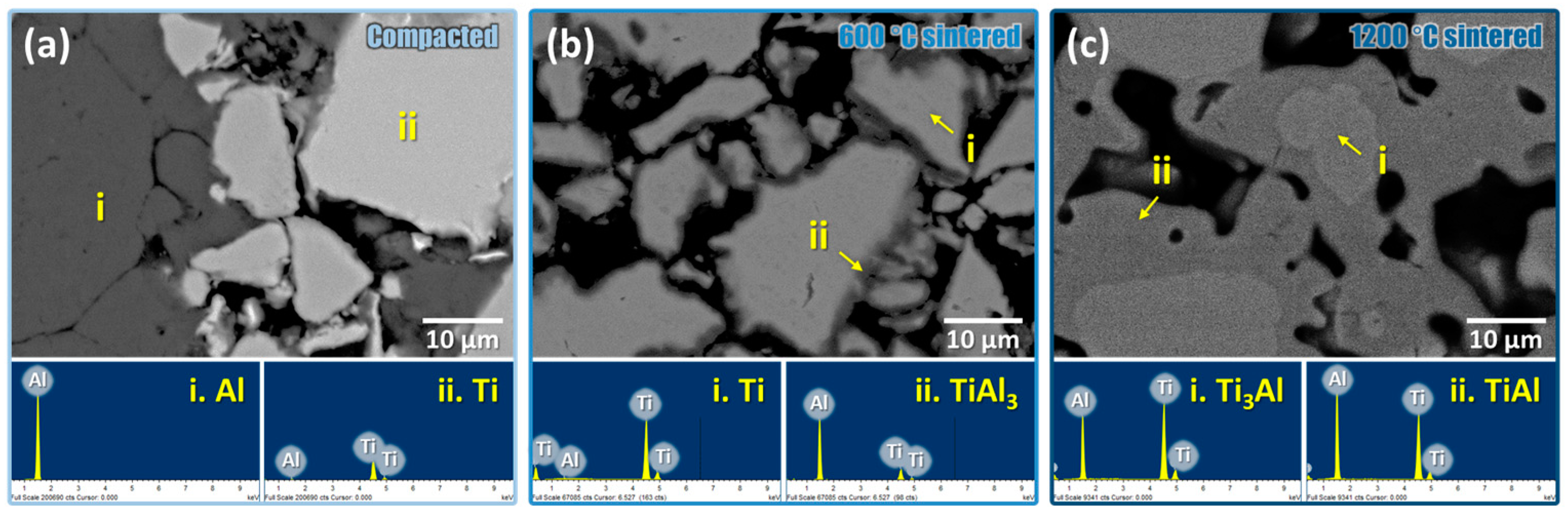

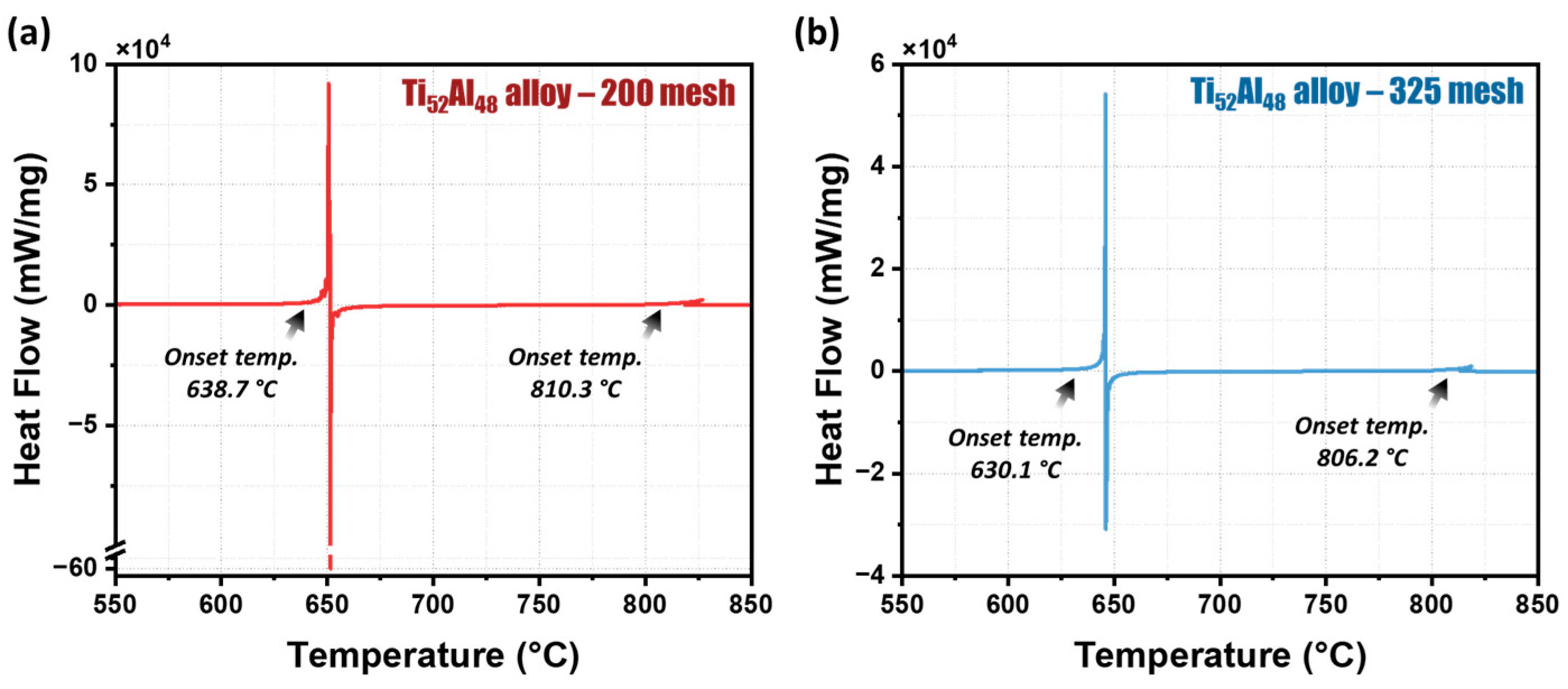

3.3. Effect of Powder Size on Intermetallic Phases

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Guan, B.Y.; Gao, S.; Lou, X.W.D. A general dual-templating approach to biomass-derived hierarchically porous heteroatom-doped carbon materials for enhanced electrocatalytic oxygen reduction. Energy Environ. Sci. 2019, 12, 648–655. [Google Scholar] [CrossRef]

- Yang, X.-Y.; Chen, L.-H.; Li, Y.; Rooke, J.C.; Sanchez, C.; Su, B.-L. Hierarchically porous materials: Synthesis strategies and structure design. Chem. Soc. Rev. 2017, 46, 481–558. [Google Scholar] [CrossRef]

- Sina, H.; Iyengar, S. Reactive synthesis and characterization of titanium aluminides produced from elemental powder mixtures. J. Therm. Anal. Calorim. 2015, 122, 689–698. [Google Scholar] [CrossRef]

- Jiang, Y.; Deng, C.; He, Y.; Zhao, Y.; Xu, N.; Zou, J.; Huang, B.; Liu, C.T. Reactive synthesis of microporous titanium-aluminide membranes. Mater. Lett. 2009, 63, 22–24. [Google Scholar] [CrossRef]

- Shi, Q.; Qin, B.; Feng, P.; Ran, H.; Song, B.; Wang, J.; Ge, Y. Synthesis, microstructure and properties of Ti–Al porous intermetallic compounds prepared by a thermal explosion reaction. RSC Adv. 2015, 5, 46339–46347. [Google Scholar] [CrossRef]

- Sun, M.-H.; Huang, S.-Z.; Chen, L.-H.; Li, Y.; Yang, X.-Y.; Yuan, Z.-Y.; Su, B.-L. Applications of hierarchically structured porous materials from energy storage and conversion, catalysis, photocatalysis, adsorption, separation, and sensing to biomedicine. Chem. Soc. Rev. 2016, 45, 3479–3563. [Google Scholar] [CrossRef]

- Zhang, G.-H.; Zhu, Q.-H.; Zhang, L.; Yong, F.; Zhang, Z.; Wang, S.-L.; Wang, Y.; He, L.; Tao, G.-H. High-performance particulate matter including nanoscale particle removal by a self-powered air filter. Nat. Commun. 2020, 11, 1653. [Google Scholar] [CrossRef]

- Sharma, P.; Yadav, P.; Ghosh, C.; Singh, B. Heavy metal capture from the suspended particulate matter by Morus alba and evidence of foliar uptake and translocation of PM associated zinc using radiotracer (65Zn). Chemosphere 2020, 254, 126863. [Google Scholar] [CrossRef] [PubMed]

- Petriev, I.; Pushankina, P.; Bolotin, S.; Lutsenko, I.; Kukueva, E.; Baryshev, M. The influence of modifying nanoflower and nanostar type Pd coatings on low temperature hydrogen permeability through Pd-containing membranes. J. Membr. Sci. 2021, 620, 118894. [Google Scholar] [CrossRef]

- Aydoğmuş, T.; Palani, D.K.H.; Kelen, F. Processing of porous β-type Ti74Nb26 alloys for biomedical applications. J. Alloys Compd. 2021, 872, 159737. [Google Scholar] [CrossRef]

- Cobbinah, P.V.; Matizamhuka, W.; Machaka, R.; Shongwe, M.B.; Yamabe-Mitarai, Y. The effect of Ta additions on the oxidation resistance of SPS-produced TiAl alloys. Int. J. Adv. Manuf. Technol. 2020, 106, 3203–3215. [Google Scholar] [CrossRef]

- Cai, X.; Bo, X.; Feng, P.; Ren, X.; Kang, X.; Xu, C.; Zhang, P. Porous NbAl3/TiAl3 intermetallic composites with controllable porosity and pore morphology prepared by two-step thermal explosion. J. Mater. Res. Technol. 2019, 8, 3188–3197. [Google Scholar] [CrossRef]

- Kothari, K.; Radhakrishnan, R.; Wereley, N.M. Advances in gamma titanium aluminides and their manufacturing techniques. Prog. Aerosp. Sci. 2012, 55, 1–16. [Google Scholar] [CrossRef]

- Jiang, Y.; He, Y.H.; Xu, N.P.; Zou, J.; Huang, B.Y.; Liu, C.T. Effects of the Al content on pore structures of porous Ti–Al alloys. Intermetallics 2008, 16, 327–332. [Google Scholar] [CrossRef]

- Kayani, S.H.; Cui, M.; Ahmed, R.T.M.; Cho, Y.-H.; Lee, J.-M.; Park, N.-K.; Ajmal, H.M.S.; Euh, K. Pore formation mechanism and intermetallic phase transformation in Ti–Al alloy during reactive sintering. J. Mater. Res. Technol. 2023, 22, 1878–1887. [Google Scholar] [CrossRef]

- Wang, Y.H.; Lin, J.P.; He, Y.H.; Wang, Y.L.; Chen, G.L. Effect of Nb on pore structure and tensile property of Ti–48Al cellular alloy. J. Alloys Compd. 2008, 456, 297–303. [Google Scholar] [CrossRef]

- Meng, X.L.; Cai, W.; Lau, K.T.; Zhao, L.C.; Zhou, L.M. Phase transformation and microstructure of quaternary TiNiHfCu high temperature shape memory alloys. Intermetallics 2005, 13, 197–201. [Google Scholar] [CrossRef]

- Ma, Y.; Fan, Q.; Zhang, J.; Shi, J.; Xiao, G.; Gu, M. Microstructural evolution during self-propagating high-temperature synthesis of Ti-Al system. J. Wuhan Univ. Technol.-Mater Sci. Ed. 2008, 23, 381–385. [Google Scholar] [CrossRef]

- He, Y.H.; Jiang, Y.; Xu, N.P.; Zou, J.; Huang, B.Y.; Liu, C.T.; Liaw, P.K. Fabrication of Ti–Al Micro/ Nanometer-Sized Porous Alloys through the Kirkendall Effect. Adv. Mater. 2007, 19, 2102–2106. [Google Scholar] [CrossRef]

- Mishin, Y.; Herzig, C. Diffusion in the Ti–Al system. Acta Mater. 2000, 48, 589–623. [Google Scholar] [CrossRef]

- Gupta, R.K.; Pant, B.; Agarwala, V.; Sinha, P.P. Differential scanning calorimetry and reaction kinetics studies of γ + α2 Ti aluminide. Mater. Chem. Phys. 2012, 137, 483–492. [Google Scholar] [CrossRef]

- Herzig, C.; Przeorski, T.; Mishin, Y. Self-diffusion in γ-TiAl: An experimental study and atomistic calculations. Intermetallics 1999, 7, 389–404. [Google Scholar] [CrossRef]

- Mackowiak, J.; Shreir, L.L. The nature and growth of interaction layers formed during the reaction between solid titanium and liquid aluminium. J. Less Common Met. 1959, 1, 456–466. [Google Scholar] [CrossRef]

- Sohn, H.Y.; Wang, X. Mathematical and experimental investigation of the self-propagating high-temperature synthesis (SHS) of TiAl3 and Ni3Al intermetallic compounds. J. Mater. Sci. 1996, 31, 3281–3288. [Google Scholar] [CrossRef]

- Mphahlele, M.R.; Olubambi, P.A.; Olevsky, E.A. Advances in Sintering of Titanium Aluminide: A Review. JOM 2023, 75, 2877–2896. [Google Scholar] [CrossRef]

- Karunanithi, R.; Prashanth, M.; Kamaraj, M.; Sivasankaran, S.; Kumaraswamidhas, L.A.; Alhomidan, A.A. Synthesis, characterization, and mechanical behavior of ultra-fine-grained Ti-6Al-5V alloy prepared by mechanical alloying and spark plasma sintering. Mater. Today Commun. 2024, 38, 108228. [Google Scholar] [CrossRef]

- Gerling, R.; Clemens, H.; Schimansky, F.P. Powder Metallurgical Processing of Intermetallic Gamma Titanium Aluminides. Adv. Eng. Mater. 2004, 6, 23–38. [Google Scholar] [CrossRef]

- Gao, H.Y.; He, Y.H.; Shen, P.Z.; Jiang, Y.; Liu, C.T. Effect of pressure on pore structure of porous FeAl intermetallics. Adv. Powder Technol. 2015, 26, 882–886. [Google Scholar] [CrossRef]

- Liang, Y.; Yang, F.; Zhang, L.; Lin, J.; Shang, S.; Liu, Z.-K. Reaction behavior and pore formation mechanism of TiAl–Nb porous alloys prepared by elemental powder metallurgy. Intermetallics 2014, 44, 1–7. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, L.; Lin, J.; Liang, Y.; He, Y.; Shang, S.; Liu, Z.-K. Pore structure and gas permeability of high Nb-containing TiAl porous alloys by elemental powder metallurgy for microfiltration application. Intermetallics 2013, 33, 2–7. [Google Scholar] [CrossRef]

- Kayani, S.H.; Park, N.-K. Effect of Cr and Nb on the phase transformation and pore formation of Ti-Al base alloys. J. Alloys Compd. 2017, 708, 308–315. [Google Scholar] [CrossRef]

- Li, K.; Zhang, T.; Zhu, Y. Reaction Behavior of Porous TiAl3 Intermetallics Fabricated by Thermal Explosion with Different Particle Sizes. Materials 2021, 14, 7417. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Zhang, W.; Peng, Y.; Fan, G.; Liu, B. Effects of TiAl Alloy as a Binder on Cubic Boron Nitride Composites. Materials 2021, 14, 6335. [Google Scholar] [CrossRef]

- Sienkiewicz, J.; Kuroda, S.; Molak, R.M.; Murakami, H.; Araki, H.; Takamori, S.; Kurzydłowski, K.J. Fabrication of TiAl intermetallic phases by heat treatment of warm sprayed metal precursors. Intermetallics 2014, 49, 57–64. [Google Scholar] [CrossRef]

- Wang, T.; Lu, Y.X.; Zhu, M.L.; Zhang, J.S.; Ji, S.J. DSC Research on Critical Temperature in Thermal Explosion Synthesis Reaction Ti+3Al→TiAl3. J. Therm. Anal. Calorim. 2002, 67, 605–611. [Google Scholar] [CrossRef]

- Školáková, A.; Leitner, J.; Salvetr, P.; Novák, P.; Deduytsche, D.; Kopeček, J.; Detavernier, C.; Vojtěch, D. Kinetic and thermodynamic description of intermediary phases formation in Ti-Al system during reactive sintering. Mater. Chem. Phys. 2019, 230, 122–130. [Google Scholar] [CrossRef]

- Sujata, M.; Bhargava, S.; Sangal, S. On the formation of TiAl3 during reaction between solid Ti and liquid Al. J. Mater. Sci. Lett. 1997, 16, 1175–1178. [Google Scholar] [CrossRef]

- Jiao, X.; Wang, X.; Feng, P.; Liu, Y.; Zhang, L.; Akhtar, F. Microstructure Evolution and Pore Formation Mechanism of Porous TiAl3 Intermetallics via Reactive Sintering. Acta Metall. Sin. Engl. Lett. 2018, 31, 440–448. [Google Scholar] [CrossRef]

- Jiao, X.; Ren, X.; Feng, P. Visible Observation and Formation Mechanism of Porous TiAl3 Intermetallics During the Continuous Sintering Process. JOM 2020, 72, 3652–3660. [Google Scholar] [CrossRef]

- Ye, S.; Hao, H.; Mo, W.; Yu, K.; Liu, L.; Deng, C.; Yu, P. Effects of cold compacting pressure on the expansion behavior of Ti-48Al during sintering. J. Alloys Compd. 2016, 673, 399–404. [Google Scholar] [CrossRef]

- Che, H.Q.; Fan, Q.C. Microstructural evolution during the ignition/quenching of pre-heated Ti/3Al powders. J. Alloys Compd. 2009, 475, 184–190. [Google Scholar] [CrossRef]

- Jiang, Y.; He, Y.; Liu, C.T. Review of porous intermetallic compounds by reactive synthesis of elemental powders. Intermetallics 2018, 93, 217–226. [Google Scholar] [CrossRef]

| Pore Parameters | 200 Mesh | 325 Mesh | ||||

|---|---|---|---|---|---|---|

| As-Compacted | 600 °C Sintered | 1200 °C Sintered | As-Compacted | 600 °C Sintered | 1200 °C Sintered | |

| Median Pore Size (µm) | 0.70 | 3.68 | 15.28 | 0.60 | 1.71 | 8.90 |

| Porosity (%) | 5.82 | 18.23 | 25.91 | 8.51 | 23.71 | 34.84 |

| Specimen | As-Compacted | 600 °C Sintered | 1200 °C Sintered | |||

|---|---|---|---|---|---|---|

| Location | Ti | Al | Ti | Al | Ti | Al |

| i (at. %) | 0.70 | 99.30 | 99.61 | 0.39 | 69.88 | 30.12 |

| ii (at. %) | 99.14 | 0.86 | 71.43 | 28.57 | 49.53 | 50.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kayani, S.H.; Ajmal, H.M.S.; Kim, B.-J.; Park, N.-K.; Euh, K. Influence of Powder Size on Pore Characteristics and Intermetallic Phase Kinetics in Porous Ti-Al Alloys. Crystals 2024, 14, 559. https://doi.org/10.3390/cryst14060559

Kayani SH, Ajmal HMS, Kim B-J, Park N-K, Euh K. Influence of Powder Size on Pore Characteristics and Intermetallic Phase Kinetics in Porous Ti-Al Alloys. Crystals. 2024; 14(6):559. https://doi.org/10.3390/cryst14060559

Chicago/Turabian StyleKayani, Saif Haider, Hafiz Muhammad Salman Ajmal, Byung-Joo Kim, Nho-Kwang Park, and Kwangjun Euh. 2024. "Influence of Powder Size on Pore Characteristics and Intermetallic Phase Kinetics in Porous Ti-Al Alloys" Crystals 14, no. 6: 559. https://doi.org/10.3390/cryst14060559

APA StyleKayani, S. H., Ajmal, H. M. S., Kim, B.-J., Park, N.-K., & Euh, K. (2024). Influence of Powder Size on Pore Characteristics and Intermetallic Phase Kinetics in Porous Ti-Al Alloys. Crystals, 14(6), 559. https://doi.org/10.3390/cryst14060559