Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition

Abstract

:1. Introduction

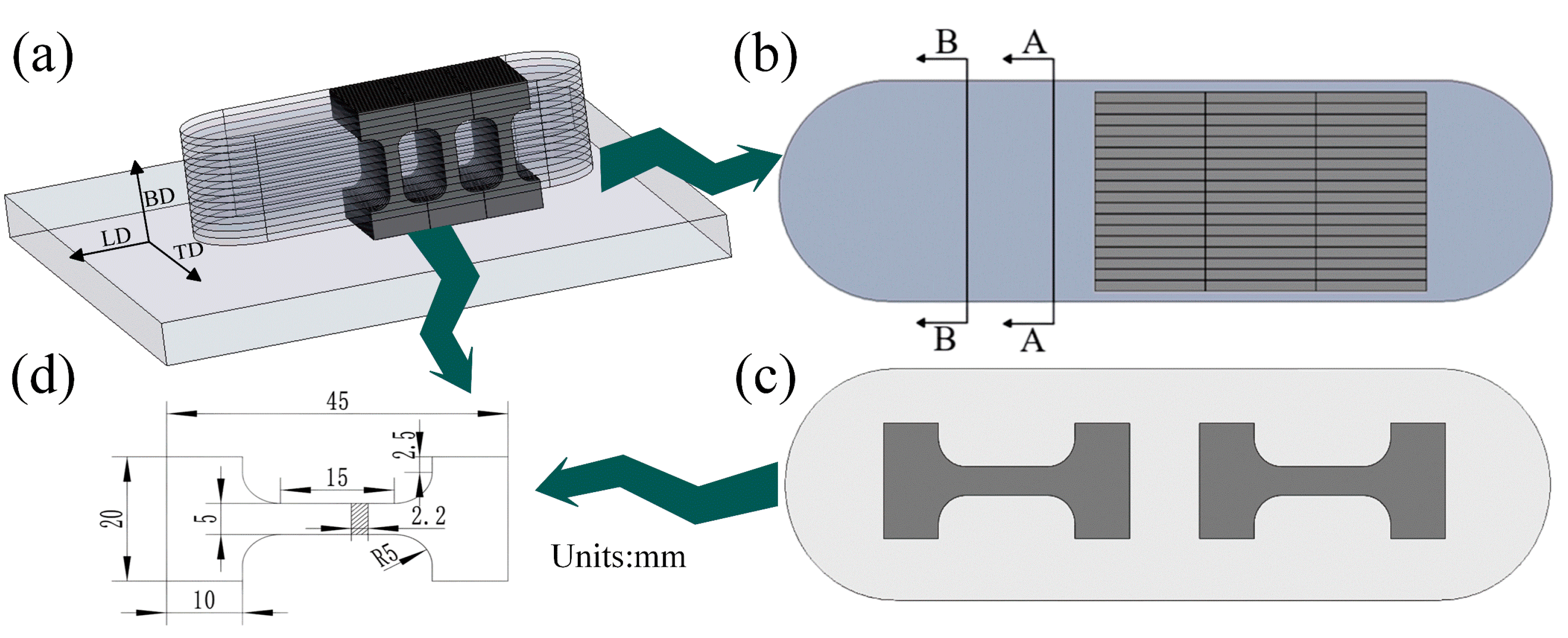

2. Materials and Methods

3. Results

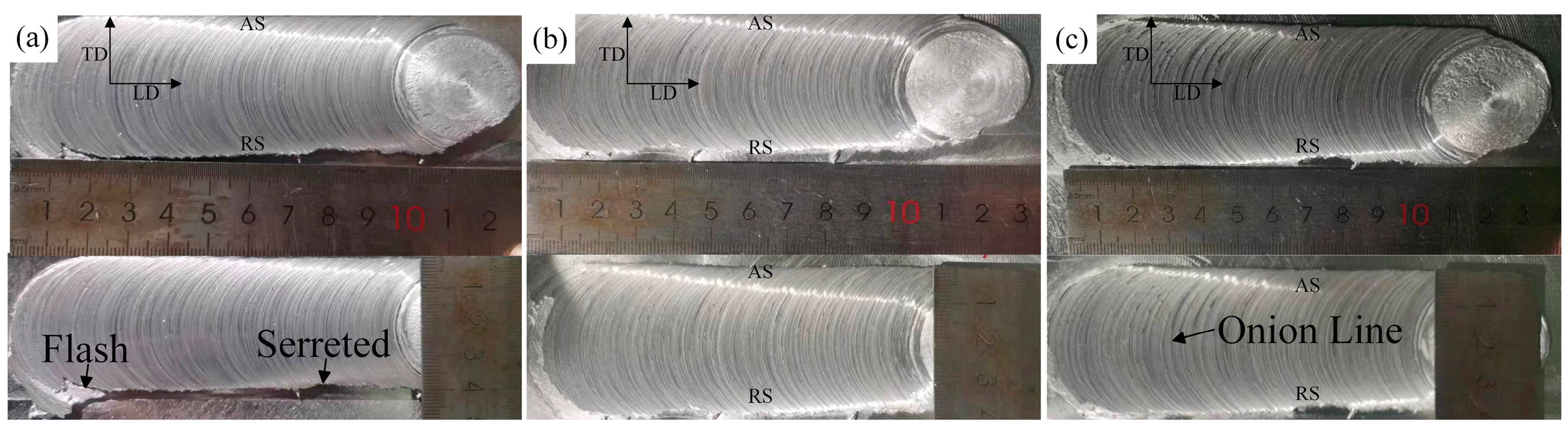

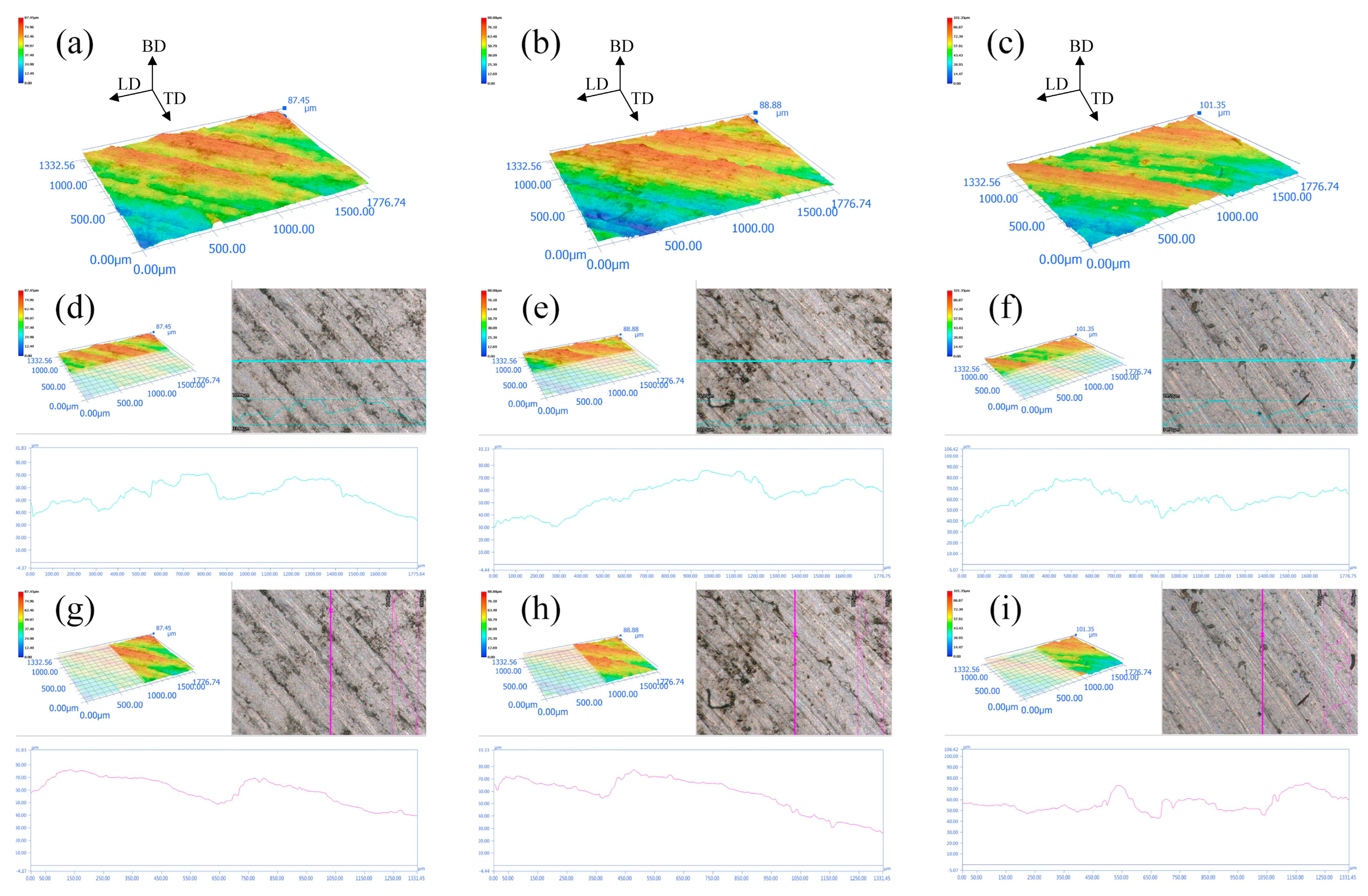

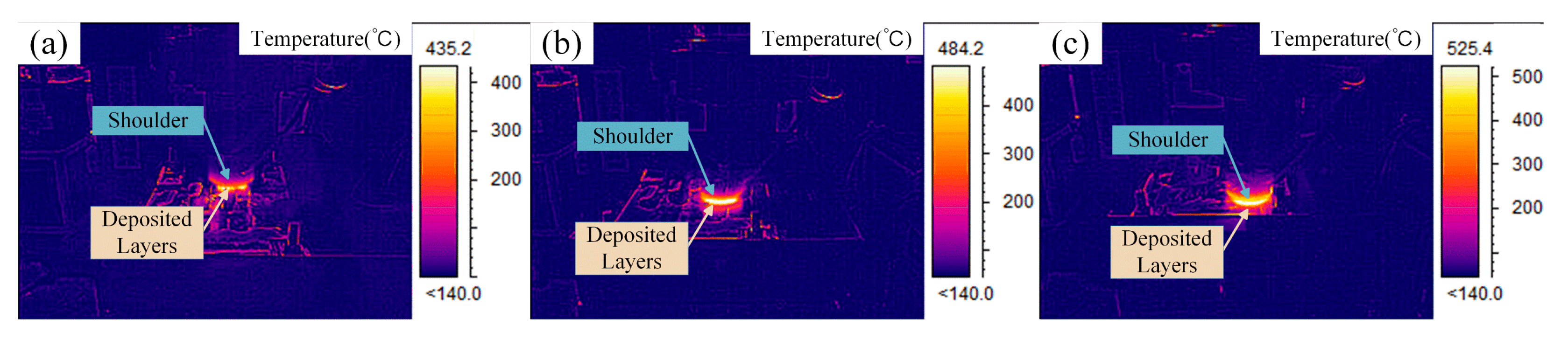

3.1. Macrostructure

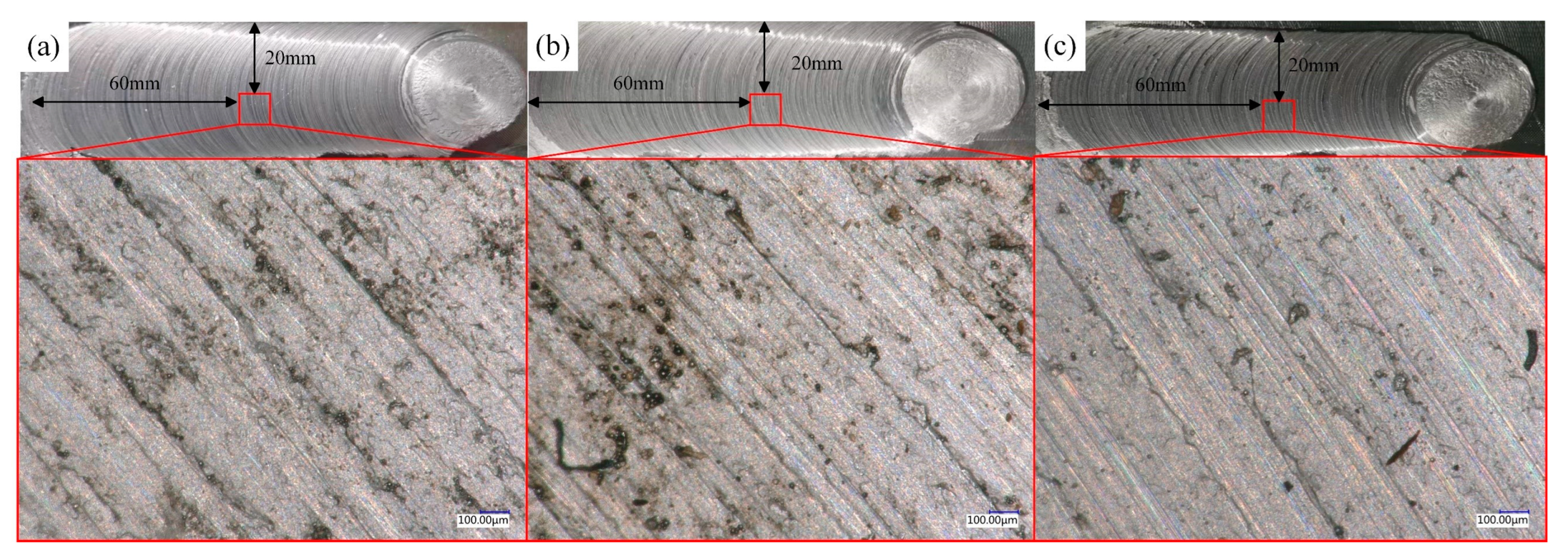

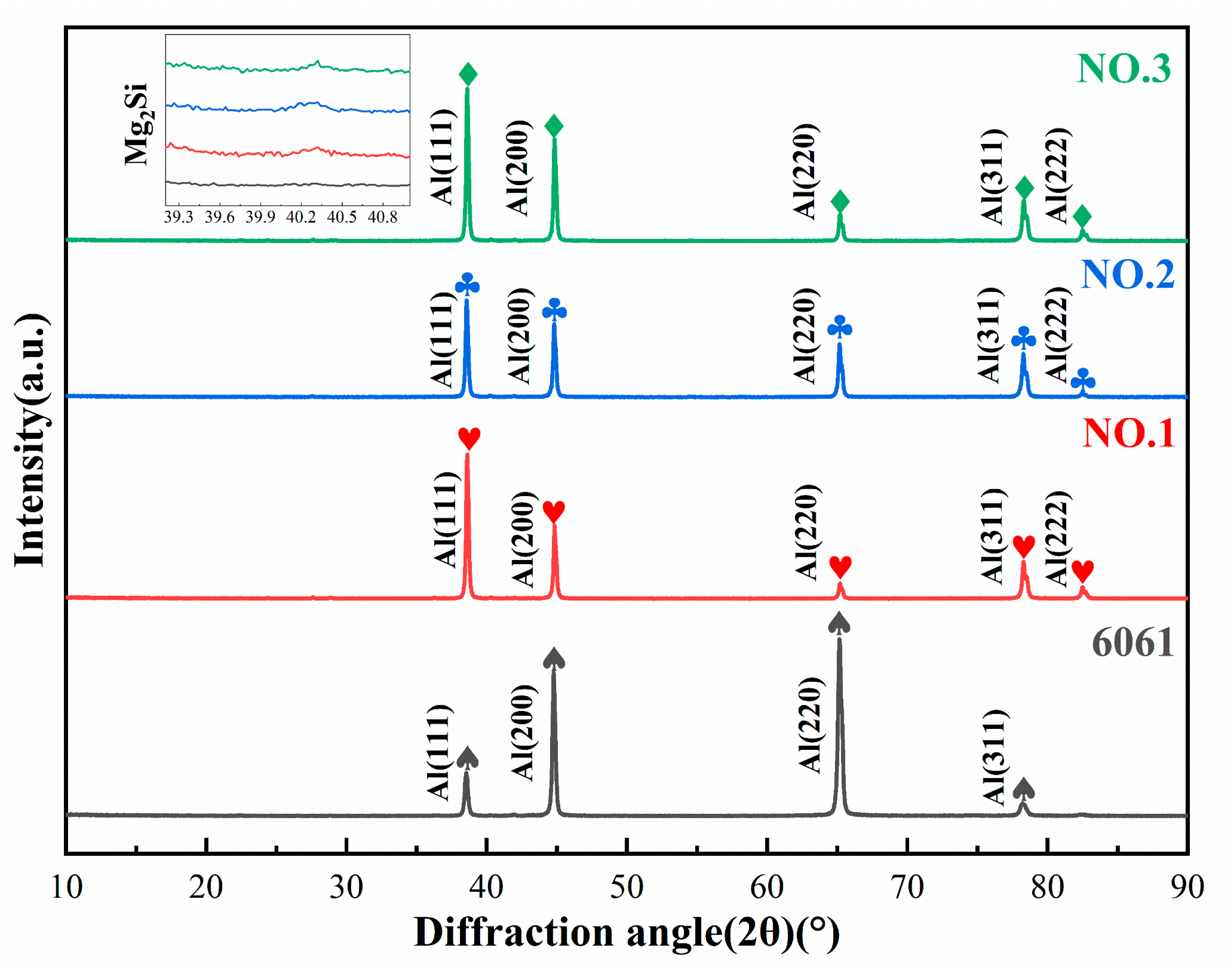

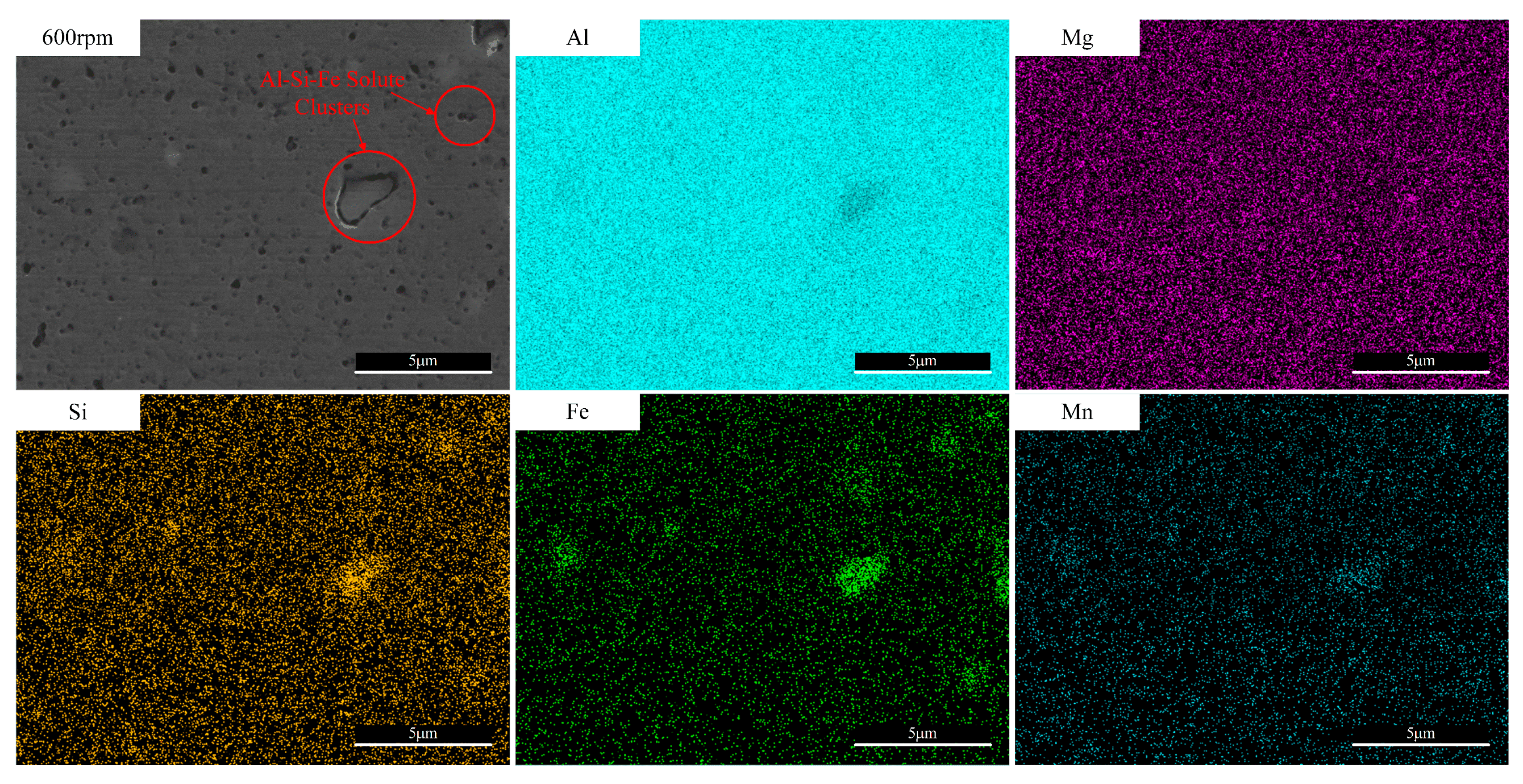

3.2. Compositional Analysis

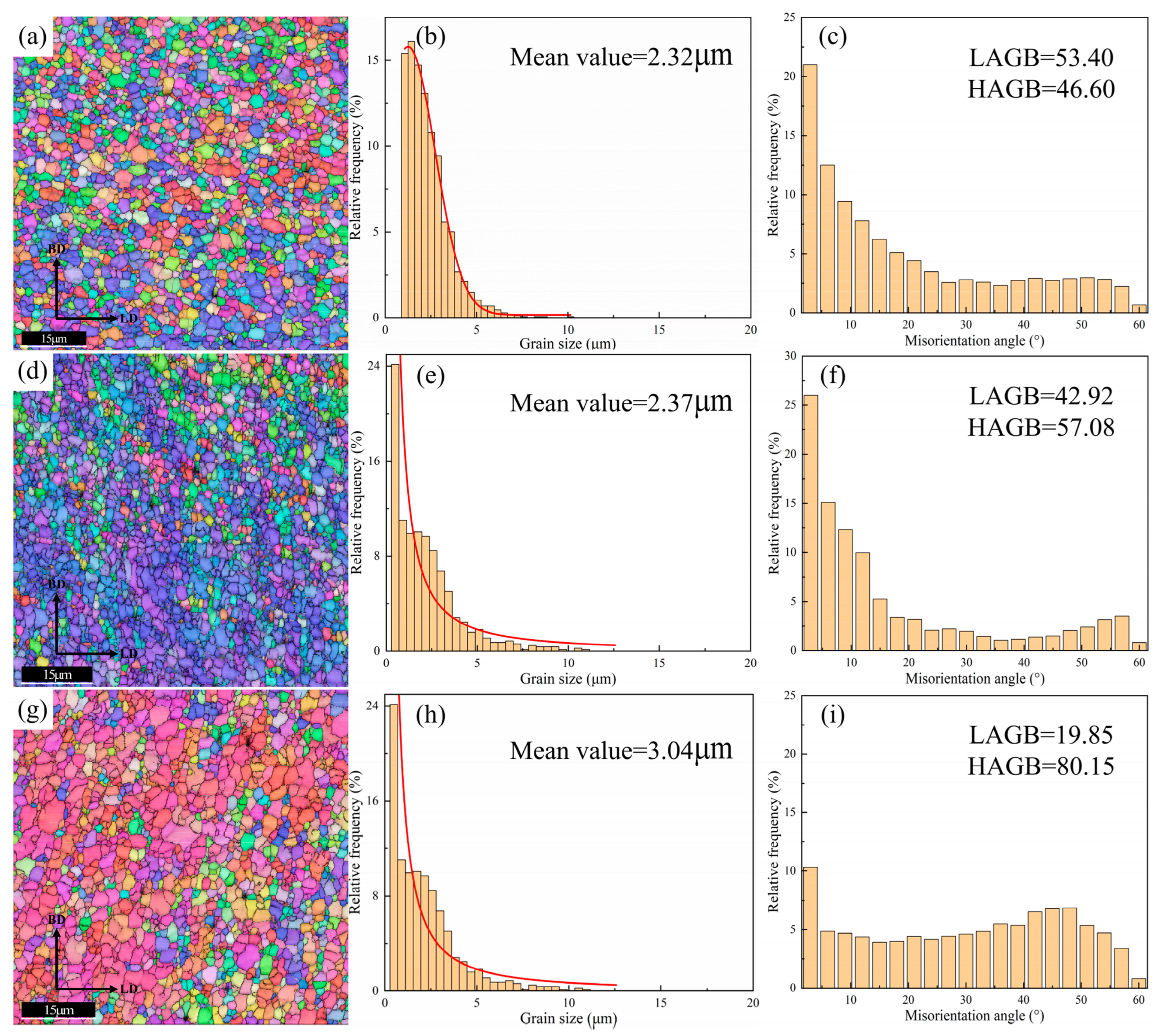

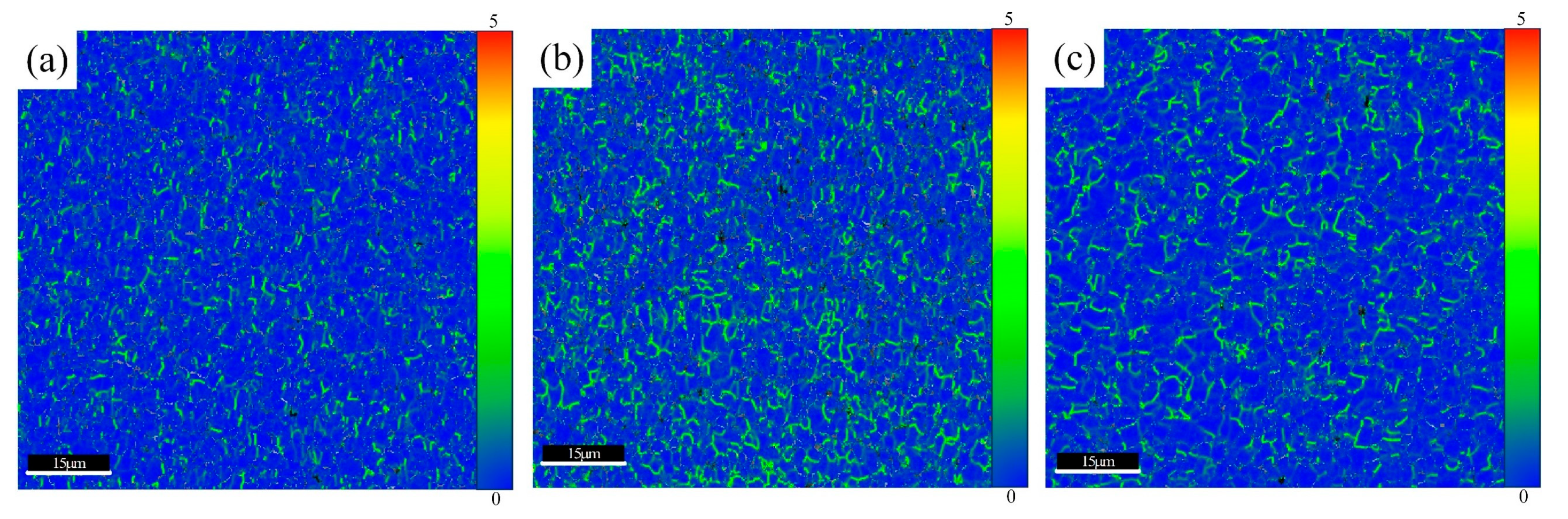

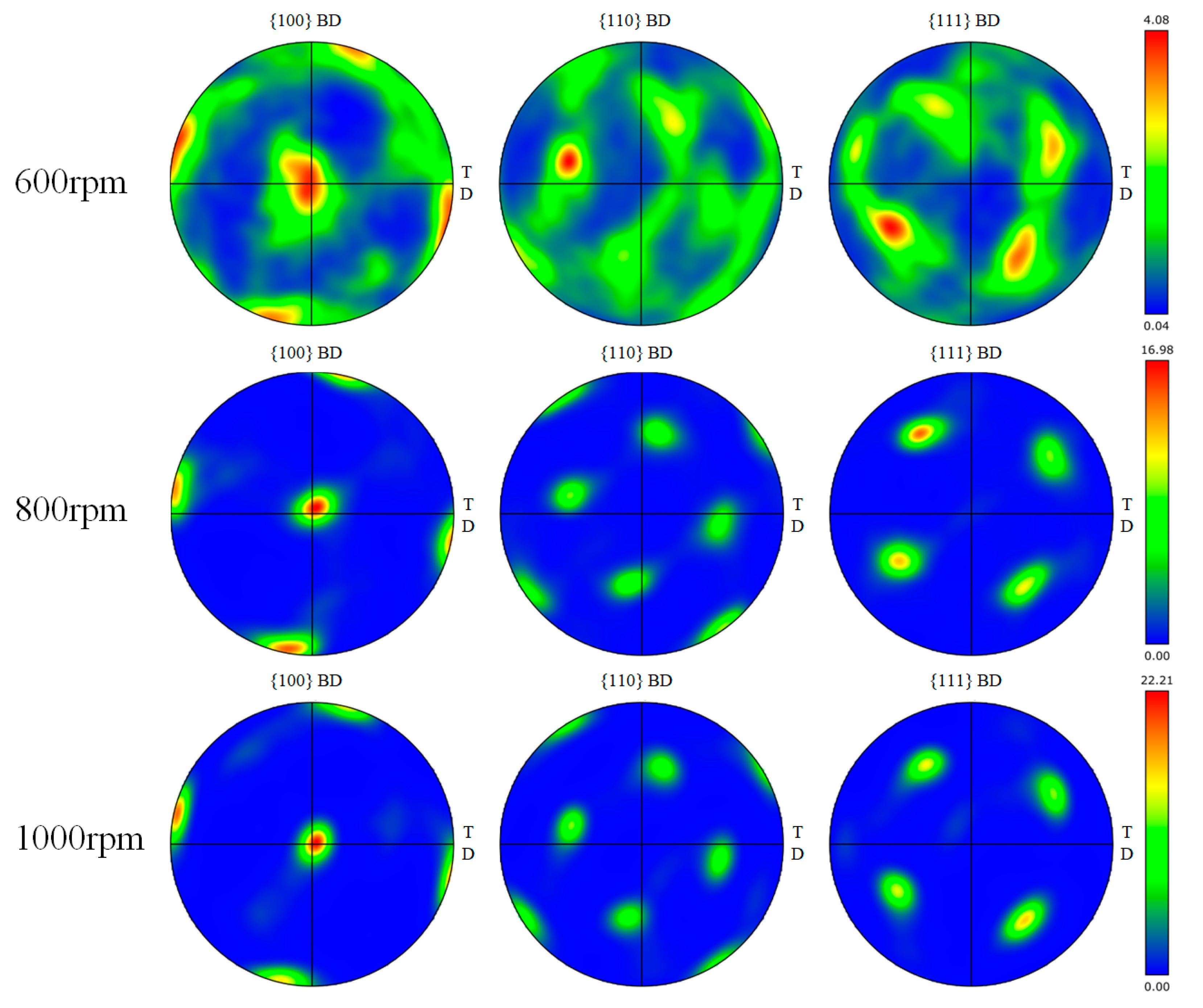

3.3. Analysis of Microstructure

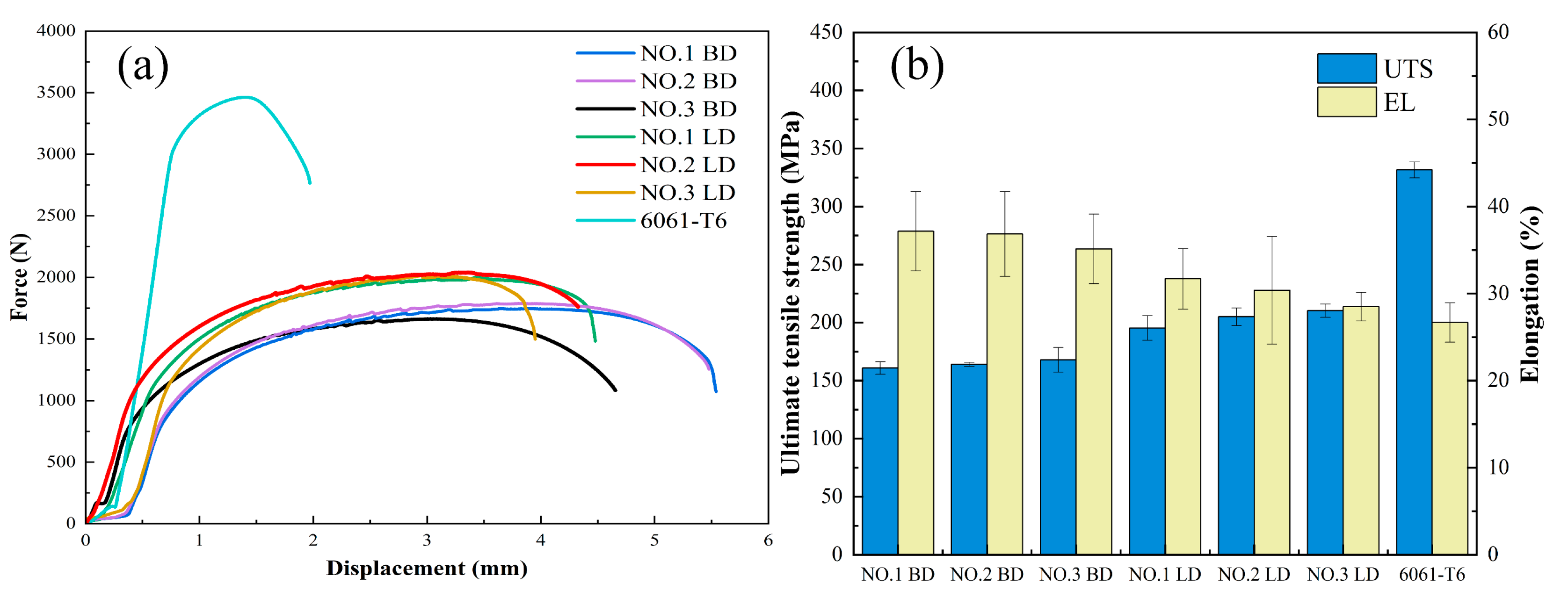

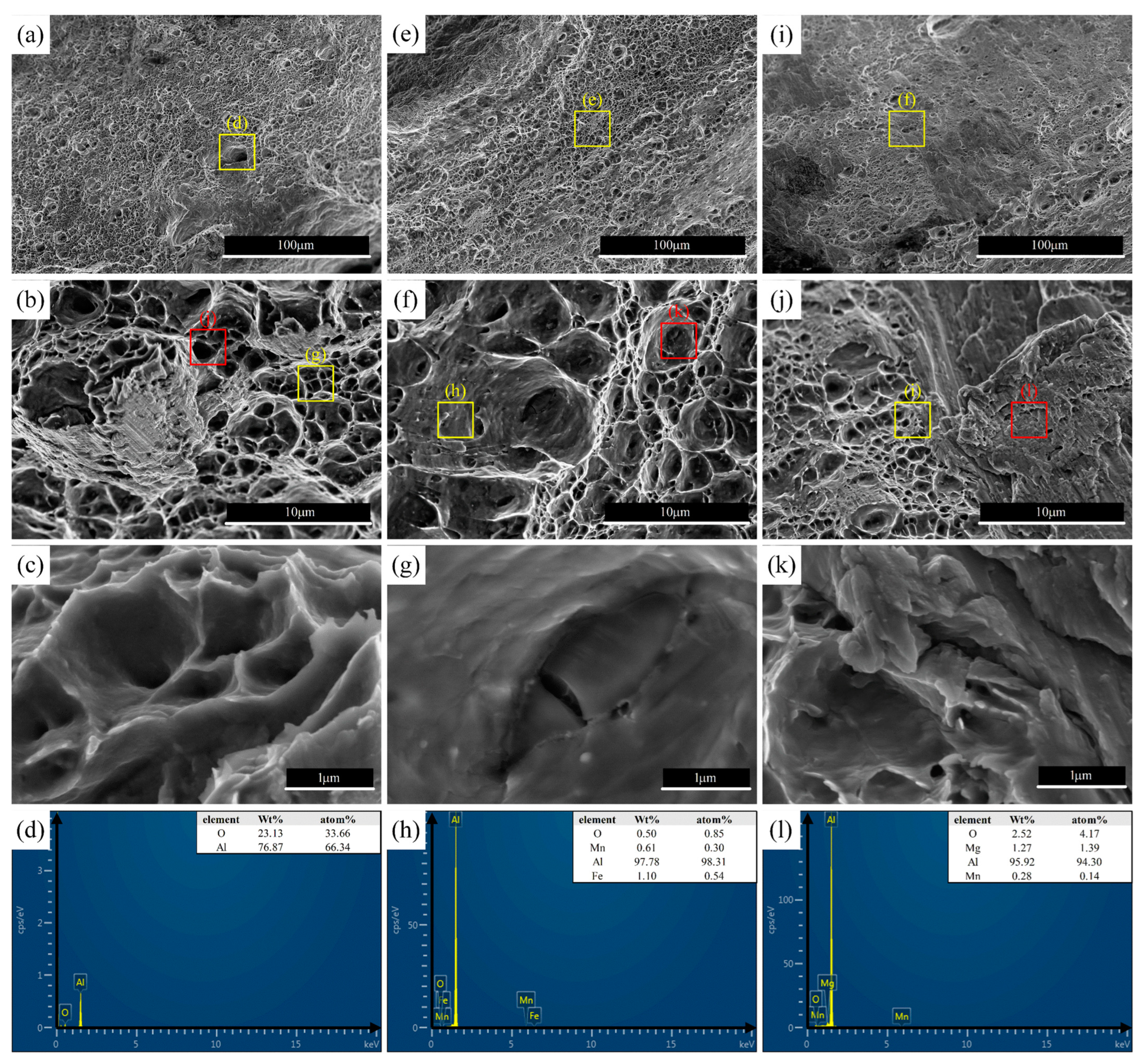

3.4. Mechanical Property

4. Discussion

- When employing AFSD at NO.3 with 6061 aluminium alloy bars measuring 28 mm × 28 mm, the surface roughness measures 101.35 μm. With an increase in rotational speed for multilayer additive materials, there is an escalation in the outward flow of material at the edges. This intensifies the non-uniformity of material flow, consequently resulting in weak bonding between layers and the emergence of holes.

- The solid solution strengthening of the deposited layer by the precipitation of Mg2Si, etc. exists in AFSD at different rotational speeds. As the rotational speed rises, it prompts the solid solution of Mg elements to return to the matrix and augments the proportion of precipitated Mn elements. These Mn elemental precipitates serve to enhance the material’s tensile strength properties. Additionally, the size of the precipitated phase increases with the escalation of the rotational speed.

- The primary crystallisation mechanism in the AFSD process is continuous dynamic recrystallisation. Elevated rotational speeds facilitate grain growth while also intensifying the transition from low-angle grain boundaries (LAGB) to high-angle grain boundaries (HAGB). Moreover, higher rotational speeds induce the secondary deformation of the recrystallised grains and augment the proportion of deformed grains.

- The UTS of the deposited layer during AFSD is positively correlated with the rotational speed. Conversely, the elongation of the deposited layer via AFSD exhibits a negative correlation with the rotational speed. An analysis of fracture morphology reveals that ductile fracture is the primary fracture mechanism, as indicated by the presence of holes. Additionally, the hardness of the material exhibits a decreasing trend from top to bottom, with the number of thermal cycles emerging as the primary factor affecting hardness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Heer, B. Additive manufacturing of multi-material structures. Mater. Sci. Eng. R Rep. 2018, 129, 1–16. [Google Scholar] [CrossRef]

- Sefene, E.M.; Hailu, Y.M.; Tsegaw, A.A. Metal hybrid additive manufacturing: State-of-the-Art. Prog. Addit. Manuf. 2022, 7, 737–749. [Google Scholar] [CrossRef]

- Kanishka, K.; Acherjee, B. A systematic review of additive manufacturing-based remanufacturing techniques for component repair and restoration br. J. Manuf. Process. 2023, 89, 220–283. [Google Scholar] [CrossRef]

- Li, H.Z.; Wang, C.M.; Zhang, H.; Zhang, J.J.; He, P.; Shao, M.H.; Zhu, X.T.; Fu, Y.Q. Research Progress of Friction Stir Additive Manufacturing Technology. Acta Metall. Sin. 2023, 59, 106–124. [Google Scholar] [CrossRef]

- Montero-Sistiaga, M.L.; Mertens, R.; Vrancken, B.; Wang, X.; Van Hooreweder, B.; Kruth, J.-P.; Van Humbeeck, J. Changing the alloy composition of Al7075 for better processability by selective laser melting. J. Mater. Process. Technol. 2016, 238, 437–445. [Google Scholar] [CrossRef]

- Peng, L.M.; Deng, Q.C.; Wu, Y.J.; Fu, P.H.; Liu, Z.Y.; Wu, Q.Y.; Chen, K.; Ding, W.J. Additive Manufacturing of Magnesium Alloys by Selective Laser Melting Technology: A Review. Acta Metall. Sin. 2023, 59, 31–54. [Google Scholar] [CrossRef]

- Kathiresan, M.; Karthikeyan, M.; Immanuel, R.J. A short review on SLM-processed Ti6Al4V composites. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023, 01, 16. [Google Scholar] [CrossRef]

- Anand, M.; Das, A.K. Issues in fabrication of 3D components through DMLS Technique: A review. Opt. Laser Technol. 2021, 139, 106914. [Google Scholar] [CrossRef]

- Samantaray, M.; Sahoo, S.; Thatoi, D. Computational modeling of heat transfer and sintering behavior during direct metal laser sintering of AlSi10Mg alloy powder. C. R. Mec. 2018, 346, 1043–1054. [Google Scholar] [CrossRef]

- Fan, Y.X.; Lin, Y.; Ao, Q.B.; Wang, J.Z. Research Progress on Additive Manufactured Ti-6Al-4V Lattice Materials. Rare Met. Mater. Eng. 2023, 52, 3630–3639. [Google Scholar] [CrossRef]

- Körner, C. Additive manufacturing of metallic components by selective electron beam melting—A review. Int. Mater. Rev. 2016, 61, 361–377. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; du Plessis, A. Metal additive manufacturing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Fang, Z.C.; Wu, Z.L.; Huang, C.G.; Wu, C.W. Review on residual stress in selective laser melting01ditive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Shaburova, N.A.; Samodurova, M.N.; Abdollahzadeh, A.; Trofimov, E.A. Additive manufacturing of high entropy alloys: A practical review. J. Mater. Sci. Technol. 2021, 77, 131–162. [Google Scholar] [CrossRef]

- Gottwald, R.B.; Griffiths, R.J.; Petersen, D.T.; Perry, M.E.J.; Yu, H.Z. Solid-State Metal Additive Manufacturing for Structural Repair. Acc. Mater. Res. 2021, 2, 780–792. [Google Scholar] [CrossRef]

- Dong, H.R.; Li, X.Q.; Xu, K.; Zang, Z.Y.; Liu, X.; Zhang, Z.J.; Xiao, W.L.; Li, Y. A Review on Solid-State-Based Additive Friction Stir Deposition. Aerospace 2022, 9, 565. [Google Scholar] [CrossRef]

- Prabhakar, D.A.P.; Shettigar, A.K.; Herbert, M.A.; Patel, G.C.M.; Pimenov, D.Y.; Giasin, K.; Prakash, C. A comprehensive review of friction stir techniques in structural materials and alloys: Challenges and trends. J. Mater. Res. Technol. 2022, 20, 3025–3060. [Google Scholar] [CrossRef]

- Yu, H.Z.; Mishra, R.S. Additive friction stir deposition: A deformation processing route to metal additive manufacturing. Mater. Res. Lett. 2021, 9, 71–83. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Noor Siddiquee, A.; Kundra, T.K. A Review on Recent Progress in Solid State Friction Based Metal Additive Manufacturing: Friction Stir Additive Techniques. Crit. Rev. Solid State Mater. Sci. 2018, 44, 345–377. [Google Scholar] [CrossRef]

- Patel, M.; Chaudhary, B.; Murugesan, J.; Jain, N.K. Additive Manufacturing of AA6063-ZrO2 Composite Using Friction Stir Surface Additive Manufacturing. Trans. Indian Inst. Met. 2023, 76, 581–588. [Google Scholar] [CrossRef]

- Chaudhary, B.; Jain, N.K.; Murugesan, J. Experimental investigation and parametric optimization of friction stir powder additive manufacturing process for aerospace-grade Al alloy. Int. J. Adv. Manuf. Technol. 2022, 123, 603–625. [Google Scholar] [CrossRef]

- Chen, H.Z.; Meng, X.C.; Chen, J.L.; Xie, Y.M.; Wang, J.Q.; Sun, S.M.; Zhao, Y.B.; Li, J.C.; Wan, L.; Huang, Y.X. Wire-based friction stir additive manufacturing. Addit. Manuf. 2023, 70, 9. [Google Scholar] [CrossRef]

- Tang, W.; Yang, X.; Tian, C. Influence of rotation speed on interfacial bonding mechanism and mechanical performance of aluminum 6061 fabricated by multilayer friction-based additive manufacturing. Int. J. Adv. Manuf. Technol. 2023, 126, 4119–4133. [Google Scholar] [CrossRef]

- Hartley, W.D.; Garcia, D.; Yoder, J.K.; Poczatek, E.; Forsmark, J.H.; Luckey, S.G.; Dillard, D.A.; Yu, H.Z. Solid-state cladding on thin automotive sheet metals enabled by additive friction stir deposition. J. Mater. Process. Technol. 2021, 291, 103557. [Google Scholar] [CrossRef]

- Luo, T.; Tang, W.S.; Wang, R.L.; Wang, S.W.; Xiao, L.; Yang, X.Q. Microstructure heterogeneity and mechanical properties of Mg-Gd-Y-Zr alloy fabricated by force-controlled additive friction stir deposition. Mater. Lett. 2023, 340, 134164. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.H.; Yu, H.Z. Morphological and microstructural investigation of the non-planar interface formed in solid-state metal additive manufacturing by additive friction stir deposition. Addit. Manuf. 2020, 35, 101293. [Google Scholar] [CrossRef]

- Avery, D.Z.; Phillips, B.J.; Mason, C.J.T.; Palermo, M.; Williams, M.B.; Cleek, C.; Rodriguez, O.L.; Allison, P.G.; Jordon, J.B. Influence of Grain Refinement and Microstructure on Fatigue Behavior for Solid-State Additively Manufactured Al-Zn-Mg-Cu Alloy. Metall. Mater. Trans. A 2020, 51, 2778–2795. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Petersen, D.T.; Garcia, D.; Yu, H.Z. Additive Friction Stir-Enabled Solid-State Additive Manufacturing for the Repair of 7075 Aluminum Alloy. Appl. Sci. 2019, 9, 3486. [Google Scholar] [CrossRef]

- Elshaghoul, Y.G.Y.; Seleman, M.; Bakkar, A.; Elnekhaily, S.A.; Albaijan, I.; Ahmed, M.M.Z.; Abdel-Samad, A.; Reda, R. Additive Friction Stir Deposition of AA7075-T6 Alloy: Impact of Process Parameters on the Microstructures and Properties of the Continuously Deposited Multilayered Parts. Appl. Sci. 2023, 13, 10255. [Google Scholar] [CrossRef]

- Phillips, B.J.; Williamson, C.J.; Kinser, R.P.; Jordon, J.B.; Doherty, K.J.; Allison, P.G. Microstructural and Mechanical Characterization of Additive Friction Stir-Deposition of Aluminum Alloy 5083 Effect of Lubrication on Material Anisotropy. Materials 2021, 14, 6732. [Google Scholar] [CrossRef]

- Shen, Z.; Zhang, M.; Li, D.; Liu, X.; Chen, S.; Hou, W.; Ding, Y.; Sun, Z.; Su, Y.; Li, W.; et al. Microstructural characterization and mechanical properties of AlMg alloy fabricated by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2023, 125, 2733–2741. [Google Scholar] [CrossRef]

- Li, Y.D.; Yang, B.B.; Zhang, M.; Wang, H.; Gong, W.; Lai, R.L.; Li, Y.P.; Teng, J.W. The corrosion behavior and mechanical properties of 5083 Al-Mg alloy manufactured by additive friction stir deposition. Corros. Sci. 2023, 213, 110972. [Google Scholar] [CrossRef]

- Ghadimi, H.; Ding, H.; Emanet, S.; Talachian, M.; Cox, C.; Eller, M.; Guo, S.M. Hardness Distribution of Al2050 Parts Fabricated Using Additive Friction Stir Deposition. Materials 2023, 16, 1278. [Google Scholar] [CrossRef]

- Rivera, O.G.; Allison, P.G.; Brewer, L.N.; Rodriguez, O.L.; Jordon, J.B.; Liu, T.; Whittington, W.R.; Martens, R.L.; McClelland, Z.; Mason, C.J.T.; et al. Influence of texture and grain refinement on the mechanical behavior of AA2219 fabricated by high shear solid state material deposition. Mater. Sci. Eng. A 2018, 724, 547–558. [Google Scholar] [CrossRef]

- Joshi, S.S.; Patil, S.M.; Mazumder, S.; Sharma, S.; Riley, D.A.; Dowden, S.; Banerjee, R.; Dahotre, N.B. Additive friction stir deposition of AZ31B magnesium alloy. J. Magnes. Alloys 2022, 10, 2404–2420. [Google Scholar] [CrossRef]

- Mason, C.J.T.; Rodriguez, R.I.; Avery, D.Z.; Phillips, B.J.; Bernarding, B.P.; Williams, M.B.; Cobbs, S.D.; Jordon, J.B.; Allison, P.G. Process-structure-property relations for as-deposited solid-state additively manufactured high-strength aluminum alloy. Addit. Manuf. 2021, 40, 101879. [Google Scholar] [CrossRef]

- Griffiths, R.J.; Garcia, D.; Song, J.; Vasudevan, V.K.; Steiner, M.A.; Cai, W.; Yu, H.Z. Solid-state additive manufacturing of aluminum and copper using additive friction stir deposition: Process-microstructure linkages. Materialia 2021, 15. [Google Scholar] [CrossRef]

- Agrawal, P.; Haridas, R.S.; Yadav, S.; Thapliyal, S.; Dhal, A.; Mishra, R.S. Additive friction stir deposition of SS316: Effect of process parameters on microstructure evolution. Mater. Charact. 2023, 195, 112470. [Google Scholar] [CrossRef]

- Alzahrani, B.; Seleman, M.; Ahmed, M.M.Z.; Elfishawy, E.; Ahmed, A.M.Z.; Touileb, K.; Jouini, N.; Habba, M.I.A. The Applicability of Die Cast A356 Alloy to Additive Friction Stir Deposition at Various Feeding Speeds. Materials 2021, 14, 6018. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Wang, Y.; Zhu, Z.; Nie, P.; Hu, F. Effect of rotational speed and feed rate on microstructure and mechanical properties of 6061 aluminum alloy manufactured by additive friction stir deposition. Int. J. Adv. Manuf. Technol. 2023, 127, 1165–1176. [Google Scholar] [CrossRef]

- Chen, L.; Lu, L.K.; Zhu, L.; Yang, Z.W.; Zhou, W.F.; Ren, X.D.; Zhang, X.Z. Microstructure Evolution and Mechanical Properties of Multilayer AA6061 Alloy Fabricated by Additive Friction Stir Deposition. Metall. Mater. Trans. A 2024, 55, 1049–1064. [Google Scholar] [CrossRef]

- Babaniaris, S.; Jiang, L.; Varma, R.K.; Farabi, E.; Dorin, T.; Barnett, M.; Fabijanic, D. Precipitation in AA6063 produced from swarf using additive friction stir deposition. Addit. Manuf. Lett. 2022, 3, 100096. [Google Scholar] [CrossRef]

- GB/T16865-2023; Test Pieces and Methods for Tensile Test for Wrought Aluminium, Magnesium and Their Alloy Products. Standardization Administration of China: Beijing, China, 2023.

- Chen, L.; Zhu, L.; Lu, L.; Yang, Z.; Ren, X.; Zhang, X. The effect of heat treatment on the microstructure and electrochemical corrosion behavior of multilayer AA6061 alloy fabricated by additive friction stir deposition. Appl. Surf. Sci. 2024, 650, 159167. [Google Scholar] [CrossRef]

- Aruga, Y.; Kozuka, M.; Takaki, Y.; Sato, T. Evaluation of Solute Clusters Associated with Bake-Hardening Response in Isothermal Aged Al-Mg-Si Alloys Using a Three-Dimensional Atom Probe. Metall. Mater. Trans. A 2014, 45, 5906–5913. [Google Scholar] [CrossRef]

- Sun, Y.C.; Zhang, B.; Xu, Z.; Wang, H.B.; Li, S.L.; Tian, S.Y. Microstructure evolution and recrystallization behavior of hot rolled AA6061 twin-roll casting plate with different manganese contents. J. Alloys Compd. 2022, 918, 165618. [Google Scholar] [CrossRef]

- Perry, M.E.J.; Rauch, H.A.; Griffiths, R.J.; Garcia, D.; Sietins, J.M.; Zhu, Y.; Zhu, Y.; Yu, H.Z. Tracing plastic deformation path and concurrent grain refinement during additive friction stir deposition. Materialia 2021, 18, 101159. [Google Scholar] [CrossRef]

- Tang, W.; Yang, X.; Tian, C.; Xu, Y. Microstructural heterogeneity and bonding strength of planar interface formed in additive manufacturing of Al−Mg−Si alloy based on friction and extrusion. Int. J. Miner. Metall. Mater. 2022, 29, 1755–1769. [Google Scholar] [CrossRef]

- Peng, Y.; Huang, B.; Zhong, Y.; Su, C.; Tao, Z.; Rong, X.; Li, Z.; Tang, H. Electrochemical corrosion behavior of 6061 Al alloy under high rotating speed submerged friction stir processing. Corros. Sci. 2023, 215, 111029. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Fan, Y.X.; Xie, L.W.; Xiao, X.; Wang, P.; Yang, S.; Jiang, C. Effect of Rotation Speed on Microstructure and Mechanical Properties of Continuous Drive Friction Welded Dissimilar Joints of 6061-T6 Al and Copper. Metals 2022, 12, 1173. [Google Scholar] [CrossRef]

- Chen, G.; Wu, K.; Wang, Y.; Sun, Y.; Wang, X.; Zhu, Z.; Hu, F. Quantitative study on the correlation between microstructure and mechanical properties of additive friction stir deposited 6061-T6 Al-Mg-Si alloy. J. Mater. Res. Technol. 2023, 25, 6725–6736. [Google Scholar] [CrossRef]

- Barrett, C.D.; Imandoust, A.; Oppedal, A.L.; Inal, K.; Tschopp, M.A.; El Kadiri, H. Effect of grain boundaries on texture formation during dynamic recrystallization of magnesium alloys. Acta Mater. 2017, 128, 270–283. [Google Scholar] [CrossRef]

- Basu, I.; Al-Samman, T. Twin recrystallization mechanisms in magnesium-rare earth alloys. Acta Mater. 2015, 96, 111–132. [Google Scholar] [CrossRef]

| Mg | Si | Fe | Cu | Mn | Ti | Cr | Zn | Al |

|---|---|---|---|---|---|---|---|---|

| 0.8–1.2 | 0.4–0.8 | 0.7 | 0.15~0.4 | 0.15 | 0.15 | 0.35 | 0.25 | Bal. |

| Parameters | ω (rpm) | ν (mm/min) | F (kN) |

|---|---|---|---|

| NO.1 | 600 | 90 | 10 |

| NO.2 | 800 | 90 | 10 |

| NO.3 | 1000 | 90 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, X.; Wang, R.; Wang, L.; Liu, M.; Li, S. Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals 2024, 14, 581. https://doi.org/10.3390/cryst14070581

Zhu X, Wang R, Wang L, Liu M, Li S. Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals. 2024; 14(7):581. https://doi.org/10.3390/cryst14070581

Chicago/Turabian StyleZhu, Xiaohu, Rui Wang, Lin Wang, Mengmeng Liu, and Songmo Li. 2024. "Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition" Crystals 14, no. 7: 581. https://doi.org/10.3390/cryst14070581

APA StyleZhu, X., Wang, R., Wang, L., Liu, M., & Li, S. (2024). Effect of Rotational Shear and Heat Input on the Microstructure and Mechanical Properties of Large-Diameter 6061 Aluminium Alloy Additive Friction Stir Deposition. Crystals, 14(7), 581. https://doi.org/10.3390/cryst14070581