Hydroxyapatite Reinforced Magnesium Alloy Composites Using the Ultrasonic-Assisted Rheo-Squeeze Casting Technique: Microstructural and Mechanical Performance Evaluation for Bone Fixture Applications

Abstract

1. Introduction

2. Materials and Method

3. Morphological and Mechanical Characterizations

4. Results and Discussion

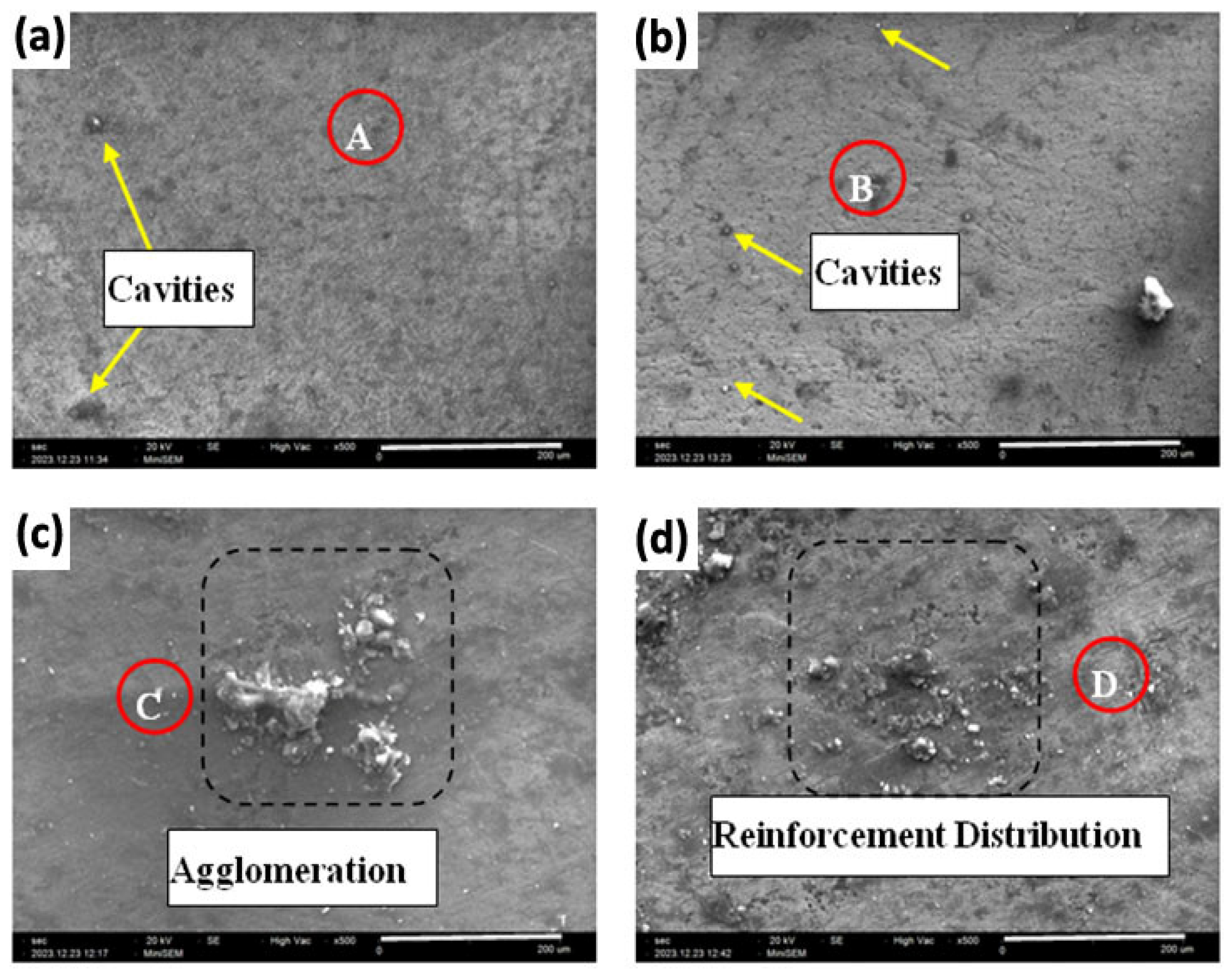

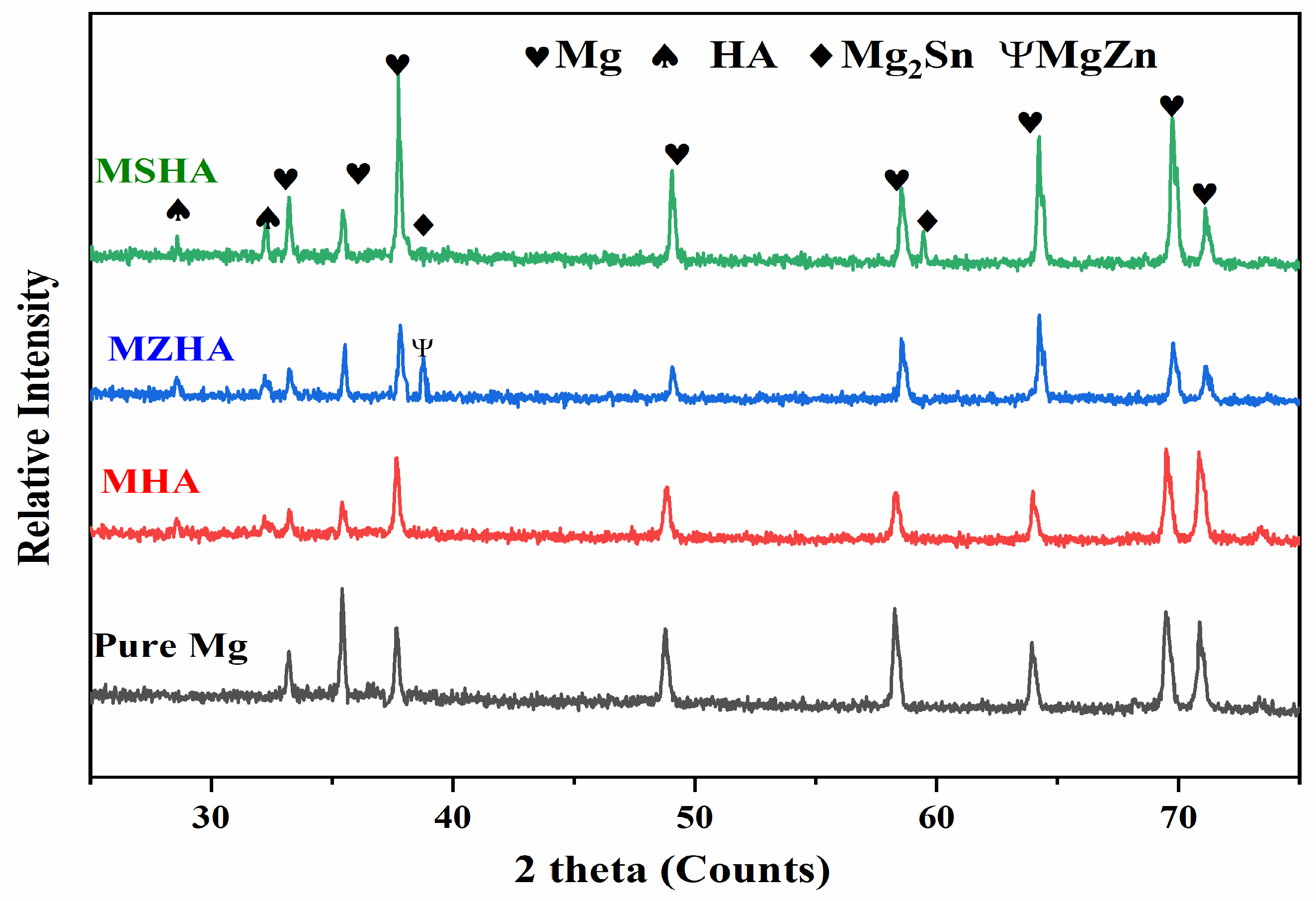

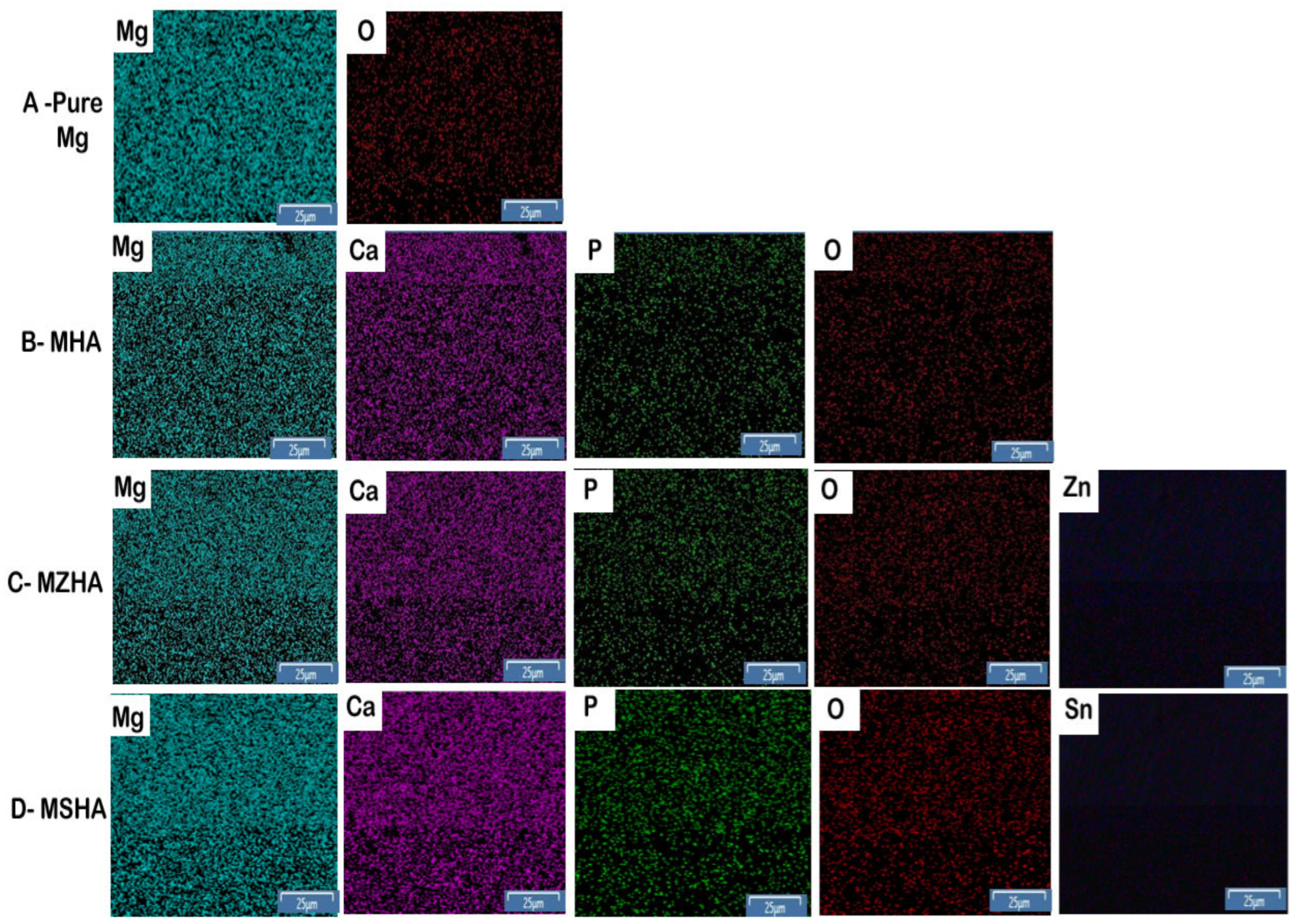

4.1. Morphology Behavior of the Composite Samples

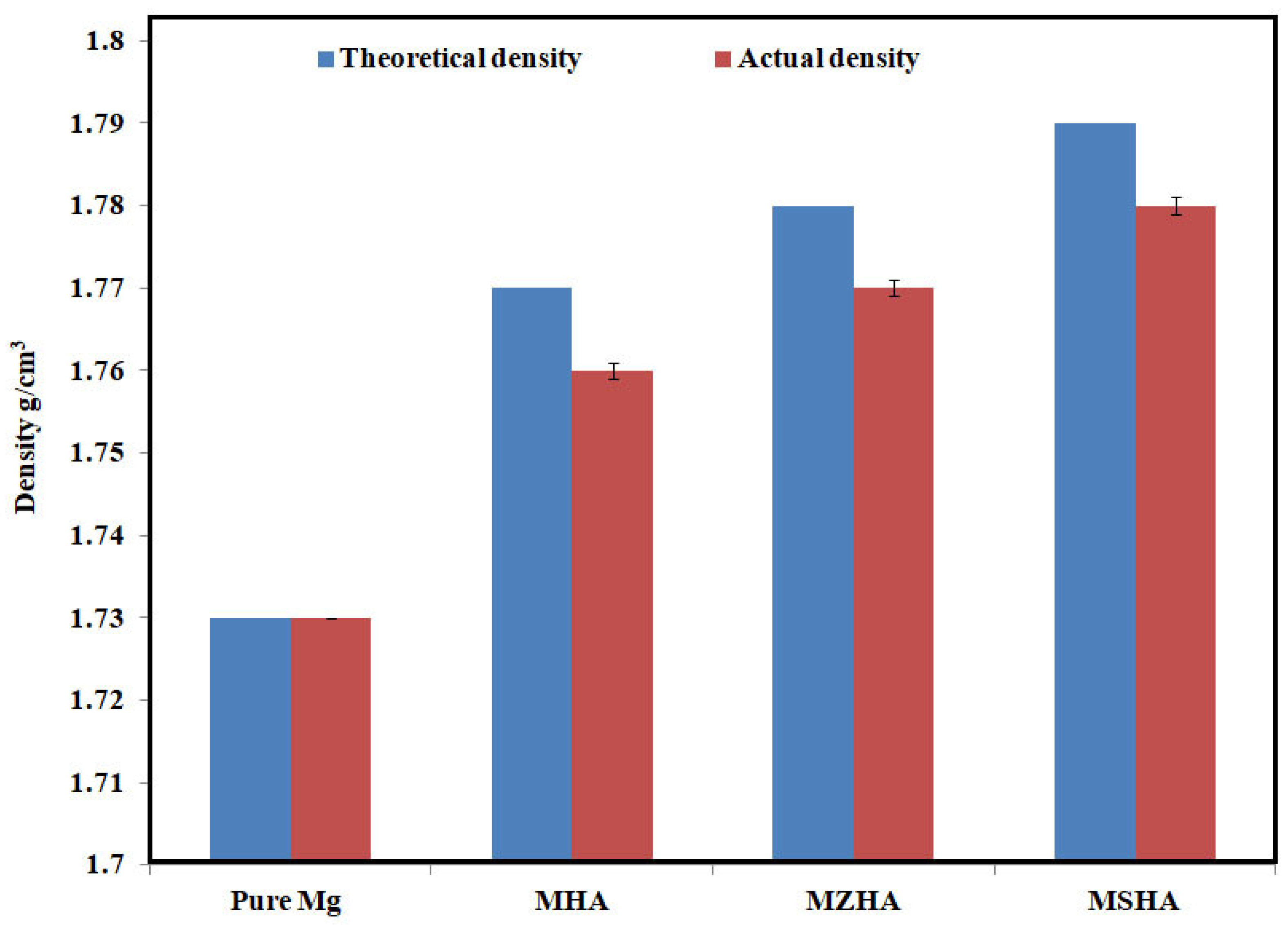

4.2. Density and Porosity

4.3. Mechanical Properties

4.3.1. Microhardness

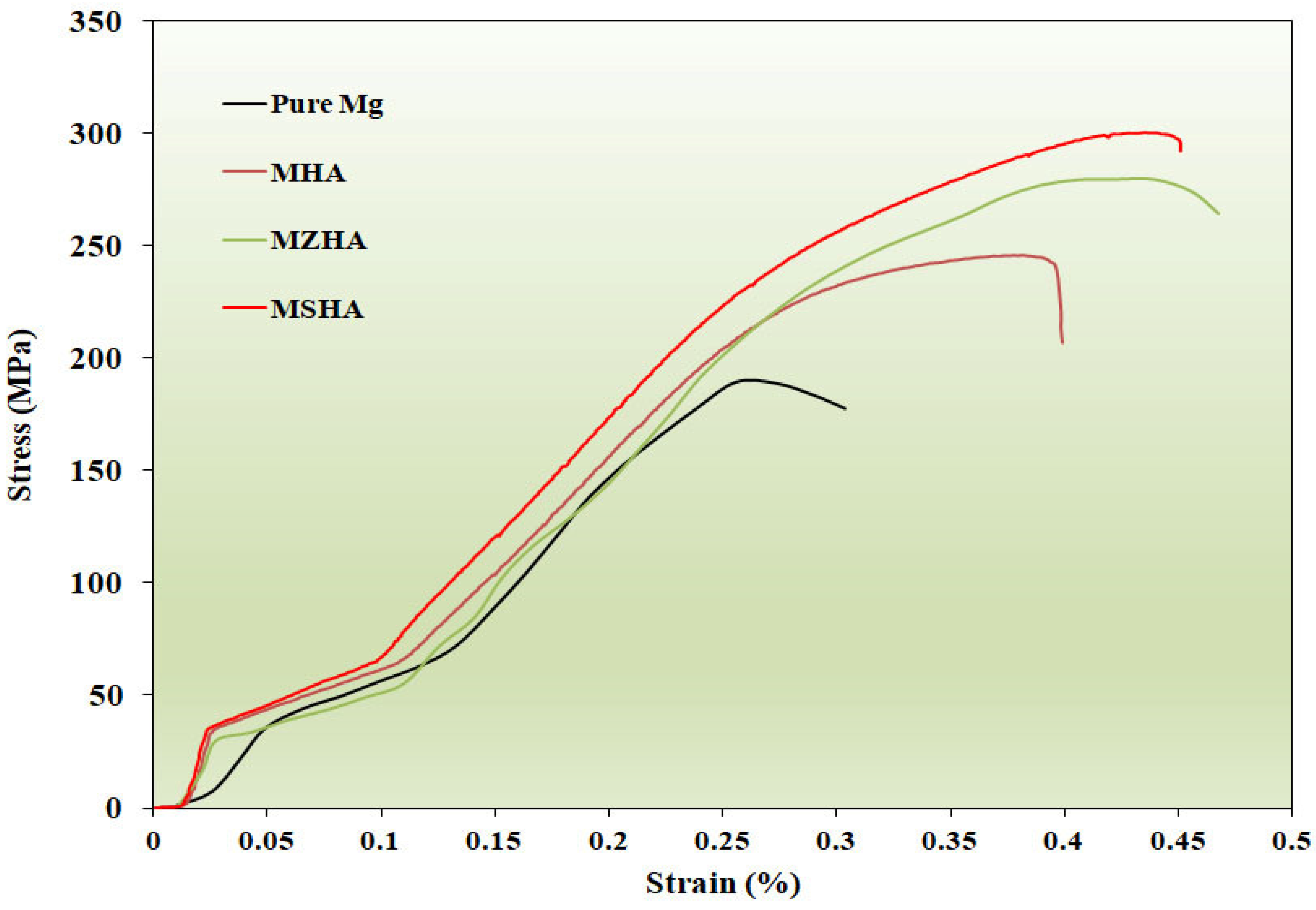

4.3.2. Compression and Tensile Performance of the Composites

4.3.3. Impact and Flexural Behavior of the Composites

4.4. Fractographical Analysis of the Compression Tested Composites

4.5. Effects of Zn and Sn in the Mg/HAP Composite

5. Conclusions

- Pure Mg, MHA, MZHA, and MSHA were successfully manufactured through ultrasonic-assisted rheo-squeeze casting.

- From the microstructural observation, the inclusion of Sn elements in the matrix attains well-grained refinement and effectively stops dislocation movement compared to the MZHA, MHA, and pure Mg. This was evidenced by the improved mechanical characteristics.

- The MSHA composite demonstrates significantly superior mechanical performance compared to its MZHA, MHA, and pure Mg counterparts. Specifically, the microhardness of MSHA demonstrates a notable increase of 64.5% compared to pure Mg and 42.7% compared to MHA.

- In terms of tensile and compression behavior, MSHA exhibits remarkable enhancements of 80.8% and 58.3%, respectively, compared to pure Mg, and 19% and 22.4%, respectively, compared to MHA. Moreover, the impact and flexural properties of MSHA are notably improved, showing enhancements of 41% and 42% compared to pure Mg, and 8% and 7% compared to MHA, respectively.

- The enhanced mechanical behavior of the MSHA composite could be attributed to the proper distribution of the Mg2Sn phase that transfers load effectively from the matrix and prevents it from deforming.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef] [PubMed]

- Rosalbino, F.; De Negri, S.; Saccone, A.; Angelini, E.M.M.A.; Delfino, S. Bio-corrosion characterization of Mg–Zn–X (X= Ca, Mn, Si) alloys for biomedical applications. J. Mater. Sci. Mater. Med. 2010, 21, 1091–1098. [Google Scholar] [CrossRef] [PubMed]

- Cui, Z.; Li, W.; Cheng, L.; Gong, D.; Cheng, W.; Wang, W. Effect of nano-HA content on the mechanical properties, degradation and biocompatible behavior of Mg-Zn/HA composite prepared by spark plasma sintering. Mater. Charact. 2019, 151, 620–631. [Google Scholar] [CrossRef]

- Tayebi, M.; Bizari, D.; Hassanzade, Z. Investigation of mechanical properties and biocorrosion behavior of in situ and ex situ Mg composite for orthopedic implants. Mater. Sci. Eng. C 2020, 113, 110974. [Google Scholar] [CrossRef] [PubMed]

- Barabás, R.; Fort, C.I.; Turdean, G.L.; Bizo, L. Influence of HAP on the morpho-structural properties and corrosion resistance of ZrO2-based composites for biomedical applications. Crystals 2021, 11, 202. [Google Scholar] [CrossRef]

- Avinashi, S.K.; Singh, P.; Sharma, K.; Hussain, A.; Singh, D.; Gautam, C. Morphological, mechanical, and biological evolution of pure hydroxyapatite and its composites with titanium carbide for biomedical applications. Ceram. Int. 2022, 48, 18475–18489. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Belov, A.A.; Buravlev, I.Y.; Mayorov, V.Y.; Fedorets, A.N.; Kornakova, Z.E. CaSiO3-HAp Metal-Reinforced Biocomposite Ceramics for Bone Tissue Engineering. J. Funct. Biomater. 2023, 14, 259. [Google Scholar] [CrossRef] [PubMed]

- Ahmadi, R.; Izanloo, S. Development of HAp/GO/Ag coating on 316 LVM implant for medical applications. J. Mech. Behav. Biomed. Mater. 2022, 126, 105075. [Google Scholar] [CrossRef] [PubMed]

- Avinashi, S.K.; Shweta; Bohra, B.; Mishra, R.K.; Kumari, S.; Fatima, Z.; Gautam, C.R. Fabrication of Novel 3-D Nanocomposites of HAp–TiC–h-BN–ZrO2: Enhanced Mechanical Performances and In Vivo Toxicity Study for Biomedical Applications. ACS Biomater. Sci. Eng. 2024, 10, 2116–2132. [Google Scholar] [CrossRef] [PubMed]

- Verma, V.; Saha, J.; Gautam, A.; Pal, K. Investigation on microstructure, mechanical, biocorrosion and biocompatibility behavior of nano-sized TiO2@ Al2O3 reinforced Mg-HAp composites. J. Alloys Compd. 2022, 910, 164866. [Google Scholar] [CrossRef]

- Parande, G.; Manakari, V.; Kopparthy, S.D.S.; Gupta, M. A study on the effect of low-cost eggshell reinforcement on the immersion, damping and mechanical properties of magnesium–zinc alloy. Compos. Part B Eng. 2020, 182, 107650. [Google Scholar] [CrossRef]

- Vignesh, P.; Ramanathan, S.; Ashokkumar, M.; Ananthi, V. Biodegradable Mg–3Zn alloy/titanium–hydroxyapatite hybrid composites: Corrosion and cytotoxicity evaluation for orthopedic implant applications. Transactions of the Indian Institute of Metals 2024, 77, 1701–1710. [Google Scholar] [CrossRef]

- Jhamb, S.K.; Goyal, A.; Pandey, A.; Verma, M.N. Mechanical, wear, and degradation behavior of biodegradable Mg-x% Sn alloy fabricated through powder mixing techniques. J. Mater. Eng. Perform. 2023, 32, 7123–7133. [Google Scholar] [CrossRef]

- Jiang, W.; Yu, W. In Vitro Degradation Behavior, Mechanical Properties, and Cytocompatibility of Biodegradable Mg-1Zn-xSn Alloys. Crystals 2022, 12, 1219. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, J.; Weiyang, J.; Qiao, B.; Wang, Y.; Li, Y.; Jiang, D. A novel biodegradable Mg-1Zn-0.5 Sn alloy: Mechanical properties, corrosion behavior, biocompatibility, and antibacterial activity. J. Magnes. Alloys 2020, 8, 374–386. [Google Scholar] [CrossRef]

- Khalajabadi, S.Z.; Kadir, M.R.A.; Izman, S.; Ebrahimi-Kahrizsangi, R. Fabrication, bio-corrosion behavior and mechanical properties of a Mg/HA/MgO nanocomposite for biomedical applications. Mater. Des. 2015, 88, 1223–1233. [Google Scholar] [CrossRef]

- Salleh, E.M.; Zuhailawati, H.; Mohd Noor, S.N.F.; Othman, N.K. In vitro Biodegradation and mechanical properties of Mg-Zn alloy and Mg-Zn-hydroxyapatite composite produced by mechanical alloying for potential application in bone repair. Metall. Mater. Trans. A 2018, 49, 5888–5903. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Farina, I.; Fraternali, F.; Feo, L. Physical-mechanical characterization of biodegradable Mg-3Si-HA composites. PSU Res. Rev. 2018, 2, 152–174. [Google Scholar] [CrossRef]

- Radha, R.; Sreekanth, D. Mechanical, in vitro corrosion and bioactivity performance of Mg based composite for orthopedic implant applications: Influence of Sn and HA addition. Biomed. Eng. Adv. 2022, 3, 100033. [Google Scholar] [CrossRef]

- Vignesh, P.; Ramanathan, S.; Ashokkumar, M.; Sonar, T.; Ananthi, V. Microstructure, Mechanical, and Electrochemical Corrosion Performance of Ti/HA (Hydroxyapatite) Particles Reinforced Mg-3Zn Squeeze Casted Composites. Int. J. Met. 2023, 18, 1348–1360. [Google Scholar] [CrossRef]

- Hu, Y.; Guo, X.; Qiao, Y.; Wang, X.; Lin, Q. Preparation of medical Mg–Zn alloys and the effect of different zinc contents on the alloy. J. Mater. Sci. Mater. Med. 2022, 33, 9. [Google Scholar] [CrossRef] [PubMed]

- Nazirah, R.; Zuhailawati, H.; Siti Nur Hazwani, M.R.; Abdullah, T.K.; Azzura, I.; Dhindaw, B.K. The Influence of Hydroxyapatite and Alumina Particles on the Mechanical Properties and Corrosion Behavior of Mg-Zn Hybrid Composites for Implants. Materials 2021, 14, 6246. [Google Scholar] [CrossRef] [PubMed]

- Verma, V.; Singh, S.; Pal, K. Exploring the potential of Mg-Zn-Mn-Ca/ZnO composites as a biodegradable alternative for fracture fixation: Microstructural, mechanical, and in-vitro biocompatibility analysis. Compos. Struct. 2023, 323, 117431. [Google Scholar] [CrossRef]

- Vignesh, P.; Ramanathan, S.; Ashokkumar, M. Evaluation of the wear performance of novel Titanium/hydroxyapatite-reinforced Mg–3Zn hybrid composites fabricated by squeeze casting. J. Bio-Tribo-Corros. 2023, 9, 38. [Google Scholar] [CrossRef]

- Arunkumar, T.; Selvakumaran, T.; Subbiah, R.; Ramachandran, K.; Manickam, S. Development of high-performance aluminium 6061/SiC nanocomposites by ultrasonic aided rheo-squeeze casting method. Ultrason. Sonochem. 2021, 76, 105631. [Google Scholar] [CrossRef] [PubMed]

- Prakash, C.; Singh, S.; Verma, K.; Sidhu, S.S.; Singh, S. Synthesis and characterization of Mg-Zn-Mn-HA composite by spark plasma sintering process for orthopedic applications. Vacuum 2018, 155, 578–584. [Google Scholar] [CrossRef]

- Bakhsheshi-Rad, H.R.; Idris, M.H.; Abdul-Kadir, M.R.; Ourdjini, A.; Medraj, M.; Daroonparvar, M.; Hamzah, E. Mechanical and bio-corrosion properties of quaternary Mg–Ca–Mn–Zn alloys compared with binary Mg–Ca alloys. Mater. Des. 2014, 53, 283–292. [Google Scholar] [CrossRef]

- Packkirisamy, V.; Sundaramurthy, R.; Mohankumar, A.; Sonar, T. Tribological and electrochemical corrosion behavior of binary Mg–3Zn novel hybrid composites for biodegradable implant applications. Mater. Test. 2024, 66, 675–686. [Google Scholar] [CrossRef]

| Specimen Code | Magnesium (99% Pure) | Hydroxyapatite (mp) (99% Pure) | Zinc (99% Pure) | Tin (99% Pure) |

|---|---|---|---|---|

| Pure Mg | 100% | - | - | - |

| MHA | 95% | 5% | - | - |

| MZHA | 94% | 5% | 1% | - |

| MSHA | 94% | 5% | - | 1% |

| Specimen Code | Yield Strength (Mpa) | Compression Strength (Mpa) |

|---|---|---|

| Pure Mg | 110 ± 2 | 189 ± 1 |

| MHA | 130 ± 1 | 245 ± 3 |

| MZHA | 152 ± 3 | 280 ± 2 |

| MSHA | 180 ± 2 | 300 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Thirugnanasambandam, A.; Mohankumar, A.; Reddy Botta, R.P.; Chong, W.W.F.; Thangamani, G.; Gupta, M. Hydroxyapatite Reinforced Magnesium Alloy Composites Using the Ultrasonic-Assisted Rheo-Squeeze Casting Technique: Microstructural and Mechanical Performance Evaluation for Bone Fixture Applications. Crystals 2024, 14, 667. https://doi.org/10.3390/cryst14070667

Thirugnanasambandam A, Mohankumar A, Reddy Botta RP, Chong WWF, Thangamani G, Gupta M. Hydroxyapatite Reinforced Magnesium Alloy Composites Using the Ultrasonic-Assisted Rheo-Squeeze Casting Technique: Microstructural and Mechanical Performance Evaluation for Bone Fixture Applications. Crystals. 2024; 14(7):667. https://doi.org/10.3390/cryst14070667

Chicago/Turabian StyleThirugnanasambandam, Arunkumar, Ashokkumar Mohankumar, Rajendra Prasad Reddy Botta, William Woei Fong Chong, Geethapriyan Thangamani, and Manoj Gupta. 2024. "Hydroxyapatite Reinforced Magnesium Alloy Composites Using the Ultrasonic-Assisted Rheo-Squeeze Casting Technique: Microstructural and Mechanical Performance Evaluation for Bone Fixture Applications" Crystals 14, no. 7: 667. https://doi.org/10.3390/cryst14070667

APA StyleThirugnanasambandam, A., Mohankumar, A., Reddy Botta, R. P., Chong, W. W. F., Thangamani, G., & Gupta, M. (2024). Hydroxyapatite Reinforced Magnesium Alloy Composites Using the Ultrasonic-Assisted Rheo-Squeeze Casting Technique: Microstructural and Mechanical Performance Evaluation for Bone Fixture Applications. Crystals, 14(7), 667. https://doi.org/10.3390/cryst14070667