Technology and Dielectric Properties of BLT4 Ceramics Modified with Special Glass

Abstract

:1. Introduction

2. Materials and Methods

3. Results

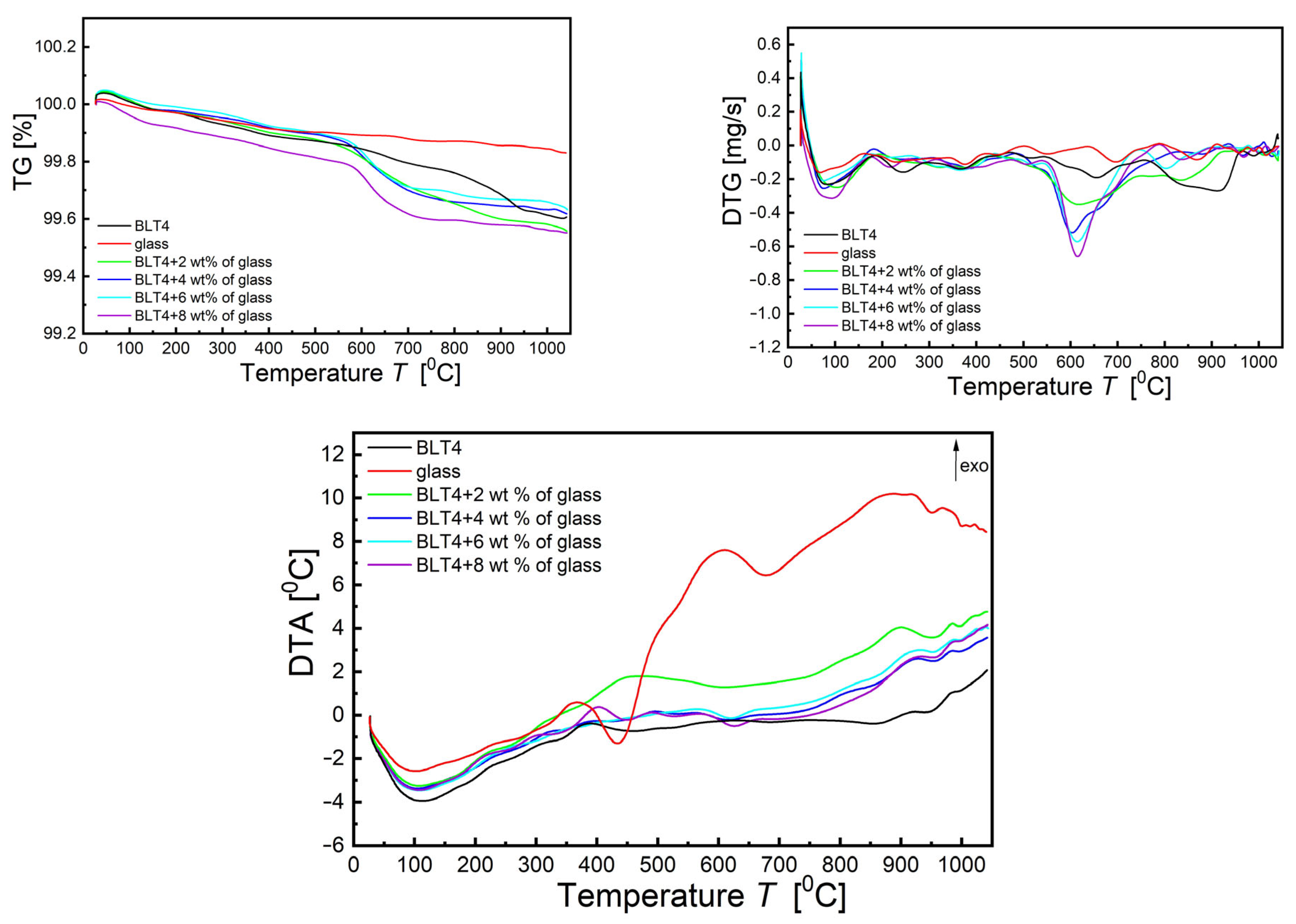

3.1. Thermal Analysis

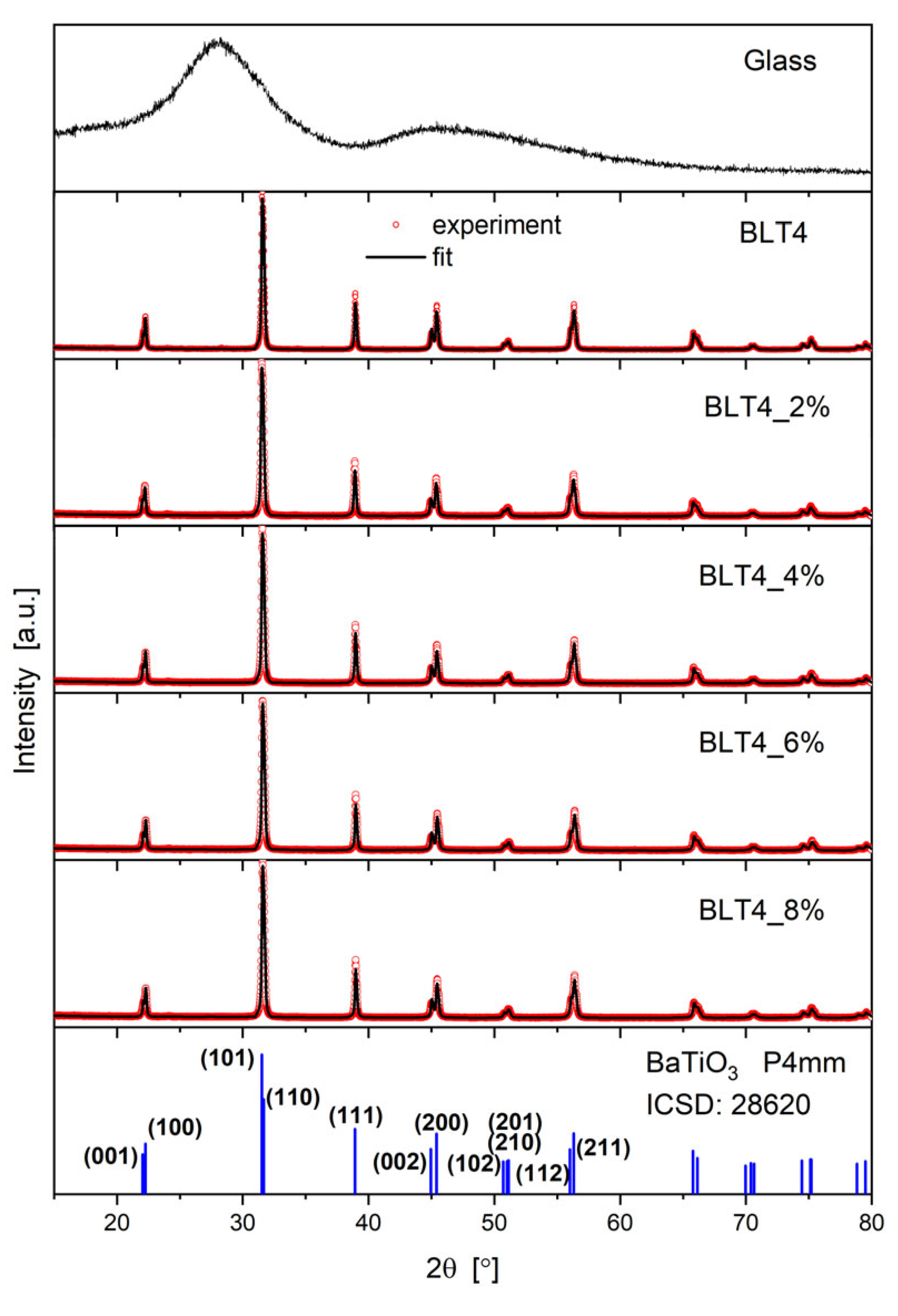

3.2. X-ray Analysis

3.3. Scanning Electron Microscopy

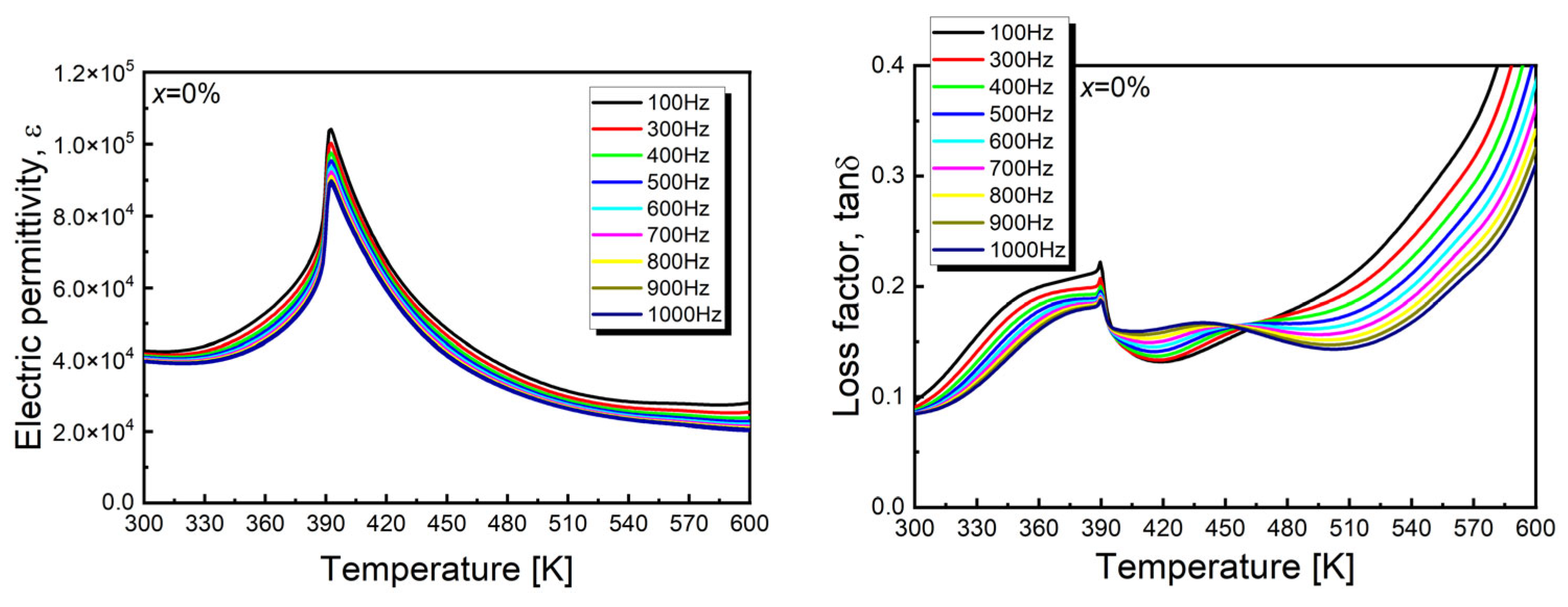

3.4. Dielectric Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sumona, H.J.; Sultan, M.S.; Urmi, S.A.; Gafur, M.A. Investigation of structural, electrical and optical properties of lanthanum and zirconium doped barium titanate ceramics. Mater. Sci. Eng. B 2023, 298, 116844. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, S.; Dong, Q.; Xu, C.; Zhu, S.; Zhang, X.; Chow, Y.T.; Wang, X.; Zhang, G.; Zhu, L.; et al. Electrospun lanthanum-doped barium titanate ceramic fibers with excellent dielectric performance. Mater. Charact. 2021, 172, 110859. [Google Scholar] [CrossRef]

- Zeng, L.; Yang, D.; Li, Z.; Xiong, W.; Hao, M.; Ma, H.; Yuan, H.; Cui, J. Microstructural changes and properties of LaxBa(1−x)(Zr0.1Ti0.9)O3 multilayer dielectric ceramics via digital light processing. Ceram. Int. 2024, 50, 19402–19411. [Google Scholar] [CrossRef]

- Kaur, S.; Karol, V.; Kumar, P.; Kaur, G.; Sharma, P.; Saroa, A.; Singh, A. Energy build-up factors estimation for BaZr0.10Ti0.90O3, Ba0.90La0.10TiO3 and Ba0.90La0.10Zr0.10Ti0.90O3 ceramics in shielding applications. Nucl. Eng. Technol. 2024, 56, 1822–1829. [Google Scholar] [CrossRef]

- Wodecka-Dus, B.; Plonska, M.; Czekaj, D. Synthesis, microstructure and the crystalline structure of the barium titanate ceramics doped with lanthanum. Arch. Metall. Mater. 2013, 58, 1305–1308. [Google Scholar] [CrossRef]

- Wodecka-Duś, B.; Adamczyk-Habrajska, M.; Goryczka, T.; Bochenek, D. Chemical and physical properties of the BLT4 ultra capacitor—A suitable material for ultracapacitors. Materials 2020, 13, 659. [Google Scholar] [CrossRef]

- Wodecka-Duś, B.; Kozielski, L.; Makowska, J.; Bara, M.; Adamczyk-Habrajska, M. Fe-Doped Barium Lanthanum Titanate as a Competitor to Other Lead-Free Piezoelectric Ceramics. Materials 2022, 15, 1089. [Google Scholar] [CrossRef]

- Ravanamma, R.; Ravi, N.; Kummara, V.K.; Khaerudini, D.S.; Kumar, K.U.; Sreenivasa Kumar, G.; Nanda Kumar Reddy, N. Yttria activated lanthanum-barium titanate ceramic electrode for fast charging supercapacitor applications. J. Mol. Struct. 2023, 1294, 136352. [Google Scholar] [CrossRef]

- Prohinig, J.M.; Kuegler, P.; Reichmann, K.; Hutter, H.; Bigl, S. The interaction of oxygen with manganese and its effect on surface state properties in PTCR BaTiO3. J. Eur. Ceram. Soc. 2022, 42, 2827–2835. [Google Scholar] [CrossRef]

- Leng, S.; Cheng, H.; Zhang, R.; Gao, C.; Li, Z. Electrical properties of La-Mn-codoped BaTiO3(Bi0.5Na0.5)TiO3 lead-free PTCR ceramics. Ceram. Int. 2021, 47, 30963–30968. [Google Scholar] [CrossRef]

- Rajib, M.; Shuvo, M.A.I.; Karim, H.; Delfin, D.; Afrin, S.; Lin, Y. Temperature influence on dielectric energy storage of nanocomposites. Ceram. Int. 2015, 41, 1807–1813. [Google Scholar] [CrossRef]

- Reavley, M.J.H.; Guo, H.; Yuan, J.; Ng, A.Y.R.; Ho, T.Y.K.; Tan, H.T.; Du, Z.; Gan, C.L. Ultrafast high-temperature sintering of barium titanate ceramics with colossal dielectric constants. J. Eur. Ceram. Soc. 2022, 42, 4934–4943. [Google Scholar] [CrossRef]

- Zhu, C.; Cai, Z.; Cao, X.; Fu, Z.; Li, L.; Wang, X. High-dielectric-constant nanograin BaTiO3-based ceramics for ultra-thin layer multilayer ceramic capacitors via grain grading engineering. Adv. Powder Mater. 2022, 1, 100029. [Google Scholar] [CrossRef]

- Gerson, R.; Marshall, T.C. Dielectric breakdown of porous ceramics. J. Appl. Phys. 1959, 30, 1650–1653. [Google Scholar] [CrossRef]

- Yu, J.; Jiang, Q.; Jia, Q.; Zhang, L.; Chiu, W.; Zeng, H. Designing a glass nanoshell on barium titanium trioxide to suppress nanocrystal growth during sintering for fine-grain dielectric ceramics. J. Mater. 2024; in press. [Google Scholar] [CrossRef]

- Manoharan, M.P.; Zou, C.; Furman, E.; Zhang, N.; Kushner, D.I.; Zhang, S.; Murata, T.; Lanagan, M.T. Flexible glass for high temperature energy storage capacitors. Energy Technol. 2013, 1, 313–318. [Google Scholar] [CrossRef]

- Wei, J.; Shang, F.; Zhang, H.; Zhu, G.; Zhao, Y.; Chen, G.; Ye, Z.G.; Xu, J. Improving the energy storage performance of batio3 based glass ceramics by reconstituting glass network structure via electronegativity tuning. J. Mater. 2024; in press. [Google Scholar] [CrossRef]

- Wang, J.; Xin, Z.; Hao, H.; Wang, Q.; Sun, X.; Liu, S. Reinforced dielectric properties and energy storage performance of BaO–Na2O–Nb2O5–SiO2–TiO2–ZrO2 dielectric glass ceramics. Ceram. Int. 2024, 50, 17283–17290. [Google Scholar] [CrossRef]

- Belova, L.A.; Goltzov, Y.I.; Prokopalo, O.I.; Rayevsky, I.P. Preparation of semiconducting BaTiO3 ceramics via liquid-phase doping. Izv. Akad. Nauk. SSSR Neorg. Mater. 1986, 22, 1004–1008. [Google Scholar]

- Freidenfel’d, E.Z.; Klyaine, R.Z.; Bogomolov, A.A. Pyroelectric properties of PbTiO3-based ceramics with glass additions. Izv. Akad. Nauk. Latv. SSR Ser. Khim. 1987, 6, 655–657. [Google Scholar]

- Howng, W.Y.; Cutchenon, C. Electrical properties of semiconducting BaTiO3 by liquid-phase sintering. Am. Ceram. Soc. Bull. 1983, 62, 231–233. [Google Scholar]

- Grossman, D.G.; Isard, J.O. Lead Titanate Glass Ceramics. J. Am. Ceram. Soc. 1969, 52, 230–231. [Google Scholar] [CrossRef]

- Yanchevskii, O.Z.; V’yunov, O.I.; Belous, A.G. Fabrication and Properties of Semiconducting Barium Lead Titanate Ceramics Containing Low-Melting Glass Additions. Inorg. Mater. 2003, 39, 645–651. [Google Scholar] [CrossRef]

- Pisarski, W.A.; Goryczka, T.; Wodecka-Duś, B.; Płońska, M.; Pisarska, J. Structure and properties of rare earth-doped lead borate glasses. Mater. Sci. Eng. B 2005, 122, 94–99. [Google Scholar] [CrossRef]

- Ziemba, B. Technologia Szkła; Wydawnictwo Arkady: Warszawa, Poland, 1987; Volume 1. [Google Scholar]

- Prasad, R.N.A.; Siva, B.V.; Neeraj, K.; Mohan, N.K.; Rojas, J.I. Influence of modifier oxides on spectroscopic features of Nd2O3 doped PbO-Ro2O3-WO3–B2O3 glasses (with Ro2O3 = Sb2O3, Al2O3, and Bi2O3). J. Lumin. 2020, 223, 117171. [Google Scholar] [CrossRef]

- Abdel-Khalek, E.K.; Mohamed, E.A.; Salem, S.M.; Kashif, I. Structural and dielectric properties of (100–x)B2O3-(x/2)Bi2O3-(x/2)Fe2O3 glasses and glass-ceramic containing BiFeO3 phase. J. Non-Cryst. Solids 2018, 492, 41–493. [Google Scholar] [CrossRef]

- Shelby, J.E. Introduction to Glass Science and Technology; Royal Society of Chemistry: Cambridge, UK, 2005. [Google Scholar]

- Hozer, L. Półprzewodnikowe Materiały Ceramiczne Z Aktywnymi Granicami Ziarn; PWN: Warszawa, Poland, 1990. [Google Scholar]

- Rao, K.S.; Kumar, V.R.; Veeraiah, N. Dielectric, magnetic and spectroscopic properties of Li2O–WO3–P2O5 glass system with Ag2O as additive. Mater. Chem. Phys. 2008, 111, 283–292. [Google Scholar] [CrossRef]

- Salem, S.M. Effect of iron on the electrical properties of lead bismuth glasses. J. Mater. Sci. 2009, 44, 5760–5767. [Google Scholar] [CrossRef]

- Upender, G.; Devi, C.S.; Mouli, V.C. Role of WO3 on DC conductivity and some optical properties of TeO2 based glasses. Mater. Res. Bull. 2012, 47, 3764–3769. [Google Scholar] [CrossRef]

- Han, J.; He, F.; Wang, L.L.; Zhang, L.X.; Ye, C.Q.; Xie, J.L.; Mei, S.X.; Jin, M.F. Effect of WO3 on the structure and properties of low sintering temperature and high strength vitrified bonds. J. Alloys Compd. 2016, 679, 54–58. [Google Scholar] [CrossRef]

- Singh, G.P.; Kaur, P.; Kaur, S.; Singh, D.P. Role of WO3 in structural and optical properties of WO3–Al2O3–PbO–B2O3 glasses. Phys. B 2011, 406, 4652–4656. [Google Scholar] [CrossRef]

- Iordanova, R.; Milanova, M.; Aleksandrov, L.; Khanna, A. Structural study of glasses in the system B2O3-Bi2O3-La2O3-WO3. J. Non-Cryst. Solids 2018, 481, 254–259. [Google Scholar] [CrossRef]

- Ali, A.A.; Fathi, A.M.; Ibrahim, S. Material characteristics of WO3/Bi2O3 substitution on the thermal, structural, and electrical properties of lithium calcium borate glasses. Appl. Phys. A 2023, 129, 299. [Google Scholar] [CrossRef]

- Pisarska, J.; Wodecka-Duś, B.; Płońska, M.; Goryczka, T.; Pisarski, W.A. Glass characterization in PbO–B2O3–Al2O3–WO3 system. Arch. Nauk. O. Mater. 2004, 25, 193–202. [Google Scholar]

- Wodecka-Dus, B.; Adamczyk, M.; Goryczka, T.; Dzik, J.; Radoszewska, D.; Kozielski, L.; Bochenek, D. The technology and structural properties of special glass modified (Ba0.6Pb0.4)TiO3 ceramics. Arch. Metall. Mater. 2016, 61, 1761–1766. [Google Scholar] [CrossRef]

- Wodecka-Duś, B.; Adamczyk-Habrajska, M.; Goryczka, T.; Radoszewska, D.; Feliksik, K.; Kozielski, L. Electric and dielectric properties of (Ba0.6Pb0.4)TiO3 ceramics modified with special glass in the range of phase transition. Process. Appl. Ceram. 2018; 12, 129–135. [Google Scholar] [CrossRef]

- Honma, T.; Maeda, K.; Nakane, S.; Shinozaki, K. Unique properties and potential of glass-ceramics. J. Ceram. Soc. Jpn. 2022, 130, 545–551. [Google Scholar] [CrossRef]

- Fu, L.; Engqvist, H.; Xia, W. Glass–Ceramics in Dentistry: A Review. Materials 2020, 13, 1049. [Google Scholar] [CrossRef]

- Ali, A.A.; Ibrahim, S.; Ahmed, E.M.; Rammah, Y.S. Influence of WO3 on gamma radiation shielding efficiency, physical and optical properties of newly developed Li2O–CaO–Bi2O3–B2O3 glasses. Radiat. Phys. Chem. 2022, 198, 110240. [Google Scholar] [CrossRef]

- Andou, M.; Higashida, Y.; Shibata, N.; Takeuchi, H.; Kasashima, T.; Ohbayashi, K. Control of dispersion frequency of BaTiO3-based ceramics applicable to thin absorber for millimeter electromagnetic wave. J. Eur. Ceram. Soc. 2006, 26, 2175–2178. [Google Scholar] [CrossRef]

- Li, W.; Yu, Z.; Wen, Q.; Feng, Y.; Fan, B.; Zhang, R.; Riedel, R. Ceramic-based electromagnetic wave absorbing materials and concepts towards lightweight, flexibility and thermal resistance. Int. Mater. Rev. 2023, 68, 487–520. [Google Scholar] [CrossRef]

- Li, X.; Yuan, G.; Zheng, M.; Li, R.; Meng, Z.; Guo, J.; Zhou, G. Fabrication and electromagnetic wave absorption property of quartz ceramics with a gradient distribution of BaTiO3. Ceram. Int. 2019, 45, 5965–5970. [Google Scholar] [CrossRef]

- Yang, Y.; Kulandaivel, A.; Mehrez, S.; Mahariq, I.; Elbadawy, I.; Mohanavel, V.; Jalil, A.T.; Saleh, M.M. Developing a high-performance electromagnetic microwave absorber using BaTiO3/CoS2/CNTs triphase hybrid. Ceram. Int. 2023, 49, 2557–2569. [Google Scholar] [CrossRef]

- Li, S.; Sheen, J.; Jang, S.; Bhalla, A.; Croos, L. Quasi lumped parameter method for microwave measurements of dielectric dispersion in ferroelectric ceramics. Ferroelectr. Lett. Sect. 1993, 16, 21–32. [Google Scholar] [CrossRef]

- Kazaoui, S.; Ravez, J.; Maglione, M.; Goux, P. Dielectric relaxation in crystals and ceramics derived from BaTiO3. Ferroelectrics 1992, 126, 203–208. [Google Scholar] [CrossRef]

- Wodecka-Duś, B. Właściwości Perowskitowej Ceramiki Ferroelektrycznej Na Bazie Tytanianu Baru; Wydawnictwo Uniwersytetu Śląskiego: Katowice, Poland, 2017. [Google Scholar]

- Cross, L.E. Relaxor Ferroelectrics. Ferroelectrics 1987, 76, 241–267. [Google Scholar] [CrossRef]

| Special Glass Content | TC [K] | εRT | εmax | tgδRT | tgδTC | T0 [K] | C [K] |

|---|---|---|---|---|---|---|---|

| 0% | 393 | 39,497 | 99,140 | 0.08 | 0.20 | 348 | 4.20 × 105 |

| 2% | 397 | 13,391 | 30,530 | 0.31 | 0.41 | 369 | 9.97 × 105 |

| 4% | 399 | 12,670 | 30,578 | 0.32 | 0.38 | 365 | 1.16 × 106 |

| 6% | 417 | 5363 | 12,407 | 0.13 | 0.16 | 342 | 9.80 × 105 |

| 8% | 408 | 10,222 | 24,593 | 0.29 | 0.31 | 356 | 1.42 × 106 |

| Special Glass Content | ΔεRT | Δεmax |

|---|---|---|

| 0% | 4387 (10%) | 22,239 (25%) |

| 2% | 16,331 (85%) | 41,512 (83%) |

| 4% | 14,971 (86%) | 38,510 (84%) |

| 6% | 4727 (75%) | 11,395 (74%) |

| 8% | 12,514 (88%) | 30,015 (87%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wodecka-Dus, B.; Makowska, J.; Pikula, T.; Panek, R.; Adamczyk-Habrajska, M.; Osińska, K. Technology and Dielectric Properties of BLT4 Ceramics Modified with Special Glass. Crystals 2024, 14, 739. https://doi.org/10.3390/cryst14080739

Wodecka-Dus B, Makowska J, Pikula T, Panek R, Adamczyk-Habrajska M, Osińska K. Technology and Dielectric Properties of BLT4 Ceramics Modified with Special Glass. Crystals. 2024; 14(8):739. https://doi.org/10.3390/cryst14080739

Chicago/Turabian StyleWodecka-Dus, Beata, Jolanta Makowska, Tomasz Pikula, Rafał Panek, Małgorzata Adamczyk-Habrajska, and Katarzyna Osińska. 2024. "Technology and Dielectric Properties of BLT4 Ceramics Modified with Special Glass" Crystals 14, no. 8: 739. https://doi.org/10.3390/cryst14080739