Dynamic Colour Changes in Thermochromic Liquid Crystal Inks: Compatibility with Bacterial Nanocellulose for Sustainable Packaging Solutions

Abstract

1. Introduction

2. Materials and Methods

2.1. Printing Inks and Printing Substrates

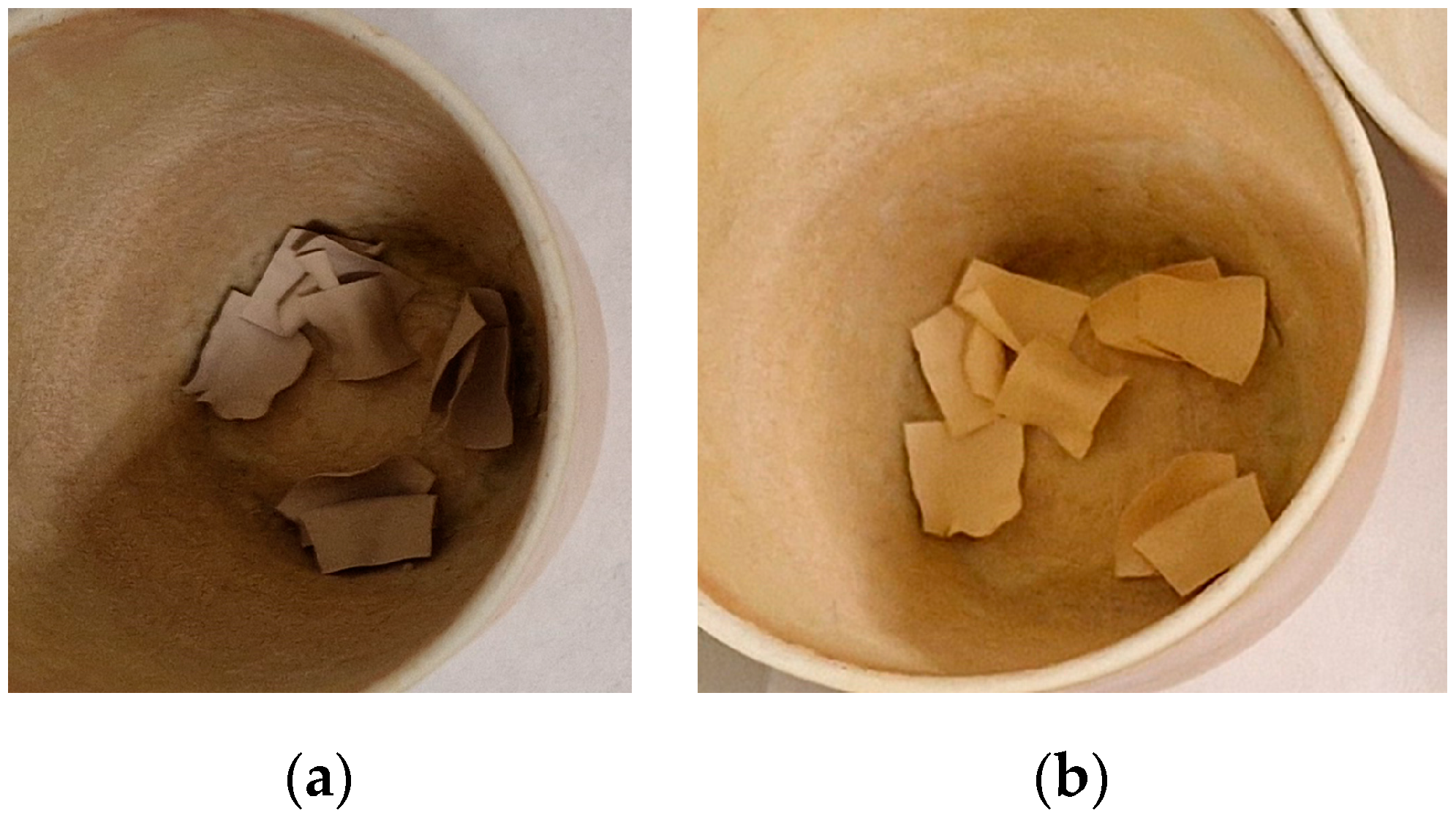

2.2. BNC Preparation

2.3. Printing Process

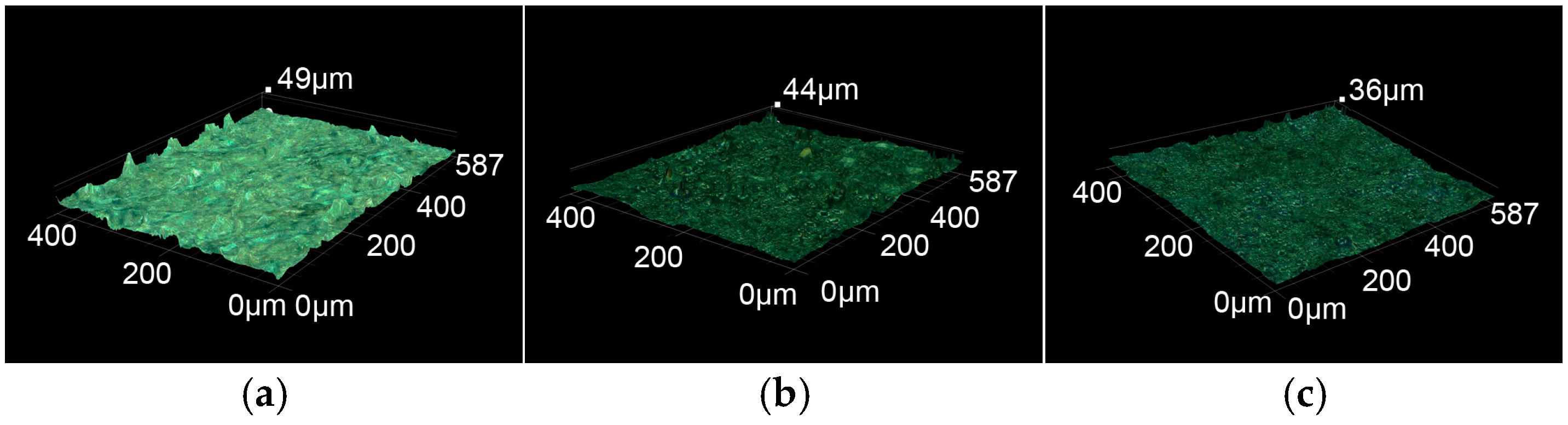

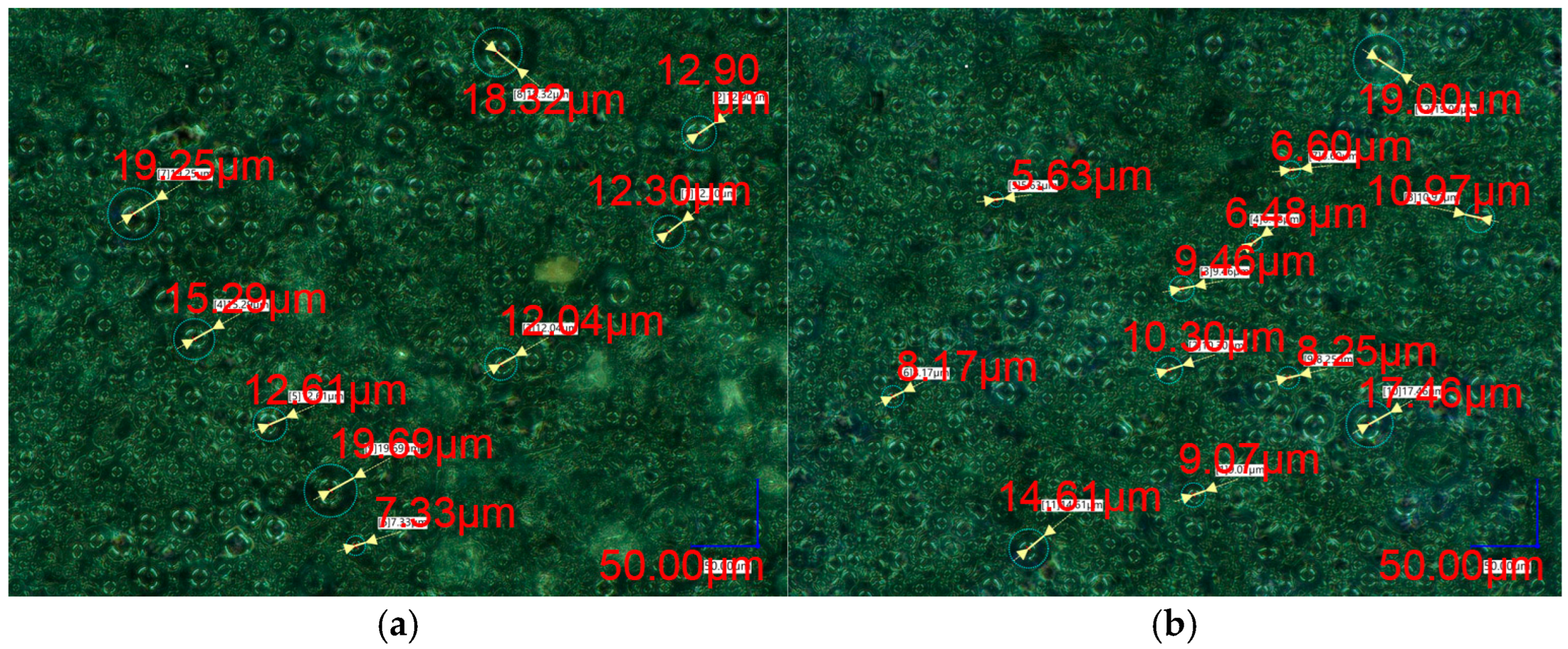

2.4. Characterization of the Printing Substrates

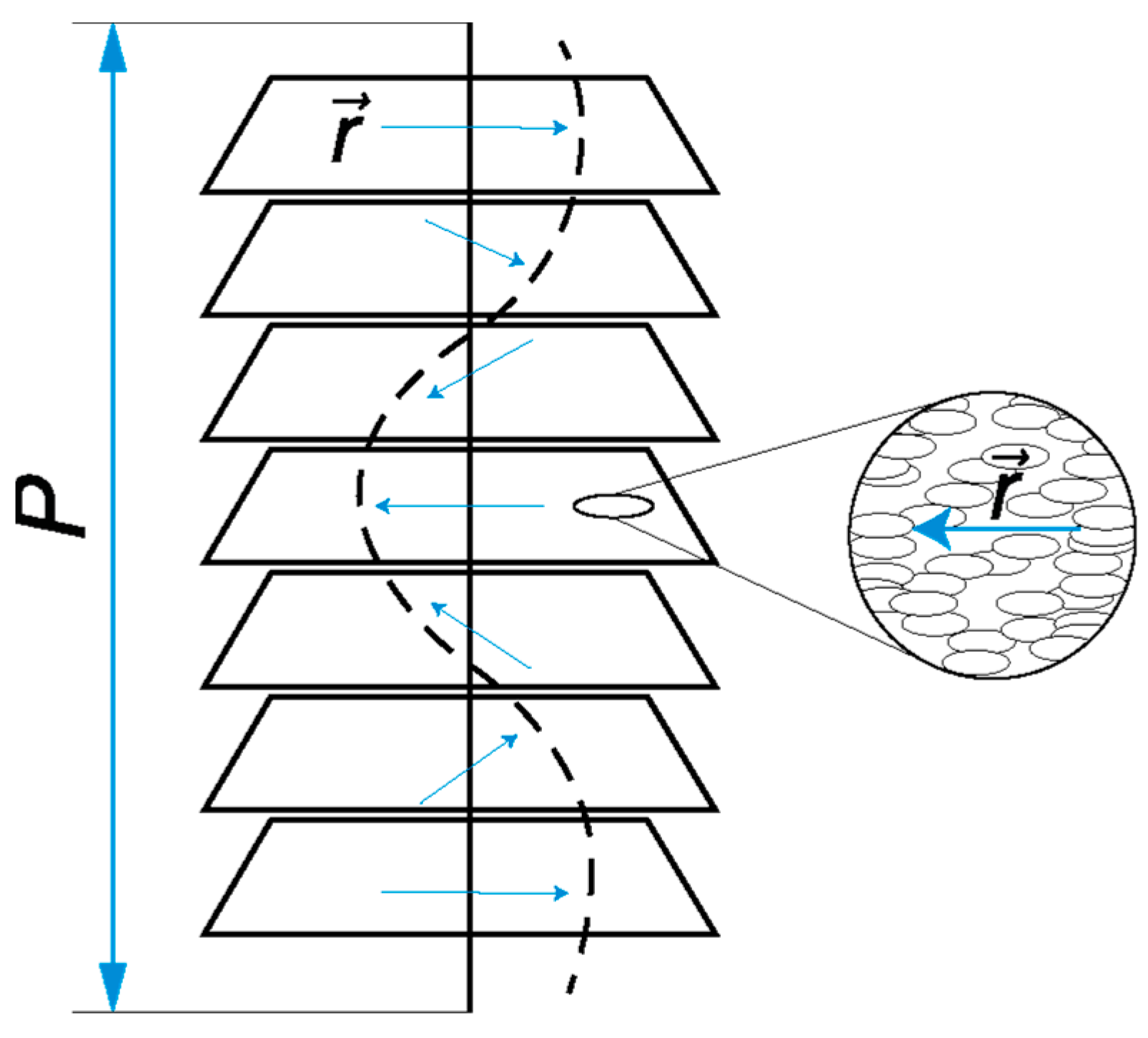

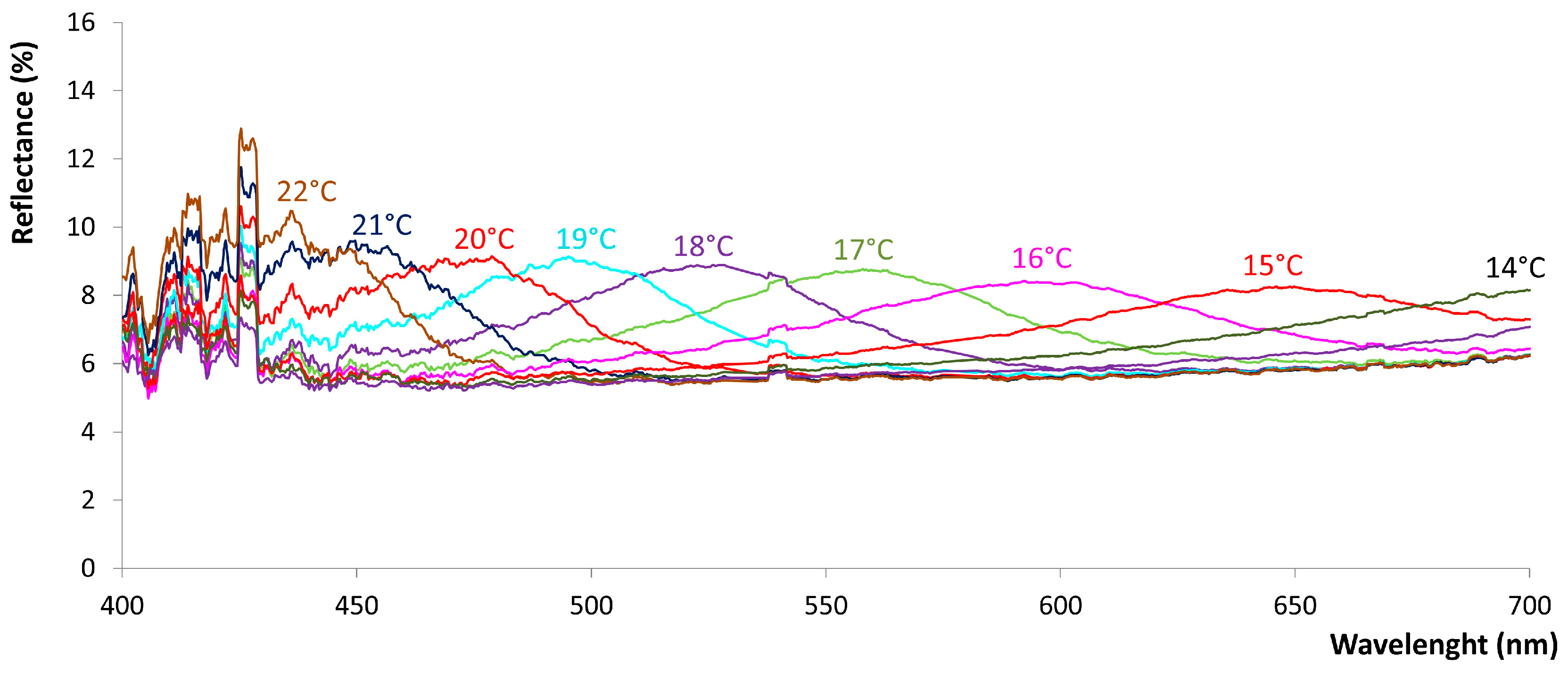

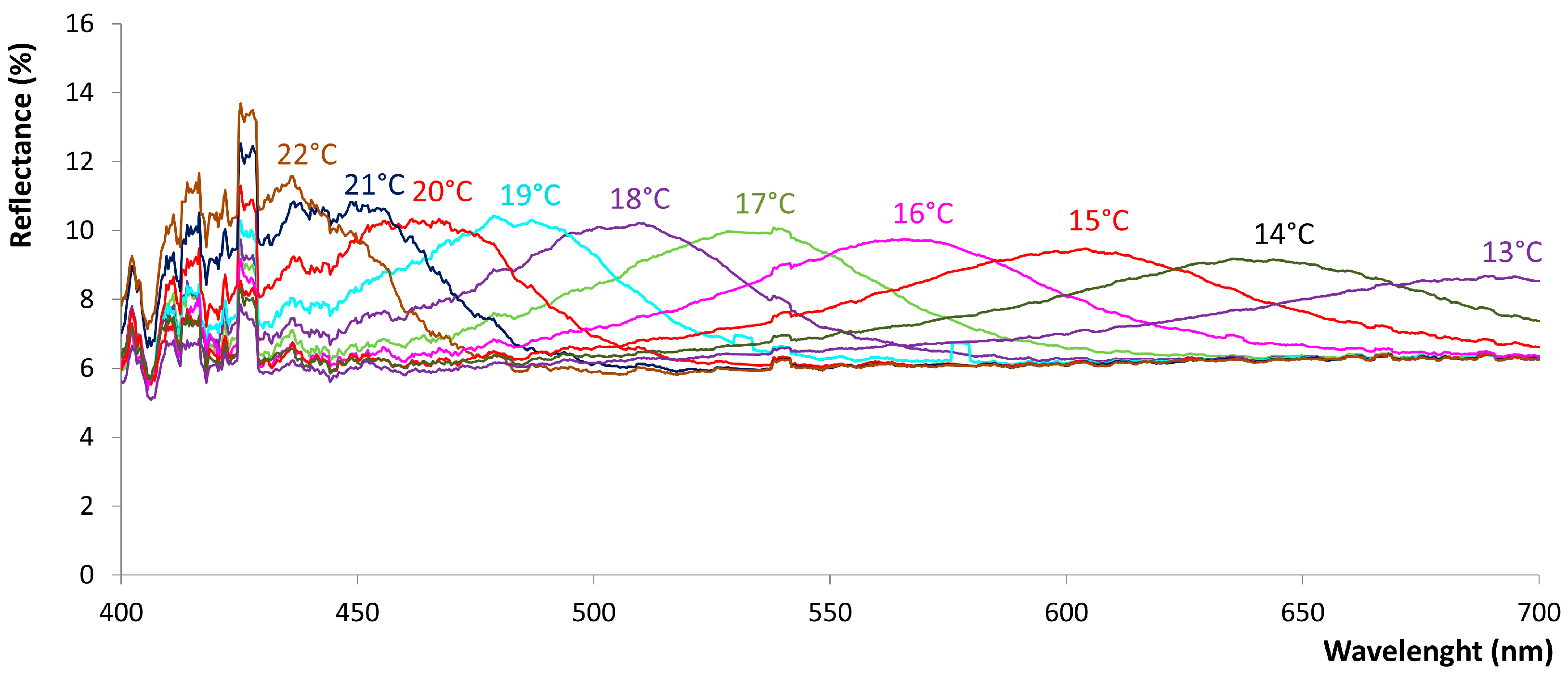

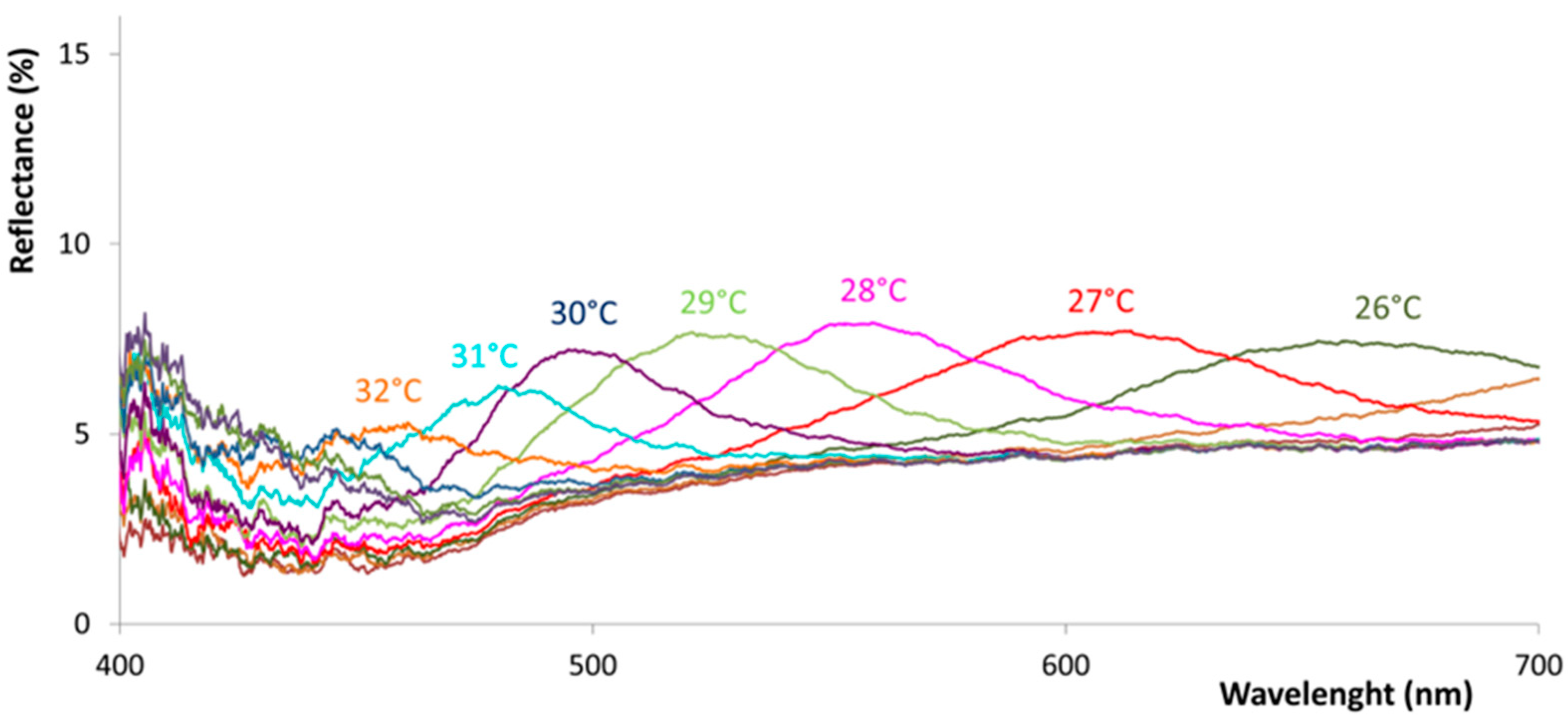

2.5. Temperature-Dependent Optical Properties of Printed TLC Inks

3. Results

3.1. Surface Morphology

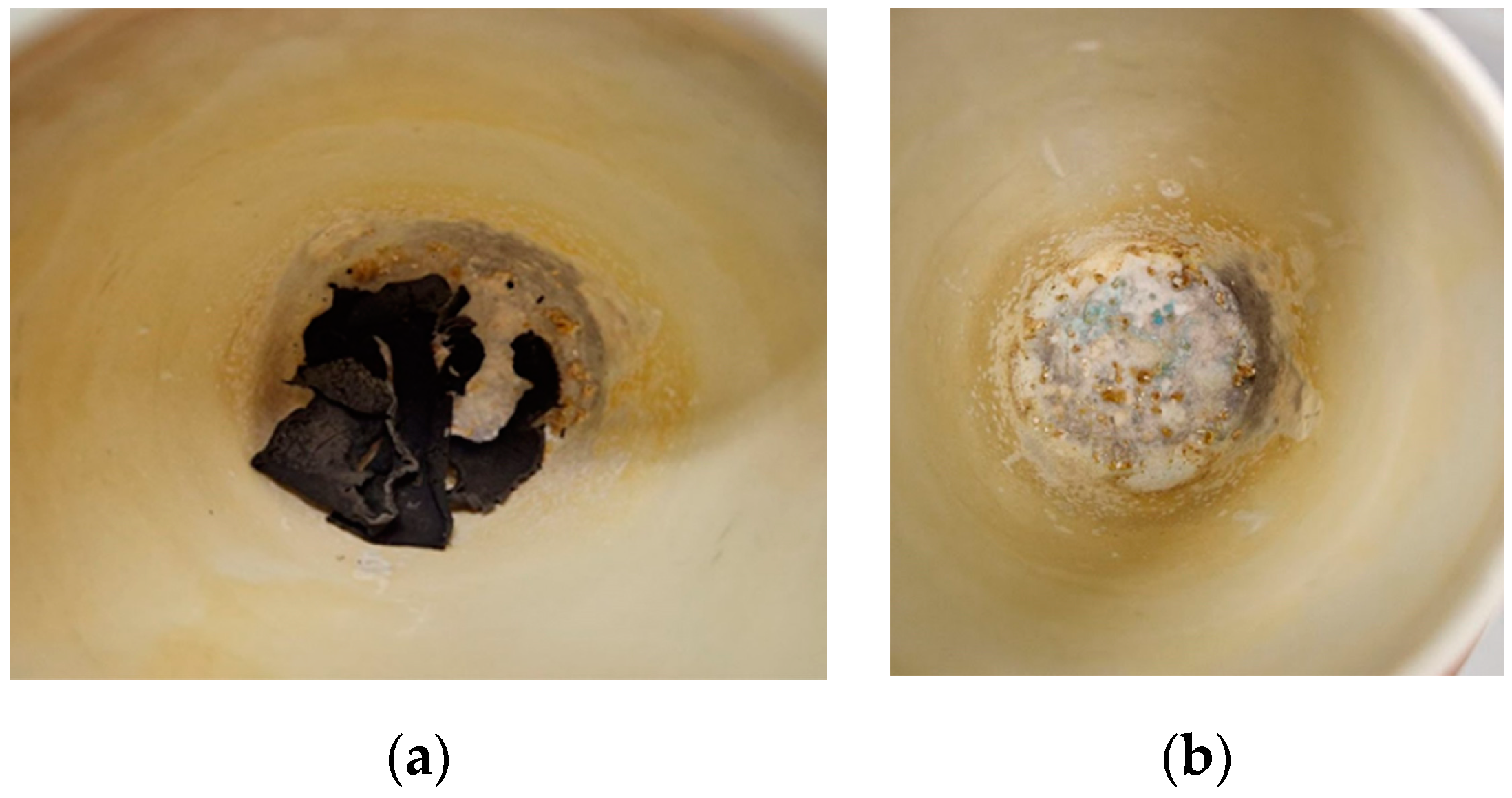

3.2. Determination of Fillers Content in UT and BNC Substrates

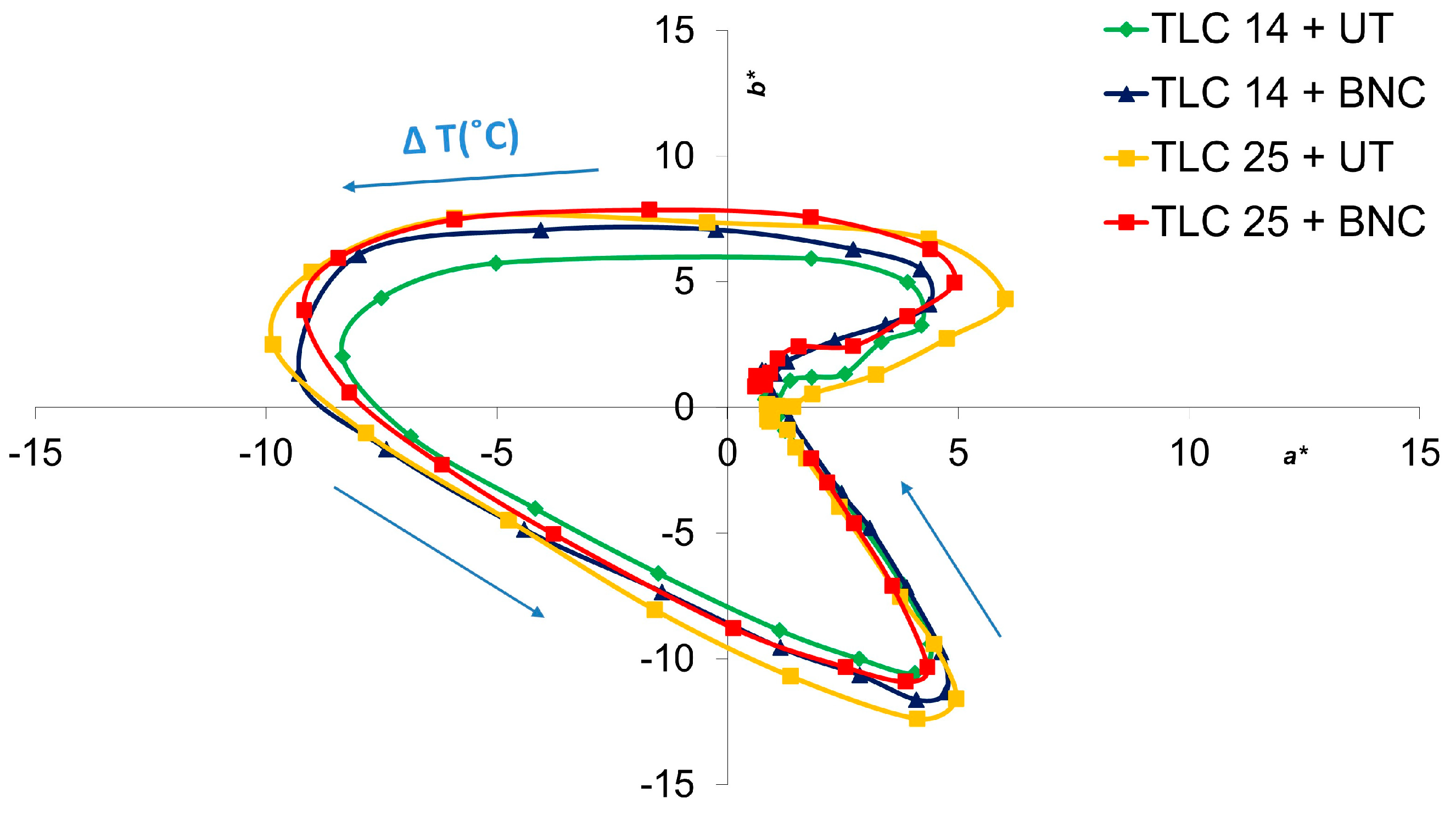

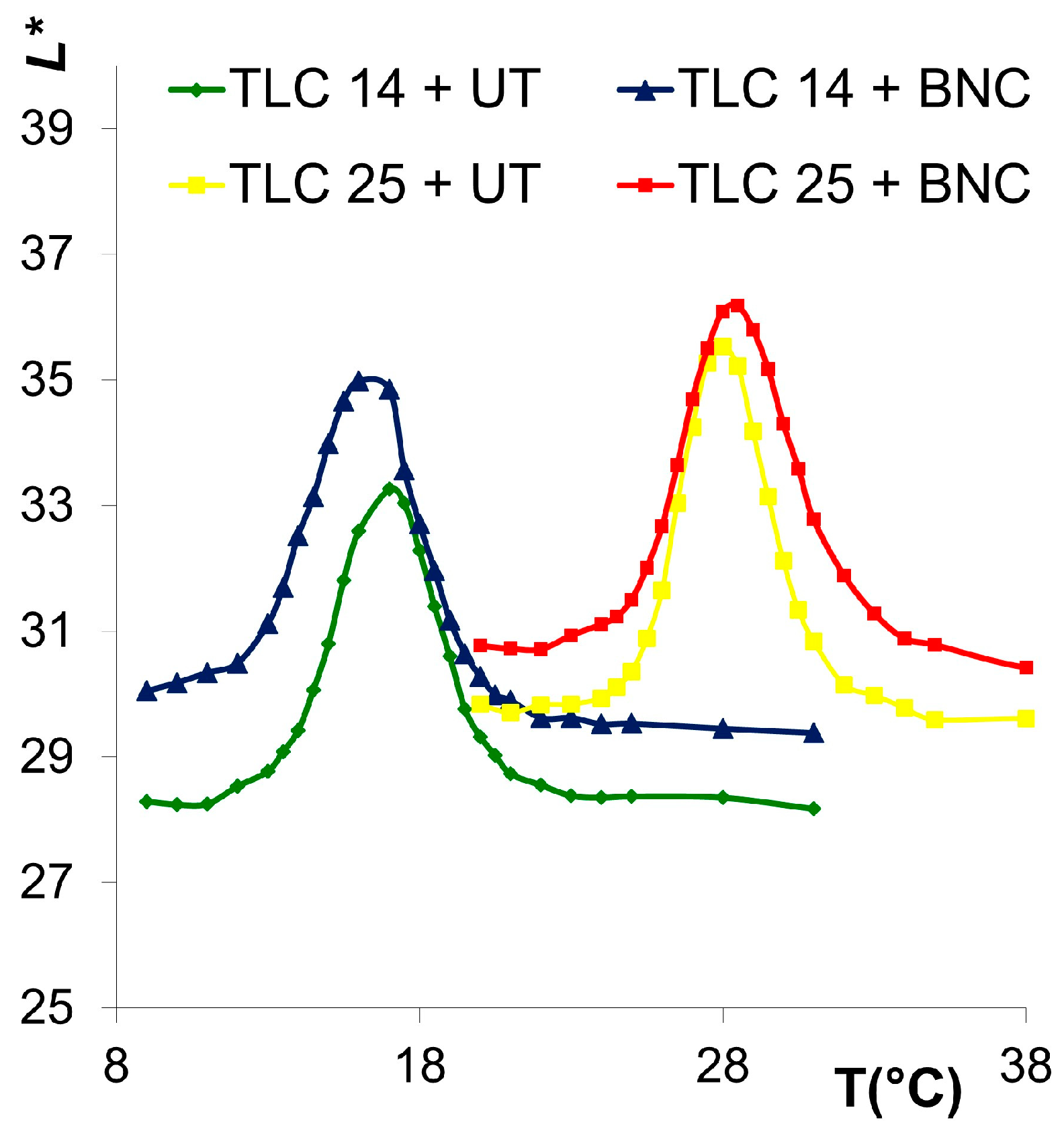

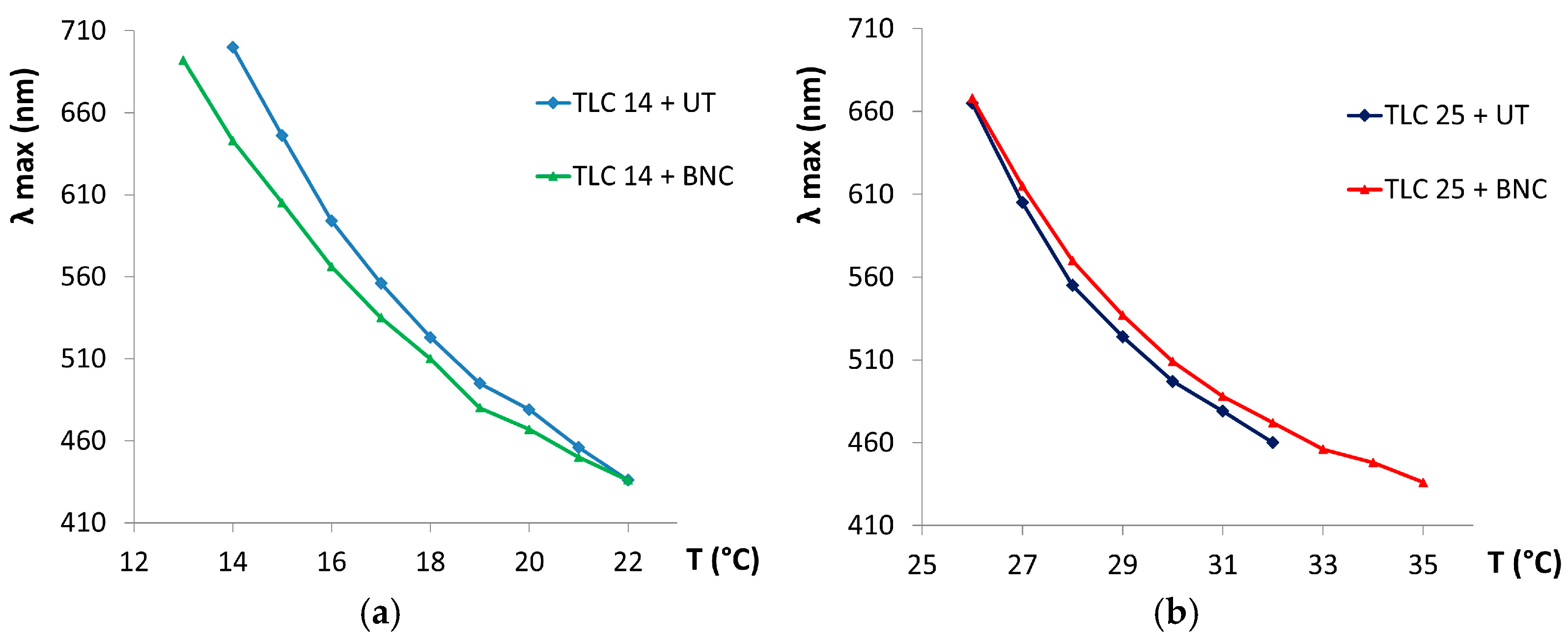

3.3. Temperature-Dependent Colorimetric Properties of Printed TLC Inks

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Taugerbeck, A.; Booth, C.J. Design and Synthesis of Chiral Nematic Liquid Crystals. In Handbook of Liquid Crystals; Wiley: Hoboken, NJ, USA, 2014; pp. 1–63. [Google Scholar] [CrossRef]

- LCR Hallcrest. Hallcrest Handbook of Thermochromic Liquid Crystal Technology.pdf. Available online: https://spotsee.io/wp-content/uploads/2021/05/RT006-Rev01-USA-Thermochromic-Handbook.pdf?srsltid=AfmBOoqBS9yrfgobRIj48S7Q0KwbZ3_zI2FCF3ukTqJNEUCaJuqjSR95 (accessed on 1 October 2024).

- Strižić Jakovljević, M.; Lozo, B.; Klanjšek Gunde, M. The properties of printing substrates required for thermochromic liquid-crystal printing inks. J. Print Media Technol. Res. 2018, 7, 165–170. [Google Scholar] [CrossRef]

- Seeboth, A.; Lötzsch, D.; Ruhmann, R.; Muehling, O. Thermochromic polymers—Function by design. Chem. Rev. 2014, 114, 3037–3068. [Google Scholar] [CrossRef] [PubMed]

- Christie, R.M.; Robertson, S.; Taylor, S. Design Concepts for a Temperature-sensitive Environment Using Thermochromic Colour Change. Colour Des. Creat. 2007, 1, 1–11. [Google Scholar]

- White, M.A.; LeBlanc, M. Thermochromism in Commercial Products. J. Chem. Educ. 1999, 76, 1201–1205. [Google Scholar] [CrossRef]

- Kerry, J.; Butler, P. Smart Packaging Technologies for Fast Moving Consumer Goods; Wiley: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Zhang, W.; Fei, L.; Zhang, J.; Chen, K.; Yin, Y.; Wang, C. Durable and tunable temperature responsive silk fabricated with reactive thermochromic pigments. Prog. Org. Coat. 2020, 147, 105697. [Google Scholar] [CrossRef]

- Štaffová, M.; Kučera, F.; Tocháček, J.; Dzik, P.; Ondreáš, F.; Jančář, J. Insight into color change of reversible thermochromic systems and their incorporation into textile coating. J. Appl. Polym. Sci. 2021, 138, 49724. [Google Scholar] [CrossRef]

- Liu, B.; Rasines Mazo, A.; Gurr, P.A.; Qiao, G.G. Reversible Nontoxic Thermochromic Microcapsules. ACS Appl. Mater. Interfaces 2020, 12, 9782–9789. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; He, Y.; Han, N.; Zhang, X.; Li, W. Synthesis and characterization of hydrophobic reversible thermochromic MicroPCMs with amino resins shell for thermal energy storage. Energy Build. 2021, 230, 110528. [Google Scholar] [CrossRef]

- He, Y.; Li, W.; Han, N.; Wang, J.; Zhang, X. Facile flexible reversible thermochromic membranes based on micro/nanoencapsulated phase change materials for wearable temperature sensor. Appl. Energy 2019, 247, 615–629. [Google Scholar] [CrossRef]

- Breheny, C.; Donlon, K.; Harrington, A.; Colbert, D.M.; Bezerra, G.S.N.; Geever, L.M. Thermochromic Polymers in Food Packaging: A Comprehensive Systematic Review and Patent Landscape Analysis. Coatings 2024, 14, 1252. [Google Scholar] [CrossRef]

- Sage, I. Thermochromic liquid crystals. Liq. Cryst. 2011, 38, 1551–1561. [Google Scholar] [CrossRef]

- Lagerwall, J.P.F.; Scalia, G. A new era for liquid crystal research: Applications of liquid crystals in soft matter nano-, bio- and microtechnology. Curr. Appl. Phys. 2012, 12, 1387–1412. [Google Scholar] [CrossRef]

- Kitzerow, H.-S.; Bahr, C. Chirality in Liquid Crystals; Springer: New York, NY, USA, 2001. [Google Scholar]

- Yoon, J.; Lee, W.; Thomas, E.L. Thermochromic block copolymer photonic gel. Macromolecules 2008, 41, 4582–4584. [Google Scholar] [CrossRef]

- Jakovljević, M.S.; Lozo, B.; Gunde, M.K. Identifying a unique communication mechanism of thermochromic liquid crystal printing ink. Crystals 2021, 11, 876. [Google Scholar] [CrossRef]

- Dermol, Š.; Borin, B.; Gregor-Svetec, D.; Slemenik Perše, L.; Lavrič, G. The Development of a Bacterial Nanocellulose/Cationic Starch Hydrogel for the Production of Sustainable 3D-Printed Packaging Foils. Polymers 2024, 16, 1527. [Google Scholar] [CrossRef] [PubMed]

- Lavrič, G.; Medvešček, D.; Skočaj, M. Papermaking properties of bacterial nanocellulose produced from mother of vinegar, a waste product after classical vinegar production. Tappi J. 2020, 19, 197–203. [Google Scholar] [CrossRef]

- Lavrič, G.; Oberlintner, A.; Filipova, I.; Novak, U.; Likozar, B.; Vrabič-Brodnjak, U. Functional Nanocellulose, Alginate and Chitosan Nanocomposites Designed as Active Film Packaging Materials. Polymers 2021, 13, 2523. [Google Scholar] [CrossRef] [PubMed]

- Mahović Poljaček, S.; Tomašegović, T.; Strižić Jakovljević, M.; Jamnicki Hanzer, S.; Murković Steinberg, I.; Žuvić, I.; Leskovac, M.; Lavrič, G.; Kavčič, U.; Karlovits, I. Starch-Based Functional Films Enhanced with Bacterial Nanocellulose for Smart Packaging: Physicochemical Properties, pH Sensitivity and Colorimetric Response. Polymers 2024, 16, 2259. [Google Scholar] [CrossRef] [PubMed]

- Pantić, M.; Nowak, M.; Lavrič, G.; Knez, Ž.; Novak, Z.; Zizovic, I. Enhancing the properties and morphology of starch aerogels with nanocellulose. Food Hydrocoll. 2024, 156, 110345. [Google Scholar] [CrossRef]

- Sefar AG. SEFAR® PET 1500. Available online: https://www.sefar.com/data/docs/zh/10855/PS-PDF-SEFAR-PET1500-AL-EN.pdf?v=1.8 (accessed on 11 December 2024.).

- ISO 25178:2016; Geometrical Product Specifications (GPS)—Surface Texture: Areal. ISO: Geneva, Switzerland, 2016.

- ISO 534:2011; Paper and Board—Determination of Thickness, Density and Specific Volume. ISO: Geneva, Switzerland, 2011.

- TAPPI-T412; Om-94 Moisture in Pulp, Paper and Paperboard. TAPPI: Peachtree Corners, GA, USA, 2016.

- TAPPI T 211; Om-02 Ash in Wood, Pulp, Paper, and Paperboard: Combustion at 525 °C. TAPPI: Peachtree Corners, GA, USA, 2007.

- TAPPI T 413 93; Ash in Wood, Pulp, Paper and Paperboard: Combustion at 900 °C. TAPPI: Peachtree Corners, GA, USA, 2007.

| TLC Ink | TA (°C) | Temperature Activation Region (°C) |

|---|---|---|

| TLC 14 | 14 | 14–19 |

| TLC 25 | 25 | 15–30 |

| Sample | Sa (µm) | Sz (µm) | Sp (µm) | Sv (µm) |

|---|---|---|---|---|

| UT, unprinted | 2 | 47 | 32 | 15 |

| BNC, unprinted | 20 | 112 | 47 | 65 |

| TLC 14 + UT | 5 | 31 | 15 | 16 |

| TLC 14 + BNC | 18 | 119 | 62 | 57 |

| TLC 25 + UT | 3 | 36 | 25 | 11 |

| TLC 25 + BNC | 13 | 97 | 47 | 50 |

| Sample | Absolute Moisture (%) | Ash Content/525 °C (%) | Ash Content/900 °C (%) |

|---|---|---|---|

| UT | 3.93 | 5 | 4.57 |

| BNC | 3.93 | 6.22 | 3.74 |

| TLC Prints | T(L*max) (°C) | λ (nm) | ∆L*max |

|---|---|---|---|

| TLC 14 + UT | 17 | 556 | 5.09 |

| TLC 14 + BNC | 16 | 566 | 5.6 |

| TLC 25 + UT | 28 | 555 | 5.94 |

| TLC 25 + BNC | 28.5 | 554 | 5.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Strižić Jakovljević, M.; Klanjšek Gunde, M.; Cigula, T.; Lavrič, G. Dynamic Colour Changes in Thermochromic Liquid Crystal Inks: Compatibility with Bacterial Nanocellulose for Sustainable Packaging Solutions. Crystals 2025, 15, 283. https://doi.org/10.3390/cryst15030283

Strižić Jakovljević M, Klanjšek Gunde M, Cigula T, Lavrič G. Dynamic Colour Changes in Thermochromic Liquid Crystal Inks: Compatibility with Bacterial Nanocellulose for Sustainable Packaging Solutions. Crystals. 2025; 15(3):283. https://doi.org/10.3390/cryst15030283

Chicago/Turabian StyleStrižić Jakovljević, Maja, Marta Klanjšek Gunde, Tomislav Cigula, and Gregor Lavrič. 2025. "Dynamic Colour Changes in Thermochromic Liquid Crystal Inks: Compatibility with Bacterial Nanocellulose for Sustainable Packaging Solutions" Crystals 15, no. 3: 283. https://doi.org/10.3390/cryst15030283

APA StyleStrižić Jakovljević, M., Klanjšek Gunde, M., Cigula, T., & Lavrič, G. (2025). Dynamic Colour Changes in Thermochromic Liquid Crystal Inks: Compatibility with Bacterial Nanocellulose for Sustainable Packaging Solutions. Crystals, 15(3), 283. https://doi.org/10.3390/cryst15030283