Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite

Abstract

1. Introduction

2. Experimental

2.1. Materials Preparation

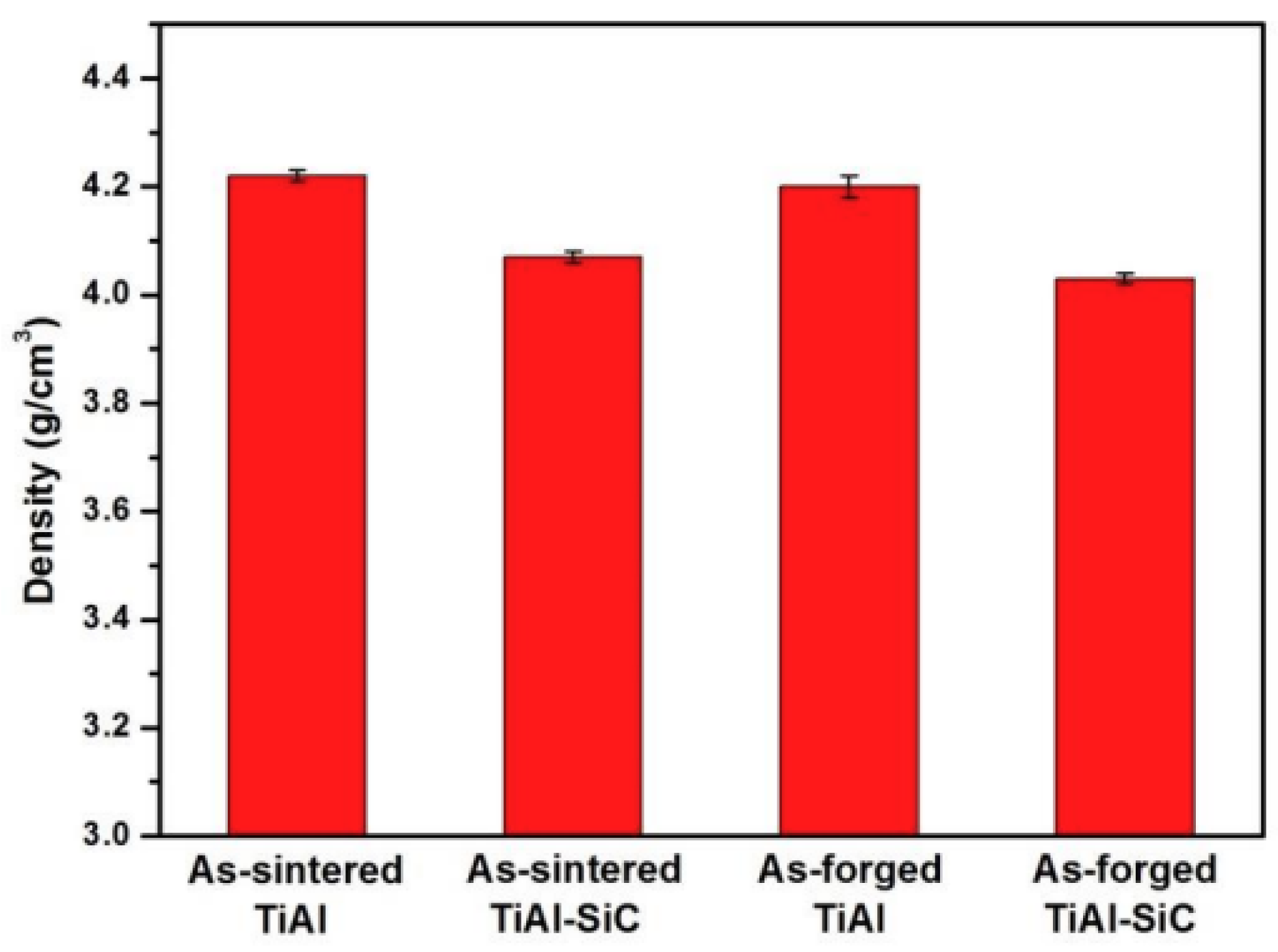

2.2. Examination of Powder Size and Material Density

2.3. Microstructure Analysis

2.4. High-Temperature Compressive Properties Test

3. Results and Discussion

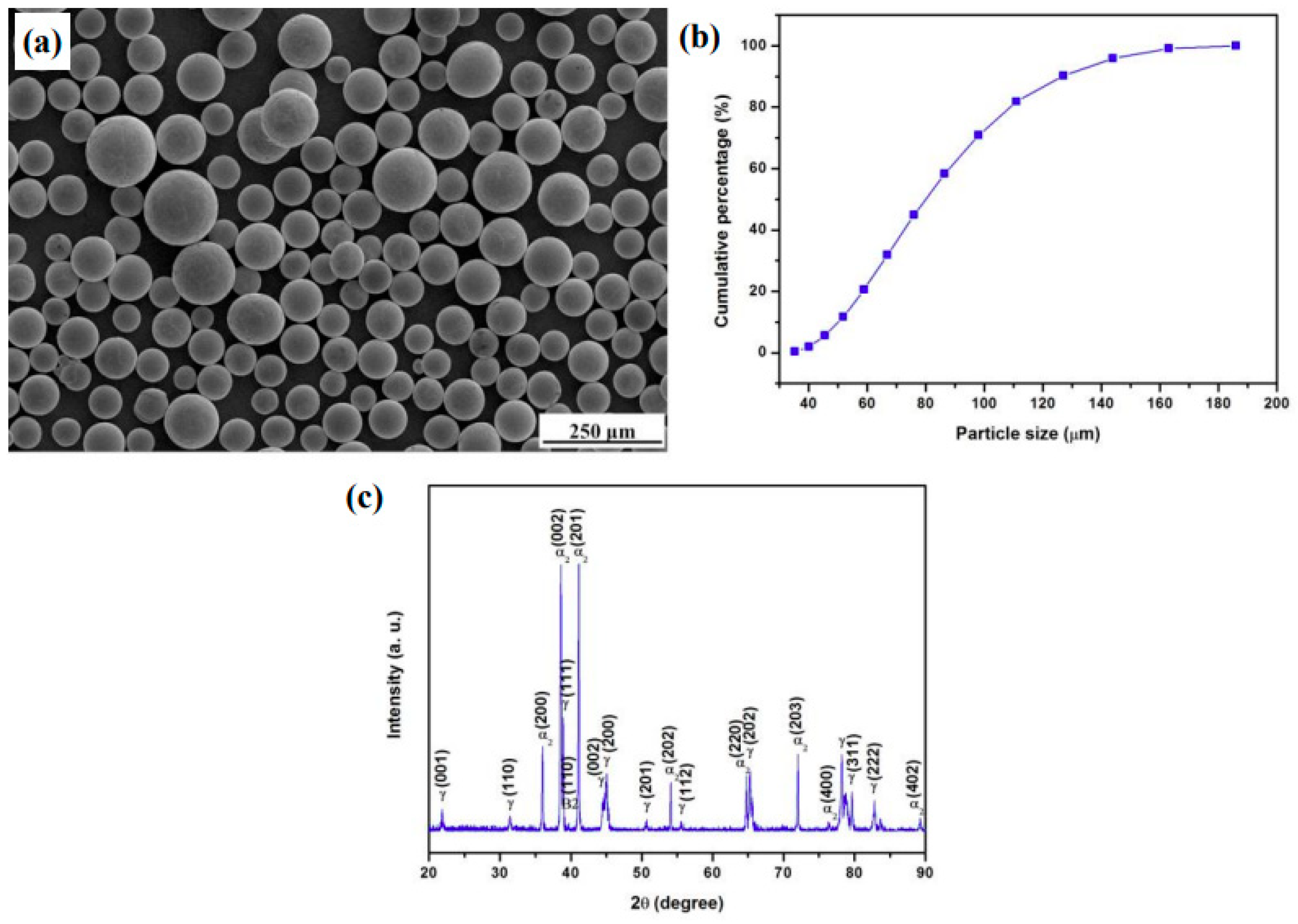

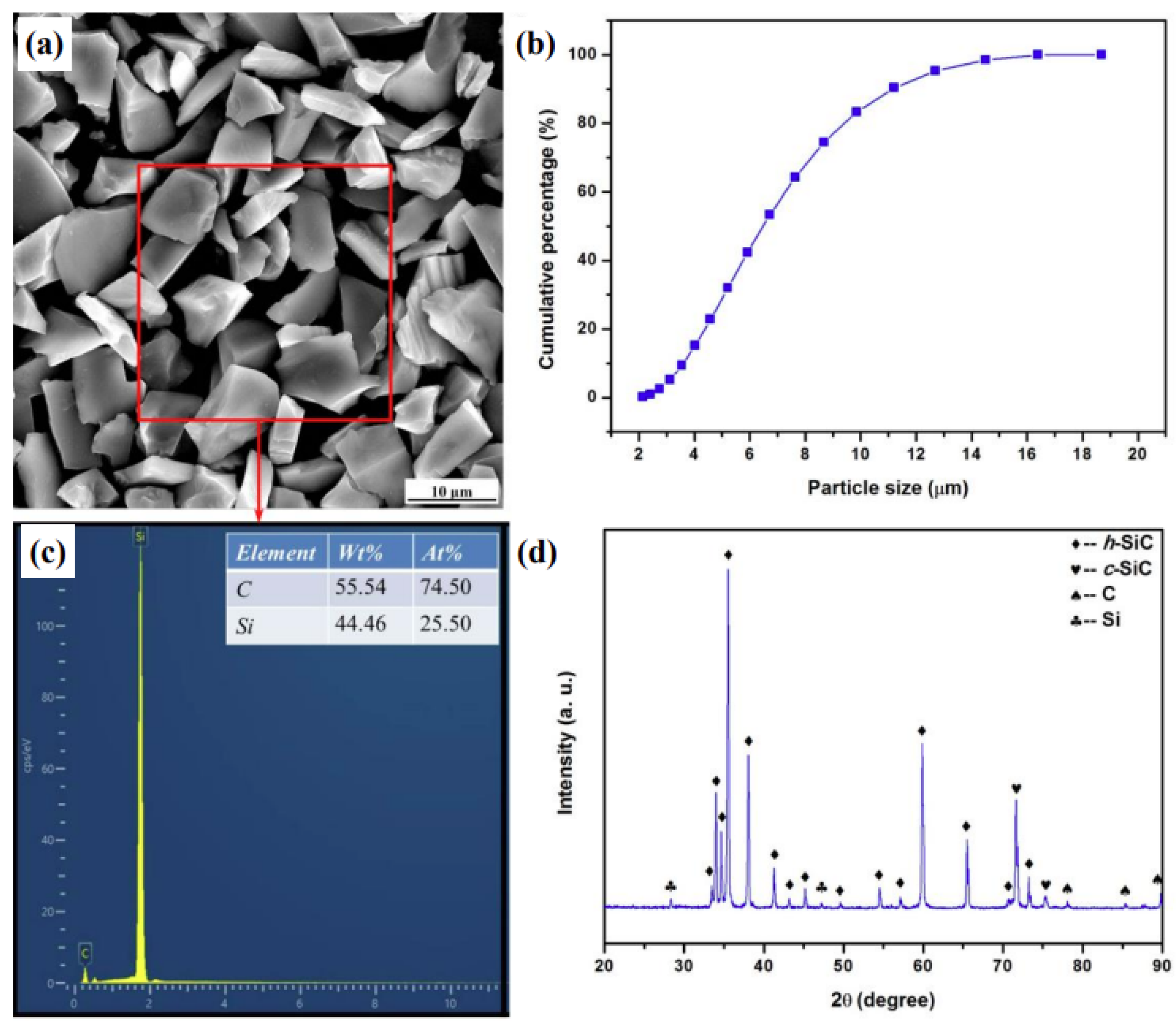

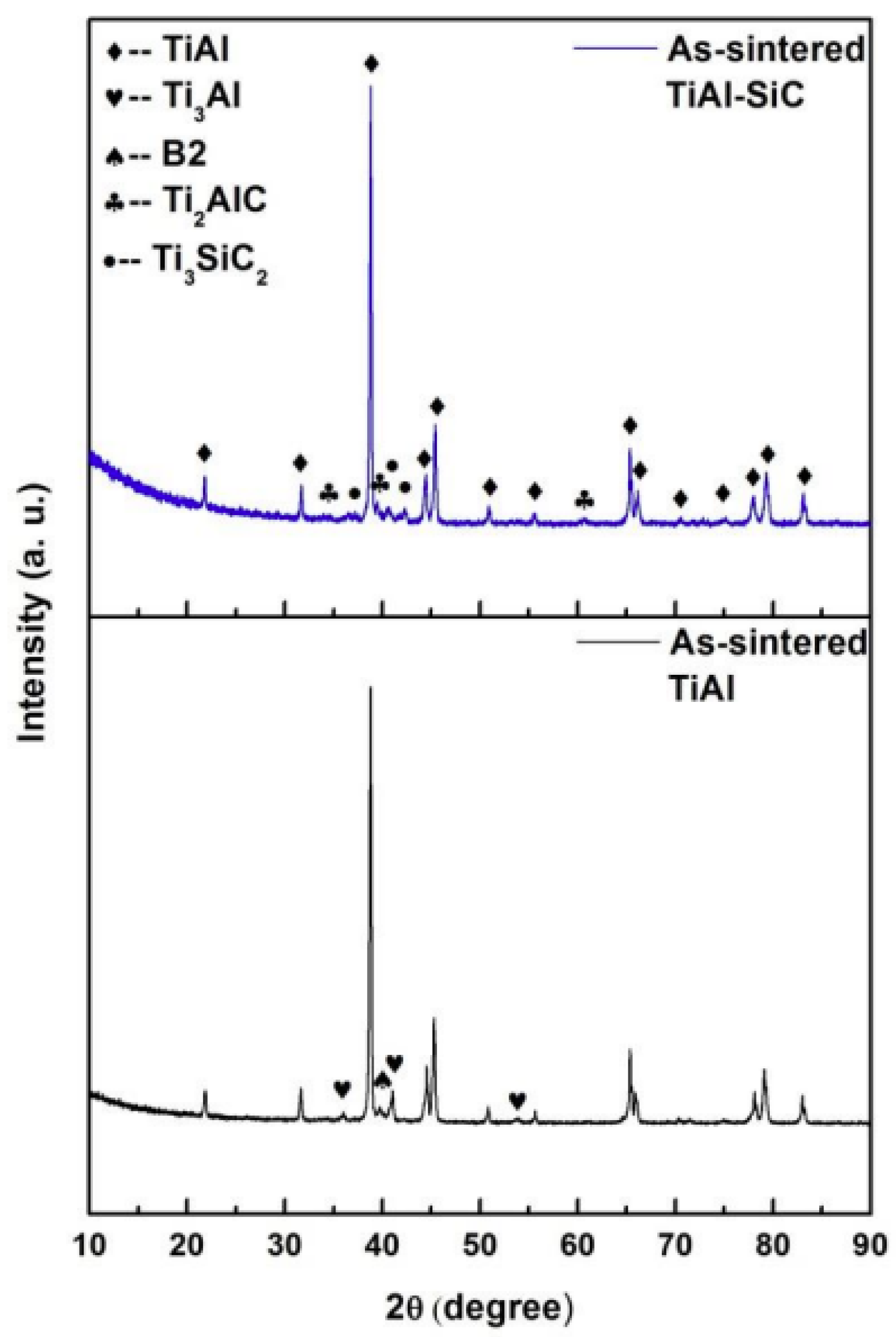

3.1. Raw Material Characterization

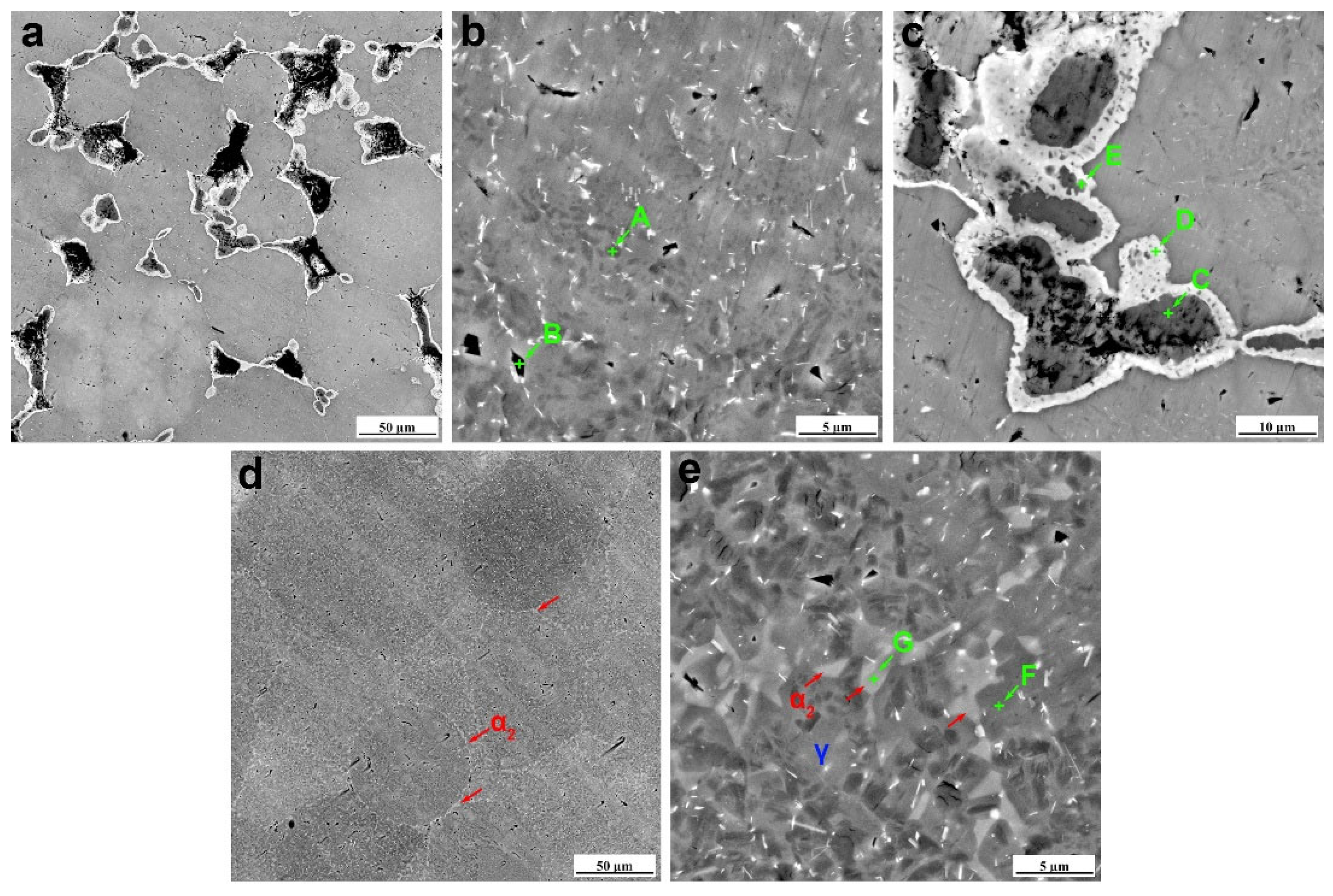

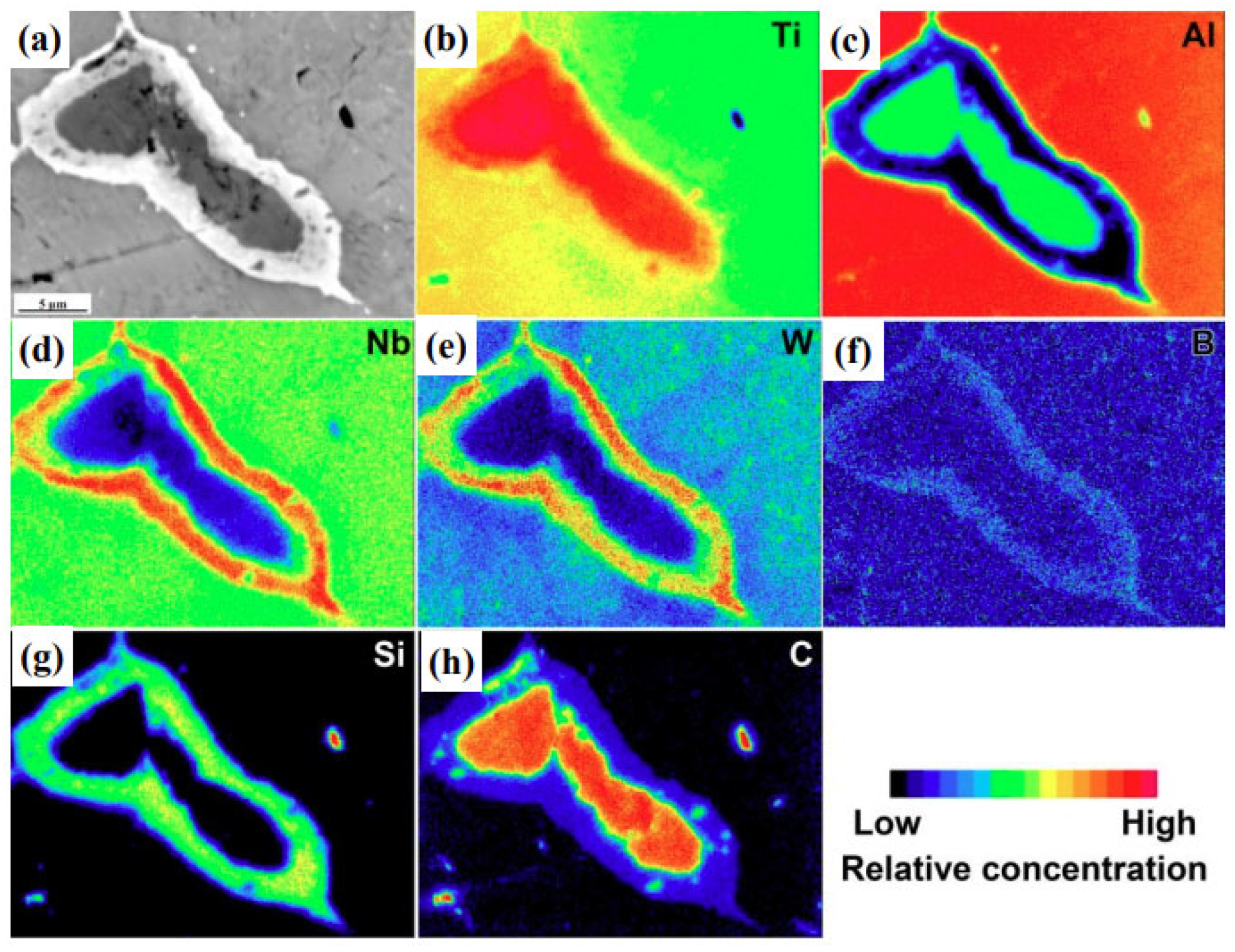

3.2. Microstructure of As-Sintered TiAl-SiC Composite

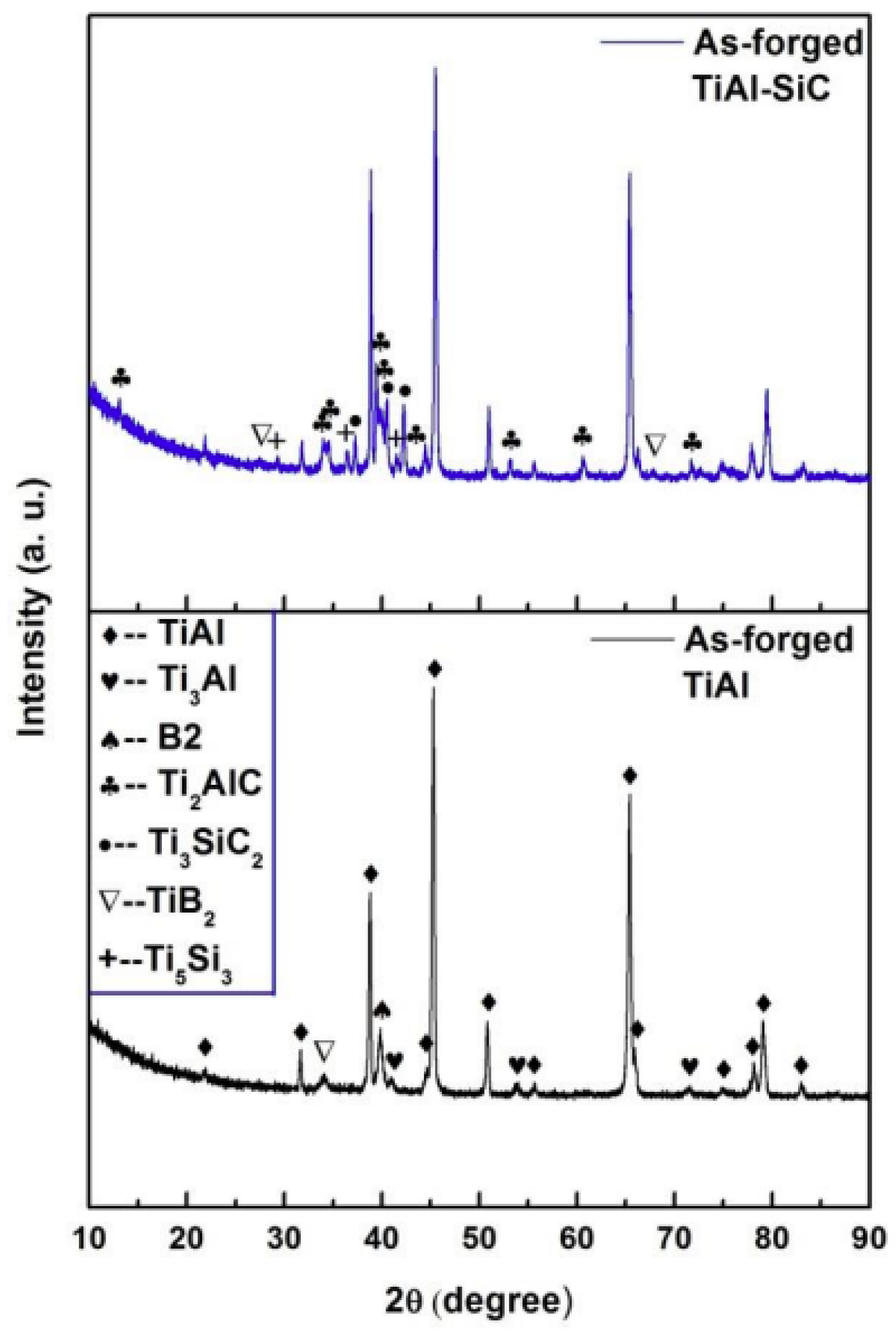

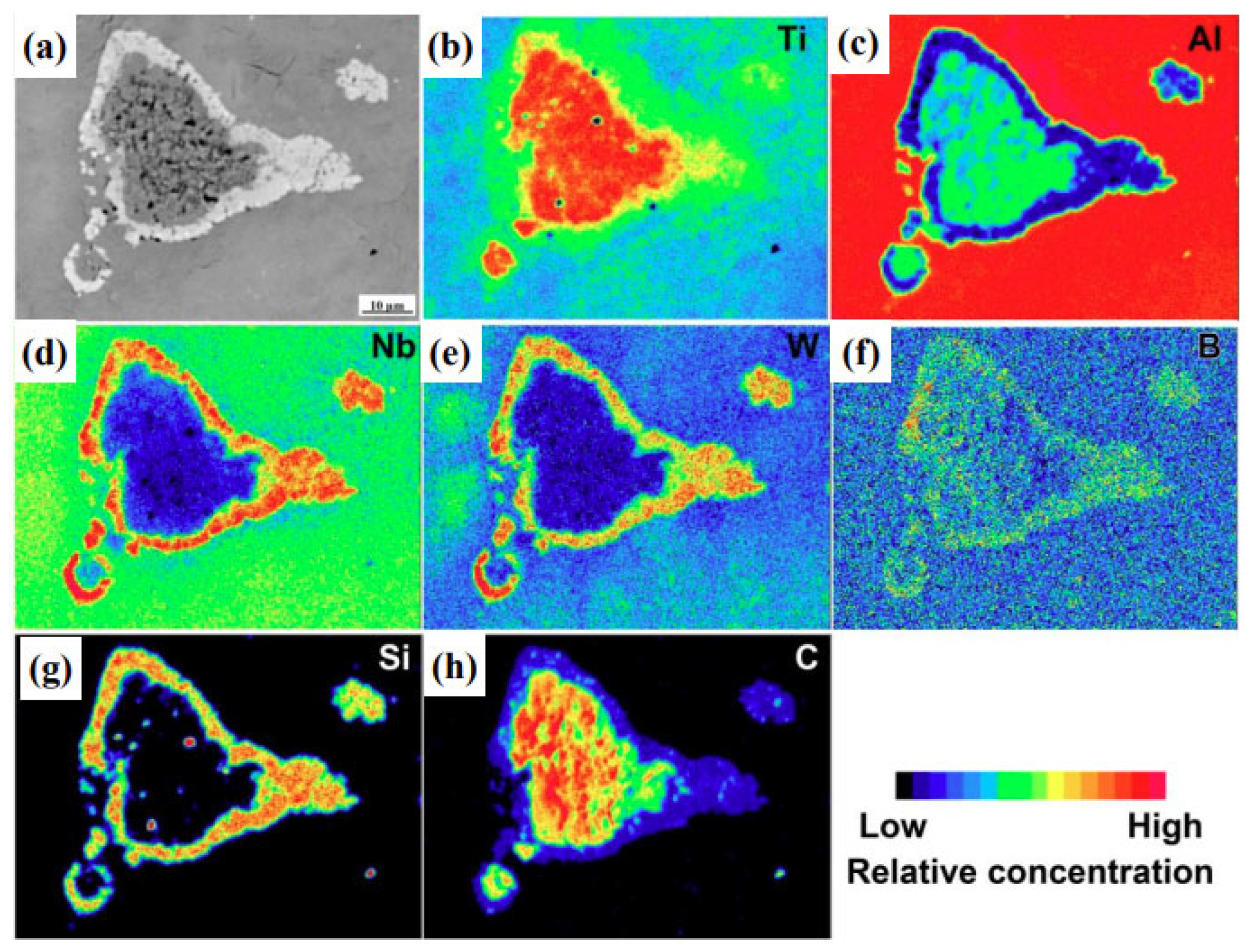

3.3. Microstructure of As-Forged TiAl-SiC Composite

3.4. High-Temperature Compressive Properties of TiAl-SiC Composite

4. Conclusions

- (1)

- The matrix of the as-sintered TiAl-SiC composite was mainly composed of γ phase and Ti2AlC precipitates with different scales, while the reinforcement phase exhibited a core-shell structure, which was mainly composed of core Ti2AlC phase, shell Ti3SiC2 phase, and fine Ti2AlC particles distributed in the outer layer. In the as-sintered TiAl-SiC composite, Ti, Al, and C were mainly distributed in the Ti2AlC phase, while the other elements were mainly enriched in the outer Ti3SiC2 phase of the reinforcement phase;

- (2)

- After hot forging, the microstructure of TiAl-SiC composite became finer and more uniform, and the phase composition changed little. The phase contents of Ti2AlC, Ti3SiC2, and TiB2 increased significantly;

- (3)

- After hot forging, the C content of each constituent phase of TiAl-SiC composite was significantly reduced mainly because the hot-forging process can effectively promote the diffusion of C element and the precipitation of C-rich phase. In addition, a granular Si-rich phase was formed inside the reinforcement phase, which was mainly because the hot-forging process can promote the diffusion of Si element, breaking the Si-rich phase and moving it;

- (4)

- The compressive yield strength of the as-forged TiAl-SiC composite decreased with the increase in temperature. When the temperature was higher than 859 °C, its yield strength was greater than that of the as-forged TiAl alloy, and the comparative result was opposite when the temperature was lower than 859 °C. This is because the core-shell structure dual MAX phases can effectively reduce the softening rate of TiAl alloy in the range of 800–900 °C, thus playing a strengthening role and increasing the service temperature of TiAl alloy.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Appel, F.; Clemens, H.; Fischer, F.D. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Luo, Y.; Liu, S.; Sun, Z.; Liu, B.; Wang, L.; Wang, Y.; Liu, Y. Microstructural evolution during annealing of a powder metallurgical TiAl–Nb composite and its effect on mechanical properties. J. Mater. Res. Technol. 2023, 25, 3654–3669. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Guo, J.; Zhang, H.; Chen, Z.; Wang, Q.; Chen, R.; Fu, H. Rapid Cellular Crystal Growth of TiAl-Based Intermetallic without Peritectic Reaction by Melt-Quenching in Ga–In Liquid. Cryst. Growth Des. 2017, 17, 1716–1728. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.; Liu, S.; Ding, H.; Yuan, S. Effect of microstructures on hot compression behavior of a Ti-43Al-2Si alloy fabricated by cold crucible continuous casting. Mater. Charact. 2018, 144, 424–430. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Evolution of rapidly grown cellular microstructure during heat treatment of TiAl-based intermetallic and its effect on micromechanical properties. Intermetallics 2021, 132, 107166. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, D.; Liu, S.; Ding, H.; Yuan, S. Hot deformation characterization of lamellar Ti-43Al-2Si alloy fabricated by cold crucible continuous casting. J. Alloys Compd. 2016, 688, 542–552. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Zhang, H.; Chen, R.; Guo, J.; Fu, H. High-density deformation nanotwin induced significant improvement in the plasticity of polycrystalline γ-TiAl-based intermetallic alloys. Nanoscale 2018, 10, 11365–11374. [Google Scholar] [CrossRef]

- Liu, S.; Ding, H.; Chen, R.; Guo, J.; Fu, H. Remarkable improvement in tensile strength of a polycrystalline γ-TiAl-based intermetallic alloy by deformation nanotwins. Mater. Sci. Eng. A 2021, 823, 141692. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Reith, M.; Franke, M.; Schloffer, M.; Korner, C. Processing 4th generation titanium aluminides via electron beam based additive manufacturing–characterization of microstructure and mechanical properties. Materialia 2020, 14, 100902. [Google Scholar] [CrossRef]

- Mayer, S.; Erdely, P.; Fischer, F.D.; Holec, D.; Kastenhuber, M.; Klein, T.; Clemens, H. Intermetallic β-Solidifying γ-TiAl Based Alloys—From Fundamental Research to Application. Adv. Eng. Mater. 2017, 19, 1600735. [Google Scholar] [CrossRef]

- Rao, K.T.V.; Odette, G.R.; Ritchie, R.O. Ductile-Reinforcement Toughening in γ-Tial Intermetallic-Matrix Composites: Effects on Fracture Toughness and Fatigue-Crack Propagation Resistance. Acta Metall. Mater. 1994, 42, 893–911. [Google Scholar]

- Ward-Close, C.M.; Minor, R.; Doorbar, P.J. Intermetallic-matrix composites-a review. Intermetallics 1996, 4, 217–229. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Liu, J.; Zhou, Y.; Li, M.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Enhanced nanohardness and new insights into texture evolution and phase transformation of TiAl/TiB2 in-situ metal matrix composites prepared via selective laser melting. Acta Mater. 2017, 136, 90–104. [Google Scholar] [CrossRef]

- Li, W.; Yang, Y.; Li, M.; Liu, J.; Cai, D.; Wei, Q.; Yan, C.; Shi, Y. Enhanced mechanical property with refined microstructure of a novel γ-TiAl/TiB2 metal matrix composite (MMC) processed via hot isostatic press. Mater. Des. 2018, 141, 57–66. [Google Scholar] [CrossRef]

- Liaquat, H.; Shi, X.; Yang, K.; Huang, Y.; Liu, X.; Wang, Z. Tribological Behavior of TiAl Metal Matrix Composite Brake Disk with TiC Reinforcement Under Dry Sliding Conditions. J. Mater. Eng. Perform. 2017, 26, 3457–3464. [Google Scholar] [CrossRef]

- Ma, C.; Gu, D.; Dai, D.; Zhang, H.; Du, L.; Zhang, H. Development of interfacial stress during selective laser melting of TiC reinforced TiAl composites: Influence of geometric feature of reinforcement. Mater. Des. 2018, 157, 1–11. [Google Scholar] [CrossRef]

- Zhang, W.; Yang, Y.Q.; Zhao, G.M.; Huang, B.; Li, M.H.; Luo, X.; Ouyang, S. Microstructure evolution of TiAl matrix in the process of magnetron sputtering and hot isostatic pressing for fabricating TiAl/SiCf composites. Intermetallics 2013, 39, 5–10. [Google Scholar] [CrossRef]

- Luo, Y.; Lu, R.; Wang, Y.; Liu, B.; Yang, H.; Liu, Y. Interfacial reaction in Al2O3 fiber reinforced TiAl matrix composite. Trans. Nonferrous Met. Soc. China 2023, 33, 2054–2063. [Google Scholar] [CrossRef]

- Luo, Y.; Wang, Y.; Wang, L.; Liu, B.; Liu, Y. Effect of Al2O3 fiber on twin intersections-induced dynamic recrystallization in fine-grained TiAl matrix composite. J. Mater. Sci. Technol. 2024, 172, 1–14. [Google Scholar] [CrossRef]

- Shu, S.; Xing, B.; Qiu, F.; Jin, S.; Jiang, Q. Comparative study of the compression properties of TiAl matrix composites reinforced with nano-TiB2 and nano-Ti5Si3 particles. Mater. Sci. Eng. A 2013, 560, 596–600. [Google Scholar] [CrossRef]

- Rao, K.P.; Zhou, J.B. Characterization and mechanical properties of in situ synthesized Ti5Si3/TiAl composites. Mater. Sci. Eng. A 2003, 356, 208–218. [Google Scholar] [CrossRef]

- Wang, X.H.; Zhou, Y.C. Stability and Selective Oxidation of Aluminum in Nano-Laminate Ti3AlC2 upon Heating in Argon. Chem. Mater. 2003, 15, 3716–3720. [Google Scholar] [CrossRef]

- Sun, Z.; Hashimoto, H.; Tian, W. Synthesis of the MAX Phases by Pulse Discharge Sintering. Int. J. Appl. Ceram. Technol. 2010, 7, 704–718. [Google Scholar] [CrossRef]

- Barsoum, M.W. The MN+1AXN phases: A new class of solids: Thermodynamically stable nanolaminates. Prog. Solid State Chem. 2000, 28, 201–281. [Google Scholar] [CrossRef]

- Hug, G.; Jaouen, M.; Barsoum, M.W. X-ray absorption spectroscopy, EELS, and full-potential augmented plane wave study of the electronic structure of Ti2AlC, Ti2AlN, Nb2AlC, and (Ti0.5Nb0.5)2AlC. Phys. Rev. B 2005, 71, 024105. [Google Scholar] [CrossRef]

- Liu, Y.-W.; Hu, R.; Zhang, T.-B. Microstructure stability of Ti2AlN/Ti-48Al-2Cr-2Nb composite at 900 °C. Trans. Nonferrous Met. Soc. China 2016, 26, 423–430. [Google Scholar] [CrossRef]

- Zhou, Y.; Sun, D.-L.; Jiang, D.-P.; Han, X.-L.; Wang, Q.; Wu, G.-H. Microstructural characteristics and evolution of Ti2AlN/TiAl composites with a network reinforcement architecture during reaction hot pressing process. Mater. Charact. 2013, 80, 28–35. [Google Scholar] [CrossRef]

- Sun, T. Fabrication and High Temperature Properties of In-Situ Synthesized Ti2AlN/TiAl Composites. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2012. (In Chinese). [Google Scholar]

- Wang, Y.; Rong, G.; Ma, T.; Chen, Z.; Zhang, X.; Zhu, D.; Fang, H.; Chen, R. In-situ synthesized a dual-scale Ti2AlC reinforced TiAl composites with superior mechanical properties. J. Mater. Res. Technol. 2024, 28, 1667–1678. [Google Scholar] [CrossRef]

- Liu, P.; Wang, Z.; Ye, F.; Hou, B.; Wang, A.; Xie, J. Hierarchically heterogeneous strategy for Ti2AlC/TiAl composite with superior mechanical properties. Compos. Part B 2024, 273, 111259. [Google Scholar] [CrossRef]

- Li, M.; Yang, W.; Li, J.; Chen, Y.; Xiao, S. Microstructures and mechanical properties of TiAl matrix composites with multi-precipitates quasi-continuous network reinforced structures. Mater. Sci. Eng. A 2024, 901, 146573. [Google Scholar] [CrossRef]

- Lapin, J.; Kamyshnykova, K. Processing, microstructure and mechanical properties of in-situ Ti3Al+TiAl matrix composite reinforced with Ti2AlC particles prepared by centrifugal casting. Intermetallics 2018, 98, 34–44. [Google Scholar] [CrossRef]

- Lapin, J.; Klimová, A.; Štamborská, M.; Kamyshnykova, K.; Pelachová, T. Development and Properties of Cast Tial Matrix In Situ Composites Reinforced with Carbide Particles. Mater. Sci. Forum 2018, 941, 1907–1913. [Google Scholar] [CrossRef]

- Kang, X.; Pu, Z.; Cao, Z.; Qin, X.; Wu, F.; Liu, C. Enhancing high-temperature mechanical property of Ti4822 alloy with in-situ Ti2AlC precipitates. Mater. Today Commun. 2024, 38, 107745. [Google Scholar] [CrossRef]

- Kang, X.; Pu, Z.; Zheng, M.; Wu, J.; Xiang, J.; Wu, F.; Liu, C. Optimization of microstructure and high-temperature mechanical properties of Ti4822/Ti2AlC composites through multiple solution-aging treatments. J. Alloys Compd. 2024, 1008, 176862. [Google Scholar] [CrossRef]

- Wang, X.; Gan, K.; Liu, B.; Yang, Q.; Zhang, Y.; Yan, D.; Li, Z. An ultrafine-grained low-activation multicomponent alloy with exceptional thermal stability and ultrahigh-temperature mechanical properties. J. Mater. Sci. Technol. 2024, 197, 116–128. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Liu, B.; Cao, Y.; Wang, J.; Liao, T.; Li, J.; Fang, Q.; Liaw, P.K.; Liu, Y. A novel cobalt-free oxide dispersion strengthened medium-entropy alloy with outstanding mechanical properties and irradiation resistance. J. Mater. Sci. Technol. 2023, 152, 190–200. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Li, Z.; Wang, B.; Cao, Y.; Liu, Y. Dynamic deformation behavior of a FeCrNi medium entropy alloy. J. Mater. Sci. Technol. 2022, 100, 120–128. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scr. Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Guo, W.; Liu, B.; Liu, Y.; Li, T.; Fu, A.; Fang, Q.; Nie, Y. Microstructures and mechanical properties of ductile NbTaTiV refractory high entropy alloy prepared by powder metallurgy. J. Alloys Compd. 2019, 776, 428–436. [Google Scholar] [CrossRef]

- Liu, Y.; Hu, R.; Yang, J.; Li, J. Tensile properties and fracture behavior of in-situ synthesized Ti2AlN/Ti48Al2Cr2Nb composites at room and elevated temperatures. Mater. Sci. Eng. A 2017, 679, 7–13. [Google Scholar] [CrossRef]

- Li, J.; Cui, X.; Guan, Y.; Jin, G.; Zheng, W.; Liu, E.; Wan, S.; Shi, Z.; Liu, A. Effect of SiC content on microstructural evolution and tribology properties of laser-clad TiC-reinforced Ti-Al-Si composite coatings. Mater. Today Commun. 2023, 35, 106019. [Google Scholar] [CrossRef]

- Zou, Q.; Lou, Z.; Guan, Y.; Li, Y.; Xu, J.; Li, Y.; Bu, L.; Wang, P.; Luo, Y.A. Effect of Ti3SiC2 Amount on Microstructures and Properties of TiAl Matrix Composites. Tribol. Lett. 2022, 70, 37. [Google Scholar] [CrossRef]

- Zou, Q.; Bu, L.; Li, Y.; Guan, Y.; Wang, P.; Lou, Z.; Luo, Y. Effects of Ti3SiC2 on microstructure and properties of TiC0.4 enhanced TiAl matrix composites. Mater. Chem. Phys. 2023, 297, 127330. [Google Scholar] [CrossRef]

- Perevislov, S.N.; Sokolova, T.V.; Stolyarova, V.L. The Ti3SiC2 max phases as promising materials for high temperature applications: Formation under various synthesis conditions. Mater. Chem. Phys. 2021, 267, 124625. [Google Scholar] [CrossRef]

- Scheu, C.; Stergar, E.; Schober, M.; Cha, L.; Clemens, H.; Bartels, A.; Schimansky, F.-P.; Cerezo, A. High carbon solubility in a γ-TiAl-based Ti-45Al-5Nb-0.5C alloy and its effect on hardening. Acta Mater. 2009, 57, 1504–1511. [Google Scholar] [CrossRef]

- Johnson, D.R.; Inui, H.; Muto, S.; Omiya, Y.; Yamanaka, T. Microstructural development during directional solidification of α-seeded TiAl alloys. Acta Mater. 2006, 54, 1077–1085. [Google Scholar] [CrossRef]

- Poulou, A.; Mellan, T.A.; Finnis, M.W. Stability of Zr-Al-C and Ti-Al-C MAX phases: A theoretical study. Phys. Rev. Mater. 2021, 5, 033608. [Google Scholar] [CrossRef]

- Kim, J.H.; Kim, S.W.; Lee, H.N.; Oh, M.H.; Inui, H.; Wee, D.M. Effects of Si and C additions on the thermal stability of directionally solidified TiAl–Nb alloys. Intermetallics 2005, 13, 1038–1047. [Google Scholar] [CrossRef]

- Tian, W.H.; Nemoto, M. Effect of carbon addition on the microstructures and mechanical properties of γ-TiAl alloys. Intermetallics 1997, 5, 237–244. [Google Scholar] [CrossRef]

- Song, L.; Hu, X.; Wang, L.; Stark, A.; Lazurenko, D.; Lorenz, U.; Lin, J.; Pyczak, F.; Zhang, T. Microstructure evolution and enhanced creep property of a high Nb containing TiAl alloy with carbon addition. J. Alloys Compd. 2019, 807, 151649. [Google Scholar] [CrossRef]

| Labels | Chemical Composition (at.%) | Identified Phases | |||||

|---|---|---|---|---|---|---|---|

| Ti | Al | Nb | W | Si | C | ||

| A | 37.71 ± 1.24 | 41.91 ± 1.27 | 6.50 ± 0.18 | 0.44 ± 0.05 | 0.01 ± 0.02 | 13.43 ± 2.63 | γ + Ti2AlC |

| B | 23.78 ± 2.19 | 24.81 ± 1.86 | 4.06 ± 0.21 | 0.29 ± 0.06 | 11.44 ± 2.14 | 35.64 ± 3.27 | Ti2AlC |

| C | 40.96 ± 2.26 | 21.31 ± 0.55 | 1.86 ± 0.46 | 0.13 ± 0.04 | 0.17 ± 0.14 | 35.57 ± 2.78 | Ti2AlC |

| D | 40.04 ± 0.50 | 13.15 ± 2.87 | 7.90 ± 0.24 | 0.80 ± 0.05 | 16.70 ± 2.80 | 21.41 ± 0.67 | Ti3SiC2 |

| E | 37.28 ± 1.82 | 14.87 ± 1.13 | 5.67 ± 0.53 | 0.47 ± 0.06 | 10.11 ± 1.25 | 31.60 ± 3.51 | Ti2AlC |

| F | 46.39 ± 0.24 | 46.28 ± 0.12 | 6.83 ± 0.09 | 0.50 ± 0.10 | -- | -- | γ |

| G | 53.43 ± 1.58 | 39.66 ± 1.49 | 6.28 ± 0.09 | 0.63 ± 0.04 | -- | -- | α2 |

| Labels | Chemical Composition (at.%) | Identified Phases | |||||

|---|---|---|---|---|---|---|---|

| Ti | Al | Nb | W | Si | C | ||

| H | 38.55 ± 0.35 | 43.26 ± 0.72 | 6.05 ± 0.05 | 0.46 ± 0.05 | 0.05 ± 0.06 | 11.63 ± 1.00 | γ + Ti2AlC |

| I | 43.10 ± 0.83 | 22.19 ± 0.02 | 3.42 ± 0.05 | 0.24 ± 0.07 | 0.35 ± 0.22 | 30.70 ± 1.01 | Ti2AlC |

| J | 42.39 ± 1.89 | 12.27 ± 0.31 | 8.44 ± 0.31 | 0.81 ± 0.11 | 17.56 ± 1.24 | 18.52 ± 2.96 | Ti3SiC2 |

| K | 40.10 ± 0.69 | 15.40 ± 0.67 | 6.56 ± 0.38 | 0.61 ± 0.09 | 11.11 ± 0.76 | 26.22 ± 1.98 | Ti2AlC |

| L | 51.80 ± 0.30 | 41.13 ± 0.33 | 6.45 ± 0.06 | 0.62 ± 0.02 | -- | -- | α2/γ |

| M | 46.17 ± 0.16 | 46.74 ± 0.07 | 6.59 ± 0.10 | 0.49 ± 0.04 | -- | -- | γ |

| N | 52.40 ± 1.20 | 40.51 ± 1.21 | 6.44 ± 0.09 | 0.65 ± 0.03 | -- | -- | α2 |

| Temperature (°C) | As-Forged TiAl Alloy | As-Forged TiAl-SiC Composite | ||

|---|---|---|---|---|

| Yield Strength σ0.2 (MPa) | Maximum Flow Stress σm (MPa) | Yield Strength σ0.2 (MPa) | Maximum Flow Stress σm (MPa) | |

| 700 | 512.77 | -- | 485.34 | -- |

| 800 | 473.14 | -- | 444.49 | 606.00 |

| 900 | 377.63 | 493.85 | 396.83 | 459.54 |

| 1000 | 206.95 | 239.73 | 227.58 | 277.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Guo, H. Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite. Crystals 2025, 15, 363. https://doi.org/10.3390/cryst15040363

Liu S, Guo H. Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite. Crystals. 2025; 15(4):363. https://doi.org/10.3390/cryst15040363

Chicago/Turabian StyleLiu, Shiqiu, and Huijun Guo. 2025. "Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite" Crystals 15, no. 4: 363. https://doi.org/10.3390/cryst15040363

APA StyleLiu, S., & Guo, H. (2025). Microstructure and High-Temperature Compressive Properties of a Core-Shell Structure Dual-MAX-Phases-Reinforced TiAl Matrix Composite. Crystals, 15(4), 363. https://doi.org/10.3390/cryst15040363