Abstract

Cubic-phase SnSe possesses exceptional crystal structure symmetry while maintaining non-harmonic bond characteristics and ultra-low lattice thermal conductivity, exhibiting superior thermoelectric (TE) application potential compared to its orthorhombic counterpart. Despite recent advancements, systematic investigations on the combined effects of composite engineering strategies in optimizing TE properties of cubic-phase SnSe-based materials remain scarce. In this study, multi-walled carbon nanotubes (MWCNTs) are incorporated into the cubic-phase Sn0.50Ag0.25Bi0.25Se0.50Te0.50 to regulate its TE performance through a combination of ultrasonic dispersion and rapid hot-pressing sintering. The introduced MWCNTs promote the formation of “high-speed channel” for carrier transport and serve as additional phonon-scattering centers, resulting in a synergistic optimization of electrical and thermal transport properties. A maximum ZT value of 0.85 is achieved in the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample at 750 K, representing a 21% improvement compared to the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample. This finding establishes a scalable nano-composite engineering paradigm for enhancing TE performance of cubic-phase SnSe-based materials.

1. Introduction

With escalating global energy consumption, numerous non-renewable resources are becoming increasingly scarce; therefore, the exploration of new energy sources has emerged as the pursuit of scientists in numerous countries. Thermoelectric material is a new type of environmental protection material with very broad application prospect; it can convert heat energy and electric energy into each other according to the thermoelectric effect and will not cause any pollution to the environment [1,2]. The conversion efficiency of thermoelectric materials is defined by the following formula [3,4,5]:

where Tave is average temperature, Th is hot-side temperature, Tc is cold-side temperature, and ZT is a dimensionless constant known as the thermoelectric figure of merit of a material and is used to evaluate the performance of thermoelectric materials, defined as, in which S, σ, and κ are Seebeck coefficient, electric conductivity, and total thermal conductivity [6,7], respectively. Owing to the complexity of the coupling relationship among S, σ, and κ, it is challenging to comprehensively regulate any one of these factors independently to enhance the thermoelectric performance. It is a prevalent approach to optimize the electrical properties generally by modulating the carrier concentration and energy band structure [8,9], such as through doping with unequal electron elements to introduce diverse defects and modulating the carrier concentration. To reduce the thermal conductivity to decrease phonon scattering would mean enhancing the scattering at grain boundaries through grain refinement or increasing the scattering at point defects through isoelectronic substitution between the matrix and impurity atoms to form a solid solution [10,11,12,13,14,15].

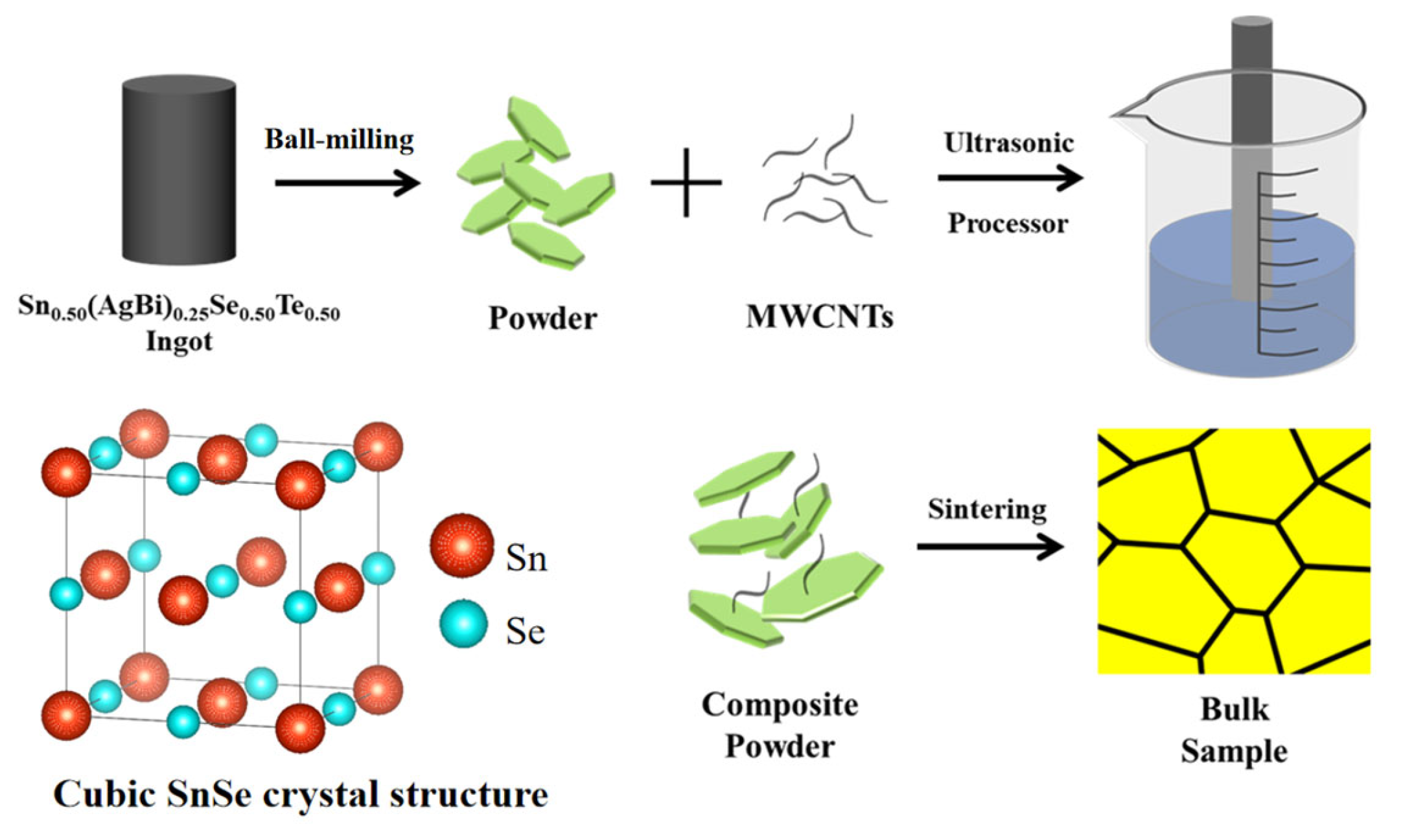

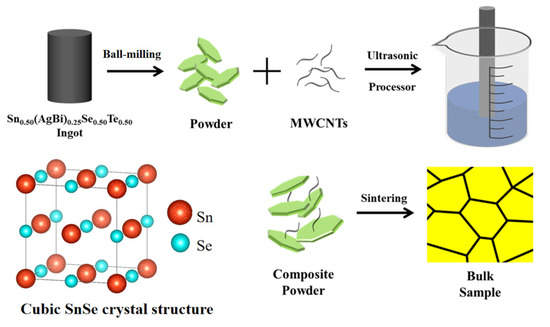

The pronounced anharmonicity inherent in SnSe bonding confers a substantial Grüneisen parameter, thus exhibiting an extremely low lattice thermal conductivity [16,17]. This characteristic has garnered significant attention for SnSe as a promising thermoelectric material. Under ambient conditions, SnSe adopts a layered orthorhombic structure (Pnma) [18,19,20,21], which undergoes a second-order phase transition at high temperatures, transforming into a high-temperature Cmcm phase characterized by enhanced crystal symmetry. Beyond these prevalent layered configurations, SnSe can also manifest in a rock salt cubic structure (Fm-3m), exclusively stable under high-pressure conditions. Cubic-phase SnSe is similar to Na-Cl in a rock salt structure, belonging to Pm-3m space group, with a high symmetry. Sn occupies the vertex of the face-centered cube, while Se occupies the face-centered position, forming an alternating and tightly packed structure, as displayed in Figure 1. It is worth noting that the formation energy between the Pnma and Fm-3m phases of SnSe is remarkably proximate [22,23], suggesting thermodynamic feasibility of the cubic phase. In the cubic phase, the heightened symmetry of the crystal structure mitigates carrier scattering, thereby augmenting carrier mobility. At the same time, this symmetry fosters a greater degeneracy number, which is conducive to the improvement of the Seebeck coefficient [8]. Moreover, the cubic phase of SnSe still retains its anharmonic bonding and ultra-low lattice thermal conductivity, presenting superior application potential compared to its orthorhombic counterpart, and has thus attracted considerable interest in recent years [24,25,26]. To stabilize the cubic phase of SnSe-based materials under ambient conditions, researchers have undertaken relentless efforts. Wang et al. [27] fabricated a cubic-structured SnSe-AgSbSe2 via hot pressing, achieving a peak ZT value of 0.82 at 842 K. Dutta et al. [28] employed density functional theory to demonstrate that the pronounced anharmonicity of Ag and Se vibrations enhances phonon scattering, crucially reducing the lattice thermal conductivity of the rock salt structure in AgSbSe2-SnSe. The electrical conductivity is further improved by Ge element doping [29]. Through synergistic structural optimization and doping modulation, the ZT value of (SnSe)0.5(AgSb0.94Se2Ge0.06)0.5 reaches 1.06 at 706 K, and the thermoelectric properties of (SnSe)0.5(AgSb0.94Se2Ge0.06)0.5 can be further improved significantly by introducing nanomaterials to the composite. While the integration of nanomaterials (such as CNTs [20] and endotaxial nano-additives [30]) into polycrystalline SnSe-based thermoelectric materials not only augments their thermoelectric performance, but also substantially enhances their mechanical properties, the comprehensive impact of composite strategies on the properties of cubic-phase SnSe-based materials remains inadequately understood.

Figure 1.

Schematic diagram of the preparation for MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites.

Herein, we successfully synthesized MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composite materials based on cubic-phase Sn0.50Ag0.25Bi0.25Se0.50Te0.5 [31,32], employing an ultrasonic dispersion and rapid high-temperature hot-pressing sintering strategy. The incorporation of MWCNTs markedly influenced its intrinsic carrier concentration, resulting in an increased electrical conductivity. Furthermore, the introduced MWCNTs served as additional scattering centers, enhancing phonon scattering and thereby reducing thermal conductivity. This composite strategy facilitated the co-optimization of thermal and electrical transport properties, offering a valuable reference for the performance enhancement of cubic-phase SnSe-based materials.

2. Materials and Methods

2.1. Synthesis of Sn0.50Ag0.25Bi0.25Se0.50Te0.50 Powder

The precise weighing of high-purity tin powder (Sn, 99.99%), selenium powder (Se, 99.99%), bismuth powder (Bi, 99.99%), tellurium particle (Te, 99.99%), and silver powder (Ag, 99.99%) were carried out based on the stoichiometric ratio of Sn0.50Ag0.25Bi0.25Se0.50Te0.50. Once these materials were weighed accurately, they were placed into a graphite crucible and subsequently transferred to a quartz ampoule for vacuum tube sealing to ensure an inert and contamination-free environment. The sealed quartz ampoule was transferred into a box furnace and heated to 1223 K at a rate of 2 K/min, so that the elements are fully integrated with little loss of composition [33,34,35]. Following a holding period of 6 h at this temperature to ensure thorough reaction, the quartz ampoule was gradually cooled down to 873 K and subjected to annealing at this temperature for an additional 48 h. To obtain Sn0.50Ag0.25Bi0.25Se0.50Te0.50 powder samples with a small particle size for the formation of uniform composites, the annealed ingots were broken by hand-grinding and ball milling 20 h with a rotational speed of 300 rpm.

2.2. Preparation of MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 Composites

The preparation process of MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites is depicted in Figure 1. The MWCNT powder (XFNANO, >95.00%, diameter 10–20 nm, length 10–30 mm, specific surface area > 120 m2/g) was combined with Sn0.50Ag0.25Bi0.25Se0.50Te0.50 powder at the following mass percentages (wt.%): 0, 0.25, 0.50, 0.75, 1.00, and 1.50. The inherent tendency of MWCNTs to aggregate at the microscopic level due to their one-dimensional long-chain structure posed a significant challenge in achieving uniform distribution within the matrix through mechanical ball milling alone. To address this problem, 1.2 g Sn0.50Ag0.25Bi0.25Se0.50Te0.50 powder with different mass ratios of MWCNT powder evenly dispersed in 20 mL of anhydrous ethanol by using an ultrasonic cell pulverizer (B-JY99-ⅡND, Bowenyiqi, Shanghai, China). The ultrasonic treatment was conducted under the following parameters: an ultrasonic power of 300 W, a duration of 15 min, and a cyclic pattern of 4 s of ultrasonic activation followed by a 4 s rest period. Following the ultrasonic dispersion, the resulting MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 anhydrous ethanol dispersion solution was dried in a vacuum drying oven to obtain the composite powders. Finally, the dried MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composite powders were transferred into a graphite mode with a diameter of 12.7 mm and sintered into the bulk samples at 733 K with a heating rate of 100 K min−1 under 48 Mpa for 15 min using the self-built rapid hot-pressing equipment.

2.3. Characterization

The phase composition of synthesized sample powders was carried out using an X-ray diffractometer (XRD, Taylor, MI, USA, Rigaku Smartlab 9 kW with Cu Kα radiation) with a work voltage of 40 kV and a scanning speed of 10°/min. Scanning electron microscopy (SEM, Hill, SC, USA) was performed with a field emission SEM (HITACHI SU3500) equipped with an energy spectrometer on the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composite powders, as well as the fresh fracture and polished surface of the sintered bulk samples. The densities of the sintered samples (were measured using the Archimedes drainage method with the following formula:

where ρ0 is the density of pure water, m1 is the sample mass, and m2 is the sample floating mass. The densification can be expressed as:

ρt is theoretical density of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites, which was calculated by the following formula:

where mMWCNTs, VMWCNTs, and rMWCNTs are the mass, volume, and density of MWCNTs, respectively. mSABST, VSABST, and rSABST are the mass, volume, and density of Sn0.50Ag0.25Bi0.25Se0.50Te0.50, respectively. The electrical conductivity and Seebeck coefficient of the samples were measured using an electrical property measurement system (ZEM-3 ULVAC-RIKO, Tongji University, Shanghai, China). The Hall coefficient was determined via the Van Der Pauw method under a reversible magnetic field with a strength of 0.8 T at room temperature, enabling the calculation of carrier mobility (μ) and carrier concentration (n). Specific heat capacity (Cp) data of the specimen were obtained from the relevant literature. The thermal diffusion coefficient (λ) was directly determined by flash laser thermal conductivity meter (Linseis, LFA 1000). The total thermal conductivity (κ) was calculated using the formula: κ = λCpD, where D is density of the prepared composites.

3. Results and Discussion

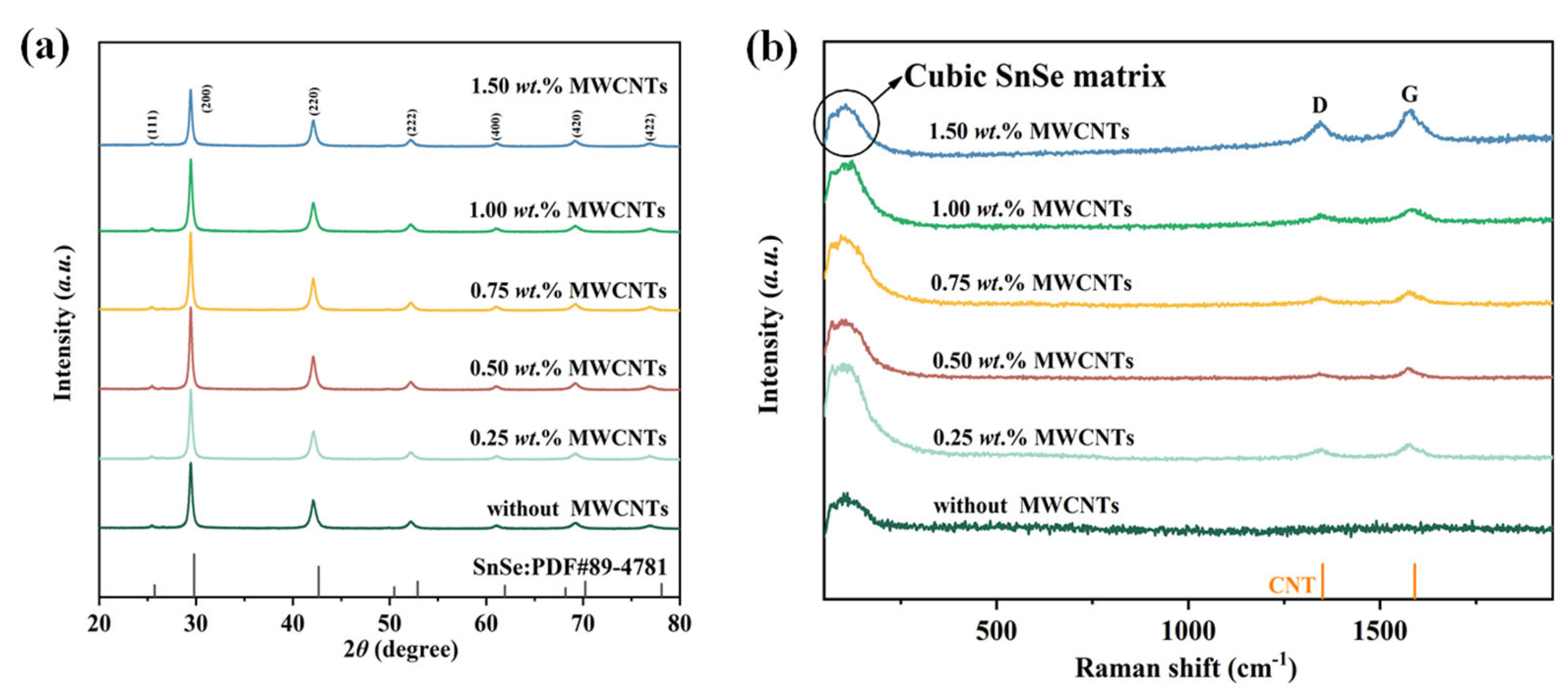

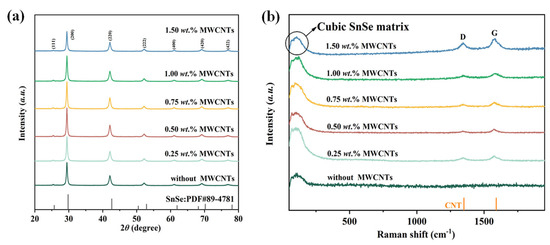

Figure 2a displays the XRD pattern of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites. All observed Bragg peaks of the synthesized polycrystalline Sn0.50Ag0.25Bi0.25Se0.50Te0.50 can be indexed as cubic-phase SnSe polycrystalline (Fm-3m space group, PDF#89-4781), confirming the successful synthesis of Sn0.50Ag0.25Bi0.25Se0.50Te0.50 polycrystalline [24,25,26,33,36]. With the introduction of MWCNTs, the position and half-peak width of all diffraction peaks in the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites are almost unchanged. This phenomenon shows that the prepared Sn0.50Ag0.25Bi0.25Se0.50Te0.50 polycrystalline does not undergo reaction and degradation through the composite process. Owing to the low diffraction peak intensity and content of the introduced MWCNTs, no obvious diffraction peak of MWCNTs was observed in the prepared composites. To confirm the presence of MWCNTs in the prepared composites, Raman spectroscopy was performed, as shown in Figure 2b. It is obvious that two distinct characteristic peaks at approximately ~1350 cm⁻1 and ~1590 cm⁻1 appeared with the introduction of MWCNTs, which corresponded to the D band and G [37] band of MWCNTs, respectively [36]. With the increase in MWCNT content, the intensities of both D and G bands gradually enhanced, which indicates that MWCNTs have been successfully introduced into the prepared composites.

Figure 2.

(a) XRD pattern and (b) Raman spectrum of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites.

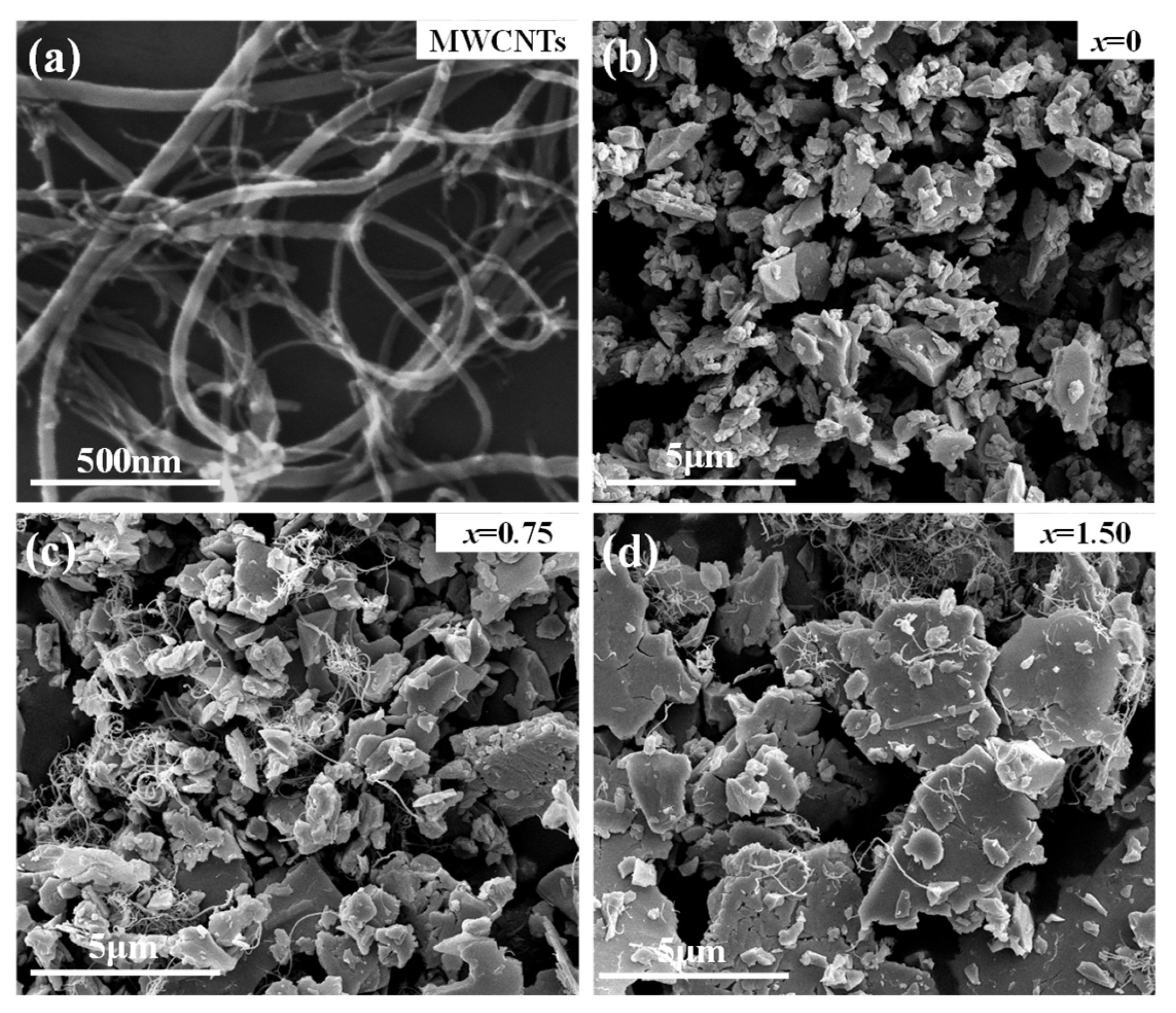

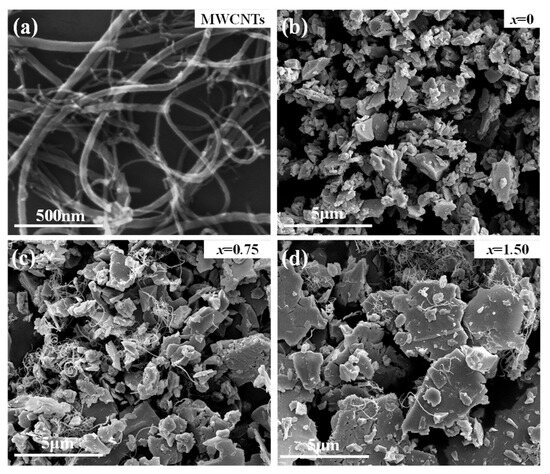

To comprehend the micro-morphological properties of the prepared composite powders, SEM was performed, as displayed in Figure 3. MWCNTs have a long chain one-dimensional structure with a length of tens of microns and a diameter of 10–20 nanometers (Figure 3a). After ultrasonic treatment, the MWCNTs were uniformly dispersed within the Sn0.50Ag0.25Bi0.25Se0.50Te0.50 matrix (Figure 3b,c). Due to the extremely high-specific surface area of MWCNTs, they easily interact and intertwine with each other, thus agglomerating into a network structure. Therefore, as the MWCNT content further increases, the effectiveness of the ultrasonication treatment diminishes, leading to a tendency for MWCNT accumulation in the prepared composite materials, as displayed in Figure 3d.

Figure 3.

SEM images of the prepared powder samples: (a) MWCNTs; x wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50, (b) x = 0 wt.%, (c) x = 0.75 wt.%, (d) x = 1.50 wt.%.

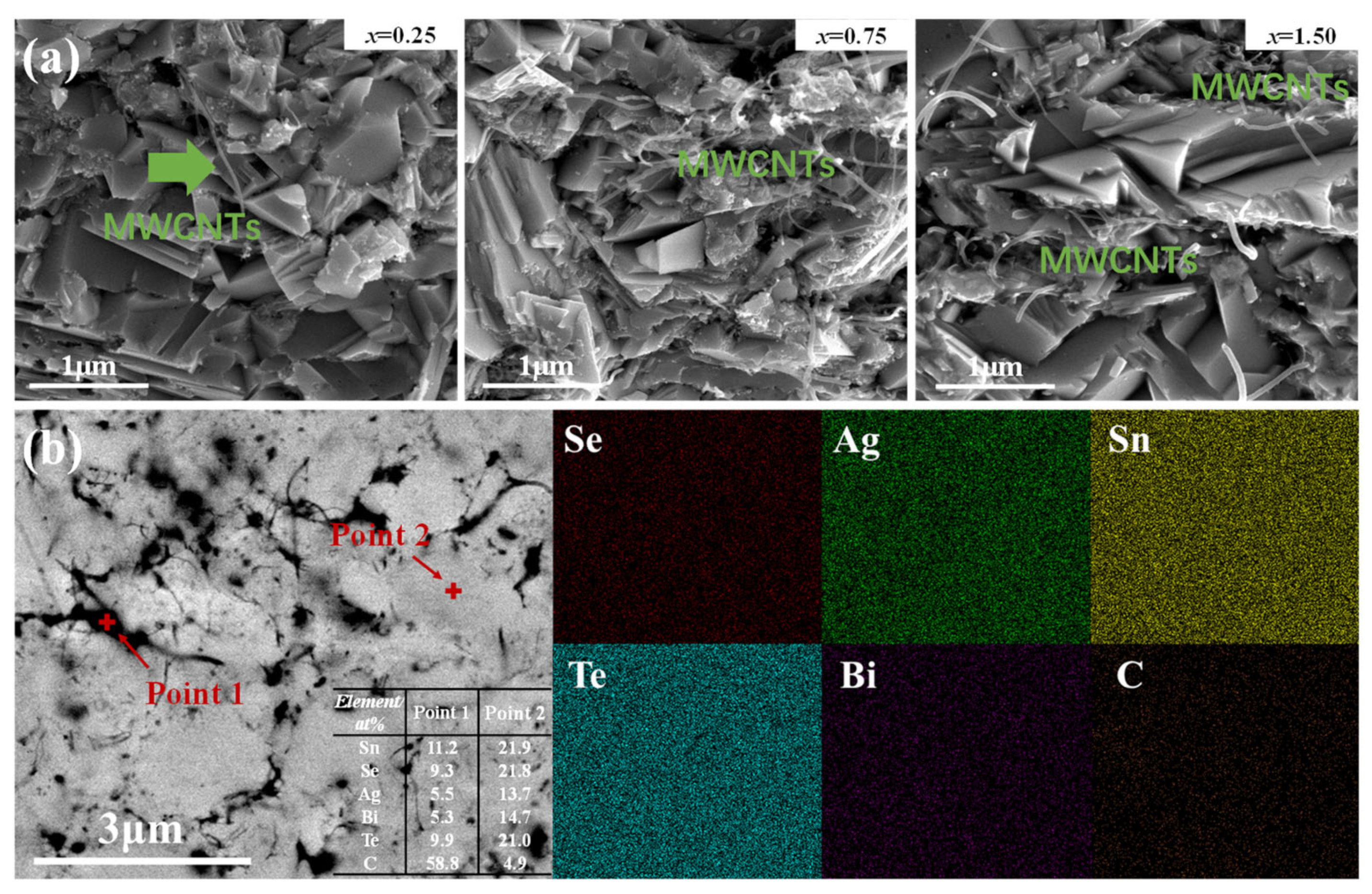

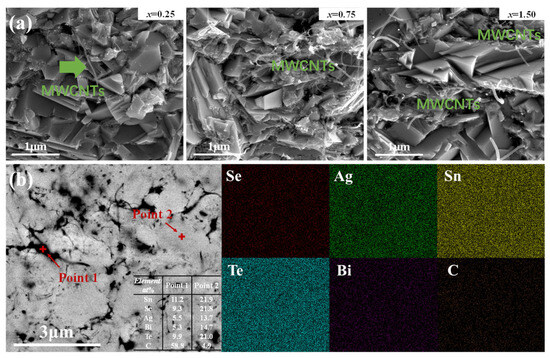

Figure 4a displays the fresh-fracture SEM images of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 bulk samples at various composite ratios. It is evident that the introduction of MWCNTs did not alter the size and morphology of the Sn0.50Ag0.25Bi0.25Se0.50Te0.50 matrix grains. The MWCNTs were predominantly distributed along the grain boundaries of the matrix, which is advantageous for enhancing both the interfacial bonding strength and carrier transport properties [38,39,40]. Figure 4b presents the surface backscattered electron (BSE) image and corresponding Energy Dispersive Spectroscopy (EDS) elemental distribution of the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 bulk sample. The elemental composition of the matrix phase is uniformly distributed in the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 bulk sample, as confirmed by EDS analysis, which showed no signs of elemental segregation.

Figure 4.

(a) Fracture surface SEM images of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 bulk samples with different MWCNTs contents; (b) Surface BSE image and EDS elemental distribution of the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 bulk sample.

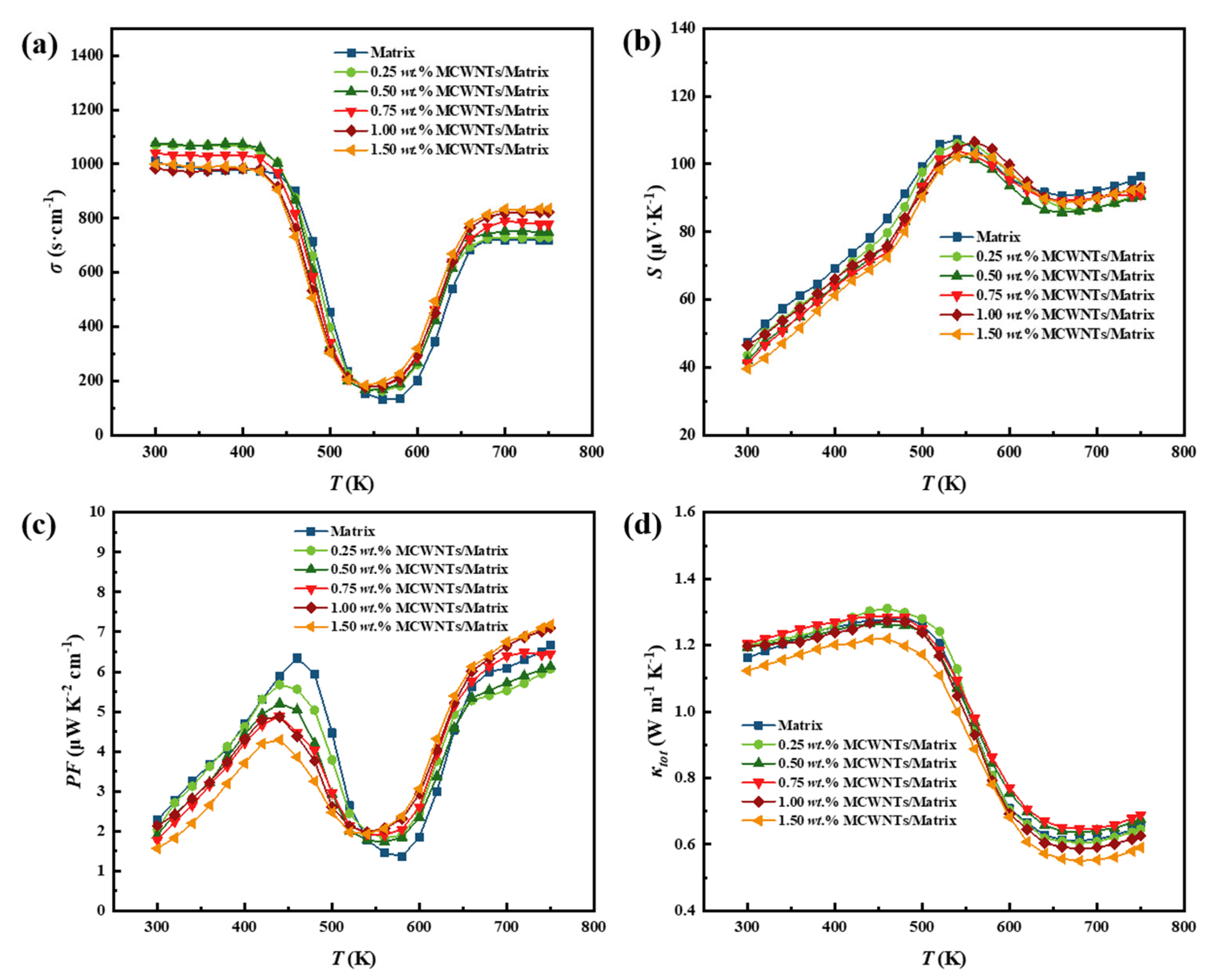

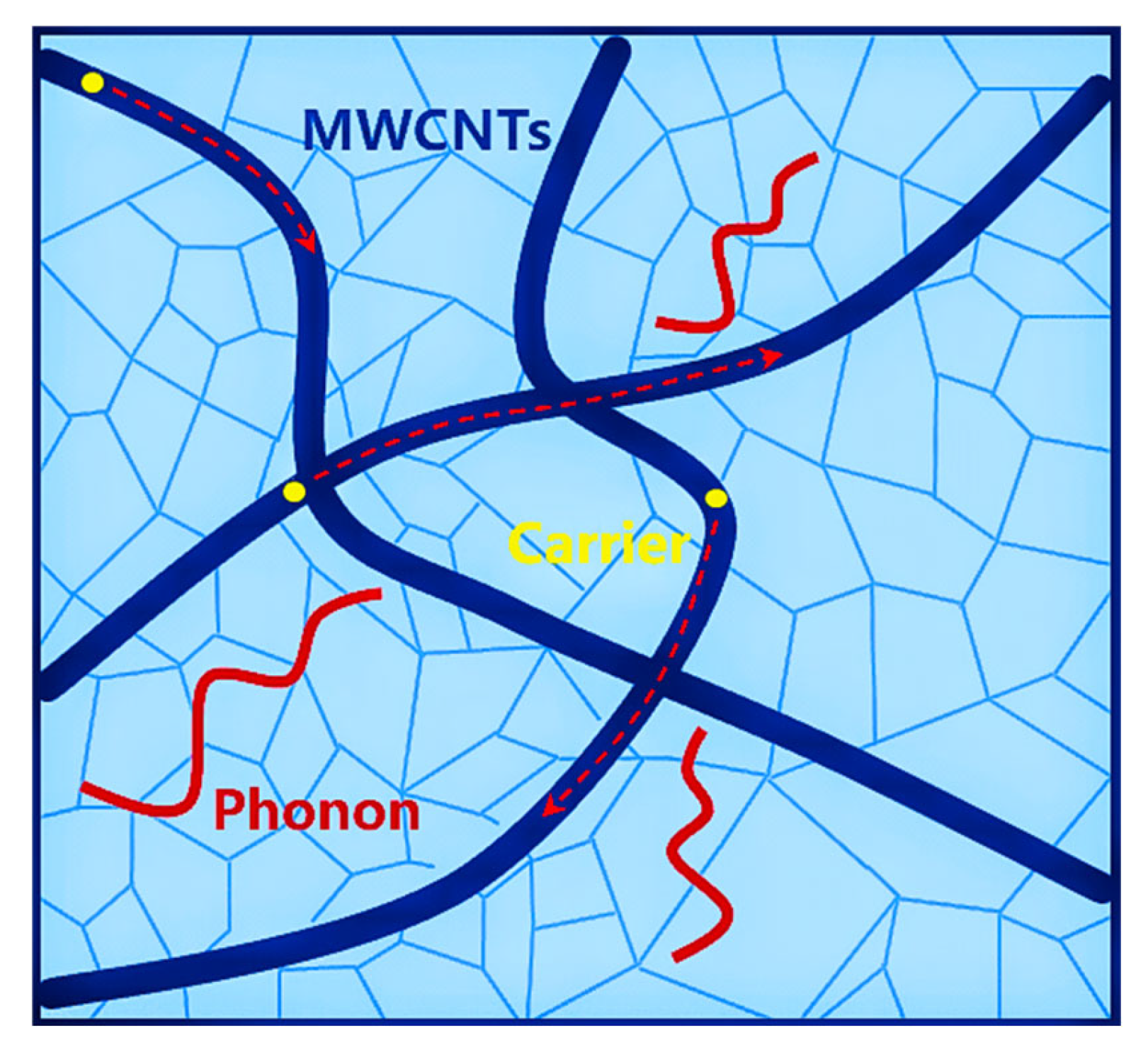

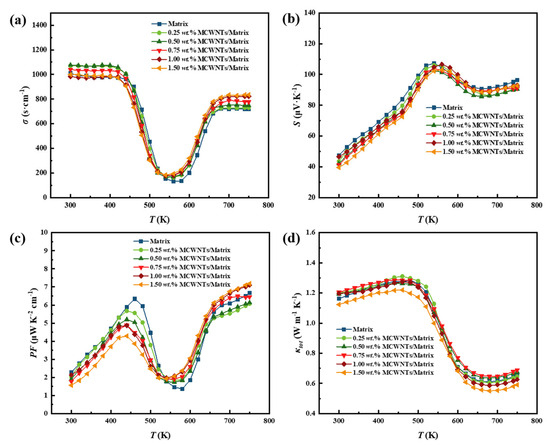

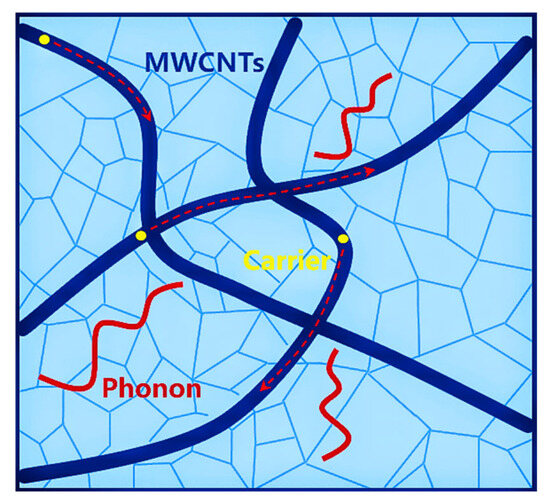

Figure 5a shows the temperature-dependent electrical conductivity curves of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites. As MWCNTs were being introduced into Sn0.50Ag0.25Bi0.25Se0.50Te0.50 matrix, the temperature-dependent trend of electrical conductivity remained consistent with that of the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50. The electrical conductivity of the prepared bulk composites increased dramatically at room temperature with the introduction of MWCNTs, which was attributed to the significantly increased carrier concentration (Table 1). The introduced MWCNTs can form a channel inside the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.5 composites, owing to their tubular nanostructure with high length-to-diameter ratio. Moreover, MWCNTs possess π-type electron clouds formed by sp2 hybridization, which exhibit near-metallic properties (i.e., high electrical conductivity). Therefore, the MWCNTs dispersed within the matrix probably form a “high-speed channel” for carrier transport [37,41,42,43,44], significantly enhancing carrier concentration while maintaining high carrier mobility, as illustrated in Figure 6. However, at higher MWCNT concentrations, a reduction in electrical conductivity was observed in the prepared composites owing to the decreased effective carrier concentration (Table 1). This decrease in carrier concentration was possibly attributed to the enhanced carrier scattering with the increased composite interfaces [37] or some agglomeration of the nanotubes in the prepared composites [42,43,44]. The electrical conductivity of all MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.5 composites decreased with the increasing temperature below 550 K, showing metal-like behavior. When the temperature exceeded this point, their electrical conductivities increased sharply, which was probably attributed to the thermal excitation of a few carriers (bipolar diffusion phenomenon) [33,34].

Figure 5.

Curves of electrical and thermal transport properties of MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 thermoelectric composites as a function of temperature: (a) electrical conductivity; (b) Seebeck coefficient; (c) power factor; (d) total thermal conductivity.

Table 1.

Density, relative density, carrier concentration (n), carrier mobility (μ), and I(D)/I(G) of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 thermoelectric composites.

Figure 6.

Schematic diagram of carrier transport high-speed pathways and phonon scattering formed by MWCNTs in the matrix.

The temperature dependence curves of Seebeck coefficient for the prepared composites are presented in Figure 5b. All samples exhibited positive Seebeck coefficients, confirming their p-type carrier transport characteristics. The temperature dependence curves of Seebeck coefficients for all MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.5 composites showed an opposite trend to their electrical conductivities. With the increase in temperature, their Seebeck coefficient increased and reached an extreme value around 550 K. Subsequently, the Seebeck coefficients of all prepared samples decreased significantly, probably under the influence of bipolar effect of carrier. Figure 5c presents the temperature-dependent power factor (PF) curves for the prepared composites. Although the introduction of MWCNTs enhanced the electrical conductivity of the prepared composites, the reduced Seebeck coefficient hindered the significant optimization of PF. A maximum PF of ~7.15 μW K−2 cm−1 was achieved in the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample at 750 K, increased by 7.51% compared with the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample.

The temperature dependency curves of total thermal conductivity for the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites are displayed in Figure 5d. Across the entire temperature range, the variation in thermal conductivity of the formed composites after MWCNT incorporation follows a trend similar to that of the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample. Initially, as the MWCNT content in the matrix increases, the total thermal conductivity of the samples rises, but it subsequently decreases with further addition of MWCNTs. This initial increase in thermal conductivity is possibly attributed to the sharp rise in carrier concentration at low MWCNT content. However, as the MWCNT content continues to increase, carriers experience enhanced scattering at the phase boundaries between the MWCNTs and the matrix. Additionally, the increased MWCNTs in the formed composites effectively scatted the phonons and hindered phonon transport, thus achieving a significant reduction in lattice thermal conductivity [45,46,47]. Moreover, the thermal conductivity of all MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.5 composites also assumed a similar trend with temperature, and gradually decreased with increasing temperature below 600 K. Subsequently, under the influence of carrier bipolar effect, their thermal conductivity showed a slightly increasing trend with increasing temperature. These phenomena were consistent with those observed in cubic-phase SnSe-based materials [48,49]. A low total thermal conductivity of 0.64 Wm−1K−1 was observed in the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composite, which is 11% lower compared to the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample.

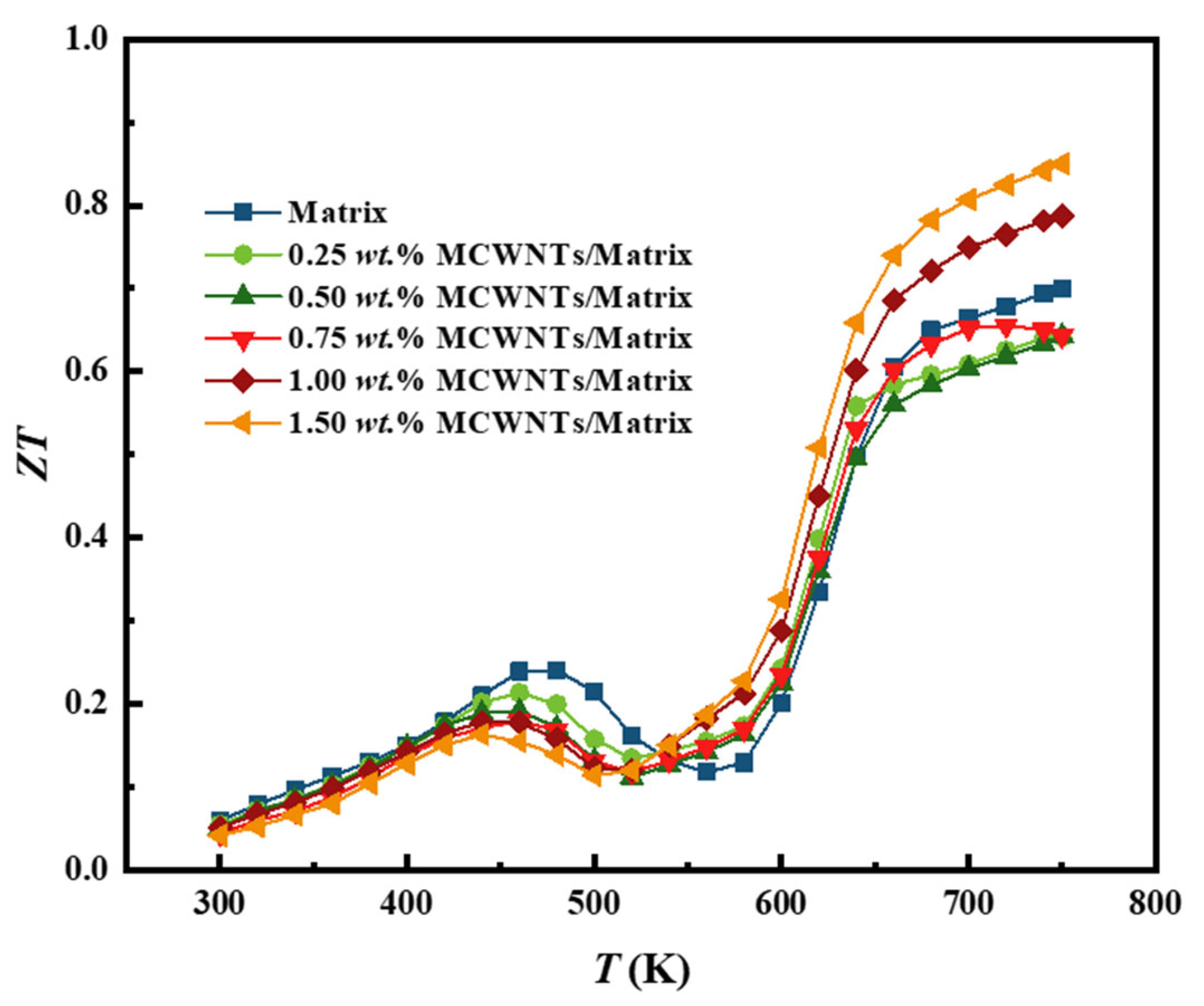

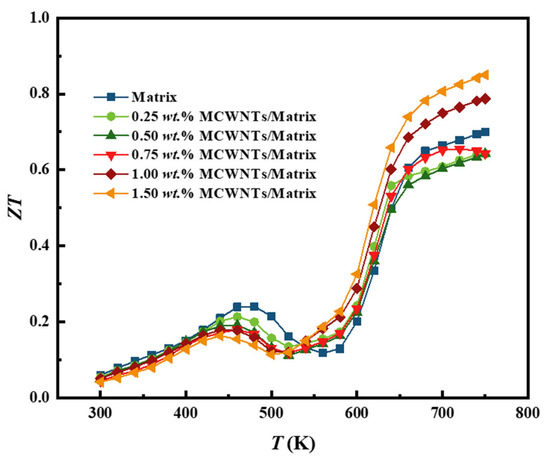

Figure 7 shows the temperature-dependent ZT value curves of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites with various MWCNT contents. The electrical and thermal transport properties of the prepared composites were synergistically optimized at higher temperatures with the introduction of MWCNTs. It can be seen that when x = 1.00 wt.% and 1.5 wt.%, the ZT of the material increases significantly at 750 K, while the ZT of other low-content composite components (x ≤ 0.75 wt.%) is lower than that of the matrix. This is because although the thermal conductivity of the low-content composite sample has a certain decrease, its power factor also has a certain decrease. In contrast, the optimization of the power factor and thermal conductivity of the two samples with high composite content is positive, and the thermoelectric properties of the materials are optimized by pairwise combination. The significant TE performance enhancements were observed in the prepared 1.50 wt.% Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composite, reached its maximum ZT value of 0.85 at 750 K. This represents a 21% enhancement compared to the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample, and a 55% improvement relative to the pure-phase SnSe. The ZT value may have certain errors in the measurement process and in the performance test process; because of the inconsistency of each sample test thickness, as well as the uncertainty in the measurement experiment that will lead to the uncertainty of the thermoelectric performance of the material measurement, the value is about 0.5–1%.

Figure 7.

Temperature-dependent ZT curve of the prepared MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 composites with various MWCNT contents.

4. Conclusions

In summary, MWCNTs were successfully incorporated into cubic-phase SnSe-based materials through a combination of ultrasonic dispersion and rapid hot-pressing sintering. The introduction of an appropriate amount of MWCNT content facilitates the formation of a “high-speed channel” of carrier transport between the cubic-phase Sn0.50Ag0.25Bi0.25Se0.50Te0.50 grains, leading to a significant increase in electrical conductivity. Furthermore, the introduced MWCNTs act as additional phonon-scattering centers, effectively impeding phonon transport and reducing thermal conductivity. Finally, a maximum ZT value of 0.85 was achieved in the prepared 1.50 wt.% MWCNTs/Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample at 750 K, representing a 21% improvement compared to the pristine Sn0.50Ag0.25Bi0.25Se0.50Te0.50 sample. The results above indicate that the addition of nanocomposites is useful to improve the thermoelectric properties of thermoelectric materials, which also provides a feasible way to improve the ZT value of cubic-phase SnSe.

Author Contributions

Z.T., Z.Z. and J.Z. designed the experiment and wrote the manuscript. W.W. and L.B. proposed the methodology and the thermoelectric performance evaluation. X.L. and Z.Z. helped with characterization of materials. C.L. and D.Z. supervised the project and conceived the idea. All authors have read and agreed to the published version of the manuscript.

Funding

This study was financially supported by the Taishan Scholar Program of Shandong Province (No. tsqn202306225), Shandong Postdoctoral Science Foundation (No. SDBX2023025), Leader of Scientific Research Studio Program of Jinan (No. 2021GXRC082), University of Jinan Disciplinary Cross-Convergence Construction Projects 2023 (Nos. XKJC-202301 and XKJC-202311), the Natural Science Foundation of Shandong Province (Nos. ZR2024QF181 and ZR2024QE044), Jinan City-School Integration Development Strategy Project (Nos. JNSX2023015 and JNSX2023018), Postdoctoral Fellowship Program of CPSF (No. GZC20230956), and China Postdoctoral Science Foundation (No. 2024M751104).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- He, J.; Tritt, T.M. Advances in thermoelectric materials research: Looking back and moving forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.; Chen, L.; Uher, C. Recent advances in high-performance bulk thermoelectric materials. Int. Mater. Rev. 2016, 61, 379–415. [Google Scholar] [CrossRef]

- Ortega, S.; Ibáñez, M.; Liu, Y.; Zhang, Y.; Kovalenko, M.V.; Cadavid, D. Bottom-up engineering of thermoelectric nanomaterials and devices from solution-processed nanoparticle building blocks. Chem. Soc. Rev. 2017, 46, 3510–3528. [Google Scholar] [CrossRef] [PubMed]

- Gayner, C.; Kar, K.K. Recent advances in thermoelectric materials. Prog. Mater. Sci. 2016, 83, 330–382. [Google Scholar] [CrossRef]

- Sootsman, J.R.; Chung, D.Y.; Kanatzidis, M.G. New and old concepts in thermoelectric materials. Angew. Chem. Int. Ed. 2009, 48, 8616–8639. [Google Scholar] [CrossRef]

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457. [Google Scholar] [CrossRef]

- Pei, Y.; LaLonde, A.D.; Wang, H.; Snyder, G.J. Low effective mass leading to high thermoelectric performance. Energy Environ. Sci. 2012, 5, 7963–7969. [Google Scholar] [CrossRef]

- Mishra, S.K.; Satpathy, S.; Jepsen, O. Electronic structure and thermoelectric properties of bismuth telluride and bismuth selenide. J. Phys.-Condens. Matter 1997, 9, 461. [Google Scholar] [CrossRef]

- Roychowdhury, S.; Ghosh, T.; Arora, R.; Samanta, M.; Lin, X.; Singh, N.K.; Soni, A.; He, J.; Waghmare, U.V.; Biswas, K. Enhanced atomic ordering leads to high thermoelectric performance in AgSbTe2. Science 2021, 371, 722–727. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Jiang, B.; Yu, Y.; Cui, J.; Liu, X.; Xie, L.; Liao, J.; Zhang, Q.; Huang, Y.; Ning, S.; Jia, B.; et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 2021, 371, 830–834. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.J.; Zhao, L.D.; Zheng, F.S.; Wu, D.; Pei, Y.L.; Tong, X.; Kanatzidis, M.G.; He, J.Q. Broad temperature plateau for thermoelectric figure of merit ZT > 2 in phase-separated PbTe0.7S0.3. Nat. Commun. 2014, 5, 4515. [Google Scholar] [CrossRef]

- Shen, D.; Tai, S.T.; Liu, K.; Wang, W.; Li, H.; Theja, V.C.; Chen, C.; Chen, Y. Point Defect Scattering and Phonon Softening for Achieving High Thermoelectric Performance in p-Type ZnSb with Optimal Carrier Concentration. ACS Appl. Mater. Interfaces 2025, 17, 17036–17044. [Google Scholar] [CrossRef]

- Chen, Y.X.; Ge, Z.H.; Yin, M.; Feng, D.; Huang, X.Q.; Zhao, W.; He, J. Understanding of the extremely low thermal conductivity in high-performance polycrystalline SnSe through potassium doping. Adv. Funct. Mater. 2016, 26, 6836–6845. [Google Scholar] [CrossRef]

- Zhao, L.; Lo, S.H.; Zhang, Y.; Sun, H.; Tan, G.; Uher, C.; Wolvrton, C.; Dravid, V.P.; Kanatzidis, M.G. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature 2014, 508, 373–377. [Google Scholar] [CrossRef]

- Li, J.; Li, D.; Qin, X.; Zhang, J. Enhanced thermoelectric performance of p-type SnSe doped with Zn. Scripta Mater. 2017, 126, 6–10. [Google Scholar] [CrossRef]

- Wubieneh, T.A.; Chen, C.; Wei, P.; Chen, S.Y.; Chen, Y.Y. The effects of Ge doping on the thermoelectric performance of p-type polycrystalline SnSe. RSC Adv. 2016, 6, 114825–114829. [Google Scholar] [CrossRef]

- Chu, F.; Zhang, Q.; Zhou, Z.; Hou, D.; Wang, L.; Jiang, W. Enhanced thermoelectric and mechanical properties of Na-doped polycrystalline SnSe thermoelectric materials via CNTs dispersion. J. Alloys Compd. 2018, 741, 756–764. [Google Scholar] [CrossRef]

- Li, J.; Xu, J.; Wang, H.; Li, J.; Xu, J.; Wang, H.; Liu, G.Q.; Tan, X.; Shao, H.; Hu, H.; et al. Enhanced thermoelectric performance in p-type polycrystalline SnSe by Cu doping. J. Mater. Sci-Mater. Electron. 2018, 29, 18727–18732. [Google Scholar] [CrossRef]

- Sun, Y.; Zhong, Z.; Shirakawa, T.; Franchini, C.; Li, D.; Li, Y.; Yunoki, S.; Chen, X.Q. Rocksalt SnS and SnSe: Native topological crystalline insulators. Phys. Rev. B 2013, 88, 235122–235128. [Google Scholar] [CrossRef]

- Zhang, Y.; Ke, X.; Chen, C.; Yang, J.; Kent, P.R.C. Thermodynamic properties of PbTe, PbSe, and PbS: First-principles study. Phys. Rev. B 2009, 80, 024304–024326. [Google Scholar] [CrossRef]

- Zhao, L.D.; Dravid, V.P.; Kanatzidis, M.G. The panoscopic approach to high performance thermoelectrics. Energy Environ. Sci. 2014, 7, 251–268. [Google Scholar] [CrossRef]

- Zhu, T.; Liu, Y.; Fu, C.; Heremans, J.P.; Snyder, J.G.; Zhao, X. Compromise and synergy in high-efficiency thermoelectric materials. Adv. Mater. 2017, 29, 1605884. [Google Scholar] [CrossRef]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced thermoelectric design: From materials and structures to devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Wang, H.X.; Mao, L.S.; Tan, X.; Tan, X.; Liu, G.Q.; Xu, J.; Shao, H.; Hu, H.; Jiang, J. Nontrivial thermoelectric behavior in cubic SnSe driven by spin-orbit coupling. Nano Energy 2018, 51, 649–655. [Google Scholar] [CrossRef]

- Dutta, M.; Pal, K.; Etter, M.; Waghmare, U.V.; Biswas, K. Emphanisis in cubic (SnSe)0.5(AgSbSe2)0.5: Dynamical off-centering of anion leads to low thermal conductivity and high thermoelectric performance. J. Am. Chem. Soc. 2021, 143, 16839–16848. [Google Scholar] [CrossRef]

- Fu, Y.; Xu, J.; Liu, G.Q.; Tan, X.; Li, Z.; Wang, X.; Shao, H.; Jiang, H.; Liang, H.; Jiang, J. Study on thermoelectric properties of polycrystalline SnSe by Ge doping. J. Electron. Mater. 2017, 46, 3182–3186. [Google Scholar] [CrossRef]

- Li, D.; Li, J.C.; Qin, X.Y.; Xin, H.X.; Song, C.J.; Wang, L. Enhanced thermoelectric performance in SnSe based composites with PbTe nano inclusions. Energy 2016, 116, 861–866. [Google Scholar] [CrossRef]

- Zhao, T.; Yang, L.Z.; Zhou, Y.; Liao, H.J.; Huang, Z.Y.; Li, J.; Lu, X.; Zhou, X.Y. Thermoelectric performance of (AgBiTe2)1-x(SnTe)x with stable cubic enabled by enhanced configurational entropy. Rare Metals 2022, 41, 4149–4155. [Google Scholar] [CrossRef]

- Nie, C.; Wang, C.; Xu, Y.; Liu, Y.; Niu, X.; Li, S.; Gong, Y.; Hou, Y.; Zhang, X.; Zhang, D.; et al. Band modification and localized lattice engineering leads to high thermoelectric performance in Ge and Bi codoped SnTe-AgBiTe2 alloys. Small 2023, 19, 2301298–2301307. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.X.; Hu, H.Y.; Man, N.; Xiong, C.L.; Xiao, Y.K.; Tan, X.J.; Liu, G.Q.; Jiang, J. Band flattening and phonon-defect scattering in cubic SnSe–AgSbTe2 alloy for thermoelectric enhancement. Mater. Today Phys. 2021, 16, 100298. [Google Scholar] [CrossRef]

- Zhu, J.L.; Bo, L.; Kong, J.B.; Hou, Y.B.; Zhao, L.H.; Li, C.C.; Zhao, D.G. Enhanced thermoelectric and mechanical properties of polycrystalline cubic SnSe by AgBiTe2 alloying. J. Alloys Comp. 2024, 971, 172754. [Google Scholar] [CrossRef]

- Lin, N.; Han, S.; Ghosh, T.; Schön, C.F.; Kim, D.; Frank, J.; Yu, Y.; Schmidt, T.; Ying, P.J.; Zhu, Y.K. Metavalent bonding in cubic SnSe alloys improves thermoelectric properties over a broad temperature range. Adv. Funct. Mater. 2024, 34, 2315652. [Google Scholar] [CrossRef]

- Roychowdhury, S.; Ghosh, T.; Arora, R.; Waghmare, U.V.; Biswas, K. Stabilizing n-type cubic GeSe by entropy-driven alloying of AgBiSe2: Ultralow thermal conductivity and promising thermoelectric performance. Angew. Chem. Int. Ed. 2018, 130, 15387–15391. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, W.; Li, J.; Zhu, J.; Wang, L.; Zhu, M.; Jiang, W. Preparation and thermoelectric properties of multi-walled carbon nanotube/polyaniline hybrid nanocomposites. J. Mater. Chem. A 2013, 1, 12109–12114. [Google Scholar] [CrossRef]

- Si, R.; Zhang, Z.; Liu, C.; Peng, Y.; Bai, X.; Feng, B.; Chen, J.; Gao, J.; Miao, L. Decoupled electron and phonon transport in thermoelectric GeTe compounded with multi-walled carbon nanotubes. Mater. Today Phys. 2023, 34, 101081. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Y.; Li, K.; Wang, J.; Dai, X.; Chong, D.; Yan, J.; Wang, H. Anisotropic electrical conductivity and isotropic seebeck coefficient feature induced high thermoelectric power factor >1800 µW m−1 K−2 in MWCNT films. Adv. Funct. Mater. 2022, 32, 2203080. [Google Scholar] [CrossRef]

- Kuznetsov, V.L.; Bokova-Sirosh, S.N.; Moseenkov, S.I.; Ishchenko, A.V.; Krasnikov, D.V.; Kazakova, M.A.; Romanenko, A.I.; Tkachev, E.N.; ObraZTsova, E.D. Raman spectra for characterization of defective CVD multi-walled carbon nanotubes. Phys. Status Solidi (B) 2014, 251, 2444–2450. [Google Scholar] [CrossRef]

- Mao, X.Y.; Shi, X.L.; Zhai, L.C.; Liu, W.D.; Chen, Y.X.; Gao, H.; Li, M.; Wang, D.Z.; Wu, H.; Zheng, Z.H.; et al. High thermoelectric and mechanical performance in the n-type polycrystalline SnSe incorporated with multi-walled carbon nanotubes. J. Mater. Sci. Technol. 2022, 114, 55–61. [Google Scholar] [CrossRef]

- Spalva, E.; Niherysh, K.; Andzane, J.; Felsharuk, A.; Erts, D. Interface-induced enhancement of thermoelectric properties of Bi2Se3-n-type MWCNT heterostructures revealed by magnetotransport analysis. J. Alloys Compd. 2025, 1020, 179299. [Google Scholar] [CrossRef]

- Ahmad, K.; Almutairi, Z. Enhanced thermoelectric properties of bismuth telluride (Bi2Te3) and multiwall carbon nanotube (MWCNT) composites. Mater. Today Commun. 2023, 35, 106228. [Google Scholar] [CrossRef]

- Shojaei, M.; Shokuhfar, A.; Zolriasatein, A.; Moghaddam, A.O. Enhanced thermoelectric performance of CuAlS2 by adding multi-walled carbon nanotubes. Adv. Powder Technol. 2022, 33, 103445. [Google Scholar] [CrossRef]

- Cherif, Y.B.; Mekhalif, Z.; Mekki, A.; Satah, Z.B.D. Effect of MWCNTs surface functionalization group nature on the thermoelectric power factor of PPy/MWCNTs nanocomposites. Synth. Metals 2022, 291, 117196. [Google Scholar] [CrossRef]

- Piao, R.; Cui, Z.; Oh, T.; Kim, S.; Jeong, J.W.; Yoo, D.Y. Synergistic effect of nickel and graphite powders on the thermoelectric properties of ultra-high-performance concrete containing steel fibers and MWCNTs. Cem. Concr. Comp. 2024, 154, 105778. [Google Scholar] [CrossRef]

- Ignatious, V.; Raveendran, N.; Prabhakaran, A.; Puli, Y.T.; Chakkooth, V.; Deb, B. MWCNT/Thienothiophene based All-Organic thermoelectric composites: Enhanced performance by realigning of the Fermi level through doping. Chem. Eng. J. 2021, 409, 128294. [Google Scholar] [CrossRef]

- Li, Z.Q.; Wang, Y.P.; Liu, D.R.; Hong, T.; Qin, B.C.; Gao, X.; Zhao, L.D. Attempts to realize promising thermoelectric performance in n-type polycrystalline SnSe with a cubic structure. J. Mater. Chem. A 2025, 13, 4899–4907. [Google Scholar] [CrossRef]

- Wang, Y.; Qin, B.; Hong, T.; Su, L.; Gao, X.; Wang, D.; Zhao, L.D. Enhanced thermoelectric perfromance in cubic form of SnSe stabilized through enformatingly alloying AgSbTe2. Acta Mater. 2022, 227, 117681. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).