Abstract

The constitutive model is widely employed to characterize the rheological properties of metallic materials under high-temperature conditions. It is typically derived from a series of high-temperature tests conducted at varying deformation temperatures, strain rates, and strains, including hot stretching, hot compression, separated Hopkinson pressure bar testing, and hot torsion. The original experimental data used for establishing the constitutive model serves as the foundation for developing phenomenological models such as Arrhenius and Johnson–Cook models, as well as physical-based models like Zerilli–Armstrong or machine learning-based constitutive models. The resulting constitutive equations are integrated into finite element analysis software such as Abaqus, Ansys, and Deform to create custom programs that predict the distributions of stress, strain rate, and temperature in materials during processes such as cutting, stamping, forging, and others. By adhering to these methodologies, we can optimize parameters related to metal processing technology; this helps to prevent forming defects while minimizing the waste of consumables and reducing costs. This study provides a comprehensive overview of commonly utilized experimental equipment and methods for developing constitutive models. It discusses various types of constitutive models along with their modifications and applications. Additionally, it reviews recent research advancements in this field while anticipating future trends concerning the development of constitutive models for high-temperature deformation processes involving metallic materials.

1. Introduction

Metal sheets, profiles, pipes, extruded components, and forged parts have increasingly found extensive applications in both social production and daily life. With the rapid advancement of science and technology alongside the intelligent manufacturing industry, higher standards have been established regarding the processing accuracy, overall mechanical properties, and surface qualities of metal products. However, lightweight high-strength alloy materials such as aluminum alloys, magnesium alloys, and titanium alloys exhibit certain limitations [1,2,3,4]; for instance, they often demonstrate poor plasticity at room temperature, susceptibility to rebound and warping deformation during heat treatment processes, severe isotropy in mechanical properties, cracking tendencies, and challenges in maintaining precision. To address these forming issues effectively, thermoplastic deformation processes, including hot forging, hot extrusion, hot rolling, hot stamping, and creep forming are commonly employed to process metal materials. During thermoplastic deformation processes, the characteristics and mechanical behavior of materials are influenced by various factors such as strain rate, strain, and temperature. Among these variables, deformation temperature, strain rate, and strain play crucial roles in affecting the work hardening mechanisms, dynamic recovery, and dynamic recrystallization behaviors of metallic materials [5,6]. Furthermore, numerical simulation technology serves as an effective approach for investigating the plastic deformation of metal materials. The accuracy of numerical simulations concerning plastic deformation is largely contingent upon the evaluation precision of the material constitutive model used. Therefore, to accurately predict the thermoplastic deformation behavior of metallic materials, it is essential to investigate the deformation characteristics across various temperature and strain rate ranges. This involves establishing appropriate and precise constitutive models that can be integrated into finite element simulation software. Such simulations are crucial for analyzing metal flow patterns, mechanical responses, size variations, microstructural evolution, damage mechanisms, and forming defects during high-temperature plastic processing. These factors play a vital role in optimizing key deformation parameters in thermal processing, thereby reducing production costs, enhancing the quality of formed components, and shortening production cycles [7,8,9,10,11]. Furthermore, the constitutive model serves as a foundational basis for developing metal hot-processing technologies, an aspect of significant practical importance in guiding the hot deformation processes of metallic materials.

2. Overview of Commonly Used Experimental Equipment and Methods for Constitutive Model Research

To acquire experimental data on the deformation processes of metallic materials and establish constitutive relationship models under varying temperatures, strain rates, and strain conditions, numerous scholars both domestically and internationally have employed diverse experimental methodologies. Among these methods, split Hopkinson pressure bar (SHPB), hot compression tests, hot tension tests, and torsion tests are particularly prevalent. The commonly utilized experimental equipment for studying the constitutive models of metallic materials includes devices such as the Hopkinson bar, Zwick/Roell Z100 universal material testing machine, Thermecmastor-Z100kn thermal simulation testing machine, Gleeble 3500 thermal simulation testing machine, and Sans CMT4104 electronic universal testing machine. Currently, many researchers have explored the relationships between process parameters during deformation and flow stress across different materials using these experiments and equipment, yielding substantial results. Zhang et al. [12] conducted high-temperature isothermal compression tests on a 2099 aluminum–lithium alloy using the Gleeble 1500 thermal simulator to investigate its thermal deformation behavior under conditions ranging from 300 to 500 °C and strain rates between 0.001 and 10 s−1. They established an Arrhenius-type constitutive equation based on strain compensation principles. Liu et al. [13] employed a separated Hopkinson pressure bar test to examine the rheological behavior of Ti-6Al-4V alloy at high strain rates (1000~8500 s−1) and elevated deformation temperatures (20~1000 °C). They formulated a modified Johnson–Cook constitutive model that accounts for the recrystallization softening effect, utilizing Fortran to create a subroutine within AdvantEdge FEM for predicting stress–strain responses and cutting morphology during the high-speed machining of titanium alloys. Zhang et al. [14] established a modified Arrhenius constitutive equation and constructed a hot working diagram of 7055 alloy through hot compression tests conducted at various temperatures (300~450 °C) and strain rates (0.01~0.4 s−1). They calculated the high-temperature rheological stress of the material, identifying optimal process parameters for hot rolling deformation. Wang et al. [15] analyzed the rheological behavior during hot stamping of AA7075 high-strength aluminum alloy using hot tensile testing methods. Zhou et al. [16] determined the relationship between deformation conditions and rheological stress throughout the deformation process of aluminum alloys via torsion tests. According to these studies, various pieces of equipment such as the Gleeble 1500/3800 thermal simulation testing machines, separated Hopkinson pressure bars, hydraulic servo testing machines, and electronic universal high-temperature testing machines can be employed to investigate the high-temperature deformation behavior of metallic materials. The selection of a specific experimental apparatus must take into account the thermal deformation conditions pertinent to the metal materials being studied. For instance, in high-speed cutting processes, it is essential to consider the coupled effects of elevated temperature and pressure. Under impact loads, metallic materials exhibit dynamic mechanical properties; thus, Hopkinson pressure bar tests are typically utilized for this purpose.

3. Typical Constitutive Models and Their Modifications During Thermal Deformation Process

3.1. Arrhenius Equation and Its Modifications

The Arrhenius equation was introduced by Sellars et al. [17] in 1966 to characterize the relationship between rheological stress (σ), deformation temperature (T), and strain rate of metallic materials during thermal deformation, employing a hyperbolic rule. Its mathematical representation is provided in Equation (1):

Among them,

In Equation (1), represents the strain rate, measured in s−1; σ denotes the rheological stress, expressed in MPa; Q signifies the activation energy for deformation, given in J·mol−1; R is the gas molar constant with a value of R = 8.315 J/(mol·K); T indicates thermodynamic temperature, K; n1 and n are hardening indices; A, and β are material constants.

Recent studies have demonstrated that strain (ε) significantly influences the flow stress of metallic materials during thermal deformation. However, traditional Arrhenius models fail to accurately capture the characteristics of rheological stress due to their disregard for how material parameters vary with increasing strain [18,19]. Therefore, it is essential to develop an Arrhenius-type constitutive model that incorporates strain coupling. Haghdadi et al. [20], Liu et al. [21], Liu et al. [22], Quan et al. [23], and Xiang et al. [24], respectively, established constitutive models for cast A356 aluminum alloy, homogeneous Al-Mg-Si-Mn-Cr alloy, 2219 aluminum alloy, extruded 7075 aluminum alloy, and Al-Mg-Si-La alloy by considering the impact of strain on material-related parameters through Z-parameter and Arrhenius-type constitutive equations. It is evident that the strain significantly affects both the activation energy for deformation and the material constants. The findings from these studies indicate that strain-dependent constitutive models can effectively evaluate the flow behavior of materials. Li et al. [25] introduced a modified variable parameter Arrhenius constitutive equation utilizing a fifth-order polynomial to fit the relationship curve between strain and various parameters (α, n, Q, LnA, and β) within this framework. This approach led to constructing a high-temperature rheological stress constitutive equation specifically for V-5Cr-5Ti alloy.

Zhao et al. [26] developed a constitutive model for the 20CrMnTi alloy that incorporates strain effects, based on Arrhenius-type constitutive equations. To enhance the accuracy of this model, a coefficient K related to deformation temperature and strain rate was introduced as a modification. The expression for the modified constitutive model of the 20CrMnTi alloy is presented in Equation (2).

Among them,

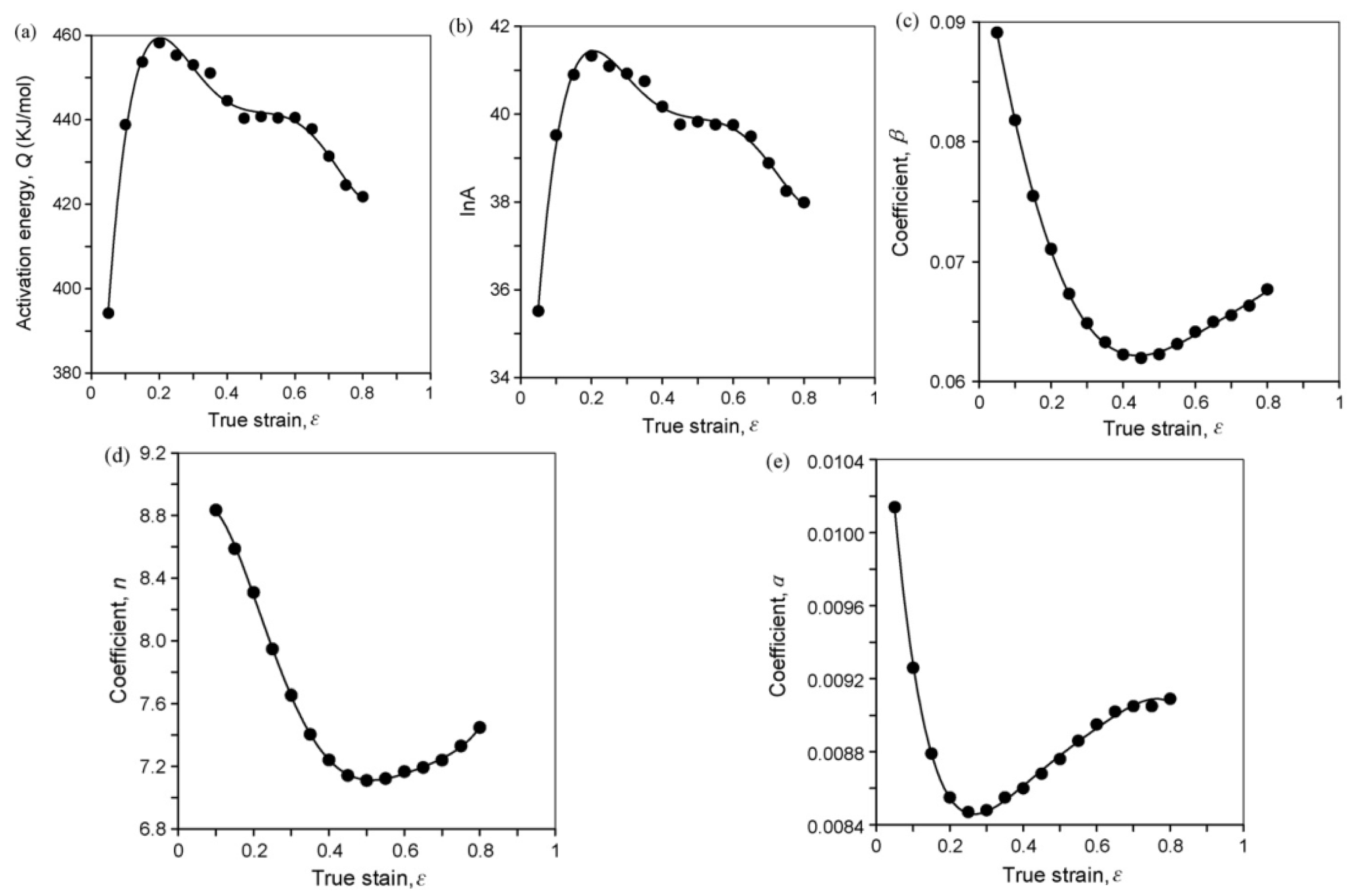

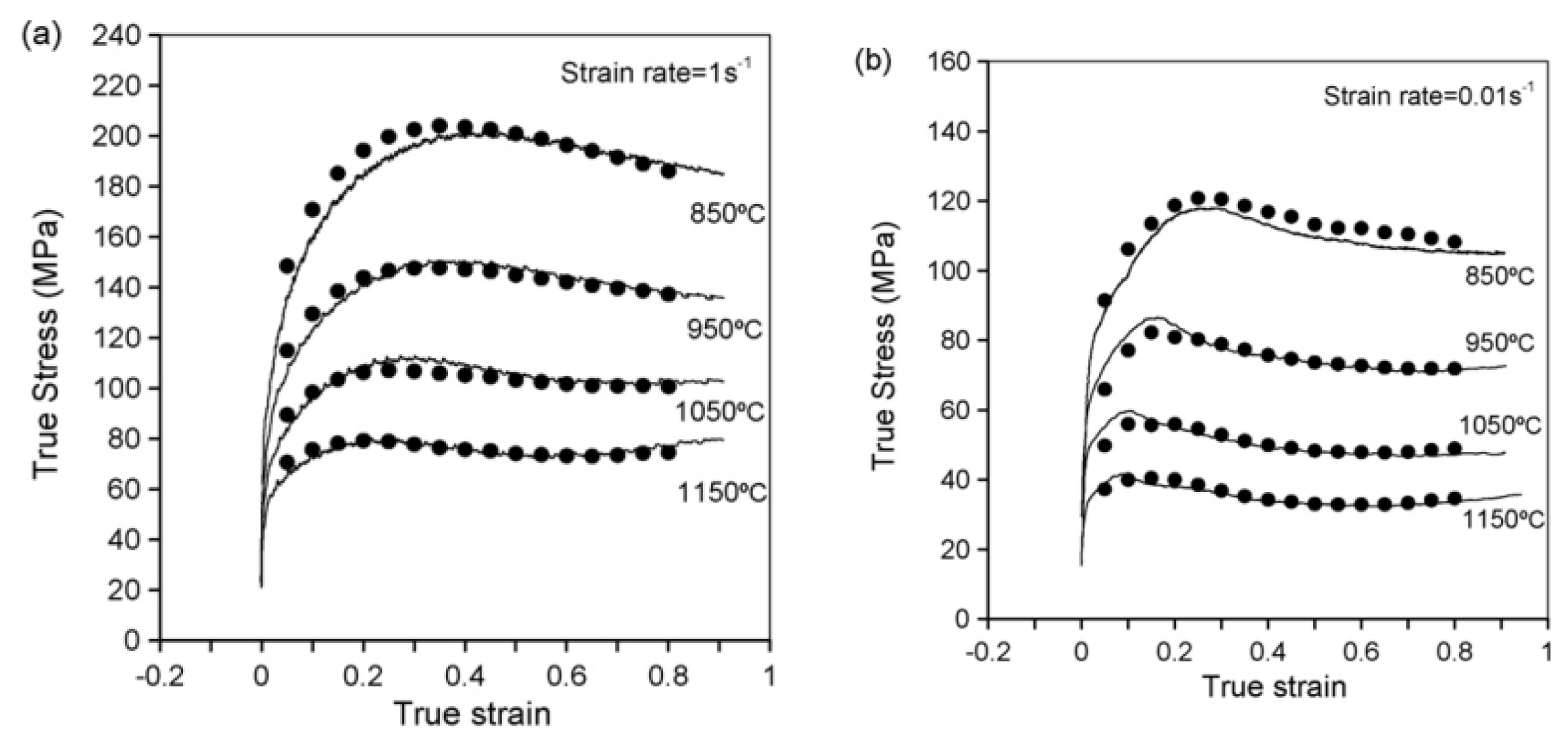

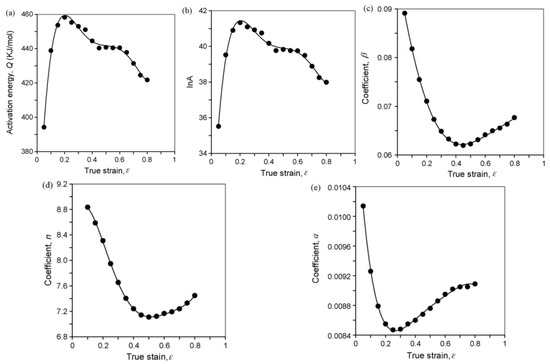

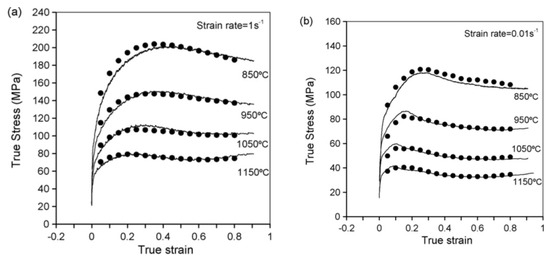

Their research findings indicate that this modified constitutive model significantly improves prediction precision and effectively forecasts the flow stress of the 20CrMnTi alloy under high-temperature conditions. Lin et al. [27] established a constitutive model for 42CrMo steel at elevated temperatures, utilizing an Arrhenius constitutive equation with strain compensation. A relationship curve between real strain and material parameters (α, n, Q, LnA, and β) was fitted using a sixth-order polynomial, as illustrated in Figure 1. By comparing predicted stress values from the model with experimental data shown in Figure 2, it is evident that the predicted flow stress aligns well with experimental results during plastic deformation. This established constitutive model accurately characterizes the rheological behavior of 42CrMo steel at high temperatures.

Figure 1.

Relationship between the material parameters of the strain-compensated Arrhenius model and true strain (ε) for 42CrMo steel: (a) Activation energy Q, (b) lnA, (c) β, (d) n, and (e) α [27].

Figure 2.

Comparison between predicted and measured flow stress curves of 42CrMo steel under strain rates of (a) 1 s−1; (b) 0.01 s−1.

Chen et al. [28] formulated an Arrhenius-type constitutive model for TA32 new titanium alloy by modifying the range of α values based on statistical theory and incorporating Tikhonov’s regularization minimization strategy function to adjust model parameters and fit regression equations. The research outcomes demonstrate that compared to models derived through traditional least squares methods, this modified Arrhenius-type equation substantially enhances prediction precision.

Jiang et al. [29] developed an Arrhenius-type constitutive model to investigate the thermal deformation behavior of Ti6Al4V alloy across a broad temperature range. Their study revealed that the alloy exhibited negative strain rate sensitivity at lower temperatures (500 °C and 600 °C), indicating that the Arrhenius model was inadequate for fitting data under these conditions, resulting in suboptimal performance. Cheng et al. [30] further demonstrated that, for the original strain-compensated Arrhenius constitutive equation, increasing the polynomial order beyond five had minimal impact on enhancing model accuracy. Under identical strain conditions, discrepancies in calculations from the Arrhenius constitutive model primarily stemmed from variations in deformation temperature and strain rate.

In addressing the influence of strain on flow stress within an improved Johnson–Cook (J–C) model, a functional form such as A + B1ε + B2ε2 or A + Bεn is employed. Building upon this concept, Wang et al. [31] proposed a preliminary enhancement to the Arrhenius model by incorporating strain effects; its mathematical representation is as follows:

The material constants B1, B2, and B3 are correlated with the strain. The parameters α, A, Z, and n are calculated at a true strain of 0.1 based on the original Arrhenius model.

Based on Equation (3), a judgment factor C has been introduced to refine stress trend predictions within the Arrhenius framework.

where C is the judging factor for the stress trend,

D1, D2, and D3 are material constants. Their research results indicate that both improved Arrhenius models have enhanced the predictability of the original model.

In summary, most of the existing literature employing Arrhenius-type equations focuses on establishing high-temperature constitutive models for metals through mathematical statistical methods, deriving variation curves of material-related parameters with respect to true strain via fittings using third- to sixth-order polynomials. The Arrhenius-type equation typically serves to articulate the relationship between steady-state stress and primary deformation parameters. When the degree of deformation is minimal, the deformation temperature remains low, or the strain rate is elevated, the material has not yet transitioned into a steady-state rheological condition. Consequently, the relationship between stress and strain cannot be accurately characterized. The complex deformation behavior exhibited by metals at high temperatures is influenced not only by primary deformation parameters but also by dynamic material mechanisms such as work hardening, dynamic recovery, and dynamic recrystallization. These factors contribute to softening phenomena and highly nonlinear behaviors, thereby complicating the stress–strain relationship further. Additionally, traditional Arrhenius-type equations involve multiple parameters and entail a complex and time-consuming solving process; they fail to adequately represent intricate thermal processing events like dynamic recovery and recrystallization. Their stability is often poor, which limits their applicability across various fields. In contrast, an improved Arrhenius model demonstrates commendable predictability throughout the entire stress range while enhancing prediction accuracy.

3.2. Johnson–Cook Model and Its Revision

The Johnson–Cook model serves as a phenomenological constitutive framework designed to characterize the rheological behavior of metallic materials under principal deformation parameters. This model boasts several advantages: it requires few parameters for its formulation, features a straightforward expression structure that facilitates convenient calculations, and proves suitable for numerical simulations, making it widely adopted in simulation software applications. The mathematical representation of the Johnson–Cook model can be expressed as in Equation (5) [32]:

In Equation (5), A denotes the yield strength of the material at reference strain rate and reference temperature; B and n are coefficients representing strain strengthening; C signifies the coefficient of strain rate sensitivity; m indicates the temperature softening coefficient; 0 represents the reference strain rate; refers to the melting point temperature of the material; T0 designates reference temperature; σ symbolizes true stress; ε stands for true strain; indicates strain rate; T represents experimental temperature.

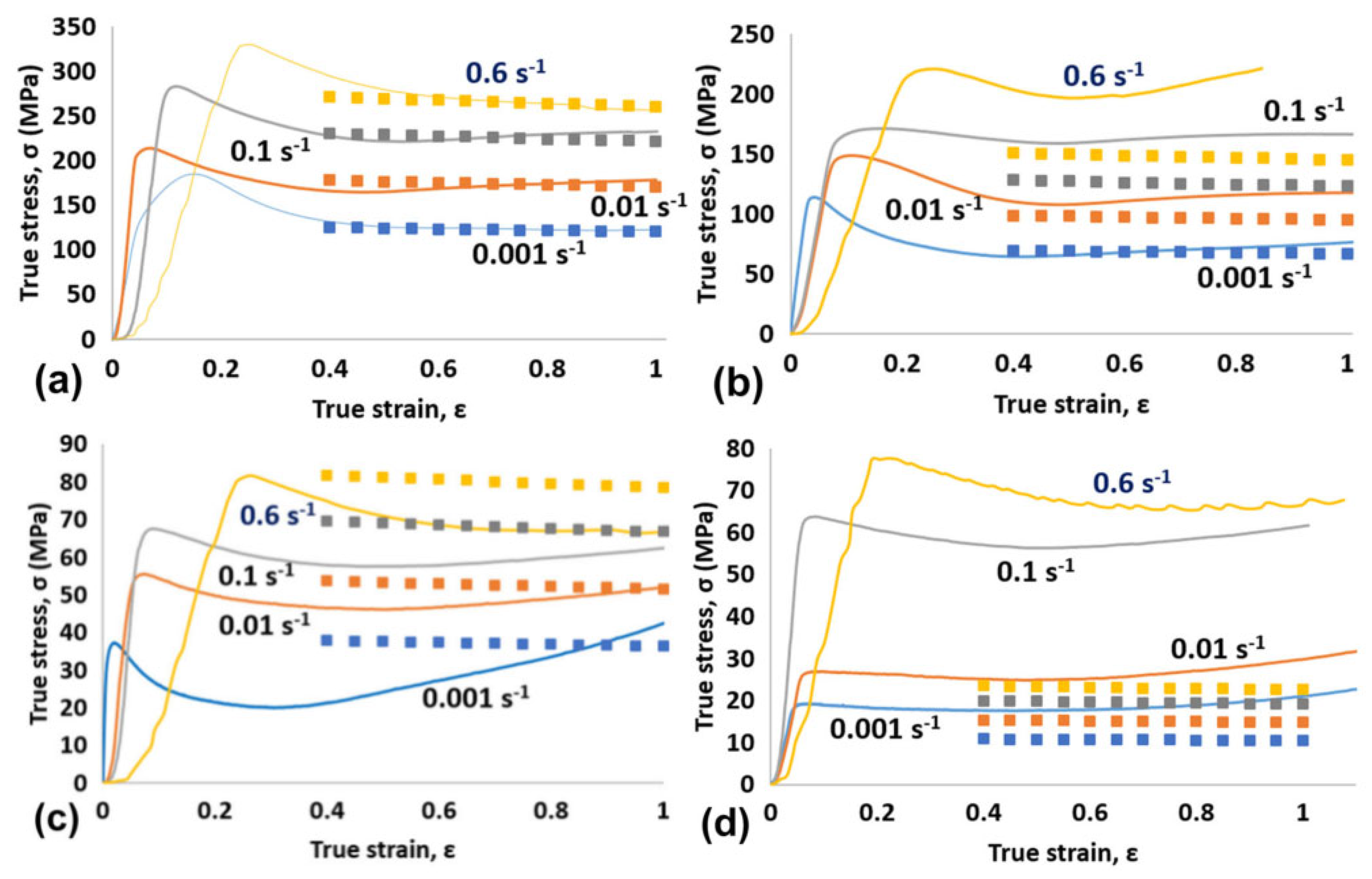

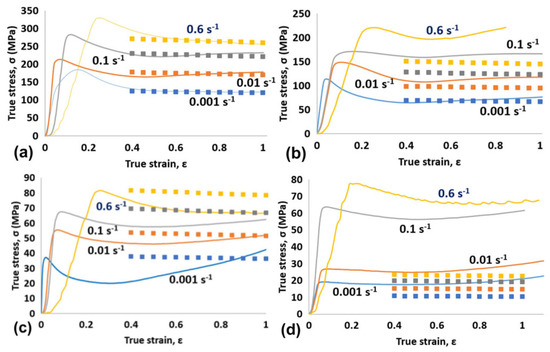

S. Rasaee et al. [33] developed a constitutive model for 2024 aluminum alloy at elevated temperatures, based on the Johnson–Cook model, and compared the predicted results with experimental data, as illustrated in Figure 3. The findings indicate that the Johnson–Cook model is inadequate in accurately predicting the rheological behavior of 2024 aluminum alloy, particularly under conditions of high strain and high temperature, where significant discrepancies arise in the model’s calculations. This limitation primarily stems from neglecting the interaction between temperature and strain when determining constants B and n in Equation (5), which prevents the simultaneous consideration of softening behavior and strain hardening [34].

Figure 3.

Comparison of the calculated flow stresses by J–C model (symbols) and measured experimental data (lines) at (a) 673 K, (b) 723 K, (c) 773 K, and (d) 823 K [33].

Researchers have established an improved constitutive model that accounts for correlation effects among parameters, as well as hardening and softening behaviors through an enhanced J–C framework. The mathematical expression is presented in Equation (6) [35]:

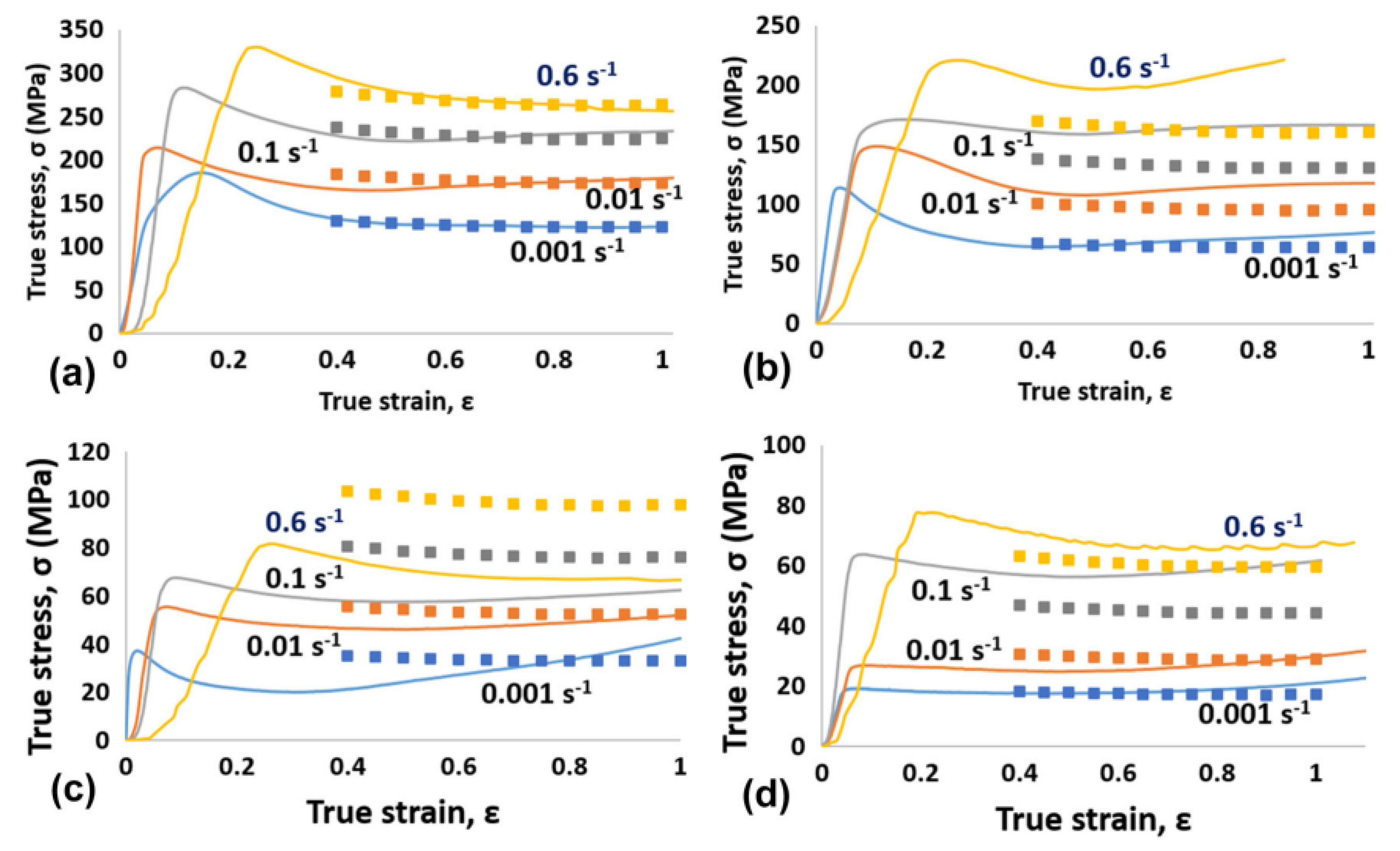

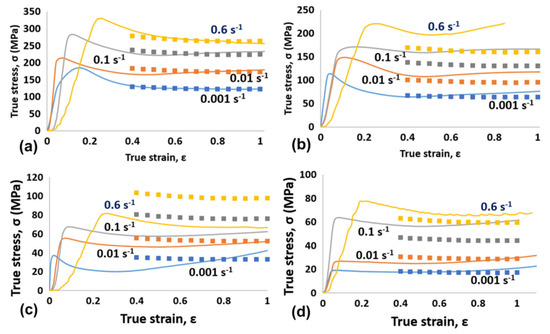

In Equation (6), A1, B1, B2, C, λ1, and λ2 are material-related constants; represents the rheological stress of the material; ε denotes plastic strain; signifies dimensionless strain rate defined by , where indicates strain rate while refers to reference plastic strain rate. S. Rasaee et al. [33] used Equation (6) to calculate the flow stress of 2024 aluminum alloy and compared it with the experimental results, as shown in Figure 4.

Figure 4.

Comparison of the calculated flow stresses by modified J–C model (symbols) and measured experimental data (lines) at (a) 673 K, (b) 723 K, (c) 773 K, and (d) 823 K [33].

Comparing Figure 3 and Figure 4, it can be seen that the modified J–C model exhibits superior prediction accuracy in predicting the flow behavior of the 2024 alloy, mainly considering the coupling effect of parameters and displaying the complex relationship between true stress and strain through the application of nonlinear fitting.

He et al. [36] investigated the high-temperature deformation behavior of X12 through hot compression tests. The results indicated that the effects of strain, strain rate, and temperature on material strain hardening are interdependent rather than independent; they interact with one another. Consequently, an improved Johnson–Cook (J–C) model that accounts for the coupling effects of strain, strain rate, and temperature has been established, represented by the following expression:

In Equation (7), A1, b1, b2, n1, λ1, and λ2 are constants specific to the material; σ denotes the rheological stress of the material; ε represents the plastic strain; is a dimensionless strain rate, defined as , where is the actual strain rate; is the reference plastic strain rate. Additionally, , where signifies the melting point temperature of the material, indicates a reference temperature, and T refers to the experimental temperature.

Liu et al. [37] examined the thermal deformation characteristics of Inconel 625 high-temperature alloy using quasi-static compression tests alongside Hopkinson pressure bar tests. Their findings revealed that Inconel 625 alloy exhibits sensitivity to both strain rate and temperature. Under conditions characterized by elevated temperatures and high strain rates, the plastic deformation process demonstrates a coupling effect involving strain hardening, strain rate hardening, and temperature softening. Notably, in the J–C constitutive model for Inconel 625 alloy, the coefficient C representing strain rate sensitivity is not constant but varies with both deformation temperature and applied strains. To address this variability in C within the J–C model framework under high-temperature and high-strain-rate conditions for Inconel 625 alloy, a power function has been introduced as shown in Equation (8):

In Equation (8), the coefficients c0 through c5 remain undetermined. By comparing the predicted rheological stress values of the improved Johnson–Cook (J–C) model with experimental data, the research findings indicate that the enhanced J–C model more accurately characterizes the thermal deformation behavior of Inconel 625 high-temperature alloy across a broader range of temperatures and strain rates.

Hui et al. [38] studied the strain sensitivity of 2A16 aluminum alloy in the range of moderate strain rates, and the research results revealed that flow stress in the low-strain-rate region for 2A16 aluminum alloy exhibits an approximately exponential relationship with logarithmic strain rate. Given that the standard J–C model represents material flow stress as a linear function of logarithmic strain rate, it is essential to modify its term related to strain rate influence. Consequently, they selected Equation (9) as the revised form for this term in their adaptation of the J–C model.

In Equation (9), C and P are undetermined material parameters specific to 2A16 aluminum alloy. The modified J–C model was utilized to predict flow stress within this alloy; research findings indicated that these predictions align closely with experimental data, effectively characterizing its dynamic mechanical behavior.

Shokry et al. [39] proposed an improved universal Johnson–Cook model that accounts for coupling effects among primary deformation parameters, thereby accurately predicting hot deformation behavior across four distinct alloy types. The mathematical expression is presented in Equation (10):

In Equation (10), the four constants Ai constitute the strain hardening term; nine constants Cij represent the strain rate term; and twenty-seven constants mijk constitute the softening term. This model contains 40 constants that are typically determined through regression analysis in MATLAB 2019.

Jiang et al. [40] performed a reverse identification study on the Johnson–Cook constitutive model parameters for 304 stainless steel by employing orthogonal experiments alongside cutting experiments and integrating genetic algorithms with finite element analysis methods.

According to least squares principles, the fitness function for the genetic algorithm is derived as shown in Equation (11):

In Equation (11), N denotes the number of experimental groups, i represents the experimental sequence number, and k1 signifies a proportional constant value −1.

To enhance both recognition accuracy and search speed in genetic algorithms, an extensive compilation of literature review data was conducted to establish a parameter range for the Johnson–Cook model.

Through cutting simulation analyses, researchers investigated how variations in parameter C from the Johnson–Cook constitutive equation influence cutting morphology, subsequently identifying an optimal value for C. Thereafter, iterative calculations were performed using genetic algorithms on MATLAB to derive precise values for four key parameters A, B, n, and m in the Johnson–Cook constitutive model. By comparing the cutting force calculated using empirical formulas with the simulated predicted cutting force, the feasibility of the reverse identification method, as well as the reliability and accuracy of the constitutive model, are validated.

Nguyen et al. [41] employed an inverse method aimed at minimizing Mean Square Errors between experimental data and theoretical calculations to precisely determine parameters within the Johnson–Cook constitutive model. Wang et al. [42] integrated multi-objective optimization techniques with Latin hypercube sampling methods, Spearman rank correlation analysis, and advanced genetic algorithms on experimental datasets collected at varying deformation temperatures and strain rates for parameter identification and optimization within the Johnson–Cook constitutive framework. Their results demonstrated that the refined Johnson–Cook model effectively predicts mechanical behavior across diverse strain rates and temperatures.

Shen et al. [43] enhanced the Johnson–Cook model by substituting the strain term with that from the Voce hardening model and adjusting both the strain rate sensitivity coefficient and thermal softening index. The improved Johnson–Cook (J–C) model demonstrates a smaller average absolute error compared to the original J–C model, allowing for a more accurate characterization of the plastic stress–strain relationship of 6061 aluminum alloy under various deformation conditions. By comparing the predictive capabilities of both the original and improved J–C models in forecasting the flow stress of aluminum alloys, one can effectively evaluate and assess the enhanced performance of the improved J–C model [44]. Lin et al. [45] introduced a combined Johnson–Cook and Zerilli–Armstrong (JC–ZA) model to elucidate the relationship between flow stress, strain rate, and forming temperature in high-strength alloy steel. The findings indicated that this JC–ZA combined model is capable of accurately predicting the flow stress behavior in high-strength alloy steels. Furthermore, future research may explore coupling either the Johnson–Cook or improved Johnson–Cook models with other frameworks such as Arrhenius modeling.

In summary, the original Johnson–Cook phenomenological model is applicable to materials exhibiting an increase in work hardening rate with strain rate, such as aluminum alloys, steel, oxygen-free high-conductivity copper (OFHC), and nickel. This model features a straightforward structure with few parameters, closely approximates real cutting scenarios, and is user-friendly. The improved Johnson–Cook model accounts for coupling effects arising from strain hardening, strain rate hardening, and thermal softening; it applies to a broad range of metal materials, including high-strength alloy steels. However, it has certain limitations when describing saturation in strain hardening. Typically combined with finite element simulation software such as Abaqus, LS-DYNA, and Deform 3D for simulating experiments on hot working processes involving metal materials, this approach facilitates design optimization while reducing testing costs. Consequently, research into macroscopic phenomenological constitutive models for metals holds significant engineering importance.

3.3. Fields–Backofen (FB) Model and Its Modifications

The Fields–Backofen model is among the most widely utilized phenomenological constitutive models, capable of characterizing the rheological stress behavior of metallic materials during elastic–plastic deformation stages. Its mathematical formulation is provided in Equation (13) [46]:

In Equation (13), σ signifies the true stress of the material; C is identified as the strengthening coefficient while n represents the strain strengthening index; m refers to the material’s strain rate sensitivity coefficient. Tong et al. [47] employed multiple linear regression techniques to determine values for both strain hardening index n and strain rate sensitivity index m. Their findings revealed that these two material parameters are not constants but rather fluctuate with changes in temperature and strain rate. By incorporating these variable material parameters into a modified Fields–Backofen equation, an accurate description of the constitutive relationship for 42CrMo steel can be achieved. Additionally, research conducted by Zhang et al. [48] indicated that, under varying deformation temperatures and strain rates, coefficients C, n, and m also exhibit variability, thus necessitating their correction. Chang et al. [49] explored quantitatively how strength coefficient C relates to both strain hardening index n and strain rate sensitivity coefficient m at corresponding deformation temperatures within the context of the Fields–Backofen model. Based on temperature fluctuations, they refined the Fields–Backofen equation and established a mathematical model characterizing plastic flow stress behavior for industrial pure titanium. Jiao et al. [50] employed the same methodology to develop a high-temperature constitutive model for 5A06-O aluminum magnesium alloy sheets, as presented in Equation (14). They integrated the temperature-dependent constitutive model into MSC software to simulate the hot medium liquid filling forming process of aluminum magnesium alloy sheets, thereby analyzing the distribution of the temperature field and examining how load conditions affect the forming performance of these sheets.

In Equation (14), σ denotes the flow stress; K, n, and m represent the strengthening coefficient, strain strengthening index, and strain rate sensitivity coefficient, respectively; T indicates temperature.

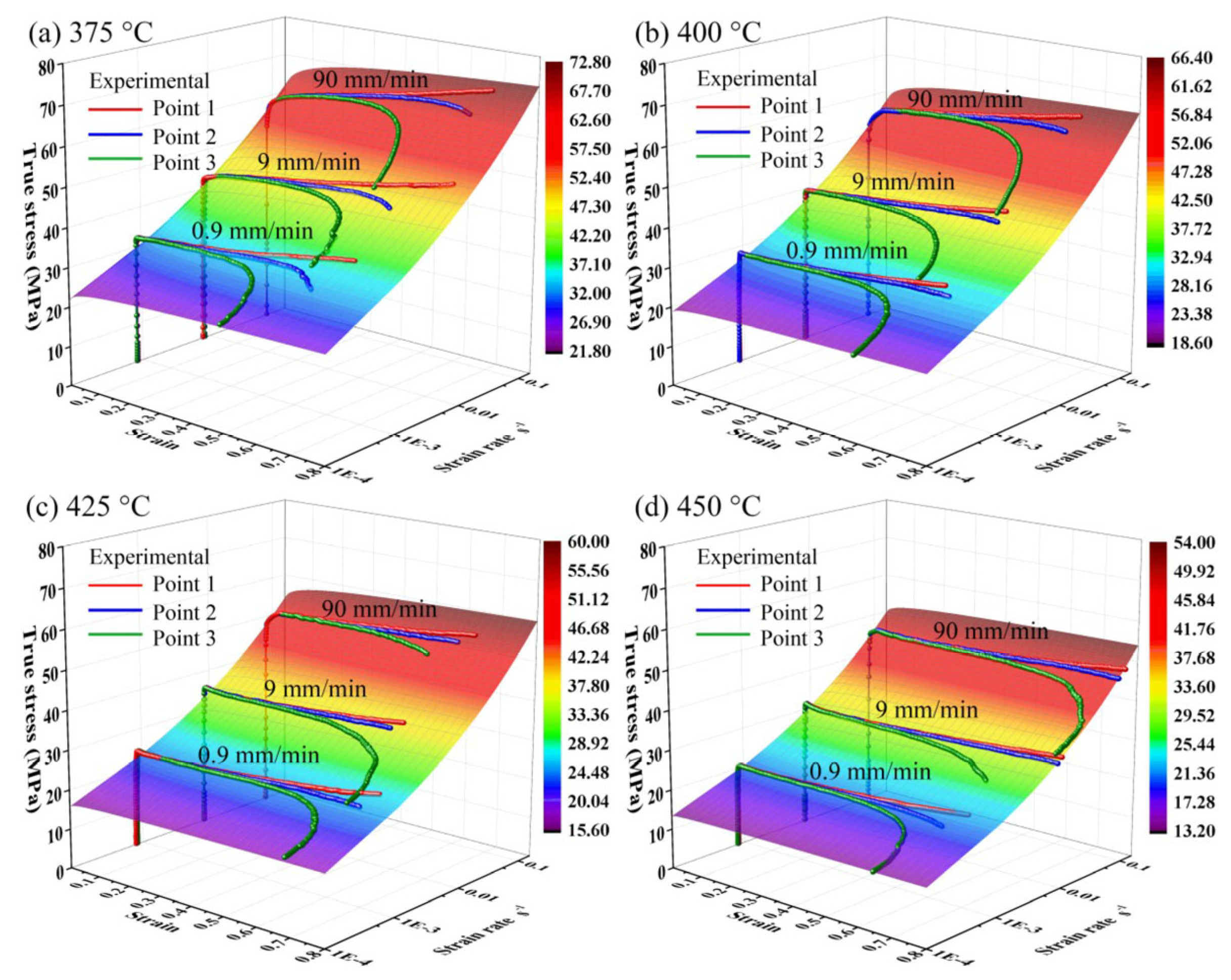

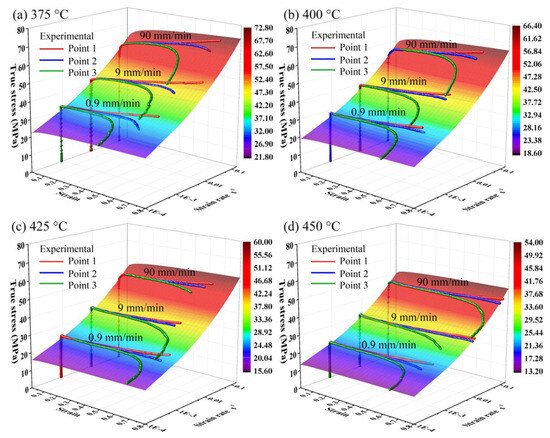

Li et al. [51] optimized parameters from various constitutive models related to AA6061-T6 aluminum alloy flow behavior using genetic algorithms. This included modifications to models such as the Johnson–Cook model, hyperbolic sine Arrhenius model, SK Paul model, modified Zerilli–Armstrong model, and modified Fields–Backofen model. Their findings demonstrated an improvement in performance across all models optimized through genetic algorithms. Huang et al. [52] investigated the hot compression behavior of 21-4N heat-resistant steel; their results indicated that, while the original Fields–Backofen model exhibited strong predictive capabilities under conditions of low temperature, low strain rate, and minimal deformation, its effectiveness diminished outside these parameters. Seshacharyulu et al. [53] established a modified Fields–Backofen constitutive equation that incorporates a softening term aimed at predicting the flow behavior of dual-phase (DP590) steel thin plates. Research conducted by He et al. [54] demonstrates that the strain rate distribution of 2024 aluminum alloy is non-uniform during the hot tensile process. As strain increases, various points exhibit trends of increasing, stabilizing, and decreasing values, leading to distinct local flow stresses at different locations. Consequently, an enhanced Fields–Backofen model has been proposed that takes into account the evolution of local strain rates rather than relying on a fixed strain rate to characterize the hot deformation behavior of 2024 aluminum alloy. The results, illustrated in Figure 5, demonstrate that the improved Fields–Backofen model exhibits greater accuracy in calculating flow stress compared to the traditional FB model.

Figure 5.

Comparisons of the flow stresses predicted by the improved FB models (colored surfaces) and the experimental flow stresses for each point at different temperatures [54].

Research conducted by Ji et al. [55] indicates that the Fields–Backofen constitutive equation effectively characterizes work hardening, strain rate sensitivity, and temperature softening effects during the hot deformation process of M50NiL steel. However, it does not accurately describe the true variation in flow stress with respect to strain during dynamic recrystallization stages. Abdullah [56] improved upon the Fields–Backofen model by incorporating a softening mechanism that enhances its ability to predict complex hot deformation behaviors in titanium-based alloys.

To conclude, although the original Fields–Backofen constitutive model features a simple form with minimal computational demands making it suitable for a wide range of metal materials, including high-strength aluminum alloys like 2024 aluminum, though it may lack some advanced predictive capabilities found in more complex models. The model provides accurate predictions for the flow stress in certain alloys [57,58]. However, it fails to account for the dependence of flow stress on key deformation parameters and softening mechanisms, leading to inaccurate predictions for the rheological stress of specific alloys [29,56,59,60]. The improved Fields–Backofen (FB) model demonstrates enhanced predictive performance for flow-induced stress compared to its original version and is well-suited for characterizing the strain hardening behavior of metallic materials such as 6061 aluminum alloy, AZ80 magnesium alloy, and 42CrMo steel at high strain rates.

3.4. Z–A Model and Its Revision

Zerilli et al. [61] developed a physically based constitutive model in 1987 that integrates strain hardening, strain rate hardening, and thermal softening mechanisms based on the theory of thermally activated dislocation motion. The mathematical formulation for this model is relatively straightforward. For face-centered cubic (FCC) materials, it is as illustrated in Equation (15):

For body-centered cubic (BCC) materials, the mathematical expression of the Z–A model is presented in Equation (16):

If we mathematically express the influence of non-thermal activation stress and yield stress on grain size as parameter C0, then the mathematical representation of the Z–A model can be articulated as follows:

For face-centered cubic materials,

For body-centered cubic materials

In Equations (15)–(18), C0, C1, C2, C3, C4, C5, and N are constants specific to each material. Each type of material structure (FCC, BCC, HCP) exhibits distinct constitutive behavior that depends on its unique dislocation characteristics. Commonly employed high-temperature constitutive models for characterizing metallic materials include Johnson–Cook model, Z–A model, Arrhenius-type equations among others. However, only the Z–A model takes into account the influence of crystal structure on the mechanical properties of materials.

The original Z–A model did not incorporate deformation parameters, which limits its ability to accurately predict the rheological behavior of metals. Numerous scholars have made modifications to the Z–A model based on this limitation [62,63,64]. Samantaray et al. [65] enhanced the physics-based Z–A model by considering the coupling effects among temperature, strain, and strain rate in order to better predict high-temperature deformation behavior in metals. The expression for the revised Z–A model is as follows:

In Equation (19), represents the flow stress; ε denotes the equivalent elastic strain; , where is the equivalent strain rate corresponding to strain rate and reference strain rate ; , where T* signifies dimensionless deformation temperature while T and Tref are the instantaneous temperature and reference temperature, respectively; C1, C2, C3, C4, C5, C6, and N are material constants with C1, C2 and N representing terms related to strain hardening; strain hardening terms C3 and C4 indicate softening terms; and C5 and C6 comprise terms associated with strain rates.

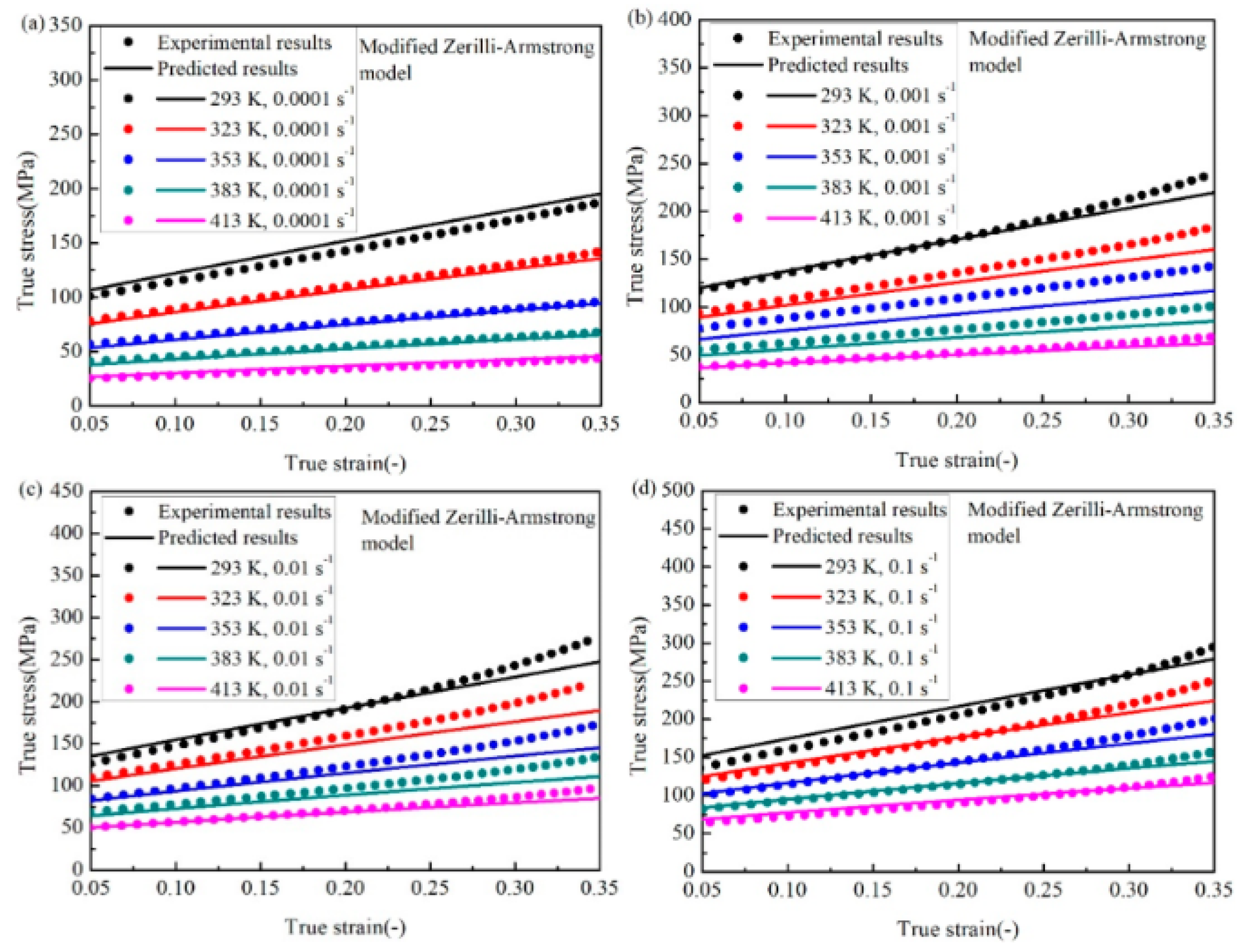

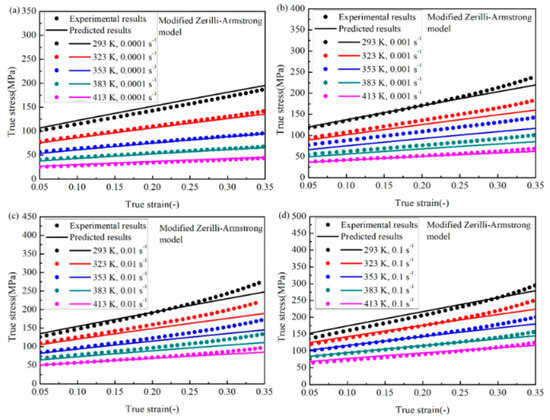

Liu et al. [66] calculated the rheological stress of C-276 Hastelloy alloy based on Equation (19). Their research findings demonstrated that the modified Z–A model can accurately predict the high-temperature deformation behavior of Hastelloy alloy. Murugesan et al. [67] and Lewis et al. [68] employed an improved Z–A model to forecast the hot deformation behavior of carbon steel and 625 alloy in AISI-1045, achieving relatively accurate results. This indicates that the Z–A model possesses significant advantages in describing the mechanical behavior of materials at high strain rates. The research conducted by Li et al. [69] revealed that, under conditions of high strain, the improved Z–A model exhibits a larger error in predicting the flow stress of SnSbCu alloy compared to low strain scenarios, suggesting certain limitations of the model at elevated strains; the result is shown in Figure 6.

Figure 6.

Comparison of the experimental data with the predictions made by the modified Z–A model at various strain rates: (a) 0.0001 s−1, (b) 0.001 s−1, (c) 0.01 s−1, and (d) 0.1 s−1 [69].

Shokry [70], Singh et al. [71], and Yu et al. [72] also utilized an enhanced Z–A model to predict the hot deformation behavior across various alloys; however, their prediction outcomes were not optimal.

In summary, while the expression for the Z–A model is relatively straightforward with commendable computational efficiency and accuracy, its primary characteristic lies in having distinct expressions tailored for different structural types due to varying strain rate control mechanisms inherent to specific structures. The Z–A model takes into account how crystal structure influences material mechanical properties. The improved version demonstrates high predictive accuracy and is applicable to most metallic materials such as Hastelloy, AISI-1045 medium carbon steel, and 625 high-temperature alloys. Nonetheless, determining material constants remains time-consuming and challenging; additionally, there are notable limitations when predicting flow stress under conditions of high strain.

3.5. Machine Learning-Based Constitutive Model

Advanced machine learning models encompass Support Vector Regression (SVR), Artificial Neural Networks (ANNs), Generalized Regression Neural Networks (GRNNs), and Random Forests (RFs). Zhou et al. [73] developed constitutive relationship models for the Ti2041 alloy under high-temperature conditions utilizing BP neural network frameworks. The findings indicated that the BP neural network model exhibits a high level of prediction accuracy, effectively forecasting the rheological stress of materials across a broad spectrum of temperatures and strain rates. Numerous researchers have employed genetic algorithms or particle swarm optimization techniques to enhance the initial weights and thresholds of BP neural networks, thereby improving the predictive performance and reliability of the optimized networks [74,75]. Ling et al. [76] investigated the hot deformation behavior of Fe2Ni2CrAl1.2 multi-element alloy through machine learning models, revealing that the PSO-SVR model demonstrated superior predictive capabilities; it adeptly captures and forecasts metal flow behavior at specified temperatures and strain rates. By leveraging trained machine learning models alongside relevant thermal processing maps, there is significant potential to enhance the accuracy in identifying optimal processing conditions. Through precise control over processing parameters, desired material properties and microstructures can be attained, offering promising advancements in material processing.

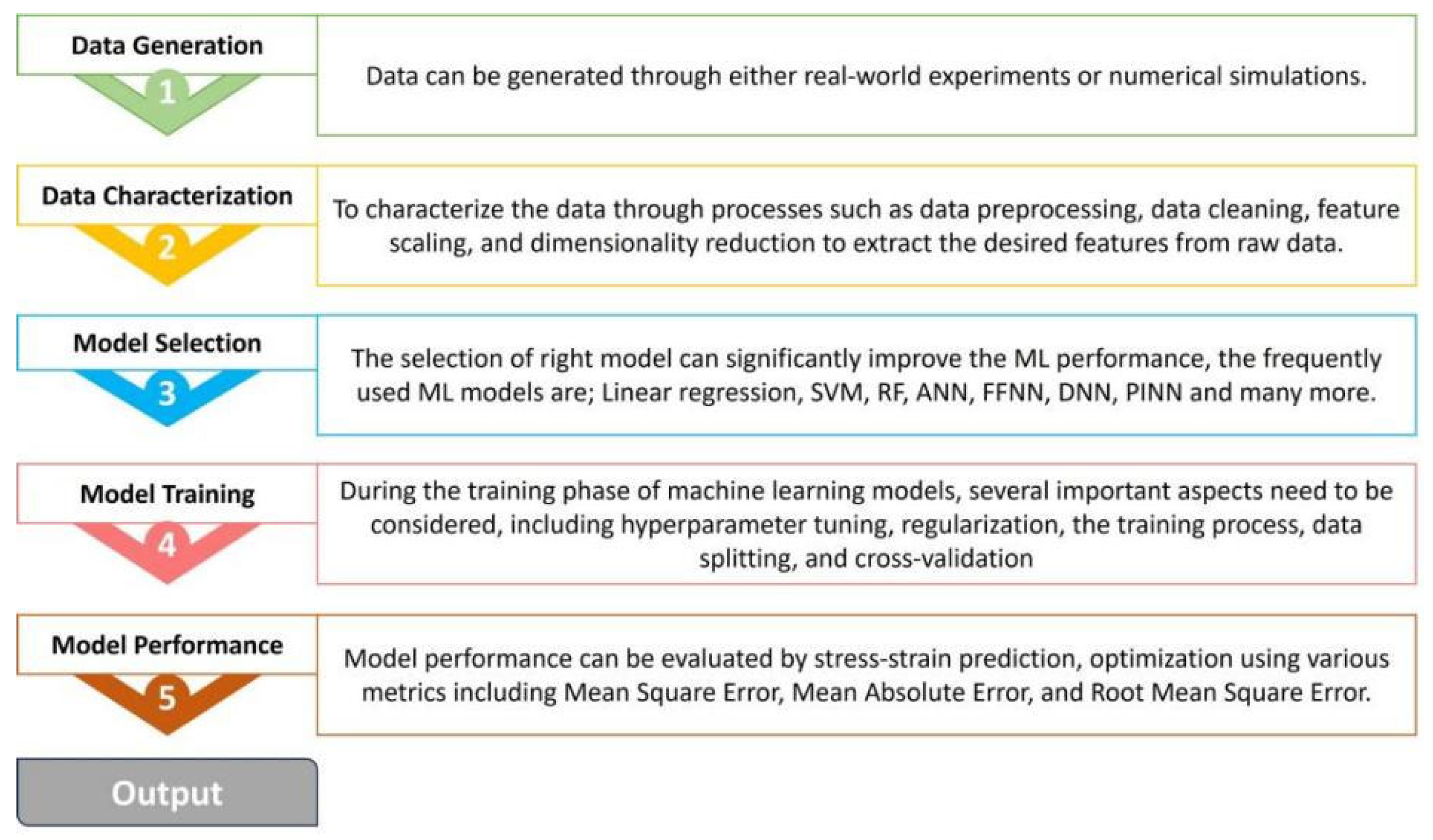

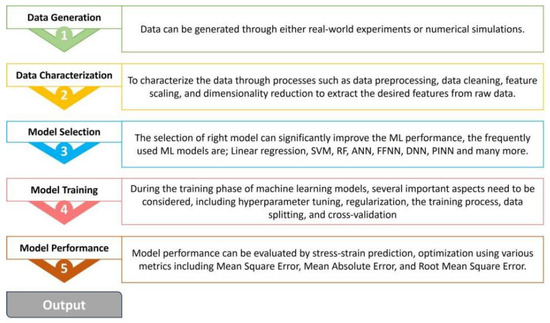

Emami et al. [77] proposed a Stacking Learning (SML) model that integrates various distinct base learners and meta-modeling strategies. This approach effectively captures complex nonlinear interactions, mitigates overfitting, and accurately predicts the flow behavior of Ti-Nb microalloyed steel during hot torsion deformation. Hussain et al. [78] provided a comprehensive overview of the developmental steps involved in creating a machine learning-based constitutive model, as illustrated in Figure 7. The initial step in data generation primarily involves acquiring the experimental data sample set necessary for constructing machine learning constitutive models through various methods, including experiments (such as hot stretching and hot compression), numerical simulations, or a combination of these techniques. The second step entails data cleaning, which aims to eliminate extraneous information from the original dataset to extract relevant features. This process aids in reducing the complexity of the dataset when investigating high-dimensional materials or three-dimensional problems. The third step is selecting an appropriate machine learning model based on whether the problem involves regression, classification, or clustering, as well as considering data types and underlying physical principles. Models commonly employed for analyzing the high-temperature rheological behavior of metallic materials typically include Artificial Neural Networks (ANNs), Tensor-Basis Neural Networks (TBNNs), Symmetric Positive Definite Neural Networks (SPD-NNs), Feedforward Neural Networks (FFNNs), and Balanced Basis Convolutional Neural Networks (ECNNs), among others. In the fourth step, the training of the model occurs by randomly partitioning the processed dataset into training samples, testing samples, and validation samples before proceeding with training the selected machine learning model. The fifth step involves evaluating parameters such as Mean Square Error (MSE), Root Mean Square Error (RMSE), correlation coefficient, and training and validation loss, along with stress–strain prediction curves to assess both the stability and accuracy of the pre-trained machine learning constitutive model in predicting high-temperature flow stress within metallic materials.

Figure 7.

Development steps of machine learning-based constitutive model [78].

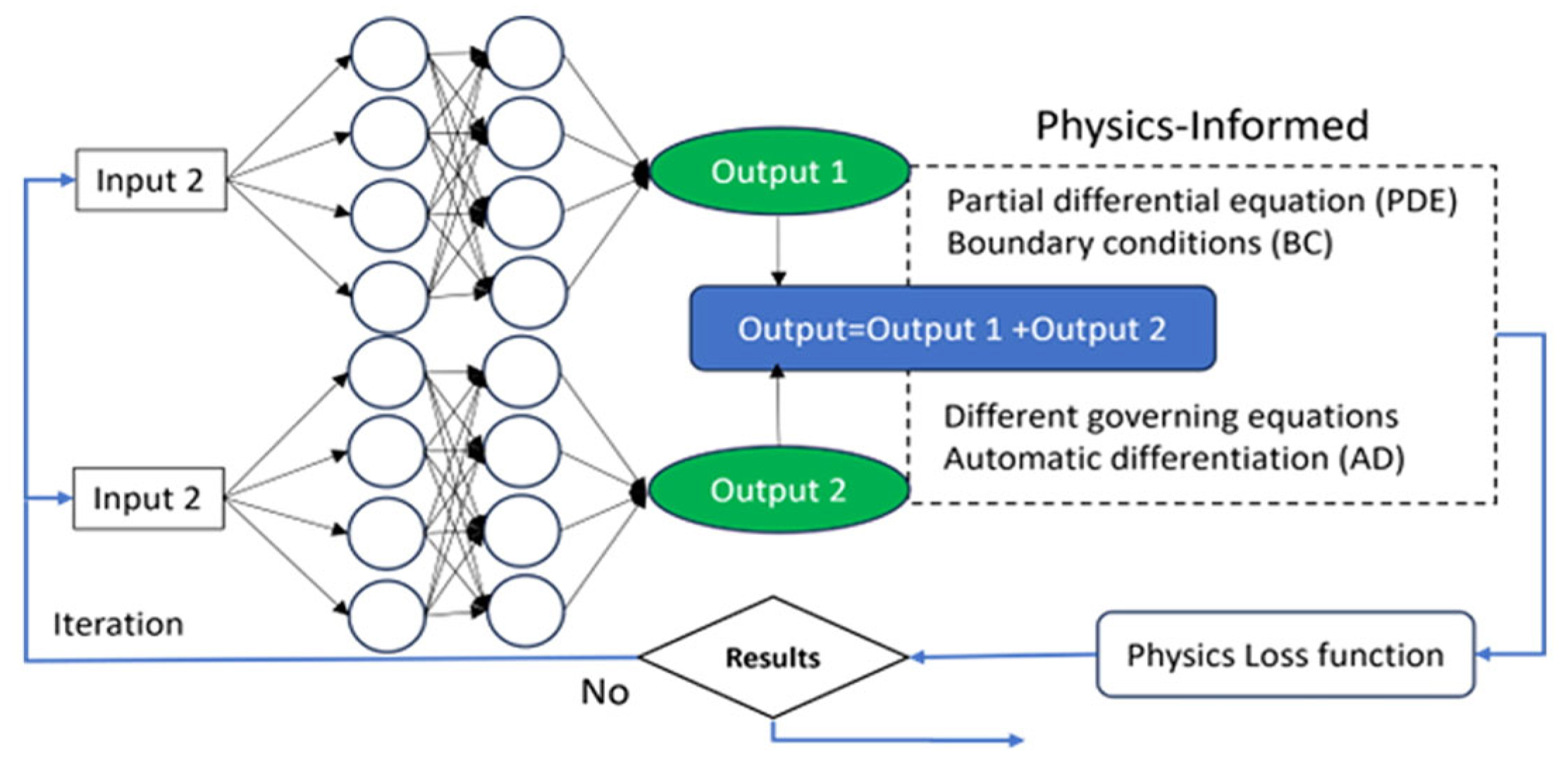

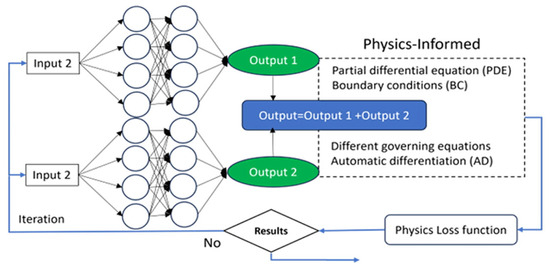

The Physical Information Neural Network (PINN) model represents a sophisticated machine learning approach that enhances model performance by addressing various challenges with greater precision while improving material modeling applicability. It integrates fundamental physical laws with engineering design knowledge alongside neural network training processes, as illustrated in Figure 8. This methodology proves effective for material modeling applications. In recent years, significant advancements in Physics-Informed Neural Networks (PINNs) have been achieved within the realm of computational mechanics. These developments include predicting the fatigue life of additively manufactured AlSi10Mg alloy [79], structural optimization [80], and the reverse engineering of structural problems [81].

Figure 8.

The schematic of machine learning-based constitutive model (PINN) [78].

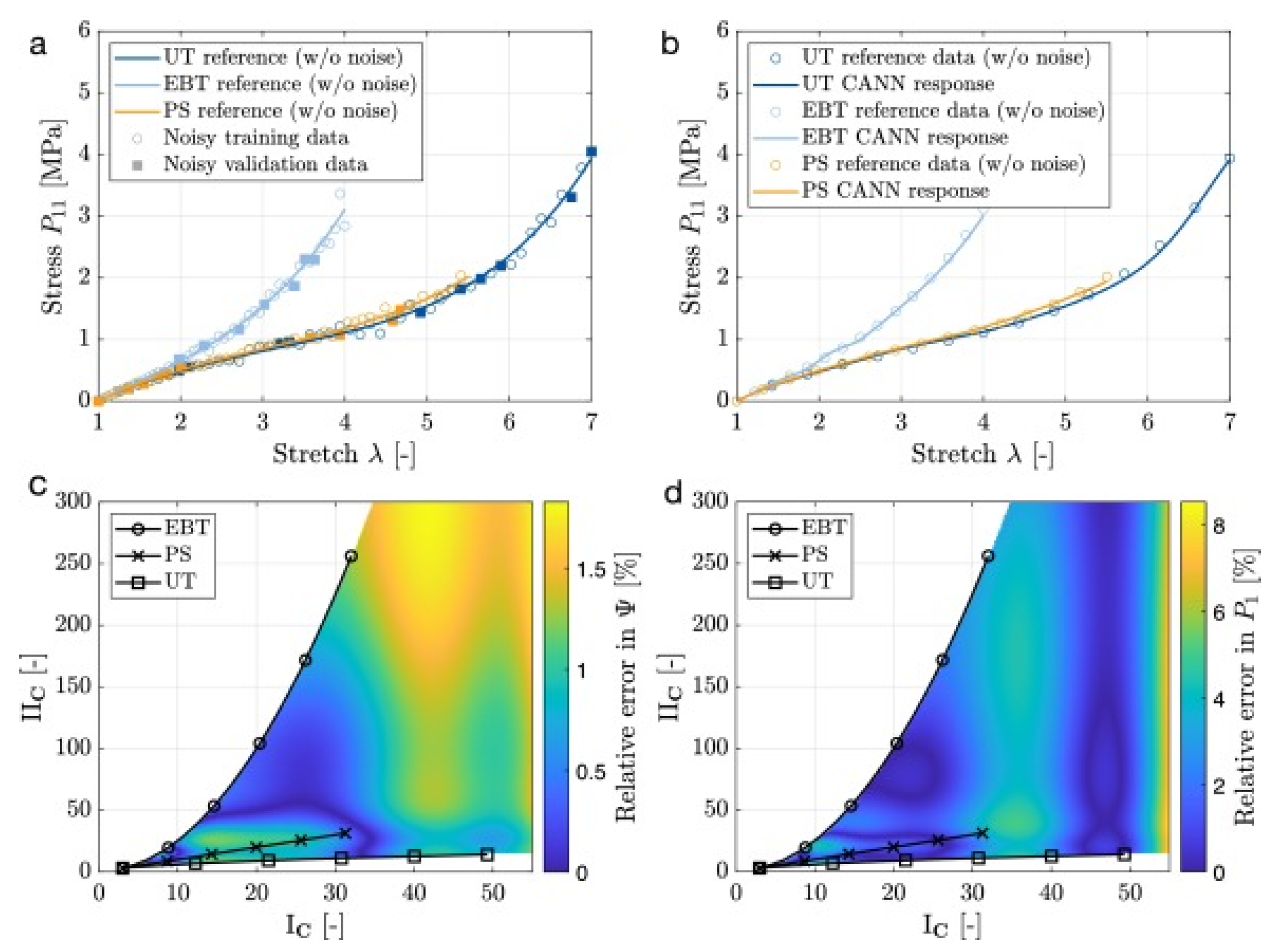

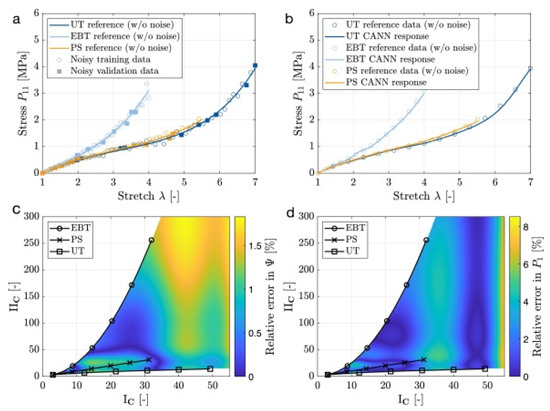

Linka et al. [82] introduced an innovative machine learning architecture for the data-driven modeling of material mechanical constitutive behavior. This approach integrates stress–strain test data with theoretical insights from materials science, along with various supplementary information such as microstructure and material processing details. The comparison between prediction value using machine learning and experimental results is shown in Figure 9b.

Figure 9.

Fifty data points per load case polluted with Gaussian noise: (a) Training data (symbols) generated with generalized Mooney–Rivlin model (solid lines); (b) constitutive behavior of trained CANN (solid lines) and corresponding validation data (symbols); (c,d) difference between generalized Mooney–Rivlin model from which CANN training data were generated and trained CANN across the whole IC-IIC invariant plane with respect to strain energy and nominal stress. The abbreviations uniaxial tension (UT), equi-biaxial tension (EBT), and pure shear (PS) are used in the figure legends [82].

Research has demonstrated that it is feasible to learn the constitutive behavior of complex nonlinear and anisotropic materials in an unsupervised manner using minimal to moderate training data and time. Utilizing stress–strain data obtained by Shoghi et al. [83] under 300 multiaxial loading conditions, alongside stress and plastic strain components simulated through crystal plasticity finite element methods, a plastic constitutive model for polycrystalline metals was developed via machine learning. This model not only characterizes initial yield behavior but also accurately describes flow stress under plastic deformation. Long et al. [84] formulated an Arrhenius-type model based on machine learning techniques, employing genetic algorithms, particle swarm optimization algorithms, and Artificial Neural Networks to investigate the hot deformation behavior of AQ80 alloy. The findings indicated that the PSO-ANN-AT model exhibited exceptional prediction accuracy and generalization capability, significantly enhancing its predictive performance.

In summary, constructing a constitutive model for metallic materials utilizing machine learning adheres to fundamental physical laws and principles while eschewing reliance on pre-existing constitutive models or physical laws. The primary advantage of this methodology lies in its independence from any prior mathematical models. It is grounded in a substantial body of experimental data and microscopic mechanical simulations to understand material behavior, allowing for the derivation of conclusions and the summarization of patterns from incomplete or extraneous information. Consequently, it is imperative to provide adequate and representative data inputs into machine learning algorithms to enable the generated models to accurately predict complex material behaviors under unknown conditions. In comparison with traditional constitutive models, machine learning-based constitutive models directly simulate the relationship between rheological stress and primary deformation parameters, thereby eliminating implicit influencing factors and demonstrating greater stability. These models exhibit superior predictive performance for metal flow stress, enhanced prediction accuracy, and reduced computational time.

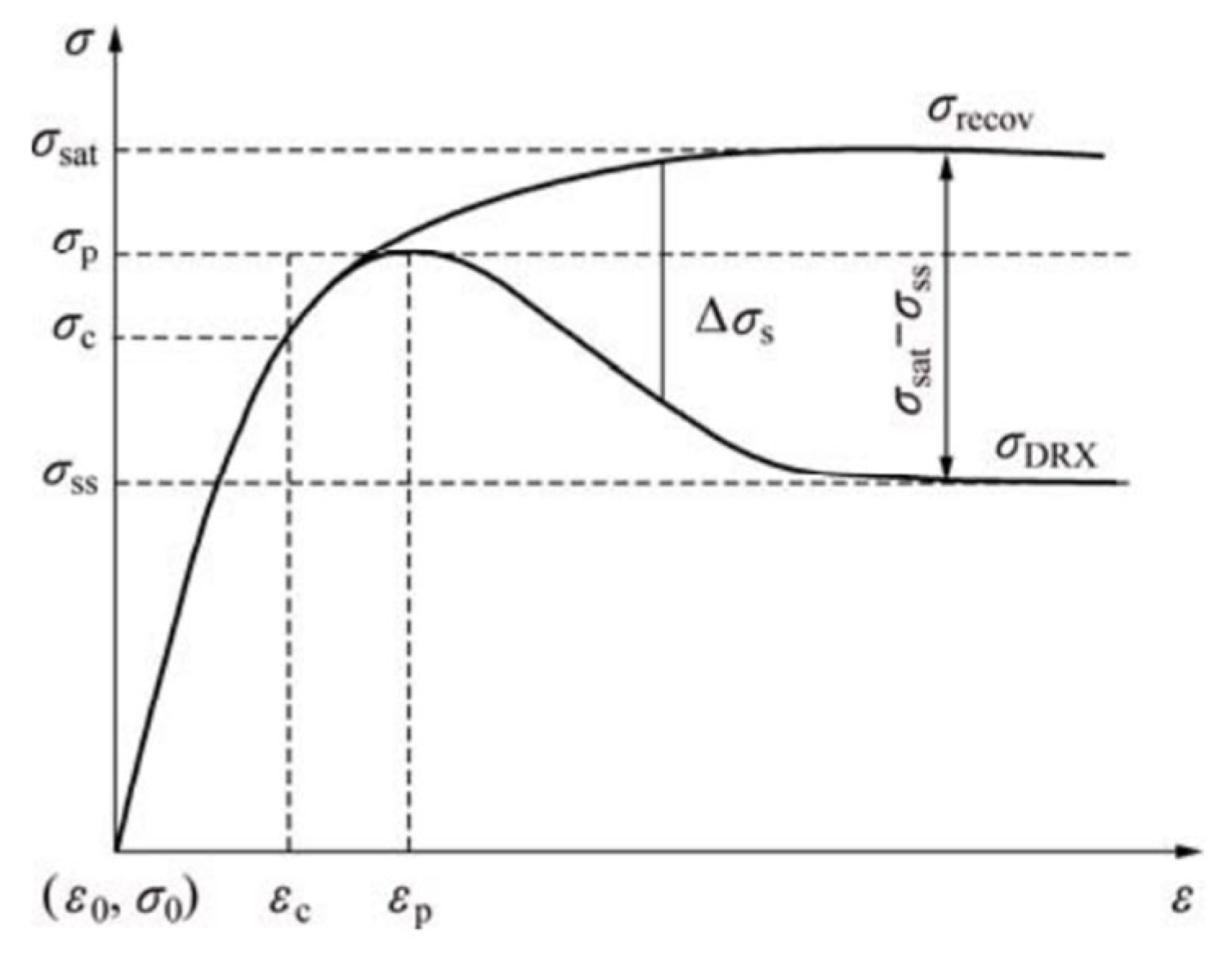

3.6. A Constitutive Model Based on Dynamic Response and Dynamic Recrystallization Mechanisms

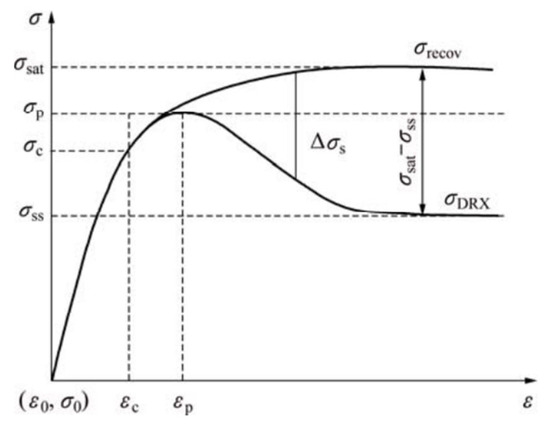

Beyond the aforementioned constitutive models, numerous researchers have explored various rheological softening mechanisms informed by dislocation density and dynamic analysis. This includes constitutive models under both dynamic recovery (DRV) and dynamic recrystallization (DRX). Figure 10 illustrates a typical curve representing both dynamic recovery and dynamic recrystallization processes. It is evident that, during high-temperature deformation, work hardening, dynamic recovery, dynamic recrystallization, and other forms of dynamic softening exert distinct influences on variations within rheological curves [85]. The rheological curve corresponding to deformation without undergoing dynamic recrystallization reflects a type that is characteristic of dynamic recovery; conversely, when deformation involves dynamic recrystallization, it manifests as a type indicative of dynamic recrystallization.

Figure 10.

Schematic illustration of typical true stress–true strain curves, showing the characteristic behaviors for materials undergoing dynamic recovery (DRV) only, versus those undergoing dynamic recrystallization (DRX) [86].

3.6.1. A Constitutive Model Based on Dislocation Recovery Velocity Mechanism

By introducing dislocation density to describe work hardening and dynamic recovery in materials, it is observed that, during the work hardening stage, dislocations continuously generate and accumulate, resulting in a significant increase in deformation resistance. Conversely, during the dynamic recovery phase, dislocations gradually decrease in number, leading to a slower rise in stress levels. The function representing dislocation density is primarily related to strain; thus, we present it as follows [87]:

In Equation (20), symbolizes dislocation density function; h serves as a work hardening parameter, indicating that the dislocation density increases due to work hardening effects; and r acts as a softening coefficient, reflecting that dislocation density diminishes due to softening processes.

The work hardening curve can be mathematically represented by Equation (21):

In Equation (21), σ denotes the rheological stress; σsat represents the steady-state stress; σ0 indicates the yield stress; r is the dynamic recovery parameter; serves as the dependent variable.

For constitutive models that are based on dynamic response, the Arrhenius equation incorporating Z–H parameters can effectively describe their rheological behavior. The mathematical expression of Z–H parameters is presented in Equation (22):

In scenarios where the DRV softening mechanism is applicable, changes in flow stress with respect to strain are relatively minor, allowing for flow stress to be approximated by σsat. Consequently, the original Arrhenius equation transforms into Equation (23):

By employing identical calculation and processing methodologies as those used for the Arrhenius equation, we derive Equation (24):

Substituting Equation (25) into Equation (21) yields a final constitutive model grounded in the DRV softening mechanism.

3.6.2. A Constitutive Model Based on Dynamic Recrystallization Mechanism

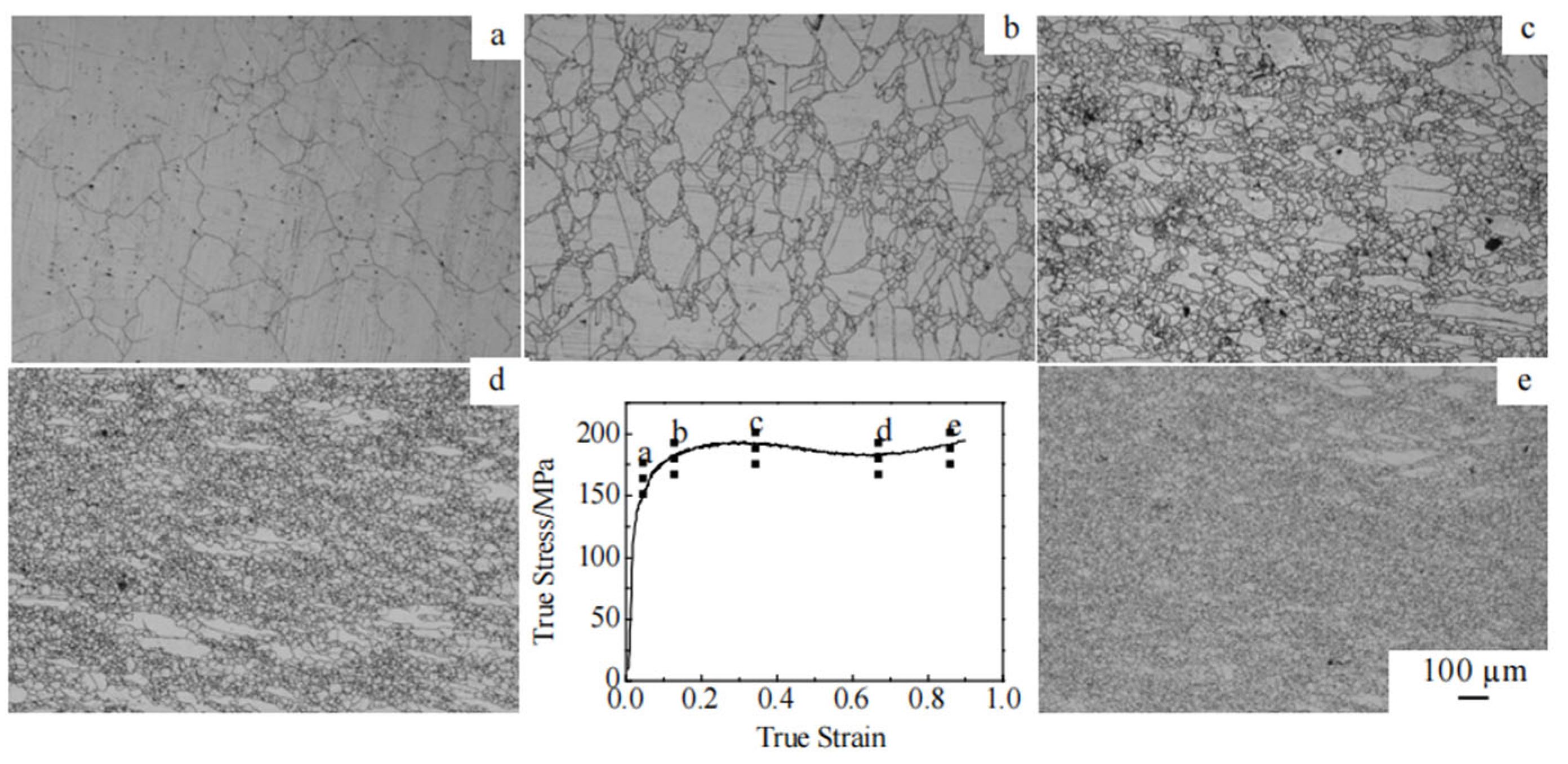

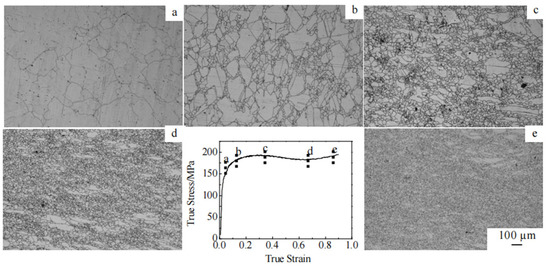

During the deformation process, as strain increases, the internal structure of the material undergoes continuous changes, as illustrated in Figure 11.

Figure 11.

The true stress–strain curve and microstructure at points a to e on the corresponding curve of 690 alloy when deformed at a strain rate of 1 s−1 at 1150 °C [88].

When strain reaches a critical value, dynamic recrystallization initiates. This phenomenon is more likely to occur at elevated temperatures and low strain rates. The dynamic recrystallization fraction can be expressed as follows [89]:

In Equation (26), represents the dynamic recrystallization fraction, σsat denotes saturation stress, and σss indicates the steady-state stress under conditions of dynamic recrystallization.

According to the kinetics of dynamic recrystallization, this fraction can also be expressed as [90]

In Equation (27), again signifies the dynamic recrystallization fraction, k1 and k2 are material constants, εp refers to peak strain, and εc denotes critical strain. To determine the material constant k1 and k2, we take logarithms on both sides of Equation (27):

The values of k1 and k2 can be obtained from the fitted curve ln [ln (1 − )] − ln.

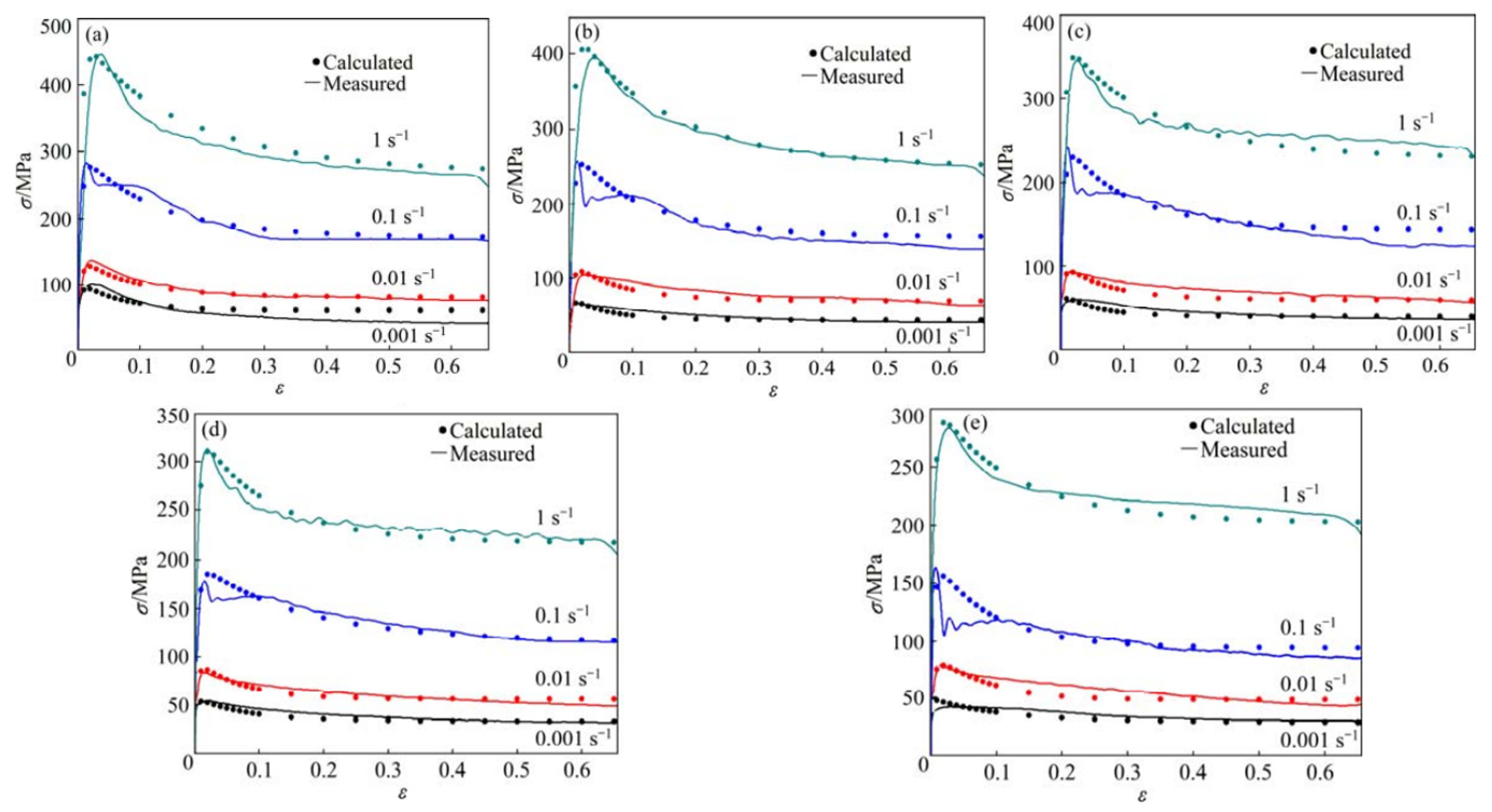

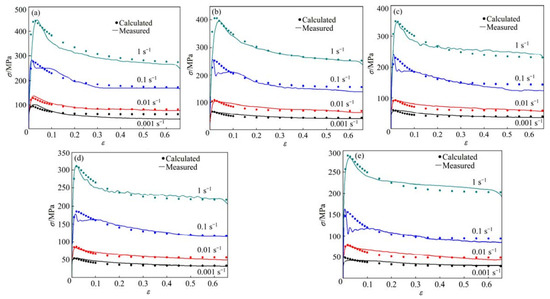

Sun et al. [86] developed a constitutive model for the Ti-22Al-25Nb alloy utilizing the aforementioned methodology, demonstrating that the predicted stress values aligned closely with those obtained from experimental data, as shown in Figure 12.

Figure 12.

Comparison of calculated and measured σ−ε curves at various temperatures: (a) 995 °C; (b) 1015 °C; (c) 1035 °C; (d) 1055 °C; (e) 1075 °C [86].

Similarly, Huang et al. [91] arrived at comparable conclusions while investigating high-temperature deformation constitutive models for CuCrZr alloy and 35 CrMo steel, based on the effects of dynamic recrystallization softening. Jiang et al. [92] proposed a unified constitutive model that accounts for the sensitivity of dislocation density to deformation conditions in order to characterize the evolution of flow stress, grain size, and dynamic recrystallization fraction in Ti-55511 alloy. The findings indicated that this established constitutive model exhibits exceptional predictive capability. In addition to the previously mentioned models, numerous researchers have formulated constitutive models that elucidate intrinsic relationships between parameters governing dynamic recrystallization behavior and primary process variables. Notable examples include the Sellars model [93,94], Yada model [95], Kim model [96], Kopp model [97], and Hensel–Spitzel model [98], among others. Given the diversity and complexity inherent in these models, this study selectively discusses and summarizes only a subset of them.

In summary, constitutive models grounded in mechanisms of dynamic recovery and dynamic recrystallization effectively consider rheological behavior as comprising two distinct phases: strain hardening prior to peak stress and strain softening following peak stress. Subsequently, a work hardening framework based on dislocation density is integrated with a phenomenological softening approach to characterize thermal deformation behaviors exhibited by metallic materials. This comprehensive modeling strategy incorporates typical microstructural characteristics alongside deformation mechanisms and macroscopic mechanical properties. While establishing such models can be relatively complex, they are characterized by high prediction accuracy. Exploring more efficient methods for determining model parameters and characterizing the microstructural features of materials remains a critical and challenging area of research.

3.7. Creep Behavior Model of High-Temperature Mechanical Properties

Creep refers to the time-dependent slow plastic deformation of metallic materials at elevated temperatures and below their yield limit stress. Excessive high-temperature creep deformation or premature creep fracture are primary failure modes for these materials [99]. Therefore, investigating the high-temperature mechanical properties and creep deformation behavior of metals holds significant importance. Research on creep primarily focuses on understanding how various mechanisms and metallurgical factors influence creep properties, as well as enhancing these properties through microstructural optimization and trace element addition. By analyzing creep laws derived from test curves, researchers study how factors such as creep stress, strain, temperature, and time affect metal material behavior under creeping conditions. Appropriate constitutive models are developed for different materials to accurately describe and analyze the three stages of creep: deceleration stage, steady-state stage, and accelerated stage [100,101,102,103]. The investigation into material properties related to creep typically employs methods such as Monkman Grant equations [104], Manson–Haferd (MH) method [105], Larson–Miller equation [106], and persistent strength method [107] to assess both creep’s characteristics and fracture life. In practical engineering applications, particular emphasis is placed on the steady-state creep stage; this phase serves as a critical approach for determining material lifespan under creeping conditions. The relationship between steady-state creep rate, applied stress during creeping processes, and temperature in metallic materials at high temperatures adheres to a power-law constitutive equation [108,109], with its calculation expressed by the following formula:

In Equation (29), denotes the steady-state creep rate; A represents a material-specific constant; σ indicates creeping stress; N is defined as the apparent stress index; Q signifies apparent activation energy for creep; R stands for gas constant; and T refers to thermodynamic temperature. Based on variations in n’s value, insights into high-temperature creep mechanisms in metals can be inferred [110,111,112]: when n equals 1, material deformation primarily occurs through diffusion control; when n equals 2, grain boundary slip predominantly drives creeping behavior; when n equals 3, dislocation slip becomes relevant to creeping processes; when n ranges between 4 and 6, dislocation climb plays a significant role in governing creepage dynamics; when the value of n exceeds 7, it is generally accepted that the power-law formula becomes invalid [113]. Consequently, relying solely on the apparent stress index is insufficient for determining the creep mechanism of alloys.

Research conducted by Maximov et al. [114] demonstrates that employing a power-law creep constitutive equation can effectively predict the high-temperature steady-state creep behavior of 2024-T3 aluminum alloy. Wilshir et al. [115] observed that, as the temperature during creep testing increased from 100 °C to 190 °C, 7010 aluminum alloy exhibited failure consistent with a power-law formula. Lin et al. [116] developed a creep constitutive model for 7075 aluminum alloy by integrating both power-law formulations and θ function methodologies. The occurrence of power-law failure within materials not only restricts the applicability of conventional creep equations but also complicates their resolution.

In summary, the creep constitutive model primarily investigates the deformation characteristics and mechanisms of high-strength aluminum alloys, stainless steel, and other metallic materials across three stages of creep.

4. Characteristics and Applications of Constitutive Models

The formulation and experimental design for phenomenological constitutive models are generally simpler than those required for physically based models. A well-developed phenomenological constitutive model can effectively predict thermal deformation behavior in metallic materials. However, these models may have limitations in accurately characterizing micro-deformation mechanisms within metals; their accuracy is largely dependent on the availability of experimental data and empirical experience. In contrast, physically based models can characterize deformation mechanisms in metallic materials by considering aspects of microstructural evolution such as grain size, dislocation density, dynamic recrystallization rate, and crack volume fraction at a microscopic level. These physical-basis models exhibit reduced reliance on extensive experimental data; however, their performance is significantly influenced by key deformation parameters. The microstructural evolution of various metal materials under different deformation environments is complex and variable; thus, a specific physical model may only be applicable to certain deformation modes corresponding to particular materials.

A well-trained constitutive model based on machine learning can accurately predict the high-temperature mechanical behavior of metallic materials with a broad range of applications. Compared to classical constitutive models, machine learning-based constitutive models do not necessitate the construction of mathematical frameworks and offer significant advantages in predicting hardening, softening, and creep behaviors during various stages of deformation. However, the stability and robustness of machine learning constitutive models are significantly influenced by the choice of machine learning algorithms, the quality of training data, and the characteristics of sample datasets. Furthermore, these models exhibit limitations in predicting deformations that fall outside their training data range. To enhance the accuracy in characterizing the physical deformation mechanisms of metallic materials, it is beneficial to integrate fundamental physical constitutive models, phenomenological constitutive models, and advanced machine learning algorithms. The utilization of machine learning models is constrained by their current complexity, which poses challenges for finite element integration. The applications and primary characteristics of various constitutive models for metal materials are summarized in Table 1.

Table 1.

A summary of important constitutive models for metal materials.

5. Conclusions

In recent years, the rapid advancement of intelligent manufacturing technology has led to heightened demands for the forming quality and surface processing accuracy of components in industries such as aerospace and automotive. This necessitates a comprehensive understanding of the high-temperature deformation behavior of metal materials. Employing methods such as high-temperature tensile tests, high-temperature compression tests, and metallographic examinations is essential to ascertain the high-temperature deformation characteristics of these materials. Establishing a constitutive relationship among deformation temperature, strain rate, strain, microstructure, and flow stress represents a crucial approach to characterizing the rheological behavior of materials. Consequently, to gain a clearer insight into classical constitutive models and their evolution, we propose the following recommendations:

(1) Numerous researchers have demonstrated that developing constitutive models based on Artificial Neural Networks or deep learning can accurately predict rheological stress during the hot deformation process of metallic materials with minimal prediction errors. However, further investigation is required on how to seamlessly integrate these Artificial Neural Network-based constitutive models with numerical simulation software for metal material forming such as Abaqus, Ansys, and DEFORM to forecast variations in stress, strain, strain rate, and temperature throughout the part forming process. This integration aims to optimize process parameters while mitigating potential defects.

(2) Existing physical constitutive models account for typical mechanisms such as work hardening, dynamic recovery, dynamic recrystallization, and softening during their formulation; however, other influencing factors, including grain size variation, phase content changes, and microstructural morphology, have not been comprehensively addressed. Therefore, based on the aforementioned influencing factors, it is imperative to conduct further research and expansion of the constitutive model. Additionally, in order to address the prediction errors associated with the constitutive model, it is essential to investigate the underlying causes of these errors under specific deformation conditions and to establish a comprehensive understanding of how friction and deformation heat impact the constitutive model.

(3) There exists relatively limited research concerning the constitutive models of metal materials post-heat treatment. In reference [117], a study was conducted on the complex rheological behavior of 6061 aluminum alloy cold-rolled plates during stretching under various heat treatment process parameters utilizing Artificial Neural Network modeling standards. However, this investigation did not explore the intricate relationships between different heat treatment parameters—such as heating temperature, holding time, and cooling method and their corresponding Johnson–Cook constitutive model parameters—nor was an explicit functional expression established linking heat treatment process parameters with mechanical property characteristics.

Author Contributions

Writing—original draft preparation, conceptualization, T.H. (Tengjiao Hong); formal analysis and data curation, D.H. (Dong Huang); software, writing—review and editing, and funding acquisition, F.D. (Fengjuan Ding); visualization and project administration, T.H. (Tengjiao Hong); visualization and methodology project administration, F.D. (Fulong Dong); investigation and supervision, D.H. (Dong Huang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Talent Introduction Project of Anhui Science and Technology University (RCYJ202105); Design and Key Technology Research of Multi-parameter Intelligent Control Instrument Junction Box (tzy202218); Natural Science Research Project of Higher Education Institutions in Anhui Province (2024AH050296); Research and Development of Fermentation Feed Drying Automatic Line (881314); Anhui Provincial Key Laboratory of Functional Agriculture and Functional Food, Anhui Science and Technology University (iFAST-2024-6); and Key technologies and applications of impinging stream based plant protection hedge spray system (2024AH050318).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data, models, and code generated or used during the study appear in the submitted article.

Acknowledgments

We would like to express our deepest gratitude to the authors of the references cited in the article for providing us with writing inspiration.

Conflicts of Interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as potential conflicts of interest.

References

- Wang, Z.; Wang, L.; Zhang, S.; Liu, X.; Xiang, Y.; Lin, Y.; Tan, J. Analytical springback modelling for thermal-mechanical bending of TA18 tube under non-isothermal loading. Appl. Math. Model. 2025, 143, 115964. [Google Scholar] [CrossRef]

- Wang, R.; Huang, J.; Tian, Z.; Bai, Z.; Li, S.; Ji, X.; Zhao, Z.; Sun, C. Study on deformation behaviour of TA2/Q345R composite plate during heat treatment process. Int. J. Mater. Form. 2024, 17, 36. [Google Scholar] [CrossRef]

- Fan, X.; Han, X.; Hu, X.; Hua, L.; Zhuang, W.; Zhang, J.; Chai, F. Microstructure and mechanical property anisotropy behaviors of AA7075 cylindrical ring processed by hot forging. J. Alloys Compd. 2025, 1016, 178865. [Google Scholar] [CrossRef]

- Iwona, B.; Dariusz, K. The Influence of the Deformation Method on the Microstructure and Properties of Magnesium Alloy Mg-Y-RE-Zr. Materials 2022, 15, 2017. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Tang, H.; Liu, T.; Li, Z.; Jiang, H.; Wang, K.; Ebrahimi, M.; Ding, W. Hot deformation constitutive model and processing maps of homogenized Al-5Mg-3Zn-1Cu alloy. J. Mater. Res. Technol. 2021, 14, 324–339. [Google Scholar] [CrossRef]

- Jia, X.D.; Yuan, R.J.; He, L.Y.; Cao, M.Y.; Wang, R.; Zhao, C.C. Plastic Deformation Behavior of 5A02 Aluminum Alloy Sheet at High Temperature. Rare Met. Mater. Eng. 2020, 49, 7. [Google Scholar]

- Ma, L.X.; He, D.Y.; Yang, B.J.; Han, X.Q.; Zhang, J.C.; Li, W.D. Construction and application of a physically-based constitutive model for superplastic deformation of near-α TNW700 titanium alloy. J. Mater. Res. Technol. 2025, 34, 2071–2089. [Google Scholar] [CrossRef]

- Zhong, M.J.; Yu, H.; Wang, Z.R.; Zhang, X.M.; Qu, J.L. Hot deformation behavior and process parameters optimization of GH4738 nickel-based superalloy. J. Mater. Res. Technol. 2024, 33, 7990–8001. [Google Scholar] [CrossRef]

- Luo, Y.W.; Shi, C.B.; Xu, H.C. Microstructure evolution and hot deformation characteristics of 15Cr-22Ni iron-base superalloy. J. Alloys Compd. 2023, 938, 168628. [Google Scholar] [CrossRef]

- Zhang, H.; Lin, Y.C.; Su, G.; Xie, Y.; Qiu, W.; Zeng, N.; Zhang, S.; Wu, G. Hot deformation physical mechanisms and a unified constitutive model of a solid solution Ti55511 alloy deformed in the two-phase region. J. Mater. Res. Technol. 2025, 34, 1591–1610. [Google Scholar] [CrossRef]

- Chen, X.M.; Ning, M.T.; Hu, H.W.; Lin, Y.C.; Zhou, X.J.; Zhang, J.; Chen, J.; Liu, Y.X. Characterization of hot deformation behavior and optimization of hot workability for GH4698 superalloy. Mater. Charact. 2023, 201, 112916. [Google Scholar] [CrossRef]

- Zhang, F.; Shen, J.; Yan, X.D. Constitutive Analysis to Predict High-Temperature Flow Stress in 2099 Al-Li Alloy. Rare Met. Mater. Eng. 2014, 43, 1312–1318. [Google Scholar]

- Liu, L.J.; Lv, M.; Wu, W.G. Recrystallization Softening Effect in the Improved Constitutive Equation for TI-6AL-4V Alloy. Rare Met. Mater. Eng. 2014, 43, 1367–1371. [Google Scholar]

- Zhang, T.; Zhang, S.H.; Li, L.; Lu, S.H.; Gong, H. Modified constitutive model and workability of 7055 aluminium alloy in hot plastic compression. J. Cent. South Univ. 2019, 26, 2930–2942. [Google Scholar] [CrossRef]

- Wang, N.; Andrey, I.; Chen, M.H.; Lucky, G.; D’Amours, G. Comparative Study on Constitutive Models for Flow Behavior of High Strength Aluminum Alloy AA7075 in Hot Stamping. Rare Met. Mater. Eng. 2020, 49, 10–20. [Google Scholar]

- Zhou, M.; Clode, M.P. Hot torsion tests to model the deformation behavior of aluminium alloys at hot working temperatures. J. Mater. Process. Technol. 1977, 72, 78. [Google Scholar] [CrossRef]

- Sellars, C.M.; McTegart, W.J. On the mechanism of hot deformation. Acta Metall. 1966, 14, 1136. [Google Scholar] [CrossRef]

- Wang, M.H.; Yang, Y.C.; Tu, S.L.; Wei, K. A modified constitutive model and hot compression instability behavior of Cu-Ag alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 764–774. [Google Scholar] [CrossRef]

- Shan, S.L.; Jie, Z.; Meng, M.Z.; Zhou, Y.T.; Gong-Ye, F.J.; Long, S.; Dong, X.G.; Liang, Q. A comparative study at the flow behavior description of 2A14 alloy using BP-ANN and strain compensated Arrhenius model. Mater. Res. Express 2020, 6, 1265h1. [Google Scholar]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abedi, H.R. The flow behavior modeling of cast A356 aluminum alloy at elevated temperatures considering the effect of strain. Mater. Sci. Eng. A 2012, 535, 252–257. [Google Scholar] [CrossRef]

- Liu, S.H.; Pan, Q.L.; Li, H. Characterization of hot deformation behavior and constitutive modeling of Al-Mg-Si-Mn-Cr alloy. J. Mater. Sci. 2019, 54, 4366–4383. [Google Scholar] [CrossRef]

- Liu, L.; Wu, Y.X. Modification of constitutive model and evolution of activation energy on 2219 aluminum alloy during warm deformation process. Trans. Nonferrous Met. Soc. China 2019, 29, 448–459. [Google Scholar] [CrossRef]

- Quan, G.Z.; Zou, Z.Y.; Wang, T. Modeling the Hot Deformation Behaviors of As-Extruded 7075 Aluminum Alloy by an Artificial Neural Network with Back-Propagation Algorithm High Temperature. Mater. Process. 2017, 36, 1–13. [Google Scholar] [CrossRef]

- Xiang, Y.L.; Xiao, S.F.; Tang, Z.H. The flow behavior of homogenizated Al-Mg-Si-La aluminum alloy during hot deformation. Mater. Res. Express 2019, 6, 066563. [Google Scholar] [CrossRef]

- Li, Y.F.; Wang, Z.H.; Zhang, L.Y.; Luo, C.; Lai, X.C. Arrhenius-type constitutive model and dynamic recrystallization behavior of V-5Cr-5Ti alloy during hot compression. Trans. Nonferrous Met. Soc. China 2015, 25, 1889–1900. [Google Scholar] [CrossRef]

- Zhao, X.-H.; Liu, D.-D.; Wu, X.H.; Liu, G.R.; Chen, L. Flow behavior and constitutive description of 20CrMnTi steel at high temperature. J. Cent. South Univ. 2018, 25, 1013–1024. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.S.; Zhang, J. Modeling of flow stress of 42CrMo steel under hot compression. Mater. Sci. Eng. A 2009, 499, 88–92. [Google Scholar] [CrossRef]

- Chen, C.; Chen, M.H.; Xie, L.S.; Gong, Z.H. Flow Behavior of TA32 Titanium Alloy at High Temperature and Its Constitutive Model. Rare Met. Mater. Eng. 2019, 48, 827–834. (In Chinese) [Google Scholar]

- Jiang, F.; Liang, Y.F.; Hong, J.; Zhang, Y.; Feng, Z.; Zhao, S. Constitutive model research on the hot deformation behavior of Ti6Al4V alloy under wide temperatures. J. Mater. Res. Technol. 2023, 23, 1062–1074. [Google Scholar] [CrossRef]

- Cheng, X.; Wang, R.; Chen, X.; Jin, S.; Qian, Q.; Wu, H. An optimized strain-compensated arrhenius constitutive model of GH4169 superalloy based on hot compression. Materials 2024, 17, 3400. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Qin, G.L.; Li, C.A. A modified Arrhenius constitutive model of 2219-O aluminum alloy based on hot compression with simulation verification. J. Mater. Res. Technol. 2022, 19, 3302–3320. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Rasaee, S.; Mirzaei, A.H. Constitutive Modeling of 2024 Aluminum Alloy Based on the Johnson-Cook Model. Trans. Indian Inst. Met. 2019, 72, 1023–1030. [Google Scholar] [CrossRef]

- Bobbili, R.; Madhu, V. Constitutive Modeling of Hot Deformation Behavior of High-Strength Armor Steel. J. Mater. Eng. Perform. 2016, 25, 1829–1838. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M.; Liu, G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6986. [Google Scholar] [CrossRef]

- He, L.J.; Chen, F.; Wang, B.; Zhu, L.B. A modified Johnson-Cook model for 10% Cr steel at elevated temperatures and a wide range of strain rates. Mater. Sci. Eng. A 2018, 715, 1–9. [Google Scholar] [CrossRef]

- Liu, E.L.; Xing, H.W.; Wang, M.M.; Xu, Z.C.; Zhao, N. J-C constitutive modeling of high temperature alloys Inconel625. Chin. J. Nonferrous Met. 2018, 28, 732–741. (In Chinese) [Google Scholar]

- Hui, X.L.; Bai, C.Y.; Ge, Y.J.; Shu, W. Dynamic properties of 2A16 aluminum alloy under intermediate strain rate. J. Vib. Shock 2017, 36, 66–70. (In Chinese) [Google Scholar]

- Shokry, A.; Gowid, S.; Kharmanda, G. An improved generic Johnson-Cook model for the flow prediction of different categories of alloys at elevated temperatures and dynamic loading conditions. Mater. Today Commun. 2021, 27, 102296. [Google Scholar] [CrossRef]

- Jiang, X.; Ding, J.; Wang, C.; Liu, H. Parameter identification of Johnson-Cook constitutive model based on genetic algorithm and simulation analysis for 304 stainless steel. Sci. Rep. 2024, 14, 21221. [Google Scholar] [CrossRef]

- Nguyen, N.; Hosseini, A. Direct calculation of Johnson-Cook constitutive material parameters for oblique cutting operations. J. Manuf. Process. 2023, 92, 226–237. [Google Scholar] [CrossRef]

- Wang, Y.T.; Zeng, X.G.; Chen, H.Y.; Yang, X.; Wang, F.; Zeng, L.X. Modified Johnson-Cook constitutive model of metallic materials under a wide range of temperatures and strain rates. Results Phys. 2021, 27, 104498. [Google Scholar] [CrossRef]

- Shen, W.J.; Xue, F.M.; Li, C.Z.; Liu, Y.; Mo, X.Y. Study on constitutive relationship of 6061 aluminum alloy based on Johnson-Cook model. Mater. Today Commun. 2023, 37, 106982. [Google Scholar] [CrossRef]

- Chen, X.M.; Lin, Y.C.; Hu, H.W.; Luo, S.C.; Zhou, X.J.; Huang, Y. An Enhanced Johnson-Cook Model for Hot Compressed A356 Aluminum Alloy. Adv. Eng. Mater. 2020, 23, 2000704. [Google Scholar] [CrossRef]

- Lin, Y.; Chen, X. A combined Johnson-Cook and Zerilli-Armstrong model for hot compressed typical high-strength alloy steel. Comput. Mater. Sci. 2010, 49, 628–633. [Google Scholar] [CrossRef]

- Zhang, Z.; Lang, L.H.; Li, T.; Liu, H. Constitutive equations of high strength aluminum alloy sheet 7B04-T6 under warm tension. J. Beijing Univ. Aeronaut. Astronaut. 2009, 35, 600–603. [Google Scholar]

- Tong, Y.; Quan, Z.G.; Luo, G.; Zhou, J. A Study on the Flow Behavior of 42CrMo Steel under Hot Compression by Thermal Physical Simulations. Adv. Mater. Res. 2010, 933, 494–499. [Google Scholar] [CrossRef]

- Zhang, Z.; Deng, Y.L.; Guo, H.; Qian, P.C.; Tang, H.Y.; Ye, L.Y. Effect of strain rate on tenile properties of Al-Zn-Mg alloy. J. Funct. Mater. 2017, 48, 7215–7220. (In Chinese) [Google Scholar]

- Chang, L.; Zhou, C.-Y.; Peng, J.; Li, J.; He, X.H. Fields-Backofen and a Modified Johnson-Cook Model for CP-Ti at Ambient and Intermediate Temperature. Rare Met. Mater. Eng. 2017, 46, 1803–1809. [Google Scholar]

- Jiao, Z.H.; Lang, L.H.; Zhao, X.N. 5A06-O aluminium-magnesium alloy sheet warm hydroforming and optimization of process parameters. Trans. Nonferrous Met. Soc. China 2021, 31, 2939–2948. [Google Scholar] [CrossRef]

- Li, S.J.; Chen, W.N.; Jain, S.; Jung, D.; Lee, J. Optimization of flow behavior models by genetic algorithm: A case study of aluminum alloy. J. Mater. Res. Technol. 2024, 31, 3349–3363. [Google Scholar] [CrossRef]

- Huang, X.; Wang, B.; Zang, Y.; Ji, H.; Guan, B.; Li, Y.; Tang, X. Constitutive relationships of 21-4N heat-resistant steel for the hot forging process. J. Mater. Res. Technol. 2020, 9, 13575–13593. [Google Scholar] [CrossRef]

- Seshacharyulu, K.; Mahalle, G.; Kotkunde, N.; Singh, S.K.; Naik, B.B. Analysis of tensile deformation behaviour of dual phase-590 steel at different temperatures and strain rates. Mater. Process. Technol. 2022, 8, 1647–1663. [Google Scholar] [CrossRef]

- He, Z.B.; Wang, Z.B.; Lin, Y.L. Hot Deformation Behavior of a 2024 Aluminum Alloy Sheet and its Modeling by Fields-Backofen Model Considering Strain Rate Evolution. Metals 2019, 9, 243. [Google Scholar] [CrossRef]

- Ji, G.L.; Li, L.; Qin, L.F.; Li, Q. Comparative study of phenomenological constitutive equations for an as-rolled M50NiL steel during hot deformation. J. Alloys Compd. 2017, 695, 2389–2399. [Google Scholar] [CrossRef]

- Abdallah, S. Modified Fields-Backofen and Zerilli-Armstrong constitutive models to predict the hot deformation behavior in titanium-based alloys. Sci. Rep. 2024, 14, 8359. [Google Scholar]

- Zhou, W.H. Plastic Deformation Behaviors of Pre-Strained Aluminum Under High Strain Rate Loadings. Master’s Thesis, Nanchang Hangkong University, Nanchang, China, 2014. (In Chinese). [Google Scholar]

- Tsao, L.C.; Wu, H.Y.; Leong, J.C.; Fang, C.J. Flow stress behavior of commercial pure titanium sheet during warm tensile deformation. Mater. Des. 2012, 34, 179–184. [Google Scholar] [CrossRef]

- Lin, H.; Meng, F.Z.; Song, Y.L.; Liu, J.N.; Qin, X.P.; Suo, L.B. A constitutive model of 6111-T4 aluminum alloy sheet based on the warm tensile test. J. Mater. Eng. Perform. 2014, 23, 1107–1113. [Google Scholar]

- Chen, F.; Jia, Z.; Zhang, X.; Jiao, Y.; Li, F.; Zhang, X. Hot deformation behavior and comparison of different constitutive models of as-cast ER8 steel. Metall. Res. Technol. 2023, 120, 403. [Google Scholar] [CrossRef]

- Zerilli, F.J.; Armstrong, R.W. Dislocation-mechanics-based constitutive relations for material dynamics calculations. J. Appl. Phys. 1987, 61, 1816–1825. [Google Scholar] [CrossRef]

- Akbari, Z.; Mirzadeh, H.; Cabrera, J.M. A simple constitutive model for predicting flow stress of medium carbon microalloyed steel during hot deformation. Mater. Eng. 2015, 77, 126–131. [Google Scholar] [CrossRef]

- Li, F.; Zhu, C.C.; Li, S.J.; Hong, J.; Zhang, P.; Yang, R.G.; Zhao, S.D. A comparative study on modified and optimized Zerilli-Armstrong and arrhenius-type constitutive models to predict the hot deformation behavior in 30Si2MnCrMoVE steel. J. Mater. Res. Technol. 2022, 20, 3918–3929. [Google Scholar] [CrossRef]

- Gurusamy, M.M.; Rao, B.C. On the performance of modifed Zerilli-Armstrong constitutive model in simulating the metal cutting process. J. Manuf. Process. 2017, 28, 253–265. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Borah, U.; Bhaduri, A.K.; Sivaprasad, P.V. A thermo-viscoplastic constitutive model to predict elevated-temperature fow behaviour in a titanium-modifed austenitic stainless steel. Mater. Sci. Eng. A 2009, 526, 1–6. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Ren, X.W.; Xiao, Z.B.; Zhang, X.Y.; Huang, Y.C. Flow stress prediction of Hastelloy C-276 alloy using modified Zerilli-Armstrong, Johnson-Cook and Arrhenius-type constitutive models. Trans. Nonferrous Met. Soc. China 2020, 30, 3031–3042. [Google Scholar] [CrossRef]

- Murugesan, M.; Jung, D.W. Two flow stress models for describing hot deformation behavior of AISI-1045 medium carbon steel at elevated temperatures. Heliyon 2019, 5, 4. [Google Scholar] [CrossRef]

- Lewis, J.; Pasco, J.; McCarthy, T.; Chadha, K.; Harding, M.; Aranas Jr, C. High strain rate and high temperature mechanical response of additively manufactured alloy 625. J. Manuf. Process. 2022, 81, 922–944. [Google Scholar] [CrossRef]

- Li, T.Y.; Zhao, B.; Lu, X.Q.; Xu, H.Z.; Zou, D.Q. A comparative study on Johnson Cook, modified Zerilli-Armstrong, and Arrhenius-type constitutive models to predict compression flow behavior of SnSbCu Alloy. Materials 2019, 12, 1726. [Google Scholar] [CrossRef] [PubMed]