Inducing Crystallinity of Metal Thin Films with Weak Magnetic Fields without Thermal Annealing

Abstract

:1. Introduction

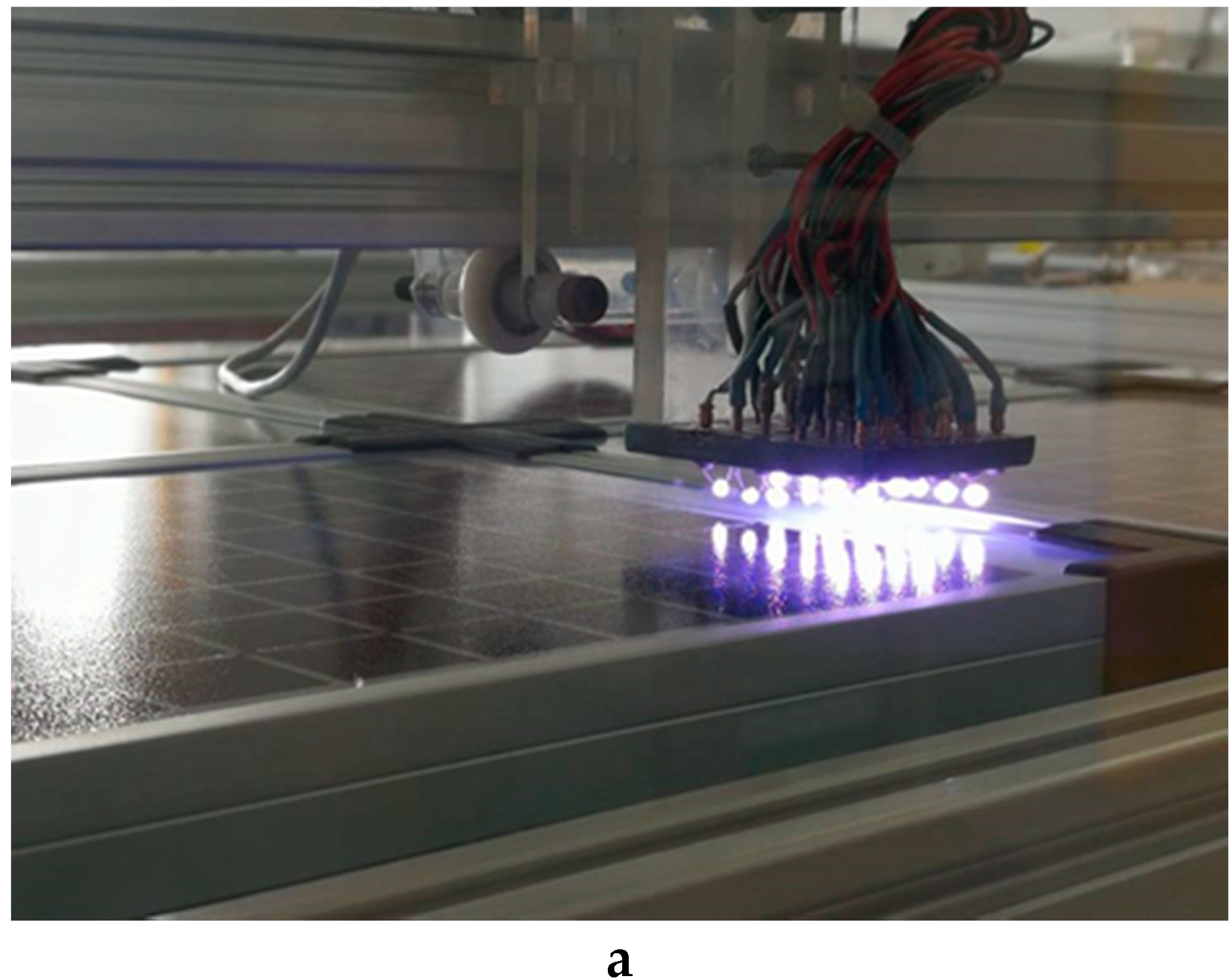

2. Materials and Methods

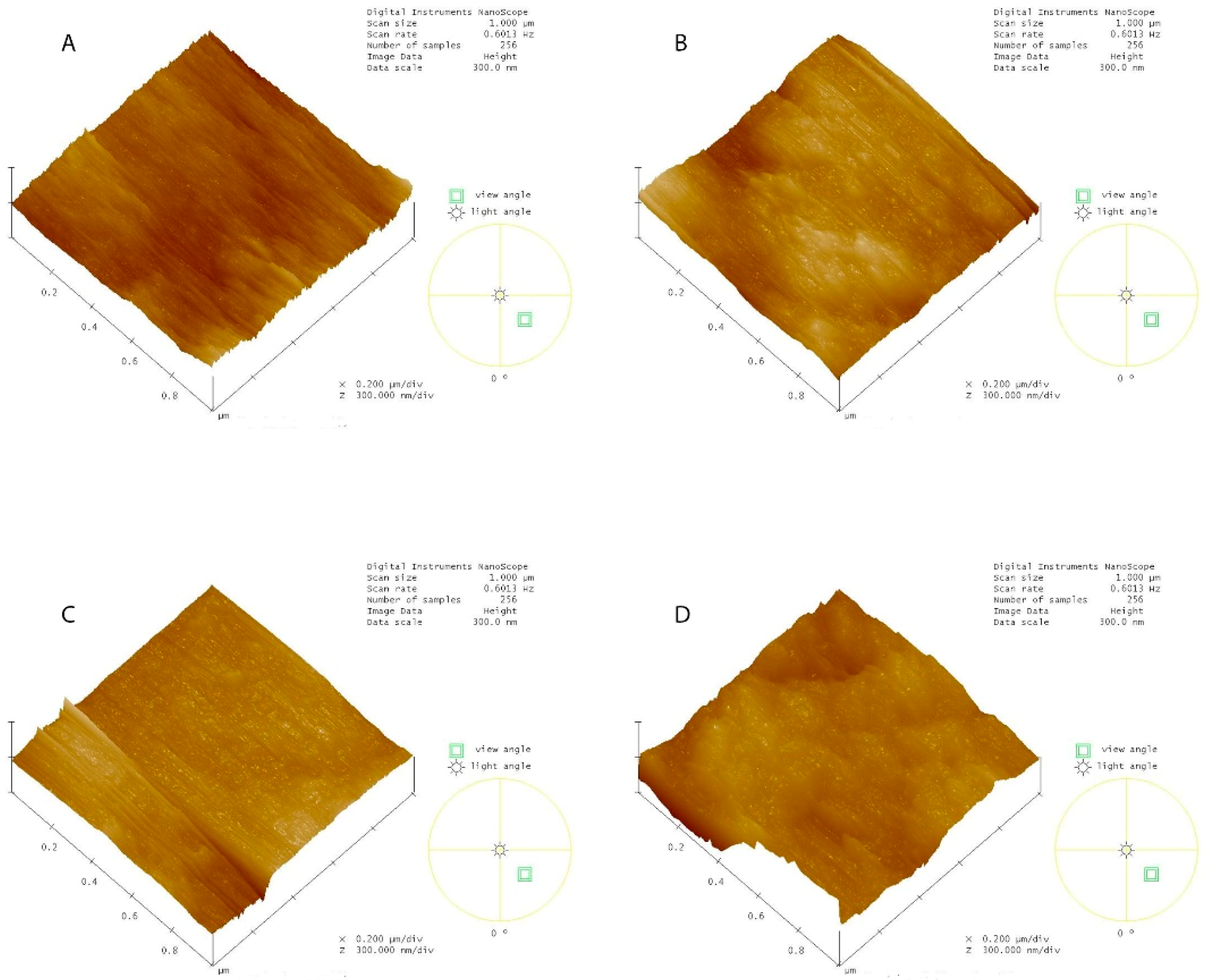

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Element | Atomic Number | Valence Electrons | Density g/cm3 | Melting Point °C |

|---|---|---|---|---|

| Al | 13 | [Ne] 3s23p1 | 2.70 | 660 |

| Fe | 26 | [Ar] 3d64s2 | 7.86 | 1535 |

| Ni | 28 | [Ar] 3d84s2 | 8.908 | 1453 |

| Cu | 29 | [Ar] 3d104s1 | 8.96 | 1085 |

| In | 49 | [Kr] 4d105s25p1 | 7.31 | 156.6 |

| Tin oxide | molecule | Sn = O | 6.95 | 1630 |

| W | 74 | [Xe] 4f145d46s2 | 19.25 | 3422 |

Appendix B

References

- Zhang, Q.M.; Xu, H.; Fang, F.; Cheng, Z.Y.; Xia, F.; You, H. Critical thickness of crystallization and discontinuous change in ferroelectric behavior with thickness in ferroelectric polymer thin films. J. Appl. Phys. 2001, 89, 2613–2616. [Google Scholar] [CrossRef]

- Chen, R.Q.; Lu, Q.Q.; Cheng, Q.D.; Ao, L.B.; Zhang, C.Y.; Hou, H.; Liu, Y.M.; Li, D.W.; Yin, D.C. An ignored variable: Solution preparation temperature in protein crystallization. Sci. Rep. 2015, 5, 7797. [Google Scholar] [CrossRef] [PubMed]

- Ferri, F.A. Low-temperature metal-induced crystallization of Mn-containing amorphous Ge thin films. J. Non Cryst. Solids 2012, 358, 58–60. [Google Scholar] [CrossRef]

- Regula, M.; Ballif, C.; Remškar, M.; Lévy, F. Crystallinity and texture promotion in WS2 thin films. J. Vac. Sci. Technol. A 1997, 15, 2323–2329. [Google Scholar] [CrossRef]

- Pellegren, J.P.; Sokalski, V.M. Thickness and interface-dependent crystallization of CoFeB alloy thin films. IEEE Trans. Magn. 2015, 51, 1–3. [Google Scholar] [CrossRef]

- Yoon, S.Y.; Kim, K.H.; Kim, C.O.; Oh, J.Y.; Jang, J. Low temperature metal induced crystallization of amorphous silicon using a Ni solution. J. Appl. Phys. 1997, 82, 5865–5867. [Google Scholar] [CrossRef]

- JohnáK, A.; ReenaáPhilip, R. Rapid room temperature crystallization of TiO2 nanotubes. CrystEngComm 2017, 19, 1585–1589. [Google Scholar]

- Su, J.; Zou, X.; Li, B.; Chen, H.; Li, X.; Yu, Q.; Mi, Q.; Chen, J.S. Accelerated room-temperature crystallization of ultrahigh-surface-area porous anatase titania by storing photogenerated electrons. Chem. Commun. 2017, 53, 1619–1621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lamberti, A.; Chiodoni, A.; Shahzad, N.; Bianco, S.; Quaglio, M.; Pirri, C.F. Ultrafast room-temperature crystallization of TiO2 nanotubes exploiting water-vapor treatment. Sci. Rep. 2015, 5, 7808–7814. [Google Scholar] [CrossRef] [PubMed]

- Dubey, A.; Kantack, N.; Adhikari, N.; Reza, K.M.; Venkatesan, S.; Kumar, M.; Khatiwada, D.; Darling, S.; Qiao, Q. Room temperature, air crystallized perovskite film for high performance solar cells. J. Mater. Chem. A 2016, 4, 10231–10240. [Google Scholar] [CrossRef]

- Ciro, J.; Betancur, R.; Mesa, S.; Jaramillo, F. High performance perovskite solar cells fabricated under high relative humidity conditions. Sol. Energy Mater. Sol. Cells 2017, 163, 38–42. [Google Scholar] [CrossRef]

- Kye, Y.H.; Yu, C.J.; Jong, U.G.; Chen, Y.; Walsh, A. Critical role of water in defect aggregation and chemical degradation of perovskite solar cells. J. Phys. Chem. Lett. 2018, 9, 2196–2201. [Google Scholar] [CrossRef] [PubMed]

- Ohsaki, H.; Shibayama, Y.; Suzuki, M.; Kinbara, A.; Yashiro, H.; Watanabe, T. Room temperature crystallization by RF plasma. Thin Solid Films 2008, 516, 4490–4494. [Google Scholar] [CrossRef]

- Ohsaki, H.; Suzuki, M.; Shibayama, Y.; Kinbara, A.; Watanabe, T. Room temperature crystallization of indium tin oxide films on glass and polyethylene terephthalate substrates using RF plasma. J. Vac. Sci. Technol. A 2007, 25, 1052–1055. [Google Scholar] [CrossRef]

- Morgese, G.; Dolcet, P.; Feis, A.; Gellini, C.; Gialanella, S.; Speghini, A.; Badocco, D.; Pastore, P.; Casarin, M.; Gross, S. Room-temperature crystallization of CuS nanostructures for photothermal applications through a nanoreactor approach. Eur. J. Inorg. Chem. 2017, 20, 2745–2754. [Google Scholar] [CrossRef]

- Bretos, I.; Jiménez, R.; Ricote, J.; Calzada, M.L. Low-temperature crystallization of solution-derived metal oxide thin films assisted by chemical processes. Chem. Soc. Rev. 2018, 47, 291–308. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Stefan, R.; Jakmunee, J.; Punyodom, W.; Singjai, P. A novel strategy for longevity prolongation of iron-based nanoparticle thin films by applied magnetic force. New J. Chem. 2018, 42, 4807–4810. [Google Scholar]

- Maillé, L.; Sant, C.; Le Paven-Thivet, C.; Legrand-Buscema, C.; Garnier, P. Structure and morphological study of nanometer W and W3O thin films. Thin Solid Films 2003, 428, 237–241. [Google Scholar] [CrossRef]

- Degen, T.; Sadki, M.; Bron, E.; König, U.; Nénert, G. The highscore suite. Powder Diffr. 2014, 29, S13–S18. [Google Scholar] [CrossRef]

- Kumpika, T.; Thongsuwan, W.; Singjai, P. Optical and electrical properties of ZnO nanoparticle thin films deposited on quartz by sparking process. Thin Solid Films 2008, 516, 5640–5644. [Google Scholar] [CrossRef]

- Chuminjak, Y.; Daothong, S.; Kuntarug, A.; Phokharatkul, D.; Horprathum, M.; Wisitsoraat, A.; Tuantranont, A.; Jakmunee, J.; Singjai, P. High-performance electrochemical energy storage electrodes based on nickel oxide-coated nickel foam prepared by sparking method. Electrochim. Acta 2017, 238, 298–309. [Google Scholar] [CrossRef]

- Chuminjak, Y.; Daothong, S.; Reanpang, P.; Mensing, J.P.; Phokharatkul, D.; Jakmunee, J.; Wisitsoraat, A.; Tuantranont, A.; Singjai, P. Electrochemical energystorage performances of nickel oxide films prepared by a sparking. RSC Adv. 2015, 5, 67795–67802. [Google Scholar] [CrossRef]

- Meuller, B.O.; Messing, M.E.; Engberg, D.L.; Jansson, A.M.; Johansson, L.I.; Norlén, S.M.; Tureson, N.; Deppert, K. Review of spark discharge generators for production of nanoparticle aerosols. Aerosol Sci. Technol. 2012, 46, 1256–1270. [Google Scholar] [CrossRef]

- Kumpika, T.; Thongsuwan, W.; Singjai, P. Atomic force microscopy imaging of ZnO nanodots deposited on quartz by sparking off different tip shapes. Surf. Interface Anal. 2007, 39, 58–63. [Google Scholar] [CrossRef]

- Kumpika, T.; Kantarak, E.; Sroila, W.; Panthawan, A.; Jhuntama, N.; Sanmuangmoon, P.; Thongsuwan, W.; Singjai, P. Superhydrophilic/superhydrophobic surfaces fabricated by spark-coating. Surf. Interface Anal. 2018, 50, 827–834. [Google Scholar] [CrossRef]

- Isaac, N.A.; Valenti, M.; Schmidt-Ott, A.; Biskos, G. Characterization of tungsten oxide thin films produced by spark ablation for NO2 gas sensing. ACS Appl. Mater. Interfaces 2016, 8, 3933–3939. [Google Scholar] [CrossRef] [PubMed]

- Vernardou, D.; Psifis, K.; Louloudakis, D.; Papadimitropoulos, G.; Davazoglou, D.; Katsarakis, N.; Koudoumas, E. Low pressure CVD of electrochromic WO3 at 400 °C. J. Electrochem. Soc. 2015, 162, H579–H582. [Google Scholar] [CrossRef]

- Sun, H.L.; Song, Z.X.; Guo, D.G.; Ma, F.; Xu, K.W. Microstructure and mechanical properties of nanocrystalline tungsten thin films. J. Mater. Sci. Technol. 2010, 26, 87–92. [Google Scholar] [CrossRef]

- Zakeri, K.; Peixoto, T.R.F.; Zhang, Y.; Prokop, J.; Kirschner, J. On the preparation of clean tungsten single crystals. Surf. Sci. 2010, 604, L1–L3. [Google Scholar] [CrossRef]

- Girault, B.; Eyidi, D.; Goudeau, P.; Sauvage, T.; Guerin, P.; Bourhis, E.L.; Renault, P.O. Controlled nanostructuration of polycrystalline tungsten thin films. J. Appl. Phys. 2013, 113, 174310. [Google Scholar] [CrossRef]

- Hao, Q.; Chen, W.; Xiao, G. Beta (β) tungsten thin films: Structure, electron transport, and giant spin Hall effect. Appl. Phys. Lett. 2015, 106, 182403. [Google Scholar] [CrossRef]

- Quintero, J.H.; Mariño, A.; Šiller, L.; Restrepo-Parra, E.; Caro-Lopera, F.J. Rocking curves of gold nitride species prepared by arc pulsed-physical assisted plasma vapor deposition. Surf. Coat. Technol. 2017, 309, 249–257. [Google Scholar] [CrossRef]

- Shalom, M.; Ressnig, D.; Yang, X.; Clavel, G.; Fellinger, T.P.; Antonietti, M. Nickel nitride as an efficient electrocatalyst for water splitting. J. Mater. Chem. A 2015, 3, 8171–8177. [Google Scholar] [CrossRef] [Green Version]

- Rudd, P.A.; Liu, S.; Gagliardi, L.; Young, V.G., Jr.; Lu, C.C. Metal-alane adducts with zero-valent nickel, cobalt, and iron. J. Am. Chem. Soc. 2011, 133, 20724–207273. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Guo, X.; Ramlawi, N.; Pfeiffer, T.V.; Geutjens, R.; Basak, S.; Nirschl, H.; Biskos, G.; Zandbergen, H.W.; Schmidt-Ott, A. Green manufacturing of metallic nanoparticles: A facile and universal approach to scaling up. J. Mater. Chem. A 2016, 4, 11222–11227. [Google Scholar] [CrossRef]

- Swann, S. Magnetron sputtering. Phys. Technol. 1988, 19, 67–75. [Google Scholar] [CrossRef]

- Matsuda, T.; Umeda, K.; Kato, Y.; Nishimoto, D.; Furuta, M.; Kimura, M. Raremetal-free high-performance Ga-Sn-O thin film transistor. Sci. Rep. 2017, 7, 44326–44332. [Google Scholar] [CrossRef] [PubMed]

- Sudha, C.; Sivanarendiran, R.; Srinivasan, K. Influence of magnetic field on the nucleation rate control of mono paracetamol. Cryst. Res. Technol. 2015, 50, 230–235. [Google Scholar] [CrossRef]

- Al Helal, A.; Soames, A.; Gubner, R.; Iglauer, S.; Barifcani, A. Influence of magnetic fields on calcium carbonate scaling in aqueous solutions at 150 °C and 1 bar. J. Colloid Interface Sci. 2018, 509, 472–484. [Google Scholar] [CrossRef] [PubMed]

- Chibowski, E.; Szcześ, A. Magnetic water treatment–a review of the latest approaches. Chemosphere 2018, 203, 54–67. [Google Scholar] [CrossRef] [PubMed]

- Thongpan, W.; Kumpika, T.; Kantarak, E.; Panthawan, A.; Pooseekheaw, P.; Singjai, P.; Tuantranont, A.; Thongsuwan, W. External-electric-field-enhanced uniformity and deposition rate of a TiO2 film prepared by the sparking process. Ukr. J. Phys. 2018, 63, 531–536. [Google Scholar] [CrossRef]

- Liu, X.; Zhuang, K.; Lin, S.; Zhang, Z.; Li, X. Determination of supercooling degree, nucleation and growth rates, and particle size for ice slurry crystallization in vacuum. Crystals 2017, 7, 128. [Google Scholar] [CrossRef]

- Kim, H.N.; Suslick, K.S. The effects of ultrasound on crystals: Sonocrystallization and sonofragmentation. Crystals 2018, 8, 280. [Google Scholar] [CrossRef]

- Zabihi, F.; Eslamian, M. Effect of the ultrasonic substrate vibration on nucleation and crystallization of PbI2 crystals and thin films. Crystals 2018, 8, 60. [Google Scholar] [CrossRef]

| Thin Film | Time of Deposition | Thickness (nm ± SD) | Roughness (nm ± SD) |

|---|---|---|---|

| Aluminum | 12 h | 530 ± 14.07 | 16.41 ± 1.691 |

| Nickel 1 | 30 min | 164.87 ± 27.4 | 33.35 ± 5.0 |

| Indium | 30 min | 137 ± 1.79 | 14.32 ± 3.12 |

| Copper | 30 min | 274.5 ± 2.012 | 10.6 ± 0.39 |

| Tungsten | 45 min | 438.9 ± 23.2 | 21.4 ± 2.3 |

| Tungsten 2 | 45 min | 618.2 ± 20.3 | 3.85 ± 0.3 |

| Tin oxide (SnO) | 45 min | 294.7 ± 31.2 | 9.5 ± 0.2 |

| Iron 1 | 45 min | 364.7 ± 2.35 | 10 ± 0.5 |

| Element | Magnetic Field | Concentration (mg/L) | Concentration mg/cm2 | Variation (%) |

|---|---|---|---|---|

| Al | 0.4 T | 9.159 | 0.229 | 1.497 |

| Sn | 0.4 T | 10.427 | 0.261 | 2.25 |

| Ni | 0 T | 0.846 | 0.021 | 0.72 |

| Ni | 0.4 T | 0.371 | 0.047 | 0.83 |

| Fe | 0 T | 0.502 | 0.013 | 0.36 |

| Fe | 0.2 T | 0.695 | 0.087 | 0.51 |

| Fe | 0.4 T | 0.564 | 0.014 | 0.88 |

| Cu | 0 T | 1.016 | 0.026 | 0.18 |

| Cu | 0.4 T | 1.005 | 0.025 | 0.39 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ručman, S.S.; Punyodom, W.; Jakmunee, J.; Singjai, P. Inducing Crystallinity of Metal Thin Films with Weak Magnetic Fields without Thermal Annealing. Crystals 2018, 8, 362. https://doi.org/10.3390/cryst8090362

Ručman SS, Punyodom W, Jakmunee J, Singjai P. Inducing Crystallinity of Metal Thin Films with Weak Magnetic Fields without Thermal Annealing. Crystals. 2018; 8(9):362. https://doi.org/10.3390/cryst8090362

Chicago/Turabian StyleRučman, Stefan S., Winita Punyodom, Jaroon Jakmunee, and Pisith Singjai. 2018. "Inducing Crystallinity of Metal Thin Films with Weak Magnetic Fields without Thermal Annealing" Crystals 8, no. 9: 362. https://doi.org/10.3390/cryst8090362

APA StyleRučman, S. S., Punyodom, W., Jakmunee, J., & Singjai, P. (2018). Inducing Crystallinity of Metal Thin Films with Weak Magnetic Fields without Thermal Annealing. Crystals, 8(9), 362. https://doi.org/10.3390/cryst8090362