Study in Optical and Mechanical Properties of Nd3+, Y3+: SrF2 Transparent Ceramics Prepared by Hot-Pressing and Hot-Forming Techniques

Abstract

:1. Introduction

2. Experimental Section

3. Result and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Hatch, S.E.; Parsons, W.F.; Weagley, R.J. Hot-pressed polycrystalline CaF2: Dy2+ laser. Appl. Phys. Lett. 1964, 5, 153–154. [Google Scholar] [CrossRef]

- Lupei, V.; Lupei, A.; Hau, S.; Gheorghe, C.; Ikesue, A. Structural and electron-phonon interaction effects in optical spectra of pr3+, and Sm3+, in YAG. J. Alloy. Compd. 2017, 706, 176–185. [Google Scholar] [CrossRef]

- Hou, X.R.; Zhou, S.M.; Jia, T.T.; Lin, H.; Teng, H. Effect of Nd concentration on structural and optical properties of Nd: Y2O3 transparent ceramic. J. Lumin. 2011, 131, 1953–1958. [Google Scholar] [CrossRef]

- Lyberis, A.; Patriarche, G.; Gredin, P.; Vivien, D.; Mortier, M. Origin of light scattering in ytterbium doped calcium fluoride transparent ceramic for high power lasers. J. Eur. Ceram. Soc. 2011, 31, 1619–1630. [Google Scholar] [CrossRef]

- Moncorgé, R.; Camy, P.; Doualana, J.L.; Braud, A.; Margerie, J.; Ramirez, L.P.; Jullien, A.; Druon, F.; Ricaud, S.; Papadopoulos, D.N.; et al. Pure and Yb3+ doped fluorites (Ca, Sr, Ba) F2: A renewal for the future high intensity laser chains. J. Lumin. 2013, 133, 276–281. [Google Scholar] [CrossRef]

- Aubry, P.; Bensalah, A.; Gredin, P.; Patriarche, G.; Vivien, D.; Mortier, M. Synthesis and optical characterizations of Yb-doped CaF2 ceramics. Opt. Mater. 2009, 31, 750–753. [Google Scholar] [CrossRef]

- Srinivasan, B.; Fontaine, B.; Gucci, F.; Dorcet, V.; Saunders, T.G.; Yu, M.; Chevire, F.; Boussard-Pledel, C.; Halet, J.; Gautier, R.; et al. Effect of the processing route on the thermoelectric performance of nanostructured CuPb18SbTe20. Inorg. Chem. Front. 2019, 6, 63–73. [Google Scholar] [CrossRef]

- Srinivasan, B.; Gellé, A.; Gucci, F.; Boussard-Pledel, C.; Fontaine, B.; Gautier, R.; Halet, J.F.; Reeceb, M.J.; Bureau, B. Realizing a stable high thermoelectric zT-2 over a broad temperature range in Ge1−x−yGaxSbyTe via band engineering and hybrid flash-SPS processing. Inorg. Chem. 2018, 57, 12976–12986. [Google Scholar] [CrossRef]

- Alombert-Goget, G.; Guyot, Y.; Guzik, M.; Boulon, G.; Ito, A.; Goto, T.; Yoshikawa, A.; Kikuchi, M. Nd3+-doped Lu2O3 transparent sesquioxide ceramics elaborated by the Spark Plasma Sintering (SPS) method. Part 1: Structural, thermal conductivity and spectroscopic characterization. Opt. Mater. 2015, 41, 3–11. [Google Scholar] [CrossRef]

- Liu, X.R.; Liu, Y.B.; Sun, Y.; Su, G.H. Fabrication of C/Cu composites by mechanical activation and spark plasma sintering. Adv. Mater. Res. 2012, 499, 223–226. [Google Scholar] [CrossRef]

- Chen, S.; Wu, Y.Q. Influence of temperature on the spark plasma sintering of calcium fluoride ceramics. J. Mater. Res. 2014, 29, 2297–2302. [Google Scholar] [CrossRef]

- Nakamura, F.; Kato, T.; Okada, G.; Kawaguchi, N.; Fukuda, K.; Yanagida, T. Scintillation and dosimeter properties of CaF2 translucent ceramic produced by SPS. J. Eur. Ceram. Soc. 2017, 37, 1702–1711. [Google Scholar] [CrossRef]

- Li, W.W.; Mei, B.C.; Li, X.J.; Song, J.H.; Zhi, G.L. Effects of Na+ on spectral properties of Er3+: CaF2 transparent ceramic. Key Eng. Mater. 2013, 531, 307–311. [Google Scholar] [CrossRef]

- Lu, G.; Mei, B.C.; Song, J.H.; Li, W.W.; Xing, R.Z. Fabrication and properties of highly transparent Nd-doped CaF2 ceramics. Mater. Lett. 2014, 115, 162–164. [Google Scholar] [CrossRef]

- Liu, Z.D.; Mei, B.C.; Song, J.H.; Li, W.W. Optical characterizations of hot-pressed erbium-doped calcium fluoride transparent ceramic. J. Am. Ceram. Soc. 2014, 97, 2506–2510. [Google Scholar] [CrossRef]

- Basiev, T.T.; Doroshenko, M.E.; Fedorov, P.P.; Konyushkin, V.A.; Kuznetsov, S.V.; Osiko, V.V.; Akchurin, M.S. Efficient laser based on CaF2–SrF2–YbF3 nanoceramics. Opt. Lett. 2008, 33, 521–523. [Google Scholar] [CrossRef]

- Akchurin, M.S.; Basiev, T.T.; Demidenko, A.A.; Doroshenko, M.E.; Fedorov, P.P.; Garibin, E.A.; Gusev, P.E.; Kuznetsov, S.V.; Krutov, M.A.; Mironov, I.A.; et al. CaF2: Yb laser ceramics. Opt. Mater. 2013, 35, 444–450. [Google Scholar] [CrossRef]

- Basiev, T.T.; Doroshenko, M.E.; Konyushkin, V.A.; Osiko, V.V. SrF2:Nd3+ laser fluoride ceramics. Opt. Lett. 2010, 35, 4009–4011. [Google Scholar] [CrossRef]

- Bol’shchikov, F.A.; Garibin, E.A.; Gusev, P.E.; Demidenko, A.A.; Kruglova, M.V.; Krutov, M.A.; Lyapin, A.A.; Mironov, I.A.; Osiko, V.V.; Reiterov, V.M.; et al. Fedorov. Nanostructured Tm: CaF2 ceramics: Potential gain media for two micron lasers. Opt. Quantum Electron. 2011, 41, 193–197. [Google Scholar] [CrossRef]

- Sulc, J.; Němec, M.; Svejkar, R.; Jelínková, H.; Doroshenko, M.E.; Fedorov, P.P.; Osiko, V.V. Diode-pumped Er: CaF2 Ceramic 2.7 μm tunable laser. Opt. Lett. 2013, 38, 3406–3409. [Google Scholar] [CrossRef]

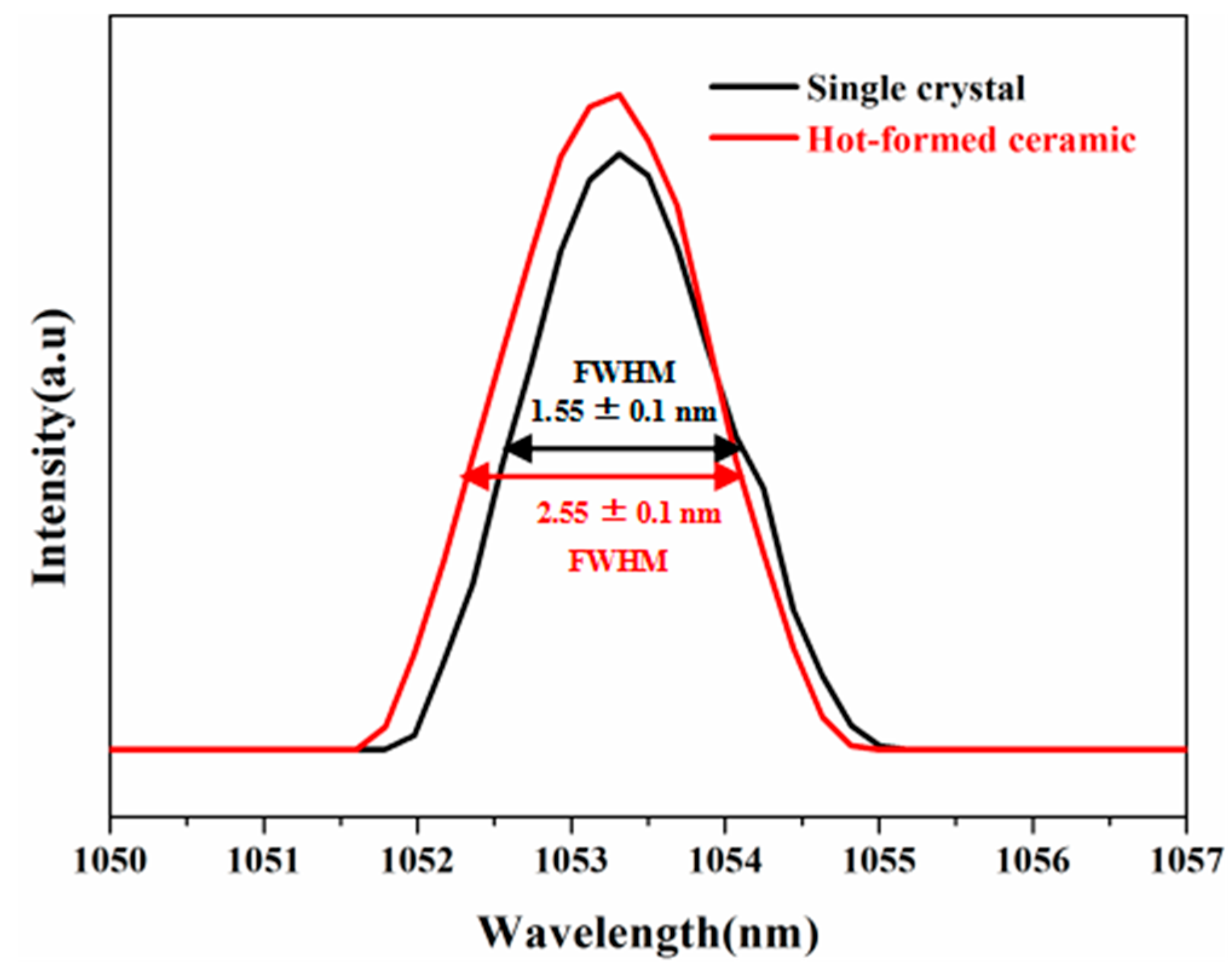

- Jelínek, M.; Kubeček, V.; Su, L.B.; Jiang, D.P.; Ma, F.K.; Zhang, Q.; Cao, Y.X.; Xu, J. Pulsed and continuous-wave laser operation of TGT-grown Nd,Y-codoped :SrF2 single crystal. Laser Phys. Lett. 2014, 11, 055001. [Google Scholar] [CrossRef]

- Sun, Z.C.; Mei, B.C.; Li, W.W.; Su, L.B. Effects of Nd concentration on microstructure and optical properties of Nd: CaF2 transparent ceramics. J. Am. Ceram. Soc. 2016, 99, 4039–4044. [Google Scholar] [CrossRef]

- Jiang, Y.G.; Jiang, B.X.; Jiang, N.; Zhang, P.D.; Chen, S.L.; Hu, X.; Zhang, G.; Fan, J.T.; Su, L.B.; Li, J.; et al. Effects of deformation rate on properties of Nd,Y-codoped CaF2 transparent ceramics. J. Eur. Ceram. Soc. 2018, 38, 2404–2409. [Google Scholar] [CrossRef]

- Basiev, T.T.; Voronov, V.V.; Konyushkin, V.A.; Kuznetsov, S.V.; Lavrishchev, S.V.; Osiko, V.V.; Fedorov, P.P. Optical lithium fluoride ceramics. Dokl. Phys. 2007, 52, 677–680. [Google Scholar] [CrossRef]

- Sitdikov, O.; Kaibyshev, R. Dislocation glide and dynamic recrystallization in LiF single crystals. Mater. Sci. Eng. A 2002, 328, 147–155. [Google Scholar] [CrossRef]

- Kim, B.N.; Hiraga, K.; Morita, K.; Yoshida, H.; Miyazaki, T.; Kagawa, Y. Microstructure and optical properties of transparent alumina. Acta Mater. 2009, 57, 1319–1326. [Google Scholar] [CrossRef]

- Jiang, Y.G.; Jiang, B.X.; Jiang, N.; Zhang, P.D.; Chen, S.L.; Gan, Q.J.; Zhang, G.; Fan, J.T.; Mao, X.J.; Su, L.B.; et al. Perfectly transparent pore-free Nd3+-doped Sr9GdF2 polycrystalline ceramics elaborated from single-crystal ceramization. J. Eur. Ceram. Soc. 2017, 37, 4912–4918. [Google Scholar] [CrossRef]

- Jiang, Y.G.; Jiang, B.X.; Zhang, P.D.; Chen, S.L.; Gan, Q.J.; Fan, J.T.; Mao, X.J.; Jiang, N.; Su, L.B.; Li, J.; et al. Transparent nd-doped Ca1-xYxF2+x ceramics prepared by the ceramization of single crystals. Mater. Des. 2017, 113, 326–330. [Google Scholar] [CrossRef]

- Yi, G.Q.; Mei, B.C.; Li, W.W.; Song, J.H.; Zhou, Z.W.; Su, L.B. Microstructural and optical properties of Pr3+:(Ca0.97Gd0.03)F2.03 transparent ceramics sintered by vacuum hot-pressing method. J. Lumin. 2019, 214, 116575. [Google Scholar] [CrossRef]

- Liu, S.D.; Dong, L.L.; Zhang, X.; Yao, Y.P.; Xu, Y.; Ren, T.Q.; Zheng, L.H.; Su, L.B.; Berkowski, M. Thermal, spectral properties and Q-switched laser operation of Nd:SrLaAlO4 crystal. Opt. Mater. 2017, 64, 351–355. [Google Scholar] [CrossRef]

- Li, S.M.; Zhang, L.H.; Li, C.; Leng, Y.X.; He, M.Z.; Chen, G.Z.; Yang, Y.L.; Zhang, S.L.; Zhang, P.X.; Chen, Z.Q.; et al. Growth, thermal conductivity, spectra, and 2 µm continuous-wave characteristics of Tm3+, Ho3+ co-doped LaF3 crystal. J. Lumin. 2019, 210, 142–145. [Google Scholar] [CrossRef]

- Li, W.W.; Huang, H.J.; Mei, B.C.; Song, J.H.; Xu, X.D. Effect of Y3+ ion doping on the microstructure, transmittance and thermal properties CaF2 transparent ceramics. J. Alloy. Compd. 2018, 747, 359–365. [Google Scholar] [CrossRef]

- Khazanov, E.N.; Taranov, A.V.; Gainutdinov, R.V.; Akchurin, M.S.; Basiev, T.T.; Konyushkin, V.A.; Fedorov, P.P.; Kuznetsov, S.V.; Osiko, V.V. A study of the structure and scattering mechanisms of subterahertz phonons in lithium fluoride single crystals and optical ceramics. J. Exp. Theor. Phys. 2010, 110, 983–988. [Google Scholar] [CrossRef]

| Material Type | Microhardness H (GPa) | Fracture ToughnessK1C (MPa m1/2) |

|---|---|---|

| hot-formed ceramic (∆a = 26%) | 2.645 | 0.51 |

| hot-formed ceramic (∆a = 45%) | 2.520 | 0.55 |

| hot-formed ceramic (∆a = 51%) | 2.570 | 0.70 |

| hot-formed ceramic (∆a = 68%) | 2.433 | 0.60 |

| hot-pressed ceramic | 2.680 | 0.80 |

| Single crystal | 2.245 | 0.48 |

| Material Type | Measured Density (g/cm3) | Relative Density (%) | Theoretical Density (g/cm3) |

|---|---|---|---|

| hot-pressed ceramics | 4.2205 | 97.15 | 4.3441 |

| hot-formed ceramics (∆a = 51%) | 4.3172 | 99.37 | |

| Single crystal | 4.3039 | 99.07 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, S.; Song, J.; Wang, W.; Mei, B.; Li, W.; Xia, Y. Study in Optical and Mechanical Properties of Nd3+, Y3+: SrF2 Transparent Ceramics Prepared by Hot-Pressing and Hot-Forming Techniques. Crystals 2019, 9, 619. https://doi.org/10.3390/cryst9120619

Qin S, Song J, Wang W, Mei B, Li W, Xia Y. Study in Optical and Mechanical Properties of Nd3+, Y3+: SrF2 Transparent Ceramics Prepared by Hot-Pressing and Hot-Forming Techniques. Crystals. 2019; 9(12):619. https://doi.org/10.3390/cryst9120619

Chicago/Turabian StyleQin, Shaoyong, Jinghong Song, Wuxiao Wang, Bingchu Mei, Weiwei Li, and Yuanming Xia. 2019. "Study in Optical and Mechanical Properties of Nd3+, Y3+: SrF2 Transparent Ceramics Prepared by Hot-Pressing and Hot-Forming Techniques" Crystals 9, no. 12: 619. https://doi.org/10.3390/cryst9120619