The Effect of Fly Ash Microspheres on the Pore Structure of Concrete

Abstract

:1. Introduction

2. Research Significance

3. Materials and Methods

- the total content of air in hardened concrete: A (%);

- the content of micropores with a diameter below 300 μm (according to the type of pore size recommended by IUPAC [27], these are classified as macropores): A300 (%);

- the surface area of air voids (indicating the relative number and size of air bubbles for a given volume of air): α (mm−1);

- the spacing factor (relative distance between the air voids): (mm).

4. Results and Discussion

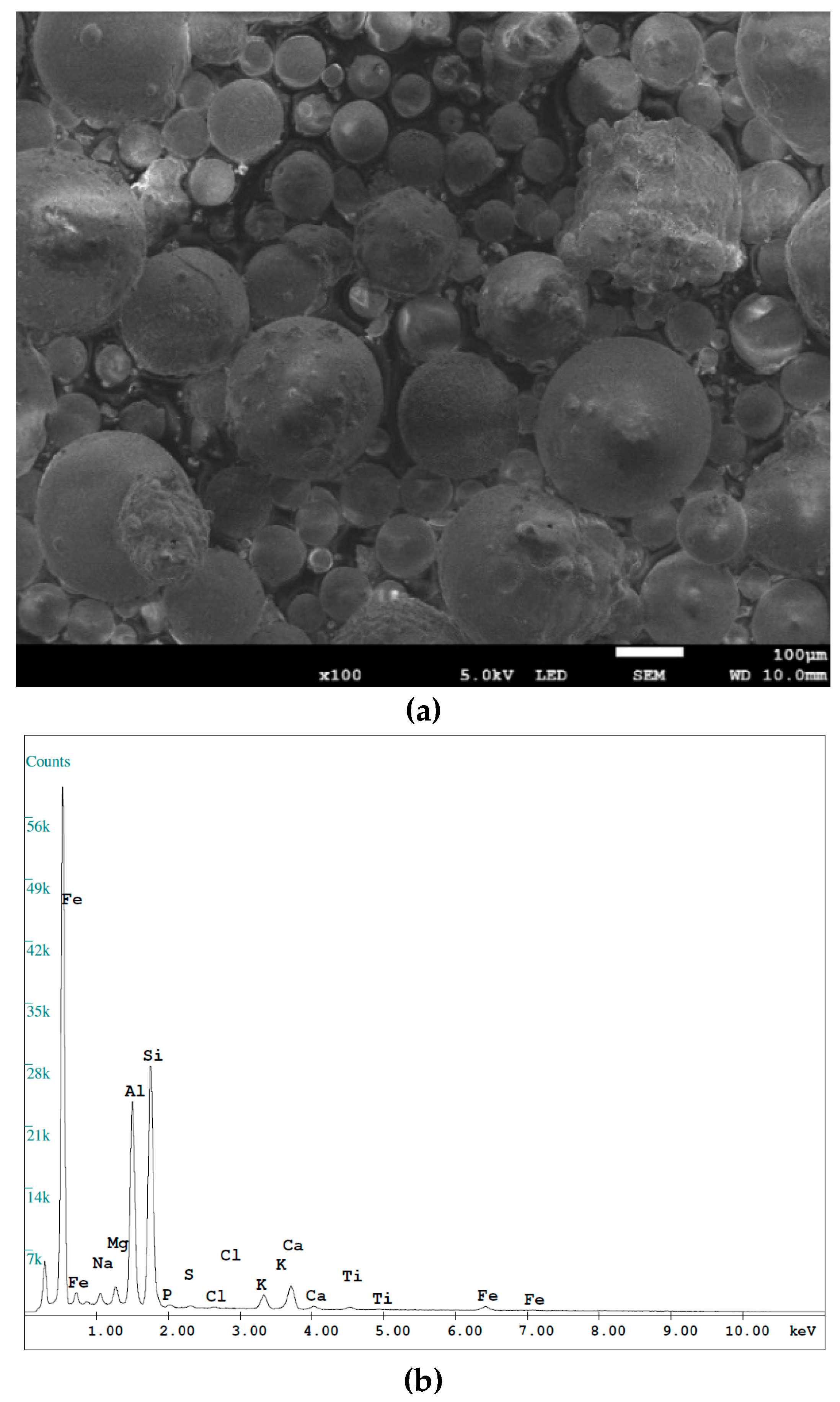

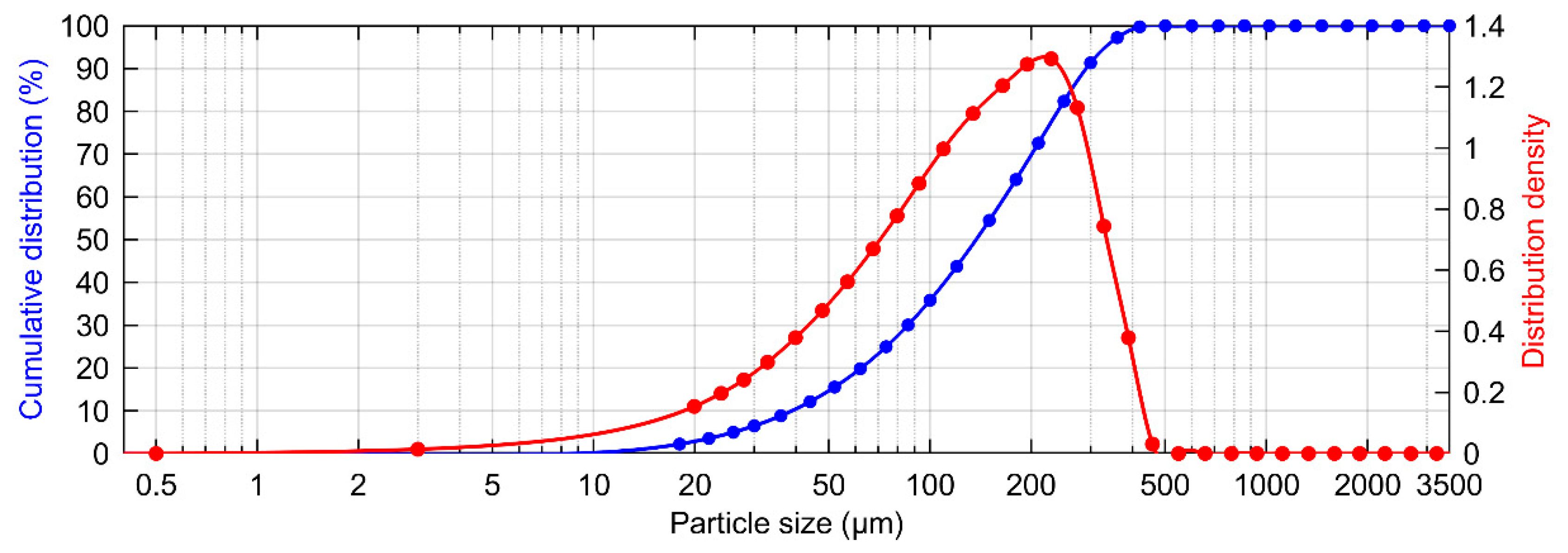

4.1. The Chemical Composition and the Particle Size Distribution of the Fly Ash Microspheres

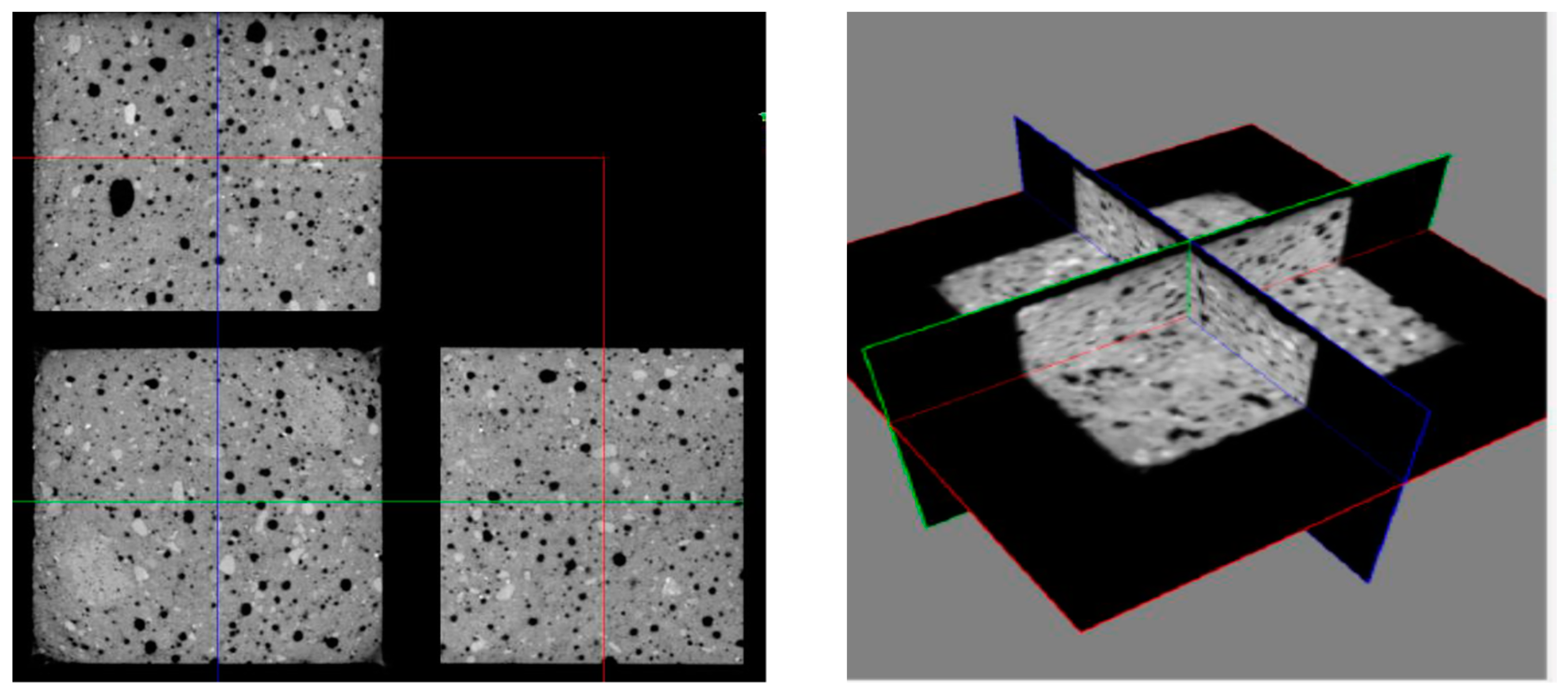

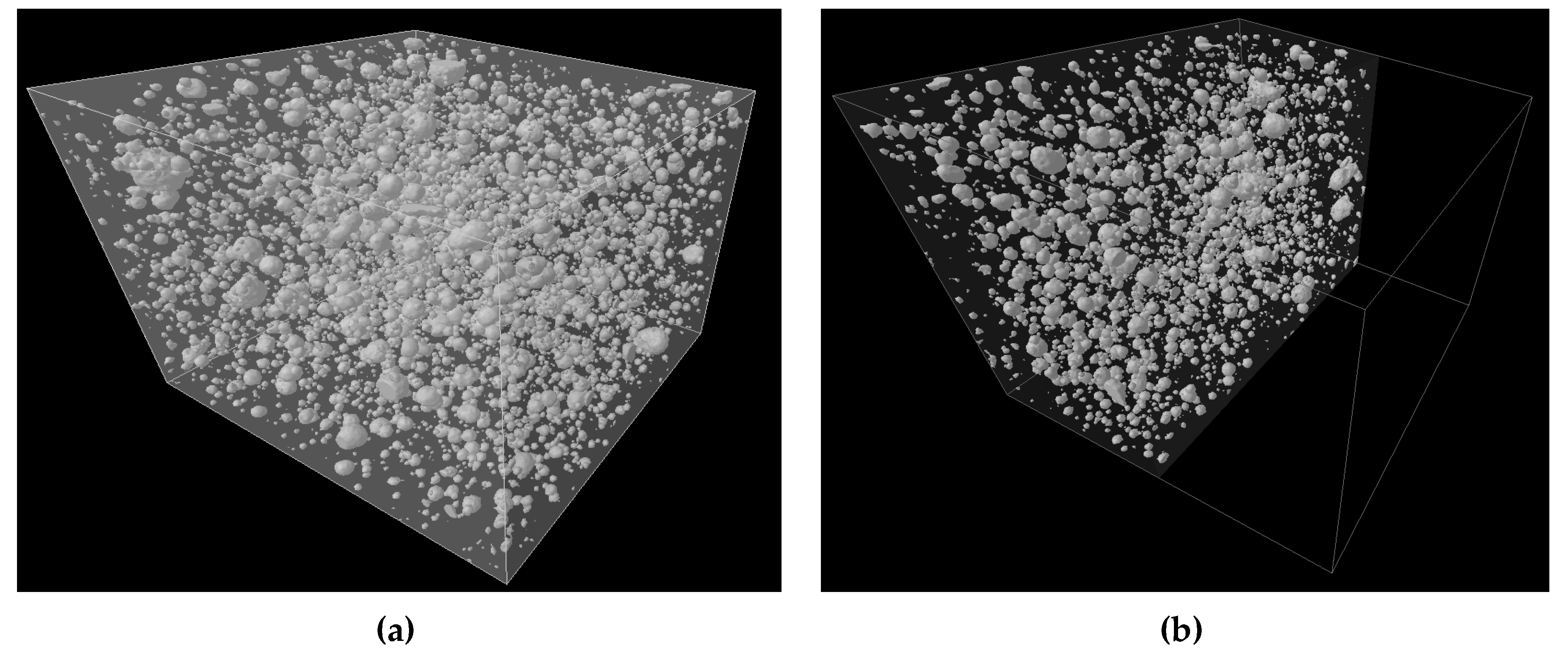

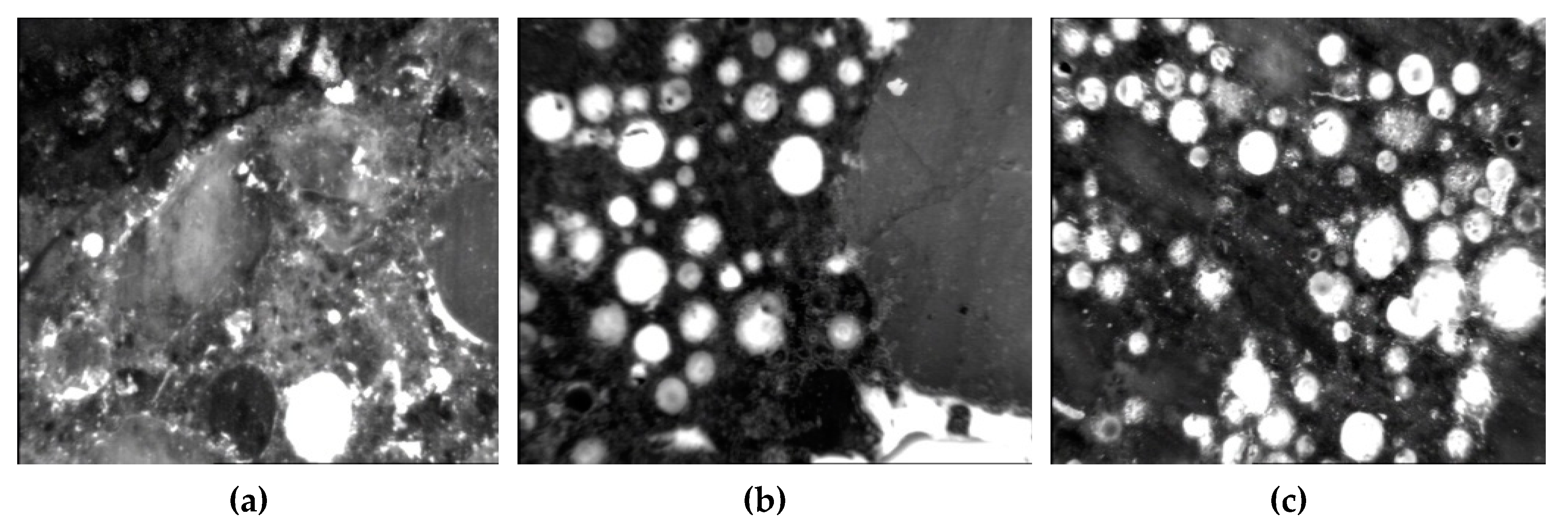

4.2. The Structure of Air Pores in X-ray Technology

4.3. The Structure of Air Pores in Concrete Using the Automatic Image Analysis System

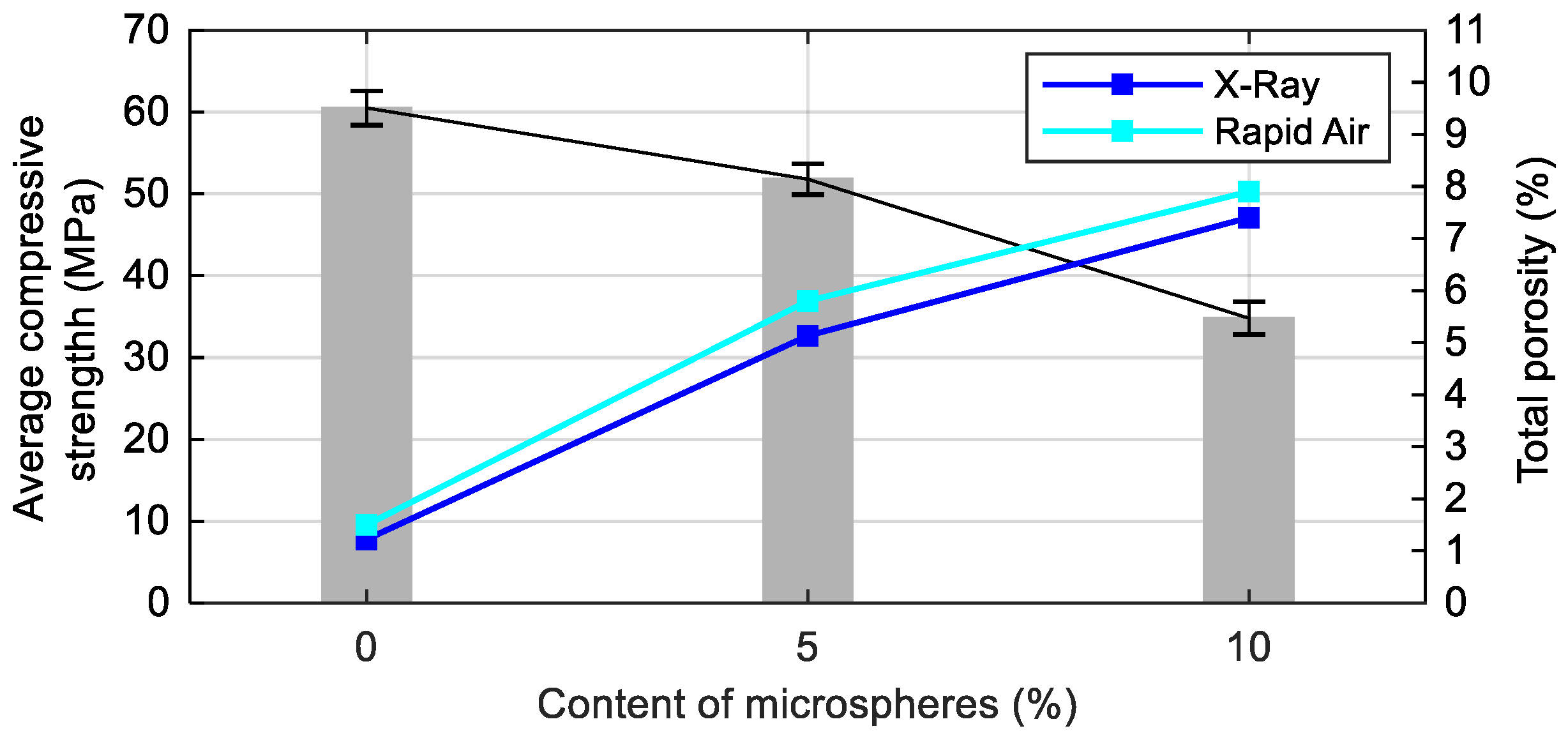

4.4. Compressive Strength versus Total Air Pores

5. Conclusions

- The 3D, X-ray micro-computed tomography is a non-destructive technique that allows for the determination the type of air void distribution present in the structure of hardened concrete. This method is very useful for testing building materials.

- The performed tests demonstrate the ability and applicability of novel image analysis methods for rapid-air void measurements of hardened concrete, with good reproducibility.

- The potential use of hollow fly ash microspheres (FAMs) as an aeration additive in building materials is one of the ways for utilizing and reducing the degree of waste accumulation in the natural environment.

- The total air content in concrete increases when increasing the cement replacement by microspheres.

- The total porosity of hardened concrete with 5% and 10% microspheres after 28 days was in the range of 5.1% to 7.4% for X-ray computed tomography, and 5.8% to 7.9% for the automatic image analysis system (Rapid Air 457). In turn, the total porosity in the concrete samples without microspheres was only 1.22% (X-ray) and 1.5% (Rapid Air), and it was lower by about 83.5% and 81.0% in relation to concrete samples containing 10% microspheres in the binder.

- The X-ray computed tomography, compared to automatic image analysis system Rapid Air 457, allows for the observation of the distribution of air pores in the three-dimensional space. An important parameter for the frost–thaw resistance of concrete is the possibility of determining the proportion of open and closed air pores in the entire cross-section of the sample.

- A larger content of closed pores compared to open pores is associated with the percentage content of microspheres in concrete. Due to their nature (their interior is filled with gases), the presence of closed pores causes an increase in the content of air voids in hardened concrete.

- The substitution of ordinary Portland cement by microspheres (5% and 10%) significantly reduced the compressive strength of concrete.

- In the future, the proper composition of microspheres may be an additional possibility for concrete aeration without the deterioration of its mechanical properties, in order to improve frost resistance.

Author Contributions

Funding

Conflicts of Interest

References

- Trofimov, B.Y.; Kramar, L.Y.; Schuldyakov, K.V. On deterioration mechanism of concrete exposed to freeze-thaw cycles. IOP Conf. Ser. Mater. Sci. Eng. 2017, 262, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Pogorelov, S.N.; Semenyak, G.S. Frost resistance of the steel fiber reinforced concrete containing active mineral additives. Procedia Eng. 2016, 150, 1491–1495. [Google Scholar] [CrossRef] [Green Version]

- EN 206–1. Concrete Part. 1: Specification, Performance, Production and Conformity; European Standards; European Committee for Standardization: Brussels, Belgium, 2003. [Google Scholar]

- Nowak-Michta, A. Influence of superplasticizer on porosity structures in hardened concretes. Procedia Eng. 2015, 108, 262–269. [Google Scholar] [CrossRef] [Green Version]

- Fenelonov, V.B.; Mel’gunov, M.S.; Parmon, V.N. The properties of cenospheres and the mechanism of their formation during high-temperature coal combustion at thermal power plans. Kona Powder Part. J. 2010, 28, 189–208. [Google Scholar] [CrossRef] [Green Version]

- Drozhzhin, V.S.; Shpirt, M.Y.; Danilin, L.D.; Kuvaev, M.D.; Pikulin, I.V.; Potemkin, G.A.; Redyushev, S.A. Formation processes and main properties of hollow aluminosilicate microspheres in fly ash from thermal power stations. Solid Fuel Chem. 2008, 42, 107–119. [Google Scholar] [CrossRef]

- Haustein, E. The selected physico-chemical properties of microspheres and possibility of their use in cement composites. Compos. Theory Pract. 2016, 16, 25–29. [Google Scholar]

- Acar, I.; Atalay, M.U. Recovery potentials of cenospheres from bituminous coal fly ashes. Fuel 2016, 180, 97–105. [Google Scholar] [CrossRef]

- Żyrkowski, M.; Neto, R.C.; Santos, L.F.; Witkowski, K. Characterization of fly-ash cenospheres from coal-fired power plant unit. Fuel 2016, 174, 49–53. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Fomenko, E.V.; Anshits, N.N.; Vasilieva, N.G.; Mikhaylova, O.A.; Rogovenko, E.S.; Zhizhaev, A.M.; Anshits, A.G. Characterization of fly ash cenospheres produced from the combustion of Ekibastuz coal. Energy Fuels 2015, 29, 5390–5403. [Google Scholar] [CrossRef]

- Liu, H.; Sun, Q.; Wang, B.; Wang, P.; Zou, J. Morphology and Composition of Microspheres in Fly Ash from the Luohuang Power Plant, Chongqing, Southwestern China. Minerals 2016, 6, 30. [Google Scholar] [CrossRef] [Green Version]

- Kurpinska, M.; Kułak, L. Predicting Performance of Lightweight Concrete with Granulated Expanded Glass and Ash Aggregate by Means of Using Artificial Neural Networks. Materials 2019, 12, 2002. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kurpińska, M.; Grzyl, B.; Pszczola, M.; Kristowski, A. The Application of Granulated Expanded Glass Aggregate with Cement Grout as an Alternative Solution for Sub-Grade and Frost-Protection Sub-Base Layer in Road Construction. Materials 2019, 12, 3528. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kurpińska, M.; Ferenc, T. Application of lightweight cement composite with foamed glass aggregate in shell structures. Shell Struct. Theory Appl. 2018, 4, 549–552. [Google Scholar]

- Liu, F.; Wang, J.; Hollingsworth, J. Internal curing of high performance concrete using cenospheres. Cem. Concr. Res. 2017, 95, 39–46. [Google Scholar] [CrossRef] [Green Version]

- Hanif, A.; Lu, Z.; Li, Z. Utilization of ash cenosphere as lighweight filler in cement-based composites—A review. Constr. Build. Mater. 2017, 144, 373–384. [Google Scholar] [CrossRef]

- Kuryłowicz-Cudowska, A. Determination of Thermophysical Parameters Involved in The Numerical Model to Predict the Temperature Field of Cast-In-Place Concrete Bridge Deck. Materials 2019, 12, 3089. [Google Scholar] [CrossRef] [Green Version]

- Mariak, A.; Kurpińska, M.; Wilde, K. Maturity curve for estimating the in-place strength of high performance concrete. MATEC Web Conf. 2019, 262, 06007. [Google Scholar] [CrossRef]

- Plessis, A.; Olawuyi, B.J.; Boshoff, W.P.; Roux, S.G. Simple and fast porosity analysis of concrete using X-ray computed tomography. Mater. Struct. 2016, 49, 553–562. [Google Scholar] [CrossRef]

- EN 197–1. Cement. Part. 1: Composition, Specifications and Conformity Criteria for Common Cements; European Standards; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- EN 12390–3. Testing Hardened Concrete. Part. 3: Compressive Strength of Test Specimens; European Standards; European Committee for Standardization: Brussels, Belgium, 2019. [Google Scholar]

- EN 196–2. Methods of Testing Cement. Part. 2: Chemical Analysis of Cement; European Standards; European Committee for Standardization: Brussels, Belgium, 2013. [Google Scholar]

- ISO 13320:2009. Particle Size Analysis-Laser Diffraction Methods. Part. I: General Principles; International Organization for Standardization; ISO: Geneva, Switzerland, 2009. [Google Scholar]

- Skarzynski, Ł.; Tejchman, J. Experimental investigations of fracture process in concrete by means of X-ray micro-computed tomography. Strain 2016, 52, 26–45. [Google Scholar] [CrossRef]

- ASTM C457.C457 M. Standard Test. Method for Microscopical Determination of Parameters of the Air-Void System in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2012. [Google Scholar]

- IUPAC. Manual of Symbols and Terminology for Physicochemical Quantities and Units; Butterworths: London, UK, 1972. [Google Scholar]

- EN 450–1. Fly Ash for Concrete. Part. 1: Definition, Specifications and Conformity Criteria; European Standards; European Committee for Standardization: Brussels, Belgium, 2012. [Google Scholar]

- ASTM C618. Standard Specification for Coal Fly Ash and Raw or Calcined natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- Powers, T.C. Air requirement of frost-resistant concrete. Proc. Highw. Res. Board 1949, 29, 184–211. [Google Scholar]

- Lindquist, W.; Montney, R. Comparison of spacing factors as measured by the air-void analyzer and ASTM C457. Int. J. Pavement Eng. 2019, 20, 1–8. [Google Scholar] [CrossRef]

| Components of Concrete (kg/m3) | |||||

|---|---|---|---|---|---|

| Cement CEM I 42.5 R | Microspheres | Sand | Coarse Aggregate | Water | |

| 0–2 mm (37%) | 2–8 mm (38%) | 8–16 mm (25%) | - | ||

| 350 | 0 (0%) | 698 | 717 | 472 | 182 |

| 343 | 17 (5%) | 672 | 691 | 454 | 182 |

| 337 | 34 (10%) | 647 | 665 | 437 | 182 |

| Components | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | K2O | SO3 | P2O5 | TiO2 | Cl | LOI |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Sample 1 | 50.6 | 29.5 | 4.0 | 6.7 | 2.1 | 1.2 | 3.1 | 0.6 | 0.7 | 1.3 | 0.2 | 0.7 |

| Sample 2 | 52.0 | 30.9 | 4.2 | 3.8 | 2.4 | 1.1 | 3.0 | 0.4 | 0.6 | 1.2 | 0.4 | 1.1 |

| Average (%) | 51.3 | 30.2 | 4.1 | 5.3 | 2.2 | 1.2 | 3.0 | 0.5 | 0.7 | 1.2 | 0.3 | 0.9 |

| Content of Microspheres in Concrete | Total Porosity (%) | Content of Air Voids (%) | ||

|---|---|---|---|---|

| <250 µm | 250–500 µm | >500 µm | ||

| 0% | 1.222 | 0.389 | 0.412 | 0.421 |

| 5% | 5.132 | 4.048 | 0.582 | 0.502 |

| 10% | 7.400 | 5.769 | 0.884 | 0.747 |

| Water/Binder Ratio (w/b) | 0.5 | |||

|---|---|---|---|---|

| Content of Microspheres in Concrete | 0% | 5% | 10% | |

| Total content of air pores (%) | closed | 1.001 | 4.534 | 6.277 |

| open | 0.221 | 0.598 | 1.123 | |

| The content of pores with a size <250 µm (%) | closed | 0.498 | 3.389 | 4.708 |

| open | 0.189 | 0.475 | 0.899 | |

| The content of pores with a size 250–500 µm (%) | closed | 0.293 | 0.628 | 0.837 |

| open | 0.021 | 0.097 | 0.172 | |

| The content of pores with a size >500 µm (%) | closed | 0.210 | 0.517 | 0.732 |

| open | 0.011 | 0.026 | 0.052 | |

| Characteristics of Air Structure in Concrete | Content of Microspheres in Concrete | ||

|---|---|---|---|

| 0% | 5% | 10% | |

| The total volume of air voids (A300) (%) | 1.5 | 5.8 | 7.9 |

| The content of micropores with a diameter below 300 μm (A300) (%) | 0.64 | 1.47 | 4.5 |

| The ratio of micropores to total air (A300/A) | 0.43 | 0.25 | 0.57 |

| The specific surface area of air voids (α) (mm−1), | 22.7 | 30.0 | 38.6 |

| The spacing factor () (mm) | 0.39 | 0.21 | 0.09 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haustein, E.; Kuryłowicz-Cudowska, A. The Effect of Fly Ash Microspheres on the Pore Structure of Concrete. Minerals 2020, 10, 58. https://doi.org/10.3390/min10010058

Haustein E, Kuryłowicz-Cudowska A. The Effect of Fly Ash Microspheres on the Pore Structure of Concrete. Minerals. 2020; 10(1):58. https://doi.org/10.3390/min10010058

Chicago/Turabian StyleHaustein, Elzbieta, and Aleksandra Kuryłowicz-Cudowska. 2020. "The Effect of Fly Ash Microspheres on the Pore Structure of Concrete" Minerals 10, no. 1: 58. https://doi.org/10.3390/min10010058

APA StyleHaustein, E., & Kuryłowicz-Cudowska, A. (2020). The Effect of Fly Ash Microspheres on the Pore Structure of Concrete. Minerals, 10(1), 58. https://doi.org/10.3390/min10010058