Hyperspectral Characteristics of Oil Sand, Part 2: Prediction of Froth Characteristics from Measurements of Froth

Abstract

:1. Introduction

2. Materials

3. Methods

3.1. Flotation Experiments

3.2. Acquisition of Reflectance Spectra

3.3. Spectral Processing with Wavelet Analysis

4. Results

4.1. Sample Suite #1 (10 Samples for Model Development)

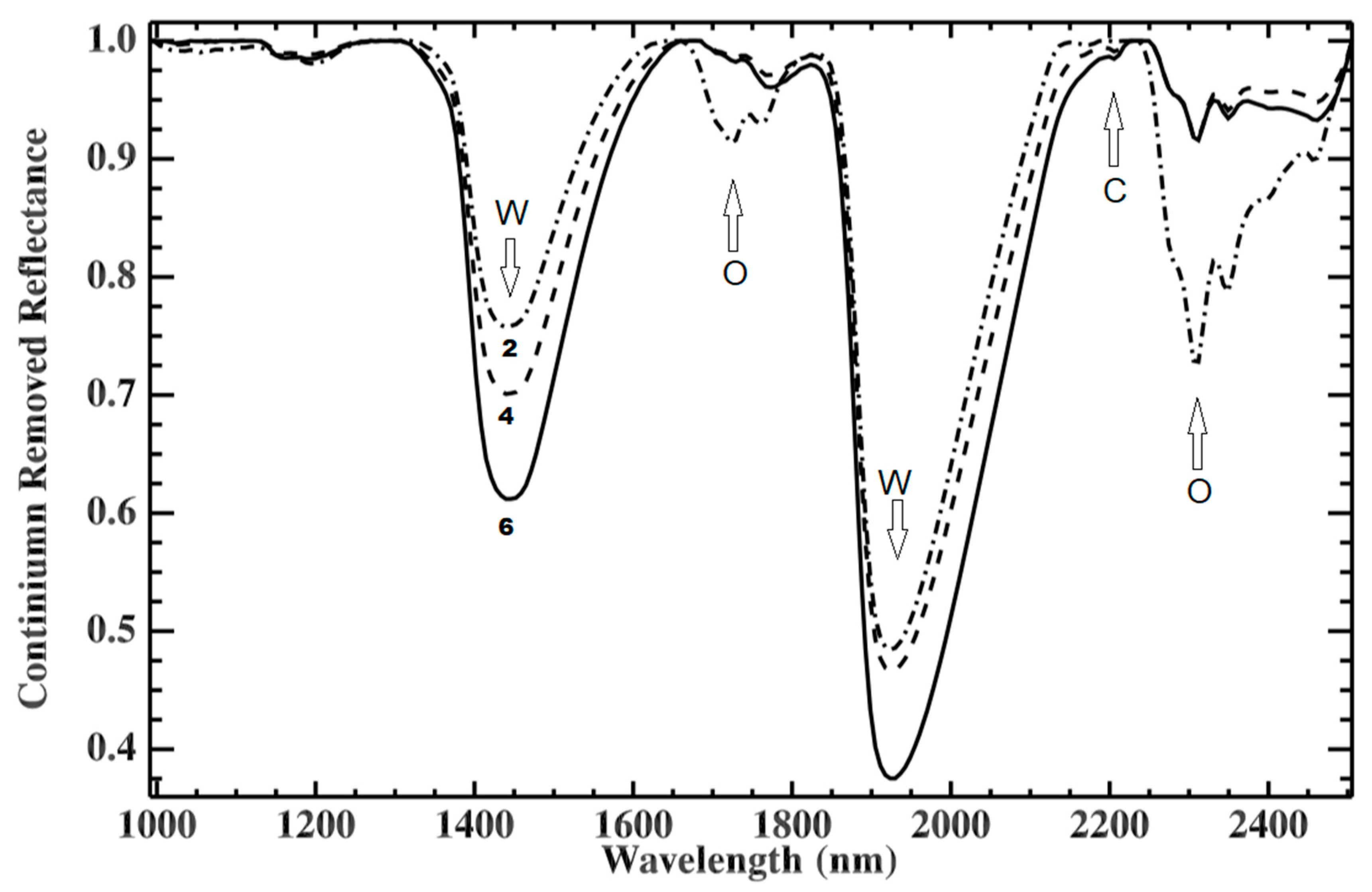

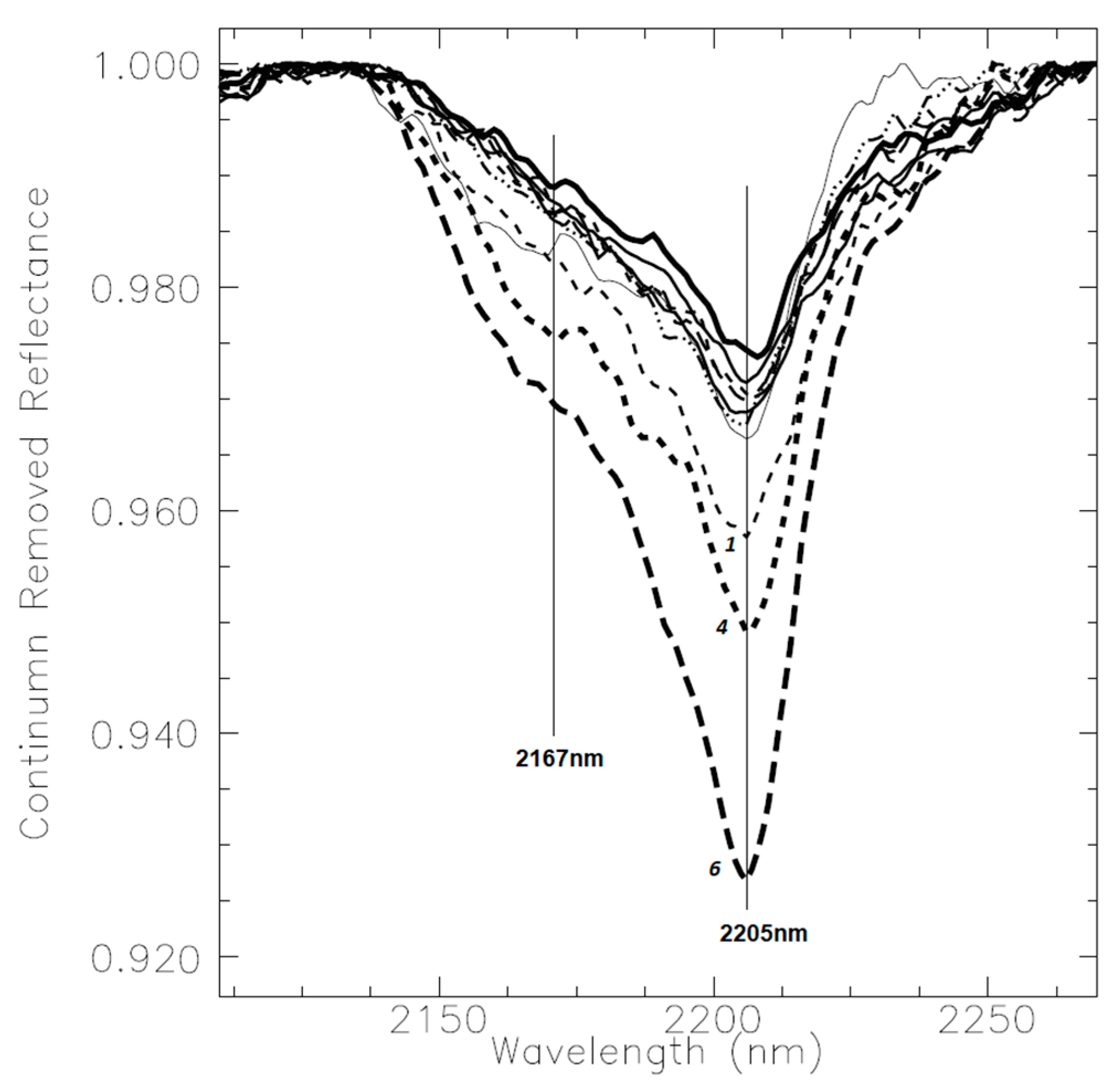

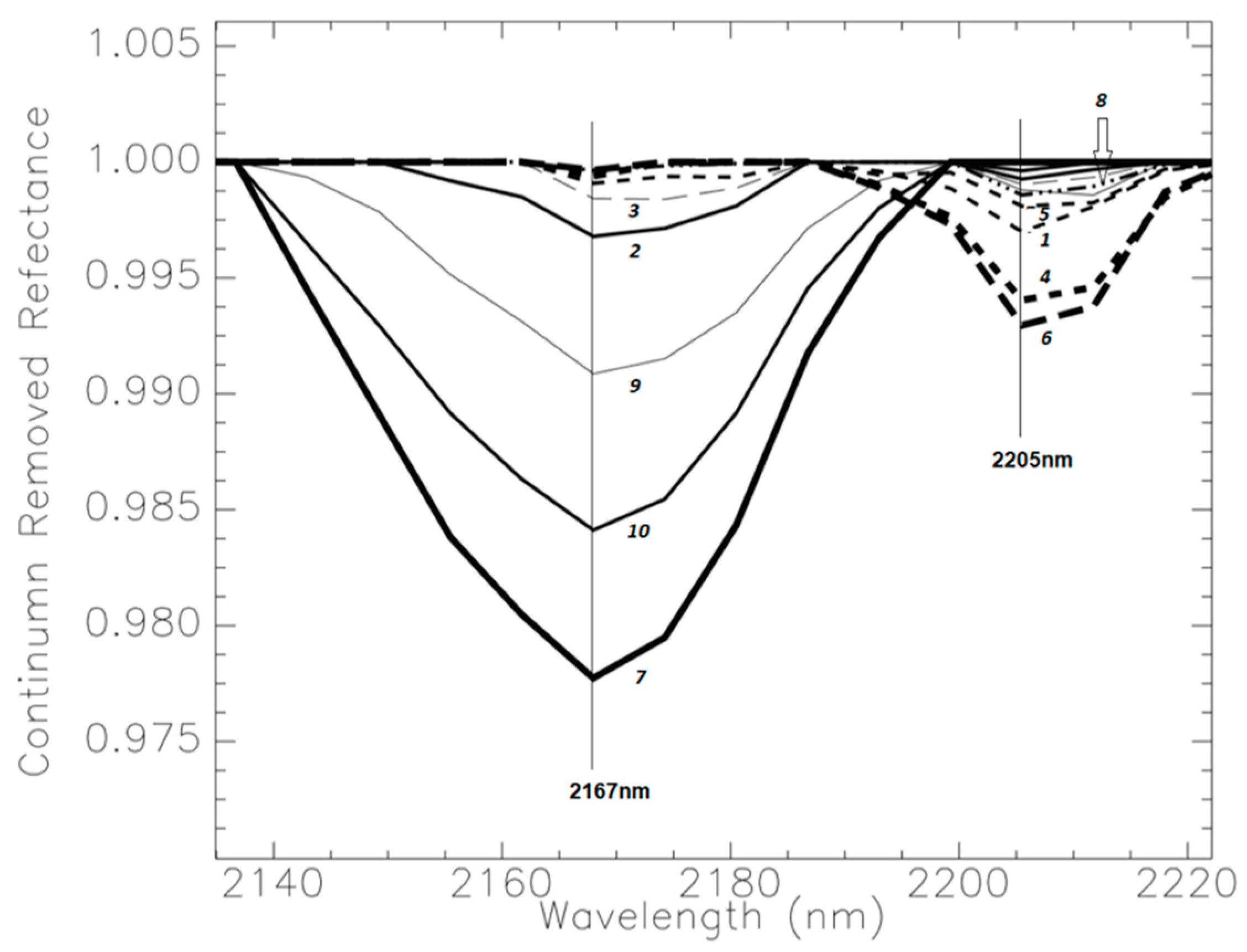

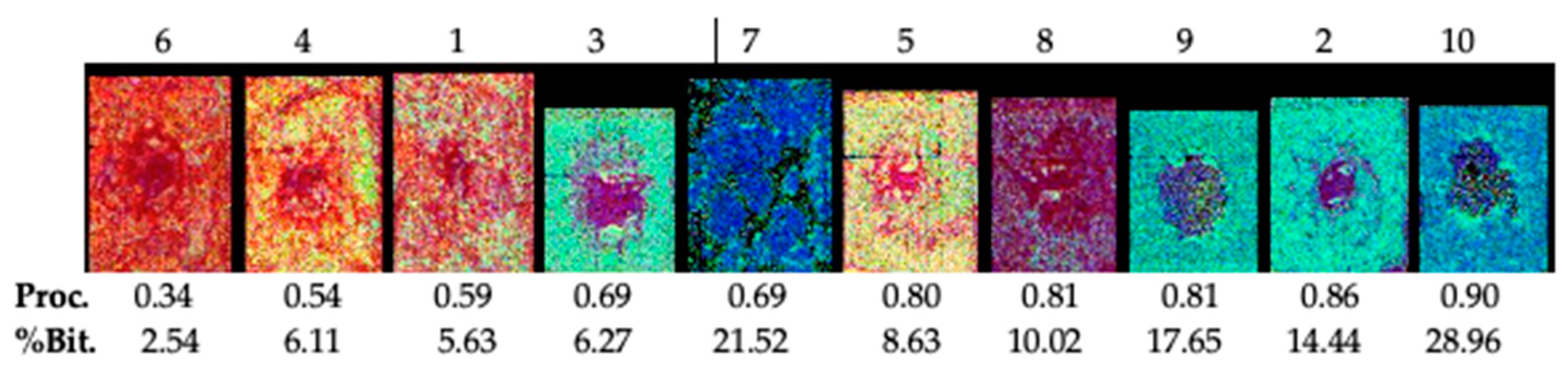

4.1.1. Type Spectra and Image Time-Series of Froth

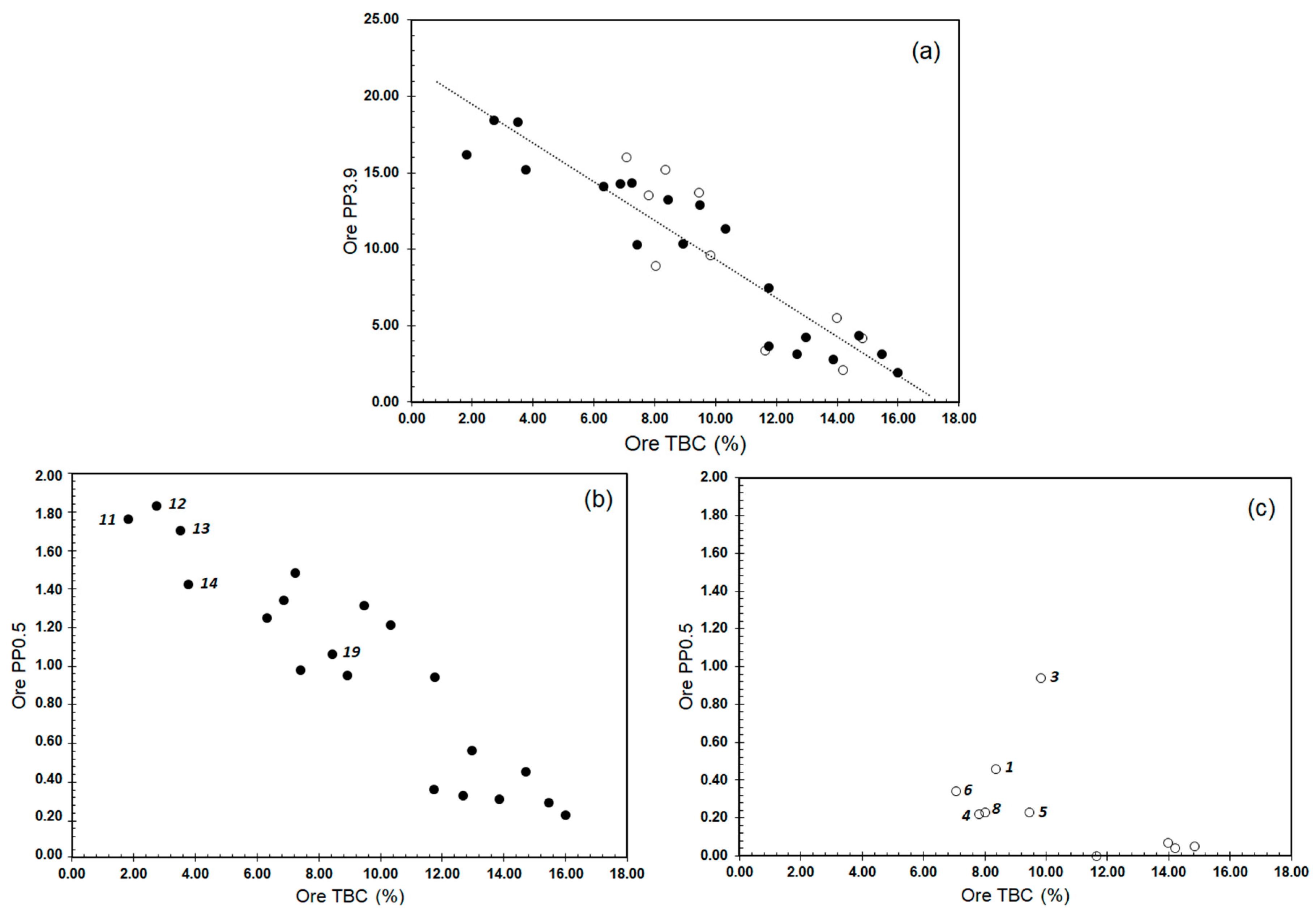

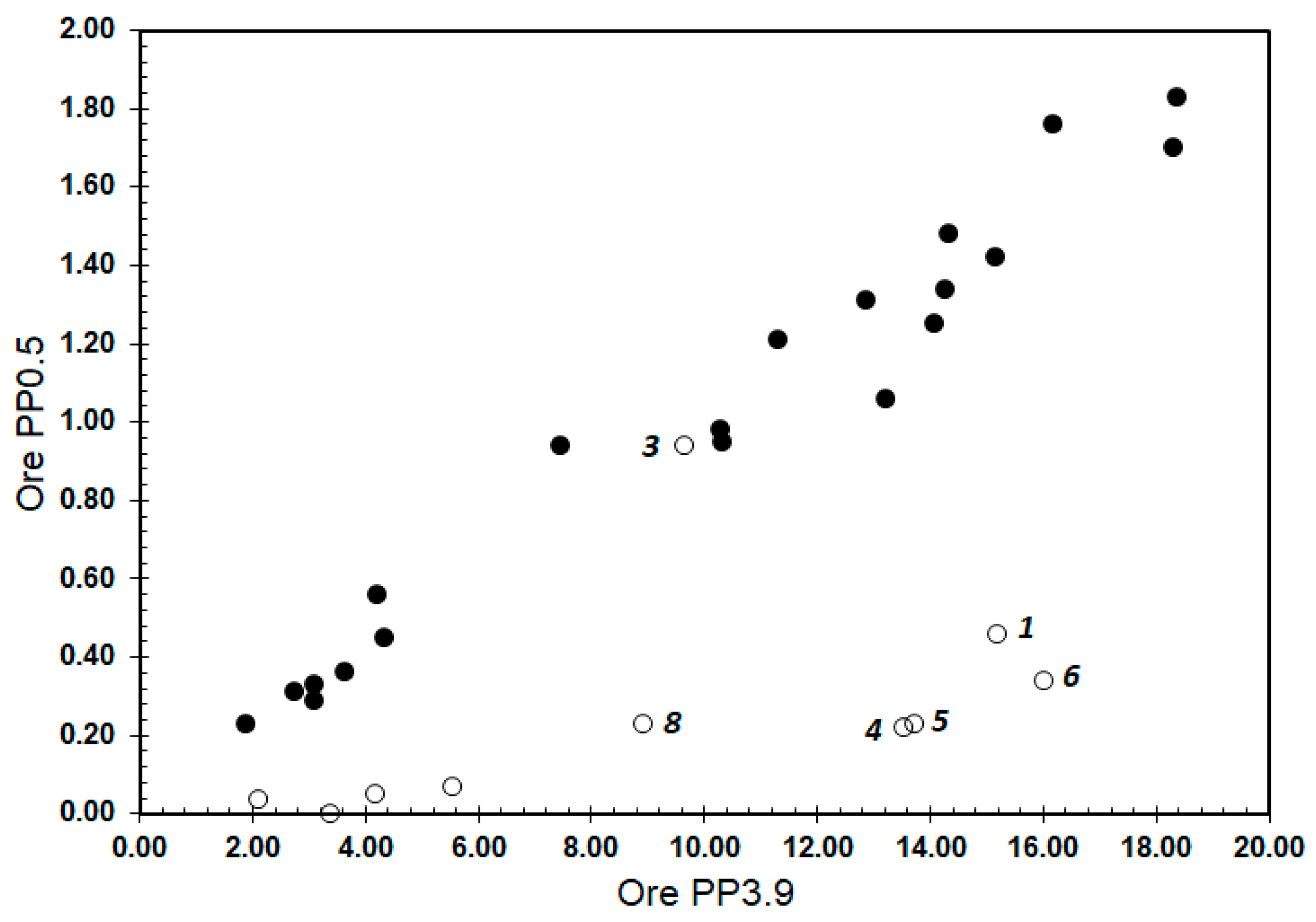

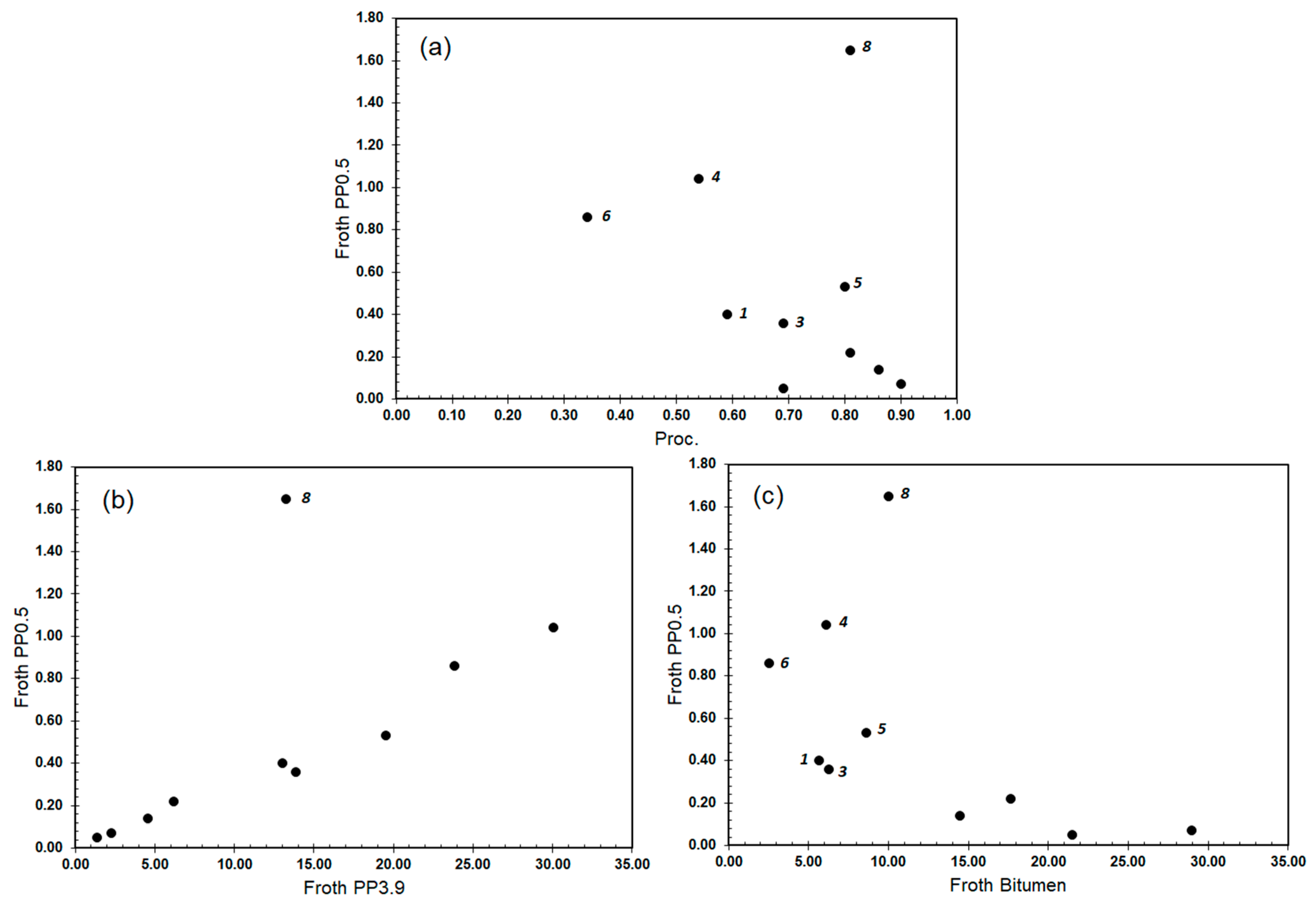

4.1.2. Links between Froth Imagery and Ore and Froth Characteristics

4.2. Predictive Models Using Spectra of Froth

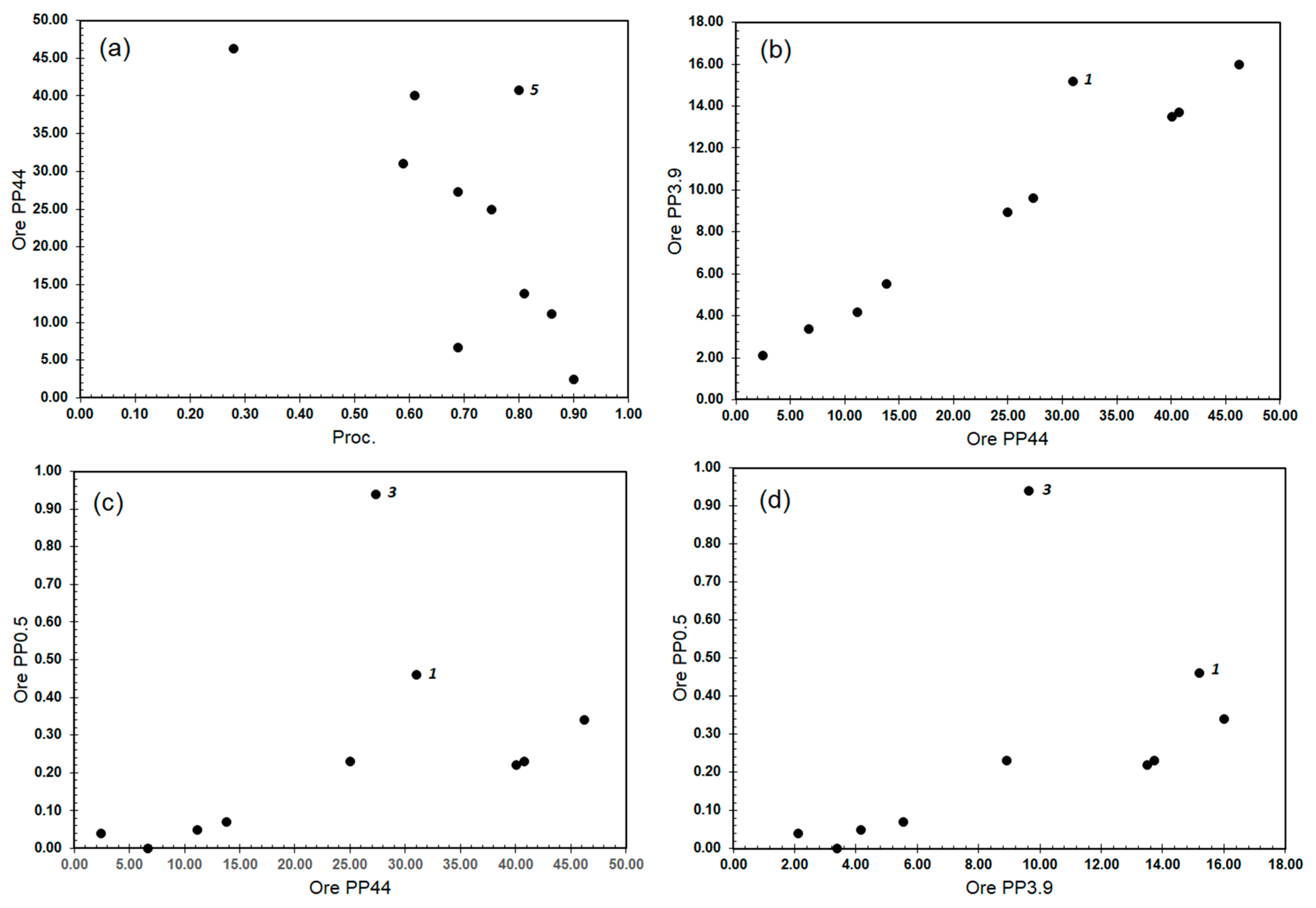

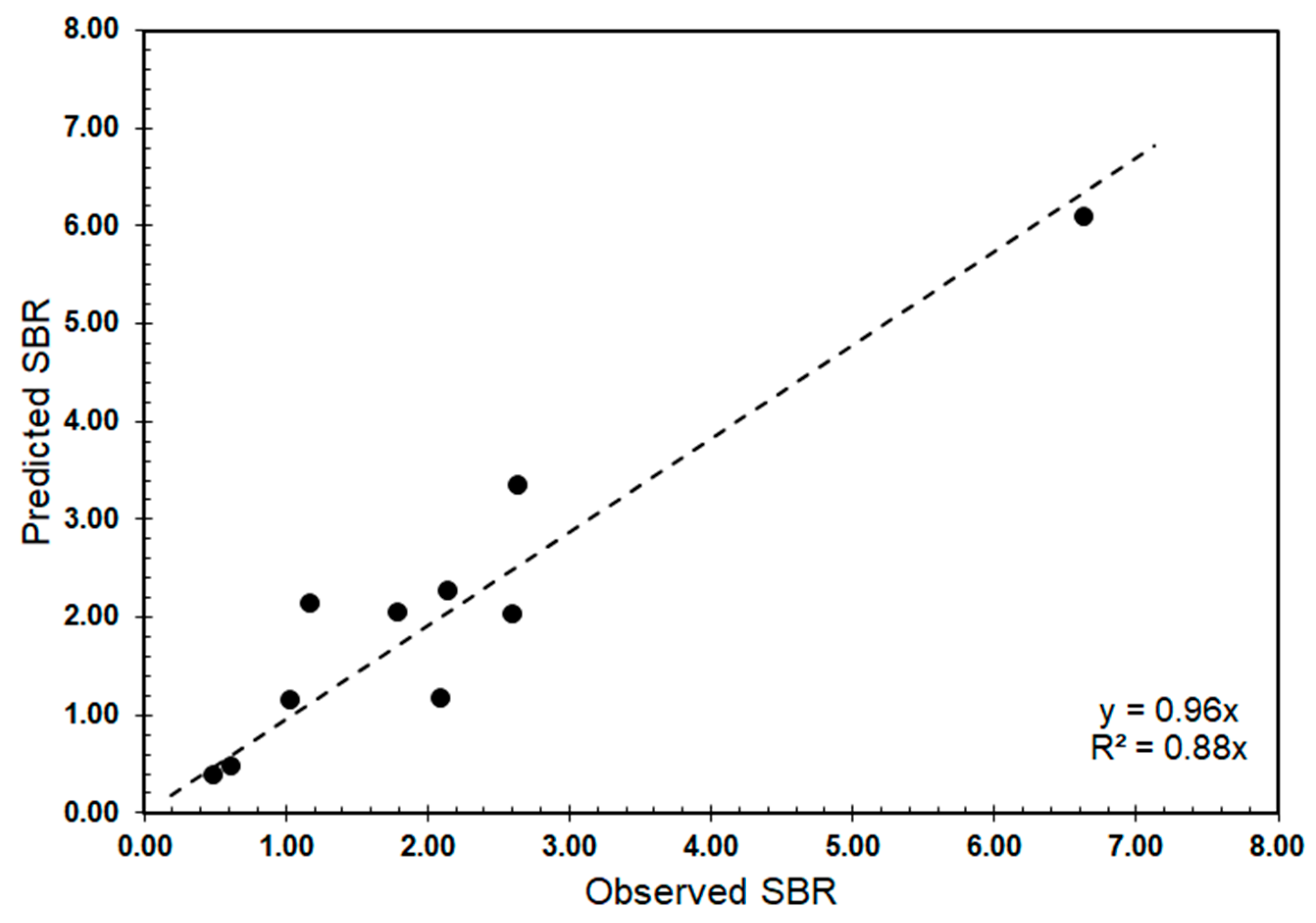

4.2.1. Prediction of Solids to Bitumen (SBR)

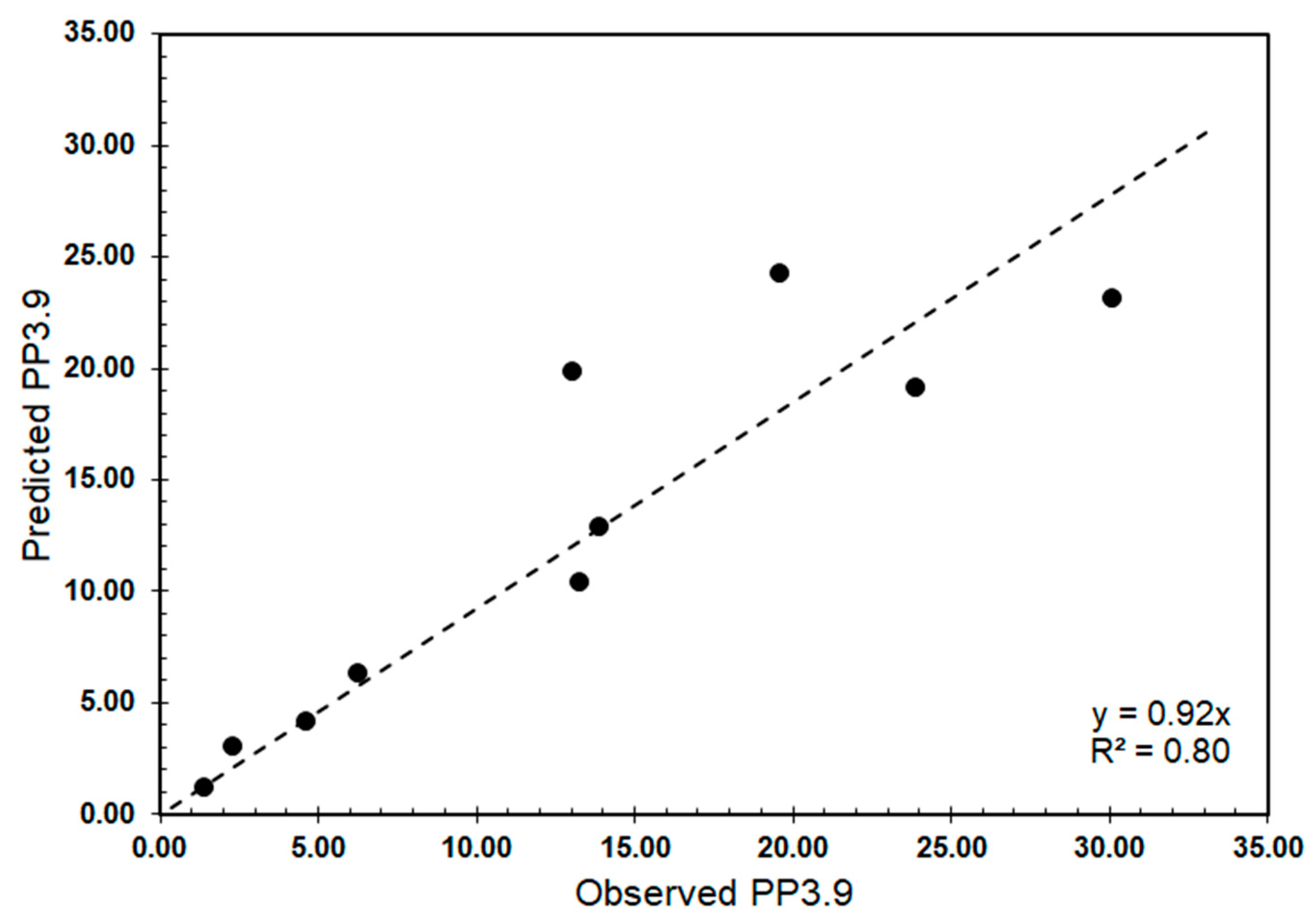

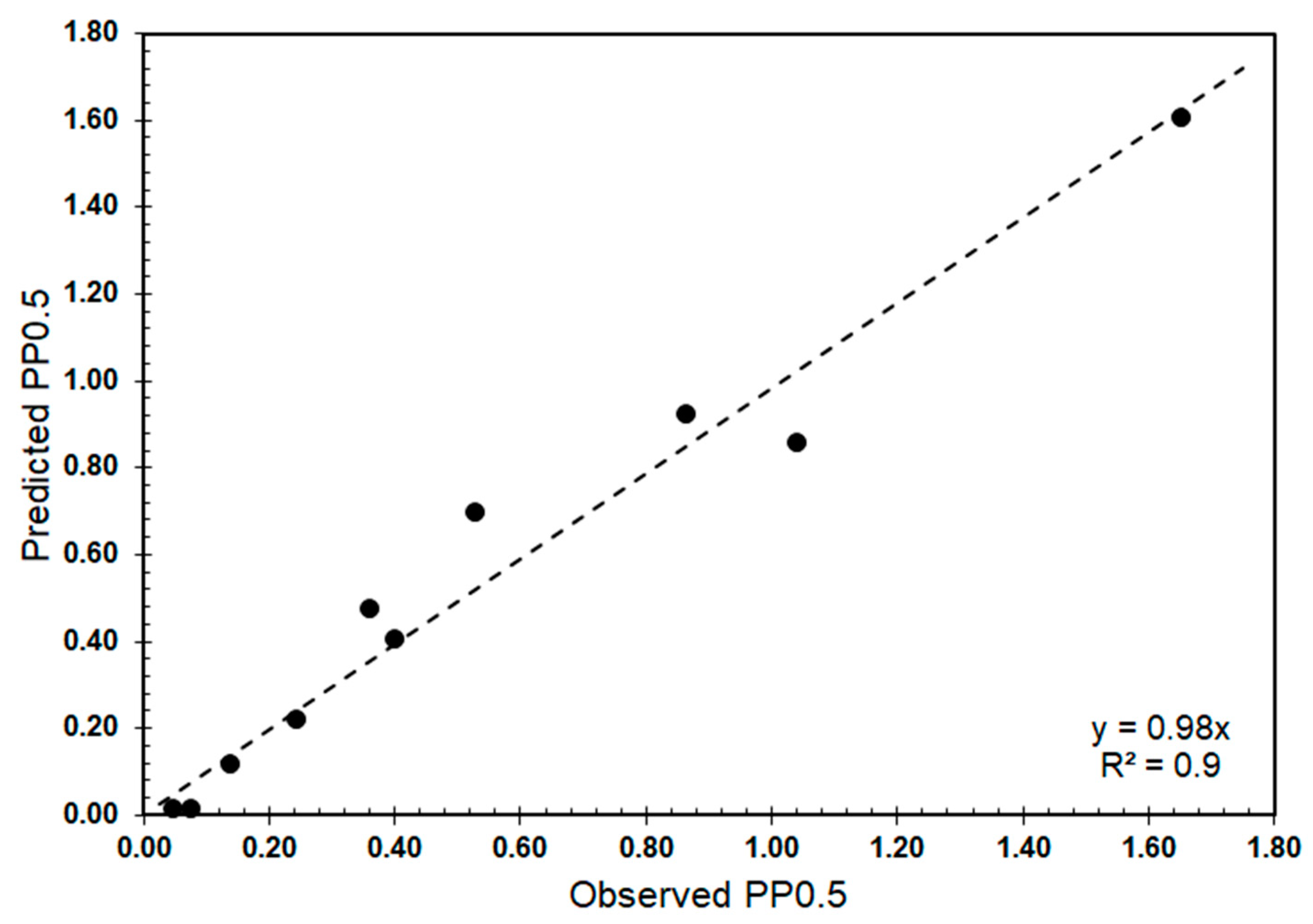

4.2.2. Prediction of Fines Content

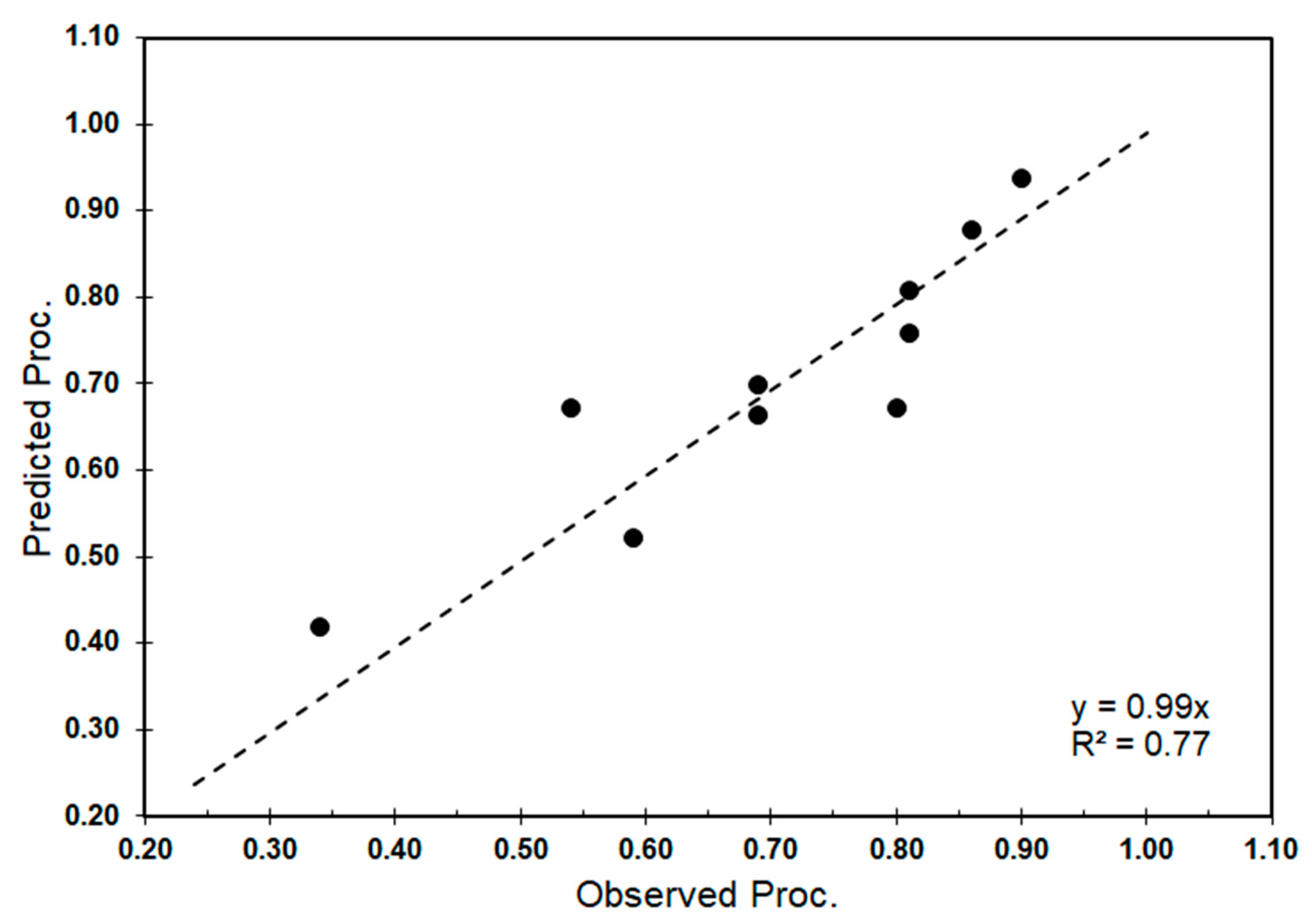

4.2.3. Prediction of Processability

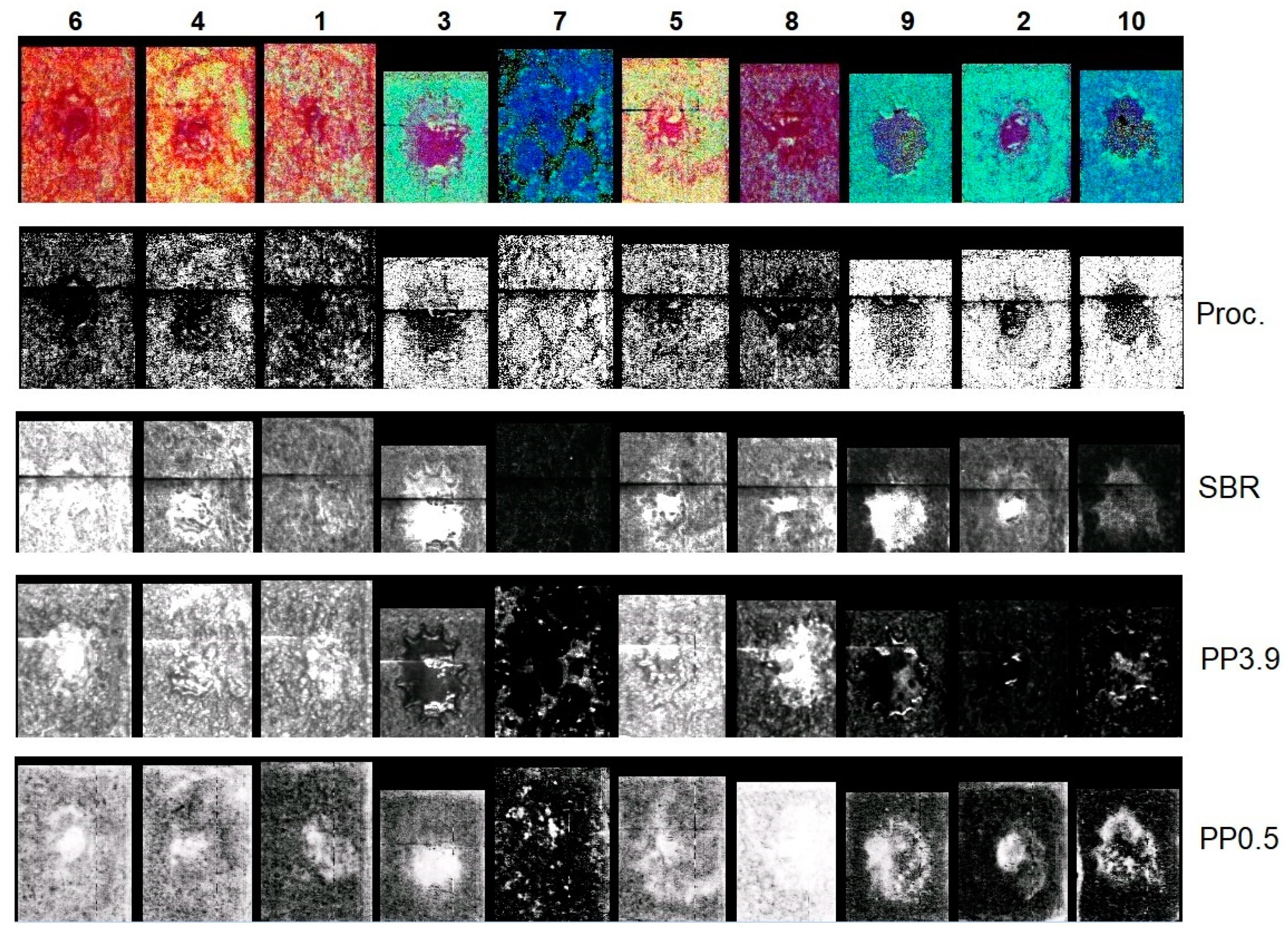

4.3. Application of Models to Froth Imagery of Sample Suite #1 (10 Samples)

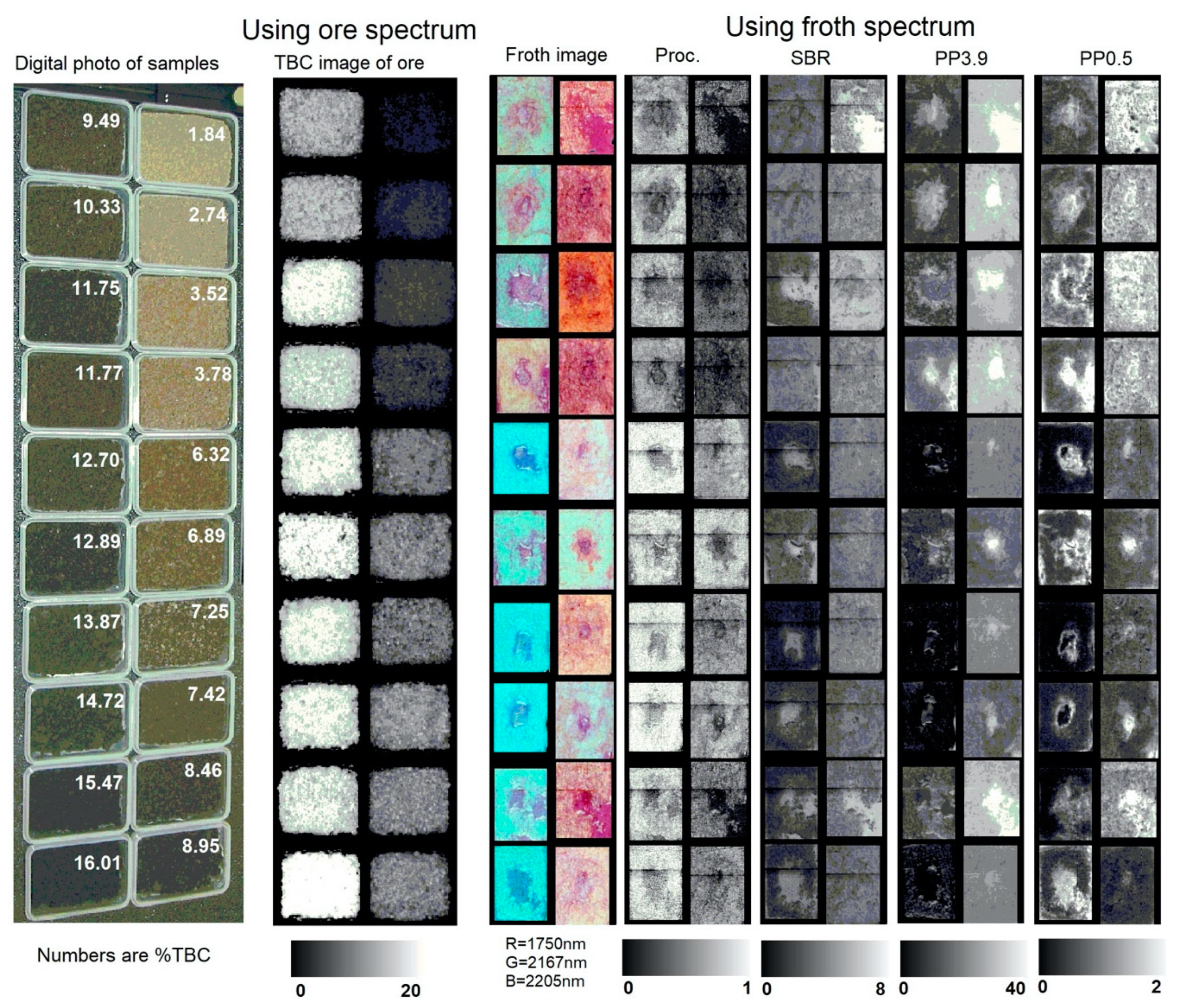

4.4. Application of Predictive Models to Froth Imagery of Sample Suite #2 (20 Samples)

5. Discussion

5.1. Spectral Measurements of Froth

5.2. Infrared Spectra as a Tool to Reveal Froths of Poorer Quality

5.3. Use of Spectral Information for Process Monitoring and Control

5.4. Relative Merit of Point and Imaging Measurements

5.5. Contrasting Results between Both Companion Papers

6. Conclusions

7. Patents

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wills, B.A.; Napier-Munn, T. Wills’ Mineral Processing Technology, 7th ed.; Butterworth-Heinemann; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Oestreich, J.; Tolley, W.; Rice, D. The development of a color sensor system to measure mineral compositions. Miner. Eng. 1995, 8, 31–39. [Google Scholar] [CrossRef]

- Hargrave, J.M.; Hall, S.T. Diagnosis of concentrate grade and mass flowrate in tin flotation from colour and surface texture analysis. Miner. Eng. 1997, 10, 613–621. [Google Scholar] [CrossRef]

- Haavisto, O.; Hyötyniemi, H. Reflectance spectroscopy in the analysis of mineral flotation slurries. J. Process. Control. 2009, 6, 14–16. [Google Scholar] [CrossRef]

- Khajehzadeh, N.; Haavisto, O.; Koresaar, L. On-stream mineral identification of tailing slurries of an iron ore concentrator using data fusion of LIBS, reflectance spectroscopy and XRF measurement techniques. Miner. Eng. 2017, 113, 83–94. [Google Scholar] [CrossRef]

- Bichard, J.A. Oil Sand Composition and behavior Research. In AOSTRA Technical Publication Series 4; Alberta Oil Sands Technology and Research Authority: Edmonton, AB, Canada, 1987; Chapter 1; pp. 6–62. [Google Scholar]

- Masliyah, J.; Zhou, Z.J.; Xu, Z.; Czarnecki, J.; Hamza, H. Understanding water-based bitumen extraction from Athabasca oil sands. Can. J. Chem. Eng. 2004, 82, 628–654. [Google Scholar] [CrossRef]

- Harjai, S.K.; Flury, C.; Masliyah, J.; Drelich, J.; Xu, Z. Robust aqueous–nonaqueous hybrid process for bitumen extraction from mineable Athabasca oil sands. Energy Fuels 2012, 26, 2920–2927. [Google Scholar] [CrossRef]

- Wiley & Sons. Wiley Critical Content—Petroleum Technology; Wiley–Interscience: Hoboken, NJ, USA, 2007; Volume 1, pp. 222–240. [Google Scholar]

- Hepler, L.G.; His, C. AOSTRA Technical Handbook on Oil Sands, Bitumen’s, and Heavy Oils. In AOSTRA Technical Publication Series 6; Alberta Oil Sands Technology and Research Authority: Edmonton, AB, Canada, 1989; Chapter 2; pp. 14–20. [Google Scholar]

- Ignasiak, T.M.; Kotlyar, L.; Longstaffe, F.J.; Strausz, O.P.; Montgomery, D.S. Separation and characterization of clay from Athabasca asphaltene. Fuel 1983, 62, 353–362. [Google Scholar] [CrossRef]

- Omotoso, O.; Mikula, R.J.; Stephens, P.W. Surface area of interstratified phyllysilicates in Athabasca oil sands from Synchrotron XRD, JCPDS–International Centre for Diffraction Data. Adv. X-ray Anal. 2002, 45, 391–396. [Google Scholar]

- Omotoso, O.E.; Mikula, R.J. High surface areas caused by smectitic interstratification of kaolinite and illite in Athabasca oil sands. Appl. Clay Sci. 2004, 25, 37–47. [Google Scholar] [CrossRef]

- Wallace, D.; Tipman, R.; Komishke, B.; Wallwork, V.; Perkins, E. Fines/water interactions and consequences of the presence of degraded illite on oil sands extractability. Can. J. Chem. Eng. 2004, 82, 667–677. [Google Scholar] [CrossRef]

- Osacky, M.; Geramian, M.; Ivey, D.G.; Lui, Q.; Etsell, T.H. Influence of nonswelling clay minerals (illite, kaolinite, and chlorite) on nonaqueous solvent extraction of bitumen. Energy Fuels 2015, 29, 4150–4159. [Google Scholar] [CrossRef]

- Geramian, M.; Osacky, M.; Ivey, D.G.; Lui, Q.; Etsell, T.H. Effect of swelling clay minerals (montorillonite and illite-smectite) on nonaqueous bitumen extraction from Alberta Oil Sands. Energy Fuels 2016, 30, 8083–8090. [Google Scholar] [CrossRef]

- Takamura, K.; Wallace, D. The Physical Chemistry of the Hot Water Process. J. Can. Pet. Tech. 1988, 27, 98–106. [Google Scholar] [CrossRef]

- Bulmer, J.T.; Starr, J. Syncrude Analytical Methods for Oil Sand and Bitumen Processing in Methods 2.9 and 2.10: Classical and Syncrude Methods for the Determination of Bitumen. In Water and Solids Content of Froth; AOSTRA: Edmonton, AB, Canada, 1979. [Google Scholar]

- Rivard, B.; Feng, J.; Gallie, A.; Sanchez-Azofeifa, A. Continuous wavelets for the improved use of spectral libraries and hyperspectral data. Remote Sens. Environ. 2008, 112, 2850–2862. [Google Scholar] [CrossRef]

| Sample ID | %Bitumen | %Water | %Solids | * pp44 | * pp3.9 | * pp0.5 | Modelling | Testing |

|---|---|---|---|---|---|---|---|---|

| Sp#1 | 8.35 | 5.39 | 86.05 | 31.00 | 15.19 | 0.46 | - | |

| Sp#2 | 14.83 | 2.58 | 83.27 | 11.13 | 4.17 | 0.05 | - | |

| Sp#3 | 9.82 | 4.46 | 83.52 | 27.30 | 9.63 | 0.94 | - | |

| Sp#4 | 7.81 | 6.72 | 85.88 | 40.06 | 13.51 | 0.22 | - | |

| Sp#5 | 9.45 | 6.84 | 83.42 | 40.75 | 13.72 | 0.23 | - | |

| Sp#6 | 7.06 | 3.53 | 89.21 | 46.24 | 16.00 | 0.34 | - | |

| Sp#7 | 11.63 | 3.36 | 84.70 | 6.71 | 3.37 | 0 | - | |

| Sp#8 | 8.02 | 7.78 | 84.42 | 24.98 | 8.92 | 0.23 | - | |

| Sp#9 | 13.97 | 3.59 | 82.26 | 13.83 | 5.53 | 0.07 | - | |

| Sp#10 | 14.20 | 3.12 | 83.16 | 2.44 | 2.11 | 0.04 | - | |

| Sp#11 | 1.84 | 12.85 | 85.32 | 59.45 | 16.18 | 1.76 | - | |

| Sp#12 | 2.74 | 11.28 | 85.87 | 54.75 | 18.38 | 1.83 | - | |

| Sp#13 | 3.52 | 9.13 | 87.28 | 53.60 | 18.30 | 1.70 | - | |

| Sp#14 | 3.78 | 12.56 | 83.44 | 44.83 | 15.15 | 1.42 | - | |

| Sp#15 | 6.32 | 8.37 | 85.32 | 49.25 | 14.08 | 1.25 | - | |

| Sp#16 | 6.89 | 8.62 | 84.6 | 51.45 | 14.28 | 1.34 | - | |

| Sp#17 | 7.25 | 7.91 | 84.62 | 47.43 | 14.33 | 1.48 | - | |

| Sp#18 | 7.42 | 9.68 | 82.49 | 32.38 | 10.28 | 0.98 | - | |

| Sp#19 | 8.46 | 7.06 | 84.6 | 25.20 | 13.23 | 1.06 | - | |

| Sp#20 | 8.95 | 8.52 | 82.66 | 21.75 | 10.31 | 0.95 | - | |

| Sp#21 | 9.49 | 7.28 | 82.8 | 39.23 | 12.88 | 1.31 | - | |

| Sp#22 | 10.33 | 7.3 | 82.15 | 34.58 | 11.30 | 1.21 | - | |

| Sp#23 | 11.75 | 5.55 | 82.29 | 10.25 | 3.65 | 0.36 | - | |

| Sp#24 | 11.77 | 6.53 | 81.27 | 22.58 | 7.47 | 0.94 | - | |

| Sp#25 | 12.7 | 5.77 | 81.59 | 8.61 | 3.09 | 0.33 | - | |

| Sp#26 | 12.98 | 4.65 | 82.59 | 11.68 | 4.21 | 0.56 | - | |

| Sp#27 | 13.87 | 4.24 | 81.85 | 7.45 | 2.75 | 0.31 | - | |

| Sp#28 | 14.72 | 4 | 81.2 | 13.45 | 4.33 | 0.45 | - | |

| Sp#29 | 15.47 | 2.23 | 82.03 | 7.28 | 3.09 | 0.29 | - | |

| Sp#30 | 16.01 | 1.54 | 82.56 | 5.16 | 1.88 | 0.23 | - |

| Sample ID | Average Froth Quality a | |||||

|---|---|---|---|---|---|---|

| Processability | %Bitumen | %Solids | Solids/Bitumen | * pp3.9 | * pp0.5 | |

| Sp#1 | 0.59 | 5.63 | 11.51 | 2.14 | 13.00 | 0.40 |

| Sp#2 | 0.86 | 14.44 | 15.93 | 1.17 | 4.58 | 0.14 |

| Sp#3 | 0.69 | 6.27 | 15.91 | 2.59 | 13.86 | 0.36 |

| Sp#4 | 0.61 | 6.11 | 14.42 | 2.64 | 30.07 | 1.04 |

| Sp#5 | 0.80 | 8.63 | 17.67 | 2.10 | 19.56 | 0.53 |

| Sp#6 | 0.28 | 2.54 | 15.72 | 6.63 | 23.84 | 0.86 |

| Sp#7 | 0.69 | 21.52 | 8.26 | 0.49 | 1.39 | 0.05 |

| Sp#8 | 0.75 | 10.02 | 17.42 | 1.79 | 13.27 | 1.65 |

| Sp#9 | 0.81 | 17.65 | 16.44 | 1.03 | 6.23 | 0.24 |

| Sp#10 | 0.90 | 28.96 | 17.32 | 0.61 | 2.27 | 0.07 |

| Wavelength (µm) | Correlation Coefficient | Scale | Features Used (-) | |||

|---|---|---|---|---|---|---|

| SBR | pp3.9 | pp0.5 | Proc. | |||

| 1.54 | 0.956 | 4 | - | |||

| 1.587 | 0.865 | 5 | - | |||

| 1.735 | 0.561 | 2 | - | |||

| 1.76 | 0.8 | 6 | - | |||

| 1.779 | 0.572 | 3 | - | |||

| 2.13 | 0.84 | 5 | - | |||

| 2.18 | 0.706 | 1 | - | |||

| 2.192 | 0.839 | 6 | - | |||

| 2.205 | 0.793 | 1 | - | |||

| 2.255 | 0.714 | 4 | - | |||

| 2.33 | 0.602 | 2 | - | |||

| 2.34 | 0.855 | 5 | - | |||

| 2.474 | 0.65 | 2 | - | |||

| 2.492 | 0.727 | 5 | - | |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rivard, B.; Feng, J.; Russell, D.; Bushan, V.; Lipsett, M. Hyperspectral Characteristics of Oil Sand, Part 2: Prediction of Froth Characteristics from Measurements of Froth. Minerals 2020, 10, 1137. https://doi.org/10.3390/min10121137

Rivard B, Feng J, Russell D, Bushan V, Lipsett M. Hyperspectral Characteristics of Oil Sand, Part 2: Prediction of Froth Characteristics from Measurements of Froth. Minerals. 2020; 10(12):1137. https://doi.org/10.3390/min10121137

Chicago/Turabian StyleRivard, Benoit, Jilu Feng, Derek Russell, Vivek Bushan, and Michael Lipsett. 2020. "Hyperspectral Characteristics of Oil Sand, Part 2: Prediction of Froth Characteristics from Measurements of Froth" Minerals 10, no. 12: 1137. https://doi.org/10.3390/min10121137