The Genetic Mechanism and Evolution Process of Overpressure in the Upper Ordovician–Lower Silurian Black Shale Formation in the Southern Sichuan Basin

Abstract

:1. Introduction

2. Geological Background

3. Samples and Analytical Methods

3.1. Samples

3.2. Overpressure Characterization

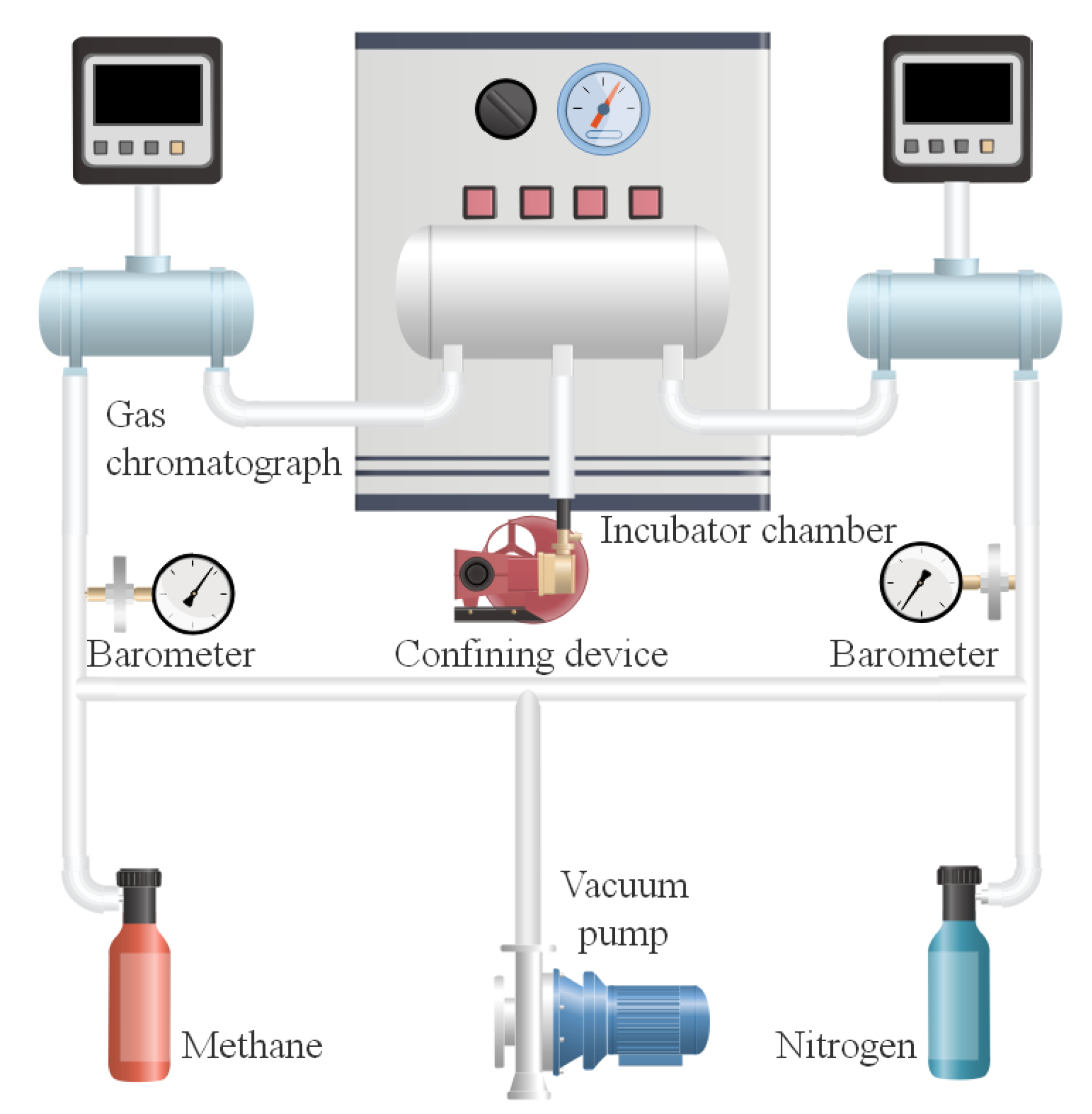

3.3. Auxiliary Experiments

4. Basin Simulation

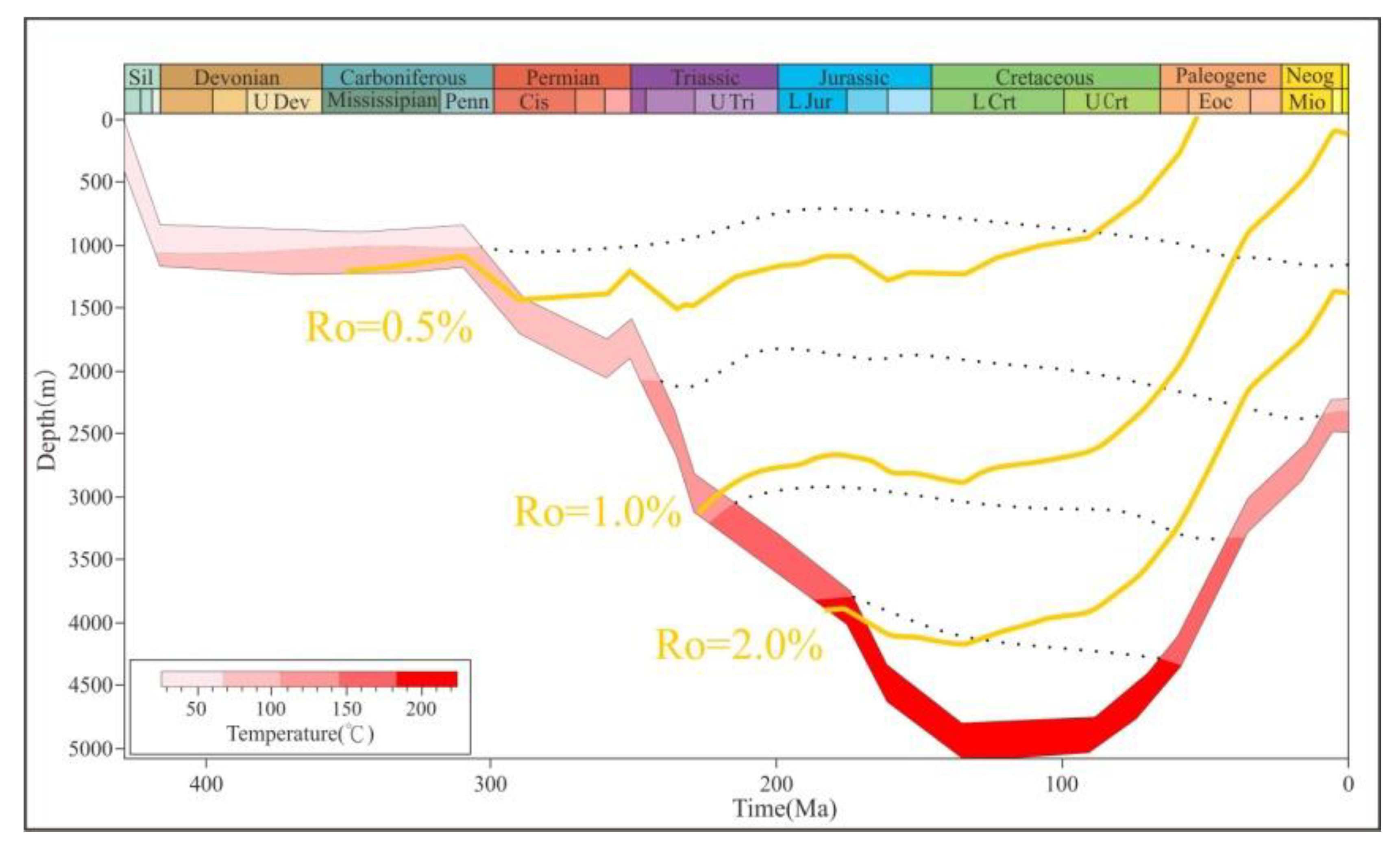

4.1. Burial and Thermal History Simulations

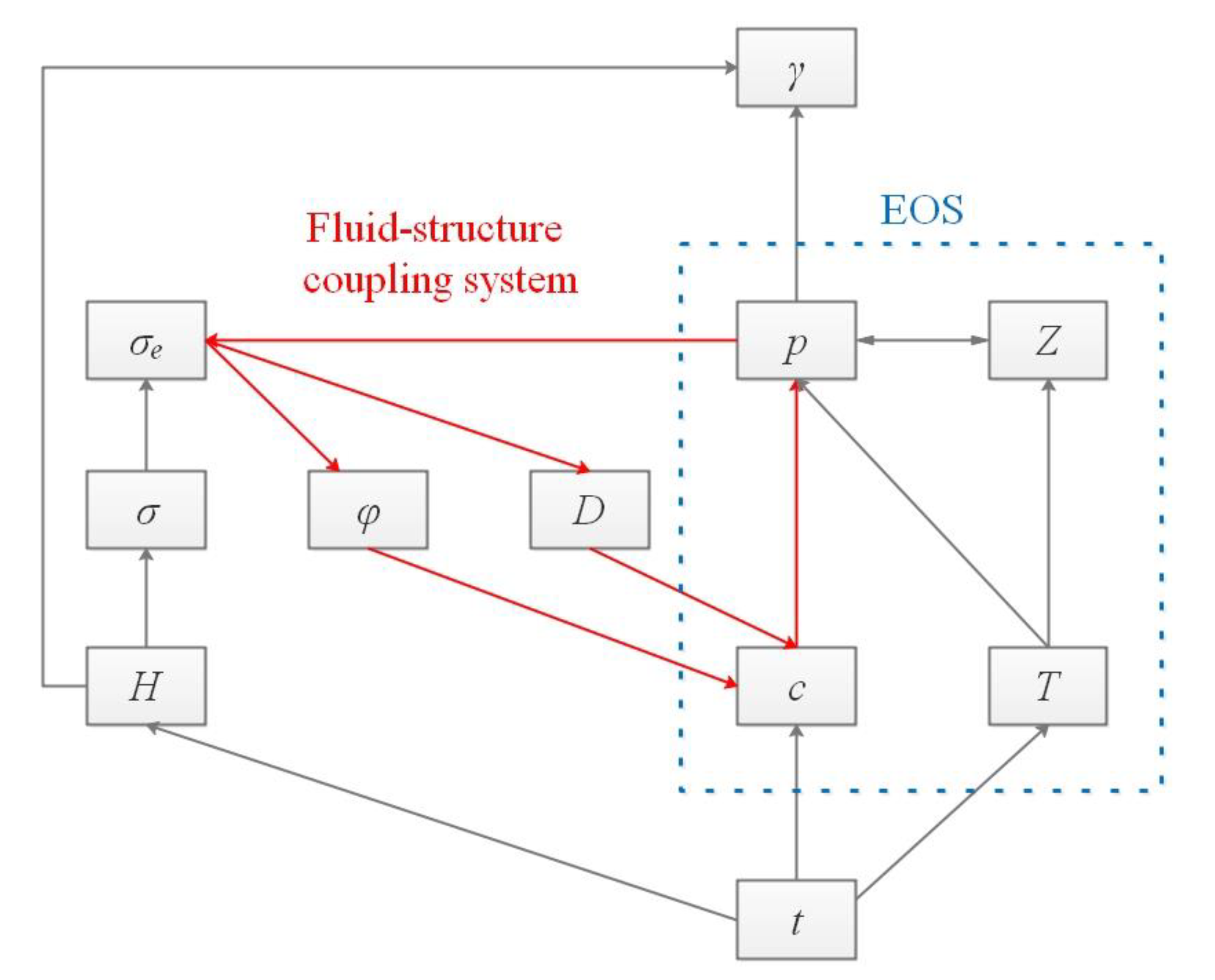

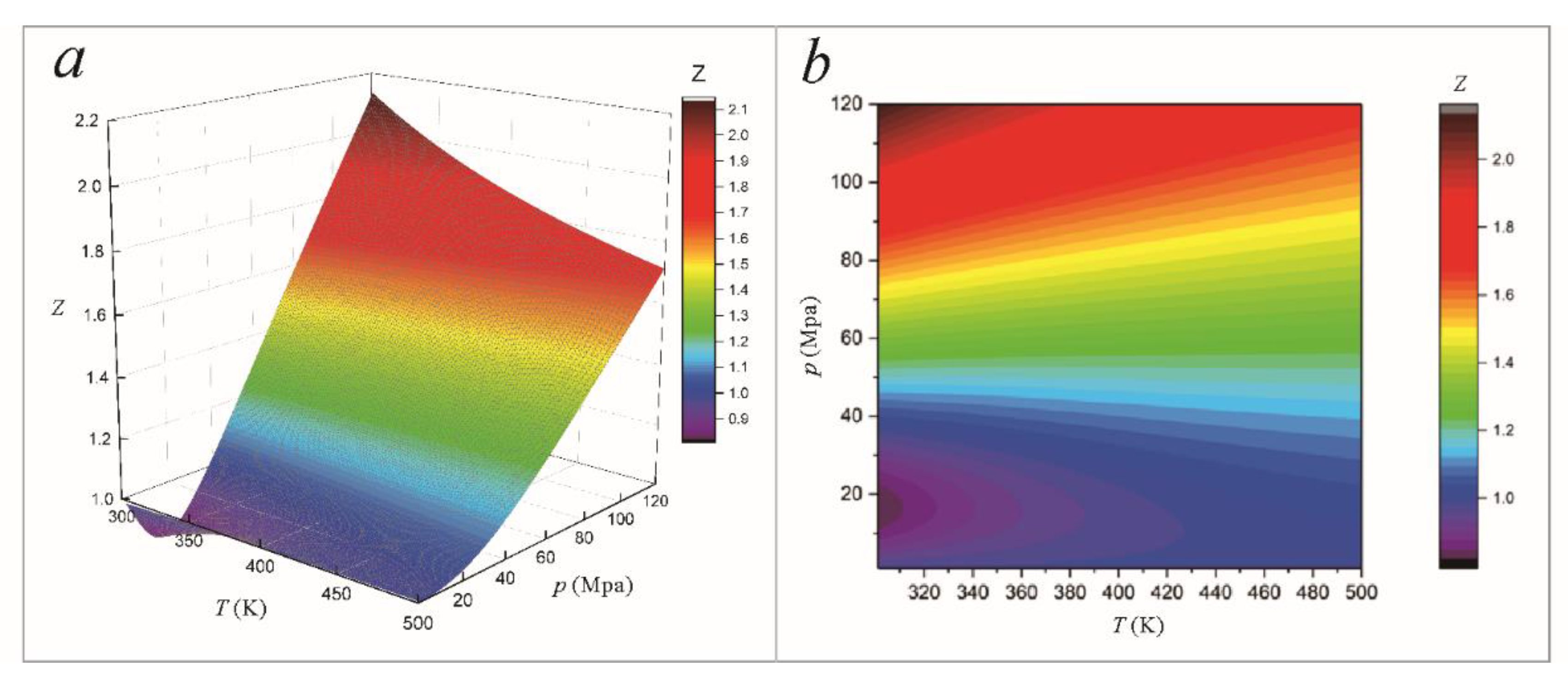

4.2. Shale Reservoir Pressure Evolution Model

- (1)

- Shale gas occurs in the organic matter pores in both the free phase and the adsorbed phase.

- (2)

- The shale reservoir is isotropic, homogeneous and linear elastic.

- (3)

- The diffusion of shale gas and the elastic change in the shale matrix are isothermal.

- (4)

- Gas sorption follows the Langmuir isothermal behavior.

5. Results

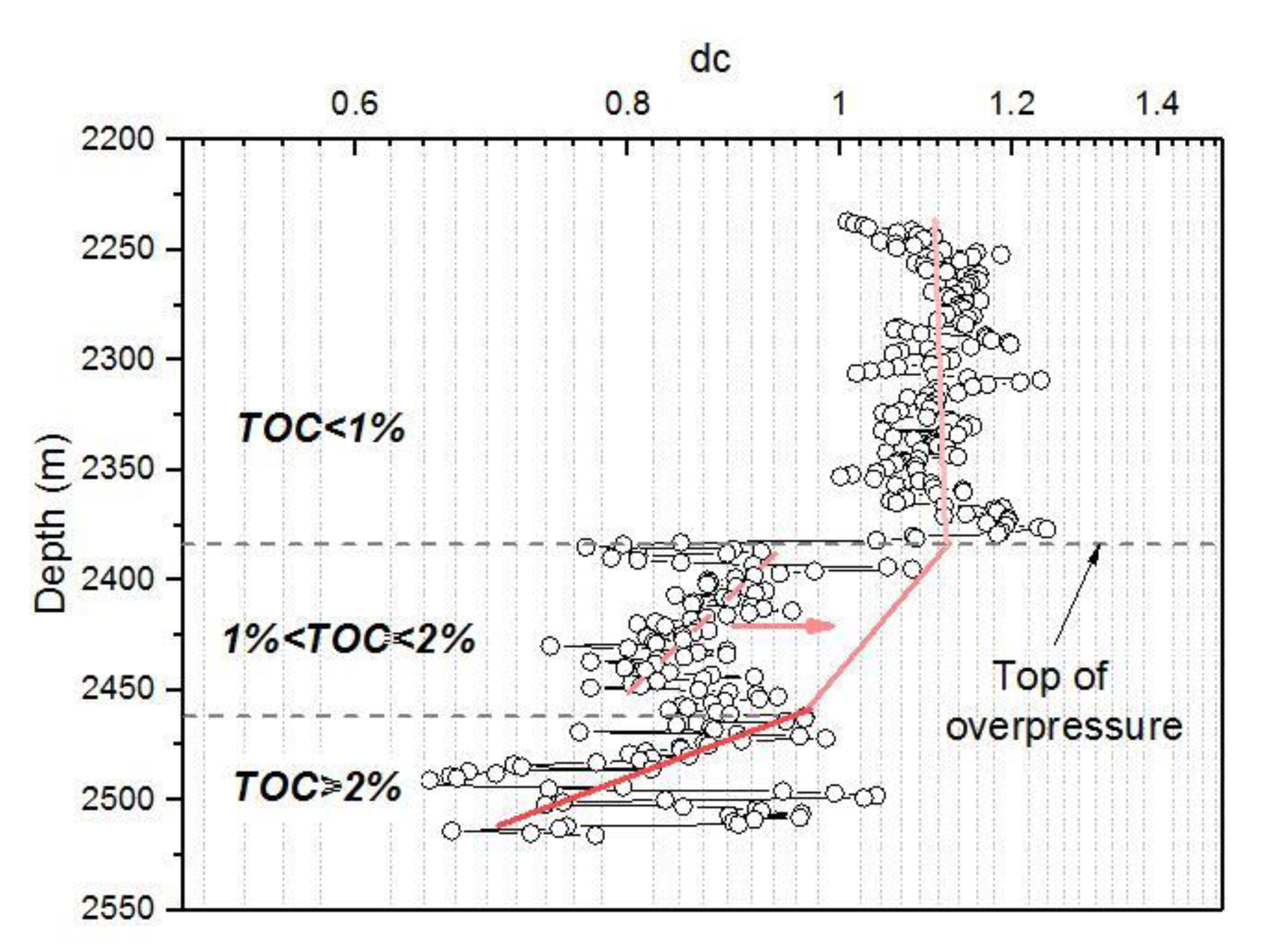

5.1. Reservoir Pressure State of CN Well in the Study Area

5.2. Burial, Thermal and Hydrocarbon Generation Histories of the O3w–S1l Shales

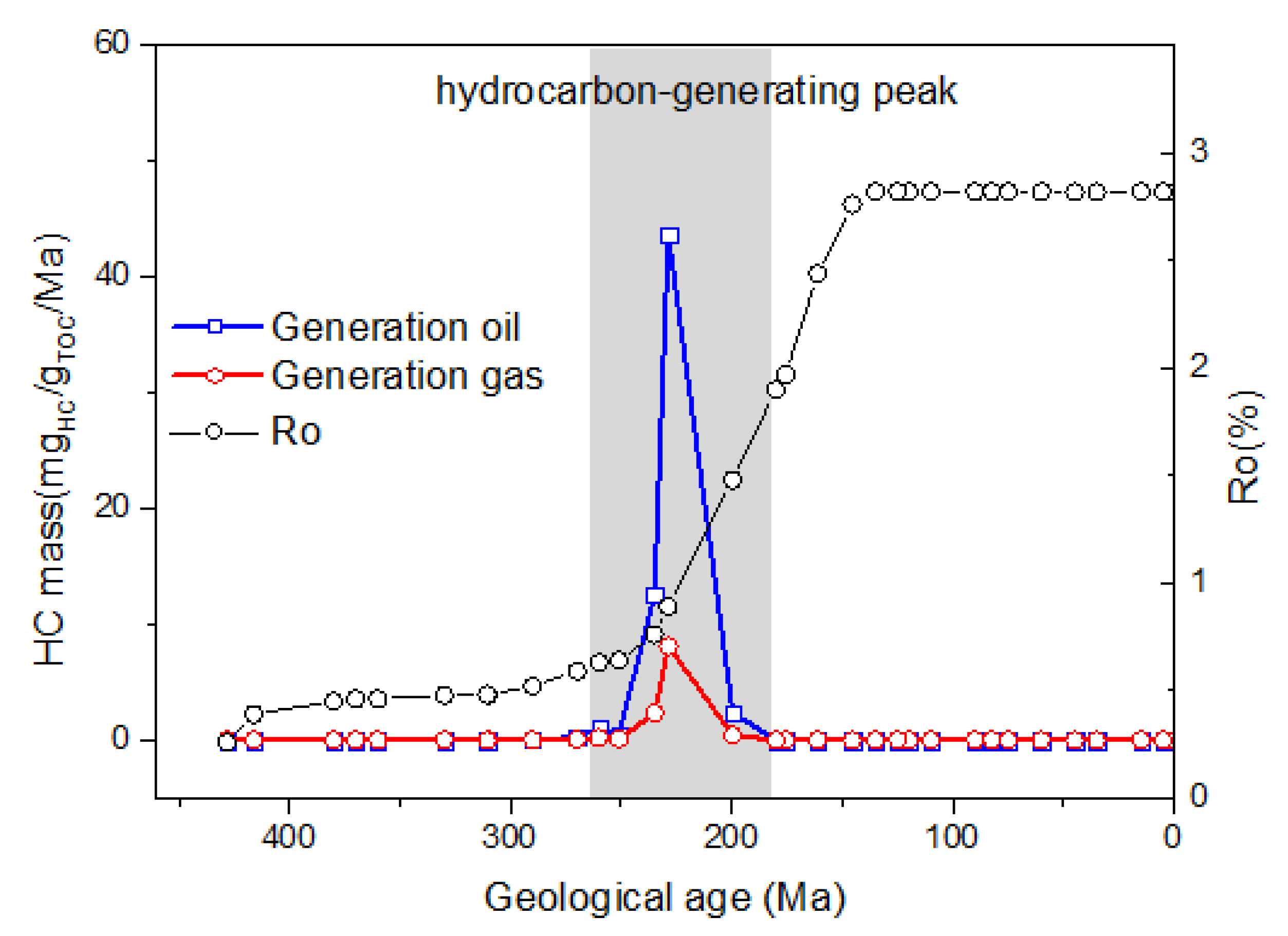

5.3. Clay Mineral Composition

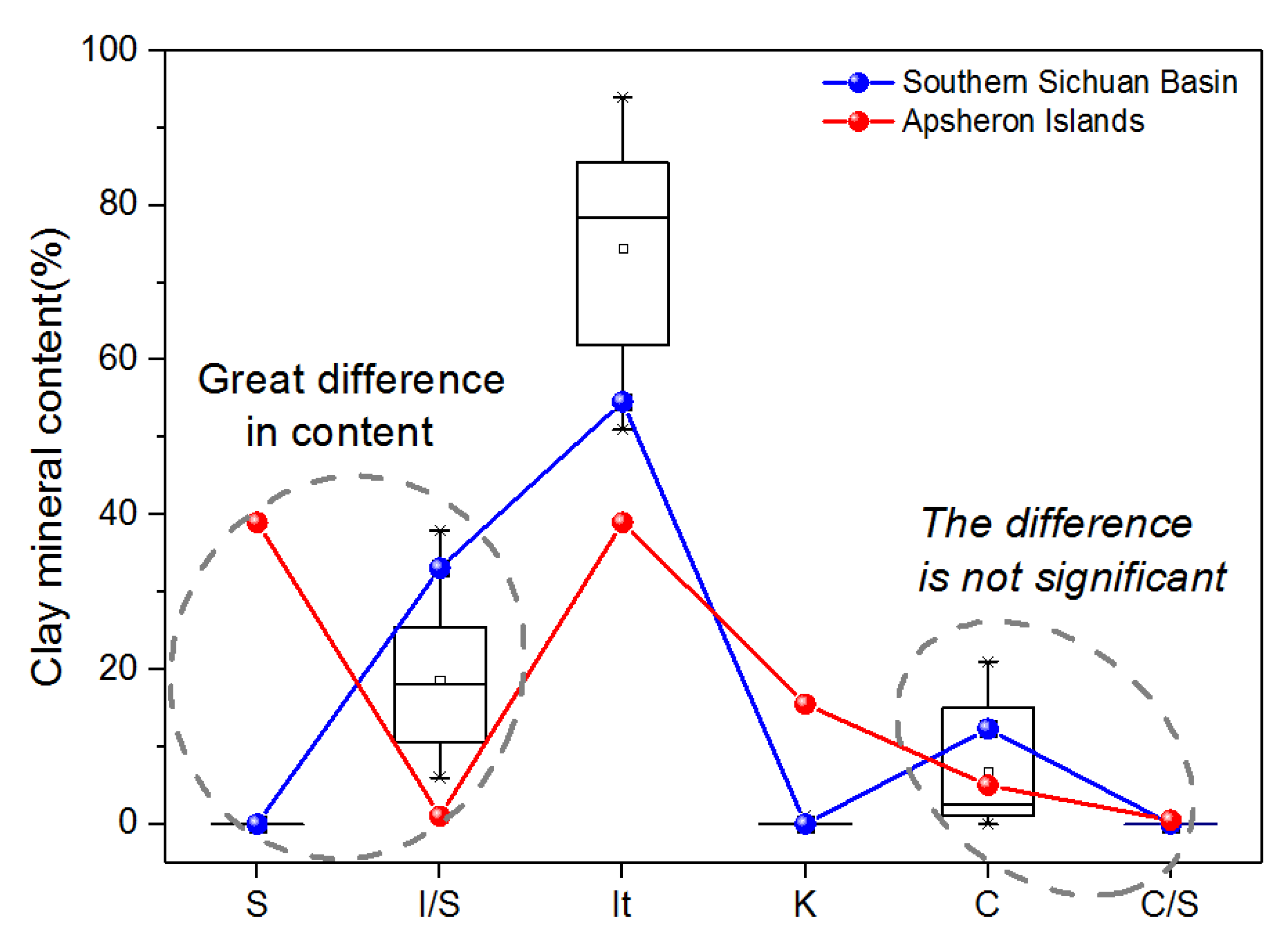

5.4. Stress Sensitivity of Shale Diffusion Coefficient

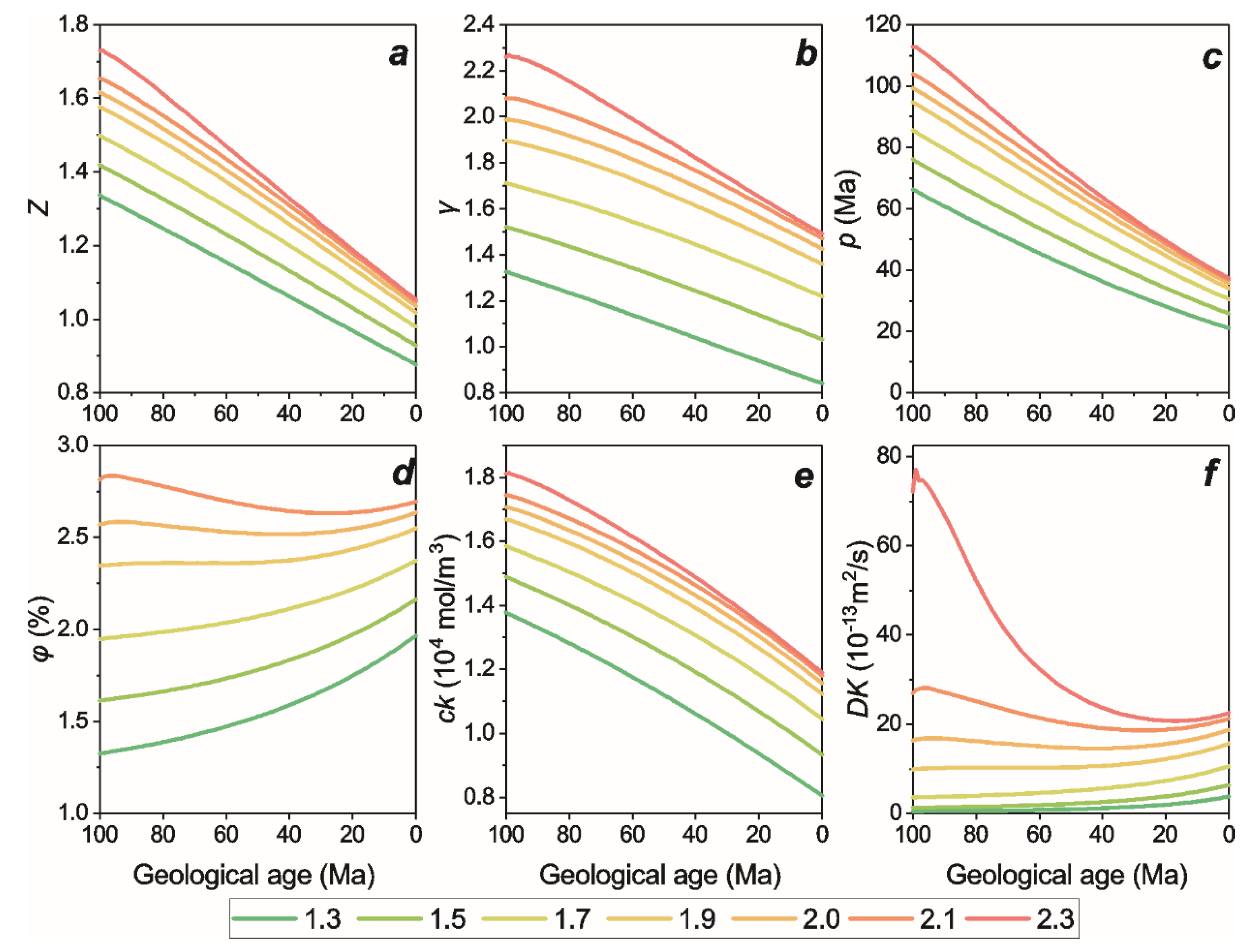

6. Discussion

6.1. Mechanism of Overpressure Generation

6.2. Overpressure Evolution of the CN Well

6.3. Factors Affecting the Evolution of the Pressure Coefficient

6.4. Shale Gas Accumulation Process of the CN Well

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Tonglou, G.; Zhang, H. Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin. Pet. Explor. Dev. 2014, 41, 31–40. [Google Scholar]

- Caineng, Z.; Zhi, Y.; Songqi, P.; Yanyan, C.; Senhu, L.; Jinliang, H.; Songtao, W.; Dazhong, D.; Shufang, W.; Feng, L. Shale gas formation and occurrence in China: An overview of the current status and future potential. Acta Geol. Sin. 2016, 90, 1249–1283. [Google Scholar] [CrossRef]

- Liu, J.; Yao, Y.; Liu, D.; Pan, Z.; Cai, Y. Comparison of three key marine shale reservoirs in the southeastern margin of the Sichuan basin, SW China. Minerals 2017, 7, 179. [Google Scholar] [CrossRef] [Green Version]

- Qu, X.; Zhu, Y.; Wang, Y.; Shang, F. The Early Silurian Sedimentary Environment of Middle-Upper Yangtze: Lithological and Palaeontological Evidence and Impact on Shale Gas Reservoir. Minerals 2019, 9, 494. [Google Scholar] [CrossRef] [Green Version]

- Huang, C.; Ju, Y.; Zhu, H.; Qi, Y.; Yu, K.; Sun, Y.; Ju, L. Nano-Scale Pore Structure and Fractal Dimension of Longmaxi Shale in the Upper Yangtze Region, South China: A Case Study of the Laifeng–Xianfeng Block Using HIM and N2 Adsorption. Minerals 2019, 9, 356. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Zhang, J.-k.; He, S.; Zhao, J.-x.; He, Z.-l.; Wo, Y.-j.; Feng, Y.-x.; Li, W. Overpressure generation and evolution in Lower Paleozoic gas shales of the Jiaoshiba region, China: Implications for shale gas accumulation. Mar. Pet. Geol. 2019, 102, 844–859. [Google Scholar] [CrossRef]

- Li, S.; Yuan, Y.; Sun, W.; Sun, D.; Jin, Z. Formation and destruction mechanism as well as major controlling factors of the Silurian shale gas overpressure in the Sichuan Basin, China. J. Nat. Gas Geosci. 2016, 1, 287–294. [Google Scholar] [CrossRef] [Green Version]

- Liu, H.; Wang, H.; Fang, C.; Guo, W.; Sun, S. The formation mechanism of over-pressure reservoir and target screening index of the marine shale in the South China. Earth Sci. Front 2016, 23, 48–54. [Google Scholar]

- Law, B.E.; Dickinson, W. Conceptual model for origin of abnormally pressured gas accumulations in low-permeability reservoirs. AAPG Bull. 1985, 69, 1295–1304. [Google Scholar]

- Spencer, C.W. Hydrocarbon generation as a mechanism for overpressuring in Rocky Mountain region. AAPG Bull. 1987, 71, 368–388. [Google Scholar]

- Barker, C. Calculated volume and pressure changes during the thermal cracking of oil to gas in reservoirs (1). AAPG Bull. 1990, 74, 1254–1261. [Google Scholar]

- Bredehoeft, J.; Wesley, J.; Fouch, T. Simulations of the origin of fluid pressure, fracture generation, and the movement of fluids in the Uinta Basin, Utah. AAPG Bull. 1994, 78, 1729–1747. [Google Scholar]

- Tingay, M.R.; Hillis, R.R.; Swarbrick, R.E.; Morley, C.K.; Damit, A.R. Origin of overpressure and pore-pressure prediction in the Baram province, Brunei. AAPG Bull. 2009, 93, 51–74. [Google Scholar] [CrossRef]

- Guo, X.; He, S.; Liu, K.; Song, G.; Wang, X.; Shi, Z. Oil generation as the dominant overpressure mechanism in the Cenozoic Dongying depression, Bohai Bay Basin, China. AAPG Bull. 2010, 94, 1859–1881. [Google Scholar] [CrossRef]

- Cao, Q.; Ye, J.; Qing, H.; Lu, J.; Huang, S.; Tang, D. Pressure evolution and hydrocarbon migration-accumulation in the Moliqing fault depression, Yitong basin, Northeast China. J. Earth Sci. 2011, 22, 351. [Google Scholar] [CrossRef]

- Guo, X.; Liu, K.; Jia, C.; Song, Y.; Zhao, M.; Lu, X. Effects of early petroleum charge and overpressure on reservoir porosity preservation in the giant Kela-2 gas field, Kuqa depression, Tarim Basin, northwest China. AAPG Bull. 2016, 100, 191–212. [Google Scholar] [CrossRef]

- Yang, Z.; He, S.; Li, Q.; Lin, S.; Pan, S. Geochemistry characteristics and significance of two petroleum systems near top overpressured surface in central Junggar Basin, NW China. Mar. Pet. Geol. 2016, 75, 341–355. [Google Scholar] [CrossRef]

- Borjigin, T.; Baojian, S.; Lingjie, Y.; Yunfeng, Y.; Zhang, W.; Cheng, T.; Binbin, X.; ZHANG, Q.; Fang, B.; Jianzhong, Q. Mechanisms of shale gas generation and accumulation in the Ordovician Wufeng-Longmaxi Formation, Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 69–78. [Google Scholar] [CrossRef]

- Jianhui, F.; Zehui, M. Main factors controlling the enrichment of shale gas in Wufeng Formation-Longmaxi Formation in Jiaoshiba area, Fuling shale gas field. China Pet. Explor. 2017, 22, 32–39. [Google Scholar]

- Zhang, J.; He, S.; Wang, Y.; Wang, Y.; Hao, X.; Luo, S.; Li, P.; Dang, X.; Yang, R. Main Mechanism for Generating Overpressure in the Paleogene Source Rock Series of the Chezhen Depression, Bohai Bay Basin, China. J. Earth Sci. 2019, 30, 775–787. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, Y.; Wang, H.; Liu, H.; Wei, W.; Fang, J. Shale gas reservoir characterisation: A typical case in the southern Sichuan Basin of China. Energy 2011, 36, 6609–6616. [Google Scholar] [CrossRef]

- Chen, S.; Zhu, Y.; Qin, Y.; Wang, H.; Liu, H.; Fang, J. Reservoir evaluation of the Lower Silurian Longmaxi Formation shale gas in the southern Sichuan Basin of China. Mar. Pet. Geol. 2014, 57, 619–630. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Lash, G.G.; Wang, Y. Multi-proxy analysis of organic matter accumulation in the Upper Ordovician–Lower Silurian black shale on the Upper Yangtze Platform, south China. Mar. Pet. Geol. 2019, 103, 473–484. [Google Scholar] [CrossRef]

- Zhang, G.; Guo, A.; Wang, Y.; Li, S.; Dong, Y.; Liu, S.; He, D.; Cheng, S.; Lu, R.; Yao, A. Tectonics of South China continent and its implications. Sci. China Earth Sci. 2013, 56, 1804–1828. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Liu, Y.; Li, W. Molecular Structure of Kerogen in the Longmaxi Shale: Insights from Solid State NMR, FT-IR, XRD and HRTEM. Acta Geol. Sin. Engl. Ed. 2019, 93, 1015–1024. [Google Scholar] [CrossRef]

- Eaton, B.A. Graphical method predicts geopressures worldwide. World Oil 1976, 183, 1. [Google Scholar]

- Eaton, B.A. The equation for geopressure prediction from well logs. In Fall Meeting of the Society of Petroleum Engineers of AIME; Society of Petroleum Engineers: Richardson, TX, USA, 1975. [Google Scholar]

- Fillippone, W. Estimation of formation parameters and the prediction of overpressures from seismic data. In SEG Technical Program Expanded Abstracts; Society of Exploration Geophysicists: Tulsa, OK, USA, 1982; pp. 502–503. [Google Scholar]

- Jorden, J.; Shirley, O. Application of drilling performance data to overpressure detection. J. Pet. Technol. 1966, 18, 1387–1394. [Google Scholar] [CrossRef]

- Rehm, B.; McClendon, R. Measurement of formation pressure from drilling data. In Fall Meeting of the Society of Petroleum Engineers of AIME; Society of Petroleum Engineers: Richardson, TX, USA, 1971. [Google Scholar]

- Chen, M.; Kang, Y.; Zhang, T.; You, L.; Li, X.; Chen, Z.; Wu, K.; Yang, B. Methane diffusion in shales with multiple pore sizes at supercritical conditions. Chem. Eng. J. 2018, 334, 1455–1465. [Google Scholar] [CrossRef]

- Burnham, A.K.; Sweeney, J.J. A chemical kinetic model of vitrinite maturation and reflectance. Geochim. Cosmochim. Acta 1989, 53, 2649–2657. [Google Scholar] [CrossRef]

- Wilkins, R.W.T.; Boudou, R.; Sherwood, N.; Xiao, X. Thermal maturity evaluation from inertinites by Raman spectroscopy: The ‘RaMM’ technique. Int. J. Coal Geol. 2014, 128–129, 143–152. [Google Scholar] [CrossRef]

- Duan, Z.; Møller, N.; Weare, J.H. An equation of state for the CH4-CO2-H2O system: I. Pure systems from 0 to 1000 C and 0 to 8000 bar. Geochim. Cosmochim. Acta 1992, 56, 2605–2617. [Google Scholar] [CrossRef]

- Yuan, H.; Liang, J.; Gong, D.; Xu, G.; Liu, S.; Wang, G. Formation and evolution of Sinian oil and gas pools in typical structures, SichuanBasin, China. Pet. Sci. 2012, 9, 129–140. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q. Structural and AFT Constraints on the Meso-Cenozoic Uplift-Subsidence between Northern Nanpanjiang and Southern Sichuan Basins. Master’s Thesis, China University of Geosciences, Beijing, China, 2010. [Google Scholar]

- Deng, B.; Liu, S.G.; Wang, G.Z.; Li, Z.W.; Liu, S.; Cao, J.X. Cenozoic uplift and exhumation in southern Sichuan Basin—Evidence from low-temperature thermochronology. Chin. J. Geophys. 2013, 56, 1958–1973. [Google Scholar]

- Wang, X.; Mou, C.; Ge, X.; Chen, X.; Zhou, K.; Wang, Q.; Liang, W.; Chen, C. Study on clay minerals in the lower Silurian Longmaxi Formation in southern Sichuan Basin and its peripher. Nat. Gas Geosci. 2014, 25, 1781–1794. [Google Scholar]

- Buryakovsky, L.A.; Djevanshir, R.D.; Chilingar, G.V. Abnormally-high formation pressures in Azerbaijan and the South Caspian Basin (as related to smectite ↔ illite transformations during diagenesis and catagenesis). J. Pet. Sci. Eng. 1995, 13, 203–218. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, Y.; Fu, C. Experimental investigation of the stress-dependent permeability in the Longmaxi Formation shale. J. Pet. Sci. Eng. 2019, 175, 932–947. [Google Scholar] [CrossRef]

- Dickinson, G. Geological aspects of abnormal reservoir pressures in Gulf Coast Louisiana. AAPG Bull. 1953, 37, 410–432. [Google Scholar]

- Mann, D.M.; Mackenzie, A.S. Prediction of pore fluid pressures in sedimentary basins. Mar. Pet. Geol. 1990, 7, 55–65. [Google Scholar] [CrossRef]

- Audet, D.M.; McConnell, J.D.C. Establishing resolution limits for tectonic subsidence curves by forward basin modelling. Mar. Pet. Geol. 1994, 11, 400–411. [Google Scholar] [CrossRef]

- Xinong, X.; Sitian, L.; Weiliang, D.; Qiming, Z. Overpressure development and hydrofracturing in the Yinggehai basin, South China Sea. J. Pet. Geol. 1999, 22, 437–454. [Google Scholar] [CrossRef]

- Ungerer, P.; Behar, E.; Discamps, D. Tentative calculation of the overall volume expansion of organic matter during hydrocarbon genesis from geochemistry data. Implications for primary migration. Adv. Org. Geochem. 1981, 10, 129–135. [Google Scholar]

- Berg, R.R.; Gangi, A.F. Primary migration by oil-generation microfracturing in low-permeability source rocks: Application to the Austin Chalk, Texas. AAPG Bull. 1999, 83, 727–756. [Google Scholar]

- Osborne, M.J.; Swarbrick, R.E. Mechanisms for generating overpressure in sedimentary basins: A reevaluation. AAPG Bull. 1997, 81, 1023–1041. [Google Scholar]

| Parameters | Mathematical Expression | Parameters | Mathematical Expression |

|---|---|---|---|

| B | a1 + a2/Tr2 + a3/Tr3 | Pr | P/Pc |

| C | a4 + a5/Tr2 + a6/Tr3 | Tr | T/Tc |

| D | a7 + a8/Tr2 + a9/Tr3 | Vr | V/Vc |

| E | a10 + a11/Tr2 + a12/Tr3 | Vc | RTc/Pc |

| F | α/Tr3 |

| Parameter | Value | Unit | Definition |

|---|---|---|---|

| ɸ0 | 3.95 | % | Porosity when the effective stress is zero |

| Cφ | −0.01 | MPa−1 | Pore compressibility |

| R | 8.314 | J/(K·mol) | Universal gas constant |

| DS | 4.99 × 10−14 | m2/s | Surface diffusion coefficient |

| DK0 | 10−11 | m2/s | Free molecular diffusion coefficient when the effective stress is zero |

| CD | −0.09 | MPa−1 | Stress sensitivity parameter of diffusion coefficient |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Zhu, Y. The Genetic Mechanism and Evolution Process of Overpressure in the Upper Ordovician–Lower Silurian Black Shale Formation in the Southern Sichuan Basin. Minerals 2020, 10, 238. https://doi.org/10.3390/min10030238

Wang X, Zhu Y. The Genetic Mechanism and Evolution Process of Overpressure in the Upper Ordovician–Lower Silurian Black Shale Formation in the Southern Sichuan Basin. Minerals. 2020; 10(3):238. https://doi.org/10.3390/min10030238

Chicago/Turabian StyleWang, Xiaoqi, and Yanming Zhu. 2020. "The Genetic Mechanism and Evolution Process of Overpressure in the Upper Ordovician–Lower Silurian Black Shale Formation in the Southern Sichuan Basin" Minerals 10, no. 3: 238. https://doi.org/10.3390/min10030238

APA StyleWang, X., & Zhu, Y. (2020). The Genetic Mechanism and Evolution Process of Overpressure in the Upper Ordovician–Lower Silurian Black Shale Formation in the Southern Sichuan Basin. Minerals, 10(3), 238. https://doi.org/10.3390/min10030238