Mechanism for the Bio-Oxidation and Decomposition of Pentlandite: Implication for Nickel Bioleaching at Elevated pH

Abstract

1. Introduction

2. Materials and Methods

2.1. Mineral and Bacteria

2.2. Leaching Experiments

2.3. Analysis Methods

3. Results

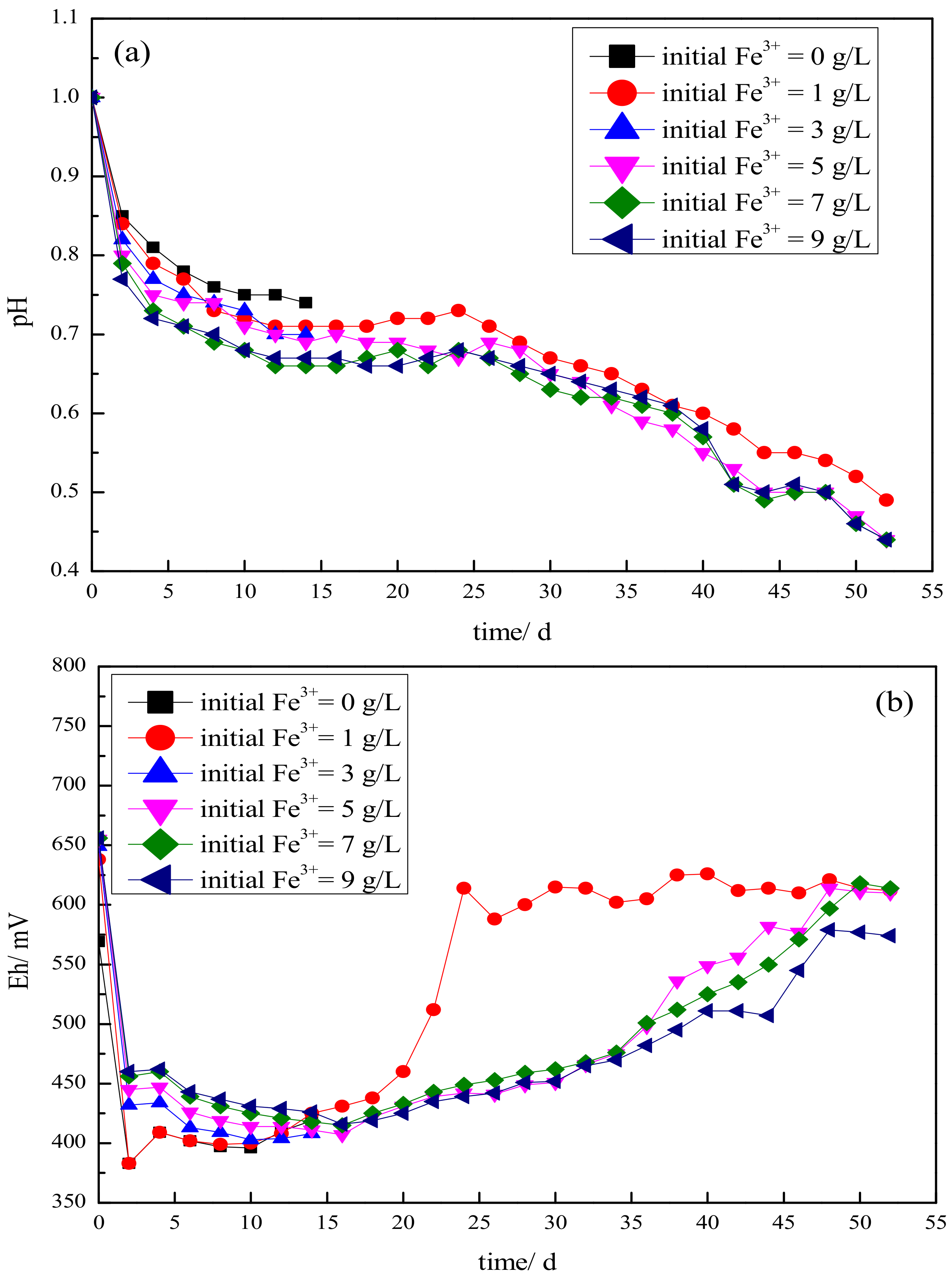

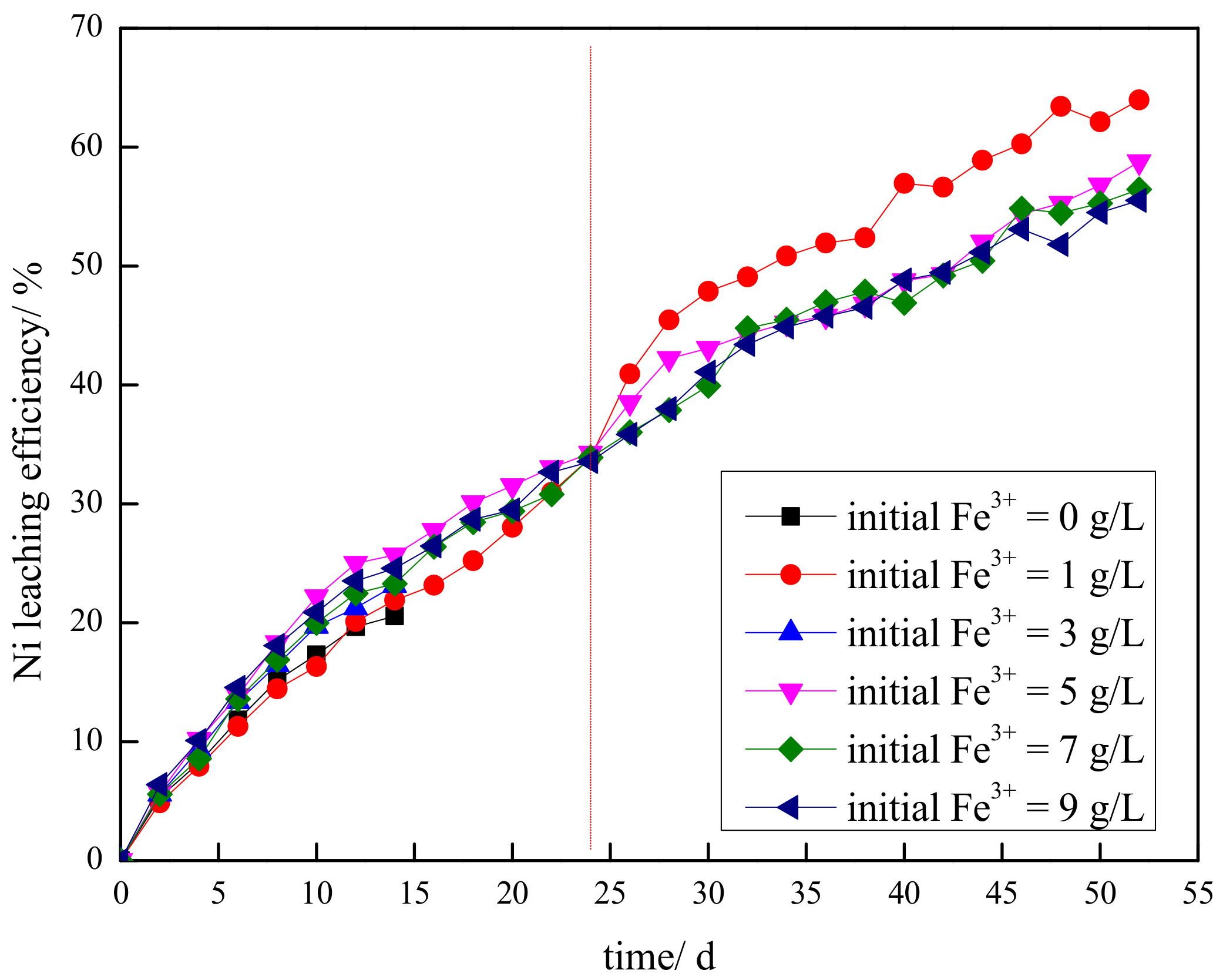

3.1. The Effect of Ferric Ions

3.1.1. Solution Chemistry

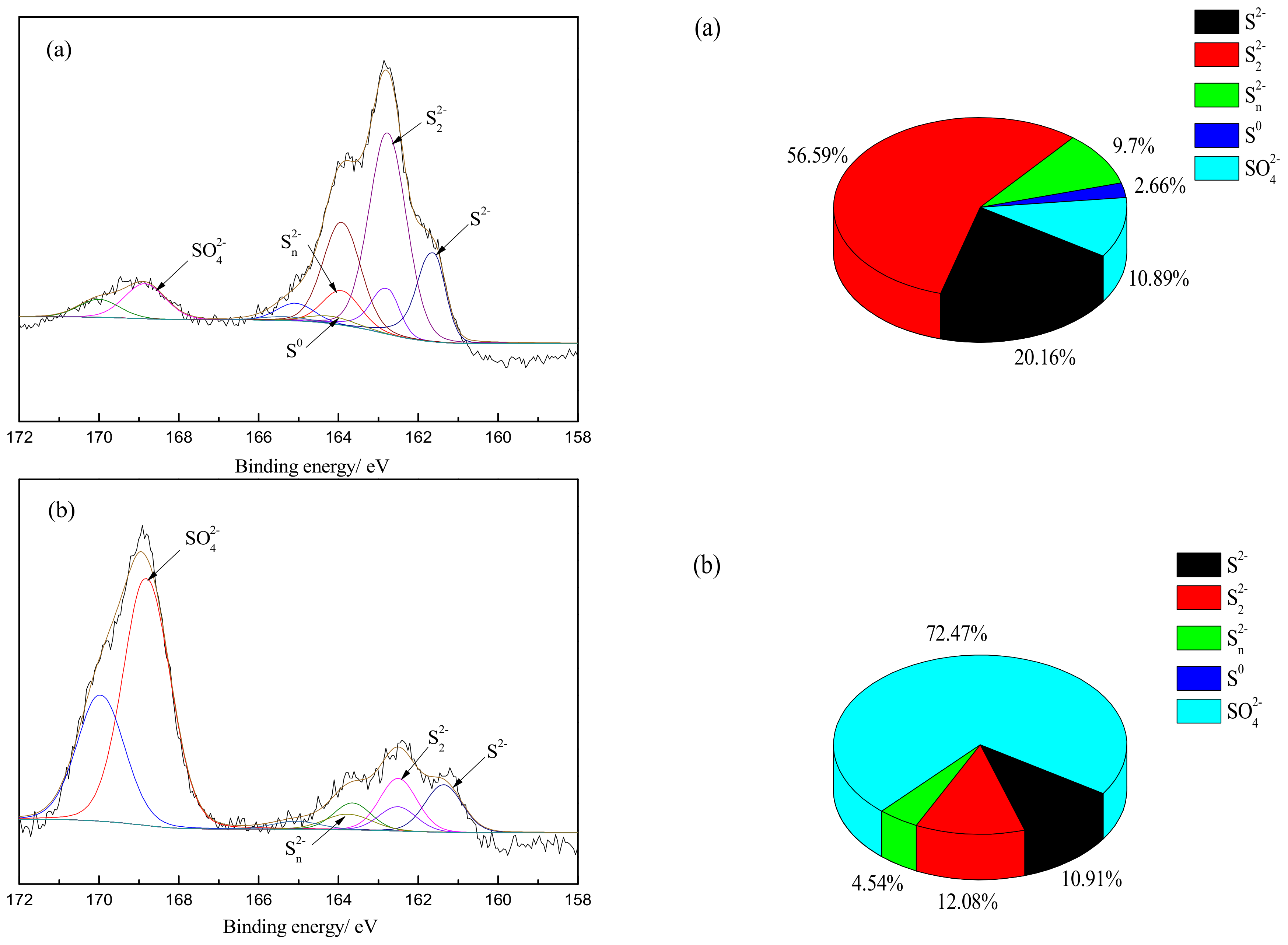

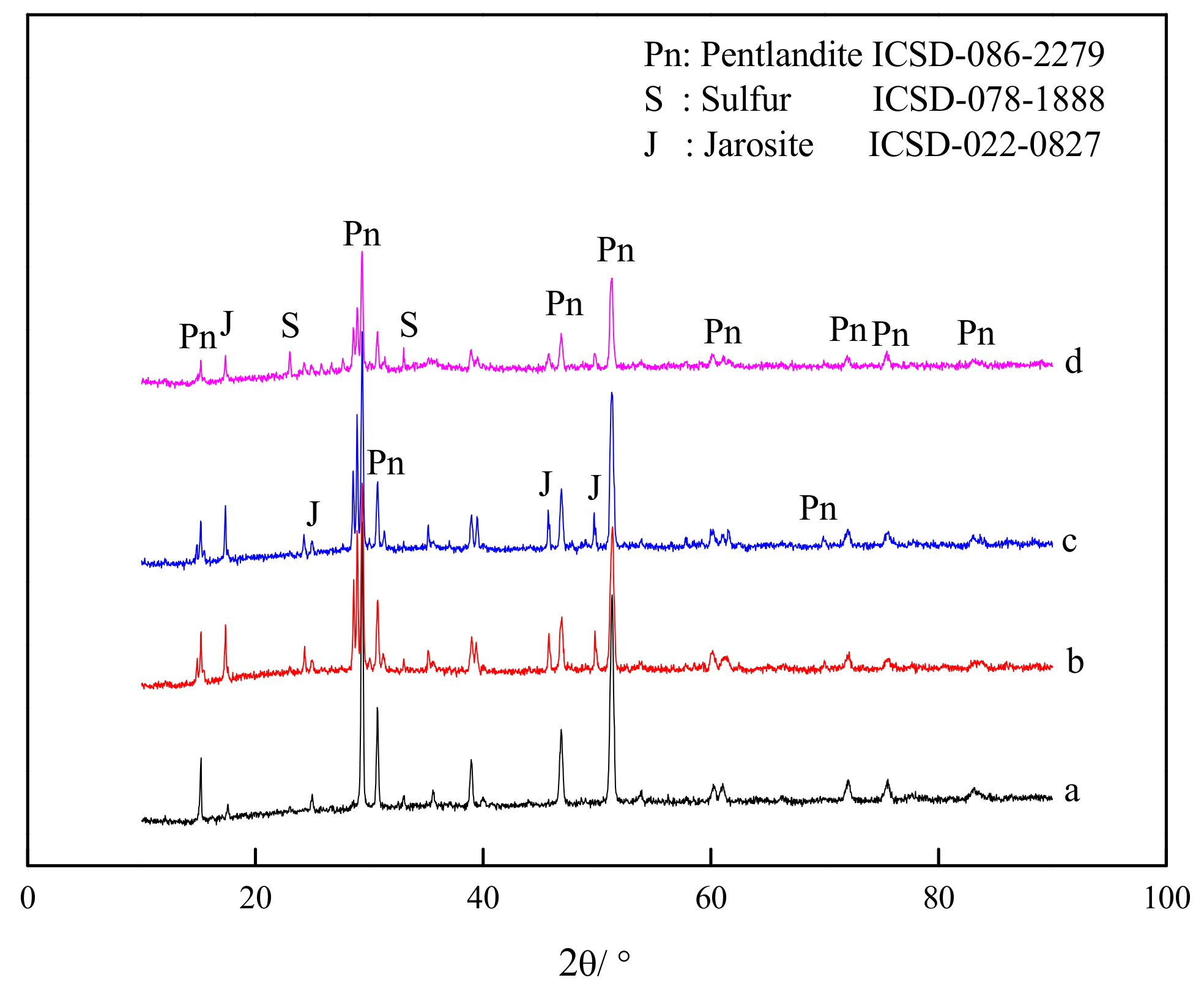

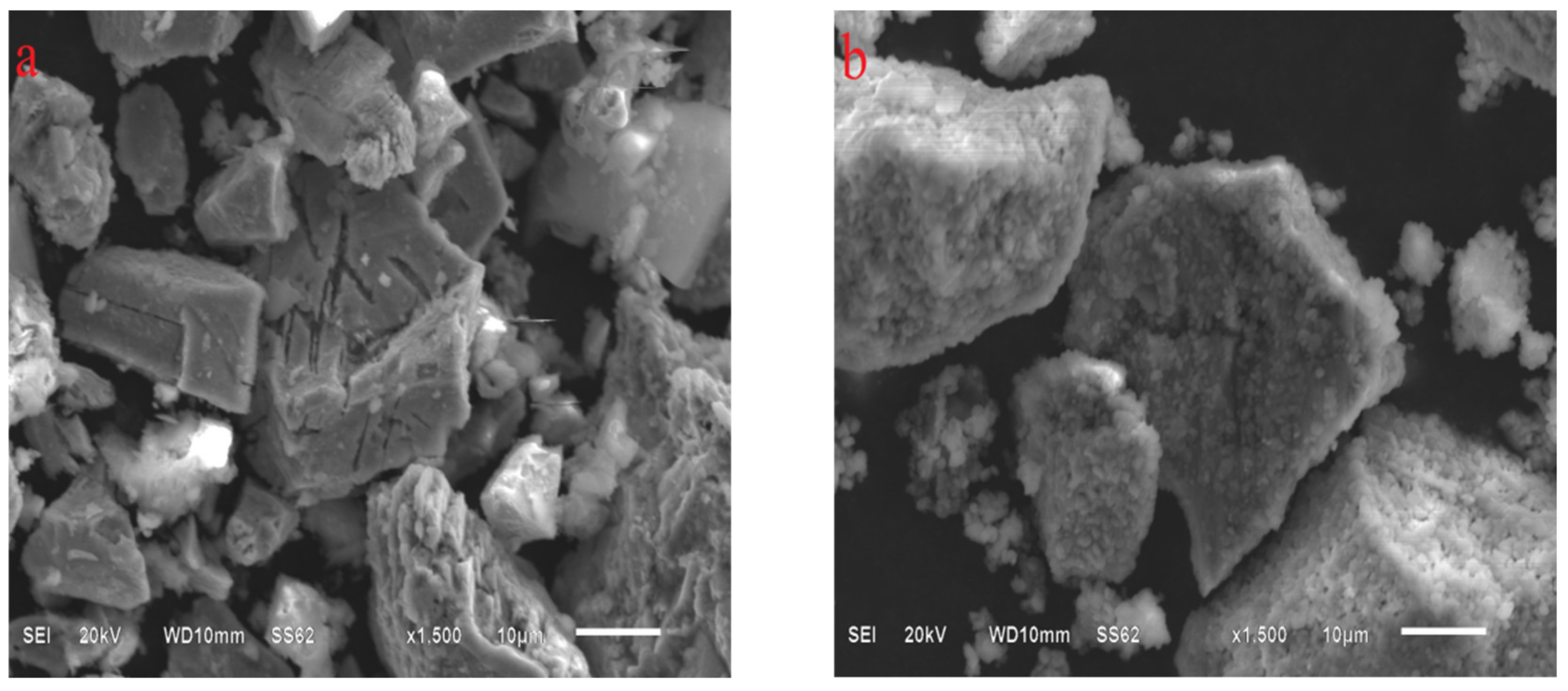

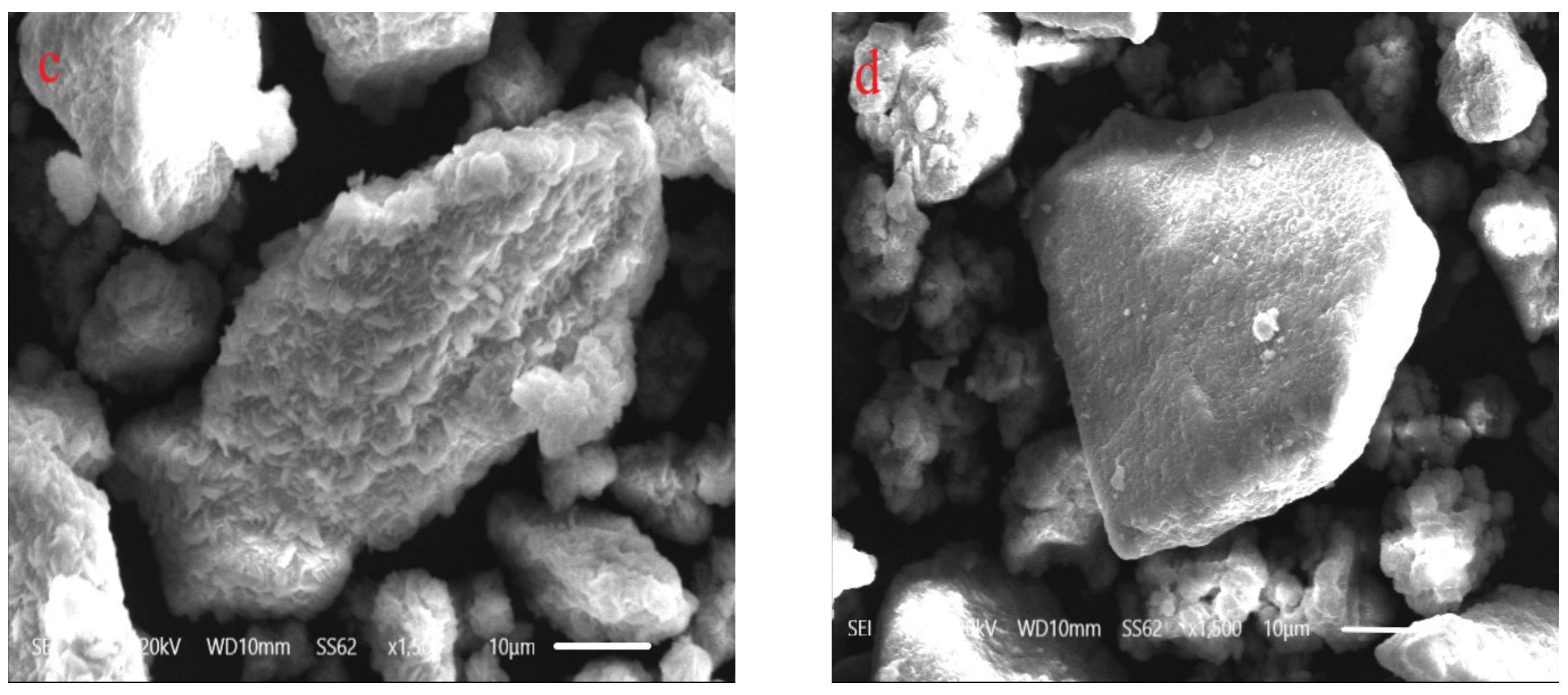

3.1.2. Mineral Surface Modification

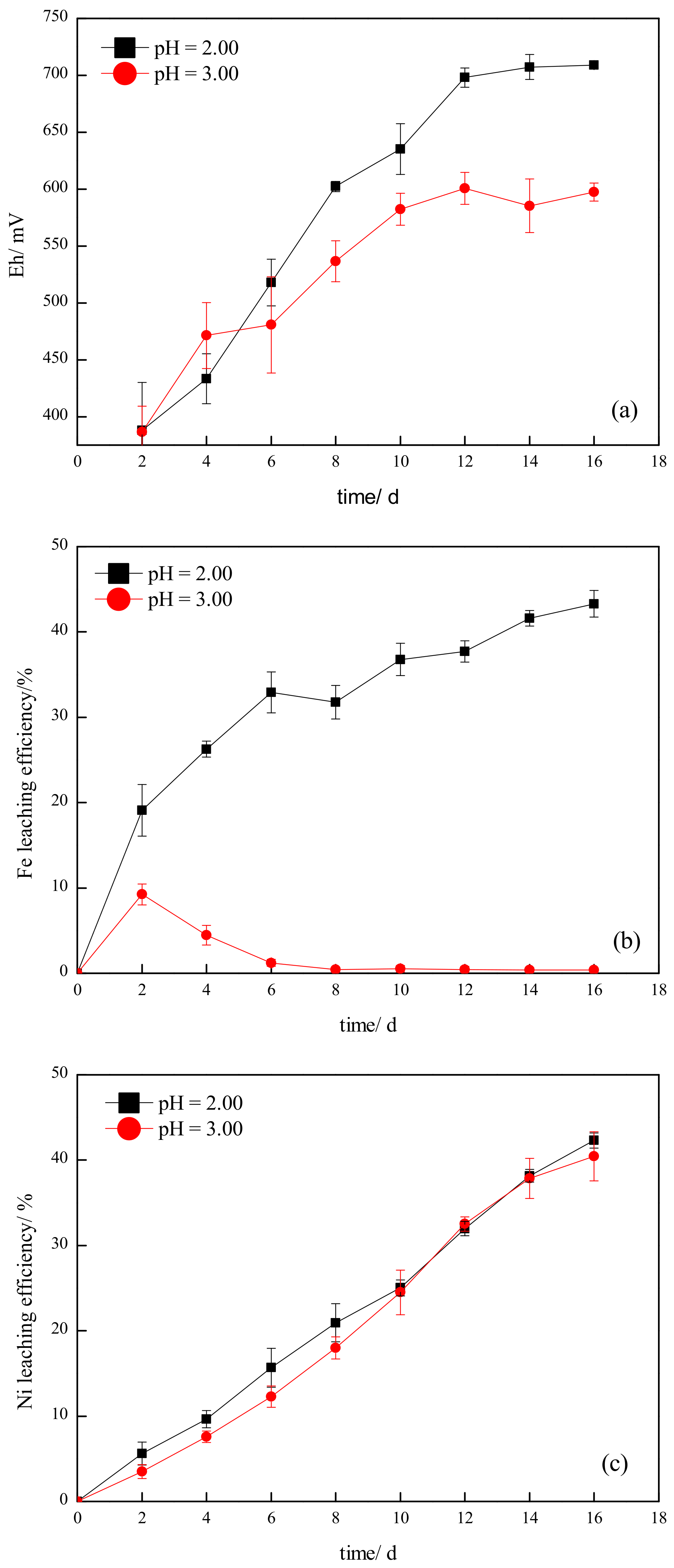

3.2. The Effect of pH Value

3.2.1. Solution Chemistry

3.2.2. Mineral Surface Modification

3.3. The Effect of Leaching Bacteria

3.3.1. Solution Chemistry

3.3.2. Mineral Surface Modification

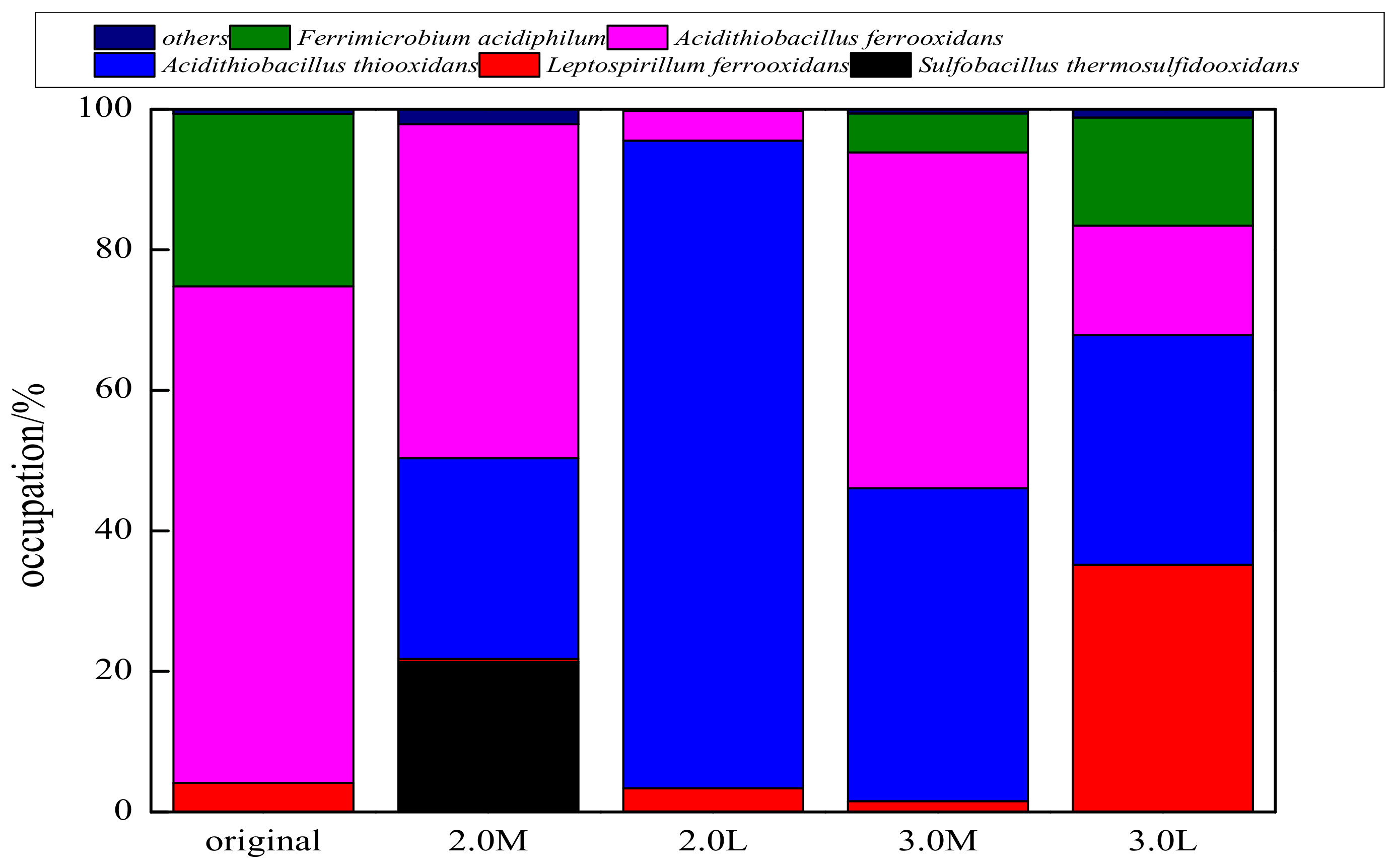

3.3.3. Mineral Surface Microbial Community

4. Discussion

4.1. The Oxidation and Decomposition Process of Pentlandite

4.2. Fe, Ni and S Species Modification During the Oxidation and Decomposition of Pentlandite

4.2.1. Fe Modification

4.2.2. Ni Modification

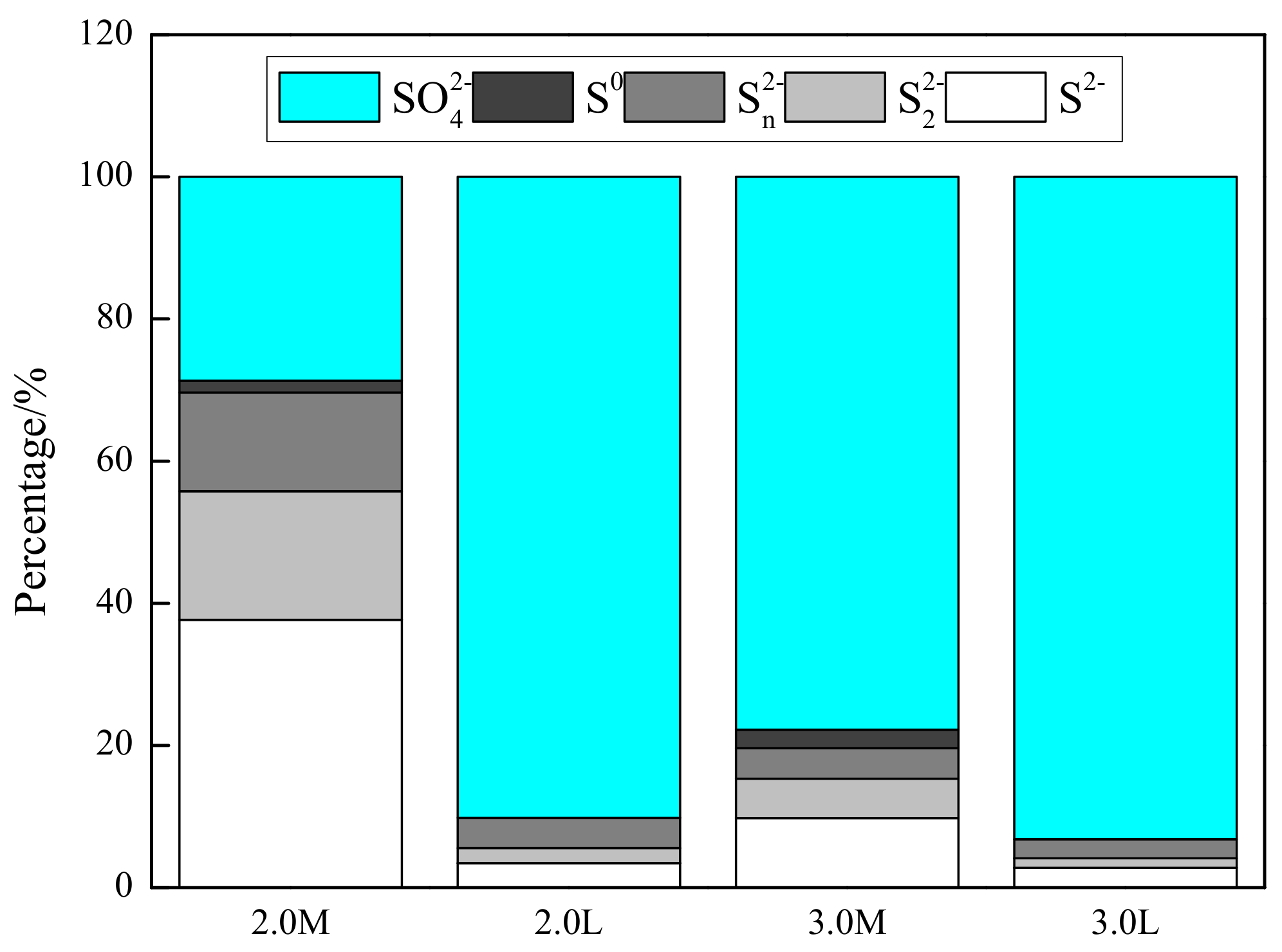

4.2.3. S Modification

4.3. Conceptual Model of the Oxidation and Decomposition of Pentlandite

4.4. Implications for Hydrometallurgical Applications in the Nickel Industry

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riekkola-Vanhanen, M. Talvivaara mining company—From a project to a mine. Miner. Eng. 2013, 48, 2–9. [Google Scholar] [CrossRef]

- Halinen, A.K.; Rahunen, N.; Kaksonen, A.H.; Puhakka, J.A. Heap bioleaching of a complex sulfide ore: Part I: Effect of pH on metal extraction and microbial composition in pH controlled columns. Hydrometallurgy 2009, 98, 92–100. [Google Scholar] [CrossRef]

- Arpalahti, A.; Lundström, M. The leaching behavior of minerals from a pyrrhotite-rich pentlandite ore during heap leaching. Miner. Eng. 2018, 119, 116–125. [Google Scholar] [CrossRef]

- Zhen, S.J.; Qin, W.Q.; Yan, Z.Q.; Zhang, Y.S.; Wang, J.; Ren, L.Y. Bioleaching of low grade nickel sulfide mineral in column reactor. Trans. Nonferrous Met. Soc. China. 2008, 18, 1480–1484. [Google Scholar] [CrossRef]

- Zhen, S.; Yan, Z.; Zhang, Y.; Wang, J.; Campbell, M.; Qin, W. Column bioleaching of a low grade nickel-bearing sulfide ore containing high magnesium as olivine, chlorite and antigorite. Hydrometallurgy 2009, 96, 337–341. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Jeffrey, M.I.; Zhu, Y.; Lawson, F. Studies of pentlandite leaching in mixed oxygenated acidic chloride-sulfate solutions. Hydrometallurgy 2000, 56, 63–74. [Google Scholar] [CrossRef]

- Baláž, P.; Boldižárová, E.; Achimovičová, M.; Kammel, R. Leaching and dissolution of a pentlandite concentrate pretreated by mechanical activation. Hydrometallurgy 2000, 57, 85–96. [Google Scholar] [CrossRef]

- Maurice, D.; Hawk, J.A. Ferric chloride leaching of a mechanically activated pentlandite–chalcopyrite concentrate. Hydrometallurgy 1999, 52, 289–312. [Google Scholar] [CrossRef]

- Fu, B.; Zhou, H.; Zhang, R.; Qiu, G. Bioleaching of chalcopyrite by pure and mixed cultures of Acidithiobacillus spp. and Leptospirillum ferriphilum. Inter. Biodeterior. Biodegrad. 2008, 62, 109–115. [Google Scholar] [CrossRef]

- Leão, V.A.; Cruz, F.L.S.; Oliveira, V.A.; Guimarães, D.; Souza, A.D. High-temperature bioleaching of nickel sulfides: Thermodynamic and kinetic implications. Hydrometallurgy 2010, 105, 103–109. [Google Scholar] [CrossRef]

- Sand, W.; Gehrke, T.; Jozsa, P.G.; Schippers, A. (Bio)chemistry of bacterial leaching—Direct vs. indirect bioleaching. Hydrometallurgy 2001, 59, 159–175. [Google Scholar] [CrossRef]

- Holmes, D.S.; Eugenia, J.; Yann, D.; Corinne, A.A.; Raquel, Q.; Violaine, B. Extending the models for iron and sulfur oxidation in the extreme Acidophile Acidithiobacillus ferrooxidans. BMC Genomics 2009, 10, 394. [Google Scholar] [CrossRef]

- Dorado, A.D.; Solé, M.; Lao, C.; Alfonso, P.; Gamisans, X. Effect of pH and Fe(III) ions on chalcopyrite bioleaching by an adapted consortium from biogas sweetening. Miner. Eng. 2012, 39, 36–38. [Google Scholar] [CrossRef][Green Version]

- Li, Q.; Tian, Y.; Fu, X.; Yin, H.; Zhou, Z.; Liang, Y.; Qiu, G.; Liu, J.; Liu, H.; Liang, Y.; et al. The Community Dynamics of Major Bioleaching Microorganisms During Chalcopyrite Leaching Under the Effect of Organics. Curr. Microbiol. 2011, 63, 164–172. [Google Scholar] [CrossRef] [PubMed]

- Cameron, R.A.; Lastra, R.; Gould, W.D.; Mortazavi, S.; Thibault, Y.; Bedard, P.L.; Morin, L.; Koren, D.W.; Kennedy, K.J. Bioleaching of six nickel sulphide ores with differing mineralogies in stirred-tank reactors at 30 °C. Miner. Eng. 2013, 49, 172–183. [Google Scholar] [CrossRef]

- Simon, A.; Paul, T.P.; Wolfgang, H. HTSeq—A Python framework to work with high-throughput sequencing data. Bioinformatics 2015, 31, 166–169. [Google Scholar] [CrossRef]

- Meruane, G.; Vargas, T. Bacterial oxidation of ferrous iron by Acidithiobacillus ferrooxidans in the pH range 2.5–7.0. Hydrometallurgy 2003, 71, 149–158. [Google Scholar] [CrossRef]

- Zhang, R.; Wei, D.; Shen, Y.; Liu, W.; Tao, L.; Cong, H. Catalytic effect of polyethylene glycol on sulfur oxidation in chalcopyrite bioleaching by Acidithiobacillus ferrooxidans. Miner. Eng. 2016, 95, 74–78. [Google Scholar] [CrossRef]

- Wu, S.F.; Yang, C.R.; Qin, W.Q.; Jiao, F.; Wang, J.; Zhang, Y.S. Sulfur composition on surface of chalcopyrite during its bioleaching at 50 °C. Trans. Nonferrous Met. Soc. 2015, 25, 4110–4118. [Google Scholar] [CrossRef]

- Pan, H.D.; Yang, H.Y.; Tong, L.L.; Zhong, C.B.; Zhao, Y.S. Control method of chalcopyrite passivation in bioleaching. Trans. Nonferrous Met. Soc. China 2012, 22, 2255–2260. [Google Scholar] [CrossRef]

- Huang, C.; Qin, C.; Feng, X.; Liu, X.; Tao, J. Chalcopyrite bioleaching of an in situ leaching system by introducing different functional oxidizers. RSC Adv. 2018, 8, 37040–37049. [Google Scholar] [CrossRef]

- Legrand, D.L. Oxidation/alteration of pentlandite and pyrrhotite surfaces at pH 9.3: Part 1. Assignment of XPS spectra and chemical trends. Am. Mineral. 2005, 90, 1042–1054. [Google Scholar] [CrossRef]

- Tao, H.; Li, D. Presentation on mechanisms and applications of chalcopyrite and pyrite bioleaching in biohydrometallurgy—A presentation. Biotechnol. Rep. 2014, 4, 107–119. [Google Scholar] [CrossRef]

- Tributsch, H. Direct versus indirect bioleaching. Hydrometallurgy 2001, 59, 177–185. [Google Scholar] [CrossRef]

- Zhang, S.; Yan, L.; Xing, W.; Chen, P.; Zhang, Y.; Wang, W. Acidithiobacillus ferrooxidans and its potential application. Extremophiles 2018, 22, 563–579. [Google Scholar] [CrossRef] [PubMed]

- Jorge, V.; Francisco, O.; Raquel, Q.; Mark, D.; Holmes, D.S. Draft genome sequence of the extremely acidophilic biomining bacterium Acidithiobacillus thiooxidans ATCC 19377 provides insights into the evolution of the Acidithiobacillus genus. J. Bacteriol. 2011, 193, 7003–7004. [Google Scholar] [CrossRef]

- Cameron, R.A.; Lastra, R.; Mortazavi, S.; Gould, W.D.; Thibault, Y.; Bedard, P.L.; Morin, L.; Kennedy, K.J. Elevated-pH bioleaching of a low-grade ultramafic nickel sulphide ore in stirred-tank reactors at 5 to 45 °C. Hydrometallurgy 2009, 99, 77–83. [Google Scholar] [CrossRef]

- Liu, H.C.; Nie, Z.Y.; Xia, J.L.; Zhu, H.R.; Yun, Y.; Zhao, C.H.; Lei, Z.; Zhao, Y.D. Investigation of copper, iron and sulfur speciation during bioleaching of chalcopyrite by moderate thermophile Sulfobacillus thermosulfidooxidans. Int. J. Miner. Process. 2015, 137, 1–8. [Google Scholar] [CrossRef]

- Li, J.; Lu, J.; Lu, X.; Tu, B.; Ouyang, B.; Han, X.; Wang, R. Sulfur transformation in microbially mediated pyrite oxidation by: Insights from X-ray photoelectron spectroscopy-based quantitative depth profiling. Geomicrobiology 2015, 33, 118–134. [Google Scholar] [CrossRef]

- Daval, D.; Hellmann, R.; Martinez, I.; Gangloff, S.; Guyot, F. Lizardite serpentine dissolution kinetics as a function of pH and temperature, including effects of elevated pCO2. Chem. Geol. 2013, 351, 245–256. [Google Scholar] [CrossRef]

- Crundwell, F.K. The mechanism of dissolution of forsterite, olivine and minerals of the orthosilicate group. Hydrometallurgy 2014, 150, 68–82. [Google Scholar] [CrossRef]

| Analyzed Samples | S2− | S22− | Sn2− | S0 | SO42− | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | |

| a | 161.5 | 1.1 | 162.7 | 1.2 | 163.6 | 1.2 | 164.6 | 1.4 | - | - |

| b | 161.5 | 1.1 | 162.7 | 1.3 | 163.8 | 1.4 | 164.2 | 1.4 | - | - |

| c | 161.3 | 1.0 | 162.5 | 1.3 | 163.6 | 1.1 | 164.3 | 1.4 | 168.5 | 1.2 |

| Analyzed Samples | S2− | S22− | Sn2− | S0 | SO42− | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | |

| a | 161.6 | 1.1 | 162.8 | 1.1 | 163.9 | 1.2 | 164.2 | 1.4 | 168.8 | 1.2 |

| b | 161.4 | 1.1 | 162.5 | 1.1 | 163.8 | 1.4 | 164.2 | 1.5 | 168.8 | 1.4 |

| Analyzed Samples | S2− | S22− | Sn2− | S0 | SO42− | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | B.E. | FWHM | |

| a | 161.5 | 1.1 | 162.6 | 1.26 | 163.6 | 1.4 | 164.6 | 1.6 | 168.6 | 1.5 |

| b | 161.5 | 1.1 | 162.9 | 1.3 | 163.6 | 1.4 | 164.4 | 1.5 | 168.7 | 1.3 |

| c | 161.4 | 1.1 | 162.5 | 1.1 | 163.6 | 1.4 | 164.6 | 1.6 | 168.9 | 1.3 |

| d | 161.4 | 1.1 | 162.6 | 1.3 | 163.6 | 1.4 | 164.5 | 1.6 | 168.8 | 1.3 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Wen, J.; Wu, B.; Chen, B. Mechanism for the Bio-Oxidation and Decomposition of Pentlandite: Implication for Nickel Bioleaching at Elevated pH. Minerals 2020, 10, 289. https://doi.org/10.3390/min10030289

Sun J, Wen J, Wu B, Chen B. Mechanism for the Bio-Oxidation and Decomposition of Pentlandite: Implication for Nickel Bioleaching at Elevated pH. Minerals. 2020; 10(3):289. https://doi.org/10.3390/min10030289

Chicago/Turabian StyleSun, Jianzhi, Jiankang Wen, Biao Wu, and Bowei Chen. 2020. "Mechanism for the Bio-Oxidation and Decomposition of Pentlandite: Implication for Nickel Bioleaching at Elevated pH" Minerals 10, no. 3: 289. https://doi.org/10.3390/min10030289

APA StyleSun, J., Wen, J., Wu, B., & Chen, B. (2020). Mechanism for the Bio-Oxidation and Decomposition of Pentlandite: Implication for Nickel Bioleaching at Elevated pH. Minerals, 10(3), 289. https://doi.org/10.3390/min10030289