Nano-Scale Pore Structure and Its Multi-Fractal Characteristics of Tight Sandstone by N2 Adsorption/Desorption Analyses: A Case Study of Shihezi Formation from the Sulige Gas Filed, Ordos Basin, China

Abstract

1. Introduction

2. Samples and Methods

2.1. Samples and Geological Setting

2.2. Experimental Methods

2.3. Fractal Model of N2 Adsorption

3. Results

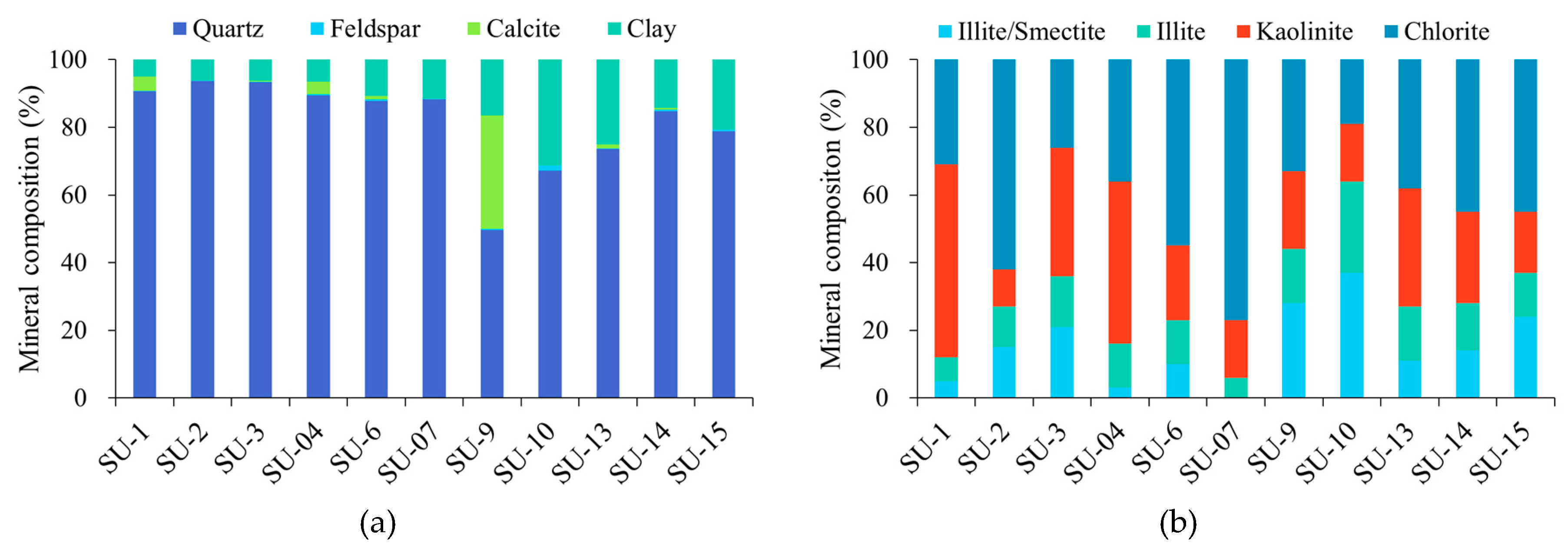

3.1. Minerals Composition

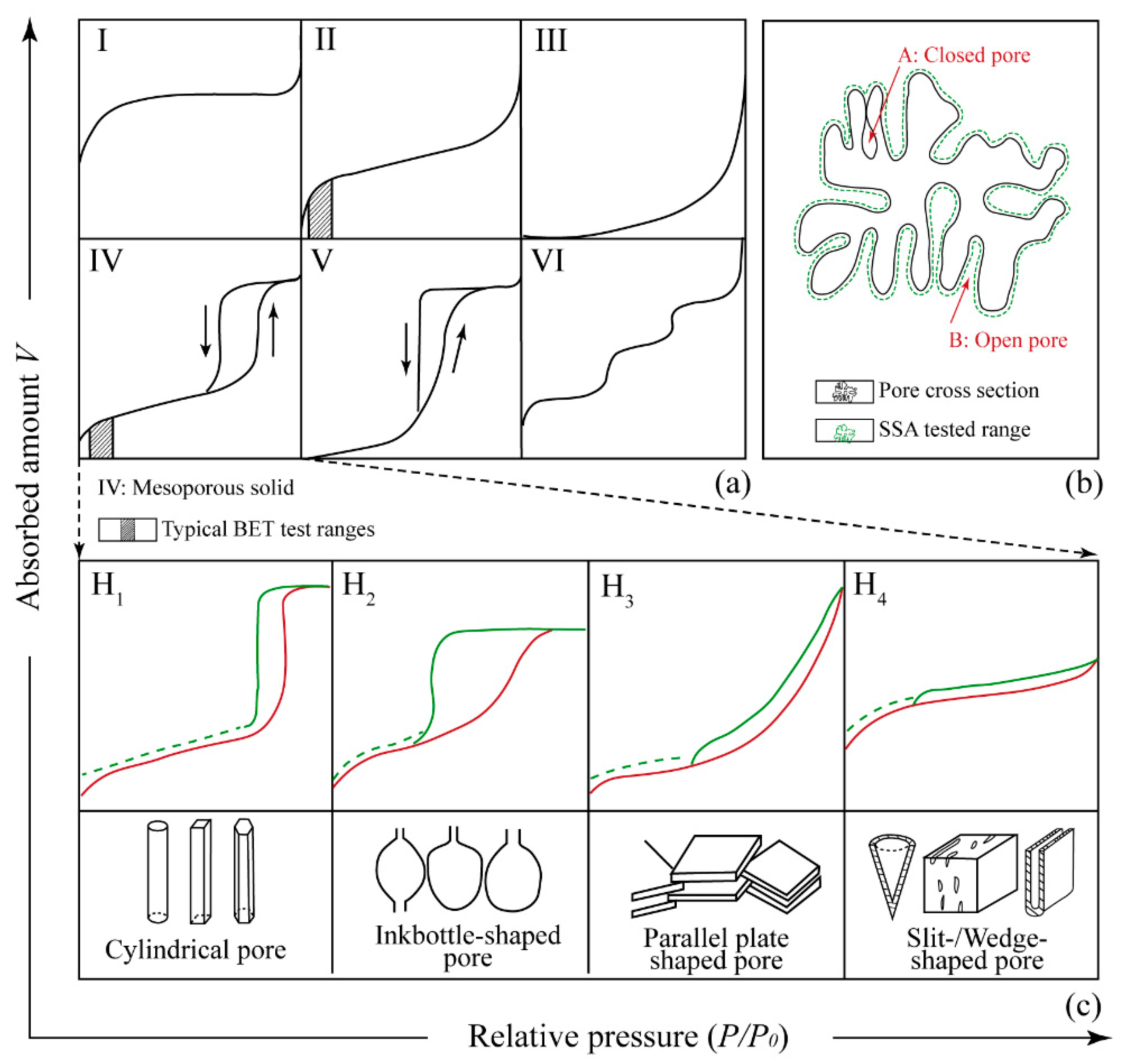

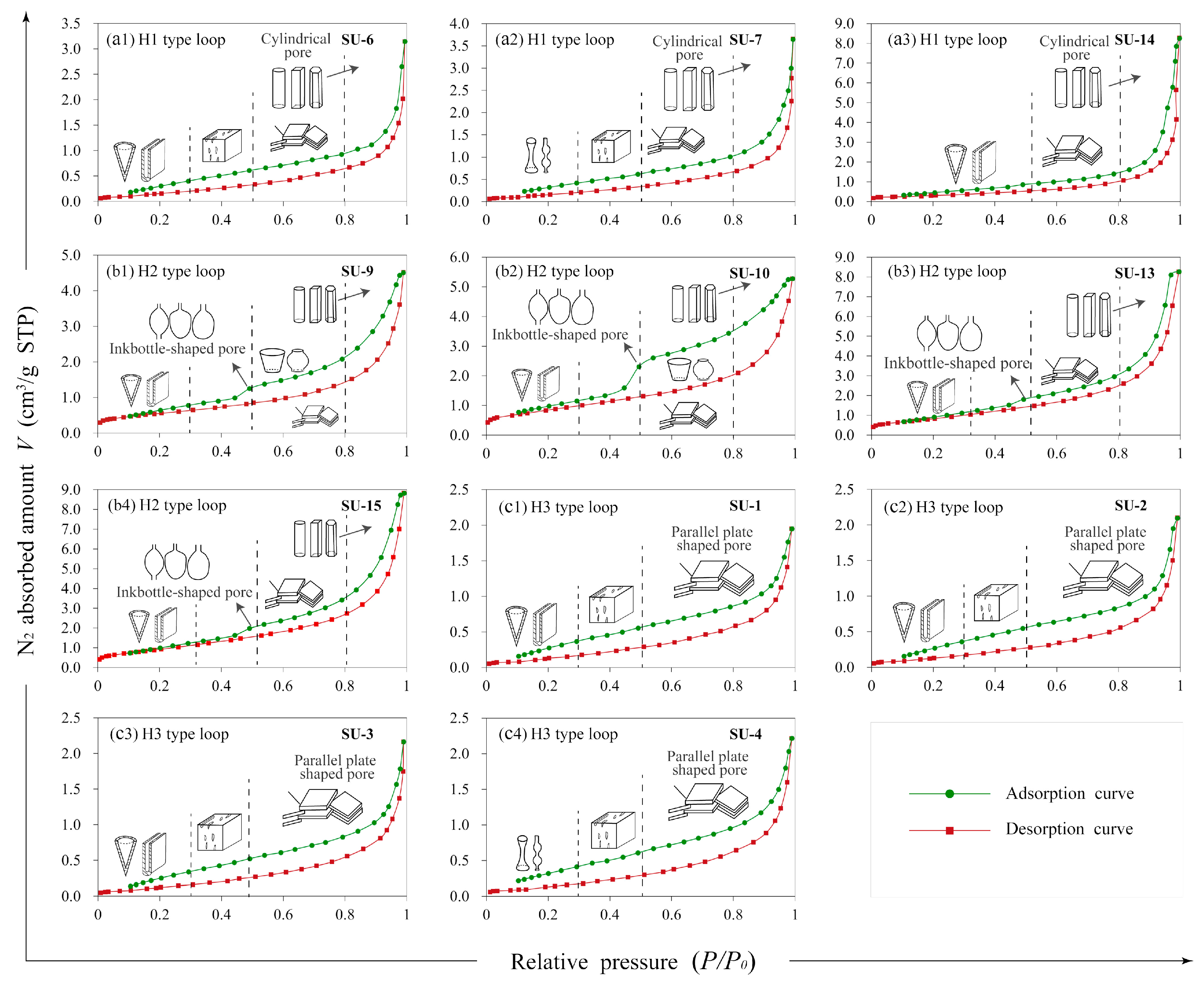

3.2. Nanoscale Pore Geometry from N2 Adsorption/Desorption Isotherms

3.3. Specific Surface Area, Pore Volume, and Pore Size Distribution

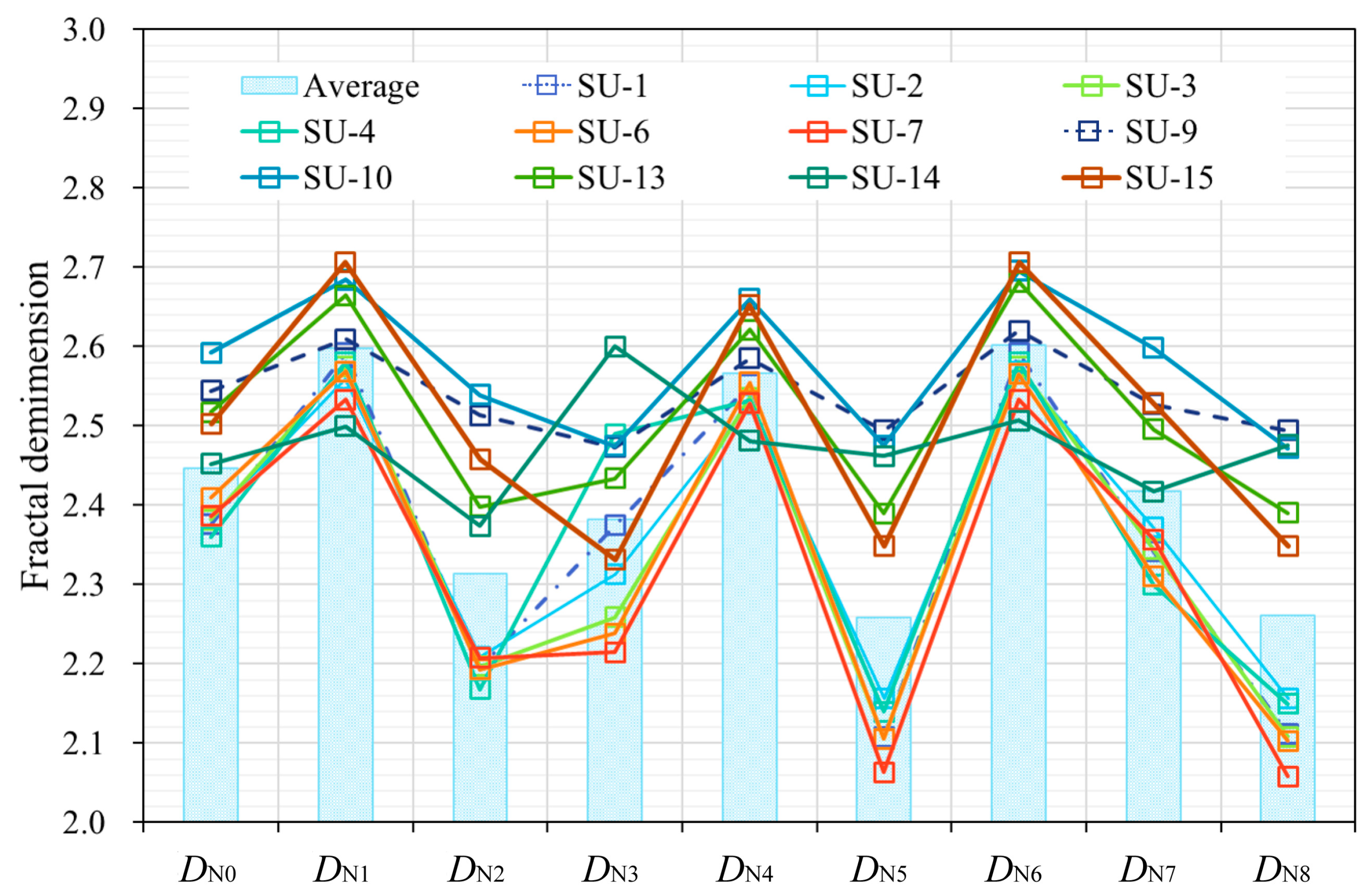

3.4. The Fractal Characteristics of Nanoscale Pores

4. Discussion

4.1. Effect of Mineral Composition on Fractal Dimensions

4.2. Effect of Pore Size Distribution on Fractal Dimensions

4.3. Compective Study of Fractal Dimensions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Zou, C.; Yang, Z.; He, D.; Wei, Y.; Li, J.; Jia, A.; Chen, J.; Zhao, Q.; Li, Y.; Li, J.; et al. Theory, technology and prospects of conventional and unconventional natural gas. Pet. Explor. Dev. 2018, 45, 604–618. [Google Scholar] [CrossRef]

- Zou, C.; Zhai, G.; Zhang, G.; Wang, H.; Zhang, G.; Li, J.; Wang, Z.; Wen, Z.; Ma, F.; Liang, Y.; et al. Formation, distribution, potential and prediction of global conventional and unconventional hydrocarbon resources. Pet. Explor. Dev. 2015, 42, 14–28. [Google Scholar] [CrossRef]

- Sun, L.; Zou, C.; Jia, A.; Wei, Y.; Zhu, R.; Wu, S.; Guo, Z. Development characteristics and orientation of tight oil and gas in China. Pet. Explor. Dev. 2019, 46, 1073–1087. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, S.; Xiao, D.; Li, B. Pore structure characteristics of tight sandstones in the northern Songliao Basin, China. Mar. Pet. Geol. 2017, 88, 170–180. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Cao, J.; Xiao, C.; Wang, S.; Pang, X.; Dai, Q.; He, Z.; Fan, X.; Yang, L.; et al. Investigation of pore structure and petrophysical property in tight sandstones. Mar. Pet. Geol. 2018, 91, 179–189. [Google Scholar] [CrossRef]

- Giacchetta, G.; Leporini, M.; Marchetti, B. Economic and environmental analysis of a Steam Assisted Gravity Drainage (SAGD) facility for oil recovery from Canadian oil sands. Appl. Energy 2015, 142, 1–9. [Google Scholar] [CrossRef]

- Du, S.; Zhao, Y.; Shi, Y. Characteristics and the formation mechanism of heterogeneous microfracture in the upper Triassic Yanchang formation tight oil sandstone of the Ordos Basin, China. J. Pet. Sci. Eng. 2020, 191, 107176. [Google Scholar] [CrossRef]

- Du, S.; Zhao, Y.; Yuan, Q. Prediction of permeability and its anisotropy of tight oil reservoir via precise pore-throat tortuosity characterization and “umbrella deconstruction” method. J. Pet. Sci. Eng. 2019, 178, 1018–1028. [Google Scholar] [CrossRef]

- Lai, J.; Wang, G.; Wang, Z.; Chen, J.; Pang, X.; Wang, S.; Zhou, Z.; He, Z.; Qin, Z.; Fan, X. A review on pore structure characterization in tight sandstones. Earth-Sci. Rev. 2018, 177, 436–457. [Google Scholar] [CrossRef]

- Liu, K.; Ostadhassan, M.; Zhou, J.; Gentzis, T.; Rezaee, R. Nanoscale pore structure characterization of the Bakken shale in the USA. Fuel 2017, 209, 567–578. [Google Scholar] [CrossRef]

- Clarkson, C.; Solano, N.; Bustin, R.; Bustin, A.; Chalmers, G.; He, L.; Melnichenko, Y.; Radlinski, A.; Blach, T. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; Freeman, W., Ed.; W.H. Freeman: San Francisco, CA, USA, 1983; Volume 173, p. 468. [Google Scholar]

- Macias-Garcia, A.; Diaz-Diez, M.; Cuerda-Correa, E.; Olivares, M.; Gañán-Gómez, J. Study of the pore size distribution and fractal dimension of HNO3-treated activated carbons. Appl. Surf. Sci. 2006, 252, 5972–5975. [Google Scholar] [CrossRef]

- Bernal, J.L.P.; López, M.A.B. The fractal dimension of stone pore surface as weathering descriptor. Appl. Surf. Sci. 2000, 161, 47–53. [Google Scholar] [CrossRef]

- Sing, K.S.W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Avnir, D.; Farin, D.; Pfeifer, P. Molecular fractal surfaces. Nature 1984, 308, 261–263. [Google Scholar] [CrossRef]

- Mandelbrot, B.B.; Passoja, D.E.; Paullay, A.J. Fractal character of fracture surfaces of metals. Nature 1984, 308, 721–722. [Google Scholar] [CrossRef]

- Li, Z.; Liu, D.; Cai, Y.; Wang, Y.; Teng, J. Adsorption pore structure and its fractal characteristics of coals by N2 adsorption/desorption and FESEM image analyses. Fuel 2019, 257, 116031. [Google Scholar] [CrossRef]

- Pan, J.; Wang, K.; Hou, Q.; Niu, Q.; Wang, H.; Ji, Z. Micro-pores and fractures of coals analysed by field emission scanning electron microscopy and fractal theory. Fuel 2016, 164, 277–285. [Google Scholar] [CrossRef]

- Yu, K.; Ju, Y.; Qi, Y.; Qiao, P.; Huang, C.; Zhu, H.; Feng, H. Fractal characteristics and heterogeneity of the nanopore structure of marine shale in Southern North China. Minerals 2019, 9, 242. [Google Scholar] [CrossRef]

- Yuan, Y.; Rezaee, R. Fractal analysis of the pore structure for clay bound water and potential gas storage in shales based on NMR and N2 gas adsorption. J. Pet. Sci. Eng. 2019, 177, 756–765. [Google Scholar] [CrossRef]

- Pfeifer, P.; Cole, M.W.; Krim, J.; Wu, Y.J. Multilayer adsorption on a fractally rough surface. Phys. Rev. Lett. 1989, 62, 1997–2000. [Google Scholar] [CrossRef]

- Zhang, S.; Tang, S.; Tang, D.; Huang, W.; Pan, Z. Determining fractal dimensions of coal pores by FHH model: Problems and effects. J. Nat. Gas Sci. Eng. 2014, 21, 929–939. [Google Scholar] [CrossRef]

- Wang, J.; Qin, Q.; Guo, L.; Feng, Y. Multi-fractal characteristics of three-dimensional distribution of reconstructed soil pores at opencast coal-mine dump based on high-precision CT scanning. Soil Tillage Res. 2018, 182, 144–152. [Google Scholar] [CrossRef]

- Zhou, X.-P.; Zhao, Z. Digital evaluation of nanoscale-pore shale fractal dimension with microstructural insights into shale permeability. J. Nat. Gas Sci. Eng. 2020, 75, 103137. [Google Scholar] [CrossRef]

- Hongchao, X.; Guanhua, N.; Shang, L.; Qian, S.; Kai, D.; Jingna, X.; Gang, W.; Yixin, L. The influence of surfactant on pore fractal characteristics of composite acidized coal. Fuel 2019, 253, 741–753. [Google Scholar] [CrossRef]

- Fan, X.; Wang, G.; Li, Y.; Dai, Q.; Linghu, S.; Duan, C.; Zhang, C.; Zhang, F. Pore structure evaluation of tight reservoirs in the mixed siliciclastic-carbonate sediments using fractal analysis of NMR experiments and logs. Mar. Pet. Geol. 2019, 109, 484–493. [Google Scholar] [CrossRef]

- Zhang, Z.; Weller, A. Fractal dimension of pore-space geometry of an Eocene sandstone formation. Geophysics 2014, 79, D377–D387. [Google Scholar] [CrossRef]

- Wang, F.; Yang, K.; You, J.; Lei, X. Analysis of pore size distribution and fractal dimension in tight sandstone with mercury intrusion porosimetry. Results Phys. 2019, 13, 102283. [Google Scholar] [CrossRef]

- Guo, X.; Huang, Z.; Zhao, L.; Han, W.; Ding, C.; Sun, X.; Yan, R.; Zhang, T.; Yang, X.; Wang, R. Pore structure and multi-fractal analysis of tight sandstone using MIP, NMR and NMRC methods: A case study from the Kuqa depression, China. J. Pet. Sci. Eng. 2019, 178, 544–558. [Google Scholar] [CrossRef]

- Han, W.; Zhou, G.; Gao, D.; Zhang, Z.; Wei, Z.; Wang, H.; Yang, H. Experimental analysis of the pore structure and fractal characteristics of different metamorphic coal based on mercury intrusion-nitrogen adsorption porosimetry. Powder Technol. 2020, 362, 386–398. [Google Scholar] [CrossRef]

- Xu, L.; Zhang, J.C.; Ding, J.; Liu, T.; Shi, G.; Li, X.; Dang, W.; Cheng, Y.; Guo, R. Pore structure and fractal characteristics of different shale lithofacies in the Dalong formation in the Western Area of the lower Yangtze platform. Minerals 2020, 10, 72. [Google Scholar] [CrossRef]

- Xi, Z.; Tang, S.; Wang, J.; Yi, J.; Guo, Y.; Wang, K. Pore structure and fractal characteristics of niutitang shale from China. Minerals 2018, 8, 163. [Google Scholar] [CrossRef]

- Huang, C.; Ju, Y.; Zhu, H.; Qi, Y.; Yu, K.; Sun, Y.; Ju, L. Nano-scale pore structure and fractal dimension of Longmaxi shale in the Upper Yangtze region, South China: A case study of the Laifeng–Xianfeng block using HIM and N2 adsorption. Minerals 2019, 9, 356. [Google Scholar] [CrossRef]

- Liu, J.; Lu, D.; Li, P. Nano-scale dual-pore-shape structure and fractal characteristics of transitional facies shale matrix. J. Nat. Gas Sci. Eng. 2019, 68, 68. [Google Scholar] [CrossRef]

- Li, Z.; Liang, Z.; Jiang, Z.; Gao, F.; Zhang, Y.; Yu, H.; Xiao, L.; Yang, Y. The impacts of matrix compositions on nanopore structure and fractal characteristics of lacustrine shales from the Changling fault depression, Songliao Basin, China. Minerals 2019, 9, 127. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, Z.; Jiang, S.; Chang, J.; Zhu, L.; Li, X.; Li, J. Full-scale pore structure and fractal dimension of the Longmaxi shale from the Southern Sichuan Basin: Investigations using FE-SEM, gas adsorption and mercury intrusion porosimetry. Minerals 2019, 9, 543. [Google Scholar] [CrossRef]

- Shan, C.; Zhao, W.; Wang, F.; Zhang, K.; Feng, Z.; Guo, L.; Ma, X.; Liao, T. Nanoscale pore structure heterogeneity and its quantitative characterization in Chang7 lacustrine shale of the southeastern Ordos Basin, China. J. Pet. Sci. Eng. 2020, 187, 106754. [Google Scholar] [CrossRef]

- He, X.; Cheng, Y.; Hu, B.; Wang, Z.; Wang, C.; Yi, M.; Wang, L. Effects of coal pore structure on methane-coal sorption hysteresis: An experimental investigation based on fractal analysis and hysteresis evaluation. Fuel 2020, 269, 117438. [Google Scholar] [CrossRef]

- Yu, S.; Bo, J.; FengLi, L.; Jiegang, L. Structure and fractal characteristic of micro- and meso-pores in low, middle-rank tectonic deformed coals by CO 2 and N 2 adsorption. Microporous Mesoporous Mater. 2017, 253, 191–202. [Google Scholar] [CrossRef]

- Zhu, J.-F.; Yang, W.; Yang, Y.-M.; Cheng, J.; Zhou, J.; Cen, K.-F. Fractal characteristics of pore structures in 13 coal specimens: Relationship among fractal dimension, pore structure parameter, and slurry ability of coal. Fuel Process. Technol. 2016, 149, 256–267. [Google Scholar] [CrossRef]

- Fu, H.; Tang, D.; Xu, T.; Xu, H.; Tao, S.; Li, S.; Yin, Z.; Chen, B.; Zhang, C.; Wang, L. Characteristics of pore structure and fractal dimension of low-rank coal: A case study of Lower Jurassic Xishanyao coal in the southern Junggar Basin, NW China. Fuel 2017, 193, 254–264. [Google Scholar] [CrossRef]

- Pan, J.; Peng, C.; Wan, X.; Zheng, D.; Lv, R.; Wang, K.; Deshun, Z. Pore structure characteristics of coal-bearing organic shale in Yuzhou coalfield, China using low pressure N 2 adsorption and FESEM methods. J. Pet. Sci. Eng. 2017, 153, 234–243. [Google Scholar] [CrossRef]

- Ma, X.; Guo, S.; Shi, D.; Zhou, Z.; Liu, G. Investigation of pore structure and fractal characteristics of marine-continental transitional shales from Longtan Formation using MICP, gas adsorption, and NMR (Guizhou, China). Mar. Pet. Geol. 2019, 107, 555–571. [Google Scholar] [CrossRef]

- Darby, B.J.; Ritts, B. Mesozoic contractional deformation in the middle of the Asian tectonic collage: The intraplate Western Ordos fold–thrust belt, China. Earth Planet. Sci. Lett. 2002, 205, 13–24. [Google Scholar] [CrossRef]

- Bai, D.; Yang, M.; Lei, Z.; Zhang, Y. Effect of tectonic evolution on hydrocarbon charging time: A case study from Lower Shihezi Formation (Guadalupian), the Hangjinqi area, northern Ordos, China. J. Pet. Sci. Eng. 2020, 184, 106465. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, R.; Zhang, F.; Lin, C.; Zhang, M. Sedimentary model reconstruction and exploration significance of Permian He 8 Member in Ordos Basin, NW China. Pet. Explor. Dev. 2019, 46, 280–292. [Google Scholar] [CrossRef]

- Tatlıer, M.; Erdem-Şenatalar, A. Method to evaluate the fractal dimensions of solid adsorbents. J. Phys. Chem. B 1999, 103, 4360–4365. [Google Scholar] [CrossRef]

- Jaroniec, M. Evaluation of the fractal dimension from a single adsorption isotherm. Langmuir 1995, 11, 2316–2317. [Google Scholar] [CrossRef]

- Avnir, D.; Jaroniec, M. An isotherm equation for adsorption on fractal surfaces of heterogeneous porous materials. Langmuir 1989, 5, 1431–1433. [Google Scholar] [CrossRef]

- Shan, C.; Zhang, T.; Liang, X.; Zhang, Z.; Wang, M.; Zhang, K.; Zhu, H. On the fundamental difference of adsorption-pores systems between vitrinite- and inertinite-rich anthracite derived from the southern Sichuan basin, China. J. Nat. Gas Sci. Eng. 2018, 53, 32–44. [Google Scholar] [CrossRef]

- Brunauer, S.; Emmett, P.H.; Teller, E. Adsorption of gases in multi-molecular layers. J. Am. Chem. Soc. 1938, 60, 309–319. [Google Scholar] [CrossRef]

- Barrett, E.P.; Joyner, L.G.; Halenda, P.P. The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J. Am. Chem. Soc. 1951, 73, 373–380. [Google Scholar] [CrossRef]

| Sample ID | Mineral Composition (%) | Clay Composition (%) | ||||||

|---|---|---|---|---|---|---|---|---|

| Q | F | C | Clay | I/S | I | K | C | |

| SU-1 | 90.6 | 0.2 | 4.2 | 5 | 5 | 7 | 57 | 31 |

| SU-2 | 93.6 | 0.2 | 6.2 | 15 | 12 | 11 | 62 | |

| SU-3 | 93.3 | 0.2 | 0.4 | 6.1 | 21 | 15 | 38 | 26 |

| SU-4 | 89.5 | 0.2 | 3.8 | 6.5 | 3 | 13 | 48 | 36 |

| SU-6 | 87.8 | 0.4 | 1 | 10.8 | 10 | 13 | 22 | 55 |

| SU-7 | 88.2 | 0.2 | 11.6 | 6 | 17 | 77 | ||

| SU-9 | 49.6 | 0.4 | 33.5 | 16.5 | 28 | 16 | 23 | 33 |

| SU-10 | 67.2 | 1.5 | 31.3 | 37 | 27 | 17 | 19 | |

| SU-13 | 73.6 | 0.2 | 1.1 | 25.1 | 11 | 16 | 35 | 38 |

| SU-14 | 84.7 | 0.5 | 0.6 | 14.2 | 14 | 14 | 27 | 45 |

| SU-15 | 78.8 | 0.6 | 20.6 | 24 | 13 | 18 | 45 | |

| Average | 81.5 | 0.4 | 6.4 | 14.0 | 16.8 | 13.8 | 28.5 | 42.5 |

| Sample ID | AM (cm3/g) | Specific Surface Area (m2/g) | Pore Volume (×10–3 cm3/g) | Pore Width (nm) | Classfication | Hysteresis Loop Type | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| SBET | SBJH | VBJH | VSF | WT | WBJH_ave | WBJH_med | WSF_med | ||||

| SU-1 | 1.950 | 0.597 | 1.014 | 3.291 | 0.250 | 20.212 | 12.983 | 2.040 | 1.835 | C | H3 |

| SU-2 | 2.100 | 0.548 | 0.944 | 3.503 | 0.247 | 23.726 | 14.840 | 2.035 | 1.967 | C | H3 |

| SU-3 | 2.166 | 0.530 | 0.925 | 3.593 | 0.220 | 25.271 | 15.547 | 3.509 | 1.728 | C | H3 |

| SU-4 | 2.217 | 0.594 | 1.044 | 3.725 | 0.334 | 23.104 | 14.271 | 2.801 | 1.718 | C | H3 |

| SU-6 | 3.148 | 0.697 | 1.124 | 5.167 | 0.288 | 27.931 | 18.379 | 2.814 | 1.727 | B | H1 |

| SU-7 | 3.652 | 0.683 | 1.188 | 5.987 | 0.326 | 33.094 | 20.151 | 2.033 | 1.728 | B | H1 |

| SU-9 | 4.512 | 2.012 | 1.932 | 7.043 | 0.746 | 13.877 | 14.583 | 3.976 | 1.108 | B | H2 |

| SU-10 | 5.279 | 3.162 | 2.862 | 8.147 | 1.198 | 10.329 | 11.387 | 2.099 | 1.067 | B | H2 |

| SU-13 | 8.261 | 3.038 | 3.858 | 13.379 | 1.055 | 16.823 | 13.872 | 2.819 | 1.071 | A | H2 |

| SU-14 | 8.266 | 1.112 | 1.519 | 13.198 | 0.518 | 45.989 | 34.762 | 2.062 | 1.728 | A | H1 |

| SU-15 | 8.831 | 3.772 | 4.368 | 13.404 | 1.272 | 13.686 | 12.275 | 2.498 | 1.104 | A | H2 |

| Sample ID | Region: 0.01 < P/P0 ≤ 0.99 | Pore size: W > 10nm | Pore size: 2 nm < W ≤ 10 nm | Pore size: W < 2nm | Pore size: W > 5nm | Pore size: W ≤ 5nm | Region 1: P/P0 > 0.8 | Region 2: 0.5 < P/P0 ≤ 0.8 | Region 3: P/P0 ≤ 0.5 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| k0 | R02 | k1 | R12 | k2 | R22 | k3 | R32 | k4 | R42 | k5 | R52 | k6 | R62 | k7 | R72 | k8 | R82 | |

| SU-1 | –0.624 | 0.959 | –0.408 | 0.999 | –0.805 | 0.989 | –0.625 | 0.928 | –0.448 | 0.992 | –0.893 | 0.982 | –0.408 | 0.999 | –0.658 | 0.994 | –0.888 | 0.978 |

| SU-2 | –0.616 | 0.971 | –0.441 | 0.996 | –0.791 | 0.992 | –0.687 | 0.979 | –0.473 | 0.993 | –0.844 | 0.992 | –0.432 | 0.996 | –0.628 | 0.992 | –0.844 | 0.990 |

| SU-3 | –0.618 | 0.965 | –0.425 | 0.990 | –0.803 | 0.991 | –0.741 | 0.969 | –0.464 | 0.991 | –0.895 | 0.993 | –0.425 | 0.990 | –0.656 | 0.998 | –0.892 | 0.991 |

| SU-4 | –0.640 | 0.965 | –0.420 | 0.999 | –0.832 | 0.993 | –0.511 | 0.972 | –0.469 | 0.990 | –0.860 | 0.980 | –0.420 | 0.999 | –0.700 | 0.996 | –0.851 | 0.975 |

| SU-6 | –0.591 | 0.962 | –0.431 | 0.994 | –0.807 | 0.994 | –0.762 | 0.971 | –0.445 | 0.995 | –0.895 | 0.994 | –0.435 | 0.993 | –0.689 | 0.997 | –0.897 | 0.993 |

| SU-8 | –0.614 | 0.965 | –0.467 | 0.985 | –0.793 | 0.990 | –0.786 | 0.962 | –0.472 | 0.993 | –0.937 | 0.991 | –0.467 | 0.985 | –0.643 | 0.996 | –0.942 | 0.989 |

| SU-9 | –0.456 | 0.995 | –0.391 | 0.991 | –0.487 | 1.000 | –0.527 | 1.000 | –0.415 | 0.993 | –0.506 | 0.998 | –0.380 | 0.991 | –0.473 | 0.999 | –0.506 | 0.997 |

| SU-10 | –0.408 | 0.982 | –0.316 | 0.978 | –0.461 | 0.995 | –0.525 | 0.973 | –0.340 | 0.986 | –0.525 | 0.996 | –0.305 | 0.974 | –0.402 | 1.000 | –0.528 | 0.996 |

| SU-13 | –0.483 | 0.972 | –0.335 | 0.985 | –0.602 | 0.993 | –0.566 | 0.992 | –0.379 | 0.958 | –0.611 | 0.997 | –0.318 | 0.929 | –0.505 | 0.999 | –0.610 | 0.996 |

| SU-14 | –0.548 | 0.994 | –0.500 | 0.977 | –0.627 | 0.999 | –0.400 | 0.949 | –0.519 | 0.987 | –0.538 | 0.980 | –0.493 | 0.972 | –0.583 | 1.000 | –0.524 | 0.978 |

| SU-15 | –0.498 | 0.963 | –0.293 | 0.931 | –0.542 | 0.994 | –0.669 | 0.970 | –0.347 | 0.959 | –0.651 | 0.993 | –0.293 | 0.931 | –0.471 | 1.000 | –0.651 | 0.993 |

| Minimum | –0.640 | 0.959 | –0.500 | 0.931 | –0.832 | 0.989 | –0.786 | 0.928 | –0.519 | 0.958 | –0.937 | 0.980 | –0.493 | 0.929 | –0.700 | 0.992 | –0.942 | 0.975 |

| Maximum | –0.408 | 0.995 | –0.293 | 0.999 | –0.461 | 1.000 | –0.400 | 1.000 | –0.340 | 0.995 | –0.506 | 0.998 | –0.293 | 0.999 | –0.402 | 1.000 | –0.506 | 0.997 |

| Average | –0.554 | 0.972 | –0.403 | 0.984 | –0.686 | 0.994 | –0.618 | 0.970 | –0.434 | 0.985 | –0.741 | 0.990 | –0.398 | 0.978 | –0.583 | 0.997 | –0.739 | 0.989 |

| Sample ID | Hysteresis Loop Types | DN0 | DN1 | DN2 | DN3 | DN4 | DN5 | DN6 | DN7 | DN8 |

|---|---|---|---|---|---|---|---|---|---|---|

| SU-1 | H3 | 2.376 | 2.592 | 2.195 | 2.375 | 2.552 | 2.107 | 2.592 | 2.342 | 2.112 |

| SU-2 | H3 | 2.384 | 2.559 | 2.209 | 2.313 | 2.527 | 2.156 | 2.568 | 2.372 | 2.156 |

| SU-3 | H3 | 2.382 | 2.575 | 2.197 | 2.259 | 2.536 | 2.105 | 2.575 | 2.344 | 2.108 |

| SU-4 | H3 | 2.360 | 2.580 | 2.168 | 2.490 | 2.531 | 2.140 | 2.580 | 2.300 | 2.150 |

| SU-6 | H1 | 2.409 | 2.569 | 2.193 | 2.238 | 2.555 | 2.105 | 2.565 | 2.311 | 2.103 |

| SU-7 | H1 | 2.386 | 2.533 | 2.207 | 2.215 | 2.528 | 2.063 | 2.533 | 2.357 | 2.058 |

| SU-14 | H1 | 2.452 | 2.500 | 2.374 | 2.600 | 2.481 | 2.462 | 2.507 | 2.417 | 2.476 |

| SU-9 | H2 | 2.544 | 2.609 | 2.513 | 2.473 | 2.585 | 2.494 | 2.620 | 2.527 | 2.494 |

| SU-10 | H2 | 2.592 | 2.685 | 2.539 | 2.475 | 2.660 | 2.475 | 2.695 | 2.598 | 2.472 |

| SU-13 | H2 | 2.517 | 2.665 | 2.398 | 2.434 | 2.621 | 2.389 | 2.682 | 2.496 | 2.390 |

| SU-15 | H2 | 2.502 | 2.707 | 2.458 | 2.331 | 2.653 | 2.349 | 2.707 | 2.529 | 2.349 |

| Minimum | 2.360 | 2.500 | 2.168 | 2.215 | 2.481 | 2.063 | 2.507 | 2.300 | 2.058 | |

| Maximum | 2.592 | 2.707 | 2.539 | 2.600 | 2.660 | 2.494 | 2.707 | 2.598 | 2.494 | |

| Average | 2.446 | 2.597 | 2.314 | 2.382 | 2.566 | 2.259 | 2.602 | 2.417 | 2.261 | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Jiang, X.; Pan, M.; Shi, Y. Nano-Scale Pore Structure and Its Multi-Fractal Characteristics of Tight Sandstone by N2 Adsorption/Desorption Analyses: A Case Study of Shihezi Formation from the Sulige Gas Filed, Ordos Basin, China. Minerals 2020, 10, 377. https://doi.org/10.3390/min10040377

Wang Z, Jiang X, Pan M, Shi Y. Nano-Scale Pore Structure and Its Multi-Fractal Characteristics of Tight Sandstone by N2 Adsorption/Desorption Analyses: A Case Study of Shihezi Formation from the Sulige Gas Filed, Ordos Basin, China. Minerals. 2020; 10(4):377. https://doi.org/10.3390/min10040377

Chicago/Turabian StyleWang, Zhelin, Xuewei Jiang, Mao Pan, and Yongmin Shi. 2020. "Nano-Scale Pore Structure and Its Multi-Fractal Characteristics of Tight Sandstone by N2 Adsorption/Desorption Analyses: A Case Study of Shihezi Formation from the Sulige Gas Filed, Ordos Basin, China" Minerals 10, no. 4: 377. https://doi.org/10.3390/min10040377

APA StyleWang, Z., Jiang, X., Pan, M., & Shi, Y. (2020). Nano-Scale Pore Structure and Its Multi-Fractal Characteristics of Tight Sandstone by N2 Adsorption/Desorption Analyses: A Case Study of Shihezi Formation from the Sulige Gas Filed, Ordos Basin, China. Minerals, 10(4), 377. https://doi.org/10.3390/min10040377