DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore Using a Particle Replacement Model

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Laboratory-Scale Jaw Crushing Tests

2.3. DEM Particle Replacement Model Parameter Calibration

2.4. Jaw Crusher DEM Simulations

3. Results

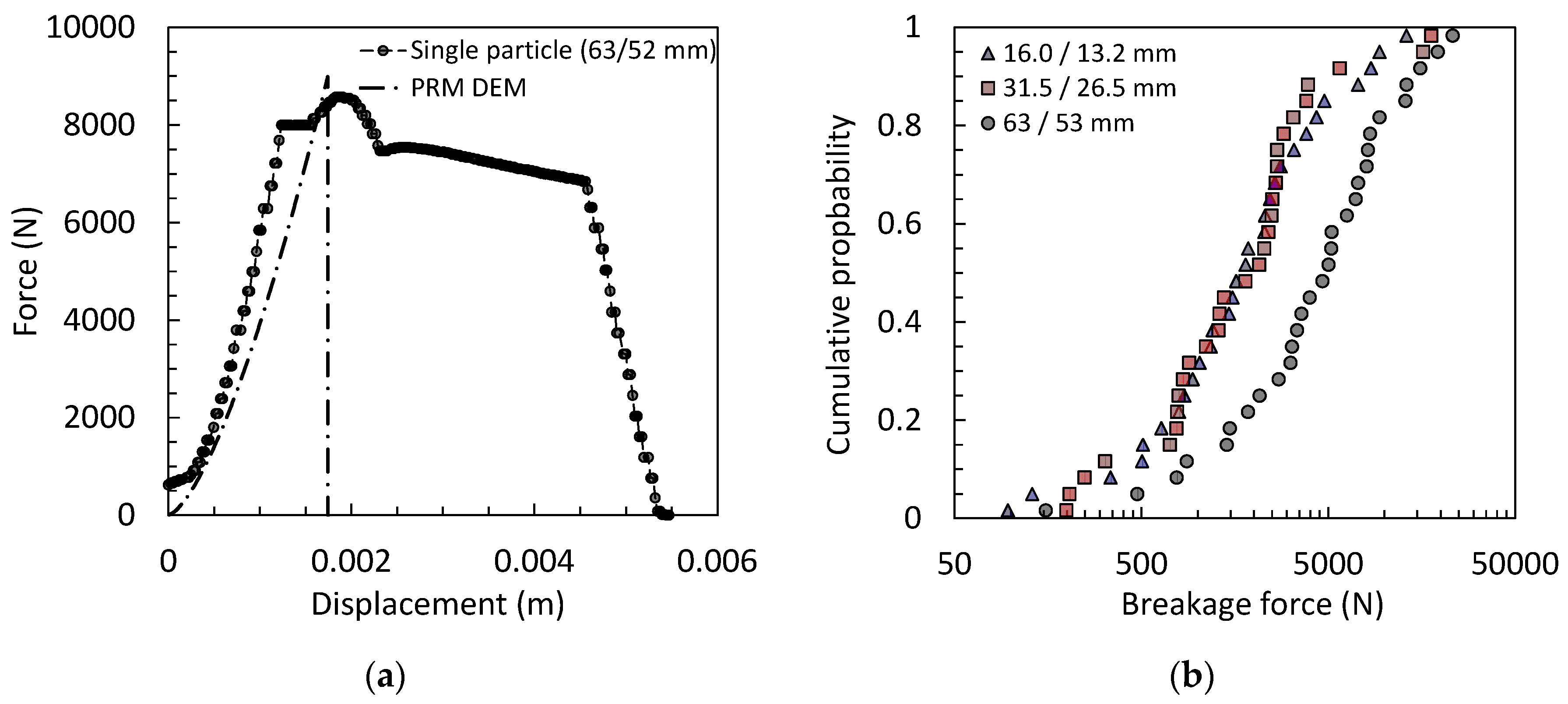

3.1. Calibration of Particle Replacement Model Parameters

3.2. DEM Simulations of the Laboratory Jaw Crusher

3.3. Sensitivity Analysis of the Jaw Crusher DEM Model

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mular, A.L.; Halbe, D.N.; Barratt, D.J. Mineral Processing Plant Design, Practice, and Control: Proceedings; SME: Englewood, CO, USA, 2002; Volume 1, ISBN 0873352238. [Google Scholar]

- Wills, B.A.; Napier-munn, T. Preface to 7th Edition. In Wills' Mineral Processing Technology; Butterworth-Heinemann: Oxford, UK, 2006; ISBN 0750644508. [Google Scholar]

- Gupta, A.; Yan, D.S. Mineral Processing Design and Operations: An Introduction; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 0444635920. [Google Scholar]

- Olaleye, B.M. Influence of some rock strength properties on jaw crusher performance in granite quarry. Min. Sci. Technol. 2010, 20, 204–208. [Google Scholar] [CrossRef]

- Naziemiec, Z.; Gawenda, T.; Tumidajski, T.; Saramak, D. The influence of transverse profile of crusher jaws on comminution effects. In Proceedings of the IMPC 2006—Proceedings of 23rd International Mineral Processing Congress, Istanbul, Turkey, 3–8 September 2006; pp. 69–74. [Google Scholar]

- Fladvad, M.; Onnela, T. Influence of jaw crusher parameters on the quality of primary crushed aggregates. Miner. Eng. 2020, 151. [Google Scholar] [CrossRef]

- Zeng, Y.; Zheng, M.; Forssberg, E. Monitoring jaw crushing parameters via vibration signal measurement. Int. J. Miner. Process. 1993, 39, 199–208. [Google Scholar] [CrossRef]

- Olawale, J.O.; Ibitoye, S.A. Failure analysis of a crusher jaw. In Handbook of Materials Failure Analysis; Butterworth-Heinemann: Oxford, UK, 2018; pp. 187–207. ISBN 9780081019283. [Google Scholar]

- Broman, J. Optimizing capacity and economy in jaw and gyratory crushers. Eng. Min. J. 1984, 185, 69–71. [Google Scholar]

- Rose, H.E.; English, J.E. Theoretical analysis of the performance of jaw crushers. IMM Trans. 1967, 76, C32. [Google Scholar]

- Andersen, J.S.; Napier-Munn, T.J. The influence of liner condition on cone crusher performance. Miner. Eng. 1990, 3, 105–116. [Google Scholar] [CrossRef]

- Lynch, A.J. Mineral Crushing and Grinding Circuits: Their Simulation, Optimisation, Design, and Control; Elsevier Science Ltd: Amsterdam, The Netherlands, 1977; Volume 1. [Google Scholar]

- Nikolov, S. A performance model for impact crushers. Miner. Eng. 2002, 15, 715–721. [Google Scholar] [CrossRef]

- Johansson, M.; Bengtsson, M.; Evertsson, M.; Hulthén, E. A fundamental model of an industrial-scale jaw crusher. Miner. Eng. 2017, 105, 69–78. [Google Scholar] [CrossRef]

- Fusheng, M.; Hui, L.; Xingxue, L.; Hongzhi, X. Jaw crusher based on discrete element method. Appl. Mech. Mater. 2013, 312, 101–105. [Google Scholar] [CrossRef]

- Legendre, D.; Zevenhoven, R. Assessing the energy efficiency of a jaw crusher. Energy 2014, 74, 119–130. [Google Scholar] [CrossRef]

- Jiménez-Herrera, N.; Barrios, G.K.P.; Tavares, L.M. Comparison of breakage models in DEM in simulating impact on particle beds. Adv. Powder Technol. 2018, 29, 692–706. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.D. Simulation of particle flows and breakage in crushers using DEM: Part 1—Compression crushers. Miner. Eng. 2015, 74, 178–197. [Google Scholar] [CrossRef]

- Barrios, G.K.P.; Jiménez-Herrera, N.; Tavares, L.M. Simulation of particle bed breakage by slow compression and impact using a DEM particle replacement model. Adv. Powder Technol. 2020. [Google Scholar] [CrossRef]

- SGC. Guía Metodológica Para el Mejoramiento Productivo del Beneficio de Oro Sin el Uso de Mercurio: Íquira (Huila). 2018. Available online: http://srvags.sgc.gov.co/Archivos_Geoportal/Geologia/Guia-metodologica-Iquira-Huila.pdf (accessed on 30 March 2020).

- Barrios, G.K.P.; Tavares, L.M. A preliminary model of high pressure roll grinding using the discrete element method and multi-body dynamics coupling. Int. J. Miner. Process. 2016, 156, 32–42. [Google Scholar] [CrossRef]

- Qian, G.; Lei, W.S.; Yu, Z.; Berto, F. Statistical size scaling of breakage strength of irregularly-shaped particles. Theor. Appl. Fract. Mech. 2019, 102, 51–58. [Google Scholar] [CrossRef]

- Rodriguez, V.A.; de Carvalho, R.M.; Tavares, L.M. Insights into advanced ball mill modelling through discrete element simulations. Miner. Eng. 2018, 127, 48–60. [Google Scholar] [CrossRef]

- Lindqvist, M.; Evertsson, C.M. Linear wear in jaw crushers. Miner. Eng. 2003, 16, 1–12. [Google Scholar] [CrossRef]

- Tavares, L.M.; King, R.P. Single-particle fracture under impact loading. Int. J. Miner. Process. 1998, 54, 1–28. [Google Scholar] [CrossRef]

- Terva, J.; Kuokkala, V.; Valtonen, K.; Siitonen, P. Effects of compression and sliding on the wear and energy consumption in mineral crushing. Wear 2018, 398–399, 116–126. [Google Scholar] [CrossRef]

- Taggart, A.F. Handbook of Mineral Dressing; Wiley: Hoboken, NJ, USA, 1945; Volume 1. [Google Scholar]

| Mineral | Percent (%) |

|---|---|

| Gangue minerals (quartz and feldspar) | 62 |

| Pyrite | 23 |

| Carbonates | 7 |

| Chalcopyrite | 4 |

| Hematite | 2 |

| Sphalerite | 1 |

| Galena | 1 |

| Parameters | Units | Value |

|---|---|---|

| Nominal throughput | kg/h | 300 |

| Power | kW | 2.2 |

| Main shaft frequency | rpm | 400 |

| Swing jaw stroke frequency | Hz | 6.0 |

| Feed (top) opening | mm × mm | 140 × 90 |

| Discharge opening | mm × mm | 140 × 7.5 (closed) |

| Swing jaw throw | mm | 10 |

| Parameters | Units | Steel | Ore |

|---|---|---|---|

| Density | kg/m3 | 7800 | 2700 |

| Shear modulus | Pa | 7 × 109 | 1 × 108 |

| Poisson’s ratio | - | 0.30 | 0.25 |

| Parameters | Units | Steel–Ore | Ore–Ore |

|---|---|---|---|

| Coefficient of restitution | - | 0.37 | 0.35 |

| Coefficient of friction | - | 0.20 | 0.34 |

| Coefficient of rolling friction | - | 0.10 | 0.25 |

| Parameter | Units | Range | |

|---|---|---|---|

| Discharge opening | mm | 2.5–7.5–12.5 | |

| Swing jaw stroke frequency | Hz | 0.5–3.0–6.0–9.0 | |

| Feed particle narrow sizes | mm | 63.0/52.0 31.5/26.5 16.0/13.2 | 100% 100% 100% |

| Feed particle size distribution | mm | 63.0/52.0 31.5/26.5 16.0/13.2 | 33.3% 33.3% 33.3% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Barrios, G.K.; Jiménez-Herrera, N.; Fuentes-Torres, S.N.; Tavares, L.M. DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore Using a Particle Replacement Model. Minerals 2020, 10, 717. https://doi.org/10.3390/min10080717

Barrios GK, Jiménez-Herrera N, Fuentes-Torres SN, Tavares LM. DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore Using a Particle Replacement Model. Minerals. 2020; 10(8):717. https://doi.org/10.3390/min10080717

Chicago/Turabian StyleBarrios, Gabriel Kamilo, Narcés Jiménez-Herrera, Silvia Natalia Fuentes-Torres, and Luís Marcelo Tavares. 2020. "DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore Using a Particle Replacement Model" Minerals 10, no. 8: 717. https://doi.org/10.3390/min10080717

APA StyleBarrios, G. K., Jiménez-Herrera, N., Fuentes-Torres, S. N., & Tavares, L. M. (2020). DEM Simulation of Laboratory-Scale Jaw Crushing of a Gold-Bearing Ore Using a Particle Replacement Model. Minerals, 10(8), 717. https://doi.org/10.3390/min10080717