Historical Outline of Iron Mining and Production in the Area of Present-Day Poland

Abstract

:1. Outline of the History of Iron Ore Mining in Present Poland

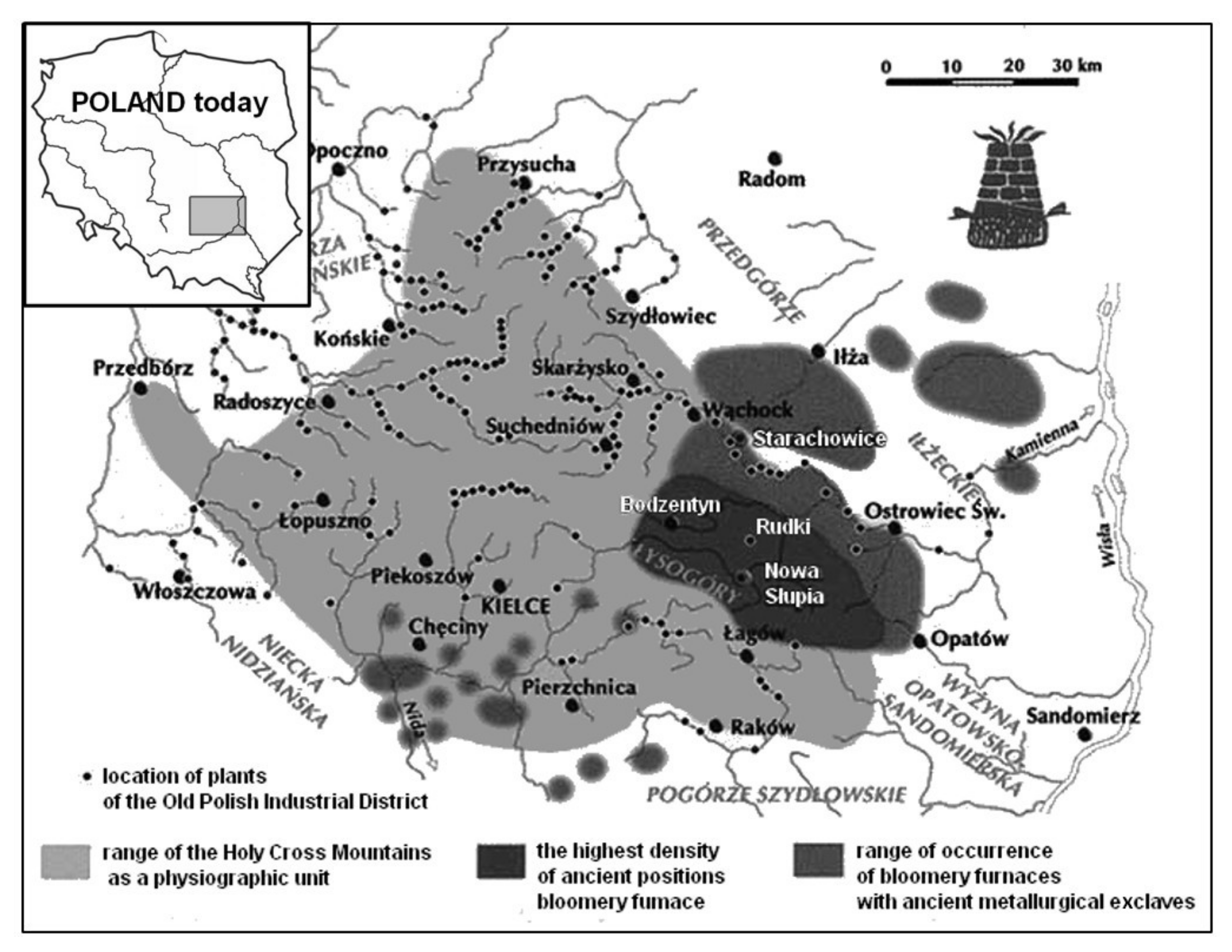

2. Exploitation and Ironworks in the Świętokrzyskie Region

3. Exploitation and Ironworks in Lower Silesia

4. Exploitation and Metallurgy in the Częstochowa Region

5. Summary

- Mining and metallurgy of iron ore on the territory of present-day Poland lasted from the 7th–5th century B.C. until the end of the 20th century A.D. The oldest traces of iron ore mining were located in the Świętokrzyskie region and the Lower Silesia area.

- Initially, mining was carried out by using open-pit methods, and bog iron ores were mainly exploited. Since the Piast and Jagiellonian dynasties, the increase in demand for iron resulted in a shift from opencast to underground mining. There was also a development of iron smelting technology from the sub-period of ore mines, which fell on the Latenian period, to he sub-period of forges (around 1200) and charcoal (around 1500) to the sub-period of coke use. The first blast furnace operated on coke was started up in Gliwice in 1796.

- In the 19th century and the first half of the 20th century, the iron industry developed well despite the partitions of Poland and the world wars. This development coincided with the industrial development of both the country and all of Europe. Many urban centers were created or developed, e.g., towns in today’s Upper Silesian Industrial Region and workers’ settlements (e.g., Blachownia). Iron ore mining ended in Poland in the seventies of the 20th century and ended with the closure of the last mine near Łęczyca, in 1989.

- Iron ore is not currently exploited in the regions presented in the article due to the large scattering of the deposits, low metal content in the ore, and a high degree of depletion of the deposits. In addition, iron ore has been identified in Poland in the north-eastern part of the country, which is the Suwałki region. However, due to the depth of the deposit (up to 2300 m) and the location of the deposit in the vicinity of the national landscape park, its exploitation is not currently planned.

- According to the list presented by the Polish Geological Institute, Poland has iron ore deposits of over 1.3 billion tons [53]. These resources are qualified as off-balance, which forces Poland to import iron from other countries. Imports of iron ore and concentrates amounted to almost 7 million tonnes. The leading suppliers were Russia and Ukraine [54].

- Currently, former iron ore exploitation traces include post-mining waste dumps, post-mining basins, and residual relics of iron ore processing. Mine heritage of the region is presented in museums of the following: The Historical and Archaeological Museum in Ostrowiec Świętokrzyski, the Museum of Nature and Technology “Ekomuzeum” in Starachowice, and The Museum of Iron Ore Mining in Częstochowa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Commeli, D.; D’orazio, M.; Folco, L.; El-Halwagy, M.; Frizzi, T.; Alberti, R.; Capogrosso, V.; Einagarr, A.; Hassan, H.; Nevin, A.; et al. The meteoritic origin of Tutankhamun’s iron dagger blade. Meteorit. Planet. Sci. 2016, 51, 1301–1309. [Google Scholar] [CrossRef]

- Kaczanowski, P.; Kozłowski, J.K. Wielka Historia Polski, tom I—Najdawniejsze Dzieje Ziem Polskich; Fogra Oficyna Wydawnicza: Kraków, Poland, 1998; pp. 165–174. [Google Scholar]

- Adamski, A. Górnictwo rud Żelaza w Regionie Częstochowskim; Zarząd Stowarzyszenia Inżynierów i Techników Górnictwa w Częstochowie: Częstochowa, Poland, 1994. [Google Scholar]

- Przybyłka, A. Rozwój górnictwa w regionie świętokrzyskim i na Górnym Śląsku. Studia i Materiały Wydziału Zarządzania i Administracji Wyższej Szkoły Pedagogicznej im. Jana Kochanowskiego w Kielcach Ewolucja Gospodarki Społeczeństwa i Systemu Prawno-Instytucjonalnego w Kierunku Budowy Ładu Zintegrowanego 2016, 2, 331–340. [Google Scholar]

- Dziekoński, T. Wydobywanie i Metalurgia Kruszców na Dolnym Śląsku od XIII do Połowy XX Wieku; Wydawnictwo Ossolineum: Wrocław, Poland, 1972. [Google Scholar]

- Jasienica, P. Polska Jagiellonów; Państwowy Instytut Wydawniczy: Warszawa, Poland, 1985. [Google Scholar]

- Osiński, J. Opisanie Polskich Żelaza Fabryk, w Którym Świadectwa Historyków Wzmiankujących Miejsca Minerałów Przytoczono; Druk. IKM i Rzeczypospolitey u XX.Scholarum Piarum: Warszawa, Poland, 1782. [Google Scholar]

- Ziemba, J. Stromą na dół Drabiną. Z Tradycji Polskiego Górnictwa; Śląski Instytut Naukowy: Katowice, Poland, 1983. [Google Scholar]

- Jasiuk, J. Szkoła Akademiczno-Górnicza. Prz. Odlew. 2006, 10–11, 608–609. [Google Scholar]

- Gazdyl, W. Geologia Złóż; Politechnika Śląska Publishing House: Gliwice, Poland, 1999. [Google Scholar]

- PIG BIP—The Polish Geological Institute—National Research Institute. Available online: https://www.pgi.gov.pl/kielce/oddzial-swietokrzyski/sep1-kielce/geologia-regionu/6468-kopaliny-mineralne.html (accessed on 2 August 2021).

- CUG. Bilans Zasobów Kopalin Użytecznych w Polsce—Part 2. Centralny Urząd Geologii (Central Geology Office). Available online: www.pgi.gov.pl/ (accessed on 6 October 2021).

- Ratajczak, T.; Rzepa, G. Polskie Rudy Darniowe; Wydawnictwo AGH: Kraków, Poland, 2011. [Google Scholar]

- Bielenin, K. Starożytne Górnictwo i Hutnictwo Żelaza w Górach Świętokrzyskich; Wydawnictwo KTN: Kielce, Poland, 1992. [Google Scholar]

- Bielenin, K.; Suliga, I. The ancient slag-pit furnace and the reduction process in the light of a new archeological concept and metallurgical research. Metall. Foundry Eng. 2008, 34, 53–78. [Google Scholar] [CrossRef] [Green Version]

- Solangaarachchi, R. History of metallurgy ancient iron smelting. Vidurava 1997, 19, 30–40. [Google Scholar]

- Thiele, A. Smelting experiments in the early medieval fajszi-type bloomery and the metallurgy of iron bloom. Period Polytech. Mech. Eng. 2010, 54, 99–104. [Google Scholar] [CrossRef]

- Rybski, J. Postscriptum do Dziejów Staropolskiego Górnictwa rud Żelaza; Świętokrzyska Biblioteka Cyfrowa: Starachowice, Poland, 1978. [Google Scholar]

- Kaptur, K. Podziemne górnictwo rud żelaza w rejonie Ostrowca Świętokrzyskiego i inwentaryzacja reliktów dawnych robót górniczych. Hered. Minariorum 2014, 1, 131–144. [Google Scholar]

- Łabęcki, H. Górnictwo w Polsce Opis Kopalnictwa i Hutnictwa Polskiego. T.1; Drukarnia Juliana Kaczanowskiego: Warszawa, Poland, 1841. [Google Scholar]

- Rauhut, M. Studia i materiały do historii starożytnego i wczesnośredniowiecznego hutnictwa żelaza w Polsce. In Studia z Dziejów Górnictwa i Hutnictwa; Keck, A., Ed.; Zakład Narodowy im. Ossolińskich: Wrocław, Poland, 1957. [Google Scholar]

- Zbierski, A. Stan badań nad historią górnictwa i hutnictwa w Polsce wczesnośredniowiecznej. In Stan Badań nad Dziejami Górnictwa i Hutnictwa w Polsce; Zakład Narodowy im. Ossolińskich: Wrocław, Poland, 1957. [Google Scholar]

- Migdalska, A.; Niemczak, K. Starożytne górnictwo i hutnictwo świętokrzyskie—Nowy kierunek badań. In Przemysł Wydobywczo-Przetwórczy Węgla i rud Żelaza a Rozwój Gospodarczy; Nowak, S., Ed.; Oficyna Wydawnicza Edward Mitek: Bydgoszcz, Poland, 2014. [Google Scholar]

- Orzechowski, S. Zaplecze osadnicze starożytnego okręgu hutniczego w Górach Świętokrzyskich i jego relacje ze strefą produkcyjną. In Hutnictwo Świętokrzyskie Oraz inne Centra i Ośrodki Starożytnej Metalurgii Żelaza na Ziemiach Polskich; Orzechowski, S., Ed.; Świętokrzyskie Stowarzyszenie Dziedzictwa Przemysłowego: Kielce, Poland, 2002; pp. 27–44. [Google Scholar]

- Bielenin, K.; Przychodni, A. Świętokrzyskie ironworking in school education. In 50 Years of Research on Ancient Świętokrzyskie Ironworking. Archaeology—Metallurgy—Education; Orzechowski, S., Suliga, I., Eds.; KTN: Kielce, Poland, 2006. [Google Scholar]

- Orzechowski, S. Region Żelaza: Centra Hutnicze Kultury Przeworskiej; Wydawnictwo Uniwersytetu Jana Kochanowskiego: Kielce, Poland, 2013. [Google Scholar]

- Nieć, M. Działalność Komisji Zasobów Kopalin w 2005 i 2006 roku. Prz. Geol. 2007, 55, 536–539. [Google Scholar]

- Heliasz, Z.; Ostaficzuk, S. Historical residues of iron ore mining in environs of the Holy Cross Mountains (the Góry Świętokrzyskie) are recognizable on the Digital Terrain Elevation Model (DEM) derived from the LIDAR data. Gospod. Surowcami Miner. 2020, 36, 161–186. [Google Scholar]

- Guldon, Z. Hutnictwo I przemysł metalowy w powiecie opoczyńskim w okresie przedrozbiorowym. In Tradycje Przemysłowe Ziemi Koneckiej; Różański, W., Ed.; Towarzystwo Przyjaciół Górnictwa Hutnictwa i Przemysłu Staropolskiego w Kielcach: Kielce, Poland, 1991; pp. 33–40. [Google Scholar]

- Król, P.; Urban, J.; Garus, R. Zabytki Górnictwa i Hutnictwa Staropolskiego Okręgu Przemysłowego w Dolinie Górnej Bobrzy; Agencja JP s.c.: Kielce, Poland, 2010. [Google Scholar]

- Radwan, M. Rudy, Kuźnice i Huty Żelaza w Polsce; WNT Warszawa: Warszawa, Poland, 1963. [Google Scholar]

- Radwan, M. Pierwotne hutnictwo żelaza na północnym zboczu Łysogór. Ziemia 1933, 6, 73–77. [Google Scholar]

- Chmielowska, A. Żelazo i przestrzeń. Koncepcja strefy przemysłowej na przykładzie brzeskiego rejonu starożytnego hutnictwa. Śląskie Spraw. Archeol. 2017, 59, 49–70. [Google Scholar]

- Kosicki, A. Produkcja żelaza w osadzie kultury przeworskiej w Namysłowie. In Hutnictwo Świętokrzyskie Oraz inne Centra i Ośrodki Starożytnej Metalurgii Żelaza na Ziemiach Polskich; Orzechowski, S., Ed.; Świętokrzyskie Stowarzyszenie Dziedzictwa Przemysłowego: Kielce, Poland, 2002; pp. 117–120. [Google Scholar]

- Madera, P. Ślady Starożytnego Hutnictwa Żelaza na Śląsku w Chronologiczno-Przestrzennym. In Hutnictwo Świętokrzyskie Oraz Inne Centra i Ośrodki Starożytnej Metalurgii Żelaza na Ziemiach Polskich; Orzechowski, S., Ed.; Świętokrzyskie Stowarzyszenie Dziedzictwa Przemysłowego: Kielce, Poland, 2002; pp. 61–71. [Google Scholar]

- Pazda, S. Brzeski Rejon Starożytnej Metalurgii Żelaza, IV–V w. n.e.; Wydawnictwo Uniwersytetu Wrocławskiego: Wrocław, Poland, 1994. [Google Scholar]

- Madera, P. Ze studiów nad piecami dymarskimi z kotlinką “bardzo dużą” na Śląsku labor et patientia. In Studia Archaeologica Stanislao Pazda Dedicata; Błażejewski, A., Pazda, S., Eds.; Instytut Archeologii Uniwersytetu Wrocławskiego: Wrocław, Poland, 2008. [Google Scholar]

- Godłowski, K. Przemiany osadnicze i kulturowe w południowej i środkowej Polsce w młodszym okresie przedrzymskim i okresie rzymskim. Prz. Archeol. 1984, 32, 105–155. [Google Scholar]

- Bielenin, K. Zarys Dziejów Hutnictwa i Naukowo-Technicznych Stowarzyszeń Hutniczych: Praca Zbiorowa; Czermiński, J., Palmrich, A., Eds.; Stowarzyszenie Inżynierów i Techników Przemysłu Hutniczego w Polsce: Warszawa, Poland, 1972. [Google Scholar]

- Lehnhardt, E.; Błażejewski, A.; Madera, P.; Meister, J. Pielgrzymowice—A Przeworsk culture iron smelting site from the roman period in Silesia. Prz. Archeol. 2019, 67, 177–230. [Google Scholar] [CrossRef]

- Hadbas, K. Zarys rozwoju produkcji i techniki w polskim górnictwie rud żelaza. Zeszyty Naukowe Akademii Techniczno-Rolniczej w Bydgoszczy 1976, 32, 31–47. [Google Scholar]

- Utrata, B. Historia Miasta Kowary. Available online: https://turysta.kowary.pl/miasto/ (accessed on 15 January 2021).

- Piątek, E.; Piątek, Z. Górnictwo rud Metali w Górach Sowich; Studio Tak: Wrocław, Poland, 2000. [Google Scholar]

- Wutke, K. Der Bergbau im Osten des Kónigreiches Preussen. Band IV; Festschrift zum XII Allgemeinen Deutschen Bergmannstage: Wrocław, Poland, 1913. [Google Scholar]

- Madziarz, M. Historyczna Technika Eksploatacji rud Żelaza na Przykładzie Kopalni “Carl Friedrich Gustaw” w Stanisławowie. In Dzieje Górnictwa—Element Europejskiego Dziedzictwa Kultury. T.2; Zagożdżon, P.P., Madziarz, M., Eds.; Oficyna Wydawnicza Politechniki Wrocławskiej: Wrocław, Poland, 2009; pp. 145–166. [Google Scholar]

- Antoniewicz, M. Zamki na Wyżynie Krakowsko—Częstochowskiej, Geneza, Funkcje, Konteksty; Wydawnictwo Szumacher: Kielce, Poland, 1998. [Google Scholar]

- Wojenka, M. Najnowsze badania archeologiczne budownictwa obronnego na Jurze Ojcowskiej. Archaeol. Hist. Pol. 2019, 26, 337–372. [Google Scholar] [CrossRef] [Green Version]

- Fajer, M. Zmiany Krajobrazu Doliny Liswarty w Ostatnim Tysiącleciu Uwarunkowane Gospodarczą Działalnością Człowieka; Prace Komisji Krajobrazu Kulturowego T.7: Sosnowiec, Poland, 2007. [Google Scholar]

- Gawor, Ł.; Warcholik, W.; Dolnicki, P. Possibilities of using and recovery of wastes after mining and preparation of iron ores from dumps in Częstochowa Ore-bearing Basin Studies of the Industrial Geography Commission of the Polish Geographical Society. Chang. Energy Sect. Serv. 2015, 29, 125–135. [Google Scholar]

- Szczepański, A.; Lasatowicz, T.; Malicki, W. Zmiany w środowisku przyrodniczym pod wpływem eksploatacji rud żelaza w rejonie częstochowskim. Zesz. Nauk. Politech. Czest. 1990, 144, 7–22. [Google Scholar]

- Polish Central Statistical Office. Roczniki GUS 1939–2020. Available online: https://stat.gov.pl/en/ (accessed on 15 October 2021).

- Gawor, Ł. Zmiany rzeźby terenu związane z historyczną eksploatacją rud żelaza w rejonie częstochowskim. CUPRUM—Czas.-Nauk.-Tech. Gor. Rud 2017, 83, 61–70. [Google Scholar]

- Centralna Baza Danych Geologicznych. Available online: www.geoportal.pgi.gov.pl (accessed on 6 October 2021).

- Główny Urząd Statystyczny. Rocznik Statystyczny Handlu Zagranicznego 2020; Zakład Wydawnictw Statystycznych: Warszawa, Poland, 2020. [Google Scholar]

| Sites | Dating |

|---|---|

| Łysa Góra | 75 A.D. (50 B.C.–200 A.D.) |

| Grzegorzewice | 25 A.D. (90 B.C.–140 A.D.) |

| 200 A.D. (150 A.D.–250 A.D.) | |

| Nowa Słupia | 65 A.D. (20 B.C.–150 A.D.) |

| 220 A.D. (140 A.D.–300 A.D.) | |

| 1020 A.D. (970 A.D.–1100 A.D.) | |

| 540 A.D. (470 A.D.–590 A.D.) | |

| Łazy | 230 A.D. (110 A.D.–340 A.D.) |

| 15 A.D. (110 B.C.–140 A.D.) | |

| 100 A.D. (30 B.C.–230 A.D.) | |

| 300 A.D. (180 A.D.–400 A.D.) | |

| Rudki | 280 A.D. (220 A.D.–330 A.D.) |

| 280 A.D. (230 A.D.–320 A.D.) | |

| Jeleniów | 1 A.D. (30 B.C.–30 A.D.) |

| 280 A.D. (45 B.C. (85 B.C.–5 B.C.) | |

| Częstocice | 210 B.C. (300 B.C.–160 B.C.) |

| Culture | MS | MW | STM | TM | U*MS | U*MW | U*STM | U*TM |

|---|---|---|---|---|---|---|---|---|

| Ł | - | - | - | - | 1 | - | 1 | - |

| PM | - | - | - | - | 1 | - | - | - |

| LT | 4 | - | 3 | - | - | - | - | 1 |

| J | 8 | - | 3 | - | - | - | - | - |

| P | 65 | 12 | 16 | 2 | 13 | 2 | 4 | - |

| LB | 2 | 1 | - | 1 | 4 | - | - | - |

| Year | Mining (Mg) |

|---|---|

| 1390 | 920 |

| 1475 | 3600 |

| 1580 | 9800 |

| 1785 | 5500 |

| 1820 | 530 |

| 1840 | 2300 |

| 1905 | 90,000 |

| 1945 | 73,228 |

| 1950–1960 | max. 200–250 thousand |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wrona, P.; Różański, Z.; Pach, G.; Niewiadomski, A.P.; Veiga, J.P. Historical Outline of Iron Mining and Production in the Area of Present-Day Poland. Minerals 2021, 11, 1136. https://doi.org/10.3390/min11101136

Wrona P, Różański Z, Pach G, Niewiadomski AP, Veiga JP. Historical Outline of Iron Mining and Production in the Area of Present-Day Poland. Minerals. 2021; 11(10):1136. https://doi.org/10.3390/min11101136

Chicago/Turabian StyleWrona, Paweł, Zenon Różański, Grzegorz Pach, Adam P. Niewiadomski, and João Pedro Veiga. 2021. "Historical Outline of Iron Mining and Production in the Area of Present-Day Poland" Minerals 11, no. 10: 1136. https://doi.org/10.3390/min11101136

APA StyleWrona, P., Różański, Z., Pach, G., Niewiadomski, A. P., & Veiga, J. P. (2021). Historical Outline of Iron Mining and Production in the Area of Present-Day Poland. Minerals, 11(10), 1136. https://doi.org/10.3390/min11101136