Environmental Evaluation of Gypsum Plasterboard Recycling

Abstract

1. Introduction

2. Materials and Methods

2.1. Investigated Recycling Process

2.2. Settings for the Environmental Evaluation

- the transportation of GPW (from construction sites or collection points) to the recycling plant,

- the recycling process,

- transportation to the gypsum plant,

- drying process, and

- transportation to the costumer.

- recovery of natural gypsum from the deposits,

- transportation to the gypsum plant,

- the drying process,

- transportation to the costumer,

- transportation to a landfill after the use phase, and

- landfilling.

- transportation to the gypsum plant,

- the drying process,

- transportation to the costumer,

- transportation to a landfill after the use phase, and

- landfilling.

2.3. Life Cycle Inventory

- transportation to the gypsum plant: 20 km

- transportation from the gypsum manufacturer to the costumer/construction site: 200 km

- transportation to a landfill after the use phase: 30 km FGD gypsum

- transportation of the GPW (from construction sites or collection points) to the recycling plant

2.4. Applied Impact Categories

3. Results

3.1. Global Warming Potential (GWP)

3.2. Acidification Potential (AP)

3.3. Eutrophication Potential (EP)

3.4. Photochemical Ozone Creation Potential (POCP)

3.5. Abiotic Depletion Potential (ADPelem.)

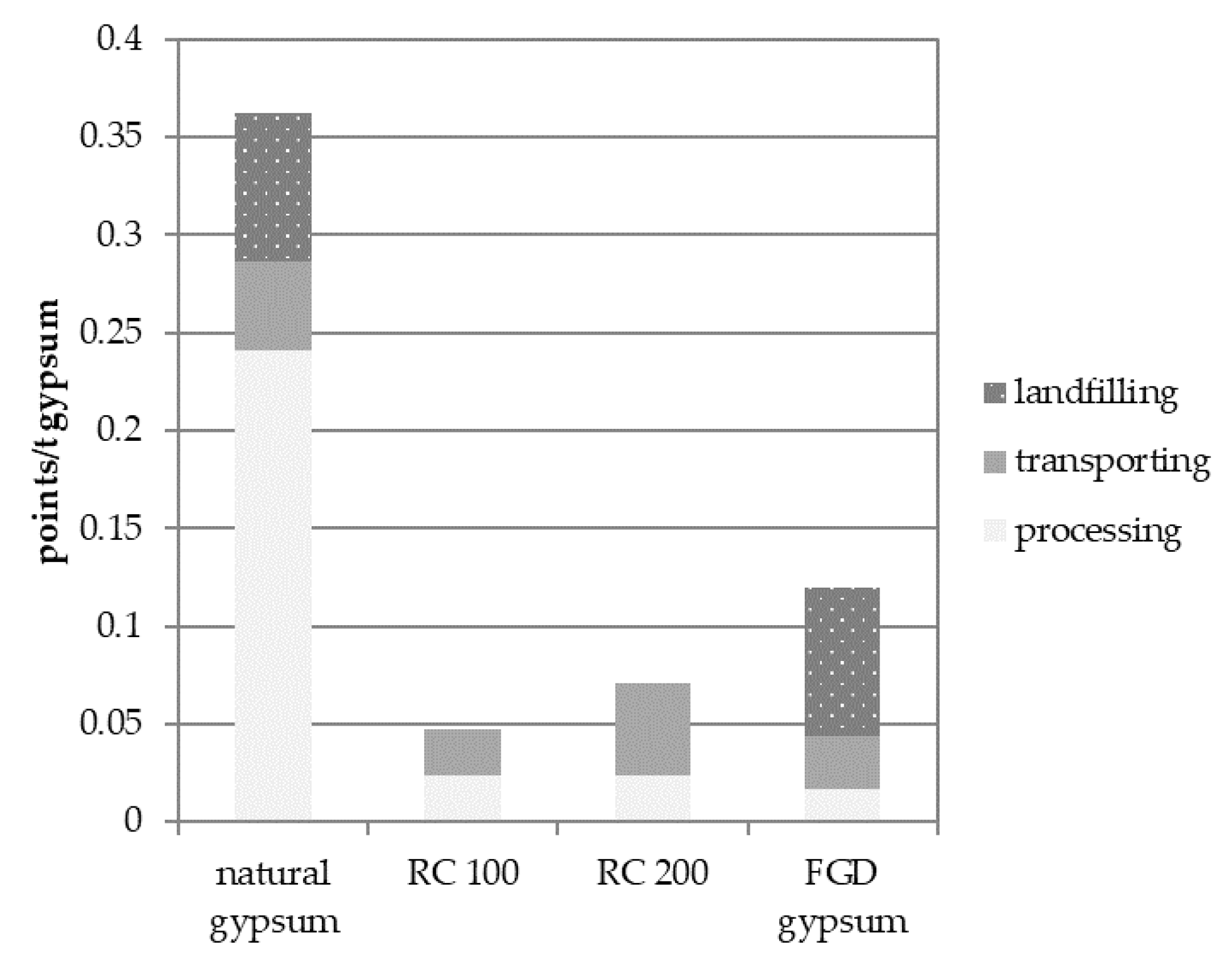

3.6. Ecological Damage Potential (EDP): Land Use Transformation

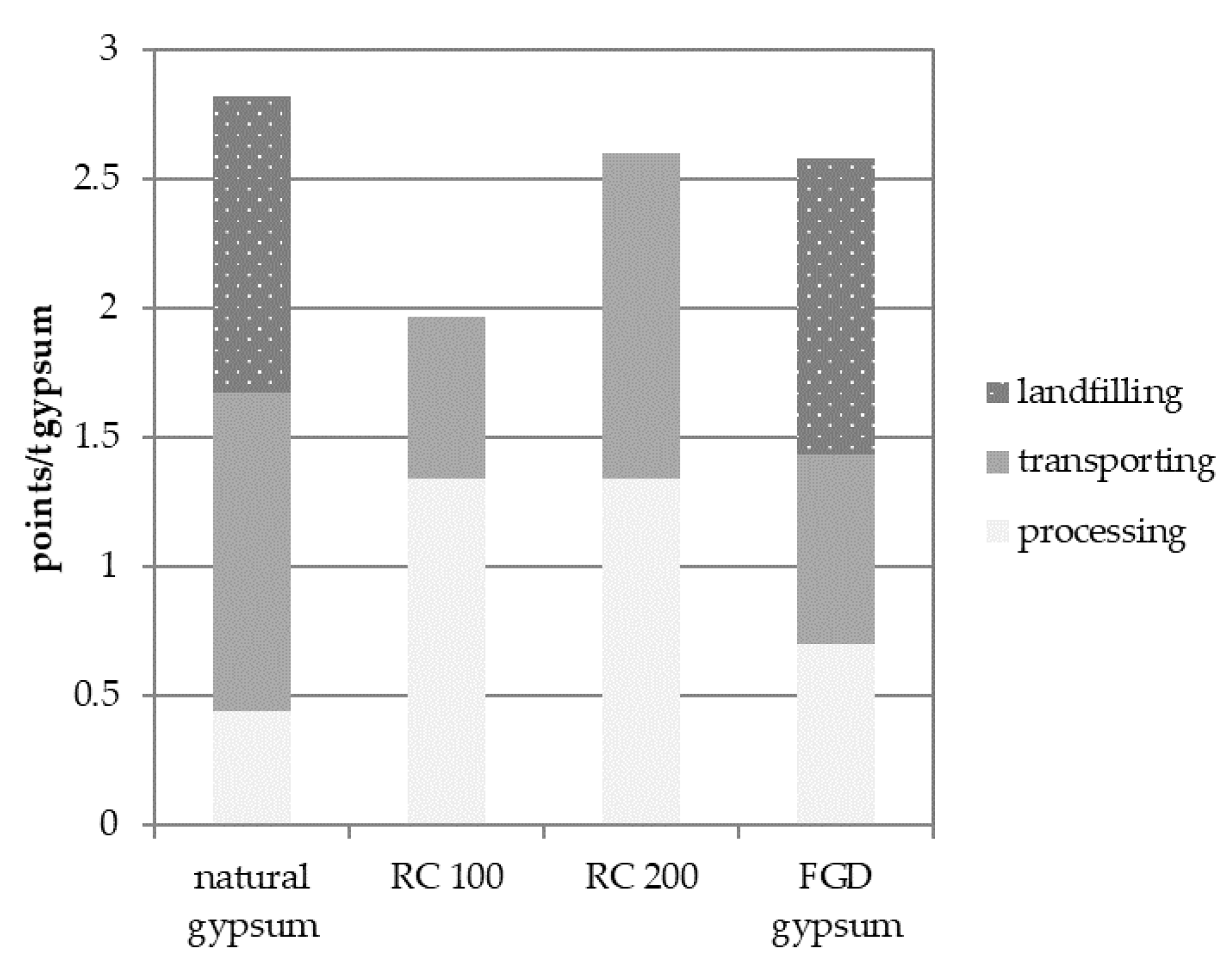

3.7. Ecological Damage Potential (EDP): Land Use, Total

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Rivero, A.J.; Sathre, R.; Navarro, J.G. Life cycle energy and material flow implications of gypsum plasterboard recycling in the European Union. Resour. Conserv. Recycl. 2016, 108, 171–181. [Google Scholar] [CrossRef]

- Zhang, C.B.; Hu, M.; Dong, L.; Gebremariam, A.; Miranda-Xicotencatl, B.; Di Maio, F.; Tukker, A. Eco-efficiency assessment of technological innovations in high-grade concrete recycling. Resour. Conserv. Recycl. 2019, 149, 649–663. [Google Scholar] [CrossRef]

- Jin, R.Y.; Chen, Q.; Soboyejo, A. Survey of the current status of sustainable concrete production in the US. Resour. Conserv. Recycl. 2015, 105, 148–159. [Google Scholar] [CrossRef]

- Colman, C.; Bulteel, D.; Rémond, S.; Zhao, Z.; Courard, L. Valorization of Fine Recycled Aggregates Contaminated with Gypsum Residues: Characterization and Evaluation of the Risk for Secondary Ettringite Formation. Materials 2020, 13, 4866. [Google Scholar] [CrossRef]

- Azevedo, A.R.G.; Vieira, C.M.F.; Ferreira, W.M.; Faria, K.C.P.; Pedroti, L.G.; Mendes, B.C. Potential use of ceramic waste as precursor in the geopolymerization reaction for the production of ceramic roof tiles. J. Build. Eng. 2020, 29, 101156. [Google Scholar] [CrossRef]

- Amaral, L.F.; Delaqua, G.C.G.; Nicolite, M.; Marvila, M.T.; de Azevedo, A.R.G.; Alexandre, J.; Vieira, C.M.F.; Monteiro, S.N. Eco-friendly mortars with addition of ornamental stone waste—A mathematical model approach for granulometric optimization. J. Clean. Prod. 2020, 248, 119283. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.G.; Barroso, L.S.; Barbosa, M.Z.; de Brito, J. Gypsum plaster using rock waste: A proposal to repair the renderings of historical buildings in Brazil. Constr. Build. Mater. 2020, 250, 118786. [Google Scholar] [CrossRef]

- German Building Material Association (BBS). The Demand for Primary and Secondary Raw Materials in the Mineral and Building Materials Industry in Germany up to 2035; German Building Material Association (BBS): Berlin, Germany, 2019. [Google Scholar]

- ACAA—American Coal Ash Association. ACAA 2019 Survey Results and Production & Use Charts. Available online: https://www.acaa-usa.org/publications/productionusereports.aspx (accessed on 8 January 2021).

- Hohmann, M. Fördermenge von Gips in Ausgewählten Ländern. Statista. Available online: https://de.statista.com/ (accessed on 8 January 2021).

- Camarini, G.; Lima, K.D.D.; Pinheiro, S.M.M. Investigation on gypsum plaster waste recycling: An eco-friendly material. Green Mater. 2015, 3, 104–112. [Google Scholar] [CrossRef]

- Geraldo, R.H.; Pinheiro, S.M.M.; Silva, J.S.; Andrade, H.M.C.; Dweck, J.; Gonçalves, J.P.; Camarini, G. Gypsum plaster waste recycling: A potential environmental and industrial solution. J. Clean. Prod. 2017, 164, 288–300. [Google Scholar] [CrossRef]

- German Building Material Association (bbs). Annual Reports (Aufgaben, Themen und Ziele—Jahresberichte der Baustoffindustrie). Available online: https://www.baustoffindustrie.de/downloads (accessed on 11 September 2020).

- US Geological Survey (USGS). Gypsum Statistics. Available online: https://www.usgs.gov (accessed on 10 September 2020).

- German Federal Statistical Office (Statistisches Bundesamt). Statistical Yearbooks (Statistische Jahrbücher). Available online: https://www.destatis.de/DE/Themen/Querschnitt/Jahrbuch/_inhalt.html (accessed on 11 September 2020).

- Stawski, T.M.; Van Driessche, A.E.S.; Ossorio, M.; Rodriguez-Blanco, J.D.; Besselink, R.; Benning, L.G. Formation of calcium sulfate through the aggregation of sub-3 nanometre primary species. Nat. Commun. 2016, 7, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.B.; Middendorf, B. Calcium sulphate hemihydrate hydration leading to gypsum crystallization. Prog. Cryst. Growth Charact. Mater. 2007, 53, 57–77. [Google Scholar] [CrossRef]

- Association of the German Gypsum Industry (Bundesverband der Gipsindustrie e.V.). Gips-Datenbuch; Association of the German Gypsum Industry: Berlin, Germany, 2013. [Google Scholar]

- Buchert, M.; Sutter, J.; Alwast, H.; Schuetz, N.; Weimann, K. Life cycle assessment of gypsum plasterboard recycling. In Umweltforschungsplan; FKZ 3715 34 320, Report; German Environment Agency: Dessau, Germany, 2017. [Google Scholar]

- Erbs, A.; Nagalli, A.; de Carvalho, K.Q.; Mymrin, V.; Passig, F.H.; Mazer, W. Properties of recycled gypsum from gypsum plasterboards and commercial gypsum throughout recycling cycles. J. Clean. Prod. 2018, 183, 1314–1322. [Google Scholar] [CrossRef]

- EU-Recycling—Editorial Staff. Gipsrecycling: Noch etliche Steine im Weg. EU-Recycling 2015. Available online: https://eu-recycling.com/Archive/9575 (accessed on 8 January 2021).

- The British Standards Institution (BSI). PAS 109:2013: Specification for the Production of Reprocessed Gypsum from Waste Pasterboards, 2nd ed.; BSI Standards Limited: London, UK, 2013. [Google Scholar]

- Association of the European Gypsum Industry (Eurogypsum). FGD Gypsum—Quality Characteristics and Analytical Methods; Eurogypsum: Brussels, Belgium, 2012. [Google Scholar]

- Rahman, M.M.; Bassuoni, M.T. Thaumasite sulfate attack on concrete: Mechanisms, influential factors and mitigation. Constr. Build. Mater. 2014, 73, 652–662. [Google Scholar] [CrossRef]

- Vegas, I.; Ibañez, J.A.; Lisbona, A.; De Cortazar, A.S.; Frías, M. Pre-normative research on the use of mixed recycled aggregattes in unbound road sections. Constr. Build. Mater. 2011, 25, 2674–2682. [Google Scholar] [CrossRef]

- Weimann, K.; Matyschik, J.; Adam, C.; Schulz, T.; Linß, E.; Mueller, A. Optimization of demolition/dismantling of buildings for the recovery and treatment of building materials considering the reduction of harmful substances (in particular sulphates) in the recycled building material and aspects of life-cycle analyses. In Umweltforschungsplan; FKZ 3709 33 317, Report; German Environment Agency: Dessau, Germany, 2012. [Google Scholar]

- Ahmed, A.; Ugai, K.; Kamei, T. Investigation of recycled gypsum in conjunction with waste plastic trays for ground improvement. Constr. Build. Mater. 2011, 25, 208–217. [Google Scholar] [CrossRef]

- Cordon, H.C.F.; Cagnoni, F.C.; Ferreira, F.F. Comparison of physical and mechanical properties of civil construction plaster and recycled waste gypsum from Sao Paulo, Brazil. J. Build. Eng. 2019, 22, 504–512. [Google Scholar] [CrossRef]

- Pantini, S.; Giurato, M.; Rigamonti, L. A LCA study to investigate resource-efficient strategies for managing post-consumer gypsum waste in Lombardy region (Italy). Resour. Conserv. Recycl. 2019, 147, 157–168. [Google Scholar] [CrossRef]

- Johansson, P.; Brander, L.; Bok, G. Solutions for reducing gypsum board waste to landfil. In Progress of Recycling in the Built Environment, Lisbon, Portugal, 11./12.10.2020; RILEM: Paris, France, 2018. [Google Scholar]

- Pedreno-Rojas, M.A.; De Brito, J.; Flores-Colen, I.; Pereira, M.F.C.; Rubio-de-Hita, P. Influence of gypsum wastes on the workability of plasters: Heating process and microstructural analysis. J. Build. Eng. 2020, 29, 1–11. [Google Scholar] [CrossRef]

- Suarez, S.; Roca, X.; Gasso, S. Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: Application to the Spanish context. J. Clean. Prod. 2016, 117, 150–159. [Google Scholar] [CrossRef]

- Association of the German Gypsum Industry (Bundesverband der Gipsindustrie e.V.). Initital Assssment for Recycling Facilities, Quality Management, Quality Characteristics and Analytical Methods; Association of the German Gypsum Industry: Berlin, Germany, 2016. [Google Scholar]

- DIN-Deutsches Institut für Normung e.V. EN ISO 14044: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; Beuth Verlag: Berlin, Germany, 2018. [Google Scholar]

- DIN-Deutsches Institut für Normung e.V. EN ISO 14040: Umweltmanagement—Environmental Management—Life Cycle Assessment—Principles Unad Framework; Beuth Verlag: Berlin, Germany, 2019. [Google Scholar]

- IFU. Umberto—Software for Life Cycle Assessment; IFU: Hamburg, Germany, 2016. [Google Scholar]

- Ecoinvent. Database Ecoinvent Data v3.1—Life Cycle Inventory (LCI) Data; Ecoinvent Centre: St. Gallen, Switzerland, 2014. [Google Scholar]

- European Commission. ILCD-Handbook: General Guide for Life Cycle Assessment—Detailed Guidance; Institute for Environment and Sustainability, Joint Research Centre: Brussels, Belgium, 2010. [Google Scholar]

- European Commission. Commission Recommendation on the use of common methods to measure and communicate the life cycle environmental performance of the products and organizations. Annex II: Product Environmental Footprint (PEF). In Official Journal of the European Union; Publications Office of the European Union: Luxembourg, 2013; Volume 56. [Google Scholar]

- IPCC—Intergovernmental Panel on Climate Change. Climate Change 2013: The Physical Science Basis; Stocker, T.F., Qin, D., Plattner, G.K., Tignor, M., Allen, S.K., Boschung, J., Nauels, A., Xia, Y., Bex, V., Midgley, P.M., Eds.; IPCC: Geneva, Switzerland, 2013. [Google Scholar]

- CML—Department of Industrial Ecology. Database CML-IA; Leiden University, Institute of Environmental Sciences: Leiden, The Netherlands, 2015. [Google Scholar]

- Koellner, T.; Scholz, R.W. Assessment of land use impacts on the natural environment—Part 2: Generic characterization factors for local species diversity in central Europe. Int. J. Life Cycle Assess. 2008, 13, 32–48. [Google Scholar]

- Koellner, T.; Scholz, R.W. Assessment of land use impacts on the natural environment—Part 1: An analytical framework for pure land occupation and land use change. Int. J. Life Cycle Assess. 2007, 12, 16–23. [Google Scholar]

| Impact Category | Unit |

|---|---|

| Global warming potential (GWP) | kg CO2 equivalents |

| Acidification potential (AP) | kg SO2 equivalents |

| Eutrophication potential | kg PO4 equivalents |

| photochemical ozone creation potential (POCP) | kg ethylene equivalents |

| abiotic depletion potential (ADPelem.) | kg Sb equivalents |

| land use transformation | points |

| Land use, total | points |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weimann, K.; Adam, C.; Buchert, M.; Sutter, J. Environmental Evaluation of Gypsum Plasterboard Recycling. Minerals 2021, 11, 101. https://doi.org/10.3390/min11020101

Weimann K, Adam C, Buchert M, Sutter J. Environmental Evaluation of Gypsum Plasterboard Recycling. Minerals. 2021; 11(2):101. https://doi.org/10.3390/min11020101

Chicago/Turabian StyleWeimann, Karin, Christian Adam, Matthias Buchert, and Juergen Sutter. 2021. "Environmental Evaluation of Gypsum Plasterboard Recycling" Minerals 11, no. 2: 101. https://doi.org/10.3390/min11020101

APA StyleWeimann, K., Adam, C., Buchert, M., & Sutter, J. (2021). Environmental Evaluation of Gypsum Plasterboard Recycling. Minerals, 11(2), 101. https://doi.org/10.3390/min11020101