Alkali-Hydrothermal Treatment of K-Rich Igneous Rocks for Their Direct Use as Potassic Fertilizers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Geological Description

2.1.1. High Atlas Tamazeght Alkaline Massif

2.1.2. Anti-Atlas Jbel Boho, El Glo’a, and Ait Saoun Complexes

2.2. Methods

2.2.1. Petrographic and Mineralogical Characterizations

2.2.2. Physical and Chemical Characterization

2.2.3. Alkali-Hydrothermal Treatment and Leaching Tests

3. Results

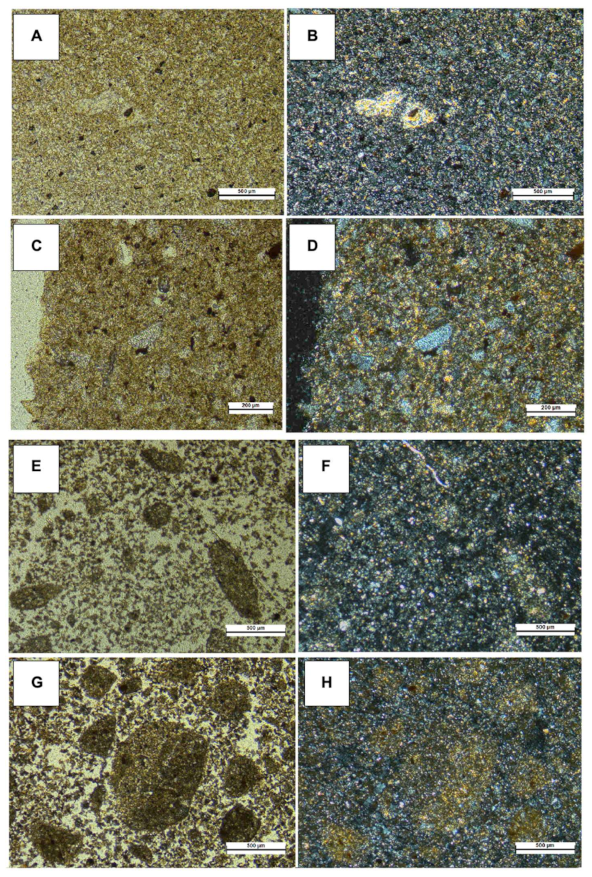

3.1. Petrographic Description

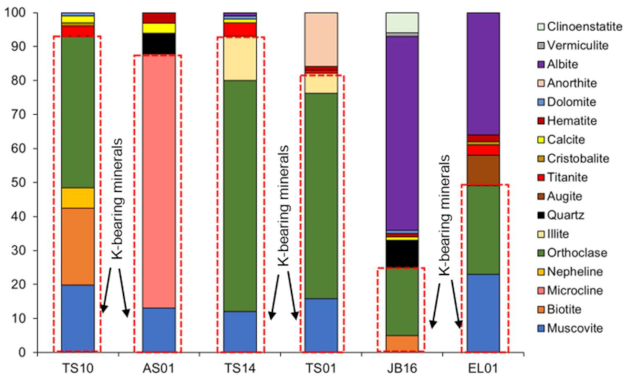

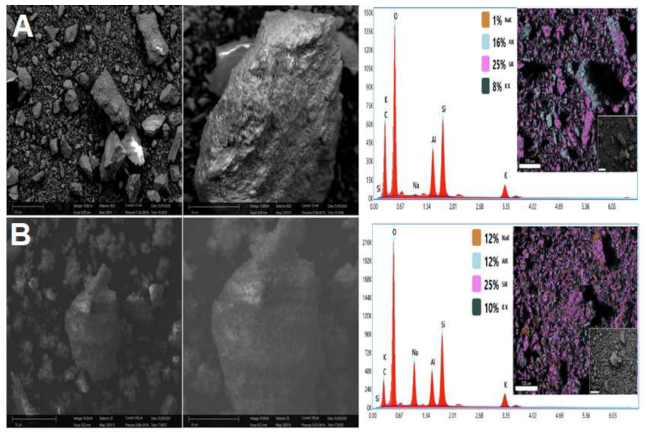

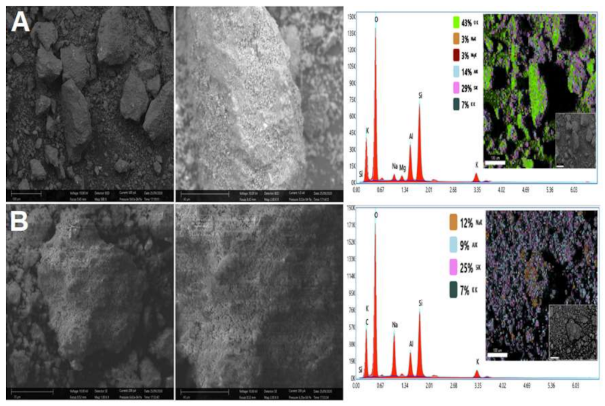

3.2. Mineralogical and Structural Characteristics

3.3. Physical and Chemical Characteristics

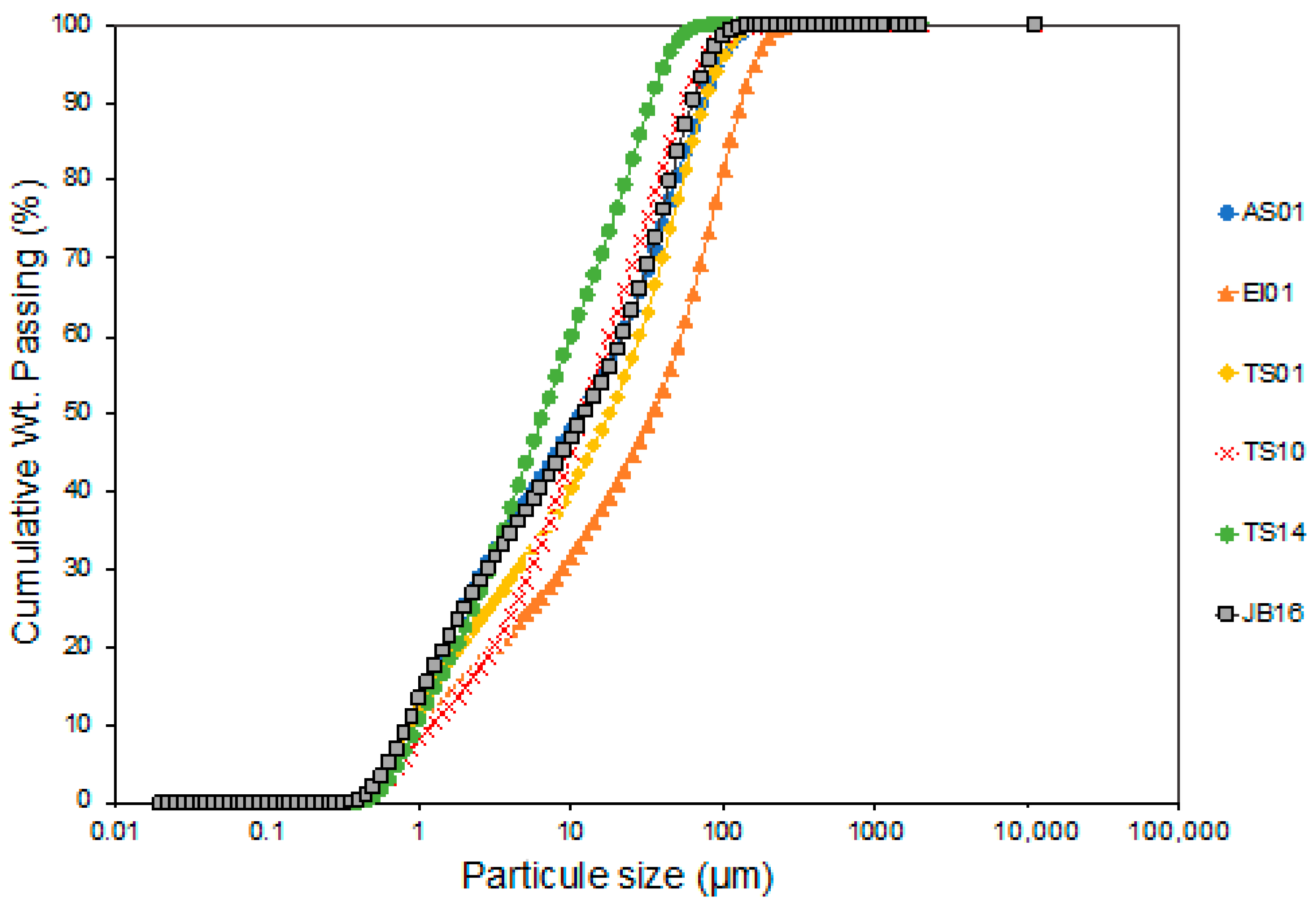

3.3.1. Physical Characteristics

3.3.2. Chemical Characteristics

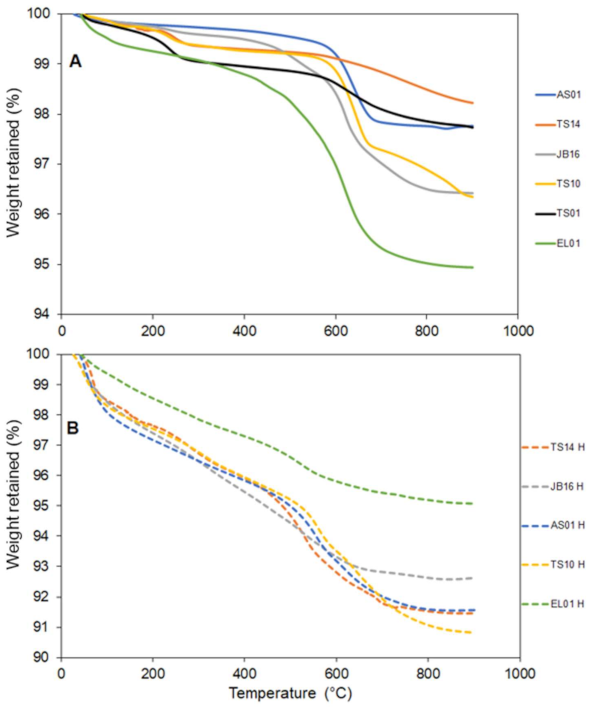

3.4. Thermogravimetry Analysis (TGA)

3.5. Fourier-Transform Infrared (FTIR)

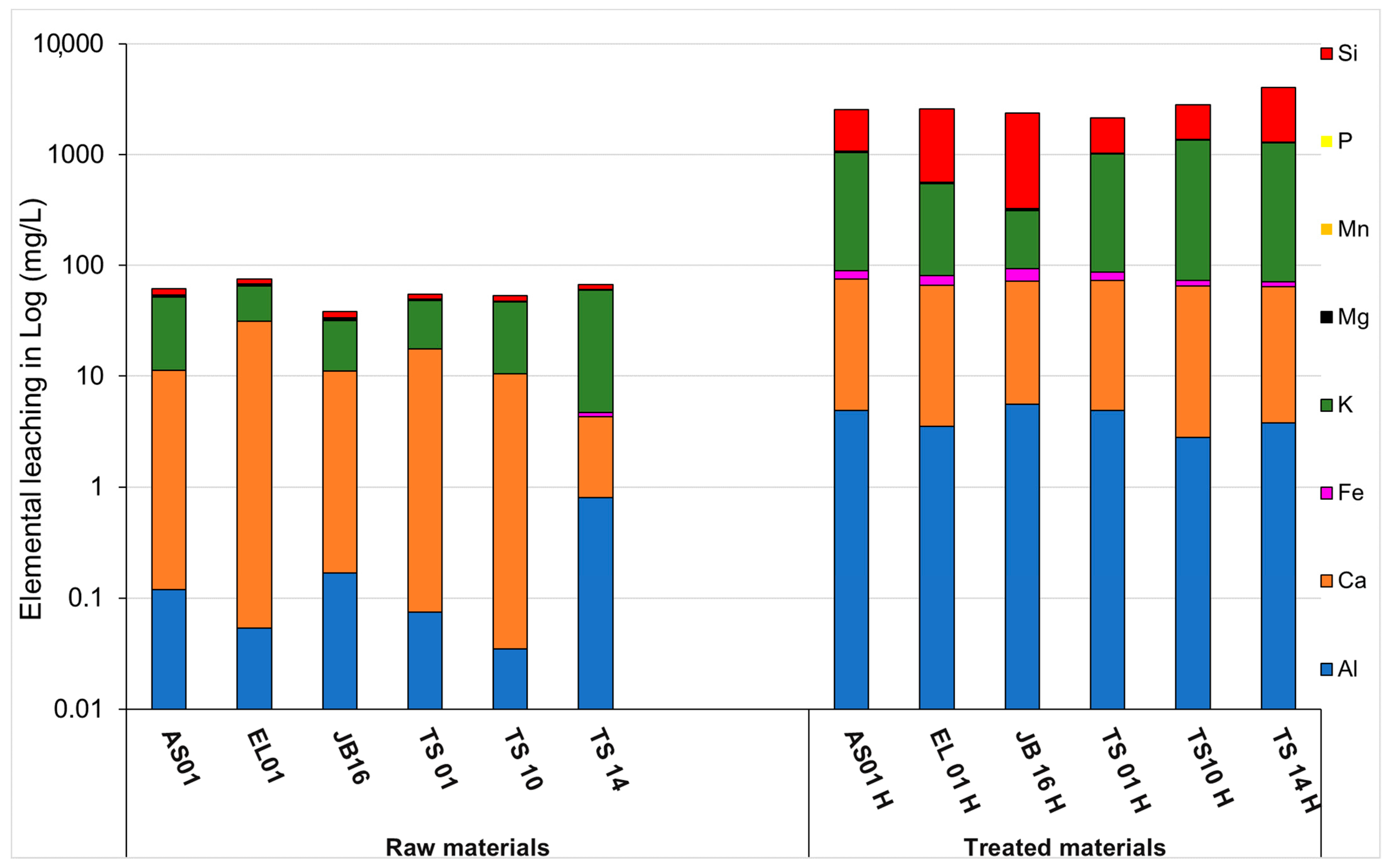

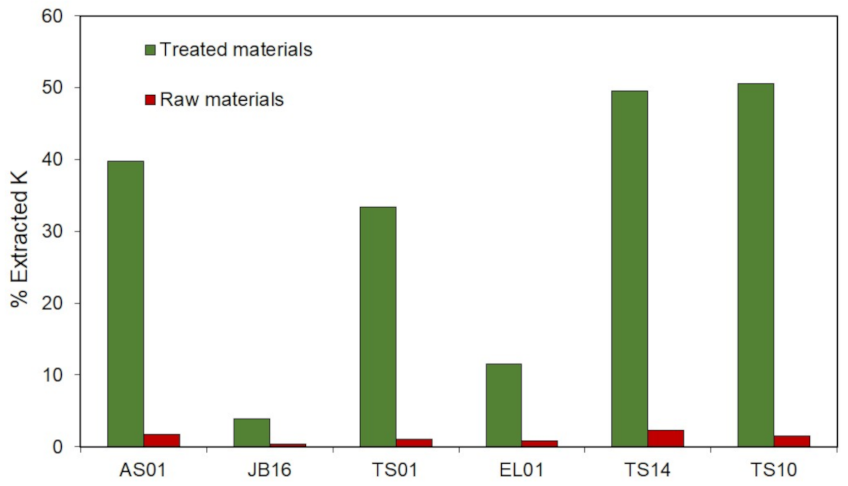

3.6. Leaching Tests

4. Discussion

5. Conclusions

- 1.

- These results confirm again the importance of petrography and alterability for predicting the leaching behavior of K-bearing rock;

- 2.

- K-rich rock needs to be hydrothermally treated before any application as fertilizer because hydrothermal treatment significantly enhances the release of potassium and other beneficial elements through the substitution ion mechanism;

- 3.

- Temperature, the initial potassium content of the rock, alterability, and particle size are found to be important factors controlling the K release; and

- 4.

- The approach used in this study provides a significant amount of sodium through the neoformed Na mineral, so it would be interesting to explore additives other than NaOH for further application in the fertilizer industry.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manning, D.A. How will minerals feed the world in 2050? Proc. Geol. Assoc. 2015, 126, 14–17. [Google Scholar] [CrossRef]

- Ciceri, D.; Allanore, A. Local fertilizers to achieve food self-sufficiency in Africa. Sci. Total. Environ. 2019, 648, 669–680. [Google Scholar] [CrossRef]

- Nail, K.P. Soil fertility and nutrient management. In Intelligent Soil Management for Sustainable Agriculture: The Nutrient Buffer Power Concept; Springer International Publishing: Cham, Switzerland, 2019; pp. 165–189. [Google Scholar]

- Sheldrick, W.F.; Lingard, J. The use of nutrient audits to determine nutrient balances in Africa. Food Policy 2004, 29, 61–98. [Google Scholar] [CrossRef]

- Cakmak, I. The role of potassium in alleviating detrimental effects of abiotic stresses in plants. J. Plant Nutr. Soil Sci. 2005, 168, 521–530. [Google Scholar] [CrossRef]

- Rawat, J.; Sanwal, P.; Saxena, J. Potassium and Its Role in Sustainable Agriculture. In Potassium Solubilizing Microorganisms for Sustainable Agriculture; Meena, V.S., Maurya, B.R., Verma, J.P., Meena, R.S., Eds.; Springer Science and Business Media LLC: New Delhi, India, 2016; pp. 235–253. Available online: http://link.springer.com/10.1007/978-81-322-2776-2_17 (accessed on 3 July 2020).

- Sanchez Pedro, A. Soil Fertility and Hunger in Africa. Science 2002, 295, 1–2. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Van Straaten, P. Farming with rocks and minerals: Challenges and opportunities. Acad. Bras. Ciênc. 2006, 78, 731–747. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tanvar, H.; Dhawan, N. Kinetic and thermodynamic study of potassium recovery from silicate rocks. Min. Process. Extr. Met. 2019, 1–13. [Google Scholar] [CrossRef]

- Hensel, J. Bread from Stones; AJ Tafel: Philadelphia, PA, USA, 1894; 148p. [Google Scholar]

- Jena, S.; Dhawan, N.; Rao, D.; Misra, P.; Mishra, B.; Das, D. Studies on extraction of potassium values from nepheline syenite. Int. J. Min. Process. 2014, 133, 13–22. [Google Scholar] [CrossRef]

- Jena, S.K.; Misra, P.K.; Das, B. Studies on Extraction of Potassium from Feldspar by Roast-leach Method Using Phosphogypsum and Sodium Chloride. Min. Process. Extr. Met. Rev. 2016, 37, 323–332. [Google Scholar] [CrossRef]

- Jena, S.K.; Dash, N.; Samal, A.K.; Misra, P.K. Competency of chlorination roasting coupled water leaching process for potash recovery from K-feldspar: Mechanism and kinetics aspects. Korean J. Chem. Eng. 2019, 36, 2060–2073. [Google Scholar] [CrossRef]

- Kumanan, M.; Sathya, G.; Nandakumar, V.; Berchmans, L.J. Extraction of potah from K-Feldspar mineral by acid and molten salt leaching process. Chem. Eng. 2016, 7, 1–10. [Google Scholar]

- Kumar, G.; Tanvar, H.; Pratap, Y.; Dhawan, N. Thermal and Mechanical Activation of Sericite for Recovery of Potash Values. Trans. Indian Inst. Met. 2018, 72, 17–25. [Google Scholar] [CrossRef]

- Samantray, J.; Anand, A.; Dash, B.; Ghosh, M.K.; Behera, A.K. Nepheline Syenite—An Alternative Source for Potassium and Aluminium. In Rare Metal Technology; Azimi, G., Kim, H., Alam, S., Ouchi, T., Neelameggham, N.R., Baba, A.A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 145–159. Available online: http://link.springer.com/10.1007/978-3-030-05740-4_15 (accessed on 28 January 2020).

- Schimicoscki, R.; Oliveira, K.; Ávila-Neto, C.N. Potassium recovery from a Brazilian glauconitic siltstone via reaction with sulfuric acid in hydrothermal conditions. Hydrometallurgy 2020, 191, 105251. [Google Scholar] [CrossRef]

- Ciceri, D.; de Oliveira, M.; Stokes, R.M.; Skorina, T.; Allanore, A. Characterization of potassium agrominerals: Correlations be-tween petrographic features, comminution and leaching of ultrapotassic syenites. Miner Eng. 2017, 102, 42–57. [Google Scholar] [CrossRef]

- Chao, J.X.; Xia, J.P.; Yang, C.Q.; Zhang, Z.S.; Ren, X.J. Research on the Thermal Decomposition Process of K-Feldspar-CaSO4-CaO System. Adv. Mater. Res. 2013, 734–737, 916–920. [Google Scholar] [CrossRef]

- Jena, S.K.; Dash, N.; Rath, S.S. Effective utilization of lime mud for the recovery of potash from mica scraps. J. Clean. Prod. 2019, 231, 64–76. [Google Scholar] [CrossRef]

- Orosco, P.; Barrios, O.; Ojeda, M. Extraction of Potassium from Microcline by Chlorination. Minerals 2019, 9, 295. [Google Scholar] [CrossRef] [Green Version]

- Rajagopala, J.; Nayak, R.; Suryanarayana, R.A. Feldspar for potassium, fertilizers, catalysts and cement—Review. Asian J. Chem. 1998, 10, 690–706. [Google Scholar]

- Hongwen, M.A.; Jing, Y.A.N.G.; Shuangqing, S.U.; Meitang, L.I.U.; Hong, Z.H.E.N.G.; Yingbin, W.A.N.G.; Hongbin, Q.I.; Pan, Z.H.A.N.G.; Wengui, Y.A.O. 20 Years advances in preparation of potassium salts from potassic rock: A review. Geol. Soc. China 2015, 89, 2058–2071. [Google Scholar] [CrossRef]

- Zhong, Y.; Gao, J.; Chen, P.; Guo, Z. Recovery of Potassium from K-Feldspar by Thermal Decomposition with Flue Gas Desul-furization Gypsum and CaCO3: Analysis of Mechanism and Kinetics. Energy Fuels 2017, 31, 699–707. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Q.; Yao, Y.; Jia, Y.; Xie, B. The extraction of potassium from K-feldspar ore by low temperature molten salt method. Chin. J. Chem. Eng. 2018, 26, 845–851. [Google Scholar] [CrossRef]

- Haseli, P.; Majewski, P.; Christo, F.C.; Hammond, B.; Bruno, F. Thermochemical and Experimental Kinetic Analysis of Potassium Extraction from Ultrapotassic Syenite Using Molten Chloride Salts. Ind. Eng. Chem. Res. 2019, 58, 7397–7407. [Google Scholar] [CrossRef]

- Elghali, A.; Benzaazoua, M.; Bussière, B.; Bouzahzah, H. Determination of the available acid-generating potential of waste rock, part II: Waste management involvement. Appl. Geochem. 2019, 100, 316–325. [Google Scholar] [CrossRef]

- Kleiv, R.; Thornhill, M. Production of mechanically activated rock flour fertilizer by high intensive ultrafine grinding. Min. Eng. 2007, 20, 334–341. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Asselin, E.; Li, Z. Laboratory and Pilot Scale Studies of Potassium Extraction from K-feldspar Decomposition with CaCl2 and CaCO3. J. Chem. Eng. Jpn. 2016, 49, 111–119. [Google Scholar] [CrossRef]

- Singh, Y.P.; Tanvar, H.; Kumar, G.; Dhawan, N. Investigation of planetary ball milling of sericite for potash recovery. Powder Technol. 2019, 351, 115–121. [Google Scholar] [CrossRef]

- Wahyudi, A.; Wahyudi, T. A Literature Study of benefiting k-bearing silicate rocks as raw materials for potas-sium fertilizer. Indones. Min. J. 2013, 16, 10. [Google Scholar]

- Liu, J.-N.; Zhai, Y.-C.; Wu, Y.; Zhang, J.; Shen, X.-Y. Kinetics of roasting potash feldspar in presence of sodium carbonate. J. Cent. South Univ. 2017, 24, 1544–1550. [Google Scholar] [CrossRef]

- Miao, S.; Liu, Z.; Ma, H.; Han, B.; Du, J.; Sun, Z.; Miao, Z. Synthesis and characterization of mesoporous aluminosilicate molecular sieve from K-feldspar. Microporous Mesoporous Mater. 2005, 83, 277–282. [Google Scholar] [CrossRef]

- Santos, W.O.; Mattiello, E.M.; Da Costa, L.M.; Abrahão, W.A.P. Characterization of verdete rock as a potential source of potassium. Rev. Ceres 2015, 62, 392–400. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Ma, H.; Gao, Y. Hydrothermal processing on potassic syenite powder: Zeolite synthesis and potassium release kinetics. Adv. Powder Technol. 2019, 30, 2483–2491. [Google Scholar] [CrossRef]

- Liu, Y.Q.; Xia, H.T.; Ma, H.W. Kinetics of Hydrothermal Decomposition of Potassium Feldspar with Calcium Hydroxide. Adv. Mater. Res. 2012, 549, 65–69. [Google Scholar] [CrossRef]

- Su, S.; Ma, H.; Chuan, X. Hydrothermal decomposition of K-feldspar in KOH–NaOH–H2O medium. Hydrometallurgy 2015, 156, 47–52. [Google Scholar] [CrossRef]

- Ciceri, D.; Allanore, A. Nutrient release from K-feldspar ore altered in hydrothermal conditions. Chem. Pap. 2019, 74, 431–440. [Google Scholar] [CrossRef]

- Ciceri, D.; De Oliveira, M.; Chen, D.P.; Allanore, A. Role of Processing Temperature and Time on the Hydrothermal Alteration of K-Feldspar Rock in Autoclave. Min. Met. Explor. 2020, 37, 955–963. [Google Scholar] [CrossRef]

- Marks, M.A.W.; Schilling, J.; Coulson, I.M.; Wenzel, T.; Markl, G. The Alkaline-Peralkaline Tamazeght Complex, High Atlas Mountains, Morocco: Mineral Chemistry and Petrological Constraints for Derivation from a Compositionally Heteroge-neous Mantle Source. J. Pet. 2008, 49, 1097–1131. [Google Scholar] [CrossRef] [Green Version]

- Bouabdellah, M.; Hoernle, K.; Kchit, A.; Duggen, S.; Hauff, F.; Klügel, A.; Lowry, D.; Beaudoin, G. Petrogenesis of the Eocene Tamazert Continental Carbonatites (Central High Atlas, Morocco): Implications for a Common Source for the Tamazert and Canary and Cape Verde Island Carbonatites. J. Pet. 2010, 51, 1655–1686. [Google Scholar] [CrossRef]

- Marks, M.A.W.; Neukirchen, F.; Vennemann, T.; Markl, G. Textural, chemical, and isotopic effects of late-magmatic carbonatitic fluids in the carbonatite–syenite Tamazeght complex, High Atlas Mountains, Morocco. Min. Pet. 2009, 97, 23–42. [Google Scholar] [CrossRef]

- Álvaro, J.J.; Ezzouhairi, H.; Vennin, E.; Ribeiro, M.; Clausen, S.; Charif, A.; Ayad, N.A.; Moreira, M. The Early-Cambrian Boho volcano of the El Graara massif, Morocco: Petrology, geodynamic setting and coeval sedimentation. J. Afr. Earth Sci. 2006, 44, 396–410. [Google Scholar] [CrossRef]

- Blein, O.; Baudin, T.; Chevremont, P.; Soulaimani, A.; Admou, H.; Gasquet, D.; Cocherie, A.; Egal, E.; Youbi, N.; Razin, P.; et al. Geochronological constraints on the polycyclic magmatism in the Bou Azzer-El Graara inlier (Central Anti-Atlas Morocco). J. Afr. Earth Sci. 2014, 99, 287–306. [Google Scholar] [CrossRef]

- Benaouda, R.; Holzheid, A.; Schenk, V.; Badra, L.; Ennaciri, A. Magmatic evolution of the Jbel Boho alkaline complex in the Bou Azzer inlier (Anti-Atlas/Morocco) and its relation to REE mineralization. J. Afr. Earth Sci. 2017, 129, 202–223. [Google Scholar] [CrossRef]

- Ducrot, J.; Lancelot, J.R. Problème de la limite Précambrien–Cambrien: Étude radiochronologique par la méthode U–Pb sur zircons du volcan du Jbel Boho (Anti-Atlas marocain). Can. J. Earth Sci. 1977, 14, 2771–2777. [Google Scholar] [CrossRef]

- Soulaimani, A.; Egal, E.; Razin, P.; Youbi, N.; Admou, H.; Blein, O.; Barbanson, L.; Gasquet, D.; Bouabdelli, M. Notice explicative carte géol. Maroc (1/50,000), feuille Al Glo"a. In Notes et Mémoires Serv. Géol. Maroc, N°532 bis; Soulaimani, A., Admou, H., Fekkak, A., Egal, E., Roger, J., Youbi, N., Razin, P., Blein, O., Baudin, T., Eds.; Anzar Conseil: Rabat, Maroc, 2013. [Google Scholar]

- Ait, A.; Ribeiro, M.L.; Charif, A.; Moreira, M.E.; Ezzouhairi, H.; Coke, C. Les volcanites d’Agdz (Ait Saoun, Anti-Atlas Central) et du Haut-Atlas occidental (Azegour et Adassil) marqueurs de l’extension crustale au passage precambrien termi-nal/cambrien au Maroc. Agadir 2005. Available online: https://www.researchgate.net/profile/Carlos_Coke/publication/266737089_Les_volcanites_dAgdz_Ait_Saoun_Anti_Atlas_Central_et_du_Haut_Atlas_Occidental_Azegour_et_Adassil_marqueurs_de_l’extension_crustale_au_passage_Precambrien_terminalCambrien_au_Maroc/links/5439d0300cf24a6ddb95dd19/Les-volcanites-dAgdz-Ait-Saoun-Anti-Atlas-Central-et-du-Haut-Atlas-Occidental-Azegour-et-Adassil-marqueurs-de-lextension-crustale-au-passage-Precambrien-terminal-Cambrien-au-Maroc.pdf (accessed on 18 August 2020).

- Boubker, C. Metallogenie Du Cuivre Associe Aux Roches Volcaniques D’age Precambrien Iii Superieur Dans L’anti-Atlas Marocain. 1996. Available online: https://www.unil.ch/files/live/sites/iste/files/shared/X.Library/PhD%20theses/Chebbaa%20Boubker%20(1996).pdf (accessed on 18 August 2020).

- Letsch, D.; Large, S.J.; Bernasconi, S.M.; Bernasconi, S.M.; Blattmann, T.M.; Klug, C.; Von Quadt, A. Northwest Africa’s Ediacaran to early Cambrian fossil record, its oldest metazoans and age constraints for the basal Taroudant Group (Morocco). Precambrian Res. 2019, 320, 438–453. [Google Scholar] [CrossRef]

- Ezzouhairi, H.; Ribeiro, M.L.; Ayad, N.A.; Moreira, M.E.; Charif, A.; Ramos, J.M.F.; De Oliveira, D.P.S.; Coke, C. The magmatic evolution at the Moroccan outboard of the West African craton between the Late Neoproterozoic and the Early Palaeozoic. Geol. Soc. Lond. Spéc. Publ. 2008, 297, 329–343. [Google Scholar] [CrossRef]

- Gasquet, D.; Levresse, G.; Cheilletz, A.; Azizi-Samir, M.R.; Mouttaqi, A. Contribution to a geodynamic reconstruction of the An-ti-Atlas (Morocco) during Pan-African times with the emphasis on inversion tectonics and metallogenic activity at the Pre-cambrian–Cambrian transition. Precambrian Res. 2005, 140, 157–182. [Google Scholar] [CrossRef]

- Nowak, S.; Lafon, S.; Caquineau, S.; Journet, E.; Laurent, B. Quantitative study of the mineralogical composition of mineral dust aerosols by X-ray diffraction. Talanta 2018, 186, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Vollprecht, D.; Berger, M.; Altenburger-Junker, I.; Neuhold, S.; Sedlazeck, K.P.; Aldrian, A.; Dijkstra, J.J.; van Zomeren, A.; Raith, J.G. Mineralogy and Leachability of Natural Rocks–A Comparison to Electric Arc Furnace Slags. Minerals 2019, 9, 501. [Google Scholar] [CrossRef] [Green Version]

- Lechler, P.; Desilets, M. A review of the use of loss on ignition as a measurement of total volatiles in whole-rock analysis. Chem. Geol. 1987, 63, 341–344. [Google Scholar] [CrossRef]

- Price, J.R.; Velbel, M.A. Chemical weathering indices applied to weathering profiles developed on heterogeneous felsic met-amorphic parent rocks. Chem. Geol. 2003, 202, 397–416. [Google Scholar] [CrossRef]

- Priyono, J.; Gilkes, R.J. High-Energy Milling Improves the Effectiveness of Silicate Rock Fertilizers: A Glasshouse Assessment. Commun. Soil Sci. Plant Anal. 2008, 39, 358–369. [Google Scholar] [CrossRef]

- Blanco, C.; González, F.; Pesquera, C.; Benito, I.; Mendioroz, S.; Pajares, J.A. Differences Between One Aluminic Palygorskite and Another Magnesic by Infrared Spectroscopy. Spectrosc. Lett. 1989, 22, 659–673. [Google Scholar] [CrossRef]

- Kanepit, V.N.; Rieder, E.É. Neutron diffraction study of cancrinite. J. Struct. Chem. 1995, 36, 694–696. [Google Scholar] [CrossRef]

- Brittaposnatzki, M.F.; Buhl, J.-C. Characterization of basic cancrinite synthesized in a butanediol-water system. Eur. J. Min. 2003, 15, 589–598. [Google Scholar] [CrossRef]

- Nath, S.; Maitra, S.; Mukherjee, S.; Kumar, S. Microstructural and morphological evolution of fly ash based geopolymers. Constr. Build. Mater. 2016, 111, 758–765. [Google Scholar] [CrossRef]

- Wernert, V.; Schaef, O.; Aloui, L.; Chassigneux, C.; Ayari, F.; Chehimi, D.B.H.; Denoyel, R. Cancrinite synthesis from natural kao-linite by high pressure hydrothermal method: Application to the removal of Cd2+ and Pb2+ from water. Microporous Mesoporous Mater. 2020, 301, 110209. [Google Scholar] [CrossRef]

- Tchakoute, H.K.; Elimbi, A.; Kenne, B.D.; Mbey, J.A.; Njopwouo, D. Synthesis of geopolymers from volcanic ash via the alkaline fusion method: Effect of Al2O3/Na2O molar ratio of soda–volcanic ash. Ceram Int. 2013, 39, 269–276. [Google Scholar] [CrossRef]

- Marsh, A.; Heath, A.; Patureau, P.; Evernden, M.; Walker, P. Phase formation behaviour in alkali activation of clay mixtures. Appl. Clay Sci. 2019, 175, 10–21. [Google Scholar] [CrossRef]

- Kumar, S.; Kristály, F.; Mucsi, G. Geopolymerisation behaviour of size fractioned fly ash. Adv. Powder Technol. 2015, 26, 24–30. [Google Scholar] [CrossRef]

- Hackbarth, K.; Gesing, T.M.; Fechtelkord, M.; Stief, F. Synthesis and crystal structure of carbonate cancrinite Na8[AlSiO4]6COH3(H2O3)4, grown under low-temperature hydrothermal conditions. Microporous Mesoporous Mater. 1999, 30, 12. [Google Scholar] [CrossRef]

- Esaifan, M.; Hourani, M.; Khoury, H.N.; Rahier, H.; Wastiels, J.; Khoury, H.N. Synthesis of hydroxysodalite zeolite by alkali-activation of basalt powder rich in calc-plagioclase. Adv. Powder Technol. 2017, 28, 473–480. [Google Scholar] [CrossRef]

- Esaifan, M.; Warr, L.N.; Grathoff, G.; Meyer, T.; Schafmeister, M.T.; Kruth, A.; Testrich, H. Synthesis of Hydroxy-Sodalite/Cancrinite Zeo-lites from Calcite-Bearing Kaolin for the Removal of Heavy Metal Ions in Aqueous Media. Minerals 2019, 9, 484. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Ma, H.; Liu, C.; Yuan, J. Synthesis of Analcime Crystals and Simultaneous Potassium Extraction from Natrolite Syenite. Adv. Mater. Sci. Eng. 2017, 2017, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Korndörfer, G.; Lepsch, I. Chapter 7 Effect of silicon on plant growth and crop yield. In Studies in Plant Science; Elsevier: Amsterdam, The Netherlands, 2001; pp. 133–147. Available online: https://linkinghub.elsevier.com/retrieve/pii/S0928342001800112 (accessed on 23 December 2020).

- Henry, D.F. Fundamentas of Soils Science, 8th ed.; Library of congress cataloging in publication data; Michigan State University: East Lansing, MI, USA, 1991; 382p. [Google Scholar]

- Candito, M.D.; Silvestri, G.P. Calcium and Magnesium Fertilization of Processing Tomatoes; Advances in Horticultural Sciences, Vol.7; University of Florence: Florence, Italy, 1993; p. 5. [Google Scholar]

- Etesami, H. Can interaction between silicon and plant growth promoting rhizobacteria benefit in alleviating abiotic and biotic stresses in crop plants? Agric. Ecosyst. Environ. 2018, 253, 98–112. [Google Scholar] [CrossRef]

- Greger, M.; Landberg, T.; Vaculík, M. Silicon Influences Soil Availability and Accumulation of Mineral Nutrients in Various Plant Species. Plants 2018, 7, 41. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manning, D.A. Mineral sources of potassium for plant nutrition. A review. Agron. Sustain. Dev. 2010, 30, 281–294. [Google Scholar] [CrossRef] [Green Version]

- Kump, L.R.; Brantley, S.L.; Arthur, M.A. Chemical Weathering, Atmospheric CO2, and Climate. Annu. Rev. Earth Planet. Sci. 2000, 28, 611–667. [Google Scholar] [CrossRef] [Green Version]

- Marshak, S. Earth: Portrait of A Planet, 5th ed.; W.W. Norton & Company: New York, NY, USA, 2015; 1p. [Google Scholar]

- Ma, X.; Yang, J.; Ma, H.; Liu, C.; Zhang, P. Synthesis and characterization of analcime using quartz syenite powder by alka-li-hydrothermal treatment. Microporous Mesoporous Mater. 2015, 201, 134–140. [Google Scholar] [CrossRef]

- Ma, X.; Yang, J.; Ma, H.; Liu, C. Hydrothermal extraction of potassium from potassic quartz syenite and preparation of alumi-num hydroxide. Int. J. Miner. Process. 2016, 147, 10–17. [Google Scholar] [CrossRef]

- Encyclopedia of Agrophysics. In Encyclopedia of Petroleum Geoscience; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2011.

- Curtin, D.; Smillie, G.W. Effects of liming on soil chemical characteristics and grass growth in laboratory and long-term field-amended soils. Plant Soil 1986, 95, 23–31. [Google Scholar] [CrossRef]

- Zdenko, R. Role of calcium in aluminium toxicity. New Phytol. 1992, 121, 499–513. [Google Scholar]

- Shen, R.F. Aluminum–Nitrogen Interactions in the Soil–Plant System. Front Plant Sci. 2018, 9, 15. [Google Scholar]

- Sade, H.; Meriga, B.; Surapu, V.; Gadi, J.; Sunita, M.S.L.; Suravajhala, P.; Kishor, P.B.K. Toxicity and tolerance of aluminum in plants: Tailoring plants to suit to acid soils. BioMetals 2016, 29, 187–210. [Google Scholar] [CrossRef] [PubMed]

- Rout, G.R.; Samantaray, S.; Das, P. Aluminium toxicity in plants: A review. Agronomie 2001, 21, 3–21. [Google Scholar] [CrossRef]

- Famoso, A.N.; Clark, R.T.; Shaff, J.E.; Craft, E.; McCouch, S.R.; Kochian, L.V. Development of a Novel Aluminum Tolerance Pheno-typing Platform Used for Comparisons of Cereal Aluminum Tolerance and Investigations into Rice Aluminum Tolerance Mechanisms. Plant Physiol. 2010, 153, 14. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.Q.; Chen, R.F.; Shen, R.F. Coadaptation of Plants to Multiple Stresses in Acidic Soils. Soil Sci. 2014, 179, 503–513. [Google Scholar] [CrossRef]

- Boyer, J. L’aluminium échangeable: Incidences agronomiques, évaluation et correction de sa toxicité dans les sols tropicaux. Cah. ORSTOM Ser. Pédol 1976, 14, 11. [Google Scholar]

- Maathuis, F.J.M. Sodium in plants: Perception, signalling, and regulation of sodium fluxes. J. Exp. Bot. 2014, 65, 849–858. [Google Scholar] [CrossRef]

- Nikos, J.; Bauder James, W.; Pearson, K. Basics of Salinity and Sodicity Effects; Department of Land Resources and Environmental Sciences: Montanta State University-Bozeman, Bozeman, MT, USA, 2002; p. 29. [Google Scholar]

- Agassi, M.; Shainberg, I.; Morin, J. Effect of Electrolyte Concentration and Soil Sodicity on Infiltration Rate and Crust For-mation. Soil Sci. Soc. Am. J. 1981, 45, 848–851. [Google Scholar] [CrossRef]

- Shainberg, I.; Letey, J. Response of soils to sodic and saline conditions. Hilgardia 1984, 52, 1–57. [Google Scholar] [CrossRef] [Green Version]

- Leonardos, O.H.; Fyfe, W.S.; Kronberg, B.I. The use of ground rocks in laterite systems: An improvement to the use of conven-tional soluble fertilizers? Chem. Geol. 1987, 60, 361–370. [Google Scholar] [CrossRef]

- Leonardos, O.H.; Theodoro, S.H.; Assad, M.L. Remineralization for sustainable agriculture: A tropical perspective from a Brazil-ian viewpoint. Nutr. Cycl. Agroecosystems 2000, 56, 2. [Google Scholar] [CrossRef]

- Gillman, G.; Burkett, D.C.; Coventry, R.J. A laboratory study of application of basalt dust to highly weathered soils: Effect on soil cation chemistry. Soil Res. 2001, 39, 799. [Google Scholar] [CrossRef]

- Gillman, G.; Burkett, D.; Coventry, R. Amending highly weathered soils with finely ground basalt rock. Appl. Geochem. 2002, 17, 987–1001. [Google Scholar] [CrossRef]

- Bartzas, G.; Zaharaki, D.; Komnitsas, K. Life cycle assessment of open field and greenhouse cultivation of lettuce and barley. Inf. Process. Agric. 2015, 2, 191–207. [Google Scholar] [CrossRef] [Green Version]

| Sample | Texture | Alteration | Fracturing | Mineral Contents | Lithology Description | Rock Nature |

|---|---|---|---|---|---|---|

| TS10 | Coarse-grained | High | High | Or, Ne, Bt, Mic, Px, Grt, Opq, Ap, Clay, Ttn, Zrc | Highly weathered rock with centimetric Kfs and Ne minerals | Nepheline syenite |

| AS01 | Microlitic | Medium to high | Low | Kfs (Or/Mc), Qtz, Opq, Clay | Less weathered, mainly composed of centimetric Kfs. Chalcedony and quartz are also present | Trachyte |

| TS14 | Coarsed-grained, porphyritic | Medium | Medium | Or, Ne, Ab, Px, Clay, Carb, Qtz, Opq, Ap, Zrc | Highly weathered rock with centimetric Kfs minerals | Syenite |

| TS01 | Coarse | High | Low | Kfs (Or/Mc), Pl, Bt, Px, Clay, Opq, Ttn, Ap, Zrc | Kfs highly altered, biotite and apatite are present | Syenite |

| JB16 | Coarse-grained | Medium | Medium | Ab, Or, Qtz, Bt, Px, Ap, Opq | Iodomorphic centimetric and altered Kfs. Apatite and quartz are also present | Syenite |

| EL01 | Microlitic | Medium | Low to medium | Or, Opq, Px/Amph | Weathered rock | Trachyte |

| Samples | SiO2 | TiO2 | Al2O3 | Fe2O3 | MnO | MgO | CaO | Na2O | K2O | P2O5 | LOI | Total | CIW |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AS01 | 55.1 | 1.5 | 15.8 | 9.7 | 0.2 | 0.1 | 1.3 | 0.1 | 13.3 | 0.4 | 2.4 | 99.9 | 91.9 |

| EL-01 | 59,6 | 0.3 | 16.2 | 4.7 | 0.1 | 0.8 | 0.5 | 2 | 7.9 | 0.1 | 2.4 | 94.6 | 86.6 |

| JB-16 | 60.7 | 0.5 | 16.7 | 6 | 0.1 | 0.9 | 1.2 | 4.9 | 5.7 | 0.2 | 2.6 | 99.5 | 73.2 |

| TS10 | 53.1 | 0.5 | 24.3 | 3.3 | 0.1 | 0.1 | 0.9 | 0.1 | 12.7 | 0.1 | 3.8 | 99 | 96.4 |

| TS14 | 53.9 | 0.7 | 23.2 | 3.8 | 0.2 | 0.1 | 0.8 | 0.3 | 13.2 | 0.1 | 1.7 | 98 | 95.5 |

| TS01 | 57.9 | 1.4 | 17.2 | 5.1 | 0.2 | 0.4 | 1 | 0.2 | 11.5 | 0.2 | 2.9 | 98 | 93.5 |

| Samples | TS01 | TS10 | TS14 | EL01 | JB16 | AS01 |

|---|---|---|---|---|---|---|

| pH (raw material) | 8.6 | 8.9 | 9.2 | 8.5 | 8.8 | 8.9 |

| pH (treated material) | 12.4 | 12.3 | 12.2 | 12.1 | 12.3 | 12.6 |

| Electricla conductivity (µS·cm−1) (raw samples) | 249.8 | 196.2 | 249.2 | 377.4 | 297.1 | 243.3 |

| Electrical conductivity (µS·cm−1) (treated samples) | 20947.4 | 23281.8 | 19790.5 | 17631.3 | 18368.7 | 19524.3 |

| Variables | Ke | Raw Materials | CIW | Ki |

| Cu | ||||

| Ke | 1 | - | - | - |

| Cu | −0.64 | 1 | - | - |

| CIW | 0.81 | −0.37 | 1 | - |

| Ki | 0.90 | −0.57 | 0.92 | 1 |

| Variables | Ke | Treated Materials | CIW | Ki |

| Cu | ||||

| Ke | 1 | - | - | - |

| Cu | −0.72 | 1 | - | - |

| CIW | 0.91 | −0.37 | 1 | - |

| Ki | 0.96 | −0.57 | 0.92 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbissik, A.; Elghali, A.; Ouabid, M.; Raji, O.; Bodinier, J.-L.; El Messbahi, H. Alkali-Hydrothermal Treatment of K-Rich Igneous Rocks for Their Direct Use as Potassic Fertilizers. Minerals 2021, 11, 140. https://doi.org/10.3390/min11020140

Mbissik A, Elghali A, Ouabid M, Raji O, Bodinier J-L, El Messbahi H. Alkali-Hydrothermal Treatment of K-Rich Igneous Rocks for Their Direct Use as Potassic Fertilizers. Minerals. 2021; 11(2):140. https://doi.org/10.3390/min11020140

Chicago/Turabian StyleMbissik, Aaron, Abdellatif Elghali, Muhammad Ouabid, Otmane Raji, Jean-Louis Bodinier, and Hicham El Messbahi. 2021. "Alkali-Hydrothermal Treatment of K-Rich Igneous Rocks for Their Direct Use as Potassic Fertilizers" Minerals 11, no. 2: 140. https://doi.org/10.3390/min11020140

APA StyleMbissik, A., Elghali, A., Ouabid, M., Raji, O., Bodinier, J.-L., & El Messbahi, H. (2021). Alkali-Hydrothermal Treatment of K-Rich Igneous Rocks for Their Direct Use as Potassic Fertilizers. Minerals, 11(2), 140. https://doi.org/10.3390/min11020140