Characterization of Coloured Gemstones by X-ray Micro Computed Tomography

Abstract

:1. Introduction

1.1. Background

1.2. The Market and Characterization

1.3. X-ray Micro Computed Tomography (μCT)

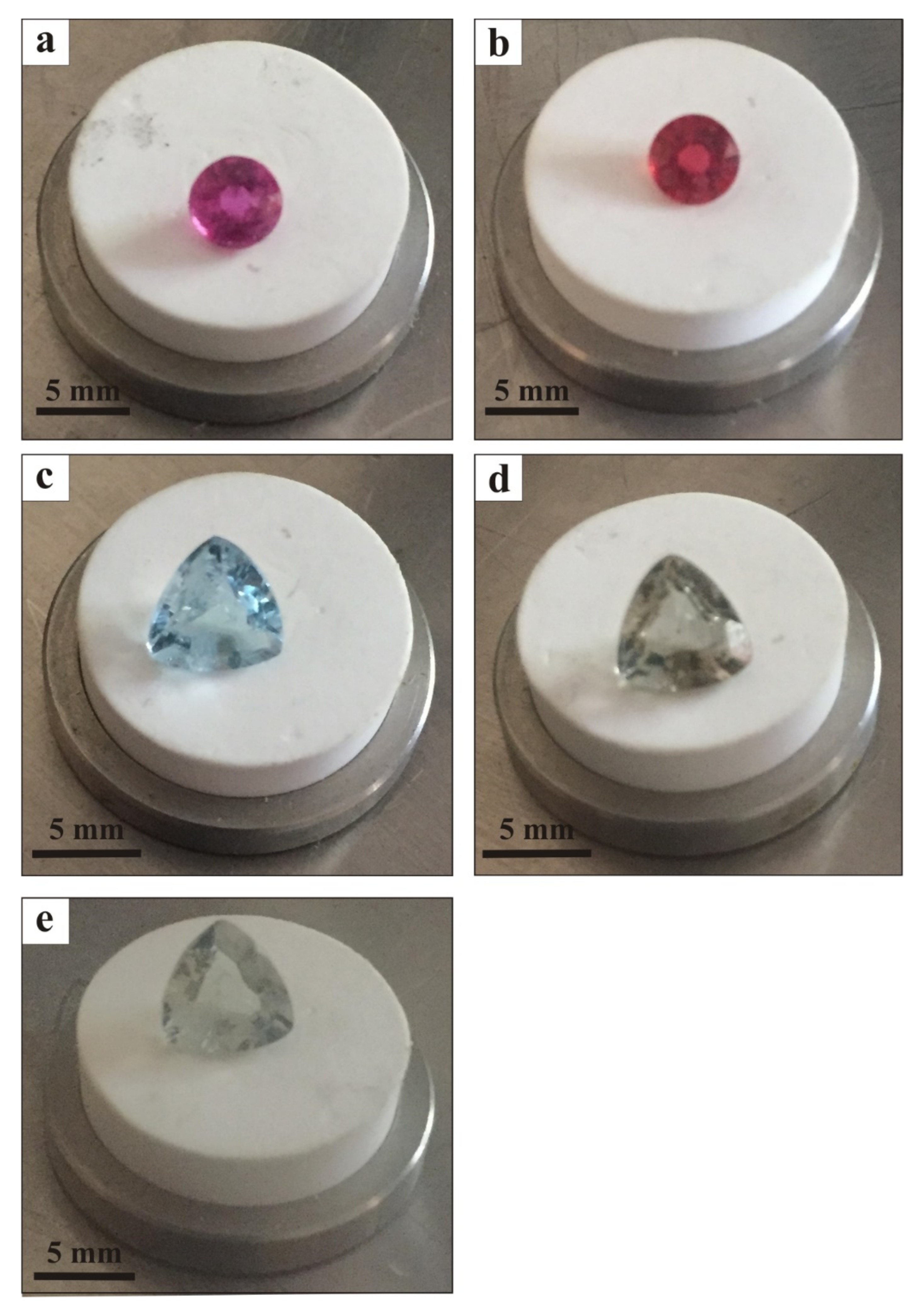

2. Materials and Methods

2.1. Fracture Filling

2.2. Fingerprint

2.3. Colour Change

3. Results

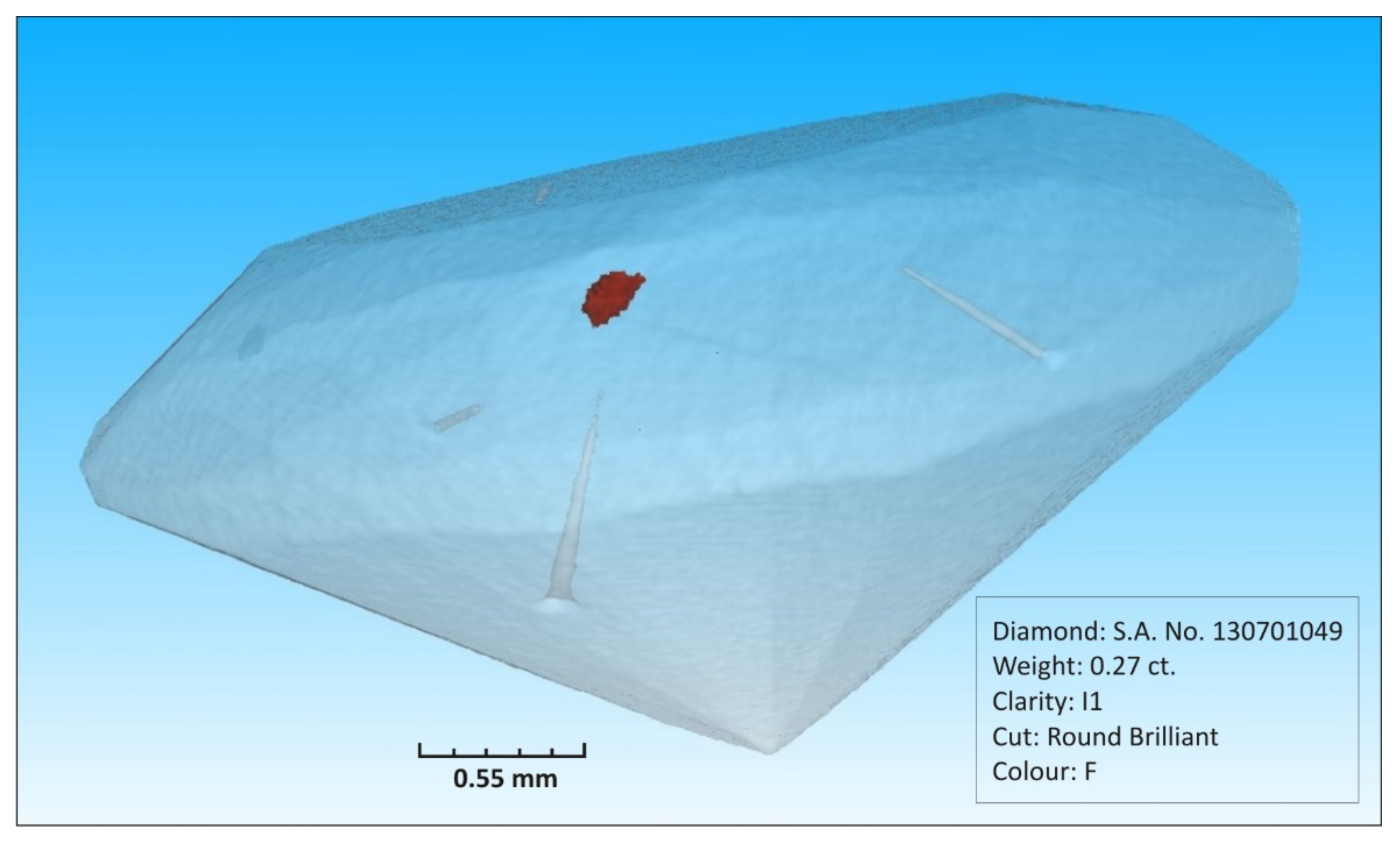

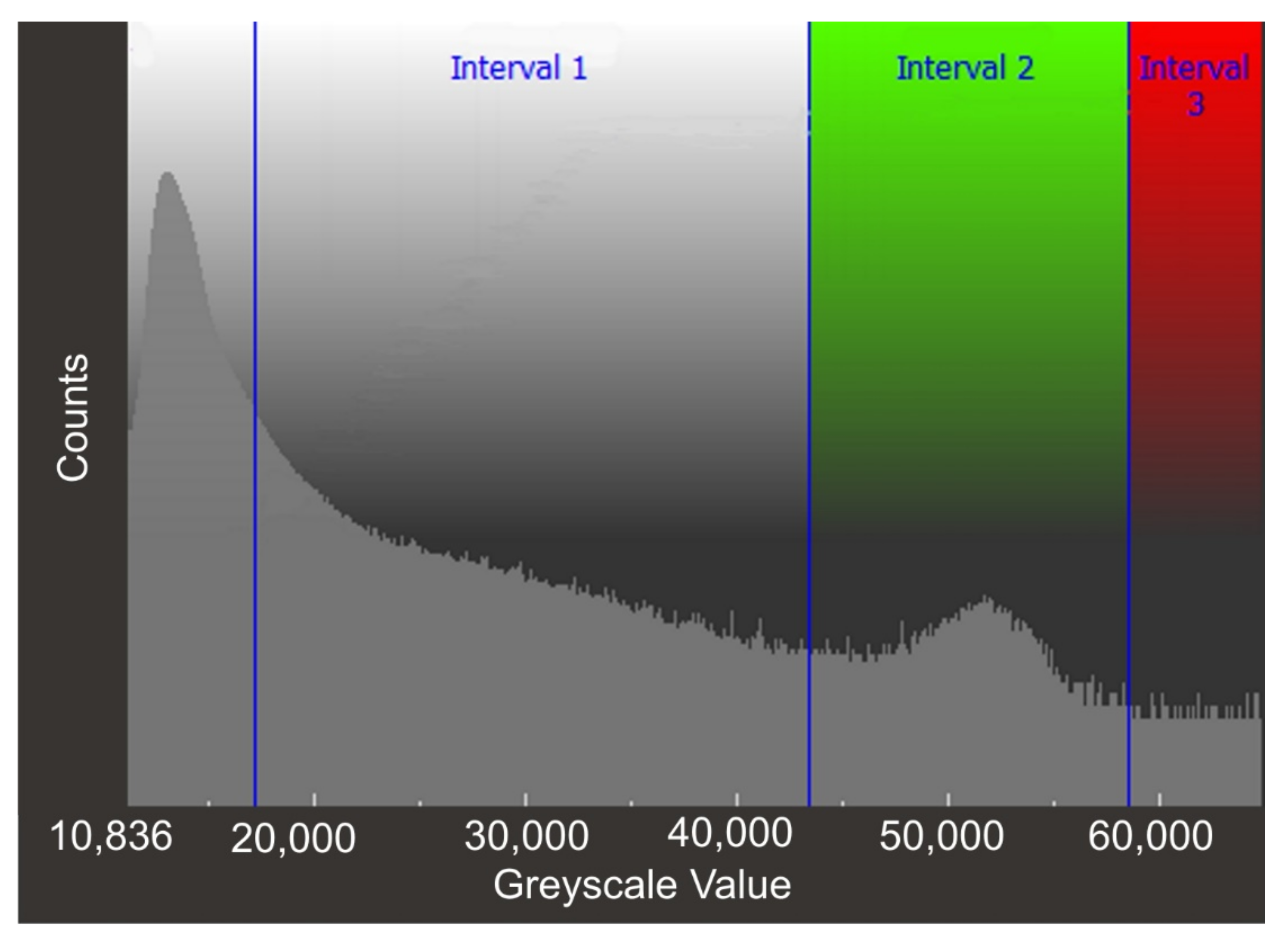

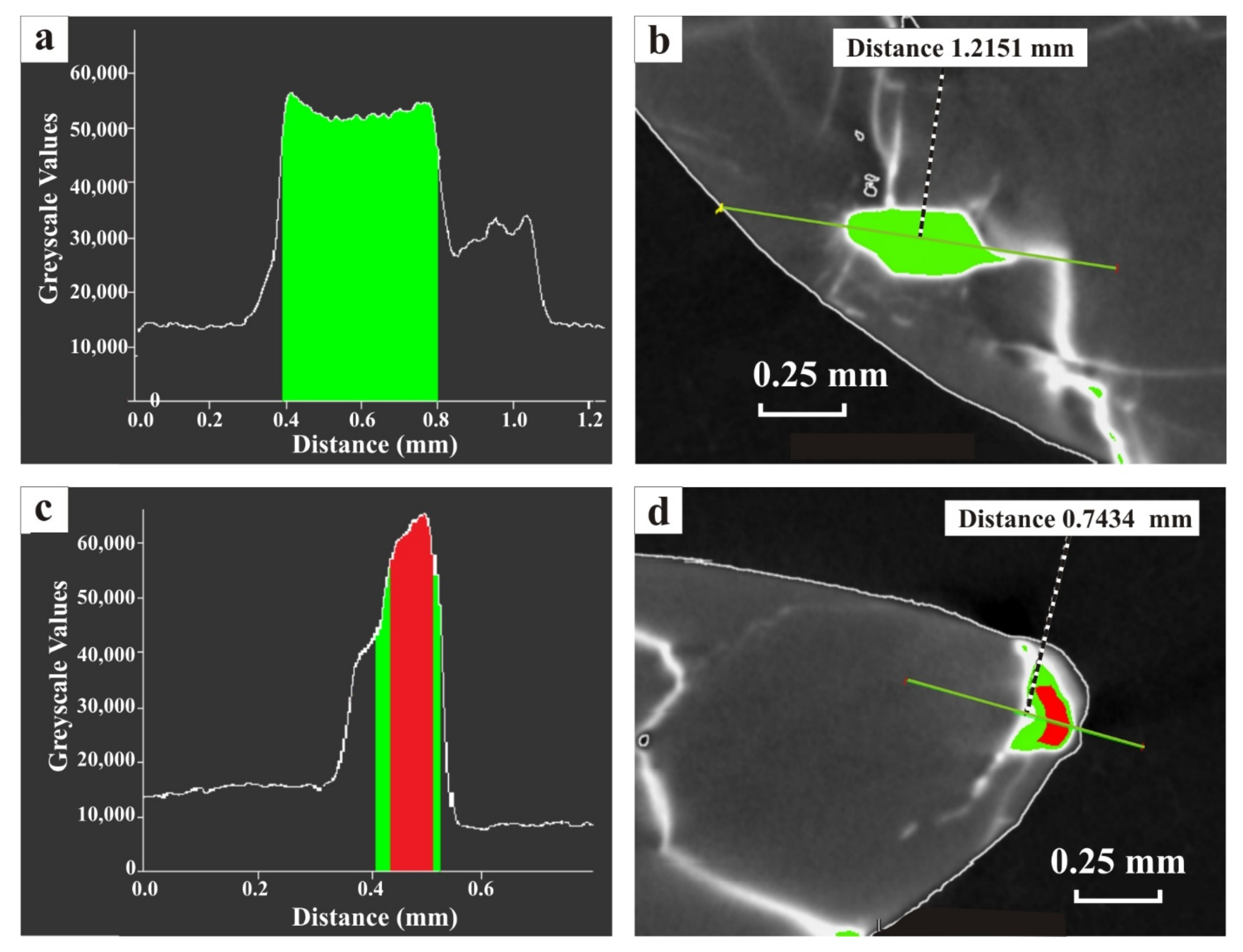

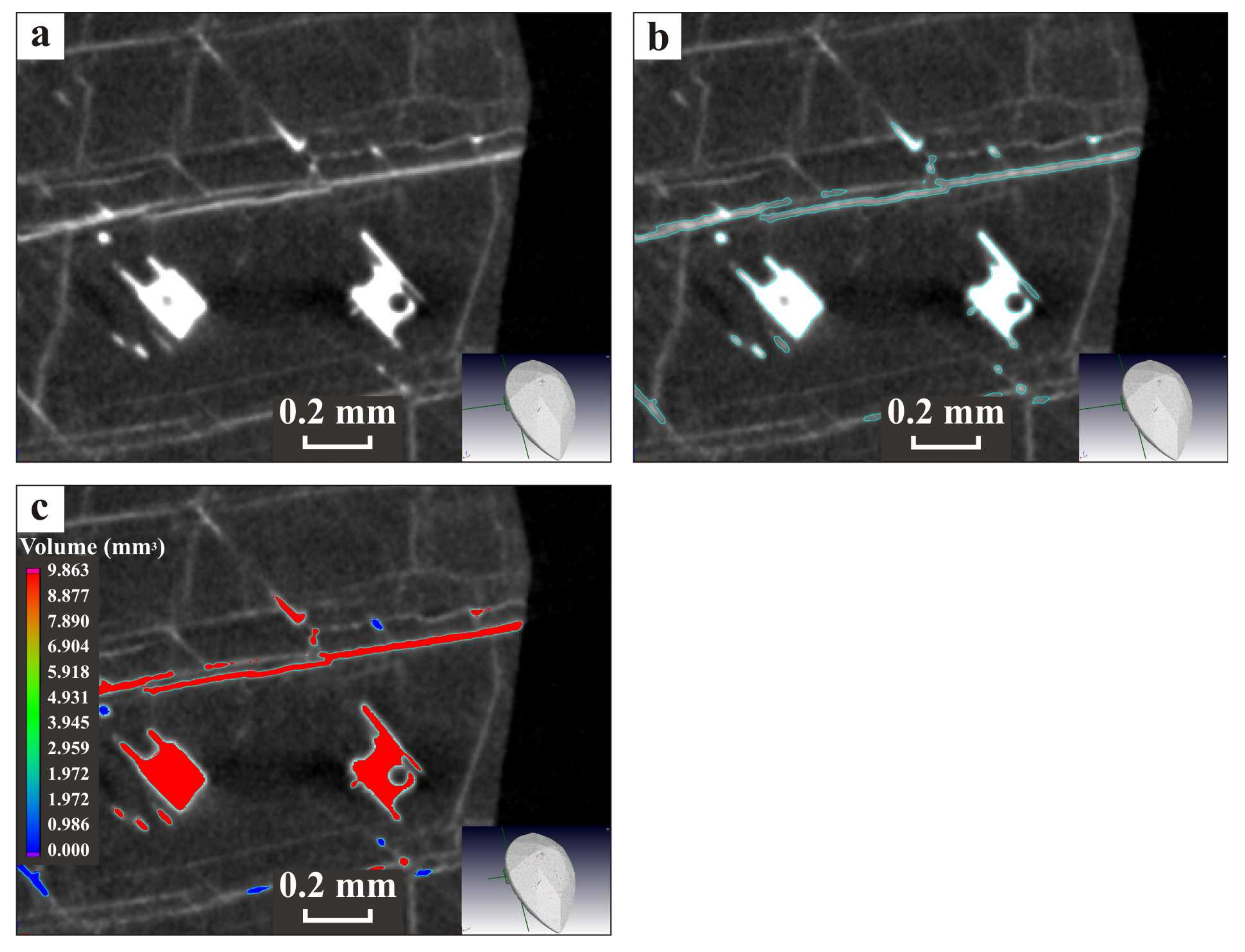

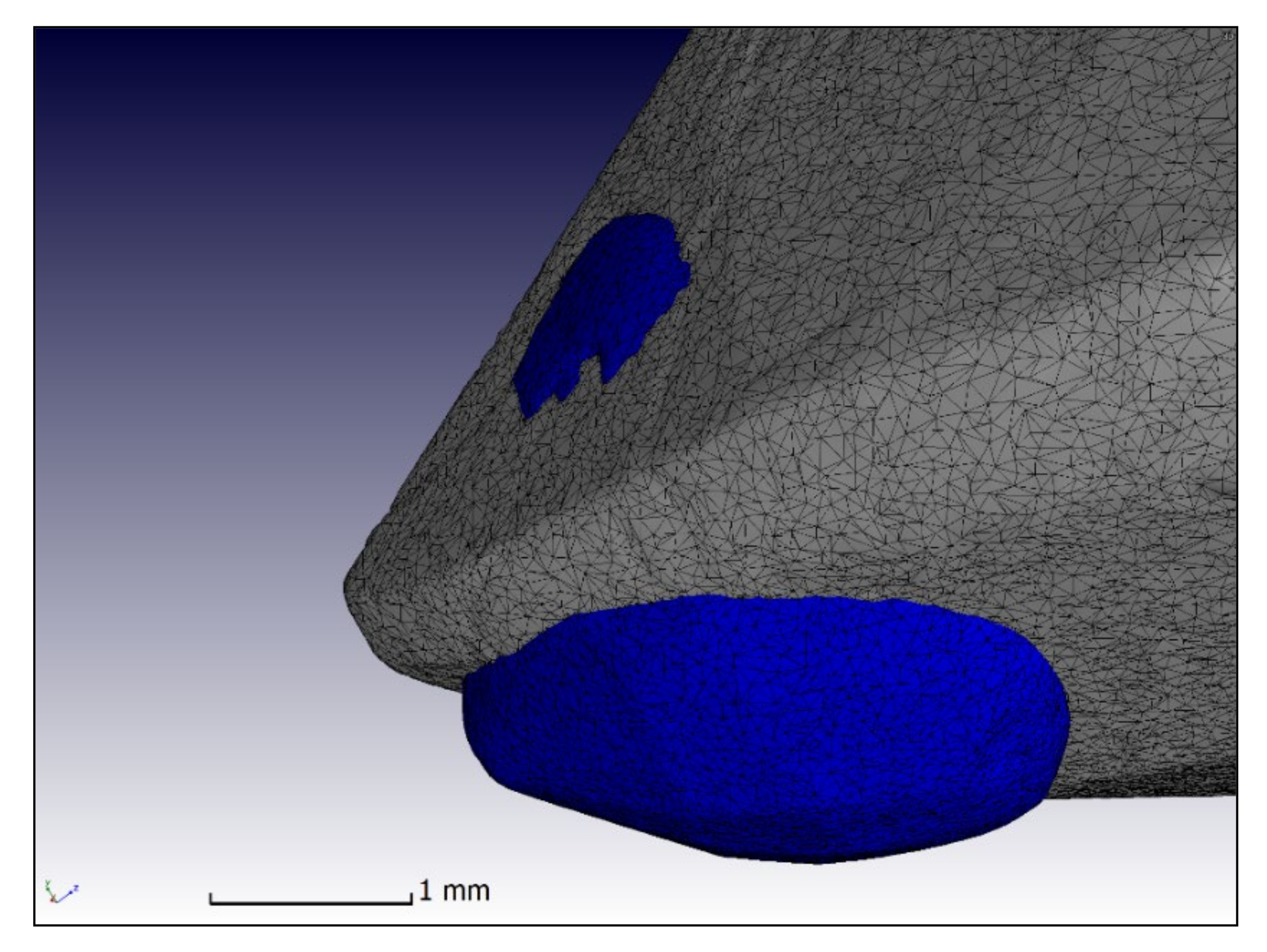

3.1. Fracture Fill Detection and Volume Calculation

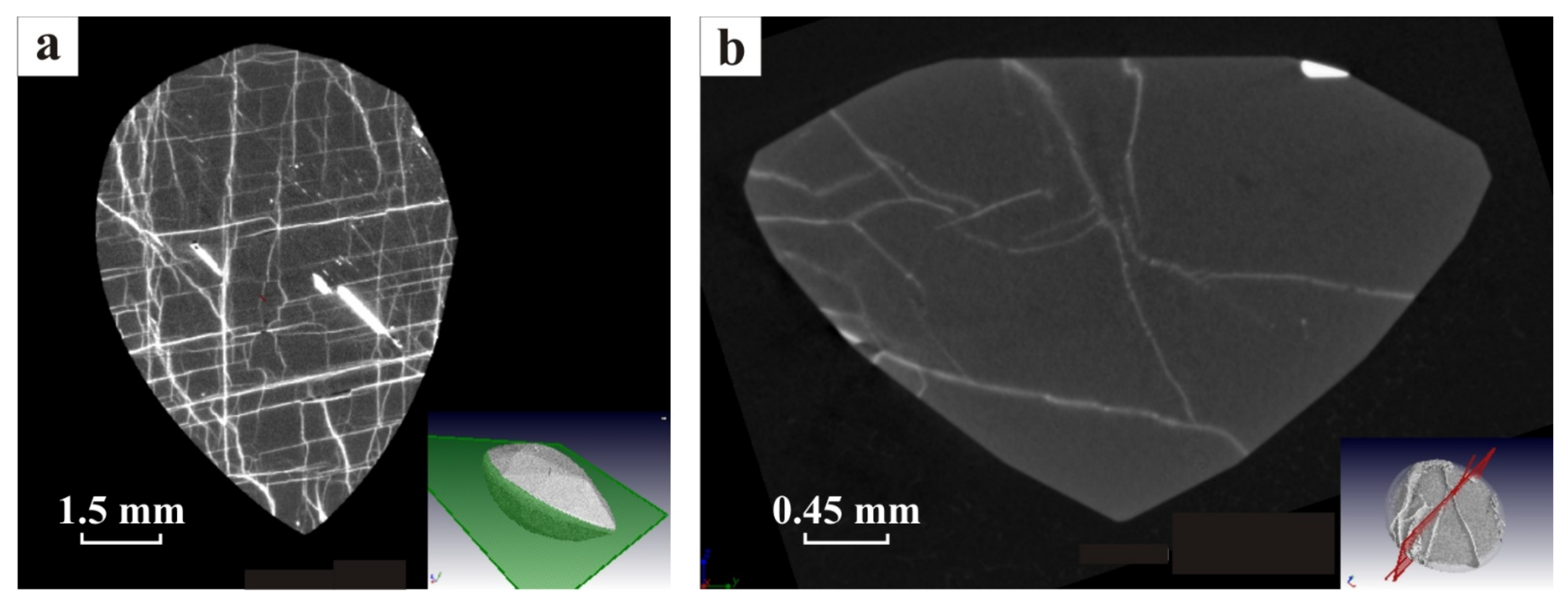

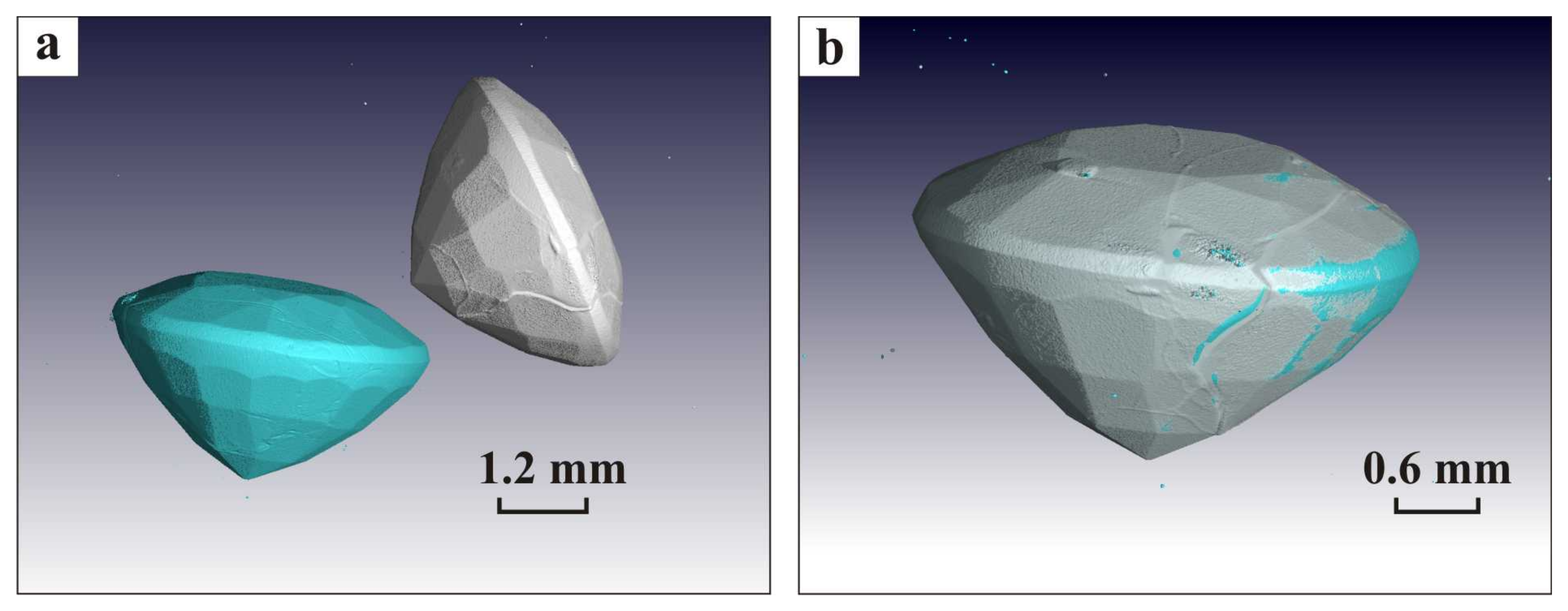

3.2. Producing a Gemstone Fingerprint

3.3. Colour Change Detection

4. Discussion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kammerling, R.C.; Koivula, J.I.; Kane, R.E. Gemstone enhancement and its detection in the 1980s. Gems Gemol. 1980. [Google Scholar] [CrossRef]

- McClure, S.F.; Smith, C.P. Gemstone enhancement and detection in the 1990s. Gems Gemol. 2000. [Google Scholar] [CrossRef]

- Breeding, C.; Shen, A.; Eaton-Magaña, S.; Rossman, G.; Shigley, J.; Gilbertson, A. Developments in gemstone analysis techniques and instrumentation during the 2000s. Gems Gemol. 2010. [Google Scholar] [CrossRef]

- Barone, G.; Bersani, D.; Lottici, P.P.; Mazzoleni, P.; Raneri, S.; Longobardo, U. Red gemstone characterization by micro-Raman spectroscopy: The case of rubies and their imitations. J. Raman Spectrosc. 2016. [Google Scholar] [CrossRef]

- Kiefert, L.; Hänni, H.A.; Chalain, J.-P.; Weber, W. Identification of filler substances in emeralds by infrared and Raman spectroscopy. J. Gemmol. 2000. [Google Scholar] [CrossRef]

- Shigley, J.E. Treated and synthetic gem materials. Curr. Sci. 2000, 79, 1566–1571. [Google Scholar]

- McClure, S.F.; Smith, C.P.; Wang, W.; Hall, M. Identification and durability of lead glass-filled rubies. Gems Gemol. 2006. [Google Scholar] [CrossRef]

- Pardieu, V.; Lomthong, P.; Sturman, N. Lead Glass-Filled Star Rubies Reportedly from Madagascar. Available online: https://www.gia.edu/UK-EN/ongoing-research/lead-glass-filled-star-rubies-reportedly-from-madagascar (accessed on 31 October 2020).

- Lowry, S. Using FTIR spectroscopy to analyze gemstones. Am. Lab. 2008, 40, 28–31. [Google Scholar]

- Chen, V. Coloured Gemstones Rise in Demand among Jewellers and Investors as the Supply Dwindles. Available online: https://www.scmp.com/magazines/style/article/1873766/coloured-gemstones-rise-demand-among-jewellers-and-investors-supply (accessed on 31 October 2020).

- CIBJO–The World Jewellery Confederation. Available online: http://www.cibjo.org/code-of-ethics/ (accessed on 19 December 2020).

- Ho, S.K. Analysis of impurity effects on the coloration of corundum by laser-induced breakdown spectroscopy (LIBS). Appl. Spectrosc. 2015. [Google Scholar] [CrossRef]

- Scarratt, K. A Discussion on Ruby-Glass Composites & Their Potential Impact on the Nomenclature in Use for Fracture-Filled or Clarity Enhanced Stones in General. Available online: https://www.gia.edu/UK-EN/gia-news-research-nr41009 (accessed on 2 November 2020).

- Clark, D. A Consumer’s Guide to Gem Grading. Available online: https://www.gemsociety.org/article/a-consumers-guide-to-gem-grading/ (accessed on 31 October 2020).

- Branstrator, B. Analysis: The State of the Colored Stone Market. Available online: https://www.nationaljeweler.com/diamonds-gems/supply/4803-the-state-of-the-colored-stone-market (accessed on 31 October 2020).

- Soldati, A.L.; Jacob, D.E.; Wehrmeister, U.; Hofmeister, W. Structural characterization and chemical composition of aragonite and vaterite in freshwater cultured pearls. Mineral. Mag. 2008. [Google Scholar] [CrossRef]

- Wehrmeister, U.; Goetz, H.; Jacob, D.E.; Soldati, A.; Xu, W.; Duschner, H.; Hofmeister, W. Visualization of the internal structures of cultured pearls by computerized X-ray microtomography. J. Gemmol. 2008. [Google Scholar] [CrossRef]

- Kawano, J. Observation of the internal structures of pearls by X-ray CT technique. Gemmology 2009, 40, 2–4. [Google Scholar]

- Krzemnicki, M.; Friess, S.; Chalus, P.; Hänni, H.; Karampelas, S. X-ray computed microtomography: Distinguishing natural pearls from beaded and non-beaded cultured pearls. Gems Gemol. 2010. [Google Scholar] [CrossRef]

- Hänni, H.A. How much glass is in the ruby? Ssef Facet. 2009, 16, 8–9. [Google Scholar]

- Bouts, A. Detection of Ruby Crystals in Marble Host Rock by X-ray Computed Tomography. J. Gemmol. 2014. [Google Scholar] [CrossRef]

- Sahoo, R.K.; Singh, S.K.; Mishra, B.K. Surface and bulk 3D analysis of natural and processed ruby using electron probe micro analyzer and X-ray micro CT scan. J. Electron Spectrosc. Relat. Phenom. 2016. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Rozendaal, A.; le Roux, S.G.; du Plessis, A.; Philander, C. Grade and product quality control by microCT scanning of the world class Namakwa Sands Ti-Zr placer deposit West Coast, South Africa: An orientation study. Miner. Eng. 2018, 116, 152–162. [Google Scholar] [CrossRef]

- Rozendaal, A.; le Roux, S.G.; du Plessis, A. Application of microCT scanning in the recovery of endo-skarn associated scheelite from the Riviera Deposit, South Africa. Miner. Eng. 2018, 116, 163–178. [Google Scholar] [CrossRef]

- Maire, E.; Withers, P.J. Quantitative X-ray tomography. Int. Mater. Rev. 2014, 59, 1–43. [Google Scholar] [CrossRef] [Green Version]

- Du Plessis, A.; Boshoff, W.P. A review of X-ray computed tomography of concrete and asphalt construction materials. Constr. Build. Mater. 2019, 199, 637–651. [Google Scholar] [CrossRef]

- Du Plessis, A.; Broeckhoven, C.; Guelpa, A.; Le Roux, S.G. Laboratory x-ray micro-computed tomography: A user guideline for biological samples. GigaScience 2017, 6, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Broeckhoven, C.; du Plessis, A. X-ray microtomography in herpetological research: A review. Amphib. Reptil. 2018. [Google Scholar] [CrossRef] [Green Version]

- Du Plessis, A.; Broeckhoven, C. Looking deep into nature: A review of micro-computed tomography in biomimicry. Acta Biomaterialia 2019, 85, 27–40. [Google Scholar] [CrossRef]

- Du Plessis, A.; Yadroitsev, I.; Yadroitsava, I.; le Roux, S.G. X-ray Microcomputed Tomography in Additive Manufacturing: A Review of the Current Technology and Applications. 3D Print. Addit. Manuf. 2018. [Google Scholar] [CrossRef] [Green Version]

- Roux, J. Classification of Diamonds by Microfocus X-Ray Computed Tomography. Unpublished Thesis, BSc honors, Department of Earth Sciences, Stellenbosch University, Stellenbosch, South Africa, 2012. [Google Scholar]

- Du Plessis, A.; le Roux, S.G.; Rozendaal, A.; Tolken, A. X-ray tomography of cut and polished diamonds. Gems Gemol. Under review.

- Du Plessis, A.; le Roux, S.G.; Rozendaal, A.; Tolken, A. X-ray tomography of cut and polished diamonds and gemstones. In Proceedings of the 35th International Geological Congress, Cape Town, South Africa, 27 August–4 September 2016. [Google Scholar]

- Du Plessis, A.; le Roux, S.G.; Guelpa, A. The CT Scanner Facility at roux University: An open access X-ray computed tomography laboratory. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 384, 42–49. [Google Scholar] [CrossRef] [Green Version]

- Boas, F.E.; Fleischmann, D. CT artifacts: Causes and reduction techniques. Imaging Med. 2012, 4, 229–240. [Google Scholar] [CrossRef] [Green Version]

- Le Roux, S.G.; du Plessis, A.; Rozendaal, A. The quantitative analysis of tungsten ore using X-ray microCT: Case study. Comput. Geosci. 2015. [Google Scholar] [CrossRef]

- Nassau, K. Gemstone Enhancement, 2nd ed.; Butterworth-Heineman: Oxford, UK, 1984. [Google Scholar]

- Pough, F.H.; Rogers, T.H. Experiments in X-ray irradiation of gem stones. Am. Mineral. J. Earth Planet. Mater. 1947, 32, 31–43. [Google Scholar]

- The Laboratory Manual Harmonisation Committee LMHC Information Sheet # 3-Corundum. Available online: https://static1.squarespace.com/static/5bfbb7e6cc8fed3bb9293bf3/t/5bfe9219f950b7627afb4cb0/1543410205254/LMHC+Information+Sheet_3_V9_2012.pdf (accessed on 21 December 2020).

- Guelpa, A.; du Plessis, A.; Kidd, M.; Manley, M. Non-destructive Estimation of Maize (Zea mays L.) Kernel Hardness by Means of an X-ray Micro-computed Tomography (μCT) Density Calibration. Food Bioprocess Technol. 2015, 8, 1419–1429. [Google Scholar] [CrossRef]

- McClure, S.F.; Moses, T.M.; Tannous, M.; Koivula, J.I. Classifying emerald clarity enhancement at the GIA Gem Trade Laboratory. Gems Gemol. 1999, 35, 176–185. [Google Scholar] [CrossRef]

- du Plessis, A.; Olawuyi, B.J.; Boshoff, W.P.; le Roux, S.G. Simple and fast porosity analysis of concrete using X-ray computed tomography. Mater. Struct./Mater. Et Constr. 2016, 49, 553–562. [Google Scholar] [CrossRef]

- OGI Systems Ltd. Scanox CAD. Available online: http://www.ogisystems.com/scanoxcad.html (accessed on 21 December 2020).

- OGI Systems Ltd. Clearex Gem. Available online: http://www.ogisystems.com/clearexgem.html (accessed on 21 December 2020).

- Gemological Institute of America Colored Gemstone and Pearl Reports. Available online: https://4cs.gia.edu/en-us/colored-gemstone-pearl-reports/ (accessed on 31 October 2020).

- De Chiffre, L.; Carmignato, S.; Kruth, J.P.; Schmitt, R.; Weckenmann, A. Industrial applications of computed tomography. Cirp Ann. Manuf. Technol. 2014, 63, 655–677. [Google Scholar] [CrossRef]

- Nassau, K. The Physics and Chemistry of Color: The Fifteen Causes of Color. Color Res. Appl. 1984, 12, 4–26. [Google Scholar] [CrossRef]

| Sample Name (Commercial Name) | Mineral | Diameter | Approximate Carat Weight | Cut | Treatment | Experiment |

|---|---|---|---|---|---|---|

| Pb-glass-filled Ruby | Corundum | 5 mm | 0.63 | Round brilliant | Fracture filled | 1,2,3 |

| EGL Ruby | Corundum | 11 × 7 mm | 2.65 | Pear brilliant | Fracture filled | 1,2 |

| Diffusion treated sapphire A | Corundum | 3 mm | 0.13 | Round brilliant | Heat treated | 2,3 |

| Diffusion treated sapphire B | Corundum | 3 mm | 0.13 | Round brilliant | Diffusion treatment | 3 |

| Diffusion treated sapphire C | Corundum | 3 mm | 0.13 | Round brilliant | Diffusion treatment | 3 |

| Yellow sapphire | Corundum | 8 × 6 mm | 1.36 | Round brilliant | 3 | |

| Indian Ruby A | Corundum | 7 mm | 1.58 | Round brilliant | 3 | |

| Indian Ruby B | Corundum | 7 mm | 1.58 | Round brilliant | 3 | |

| Indian Ruby C | Corundum | 7 mm | 1.58 | Round brilliant | 3 | |

| Emerald (Colombian) | Beryl | 7 mm | 1.67 | Round brilliant | 3 | |

| Topaz A (London blue) | Topaz | 6 mm | 0.83 | Trillion | 3 | |

| Topaz B (Sky blue) | Topaz | 6 mm | 0.83 | Trillion | 3 | |

| Hydro Amethyst | Quartz | 12 mm | 5.67 | Cushion rose cut | 3 | |

| Tanzanite | Zoisite | 8 × 5 mm | 2.14 | Cabochon | 3 |

| CT-Scan Resolution | Volume of Entire Stone (mm3) | Volume of Fracture Filling Material (mm3) | Percentage Fracture Filling Material |

|---|---|---|---|

| 10 µm Scan | 148.03137 | 19.18086 | 12.957% |

| 5 µm Scan | 148.24036 | 10.15460 | 6.85% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Heyn, R.; Rozendaal, A.; Du Plessis, A.; Mouton, C. Characterization of Coloured Gemstones by X-ray Micro Computed Tomography. Minerals 2021, 11, 178. https://doi.org/10.3390/min11020178

Heyn R, Rozendaal A, Du Plessis A, Mouton C. Characterization of Coloured Gemstones by X-ray Micro Computed Tomography. Minerals. 2021; 11(2):178. https://doi.org/10.3390/min11020178

Chicago/Turabian StyleHeyn, René, Abraham Rozendaal, Anton Du Plessis, and Carene Mouton. 2021. "Characterization of Coloured Gemstones by X-ray Micro Computed Tomography" Minerals 11, no. 2: 178. https://doi.org/10.3390/min11020178

APA StyleHeyn, R., Rozendaal, A., Du Plessis, A., & Mouton, C. (2021). Characterization of Coloured Gemstones by X-ray Micro Computed Tomography. Minerals, 11(2), 178. https://doi.org/10.3390/min11020178