Climate Resilience of Internally-Insulated Historic Masonry Assemblies: Comparison of Moisture Risk under Current and Future Climate Scenarios

Abstract

1. Introduction

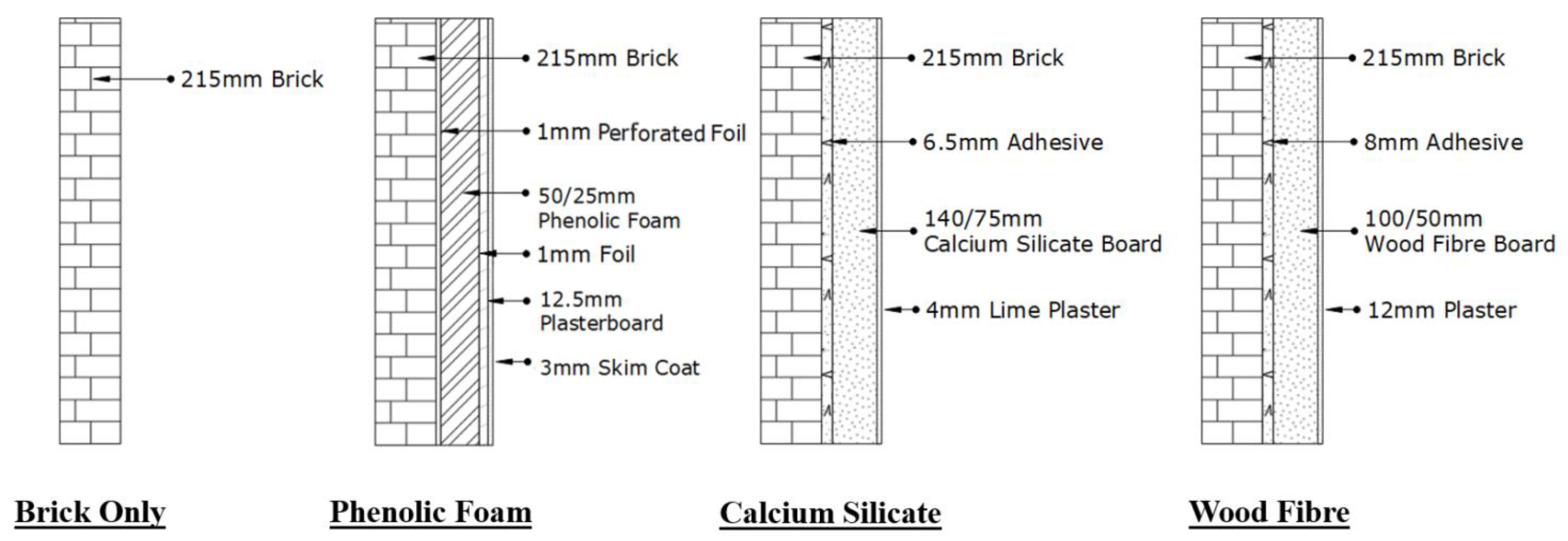

2. Materials and Methods

3. Results

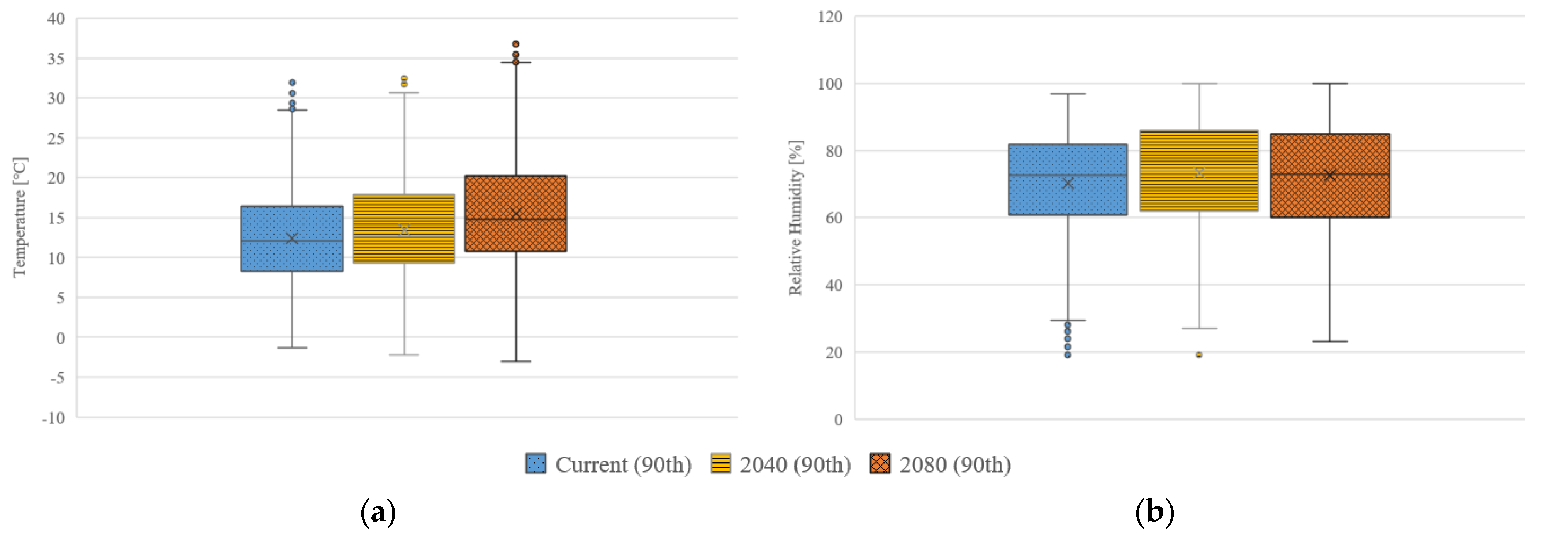

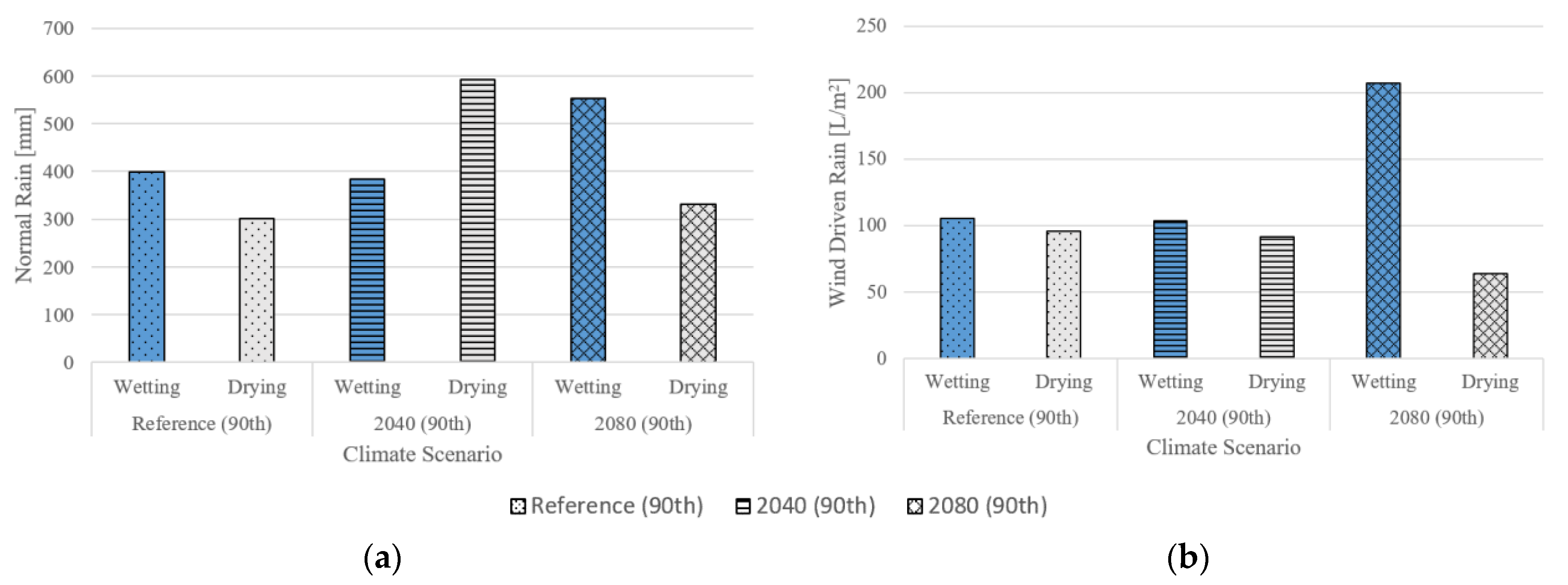

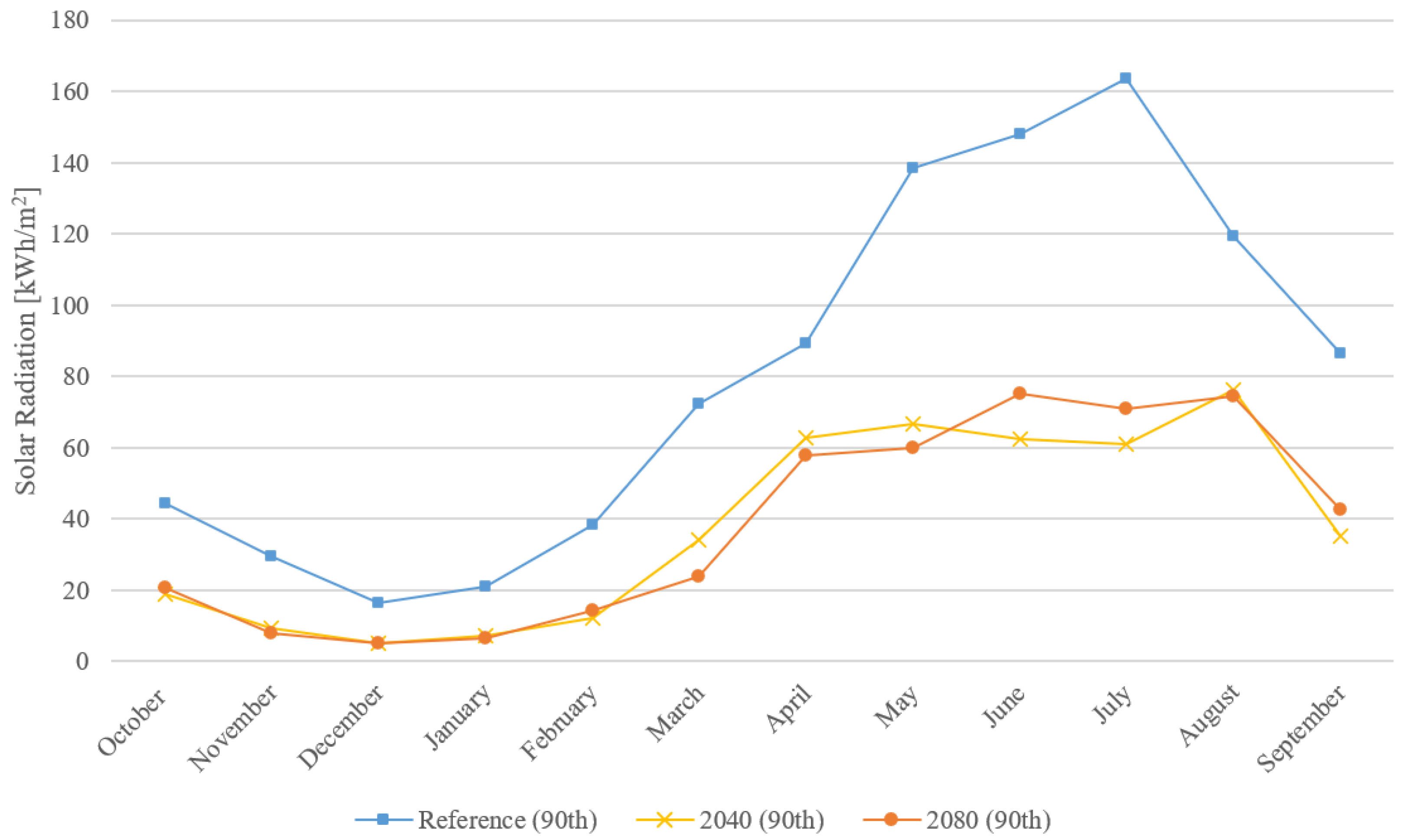

3.1. Climate Analysis

3.2. Hygrothermal Simulations

3.2.1. Moisture Accumulation

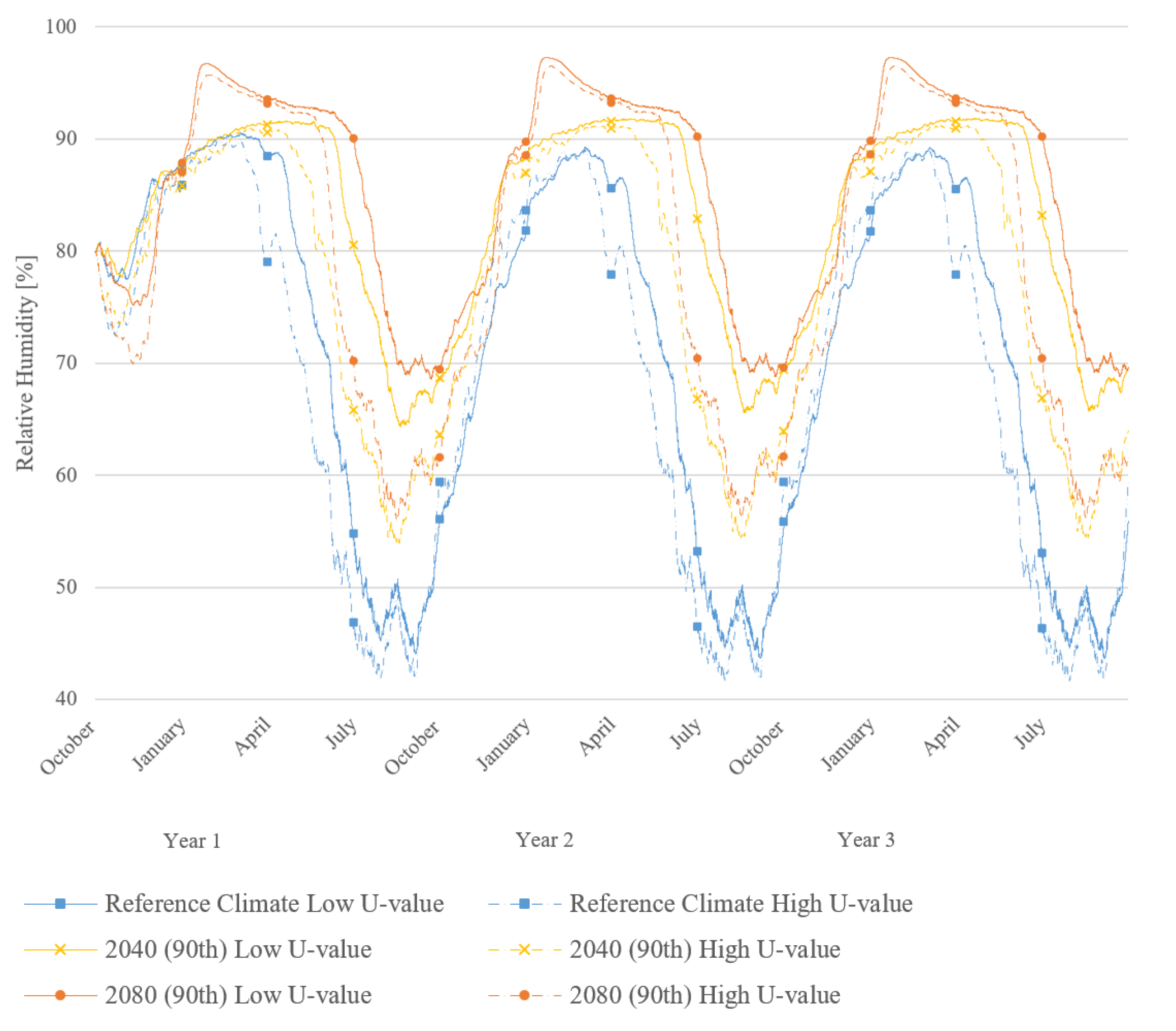

3.2.2. Interstitial Condensation and Mould Risk

3.2.3. Freeze-Thaw Risk

3.2.4. Summary of Results

4. Discussion

5. Conclusions

- current U-value standards have low moisture risk in the reference climate but will suffer high risks with the projected future moisture loads if unchanged;

- thinner insulation assemblies performed better in all scenarios and should be allowed for solid wall retrofits;

- calcium silicate (high absorptivity) performed best under future climate conditions; and

- additional moisture interventions will be needed to reduce the high risks of future moisture loads.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- HM Government. UK becomes First Major Economy to Pass Net Zero Emissions Law. Available online: https://www.gov.uk/government/news/uk-becomes-first-major-economy-to-pass-net-zero-emissions-law (accessed on 4 June 2020).

- CCC. Buildings Factsheet; Climate Change Committee: London, UK, August, 2014. [Google Scholar]

- HM Government. English Housing Survey 2018 to 2019: Headline Report. Available online: https://www.gov.uk/government/statistics/english-housing-survey-2018-to-2019-headline-report (accessed on 4 June 2020).

- Marincioni, V.; Gori, V.; de Place Hansen, E.J.; Herrera-Avellanosa, D.; Mauri, S.; Giancola, E.; Egusquiza, A.; Buda, A.; Leonardi, E.; Rieser, A. How Can Scientific Literature Support Decision-Making in the Renovation of Historic Buildings? An Evidence-Based Approach for Improving the Performance of Walls. Sustainability 2021, 13, 2266. [Google Scholar] [CrossRef]

- BSI. BS 5250:2011 Code of Practice for Control of Condensation in Buildings; British Standards Institution: London, UK, 2011. [Google Scholar]

- Odgaard, T.; Bjarløv, S.P.; Rode, C. Interior insulation—Experimental investigation of hygrothermal conditions and damage evaluation of solid masonry façades in a listed building. Build. Environ. 2018, 129, 1–14. [Google Scholar] [CrossRef]

- Marincioni, V.; Altamirano-Medina, H.; Ridley, I. Performance of Internal Wall Insulation Systems-Experimental Test for the Validation of a Hygrothermal Simulation Tool. In 10th Nordic Symposium of Building Physics; Building Physics, LTH, Lund University: Lund, Sweden, 2014. [Google Scholar]

- WHO. Damp and Mould: Health Risks Preventions and Remedial Actions; WHO: Geneva, Switzerland, 2009. [Google Scholar]

- Zhou, X.; Derome, D.; Carmeliet, J. Hygrothermal modeling and evaluation of freeze-thaw damage risk of masonry walls retrofitted with internal insulation. Build. Environ. 2017, 125, 285–298. [Google Scholar] [CrossRef]

- Blocken, B.B.; Carmeliet, J.J. A review of wind-driven rain research in building science. J. Wind. Eng. Ind. Aerodyn. 2004, 92, 1079–1130. [Google Scholar] [CrossRef]

- Straube, J.; Schumacher, C. Interior Insulation Retrofits of Load-Bearing Masonry Walls in Cold Climates. J. Green Build. 2007, 2, 42–50. [Google Scholar] [CrossRef]

- Karagiozis, A.N.; Salonvaara, M.; Holm, A.; Kuenzel, H. Influence of Wind-Driven Rain Data on Hygrothermal Performance. In Proceedings of the Eighth International IBPSA Conference, Eindhoven, The Netherlands, 11–14 August 2003. [Google Scholar]

- Abuku, M.; Janssen, H.; Roels, S. Impact of wind-driven rain on historic brick wall buildings in a moderately cold and humid climate: Numerical analyses of mould growth risk, indoor climate and energy consumption. Energy Build. 2009, 41, 101–110. [Google Scholar] [CrossRef]

- Bottino-Leone, D.; Larcher, M.; Herrera-Avellanosa, D.; Haas, F.; Troi, A. Evaluation of natural-based internal insulation systems in historic buildings through a holistic approach. Energy 2019, 181, 521–531. [Google Scholar] [CrossRef]

- Nielsen, A.; Møller, E.B.; Rasmussen, T.V.; de Hansen, E.J.P. Use of Sensitivity Analysis to Evaluate Hygrothermal Conditions in Solid Brick Walls with Interior Insulation. In Proceedings of the 5th International Building Physical Conference, Kyoto, Japan, 28–31 May 2012; pp. 377–384. [Google Scholar]

- De Mets, T.; Tilmans, A.; Loncour, X. Hygrothermal Assessment of Internal Insulation Systems of Brick Walls through Numerical Simulation and Full-Scale Laboratory Testing. Energy Procedia 2017, 132, 753–758. [Google Scholar] [CrossRef]

- Baker, P. Hygrothermal Modelling of Shrewsbury Flaxmill Maltings; Historic England: London, UK, 2015.

- Knarud, J.; Geving, S.; Kvande, T. Hygrothermal Simulations of Internally Insulated Massive Masonry Walls Exposed to Driving Rain in Cold Climate. In 10th Nordic Symposium on Building Physics; Building Physics, LTH, Lund University: Lund, Sweden, 2014; pp. 1141–1148. [Google Scholar]

- Kendon, E.; Fosser, G.; Murphy, J.; Chan, S.; Clark, R.; Harris, G.; Lock, A.; Lowe, J.; Martin, G.; Pirret, J.; et al. UKCP Convection-Permitting Model Projections: Science Report. 2019, No. September, 1–153. Available online: https://doi.org/https://www.metoffice.gov.uk/pub/data/weather/uk/ukcp18/science-reports/UKCP-Convection-permitting-model-projections-report.pdf (accessed on 25 May 2020).

- Orr, S.A.; Young, M.; Stelfox, D.; Curran, J.; Viles, H. Wind-driven rain and future risk to built heritage in the United Kingdom: Novel metrics for characterising rain spells. Sci. Total. Environ. 2018, 640–641, 1098–1111. [Google Scholar] [CrossRef]

- Nik, V.M.; Mundt-Petersen, S.; Kalagasidis, A.S.; De Wilde, P. Future moisture loads for building facades in Sweden: Climate change and wind-driven rain. Build. Environ. 2015, 93, 362–375. [Google Scholar] [CrossRef]

- Hao, L.; Del Pero, C.; Matiu, M.; Troi, A. Climate Change Impact on Hygrothermal Performance of Energy-Retrofitted Historic Buildings: Numerical Simulations of Internally Insulated Masonry Walls in South Tyrol. In Proceedings of the Adapt Northern Heritage Conference, Online, 5–6 May 2020. [Google Scholar]

- Cabrera, P.; Samuelson, H.W. Simulating Mold Risks under Future Climate Conditions. In Proceedings of the Building Simulation 2019, Rome, Italy, 2–4 September 2019. [Google Scholar]

- Little, J.; Ferraro, C.; Aregi, B. Assessing Risks in Insulation Retrofits Using Hygrothermal Software Tools Heat and Moisture Transport in Internally Insulated Stone Walls; Historic Environment Scotland: Edinburgh, UK, 2015.

- UK Met Office. UK Hourly Weather Observations. Available online: http://data.ceda.ac.uk/badc/ukmo-midas-open/data (accessed on 15 July 2020).

- Kehrer, M. WUFI Workshop NBI/SINTEF 2008 Radiation Effects on Exterior Surfaces. Available online: http://www.wufi.no/workshop-08/RadiationEffectsOnExteriorSurfaces_E.pdf (accessed on 15 July 2020).

- UK Met Office. UKCP18 Local Projections 2.2km Grid. Available online: http://data.ceda.ac.uk/badc/ukcp18/data/land-cpm/uk/2.2km/rcp85 (accessed on 15 July 2020).

- Berrizbeitia, S.E.; Gago, E.J.; Muneer, T. Empirical Models for the Estimation of Solar Sky-Diffuse Radiation. A Review and Experimental Analysis. Energies 2020, 13, 701. [Google Scholar] [CrossRef]

- Belcher, S.; Hacker, J.; Powell, D. Constructing design weather data for future climates. Build. Serv. Eng. Res. Technol. 2005, 26, 49–61. [Google Scholar] [CrossRef]

- Sontag, L.; Nicolai, A.; Vogelsang, S. Validierung der Solverimplementierung des Hygrothermischen Simulationsprogramms Delphin. Technical Report. Available online: http://nbn-resolving.de/urn:nbn:de:bsz:14-qucosa-128968 (accessed on 15 April 2020).

- Zhao, J.; Plagge, R.; Ramos, N.M.M.; Simões, M.L.; Grunewald, J. Application of clustering technique for definition of generic objects in a material database. J. Build. Phys. 2015, 39, 124–146. [Google Scholar] [CrossRef]

- BRE. Solid Wall Heat Losses and the Potential for Energy Saving: Classification of Solid Walls; Building Research Establishment: Watford, UK, 2016. [Google Scholar]

- Li, F.G.N.; Smith, A.; Biddulph, P.; Hamilton, I.G.; Lowe, R.; Mavrogianni, A.; Oikonomou, E.; Raslan, R.; Stamp, S.; Stone, A.; et al. Solid-wallU-values: Heat flux measurements compared with standard assumptions. Build. Res. Inf. 2015, 43, 238–252. [Google Scholar] [CrossRef]

- HM Government. Conservation of Fuel and Power: Approved Document Part L. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/540327/BR__PDF__AD_L1B_2013_with_2016_amendments.pdf (accessed on 6 August 2020).

- STBA. A Guide to the Responsible Retrofit of Traditional Homes in Bristol Solid Wall Insulation A Bristolian’s Guide To; Sustainable Traditional Buildings Alliance: London, UK, 2015. [Google Scholar]

- Kingspan. Kooltherm K118 Insulated Plasterboard|Internal Wall Insulation|Kingspan|Great Britain. Available online: https://www.kingspan.com/gb/en-gb/products/insulation/insulation-boards/kooltherm/kooltherm-k118-insulated-plasterboard (accessed on 24 August 2020).

- Ecological Building Systems. Calsitherm Climate Board|Ecological Building Systems. Available online: https://www.ecologicalbuildingsystems.com/product/calsitherm-climate-board (accessed on 24 August 2020).

- Natural Building Technologies. Internal Wall Insulation Dry Lined—Natural Building Technologies. Available online: https://www.natural-building.co.uk/system/internal-wall-insulation-dry-lined/ (accessed on 24 August 2020).

- Vereecken, E.; Roels, S. Capillary Active Interior Insulation Systems for Wall Retrofitting: A More Nuanced Story. Int. J. Arch. Heritage 2016, 10, 558–569. [Google Scholar] [CrossRef]

- Palmer, J.; Terry, N. Solid Wall Insulation: Best Practice and Innovation; Department for Business, Energy & Industrial Strategy: London, UK, 2017. Available online: https://www.gov.uk/government/publications/understanding-best-practice-in-deploying-external-solid-wall-insulation-and-internal-wall-insulation-in-the-uk (accessed on 25 February 2021).

- Straube, J.; Burnett, E.F. Simplified Prediction of Driving Rain on Buildings. In Proceedings of the International Building Physics Conference, Eindhoven, The Netherlands, 18–21 September 2000. [Google Scholar]

- Hukka, A.; Viitanen, H.A. A mathematical model of mould growth on wooden material. Wood Sci. Technol. 1999, 33, 475–485. [Google Scholar] [CrossRef]

- Ojanen, T.; Viitanen, H.; Peuhkuri, R.; Vinha, J.; Salminen, K. Mold growth modeling of building structures using sensitivity classes of materials. In Proceedings of the 11th International Conference on Thermal Performance of the Exterior Envelopes of Whole Buildings, Buildings XI, Clearwater, Pinellas County, FL, USA, 5–9 December 2010. [Google Scholar]

- Vandemeulebroucke, I.; Calle, K.; Caluwaerts, S.; De Kock, T.; Bossche, N.V.D. Does historic construction suffer or benefit from the urban heat island effect in Ghent and global warming across Europe? Can. J. Civ. Eng. 2019, 46, 1032–1042. [Google Scholar] [CrossRef]

- Leeds Sustainability Institute. Thin Internal Wall Insulation: Measuring Energy Performance Improvements in Dwellings; Leeds Sustainability Institute: Leeds, UK, 2019. [Google Scholar]

- Zhao, J.; Meissener, F. Experimental investigation of moisture properties of historic building material with hydrophobization treatment. Energy Procedia 2017, 132, 261–266. [Google Scholar] [CrossRef]

- SPAB. A Guide to the Repair of Old Brick Walls. Available online: https://www.spab.org.uk/advice/guide-repair-old-brick-walls (accessed on 14 September 2020).

- Historic England. Repointing Brick and Stone Walls Guidelines for Best Practice; Historic England: London, UK, 2017.

- Lo, Y.T.E.; Mitchell, D.M.; Bohnenstengel, S.I.; Collins, M.; Hawkins, E.; Hegerl, G.C.; Joshi, M.; Stott, P.A. U.K. Climate Projections: Summer Daytime and Nighttime Urban Heat Island Changes in England’s Major Cities. J. Clim. 2020, 33, 9015–9030. [Google Scholar] [CrossRef]

- Blocken, B.; Carmeliet, J. Validation of CFD simulations of wind-driven rain on a low-rise building facade. Build. Environ. 2007, 42, 2530–2548. [Google Scholar] [CrossRef]

- Marincioni, V.; Marra, G.; Altamirano-Medina, H. Development of predictive models for the probabilistic moisture risk assessment of internal wall insulation. Build. Environ. 2018, 137, 257–267. [Google Scholar] [CrossRef]

| Hourly Variable Required | Units | Available Time Resolution in Observed Data | Available Time Resolution in UKCP18 |

|---|---|---|---|

| Air Temperature | °C | Hourly | Hourly |

| Precipitation | mm | Hourly | Hourly |

| Relative Humidity | % | Hourly | Daily at 12 p.m. |

| Global Horizontal Radiation Shortwave | W/m2 | Hourly | Daily at 12 p.m. |

| Diffuse Shortwave Radiation | W/m2 | Hourly | Unavailable |

| Atmospheric Counter Radiation | W/m2 | Unavailable | Unavailable |

| Wind Speed | m/s | Hourly | Daily at 12 p.m. Northward and Eastward Wind Vectors Given |

| Wind Direction | ° Clockwise from North | Hourly | |

| Cloud Index | Oktas [0, 8] converted to [0, 1] | Hourly | Daily at 12 p.m. |

| ρ [kg/m3] | θpor [m3/m3] | μ [-] | Cp [J/kgK] | Wsat [kg/m3] | Aw [kg/m2s0.5] | λ [W/mK] | ||

|---|---|---|---|---|---|---|---|---|

| Existing Condition | Brick ZG | 1715 | 0.356 | 22.2 | 920 | 322.1 | 0.137 | - |

| Phenolic Foam [36] | Brick ZG | 1715 | 0.356 | 22.2 | 920 | 322.1 | 0.137 | 0.54 |

| Low-e Perforated Composite Foil | 1276 | 0.114 | 600.0 | 1000 | 113.0 | 0 | 0.23 | |

| Phenolic Foam | 35 | 0.987 | 113.7 | 1470 | 501.2 | 0.009 | 0.02 | |

| Low-e Composite Foil | 1276 | 0.114 | 94,384.5 | 1000 | 113.0 | 0 | 0.23 | |

| Plasterboard | 1043 | 0.606 | 11.3 | 1047 | 356.0 | 0.367 | 0.26 | |

| Skim Coat | 1043 | 0.606 | 11.3 | 1047 | 356.0 | 0.367 | 0.26 | |

| Calcium Silicate [37] | Brick ZG | 1715 | 0.356 | 22.2 | 920 | 322.1 | 0.137 | 0.54 |

| Calcium Silicate KP Glue Mortar | 1410 | 0.468 | 22.9 | 1059 | 340.0 | 0.004 | 0.60 | |

| Calcium Silicate Climate Board | 187 | 0.930 | 3.6 | 1100 | 916.4 | 0.766 | 0.06 | |

| Calcium Silicate KP Lime Plaster | 1250 | 0.528 | 12.1 | 999 | 452.2 | 0.134 | 0.57 | |

| Wood Fibre [38] | Brick ZG | 1715 | 0.356 | 22.2 | 920 | 322.1 | 0.137 | 0.54 |

| Mineral Fine Plaster (Light) | 586 | 0.779 | 12.6 | 1198 | 360.0 | 0.073 | 0.13 | |

| Wood Fibre Board | 150 | 0.981 | 3.0 | 2000 | 600.0 | 0.070 | 0.04 | |

| Gypsum Board | 850 | 0.650 | 10.0 | 850 | 551.0 | 0.277 | 0.20 |

| Existing | Low U-Value | High U-Value | ||||||

|---|---|---|---|---|---|---|---|---|

| Brick Only | Calcium Silicate | Phenolic Foam | Wood Fibre | Calcium Silicate | Phenolic Foam | Wood Fibre | ||

| Reference Climate | Hours with ice present | 9 | 27 | 27 | 27 | 27 | 27 | 25 |

| Number of FT cycles | 3 | 3 | 3 | 3 | 3 | 3 | 5 | |

| Sum of ice content [kg/m3] | 24.1 | 263.3 | 266.0 | 251.7 | 201.6 | 205.8 | 192.5 | |

| 2080 (90th) Climate | Hours with ice present | 0 | 18 | 22 | 20 | 12 | 12 | 12 |

| Number of FT cycles | 0 | 3 | 3 | 3 | 3 | 3 | 3 | |

| Sum of ice content [kg/m3] | 0 | 66.3 | 70.7 | 64.9 | 26.8 | 28.2 | 23.1 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, J.; Marincioni, V.; Orr, S.A.; Altamirano-Medina, H. Climate Resilience of Internally-Insulated Historic Masonry Assemblies: Comparison of Moisture Risk under Current and Future Climate Scenarios. Minerals 2021, 11, 271. https://doi.org/10.3390/min11030271

Lu J, Marincioni V, Orr SA, Altamirano-Medina H. Climate Resilience of Internally-Insulated Historic Masonry Assemblies: Comparison of Moisture Risk under Current and Future Climate Scenarios. Minerals. 2021; 11(3):271. https://doi.org/10.3390/min11030271

Chicago/Turabian StyleLu, Jacqueline, Valentina Marincioni, Scott Allan Orr, and Hector Altamirano-Medina. 2021. "Climate Resilience of Internally-Insulated Historic Masonry Assemblies: Comparison of Moisture Risk under Current and Future Climate Scenarios" Minerals 11, no. 3: 271. https://doi.org/10.3390/min11030271

APA StyleLu, J., Marincioni, V., Orr, S. A., & Altamirano-Medina, H. (2021). Climate Resilience of Internally-Insulated Historic Masonry Assemblies: Comparison of Moisture Risk under Current and Future Climate Scenarios. Minerals, 11(3), 271. https://doi.org/10.3390/min11030271