Influence of Strain Rate, Temperature and Chemical Composition on High Silicon Ductile Iron

Abstract

:1. Introduction

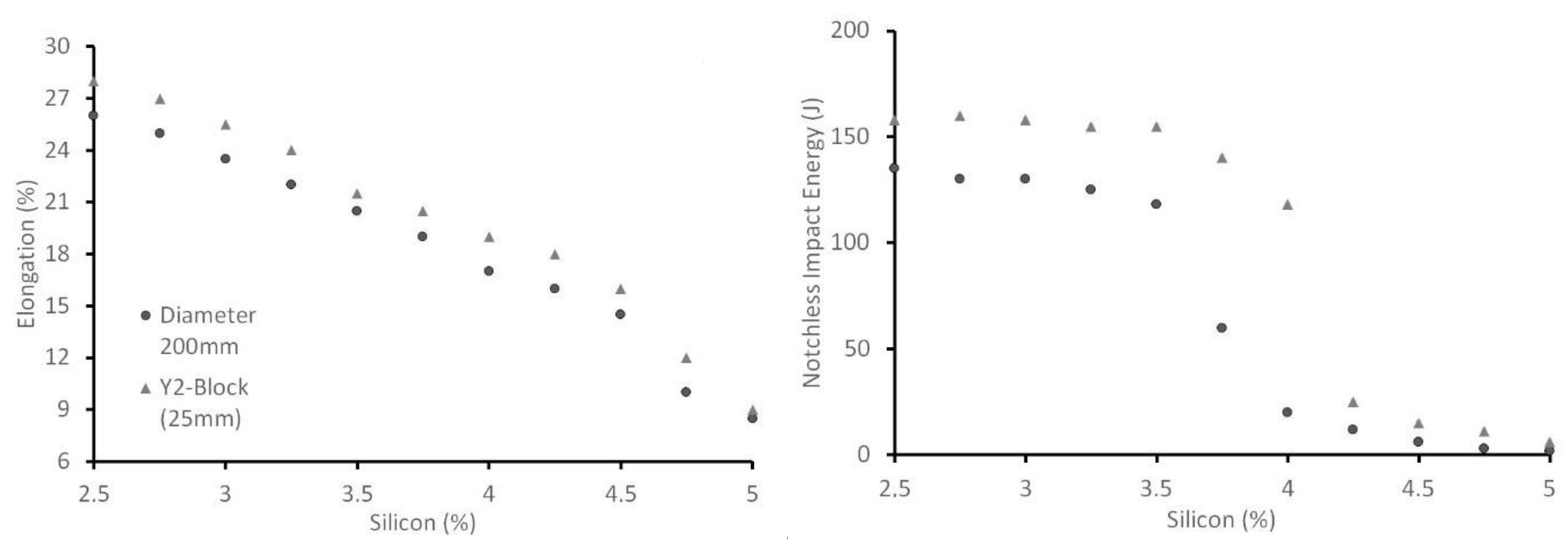

2. Dynamic Failure of Cast Irons

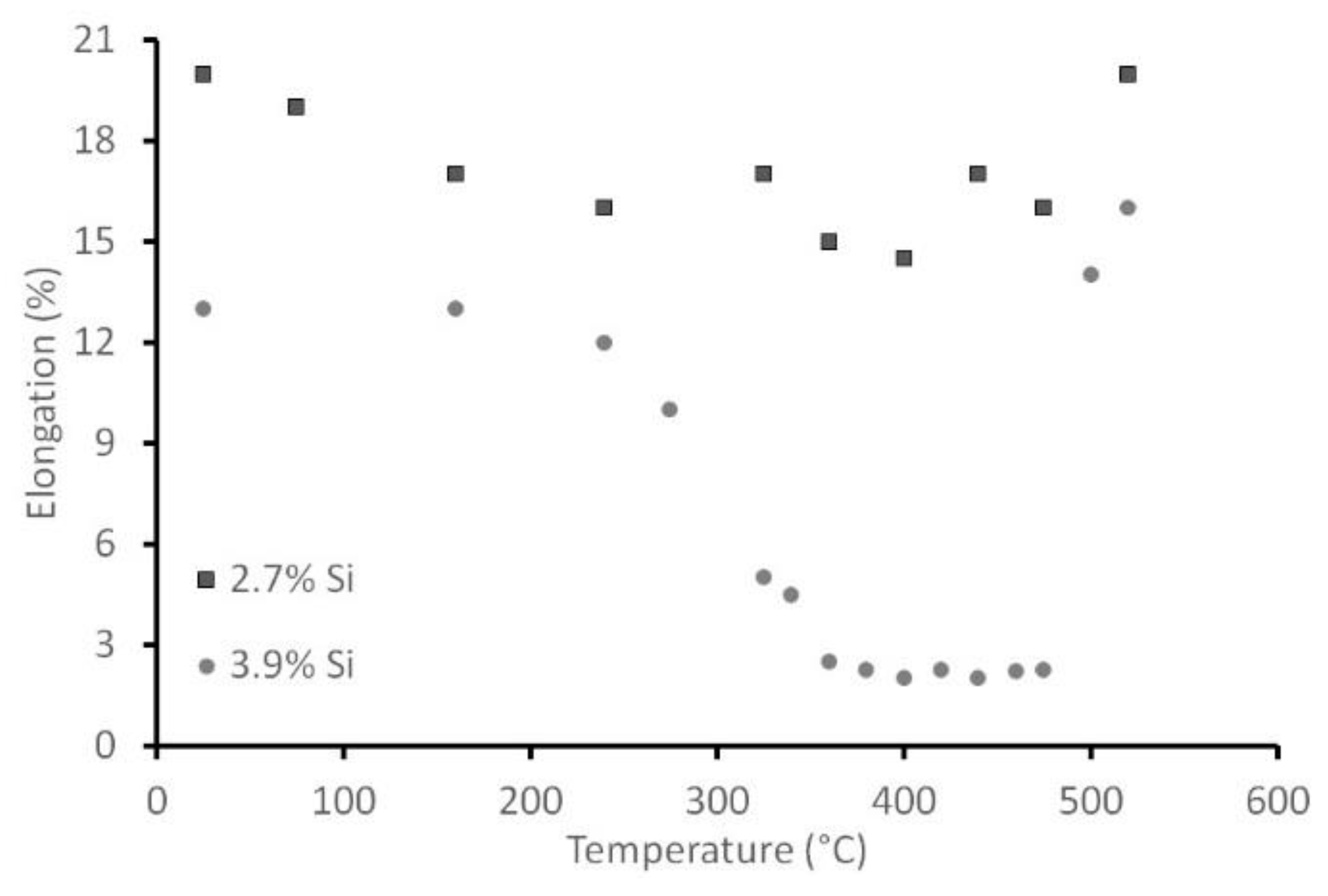

3. Effect of Elongation and Impact Properties on High Silicon Ductile Iron

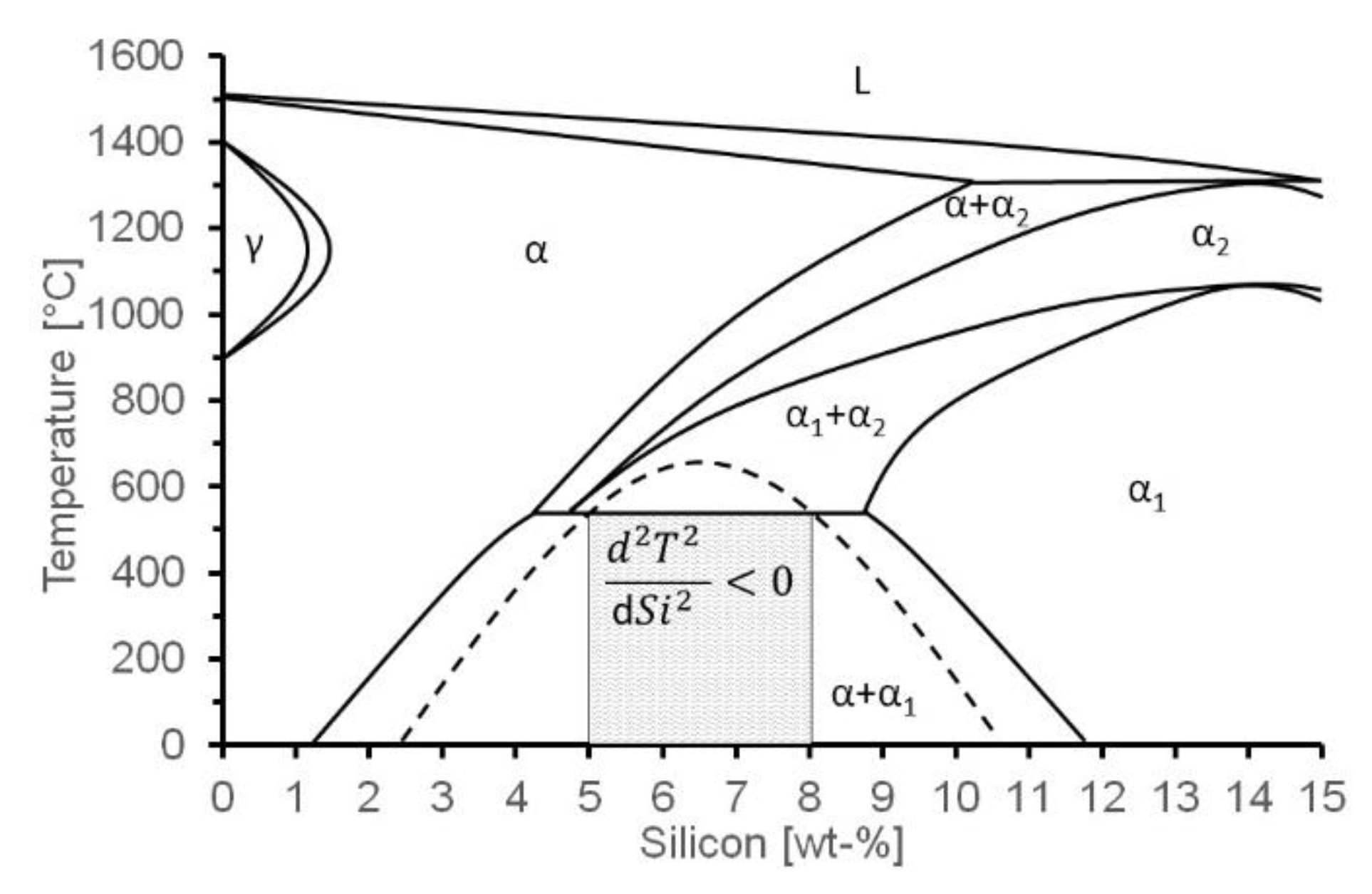

4. Deformation Mechanisms Related to High Silicon Ductile Iron

5. Graphite Degeneracy of High Silicon Iron

6. Graphite Morphology and Fatigue Strength

7. Thermal Conductivity of High Silicon Iron

8. Intergranular and Transgranular Embrittlement

9. Alleviating Intercritical Embrittlement in High Silicon Iron

10. Dross Formation in High Silicon Iron

11. Alloying Strategies for High Silicon Iron

12. Microcomposite Structurization of Ferrite in High Silicon Iron

13. Advanced Metallurgy of High Silicon Ductile Iron

14. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Morino, K.; Nisitani, H.; Nishimura, F. Study on Factors Controlling Low Cycle Fatigue Life. JSME Int. J. Ser. A 1998, 41, 243–251. [Google Scholar] [CrossRef] [Green Version]

- Flinn, R.A.; Reeseand, J.D.; Spindler, W.A. Risering of ductile iron. AFS Trans. 1955, 63, 720–725. [Google Scholar]

- Skaland, T. A new method for chill and shrinkage control in ladle treated ductile iron. Foundry Trade J. 2004, 178, 396–400. [Google Scholar]

- Siclari, R.; Margaria, T.; Berthelet, E.; Fourmann, J.; Koch, M. Micro-shrinkage in ductile Iron/mechanism and solution. In Proceedings of the 66th World Foundry Conference Instanbul, Istanbul, Turkey, 6–9 September 2004; pp. 863–873. [Google Scholar]

- De la Torre, U.; Loizaga, A.; Lacaze, J.; Sertucha, J. As cast high silicon ductile irons with optimised mechanical properties and remarkable fatigue properties. Mater. Sci. Technol. 2014, 30, 1425–1431. [Google Scholar] [CrossRef] [Green Version]

- Kanno, T. Problems and Improvements on the Production of Large Casting with Hi–Si Ductile Iron. Int. J. Met. 2018. [Google Scholar] [CrossRef]

- Hartung, C.; Logan, R.; Plowman, A.; Wilkinson, D.; Hoel, E.G.; Ott, E. Research on Solution Strengthened Ferritic Ductile Iron (SSFDI) Structure and Properties Using Different Treatment and Inoculation Materials. Int. J. Met. 2020, 14, 1195–1209. [Google Scholar] [CrossRef]

- Hammersberg, P.; Hamberg, K.; Borgström, H.; Lindkvist, J.; Björkegren, L.-E. Variation of Tensile Properties of High Silicon Ductile Iron. Mater. Sci. Forum 2018, 925, 280–287. [Google Scholar] [CrossRef] [Green Version]

- Nishi, S.; Kobayashi, T.; Taga, S. The effect of microstructure on the toughness of ferritic nodular cast iron. J. Mater. Sci. 1976, 11, 723–730. [Google Scholar] [CrossRef]

- Menk, W. A New High Strength High Ductile Nodular Iron. Mater. Sci. Forum 2018, 925, 224–230. [Google Scholar] [CrossRef] [Green Version]

- Ikeda, T.; Umetani, T.; Kai, N.; Noda, N.A.; Sano, Y. Strain rate & T insensitiveness of notch-bend strength for high Si ductile cast iron. ISIJ Int. 2016, 56, 868–874. [Google Scholar]

- Ikeda, T.; Umetani, T.; Kai, N.; Ogi, K.; Noda, N.A.; Sano, Y. Influence of %Si, strain rate & T on toughness & strength of SSF D. Mater. Trans. 2016, 57, 2132–2138. [Google Scholar]

- Ikeda, T.; Umetani, T.; Kai, N.; Ogi, K.; Akagi, D.; Noda, N.A.; Sano, Y. Notch strength of high silicon ductile cast iron and wide applicability to structural design (Japanese). Trans. JSME 2017, 83, 1–12. [Google Scholar]

- Ahmad, M.; Lindkvist, J.; Andersson, M. Influence of strain rate on ductile versus brittle fracture for ductile cast iron EN-GJS-500-14 in V-notch three-point bending tests. MATEC Web Conf. 2018, 188, 02019. [Google Scholar] [CrossRef]

- Johnson, W.C.; Kovacs, B.V. The effect of additives on the eutectoid transformation of ductile iron. Metall. Trans. 1978, 9, 219–229. [Google Scholar] [CrossRef]

- Guiva, V.A.; Lyubchenko, A.P.; Mozharov, M.V. Distribution of Cerium in Magnesium Cast Iron. Met. Sci. Heat Treat. 1970, 12, 994–997. [Google Scholar] [CrossRef]

- Spindler, W.A.; Flinn, R.A. Ductile Iron Cerium Distribution Determination by Autoradiographic Technique. AFS Trans. 1962, 86, 1017–1028. [Google Scholar]

- Sofue, M.; Okada, S.; Sasaki, T. High Quality Ductile Cast Iron with Improved Fatigue Strength. AFS Trans. 1978, 86, 173–182. [Google Scholar]

- Iacoviello, F.; di Bartolomeo, O.; di Cocco, V.; Piacente, V. Damaging micromechanisms in ferritic–pearlitic ductile cast irons. Mater. Sci. Eng. 2008, 478, 181–186. [Google Scholar] [CrossRef]

- Di Cocco, V.; Iacoviello, F.; Cavallini, M. Damaging micromechanisms characterization of a ferritic ductile cast iron. Eng. Fract. Mech. 2010, 77, 2016–2023. [Google Scholar] [CrossRef]

- Ghassemali, E.; Hernando, J.C.; Stefanescu, D.M.; Dioszegi, A.; Jarfors, A.E.; Dluhoš, J.; Petrenec, M. Revisiting the graphite nodule in ductile iron. Scr. Mater. 2019, 161, 66–69. [Google Scholar] [CrossRef]

- Lin, H.M.; Lui, T.S.; Chen, L.H. Effect of cyclic heating on ductility deterioration of high silicon ferritic spheroidal graphite cast iron by salt bath. Int. J. Cast Met. Res. 2003, 16, 487–495. [Google Scholar] [CrossRef]

- Cheng, C.P.; Lui, T.S.; Chen, L.H. Effect of Residual Magnesium Content on Thermal Fatigue Cracking Behavior of High-Silicon Spheroidal Graphite Cast Iron. Metall. Mater. Trans. A 1999, 30, 1549–1558. [Google Scholar] [CrossRef]

- Matsushita, T.; Ghassemali, E.; Saro, A.G.; Elmquist, L.; Jarfors, A.E.W. On Thermal Expansion and Density of CGI and SGI Cast Irons. Metals 2015, 5, 1000–1019. [Google Scholar] [CrossRef] [Green Version]

- Jalava, K.; Soivio, K.; Laine, J.; Orkas, J. Effect of Silicon and Microstructure on Spheroidal Graphite Cast Iron Thermal Conductivity at Elevated Temperatures. Int. J. Met. 2018, 12, 480–486. [Google Scholar] [CrossRef]

- Shiao, F.T.; Lui, T.S.; Chen, L.H.; Chen, S.F. Eutectic Cell Wall Morphology and Tensile Embrittlement in Ferritic Spheroidal Graphite Iron. Metall. Mater. Trans. A 1999, 30, 1775–1784. [Google Scholar] [CrossRef]

- Ghassemali, E.; Jarfors, A.E.; Diószegi, A. On the Formation of Micro-Shrinkage Porosities in Ductile Iron Cast Components. Metals 2018, 8, 551. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.F.; Lui, T.S.; Chen, L.H. The effect of phosphorus segregation on the intermediate-temperature embrittlement of ferritic, spheroidal graphite cast iron. Met. Mater. Trans. A 1994, 25, 557–561. [Google Scholar] [CrossRef]

- Chao, C.G.; Lui, T.S.; Hon, M.H. The Effect of Microstructure of Ferritic Spheroidal Graphite Cast Irons on Intergranular Fracture at Intermediate Temperatures. Metall. Trans. A 1989, 20, 431–436. [Google Scholar] [CrossRef]

- Bak, C.; Degois, M.; Schissler, J.M. Scanning Electron Microscope Examination of the Embrittlement of Ferritic Ductile Cast Iron. AFS Trans. 1980, 88, 301–312. [Google Scholar]

- Shiao, F.T.; Lui, T.S.; Chen, L.H.; Song, J.M. The relationship between inclusion clustering and embrittlement of ferritic spheroidal graphite cast iron at intermediate low temperatures. Int. J. Cast Met. Res. 2001, 14, 137–145. [Google Scholar] [CrossRef]

- Yanagisawa, O. Tensile and Fatigue Strength and Fracture of Spheroidal Graphite Cast Iron with Ferritic Matrix in the Temperature Range between Room Temperature and 500 °C. J. Jpn. Foundrymen’s Soc. 1980, 52, 331–336. [Google Scholar]

- Wright, R.N.; Farrell, T.R. Elevated temperature brittleness of ferritic ductile iron. Trans. Am. Foundrymen’s Soc. 1985, 93, 853–866. [Google Scholar]

- Li, D.; Sloss, C. Brittleness at Medium Temperatures of Spheroidal Graphite, Mixed Graphite, and Compacted Graphite High-Silicon Molybdenum Cast Irons. AFS Trans. 2015, 123, 243–253. [Google Scholar]

- Raymond, F.T. Ferritic Ductile Cast Iron for Elevated Temperature Applications; General Electric Company: New York, NY, USA, 1993. [Google Scholar]

- Li, D.; Nelson, L.R. Ferritic High-Silicon Cast Irons; Wescast Ind. Inc.: Stratford, ON, Canada, 2008. [Google Scholar]

- Toshitsugu, O.I.; Minoru, F. Mechanical Properties of Rapidly Solidified High Silicon Ductile Cast Iron of Hypereutectic Composition. J. Jpn. Foundrymen’s Soc. 1981, 53, 233–239. [Google Scholar]

- Ohide, T.; Ohira, G. On the Rapid Cooled Structure of High Silicon Cast Iron. J. Jpn. Foundrymen’s Soc. 1980, 52, 17–21. [Google Scholar]

- Jafar, K.-A.; Behnam, A.-A. Influence of Mold Preheating and Silicon Content on Microstructure and Casting Properties of Ductile Iron in Permanent Mold. J. Iron Steel Res. Int. 2011, 18, 34–39. [Google Scholar]

- Chao, C.G.; Lui, T.S.; Hon, M.H. The Effect of Triaxial Stress Field on Intermediate Temperature Embrittlement of Ferritic Spheroidal Graphite Cast Irons. Metall. Trans. A 1988, 19, 1213–1219. [Google Scholar] [CrossRef]

- Lin, Y.F.; Lui, T.S.; Chen, L.H. Study on the relationship between intermediate-temperature embrittlement and triaxial stress induced by the ellipsoidal graphite in hot-rolled ferritic spheroidal graphite cast iron. Metall. Mater. Trans. A 1995, 26, 1101–1106. [Google Scholar] [CrossRef]

- Stets, W.; Löblich, H.; Gassner, G.; Schumacher, P. Solution Strengthened Ferritic Ductile Cast Iron Properties, Production and Application. Int. J. Met. 2014, 8, 35–40. [Google Scholar] [CrossRef]

- Sil’man, G.I.; Kamynin, V.V.; Kharitonenko, S.A. Effect of silicon on the structure and properties of high-strength spherulitic iron. Met. Sci. Heat Treat. 2006, 48, 268–271. [Google Scholar] [CrossRef]

- Silman, G.I. Special features of microcomposite structurization of ferrite in iron with elevated silicon content. Met. Sci. Heat Treat. 2009, 51, 522–527. [Google Scholar] [CrossRef]

- Franzen, D.; Weiß, P.; Pustal, B.; Bührig-Polaczek, A. Influence of aluminium on silicon microsegregation in solution strengthened ductile iron. Mater. Sci. Technol. 2019, 35, 687–694. [Google Scholar] [CrossRef]

- Riebisch, M.; Weiß, P.; Cremer, C.; Aboulkhair, I.; Bührig-Polaczek, A. Properties and microstructure of copper-alloyed solid solution-strengthened ductile iron. Mater. Sci. Technol. 2018, 34, 725–730. [Google Scholar] [CrossRef]

- Weiß, P.; Tekavčič, A.; Bührig-Polaczek, A. Mechanistic approach to new design concepts for high silicon ductile iron. Mater. Sci. Eng. A 2018, 713, 67–74. [Google Scholar] [CrossRef]

- Doris, C.M. Research of Metallurgical Influences onto Mechanical Properties and Microstructure of Modern Cast Irons with Higher Silicon-Content. Diploma Thesis, Montanuniversität Leoben, ÖGI, Leoben, Austria, 2016. Available online: https://pure.unileoben.ac.at/portal/files/1876268/AC13288838n01vt.pdf (accessed on 6 April 2021).

- Rilwan, O. High Strength Solution-Strengthened Ferritic Ductile Cast Iron. Master’s Thesis, Alto University, Espoo, Finland, 2015. Available online: http://urn.fi/URN:NBN:fi:aalto-201509184417 (accessed on 6 April 2021).

- Riebisch, M.; Sönke, H.G.; Pustal, B.; Bührig-Polaczek, A. Influence of carbide-promoting elements on the pearlite content and the tensile properties of high silicon ssdi ductile iron. Int. J. Met. 2018, 12, 106–112. [Google Scholar] [CrossRef]

- Sameshima, D.; Nakamura, T.; Horikawa, N.; Oguma, H.; Endo, T. The Effects of Fracture Origin Size on Fatigue Properties of Ductile Cast Iron with Small Chill Structures. J. Solid Mech. Mater. Eng. 2009, 3, 440–448. [Google Scholar] [CrossRef] [Green Version]

- Sil’man, G.I.; Kamynin, V.V.; Tarasov, A.A. Effect of copper on structure formation in cast iron. Met. Sci. Heat Treat. 2003, 45, 254–258. [Google Scholar] [CrossRef]

- Simonovic, D.; Ande, C.K.; Duff, A.I.; Syahputra, F.; Sluiter, M.H.F. Diffusion of carbon in bcc Fe in the presence of Si. Phys. Rev. B 2010, 81, 054116. [Google Scholar] [CrossRef] [Green Version]

- Sil’man, G.I.; Zhukov, A.A. Heterogenization of ferrite in silicon cast irons. Met. Sci. Heat Treat. 1978, 20, 541–544. [Google Scholar] [CrossRef]

- Wittig, J.E.; Frommeyer, G. Deformation and fracture behavior of rapidly solidified and annealed iron-silicon alloys. Metall. Mater. Trans. A 2008, 39, 252–265. [Google Scholar] [CrossRef] [Green Version]

- Horopter, N. OED Online. Oxford University Press (Subscription Service). Available online: https://www.oed.com/view/Entry/88545?rskey=I7vLgF&result=2 (accessed on 26 September 2019).

- Hofmann, S.; Lejček, P. Segregation at special grain boundaries in fe-si alloy bicrystals. J. Phys. Colloq. 1990, 51, C1-179–C1-184. [Google Scholar] [CrossRef]

- Riebisch, M.; Seiler, C.; Pustal, B.; Bührig-Polaczek, A. Microstructure of as-cast high-silicon ductile iron produced via permanent mold casting. Int. J. Met. 2019, 13, 112–120. [Google Scholar] [CrossRef]

- Vazehrad, S.; Elfsberg, J.; Diószegi, A. Study of microstructure and silicon segregation in cast iron using color etching and electron microprobe analysis. Mater. Charact. 2015, 104, 132–138. [Google Scholar] [CrossRef]

- Ruxanda, R.E.; Stefanescu, D.M.; Piwonka, T.S. Microstructure Characterization of Ductile Thin Wall Iron Castings. AFS Trans. 2002, 110, 1131–1247. [Google Scholar]

| ID | C | Si | Mn | P | S | Cr | Ni | Cu | Al | Mg |

|---|---|---|---|---|---|---|---|---|---|---|

| HSI | 3.41 | 3.78 | 0.19 | 0.015 | 0.006 | 0.04 | 0.07 | 0.07 | 0.004 | 0.048 |

| GJS 400-18 | 3.69 | 2.18 | 0.14 | 0.027 | 0.006 | 0.03 | 0.027 | 0.06 | 0.009 | 0.038 |

| Application | Strain Rate | Temperature | R Parameter |

|---|---|---|---|

| Tensile testing | 10−4 to 10−5 s−1 | RT | 6864 to 8923 |

| Component use | 10−2 s−1 | −20 °C to RT | ~4500 to ~5500 |

| Crash test | 101 s−1 | RT | ~4500 |

| Impact testing | 102 s−1 | −40 °C to RT | 3524 to 4118 |

| ID | GR Area (%) | Gr Spacing (µm) | Gr Diam. (µm) | Grain Size (µm) | GB Area (µm2) | GB Length (µm) |

|---|---|---|---|---|---|---|

| GJS400-18 | 14.3 | 73.2 | 52.0 | 44.2 | 1130 | 40 |

| GJS500-7 | 13.6 | 70.6 | 40.4 | 40.3 | 7800 | 137 |

| GJS500-14 | 14.8 | 71.2 | 48.2 | 41.2 | 9350 | 167 |

| Type | C | Si | Mn | Mg | Pearlite (%) | Nodularity (%) | Nodules/mm2 | CE | Rp | Rm | A % | Part |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.0Si | 3.02 | 4.02 | 0.17 | 0.028 | 4.05 | 76 | 415 | 2 | 422 | 548 | 16.85 | Y2 |

| 0.5Mn | 2.95 | 3.82 | 0.52 | 0.045 | 3.93 | 88 | 421 | 6 | 434 | 562 | 16.89 | Y2 |

| 0.3Mo | 2.85 | 4.21 | 0.18 | 0.036 | 3.92 | 90 | 443 | 0.3 | 444 | 574 | 16.2 | Y2 |

| 0.2Nb | 2.89 | 3.88 | 0.19 | 0.04 | 3.88 | 87 | 414 | 0 | 446 | 570 | 17.77 | Y2 |

| 0.1Cr | 2.88 | 4.26 | 0.18 | 0.036 | 3.97 | 87 | 564 | 0.8 | 439 | 565 | 18.31 | Y2 |

| 4.0Si | 3.02 | 4.02 | 0.17 | 0.028 | 4.05 | 72 | 242 | 2.4 | 417 | 539 | 18.45 | Y4 |

| 0.5Mn | 2.95 | 3.82 | 0.52 | 0.045 | 3.93 | 86 | 268 | 4.5 | 427 | 555 | 17.19 | Y4 |

| 0.3Mo | 2.85 | 4.21 | 0.18 | 0.036 | 3.92 | 81 | 261 | 4.6 | 436 | 563 | 13.61 | Y4 |

| 0.2Nb | 2.89 | 3.88 | 0.19 | 0.04 | 3.88 | 83 | 240 | 0 | 439 | 565 | 17.01 | Y4 |

| 0.1Cr | 2.88 | 4.26 | 0.18 | 0.036 | 3.97 | 82 | 361 | 2.6 | 432 | 554 | 15.15 | Y4 |

| 4.0Si | 3.02 | 4.02 | 0.17 | 0.028 | 4.05 | 72 | 136 | 4.4 | 412 | 524 | 12.19 | Cyl. |

| 0.5Mn | 2.95 | 3.82 | 0.52 | 0.045 | 3.93 | 74 | 105 | 6.1 | 419 | 529 | 9.16 | Cyl. |

| 0.3Mo | 2.85 | 4.21 | 0.18 | 0.036 | 3.92 | 68 | 95 | 3.2 | 426 | 532 | 6.93 | Cyl. |

| 0.2Nb | 2.89 | 3.88 | 0.19 | 0.04 | 3.88 | 79 | 106 | 4 | 428 | 544 | 12.52 | Cyl. |

| 0.1Cr | 2.88 | 4.26 | 0.18 | 0.036 | 3.97 | 71 | 159 | 3.9 | 424 | 534 | 10.64 | Cyl. |

| Type | C | Si | Mn | P | S | Mg | Pearlite (%) | Nodularity (%) | Nodules/mm2 | CEV | Rp | Rm | A% |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1.0Co | 3.08 | 4.37 | 0.17 | 0.010 | 0.003 | 0.029 | 0 | 93 | 393 | 4.18 | 498 | 630 | 15 |

| 2.0Co | 3.07 | 4.22 | 0.17 | 0.011 | 0.004 | 0.031 | 4.5 | 97 | 314 | 4.13 | 486 | 623 | 17.3 |

| 0.5Mn | 3.06 | 4.36 | 0.46 | 0.005 | 0.006 | 0.041 | 0 | 98 | 420 | 4.15 | 501 | 628 | 17.2 |

| 1.0Mn | 3.05 | 4.31 | 0.88 | 0.004 | 0.008 | 0.038 | 2.2 | 98 | 283 | 4.13 | 503 | 629 | 17 |

| 1.0Ni | 3.02 | 4.16 | 0.11 | 0.007 | 0.007 | 0.032 | 0.6 | 75 | 281 | 4.06 | 480 | 602 | 11.8 |

| 1.3Ni | 3.01 | 4.36 | 0.12 | 0.004 | 0.007 | 0.038 | 0.9 | 97 | 383 | 4.1 | 524 | 677 | 13.7 |

| 0.03P | 3.1 | 4.29 | 0.38 | 0.032 | 0.01 | 0.04 | 0.4 | 98 | 264 | 4.19 | 497 | 616 | 17.7 |

| 0.5Cu | 2.99 | 4.26 | 0.13 | 0.015 | 0.003 | 0.035 | 0 | 97 | 379 | 4.06 | 502 | 620 | 17.8 |

| 0.7Cu | 3.11 | 4.26 | 0.26 | 0.034 | 0.007 | 0.038 | 9.1 | 99 | 271 | 4.19 | 418 | 632 | 14.6 |

| 0.5Mo | 2.96 | 3.95 | 0.12 | 0.006 | 0.005 | 0.039 | 6.9 | 96 | 329 | 3.95 | 492 | 591 | 17.3 |

| 1.0Mo | 3.12 | 3.93 | 0.11 | 0.006 | 0.006 | 0.037 | 18 | 98 | 267 | 4.11 | 464 | 600 | 15.9 |

| 0.4Cu | 2.79 | 4.32 | 0.17 | 0.043 | 0.011 | 0.033 | 17 | 80 | 404 | 3.89 | 454 | 596 | 18.4 |

| 4.4Si | 2.79 | 4.37 | 0.11 | 0.027 | 0.011 | 0.033 | 0 | 80 | 230 | 3.9 | 505 | 612 | 13.6 |

| 4.3Si | 2.74 | 4.39 | 0.29 | 0.018 | 0.003 | 0.03 | <2 | 86 | 286 | 3.96 | 498 | 612 | 17.8 |

| 2.0Co | 2.7 | 4.38 | 0.29 | 0.017 | 0.003 | 0.03 | <4 | 88 | 352 | 3.96 | 510 | 649 | 19 |

| 4.0Co | 2.65 | 4.36 | 0.30 | 0.016 | 0.002 | 0.03 | <4 | 88 | 392 | 3.96 | 525 | 686 | 19.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borgström, H. Influence of Strain Rate, Temperature and Chemical Composition on High Silicon Ductile Iron. Minerals 2021, 11, 391. https://doi.org/10.3390/min11040391

Borgström H. Influence of Strain Rate, Temperature and Chemical Composition on High Silicon Ductile Iron. Minerals. 2021; 11(4):391. https://doi.org/10.3390/min11040391

Chicago/Turabian StyleBorgström, Henrik. 2021. "Influence of Strain Rate, Temperature and Chemical Composition on High Silicon Ductile Iron" Minerals 11, no. 4: 391. https://doi.org/10.3390/min11040391