Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications

Abstract

1. Introduction

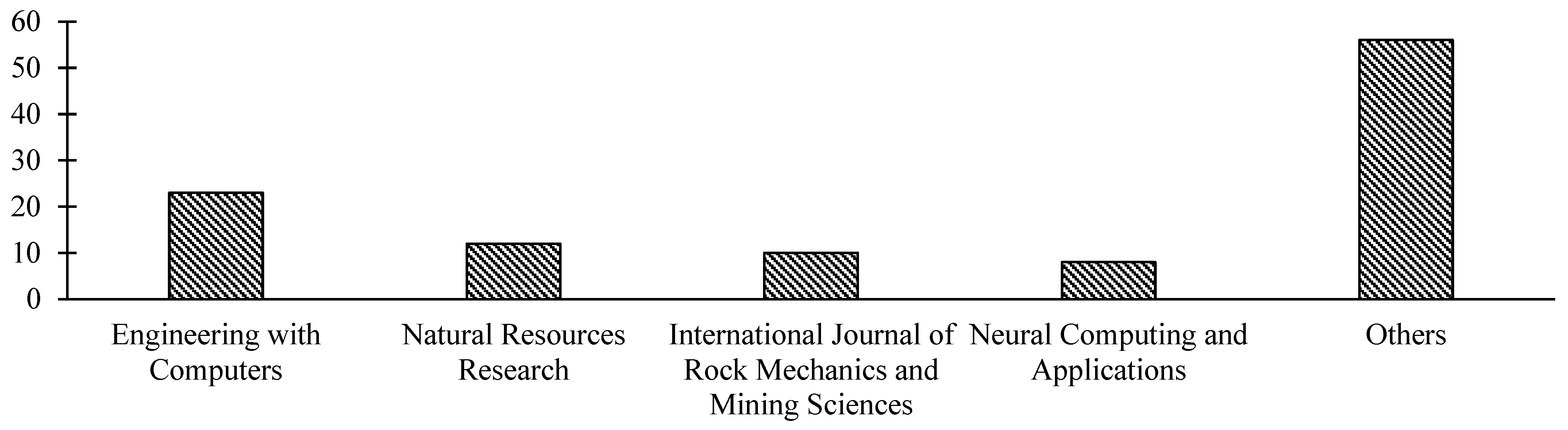

2. Methodology

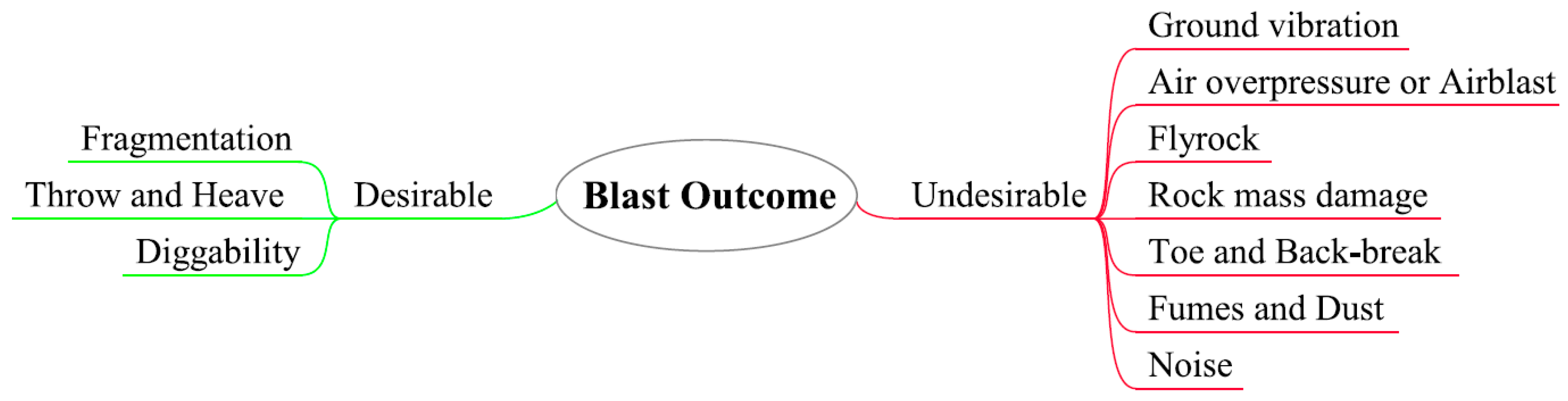

3. Rock Fragmentation and Blast Impact Phenomena

4. Empirical Models

5. Machine Learning Models

5.1. Ground Vibration

5.2. Airblast

5.3. Flyrock

6. Discussion and Future Trends

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yu, Z.; Shi, X.; Zhou, J.; Chen, X.; Qiu, X. Effective Assessment of Blast-Induced Ground Vibration Using an Optimized Random Forest Model Based on a Harris Hawks Optimization Algorithm. Appl. Sci. 2020, 10, 1403. [Google Scholar] [CrossRef]

- Bayat, P.; Monjezi, M.; Mehrdanesh, A.; Khandelwal, M. Blasting pattern optimization using gene expression programming and grasshopper optimization algorithm to minimise blast-induced ground vibrations. Eng. Comput. 2021, 1–10. [Google Scholar] [CrossRef]

- Abbaspour, H.; Drebenstedt, C.; Badroddin, M.; Maghaminik, A. Optimized design of drilling and blasting operations in open pit mines under technical and economic uncertainties by system dynamic modelling. Int. J. Min. Sci. Technol. 2018, 28, 839–848. [Google Scholar] [CrossRef]

- Zou, B.; Luo, Z.; Wang, J.; Hu, L. Development and Application of an Intelligent Evaluation and Control Platform for Tunnel Smooth Blasting. Geofluids 2021, 2021, 6669794. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Armaghani, D.J.; Haghighi, M.; Ghaleini, E.N. A neuro-genetic predictive model to approximate overbreak induced by drilling and blasting operation in tunnels. Bull. Int. Assoc. Eng. Geol. 2019, 78, 981–990. [Google Scholar] [CrossRef]

- Ocak, I.; Bilgin, N. Comparative studies on the performance of a roadheader, impact hammer and drilling and blasting method in the excavation of metro station tunnels in Istanbul. Tunn. Undergr. Space Technol. 2010, 25, 181–187. [Google Scholar] [CrossRef]

- Singh, R.K.; Sawmliana, C.; Hembram, P. Time-constrained demolition of a concrete cofferdam using controlled blasting. Innov. Infrastruct. Solut. 2020, 6, 20. [Google Scholar] [CrossRef]

- Tille, R.N. Artificial Neural Network Approach to Predict Blast-Induced Ground Vibration, Airblast and Rock Fragmentation. Master’s Thesis, Missouri University of Science and Technology, Rolla, MO, USA, 2016. [Google Scholar]

- Bilim, N.; Çelik, A.; Kekeç, B. A study in cost analysis of aggregate production as depending on drilling and blasting design. J. Afr. Earth Sci. 2017, 134, 564–572. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.N.; Gupta, N. Prediction of Blast-Induced Flyrock in Opencast Mines Using ANN and ANFIS. Geotech. Geol. Eng. 2015, 33, 875–891. [Google Scholar] [CrossRef]

- Monjezi, M.; Khoshalan, H.A.; Varjani, A.Y. Prediction of flyrock and backbreak in open pit blasting operation: A neuro-genetic approach. Arab. J. Geosci. 2012, 5, 441–448. [Google Scholar] [CrossRef]

- Murmu, S.; Maheshwari, P.; Verma, H.K. Empirical and probabilistic analysis of blast-induced ground vibrations. Int. J. Rock Mech. Min. Sci. 2018, 103, 267–274. [Google Scholar] [CrossRef]

- Karnen, B. Rock Blasting and Water Quality Measures that Can Be Taken to Protect Water Quality and Mitigate Impacts; New Hampshire Department of Environmental Services: Concord, NH, USA, 2010. [Google Scholar]

- Hawkins, J. Impacts of Blasting on Domestic Water Wells. In Workshop on Mountaintop Mining Effects on Groundwater; OSMRE: Washington DC, USA, 2000; pp. 1–10. [Google Scholar]

- Pelham, K.; Lane, D.; Smerenkanicz, J.R.; Miller, W. A Proactive Approach To Limit Potential Impacts from Blasting to Drinking Water Supply Wells. In Proceedings of the 60th Highway Geology Symposium, Windham, NH, USA, 29 September–1 October 2009; pp. 1–19. [Google Scholar]

- Birch, W.J.; Hosein, S.; Tompkin, S. Blasting in proximity to a world heritage site—A success story. In Proceedings of the 16th Extractive Industry Geology Conference, Portsmouth, UK, 8–11 September 2010; pp. 139–145. [Google Scholar]

- Varris, P.; Thorpe, M. Community concerns and input for open pit closure in a West African urban setting. In Proceedings of the Seventh International Conference on Mine Closure, Brisbane, Australia, 25–27 September 2012. [Google Scholar]

- Bansah, K.J.; Kansake, B.A.; Dumakor-Dupey, N.K. Baseline Structural Assessment: Mechanism for Mitigating Potential Conflicts Due to Blast Vibration. In Proceedings of the 4th UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, 3–6 August 2016; pp. 42–48. [Google Scholar]

- Torres, V.N.; Silveira, L.G.; Lopes, P.; Lima, H. Assessing and controlling of bench blasting-induced vibrations to minimize impacts to a neighboring community. J. Clean. Prod. 2018, 187, 514–524. [Google Scholar] [CrossRef]

- Agrawal, H.; Mishra, A.K. An innovative technique of simplified signature hole analysis for prediction of blast-induced ground vibration of multi-hole/production blast: An empirical analysis. Nat. Hazards 2020, 100, 111–132. [Google Scholar] [CrossRef]

- Karadogan, A.; Kahriman, A.; Ozer, U. A new damage criteria norm for blast-induced ground vibrations in Turkey. Arab. J. Geosci. 2013, 7, 1617–1626. [Google Scholar] [CrossRef]

- McKenzie, C.K. Flyrock range and fragment size prediction. In Proceedings of the 35th Annual Conference on Explosives and Blasting Technique, Denver, CO, USA, 8 – 11 February 2009; Volume 2. [Google Scholar]

- Blanchier, A. Quantification of the levels of risk of flyrock. In Rock Fragmentation by Blasting, Proceedings of the 10th International Symposium on Rock Fragmentation by Blasting, Fragblast 10, New Delhi, India,26–29 November 2012; CRC Press: Leiden, The Netherlands, 2013; pp. 549–553. [Google Scholar]

- Chiapetta, R.F.; Borg, D.G. Increasing productivity through field control and high-speed photography. In Proceedings of the 1st Int. Symp. on Rock Fragmentation by Blasting, Lulea, Sweden, 23–26 August 1983; pp. 301–331. [Google Scholar]

- Richards, A.; Moore, A. Flyrock control-by chance or design. In Proceedings of the Annual Conference on Explosives and Blasting Technique, New Orleans, LA, USA, 1–4 February 2004; Volume 1, pp. 335–348. [Google Scholar]

- Lundborg, N. The Probability of Flyrock; SveDeFo: Stockholm; Sweden, 1981. [Google Scholar]

- Bajpayee, T.S.; Verakis, H.C.; Lobb, T.E. Blasting safety–revisiting site security. In Proceedings of the 31st Annual Conference of Explosives and Blasting Technique, Orlando, FL, USA, 6–9 February 2005; pp. 1–13. Available online: https://www.cdc.gov/niosh/mining/userfiles/works/pdfs/bsrss.pdf (accessed on 5 January 2021).

- Bendezu, M.; Romanel, C.; Roehl, D. Finite element analysis of blast-induced fracture propagation in hard rocks. Comput. Struct. 2017, 182, 1–13. [Google Scholar] [CrossRef]

- Singh, T.N.; Singh, V. An intelligent approach to prediction and control ground vibration in mines. Geotech. Geol. Eng. 2005, 23, 249–262. [Google Scholar] [CrossRef]

- Singh, T.N.; Kanchan, R.; Verma, A.K. Prediction of Blast Induced Ground Vibration and Frequency Using an Artificial Intelligent Technique. Noise Vib. Worldw. 2004, 35, 7–15. [Google Scholar] [CrossRef]

- Rebala, G.; Ravi, A.; Churiwala, S. An Introduction to Machine Learning; Springer Science and Business Media LLC: Berlin, Germany, 2019. [Google Scholar]

- Das, A.; Sinha, S.; Ganguly, S. Development of a blast-induced vibration prediction model using an artificial neural network. J. South. Afr. Inst. Min. Metall. 2019, 119, 187–200. [Google Scholar] [CrossRef]

- Sanchidrián, J.A.; Segarra, P.; López, L.M. Energy components in rock blasting. Int. J. Rock Mech. Min. Sci. 2007, 44, 130–147. [Google Scholar] [CrossRef]

- Raina, A.K.; Murthy, V.M.S.R.; Soni, A.K. Flyrock in bench blasting: A comprehensive review. Bull. Int. Assoc. Eng. Geol. 2014, 73, 1199–1209. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T. Evaluation of blast-induced ground vibration predictors. Soil Dyn. Earthq. Eng. 2007, 27, 116–125. [Google Scholar] [CrossRef]

- Jimeno, C.L.; Jimeno, E.L.; Carcedo, F.J.A.; de Ramiro, Y.V. Drilling and Blasting of Rocks; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Changyou, L.; Jingxuan, Y.; Bin, Y. Rock-breaking mechanism and experimental analysis of confined blasting of borehole surrounding rock. Int. J. Min. Sci. Technol. 2017, 27, 795–801. [Google Scholar] [CrossRef]

- Cho, S.H.; Kaneko, K. Influence of the applied pressure waveform on the dynamic fracture processes in rock. Int. J. Rock Mech. Min. Sci. 2004, 41, 771–784. [Google Scholar] [CrossRef]

- Gui, Y.; Zhao, Z.; Zhou, H.; Goh, A.; Jayasinghe, L. Numerical Simulation of Rock Blasting Induced Free Field Vibration. Procedia Eng. 2017, 191, 451–457. [Google Scholar] [CrossRef]

- Cho, S.; Nakamura, Y.; Mohanty, B.; Yang, H.; Kaneko, K. Numerical study of fracture plane control in laboratory-scale blasting. Eng. Fract. Mech. 2008, 75, 3966–3984. [Google Scholar] [CrossRef]

- Fourney, W.L. 2—Mechanisms of Rock Fragmentation by Blasting. In Excavation, Support and Monitoring; Hudson, J.A., Ed.; Pergamon: Oxford, UK, 1993; pp. 39–69. [Google Scholar]

- Bhandari, S. Operations, Engineering Rock Blasting; A.A. Balkema: Rotterdam, The Netherlands, 1997. [Google Scholar]

- Kumar, R.; Choudhury, D.; Bhargava, K. Determination of blast-induced ground vibration equations for rocks using mechanical and geological properties. J. Rock Mech. Geotech. Eng. 2016, 8, 341–349. [Google Scholar] [CrossRef]

- Davies, B.I.; Farmer, P.A. Engineer, and Undefined 1964, Ground Vibration from Shallow Sub-Surface Blasts. Available online: https://trid.trb.org/view/140358 (accessed on 17 October 2020).

- Ragam, P.; Nimaje, D.S. Evaluation and prediction of blast-induced peak particle velocity using artificial neural network: A case study. Noise Vib. Worldw. 2018, 49, 111–119. [Google Scholar] [CrossRef]

- Monjezi, M.; Ghafurikalajahi, M.; Bahrami, A. Prediction of blast-induced ground vibration using artificial neural networks. Tunn. Undergr. Space Technol. 2011, 26, 46–50. [Google Scholar] [CrossRef]

- Rai, R.; Singh, T.N. A new predictor for ground vibration prediction and its comparison with other predictors. Indian J. Eng. Mater. Sci. 2004, 11, 178–184. [Google Scholar]

- Saadat, M.; Khandelwal, M.; Monjezi, M. An ANN-based approach to predict blast-induced ground vibration of Gol-E-Gohar iron ore mine, Iran. J. Rock Mech. Geotech. Eng. 2014, 6, 67–76. [Google Scholar] [CrossRef]

- Siskind, D.E.; Stagg, M.S.; Kopp, J.W.; Dowding, C.H. Structure Response and Damage Produced by Ground Vibration from Surface Mine Blasting; US Department of the Interior, Bureau of Mines: New York, NY, USA, 1980. [Google Scholar]

- Hasanipanah, M.; Armaghani, D.J.; Khamesi, H.; Amnieh, H.B.; Ghoraba, S. Several non-linear models in estimating air-overpressure resulting from mine blasting. Eng. Comput. 2016, 32, 441–455. [Google Scholar] [CrossRef]

- Bansah, N.K.; Arko-Gyimah, K.J.; Kansake, K.; Dumakor-Dupey, B.A. Mitigating Blast Vibration Impact. In Proceedings of the 4th UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, 3–6 August 2016; pp. 30–36. [Google Scholar]

- Nguyen, H.; Bui, X.-N. Soft computing models for predicting blast-induced air over-pressure: A novel artificial intelligence approach. Appl. Soft Comput. 2020, 92, 106292. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Mohamad, E.T.; Hajihassani, M.; Abad, S.V.A.N.K.; Marto, A.; Moghaddam, M.R. Evaluation and prediction of flyrock resulting from blasting operations using empirical and computational methods. Eng. Comput. 2016, 32, 109–121. [Google Scholar] [CrossRef]

- Gupta, R.N. Surface Blasting and Its Impact on Environment. Impact of Mining on Environment; Ashish Publishing House: New Delhi, India, 1980; pp. 23–24. [Google Scholar]

- Russell, S.; Norvig, P. Artificial Intelligence: A Modern Approach, 3rd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Wiley, V.; Lucas, T. Computer Vision and Image Processing: A Paper Review. Int. J. Artif. Intell. Res. 2018, 2, 22–31. [Google Scholar] [CrossRef]

- Tuşa, L.; Kern, M.; Khodadadzadeh, M.; Blannin, R.; Gloaguen, R.; Gutzmer, J. Evaluating the performance of hyperspectral short-wave infrared sensors for the pre-sorting of complex ores using machine learning methods. Miner. Eng. 2020, 146, 106150. [Google Scholar] [CrossRef]

- Guo, H.; Nguyen, H.; Vu, D.-A.; Bui, X.-N. Forecasting mining capital cost for open-pit mining projects based on artificial neural network approach. Resour. Policy 2019, 101474. [Google Scholar] [CrossRef]

- Zhang, H.; Nguyen, H.; Bui, X.-N.; Nguyen-Thoi, T.; Bui, T.-T.; Nguyen, N.; Vu, D.-A.; Mahesh, V.; Moayedi, H. Developing a novel artificial intelligence model to estimate the capital cost of mining projects using deep neural network-based ant colony optimization algorithm. Resour. Policy 2020, 66, 101604. [Google Scholar] [CrossRef]

- Simeone, O. A Very Brief Introduction to Machine Learning With Applications to Communication Systems. IEEE Trans. Cogn. Commun. Netw. 2018, 4, 648–664. [Google Scholar] [CrossRef]

- Awad, M.; Khanna, R. Efficient Learning Machines; Apress: Berkeley, CA, USA, 2015. [Google Scholar]

- Jakhar, D.; Kaur, I. Artificial intelligence, machine learning and deep learning: Definitions and differences. Clin. Exp. Dermatol. 2020, 45, 131–132. [Google Scholar] [CrossRef]

- Vieira, S.; Pinaya, W.; Mechelli, A. Introduction to machine learning. In Machine Learning; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 1–20. [Google Scholar]

- Kubat, M. An Introduction to Machine Learning; Springer: Cham, Switzerland, 2017. [Google Scholar]

- Alpaydin, E. Introduction to Machine Learning Ethem Alpaydin, 3rd ed.; MIT Press: Cambridge, MA, USA, 2014. [Google Scholar]

- Shanmuganathan, S. Artificial neural network modelling: An introduction. In Studies in Computational Intelligence; Springer: Cham, Switzerland, 2016. [Google Scholar]

- Kelleher, J.D.; Mac Namee, B.; D’arcy, A. Fundamentals of Machine Learning for Predictive Data Analytics: Algorithms, Worked Examples, and Case Studies; MIT Press: Cambridge, MA, USA, 2015. [Google Scholar]

- Samuel, A.L. Some Studies in Machine Learning. IBM J. Res. Dev. 1959, 3, 210–229. [Google Scholar] [CrossRef]

- Tong, J.C.; Ranganathan, S. Computational T cell vaccine design. In Computer-Aided Vaccine Design; Elsevier: Amsterdam, The Netherlands, 2013; pp. 59–86. [Google Scholar]

- Nguyen, H.; Bui, X.-N.; Choi, Y.; Lee, C.W.; Armaghani, D.J. A Novel Combination of Whale Optimization Algorithm and Support Vector Machine with Different Kernel Functions for Prediction of Blasting-Induced Fly-Rock in Quarry Mines. Nat. Resour. Res. 2021, 30, 191–207. [Google Scholar] [CrossRef]

- Pisner, D.A.; Schnyer, D.M. Chapter 6—Support Vector Machine. Machine Learning: Methods and Applications to Brain Disorders; Mechelli, A., Vieira, S.B.T.-M.L., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 101–121. [Google Scholar]

- Nguyen, H.; Bui, X.-N. Predicting Blast-Induced Air Overpressure: A Robust Artificial Intelligence System Based on Artificial Neural Networks and Random Forest. Nat. Resour. Res. 2019, 28, 893–907. [Google Scholar] [CrossRef]

- Misra, S.; Li, H. Chapter 9—Noninvasive Fracture Characterization Based on the Classification of Sonic Wave Travel Times. Machine Learning for Subsurface Characterization; Misra, S., Li, H., He, J., Eds.; Gulf Professional Publishing: Huston, TX, USA, 2020; pp. 243–287. [Google Scholar]

- Bui, X.-N.; Nguyen, H.; Le, H.-A.; Bui, H.-B.; Do, N.-H. Prediction of Blast-induced Air Over-pressure in Open-Pit Mine: Assessment of Different Artificial Intelligence Techniques. Nat. Resour. Res. 2019, 29, 571–591. [Google Scholar] [CrossRef]

- Rasmussen, C.E. Gaussian Processes in Machine Learning. In Summer School on Machine Learning; Springer: Cham, Switzerland, 2004; pp. 63–71. [Google Scholar] [CrossRef]

- Zimmermann, H.-J. Fuzzy set theory. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 317–332. [Google Scholar] [CrossRef]

- Gupta, M.; Kiszka, J. Fuzzy Sets, Fuzzy Logic, and Fuzzy Systems; Elsevier BV: Amsterdam, The Netherlands, 2003; pp. 355–367. [Google Scholar]

- Fişne, A.; Kuzu, C.; Hüdaverdi, T. Prediction of environmental impacts of quarry blasting operation using fuzzy logic. Environ. Monit. Assess. 2010, 174, 461–470. [Google Scholar] [CrossRef] [PubMed]

- Monjezi, M.; Rezaei, M.; Yazdian, A. Prediction of backbreak in open-pit blasting using fuzzy set theory. Expert Syst. Appl. 2010, 37, 2637–2643. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T. Prediction of blast induced ground vibrations and frequency in opencast mine: A neural network approach. J. Sound Vib. 2006, 289, 711–725. [Google Scholar] [CrossRef]

- Yan, Y.; Hou, X.; Fei, H. Review of predicting the blast-induced ground vibrations to reduce impacts on ambient urban communities. J. Clean. Prod. 2020, 260, 121135. [Google Scholar] [CrossRef]

- Amnieh, H.B.; Mozdianfard, M.; Siamaki, A. Predicting of blasting vibrations in Sarcheshmeh copper mine by neural network. Saf. Sci. 2010, 48, 319–325. [Google Scholar] [CrossRef]

- Rajabi, A.M.; Vafaee, A. Prediction of blast-induced ground vibration using empirical models and artificial neural network (Bakhtiari Dam access tunnel, as a case study). J. Vib. Control. 2020, 26, 520–531. [Google Scholar] [CrossRef]

- Dehghani, H.; Ataee-Pour, M. Development of a model to predict peak particle velocity in a blasting operation. Int. J. Rock Mech. Min. Sci. 2011, 48, 51–58. [Google Scholar] [CrossRef]

- Taqieddin, S.A.; Ash, R.; Smith, N.; Brinkmann, J. Effects of some blast design parameters on ground vibrations at short scaled distances. Min. Sci. Technol. 1991, 12, 167–178. [Google Scholar] [CrossRef]

- Rathore, S.; Jain, S.; Parik, S. Comparison of two near-field blast vibration estimation models: A theoretical study. Rock Fragmentation by Blasting; CRC Press: Leiden, The Netherlands, 2012; pp. 485–492. [Google Scholar]

- Álvarez-Vigil, A.; González-Nicieza, C.; Gayarre, F.L.; Álvarez-Fernández, M. Predicting blasting propagation velocity and vibration frequency using artificial neural networks. Int. J. Rock Mech. Min. Sci. 2012, 55, 108–116. [Google Scholar] [CrossRef]

- Görgülü, K.; Arpaz, E.; Demirci, A.; Koçaslan, A.; Dilmaç, M.K.; Yüksek, A.G. Investigation of blast-induced ground vibrations in the Tülü boron open pit mine. Bull. Int. Assoc. Eng. Geol. 2013, 72, 555–564. [Google Scholar] [CrossRef]

- Lawal, A.I.; Idris, M.A. An artificial neural network-based mathematical model for the prediction of blast-induced ground vibrations. Int. J. Environ. Stud. 2019, 77, 318–334. [Google Scholar] [CrossRef]

- Monjezi, M.; Bahrami, A.; Varjani, A.Y. Simultaneous prediction of fragmentation and flyrock in blasting operation using artificial neural networks. Int. J. Rock Mech. Min. Sci. 2010, 47, 476–480. [Google Scholar] [CrossRef]

- Singh, T.N.; Kanchan, R.; Saigal, K.; Verma, A.K. Prediction of p-wave velocity and anisotropic property of rock using artificial neural network technique. J. Sci. Ind. Res. 2004, 63, 32–38. [Google Scholar]

- Khandelwal, M.; Singh, T. Prediction of blast-induced ground vibration using artificial neural network. Int. J. Rock Mech. Min. Sci. 2009, 46, 1214–1222. [Google Scholar] [CrossRef]

- Mohamed, M.T. Artificial neural network for prediction and control of blasting vibrations in Assiut (Egypt) limestone quarry. Int. J. Rock Mech. Min. Sci. 2009, 46, 426–431. [Google Scholar] [CrossRef]

- Khandelwal, M.; Kumar, D.L.; Yellishetty, M. Application of soft computing to predict blast-induced ground vibration. Eng. Comput. 2009, 27, 117–125. [Google Scholar] [CrossRef]

- Monjezi, M.; Bahrami, A.; Varjani, A.Y.; Sayadi, A.R. Prediction and controlling of flyrock in blasting operation using artificial neural network. Arab. J. Geosci. 2009, 4, 421–425. [Google Scholar] [CrossRef]

- Arthur, C.K.; Temeng, V.A.; Ziggah, Y.Y. Soft computing-based technique as a predictive tool to estimate blast-induced ground vibration. J. Sustain. Min. 2019, 18, 287–296. [Google Scholar] [CrossRef]

- Xue, X.; Yang, X. Predicting blast-induced ground vibration using general regression neural network. J. Vib. Control. 2013, 20, 1512–1519. [Google Scholar] [CrossRef]

- Nguyen, H.; Bui, X.-N.; Bui, H.-B.; Mai, N.-L. A comparative study of artificial neural networks in predicting blast-induced air-blast overpressure at Deo Nai open-pit coal mine, Vietnam. Neural Comput. Appl. 2020, 32, 3939–3955. [Google Scholar] [CrossRef]

- Dreiseitl, S.; Ohno-Machado, L. Logistic regression and artificial neural network classification models: A methodology review. J. Biomed. Inform. 2002, 35, 352–359. [Google Scholar] [CrossRef]

- Piotrowski, A.P.; Napiorkowski, J. A comparison of methods to avoid overfitting in neural networks training in the case of catchment runoff modelling. J. Hydrol. 2013, 476, 97–111. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhou, J.; Khandelwal, M.; Yang, H.; Yang, P.; Li, C. Performance evaluation of hybrid WOA-XGBoost, GWO-XGBoost and BO-XGBoost models to predict blast-induced ground vibration. Eng. Comput. 2021, 1–18. [Google Scholar] [CrossRef]

- Paneiro, G.; Durão, F.O.; Silva, M.C.E.; Bernardo, P.A. Neural network approach based on a bilevel optimization for the prediction of underground blast-induced ground vibration amplitudes. Neural Comput. Appl. 2019, 32, 5975–5987. [Google Scholar] [CrossRef]

- Amiri, M.; Hasanipanah, M.; Amnieh, H.B. Predicting ground vibration induced by rock blasting using a novel hybrid of neural network and itemset mining. Neural Comput. Appl. 2020, 32, 14681–14699. [Google Scholar] [CrossRef]

- Shi, X.-Z.; Zhou, J.; Wu, B.-B.; Huang, D.; Wei, W. Support vector machines approach to mean particle size of rock fragmentation due to bench blasting prediction. Trans. Nonferrous Met. Soc. China 2012, 22, 432–441. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Monjezi, M.; Shahnazar, A.; Armaghani, D.J.; Farazmand, A. Feasibility of indirect determination of blast induced ground vibration based on support vector machine. Measurement 2015, 75, 289–297. [Google Scholar] [CrossRef]

- Dindarloo, S. Peak particle velocity prediction using support vector machines: A surface blasting case study. J. South. Afr. Inst. Min. Metall. 2015, 115, 637–643. [Google Scholar] [CrossRef]

- Khandelwal, M. Evaluation and prediction of blast-induced ground vibration using support vector machine. Int. J. Rock Mech. Min. Sci. 2010, 47, 509–516. [Google Scholar] [CrossRef]

- Khandelwal, M. Blast-induced ground vibration prediction using support vector machine. Eng. Comput. 2011, 27, 193–200. [Google Scholar] [CrossRef]

- Verma, A.K.; Singh, T.N. Comparative study of cognitive systems for ground vibration measurements. Neural Comput. Appl. 2012, 22, 341–350. [Google Scholar] [CrossRef]

- Temeng, V.A.; Arthur, C.K.; Ziggah, Y.Y. Suitability assessment of different vector machine regression techniques for blast-induced ground vibration prediction in Ghana. Model. Earth Syst. Environ. 2021, 1–13. [Google Scholar] [CrossRef]

- Mohammadnejad, M.; Gholami, R.; Ramezanzadeh, A.; Jalali, M.E. Prediction of blast-induced vibrations in limestone quarries using Support Vector Machine. J. Vib. Control. 2012, 18, 1322–1329. [Google Scholar] [CrossRef]

- Fattahi, H.; Hasanipanah, M. Prediction of Blast-Induced Ground Vibration in a Mine Using Relevance Vector Regression Optimized by Metaheuristic Algorithms. Nat. Resour. Res. 2021, 30, 1849–1863. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Naderi, R.; Kashir, J.; Noorani, S.A.; Qaleh, A.Z.A. Prediction of blast-produced ground vibration using particle swarm optimization. Eng. Comput. 2017, 33, 173–179. [Google Scholar] [CrossRef]

- Shahnazar, A.; Rad, H.N.; Hasanipanah, M.; Tahir, M.M.; Armaghani, D.J.; Ghoroqi, M. A new developed approach for the prediction of ground vibration using a hybrid PSO-optimized ANFIS-based model. Environ. Earth Sci. 2017, 76, 527. [Google Scholar] [CrossRef]

- Arthur, C.K.; Temeng, V.A.; Ziggah, Y.Y. Novel approach to predicting blast-induced ground vibration using Gaussian process regression. Eng. Comput. 2020, 36, 29–42. [Google Scholar] [CrossRef]

- Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Pham, B.T. Prediction of ground vibration induced by blasting operations through the use of the Bayesian Network and random forest models. Soil Dyn. Earthq. Eng. 2020, 139, 106390. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Armaghani, D.J.; Tahir, M.M.; Pham, B.T.; Van Huynh, V. A Combination of Feature Selection and Random Forest Techniques to Solve a Problem Related to Blast-Induced Ground Vibration. Appl. Sci. 2020, 10, 869. [Google Scholar] [CrossRef]

- Taheri, K.; Hasanipanah, M.; Golzar, S.B.; Majid, M.Z.A. A hybrid artificial bee colony algorithm-artificial neural network for forecasting the blast-produced ground vibration. Eng. Comput. 2016, 33, 689–700. [Google Scholar] [CrossRef]

- Huang, J.; Koopialipoor, M.; Armaghani, D.J. A combination of fuzzy Delphi method and hybrid ANN-based systems to forecast ground vibration resulting from blasting. Sci. Rep. 2020, 10, 19397. [Google Scholar] [CrossRef]

- Fouladgar, N.; Hasanipanah, M.; Amnieh, H.B. Application of cuckoo search algorithm to estimate peak particle velocity in mine blasting. Eng. Comput. 2016, 33, 181–189. [Google Scholar] [CrossRef]

- Arthur, C.K.; Temeng, V.A.; Ziggah, Y.Y. A Self-adaptive differential evolutionary extreme learning machine (SaDE-ELM): A novel approach to blast-induced ground vibration prediction. SN Appl. Sci. 2020, 2, 1845. [Google Scholar] [CrossRef]

- Ding, Z.; Nguyen, H.; Bui, X.-N.; Zhou, J.; Moayedi, H. Computational Intelligence Model for Estimating Intensity of Blast-Induced Ground Vibration in a Mine Based on Imperialist Competitive and Extreme Gradient Boosting Algorithms. Nat. Resour. Res. 2020, 29, 751–769. [Google Scholar] [CrossRef]

- Shang, Y.; Nguyen, H.; Bui, X.-N.; Tran, Q.-H.; Moayedi, H. A Novel Artificial Intelligence Approach to Predict Blast-Induced Ground Vibration in Open-Pit Mines Based on the Firefly Algorithm and Artificial Neural Network. Nat. Resour. Res. 2020, 29, 723–737. [Google Scholar] [CrossRef]

- Ding, X.; Hasanipanah, M.; Rad, H.N.; Zhou, W. Predicting the blast-induced vibration velocity using a bagged support vector regression optimized with firefly algorithm. Eng. Comput. 2020, 1–12. [Google Scholar] [CrossRef]

- Bayat, P.; Monjezi, M.; Rezakhah, M.; Armaghani, D.J. Artificial Neural Network and Firefly Algorithm for Estimation and Minimization of Ground Vibration Induced by Blasting in a Mine. Nat. Resour. Res. 2020, 29, 4121–4132. [Google Scholar] [CrossRef]

- Chen, W.; Hasanipanah, M.; Rad, H.N.; Armaghani, D.J.; Tahir, M.M. A new design of evolutionary hybrid optimization of SVR model in predicting the blast-induced ground vibration. Eng. Comput. 2021, 37, 1455–1471. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Shahnazar, A.; Amnieh, H.B.; Armaghani, D.J. Prediction of air-overpressure caused by mine blasting using a new hybrid PSO–SVR model. Eng. Comput. 2017, 33, 23–31. [Google Scholar] [CrossRef]

- Khandelwal, M.; Singh, T.N. Prediction of Blast Induced Air Overpressure in Opencast Mine. Noise Vib. Worldw. 2005, 36, 7–16. [Google Scholar] [CrossRef]

- Mohamed, M.T. Performance of fuzzy logic and artificial neural network in prediction of ground and air vibrations. Int. J. Rock Mech. Min. Sci. 2011, 48, 845–851. [Google Scholar] [CrossRef]

- Khandelwal, M.; Kankar, P.K. Prediction of blast-induced air overpressure using support vector machine. Arab. J. Geosci. 2009, 4, 427–433. [Google Scholar] [CrossRef]

- Mohamad, E.T.; Armaghani, D.J.; Hasanipanah, M.; Murlidhar, B.R.; Alel, M.N.A. Estimation of air-overpressure produced by blasting operation through a neuro-genetic technique. Environ. Earth Sci. 2016, 75, 174. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hasanipanah, M.; Mahdiyar, A.; Majid, M.Z.A.; Amnieh, H.B.; Tahir, M.M.D. Airblast prediction through a hybrid genetic algorithm-ANN model. Neural Comput. Appl. 2018, 29, 619–629. [Google Scholar] [CrossRef]

- Hajihassani, M.; Armaghani, D.J.; Sohaei, H.; Mohamad, E.T.; Marto, A. Prediction of airblast-overpressure induced by blasting using a hybrid artificial neural network and particle swarm optimization. Appl. Acoust. 2014, 80, 57–67. [Google Scholar] [CrossRef]

- AminShokravi, A.; Eskandar, H.; Derakhsh, A.M.; Rad, H.N.; Ghanadi, A. The potential application of particle swarm optimization algorithm for forecasting the air-overpressure induced by mine blasting. Eng. Comput. 2018, 34, 277–285. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hajihassani, M.; Marto, A.; Faradonbeh, R.S.; Mohamad, E.T. Prediction of blast-induced air overpressure: A hybrid AI-based predictive model. Environ. Monit. Assess. 2015, 187, 666. [Google Scholar] [CrossRef]

- Nguyen, H.; Bui, X.-N.; Tran, Q.-H.; Van Hoa, P.; Nguyen, D.-A.; Hoang, B.B.; Le, Q.-T.; Do, N.-H.; Bao, T.D.; Bui, H.-B.; et al. A comparative study of empirical and ensemble machine learning algorithms in predicting air over-pressure in open-pit coal mine. Acta Geophys. 2020, 68, 325–336. [Google Scholar] [CrossRef]

- The Institute of Makers of Explosives. Glossary of Commercial Explosives Industry Terms; IME: Washington, DC, USA, 1997. [Google Scholar]

- Amini, H.; Gholami, R.; Monjezi, M.; Torabi, S.R.; Zadhesh, J. Evaluation of flyrock phenomenon due to blasting operation by support vector machine. Neural Comput. Appl. 2011, 21, 2077–2085. [Google Scholar] [CrossRef]

- Stojadinovic, S.; Pantovic, R.; Zikic, M. Prediction of flyrock trajectories for forensic applications using ballistic flight equations. Int. J. Rock Mech. Min. Sci. 2011, 48, 1086–1094. [Google Scholar] [CrossRef]

- Li, D.; Koopialipoor, M.; Armaghani, D.J. A Combination of Fuzzy Delphi Method and ANN-based Models to Investigate Factors of Flyrock Induced by Mine Blasting. Nat. Resour. Res. 2021, 30, 1905–1924. [Google Scholar] [CrossRef]

- Manoj, K.; Monjezi, M. Prediction of flyrock in open pit blasting operation using machine learning method. Int. J. Min. Sci. Technol. 2013, 23, 313–316. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Hasanipanah, M.; Amnieh, H.B.; Mohamad, E.T. Feasibility of ICA in approximating ground vibration resulting from mine blasting. Neural Comput. Appl. 2018, 29, 457–465. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Armaghani, D.J.; Amnieh, H.B.; Majid, M.Z.A.; Tahir, M.M.D. Application of PSO to develop a powerful equation for prediction of flyrock due to blasting. Neural Comput. Appl. 2017, 28, 1043–1050. [Google Scholar] [CrossRef]

- Lu, X.; Hasanipanah, M.; Brindhadevi, K.; Amnieh, H.B.; Khalafi, S. ORELM: A Novel Machine Learning Approach for Prediction of Flyrock in Mine Blasting. Nat. Resour. Res. 2020, 29, 641–654. [Google Scholar] [CrossRef]

- Armaghani, D.J.; Koopialipoor, M.; Bahri, M.; Hasanipanah, M.; Tahir, M.M. A SVR-GWO technique to minimize flyrock distance resulting from blasting. Bull. Int. Assoc. Eng. Geol. 2020, 79, 1–17. [Google Scholar] [CrossRef]

- Murlidhar, B.R.; Kumar, D.; Armaghani, D.J.; Mohamad, E.T.; Roy, B.; Pham, B.T. A Novel Intelligent ELM-BBO Technique for Predicting Distance of Mine Blasting-Induced Flyrock. Nat. Resour. Res. 2020, 29, 4103–4120. [Google Scholar] [CrossRef]

- Dehghani, H.; Pourzafar, M.; Zadeh, M.A. Prediction and minimization of blast-induced flyrock using gene expression programming and cuckoo optimization algorithm. Environ. Earth Sci. 2021, 80, 12. [Google Scholar] [CrossRef]

- Vasović, D.; Kostić, S.; Ravilić, M.; Trajković, S. Environmental impact of blasting at Drenovac limestone quarry (Serbia). Environ. Earth Sci. 2014, 72, 3915–3928. [Google Scholar] [CrossRef]

- Taylor, S. Tahoe Suspends Mining at Peru Operation after Protest. Reuters. 2018. Available online: https://www.reuters.com/article/us-tahoe-resources-protest-peru/tahoe-suspends-mining-at-peru-operation-after-protest-idUSKCN1LG21G (accessed on 14 January 2021).

- Jha, A.; Rajagopal, S.; Sahu, R.; Purushotham, T. Detection of Geological Features using Aerial Image Analysis and Machine Learning. In Proceedings of the 46th Annual Conference on Explosives & Blasting Technique, Denver, CO, USA, 26–29 January 2020; pp. 1–11. [Google Scholar]

- Monjezi, M.; Baghestani, M.; Faradonbeh, R.S.; Saghand, M.P.; Armaghani, D.J. Modification and prediction of blast-induced ground vibrations based on both empirical and computational techniques. Eng. Comput. 2016, 32, 717–728. [Google Scholar] [CrossRef]

- Hudaverdi, T. Application of multivariate analysis for prediction of blast-induced ground vibrations. Soil Dyn. Earthq. Eng. 2012, 43, 300–308. [Google Scholar] [CrossRef]

- Faradonbeh, R.S.; Monjezi, M. Prediction and minimization of blast-induced ground vibration using two robust meta-heuristic algorithms. Eng. Comput. 2017, 33, 835–851. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Fallah, A.; Armaghani, D.J.; Azizi, A.; Mohamad, E.T. Three hybrid intelligent models in estimating flyrock distance resulting from blasting. Eng. Comput. 2019, 35, 243–256. [Google Scholar] [CrossRef]

- Monjezi, M.; Mohamadi, H.A.; Barati, B.; Khandelwal, M. Application of soft computing in predicting rock fragmentation to reduce environmental blasting side effects. Arab. J. Geosci. 2012, 7, 505–511. [Google Scholar] [CrossRef]

- Monjezi, M.; Mehrdanesh, A.; Malek, A.; Khandelwal, M. Evaluation of effect of blast design parameters on flyrock using artificial neural networks. Neural Comput. Appl. 2013, 23, 349–356. [Google Scholar] [CrossRef]

- Guo, H.; Zhou, J.; Koopialipoor, M.; Armaghani, D.J.; Tahir, M.M. Deep neural network and whale optimization algorithm to assess flyrock induced by blasting. Eng. Comput. 2021, 37, 173–186. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.; Raina, A. Prediction of blast-induced flyrock in Indian limestone mines using neural networks. J. Rock Mech. Geotech. Eng. 2014, 6, 447–454. [Google Scholar] [CrossRef]

- Bahrami, A.; Monjezi, M.; Goshtasbi, K.; Ghazvinian, A. Prediction of rock fragmentation due to blasting using artificial neural network. Eng. Comput. 2010, 27, 177–181. [Google Scholar] [CrossRef]

- Sayadi, A.R.; Monjezi, M.; Talebi, N.; Khandelwal, M. A comparative study on the application of various artificial neural networks to simultaneous prediction of rock fragmentation and backbreak. J. Rock Mech. Geotech. Eng. 2013, 5, 318–324. [Google Scholar] [CrossRef]

- Enayatollahi, I.; Bazzazi, A.A.; Asadi, A. Comparison Between Neural Networks and Multiple Regression Analysis to Predict Rock Fragmentation in Open-Pit Mines. Rock Mech. Rock Eng. 2014, 47, 799–807. [Google Scholar] [CrossRef]

- Ebrahimi, E.; Monjezi, M.; Khalesi, M.R.; Armaghani, D.J. Prediction and optimization of back-break and rock fragmentation using an artificial neural network and a bee colony algorithm. Bull. Int. Assoc. Eng. Geol. 2016, 75, 27–36. [Google Scholar] [CrossRef]

- Monjezi, M.; Amiri, H.; Farrokhi, A.; Goshtasbi, K. Prediction of Rock Fragmentation Due to Blasting in Sarcheshmeh Copper Mine Using Artificial Neural Networks. Geotech. Geol. Eng. 2010, 28, 423–430. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, A.K.; Choudhary, B.S. Prediction of back break in blasting using random decision trees. Eng. Comput. 2021, 1–7. [Google Scholar] [CrossRef]

- Monjezi, H.D.M. Evaluation of effect of blasting pattern parameters on back break using neural networks. Int. J. Rock Mech. Min. Sci. 2008, 45, 1446–1453. [Google Scholar] [CrossRef]

- Temeng, V.A.; Ziggah, Y.Y.; Arthur, C.K. Blast-Induced Noise Level Prediction Model Based on Brain Inspired Emotional Neural Network. J. Sustain. Min. 2021, 20, 28–39. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Faradonbeh, R.S.; Amnieh, H.B.; Armaghani, D.J.; Monjezi, M. Forecasting blast-induced ground vibration developing a CART model. Eng. Comput. 2017, 33, 307–316. [Google Scholar] [CrossRef]

- Ouchterlony, F.; Sanchidrián, J. A review of development of better prediction equations for blast fragmentation. J. Rock Mech. Geotech. Eng. 2019, 11, 1094–1109. [Google Scholar] [CrossRef]

- Cunningham, C.V.B. The Kuz-Ram fragmentation model—20 years on. In Brighton Conference proceedings; European Federation of Explosives Engineers: Brighton, UK, 2005. [Google Scholar]

- Ouchterlony, F. The Swebrec© function: Linking fragmentation by blasting and crushing. Min. Technol. 2005, 114, 29–44. [Google Scholar] [CrossRef]

- Spathis, A.T. Formulae and techniques for assessing features of blast-induced fragmentation distributions. In Fragblast 9, Proceedings of the 9th International Symposium on Rock Fragmentation by Blasting, Granada, Spain, 13–17 August 2009; Taylor & Francis Group: London, UK, 2010. [Google Scholar]

- Lawal, A.I. A new modification to the Kuz-Ram model using the fragment size predicted by image analysis. Int. J. Rock Mech. Min. Sci. 2021, 138, 104595. [Google Scholar] [CrossRef]

- An, H.; Song, Y.; Liu, H.; Han, H. Combined Finite-Discrete Element Modelling of Dynamic Rock Fracture and Fragmentation during Mining Production Process by Blast. Shock. Vib. 2021, 2021, 6622926. [Google Scholar] [CrossRef]

- Tao, J.; Yang, X.-G.; Li, H.-T.; Zhou, J.-W.; Qi, S.-C.; Lu, G.-D. Numerical investigation of blast-induced rock fragmentation. Comput. Geotech. 2020, 128, 103846. [Google Scholar] [CrossRef]

- Fu, Y.; Aldrich, C. Deep Learning in Mining and Mineral Processing Operations: A Review. IFAC-PapersOnLine 2020, 53, 11920–11925. [Google Scholar] [CrossRef]

- Andersson, T.; Thurley, M.; Carlson, J. A machine vision system for estimation of size distributions by weight of limestone particles. Miner. Eng. 2012, 25, 38–46. [Google Scholar] [CrossRef]

- Esmaeili, M.; Salimi, A.; Drebenstedt, C.; Abbaszadeh, M.; Bazzazi, A.A. Application of PCA, SVR, and ANFIS for modeling of rock fragmentation. Arab. J. Geosci. 2015, 8, 6881–6893. [Google Scholar] [CrossRef]

- Dunford, J. Control and Prediction of Blast Fragmentation and its Impact on Comminution; University of Exeter: Exeter, UK, 2016. [Google Scholar]

- Monjezi, M.; Rezaei, M.; Varjani, A.Y. Prediction of rock fragmentation due to blasting in Gol-E-Gohar iron mine using fuzzy logic. Int. J. Rock Mech. Min. Sci. 2009, 46, 1273–1280. [Google Scholar] [CrossRef]

- Shams, S.; Monjezi, M.; Majd, V.J.; Armaghani, D.J. Application of fuzzy inference system for prediction of rock fragmentation induced by blasting. Arab. J. Geosci. 2015, 8, 10819–10832. [Google Scholar] [CrossRef]

- Zhou, J.; Li, C.; Arslan, C.A.; Hasanipanah, M.; Amnieh, H.B. Performance evaluation of hybrid FFA-ANFIS and GA-ANFIS models to predict particle size distribution of a muck-pile after blasting. Eng. Comput. 2021, 37, 265–274. [Google Scholar] [CrossRef]

- Iphar, M.; Yavuz, M.; Ak, H. Prediction of ground vibrations resulting from the blasting operations in an open-pit mine by adaptive neuro-fuzzy inference system. Environ. Earth Sci. 2007, 56, 97–107. [Google Scholar] [CrossRef]

- Hasanipanah, M.; Amnieh, H.B.; Arab, H.; Zamzam, M.S. Feasibility of PSO–ANFIS model to estimate rock fragmentation produced by mine blasting. Neural Comput. Appl. 2018, 30, 1015–1024. [Google Scholar] [CrossRef]

- Sayevand, K.; Arab, H. A fresh view on particle swarm optimization to develop a precise model for predicting rock fragmentation. Eng. Comput. 2019, 36, 533–550. [Google Scholar] [CrossRef]

- Zhang, S.; Bui, X.-N.; Trung, N.-T.; Nguyen, H.; Bui, H.-B. Prediction of Rock Size Distribution in Mine Bench Blasting Using a Novel Ant Colony Optimization-Based Boosted Regression Tree Technique. Nat. Resour. Res. 2019, 29, 867–886. [Google Scholar] [CrossRef]

- Gao, W.; Karbasi, M.; Hasanipanah, M.; Zhang, X.; Guo, J. Developing GPR model for forecasting the rock fragmentation in surface mines. Eng. Comput. 2018, 34, 339–345. [Google Scholar] [CrossRef]

- Xie, C.; Nguyen, H.; Bui, X.-N.; Choi, Y.; Zhou, J.; Nguyen-Trang, T. Predicting rock size distribution in mine blasting using various novel soft computing models based on meta-heuristics and machine learning algorithms. Geosci. Front. 2021, 12, 101108. [Google Scholar] [CrossRef]

- Amiri, M.; Amnieh, H.B.; Hasanipanah, M.; Khanli, L.M. A new combination of artificial neural network and K-nearest neighbors models to predict blast-induced ground vibration and air-overpressure. Eng. Comput. 2016, 32, 631–644. [Google Scholar] [CrossRef]

- Hajihassani, M.; Armaghani, D.J.; Monjezi, M.; Mohamad, E.T.; Marto, A. Blast-induced air and ground vibration prediction: A particle swarm optimization-based artificial neural network approach. Environ. Earth Sci. 2015, 74, 2799–2817. [Google Scholar] [CrossRef]

- Asl, P.F.; Monjezi, M.; Hamidi, J.K.; Armaghani, D.J. Optimization of flyrock and rock fragmentation in the Tajareh limestone mine using metaheuristics method of firefly algorithm. Eng. Comput. 2018, 34, 241–251. [Google Scholar] [CrossRef]

- Trivedi, R.; Singh, T.; Raina, A. Simultaneous prediction of blast-induced flyrock and fragmentation in opencast limestone mines using back propagation neural network. Int. J. Min. Miner. Eng. 2016, 7, 237. [Google Scholar] [CrossRef]

- Ajiboye, A.R.; Abdullah-Arshah, R.; Qin, H.; Isah-Kebbe, H. Evaluating the effect of dataset size on predictive model using supervised learning technique. Int. J. Softw. Eng. Comput. Syst. 2015, 1, 75–84. [Google Scholar] [CrossRef]

- Ganguli, R.; Dagdelen, K.; Grygiel, E. System Engineering. In SME Mining Engineering Handbook; Darling, P., Ed.; Society for Mining Metallurgy: Englewood, CO, USA, 2011; Volume 1, pp. 839–853. [Google Scholar]

| Blast Impact | Country | ||

|---|---|---|---|

| USA | Canada | Australia | |

| Ground vibration | Maximum allowable PPV: 0–300 ft for PPV ≤ 1.25 in./s 301–5000 ft for PPV ≤ 1.00 in./s >5001 ft for PPV ≤ 0.75 in./s Frequency: 0.03 in for 1–3.5 Hz 0.75 in./s for 3.5–12 Hz 0.01 in. for 12–30 Hz 2.0 in./s for 30–100 Hz | PPV ≤ 12.5 mm/s measured below grade or less than 1 m above grade. | Must not exceed a PPV of 5 mm/s for nine out of any ten consecutive blasts initiated, regardless of the interval between blasts, but never over 10 mm/s for any blast. |

| Airblast | ≤0.1 Hz: peak ≤ 134 dB ≤2 Hz: peak ≤ 133 dB ≤6 Hz: peak ≤ 129 dB C-weighted--slow response: 105 dBC | ≤128 dB | Must not be more than 115 dB(lin) peak for nine out of any ten consecutive blasts initiated, regardless of the interval between blasts, but never over 120 dB(lin) peak for any blast. |

| Flyrock | Shall not cast: More than one-half the distance to the nearest dwelling. Beyond the area of control required under 30 CFR 816.66(c); or Beyond the permit boundary. | The blaster must take precautions for the protection of persons and property, including proper loading and stemming of holes, and where necessary, the use of cover for the blast or other effective means of controlling the blast or resultant flying material. | If debris from blasting in a surface mining operation could constitute a danger to any person or property, each responsible person at the mine must ensure that such precautions are taken as are necessary to prevent injury to persons and to minimize the risk of damage to property. |

| Noise | 70 dBA (EPA) | ≤55 dBA daytime (Leq D) ≤45 dBA at (Leq N) nighttime | No worker to be exposed to noise with a level exceeding 140 dB(lin) peak |

| Blast Impact | Count |

|---|---|

| Ground vibration | 58 |

| Flyrock | 15 |

| Fragmentation | 13 |

| Airblast | 11 |

| Backbreak | 3 |

| Overbreak | 1 |

| Noise | 1 |

| Ground vibration and airblast | 3 |

| Flyrock and fragmentation | 3 |

| Backbreak and fragmentation | 2 |

| Flyrock and backbreak | 1 |

| Ground vibration, airblast, and fragmentation | 1 |

| Prediction Model | Equation | Reference |

|---|---|---|

| USBM | [44] | |

| Langefors–Kihlstrom | [45] | |

| General predictor | [43] | |

| Ambraseys–Hendron | [46] | |

| Indian Standard | [46] | |

| Ghosh–Daemen 1 | [43] | |

| Ghosh–Daemen 2 | [43] | |

| Gupta et al. | [43] | |

| CMRI predictor | [43] | |

| Rai–Singh | [47] |

| Prediction Model | Equation | Reference |

|---|---|---|

| USBM | [49] | |

| NAASRA | [50] | |

| Ollofson; Persson et al. | [51] | |

| Holmberg-Persson | [51] | |

| Mckenzie | [52] |

| Prediction Model | Equation | Reference |

|---|---|---|

| Lundborg et al. | [53] | |

| Chiapetta et al. | [34] | |

| Gupta | [54] |

| ML Method | Other Models | Operation | Parameter | Dataset | Impact | Performance (R2) | Reference |

|---|---|---|---|---|---|---|---|

| ANN | USBM, Langefors–Kihlstrom, Ambraseys–Hendron, Bureau of Indian Standard, CMRI predictor | Coal mine | Q, D | 130 | Ground vibration | 0.919 | [94] |

| ANN | MVR | Coal mine | Q, D, HD, HZ, B, ST CH, BI, E, V, PV, VOD, ED | 150 | Ground vibration | 0.9994 | [80] |

| SVM | USBM, Ambraseys–Hendron, Davies et al., Indian Standard | Dam construction | Q, D | 80 | Ground vibration | 0.957 | [105] |

| GA-ANN | ANN, USBM, and MLR | Quarry | Q, D | 97 | Airblast | 0.965 | [132] |

| PSO | MLR | Quarry | S, B, ST, PF, RD | 76 | Flyrock | 0.966 | [143] |

| PSO–ANN | ICA, GA | Quarry | HD, HZ, BS, Q, PF | 262 | Flyrock | 0.943 | [154] |

| ANN | MVR | Copper mine | B, S, Q, PF, ST, HD, NR, BH | 135 | Fragmentation | 0.94 | [155] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dumakor-Dupey, N.K.; Arya, S.; Jha, A. Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications. Minerals 2021, 11, 601. https://doi.org/10.3390/min11060601

Dumakor-Dupey NK, Arya S, Jha A. Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications. Minerals. 2021; 11(6):601. https://doi.org/10.3390/min11060601

Chicago/Turabian StyleDumakor-Dupey, Nelson K., Sampurna Arya, and Ankit Jha. 2021. "Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications" Minerals 11, no. 6: 601. https://doi.org/10.3390/min11060601

APA StyleDumakor-Dupey, N. K., Arya, S., & Jha, A. (2021). Advances in Blast-Induced Impact Prediction—A Review of Machine Learning Applications. Minerals, 11(6), 601. https://doi.org/10.3390/min11060601