Status of Recovery of Strategic Metals from Spent Secondary Products

Abstract

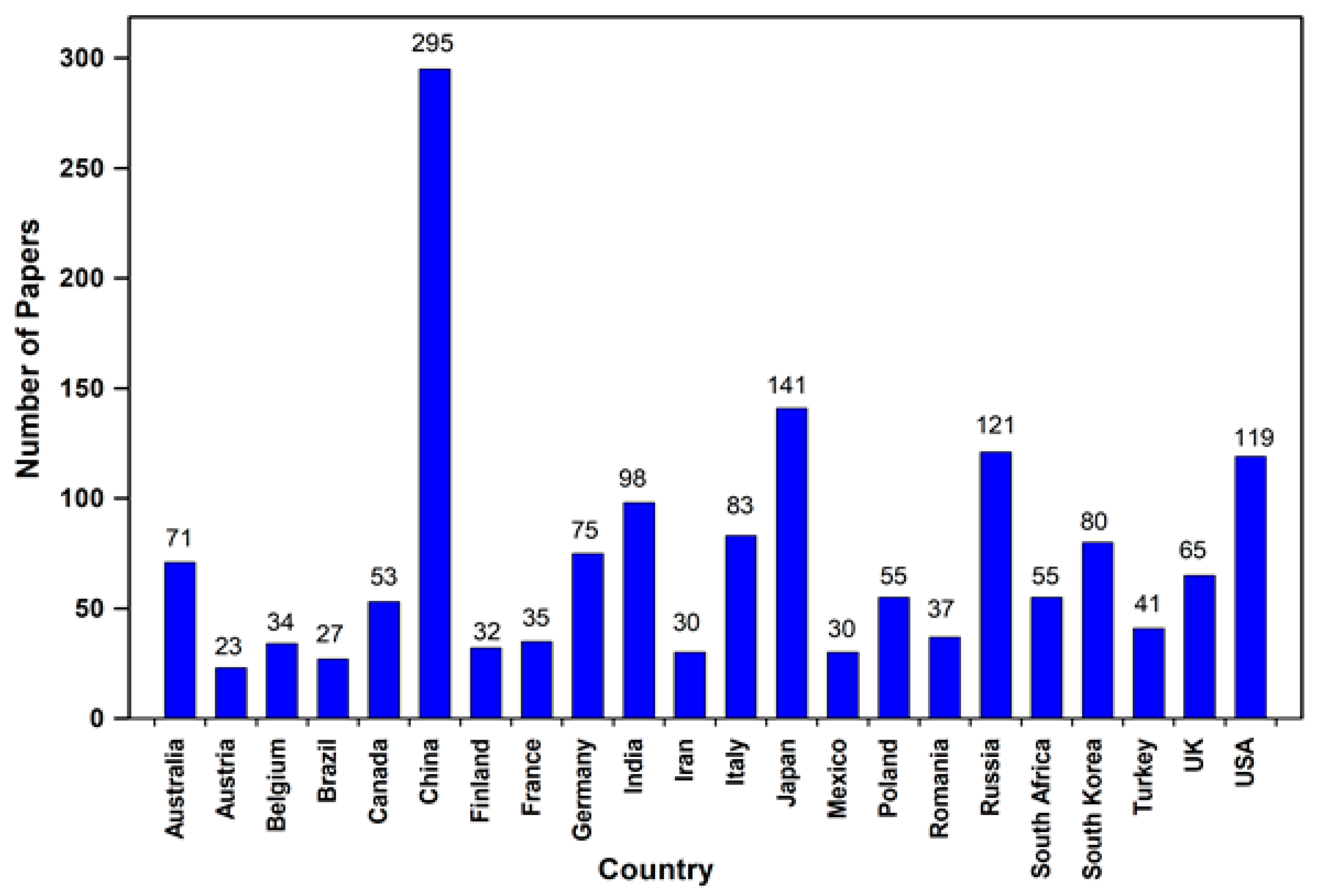

:1. Introduction

2. Recovery of PGMs from Catalytic Converters

2.1. Composition of a Catalytic Converter

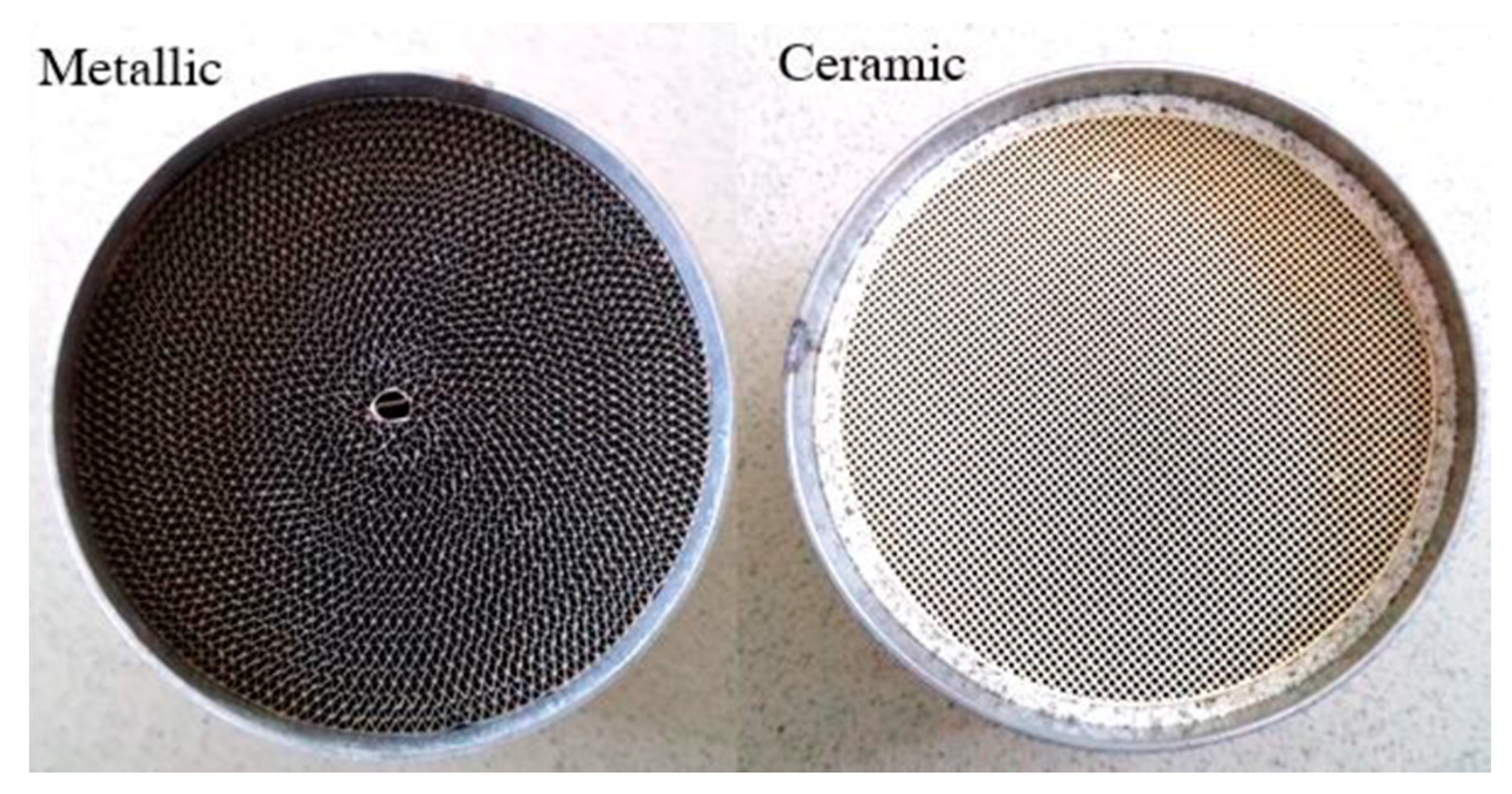

2.1.1. Metallic Monolith

2.1.2. Ceramic Monolith

2.2. Methods of Recovery of Precious Metals from Catalytic Converters

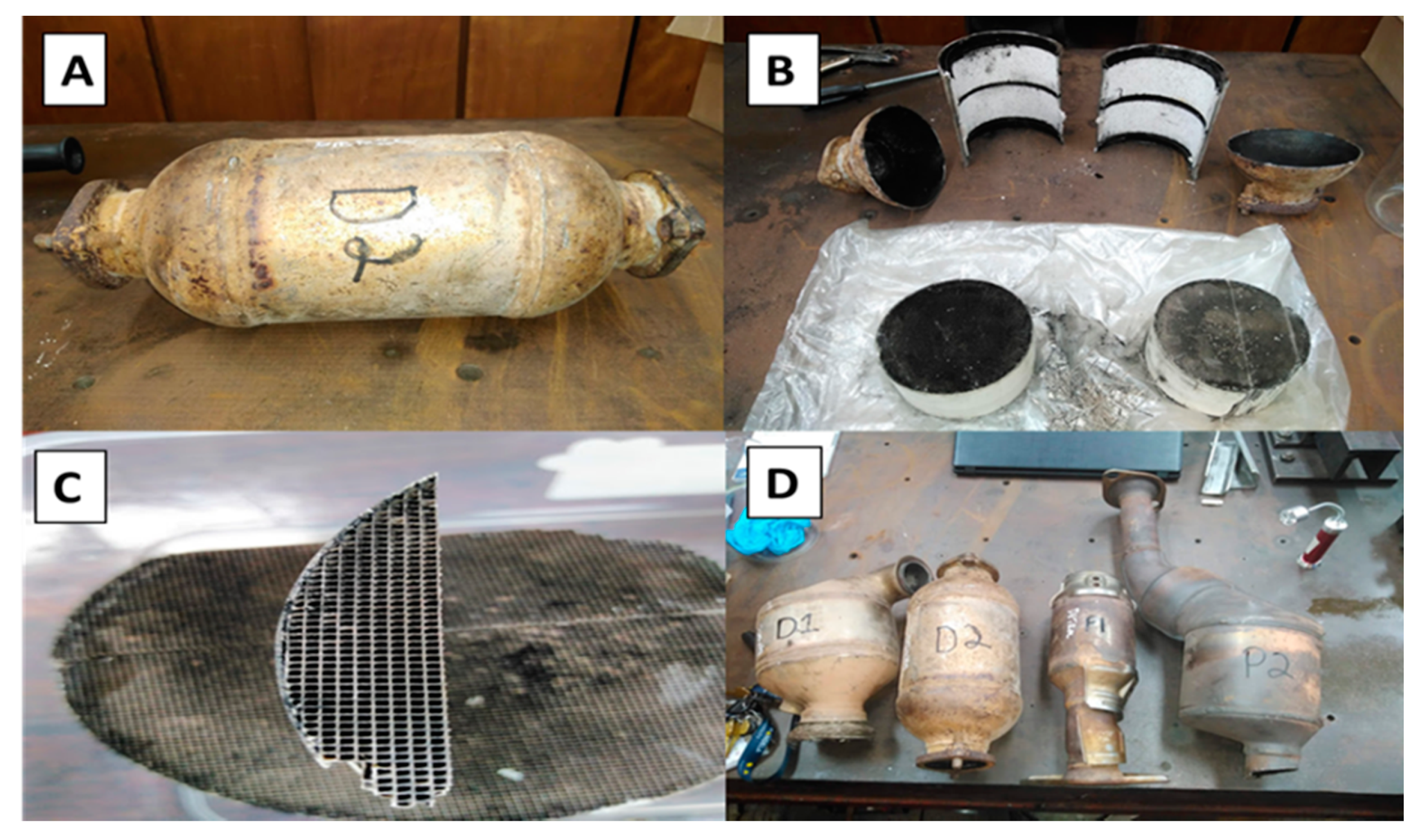

2.2.1. Dismantling Process

2.2.2. Preprocessing

2.2.3. Leaching Process

2.2.4. Recovery and Purification of Leachates

| Method of Extraction | Recovery (%) | Results and Notes | Reference |

|---|---|---|---|

| Solvent extraction | Pt (80%) Pd (98%) | Pt and Pd were coextracted using 0.01 M tri-isooctylamine (Alamine 308) dissolved in kerosene with a 5% v/v n-decanol used as a modifier, shaken for 30 min at 300 r/min, 1:1 O/A volume ratio at an optimum 5 M HCl. The recovery for Pt and Pd using Alamine 308 was 95% and 81%, respectively. | [46] |

| Cloud point extraction (CPE) | Pd (97%) Pt (96%) Rh (91%) | The recovery of Pd, Pt, and Rh using CPE was 97%, 96%, and 91%, respectively, after complexation with 2-mercaptobenzothiazole (complexing agent) in the presence of Triton X-100 (surfactant) and tin (II) chloride dihydrate as a reductant, at 90 °C with an incubation time of 120 min. | [46] |

| Precipitation | Pt (91.9%) Pd (98.9%) | The recovery efficiency of Pt and Pd was 92% and 99%, respectively, precipitated using ammonium chloride (NH4Cl) and sodium chlorate (NaClO3) as precipitation agents at 50 °C for 1 h. | [27] |

| Precipitation/reduction | Pt (>98%) | Pt leaching efficiency was optimized by employing a response surface methodology followed by reduction. Pt leaching efficiency was over 98% under the optimized conditions: 1.45 M HCl, 4.55 M NaCl, 10% H2O2/spent catalysts of 0.66 mL/g, and 1:4.85 of S/L. The purity of Pt was over 90% by the reduction of iron powder. | [47] |

| Precipitation | Pt (99.5%) Pd (99.3%) Rh (95%) | The individual precipitation of Pt over Pd and Rh from each other was performed by adding NH4Cl (290 g/L) at 40 °C to their solution, where a yellowish Pt precipitate of (NH4)2[PtCl6] was obtained and calcined at 800 °C to obtain a fine pure Pt powder of 99.5%. A measurement of 3 g of sodium chlorate (NaClO3) was added to obtain a bright red precipitate of insoluble (NH4)2[PdCl6] and calcined at 900 °C where a pure Pd powder of 99.3% was obtained. The rhodium species in the filtrate was precipitated using KOH as a lemon-yellow rhodium hydroxide (Rh(OH)3). The complete decomposition in the air for Rh(OH)3 to Rh2O3 and then Rh metal was performed by ignition at 1150 °C to produce a grey Rh metal powder of 95.4% purity. | [45] |

| Solvent extraction and cementation | Pt (99.9%) Pd (99.9%) Rh (83.0%) | Tri-isooctylamine (Alamine 308) was used to selectively extract both Pt (99.9%) and Pd (99.9%). Rh was recovered by cementation using zinc metal powder; about 83% was recovered. | [63] |

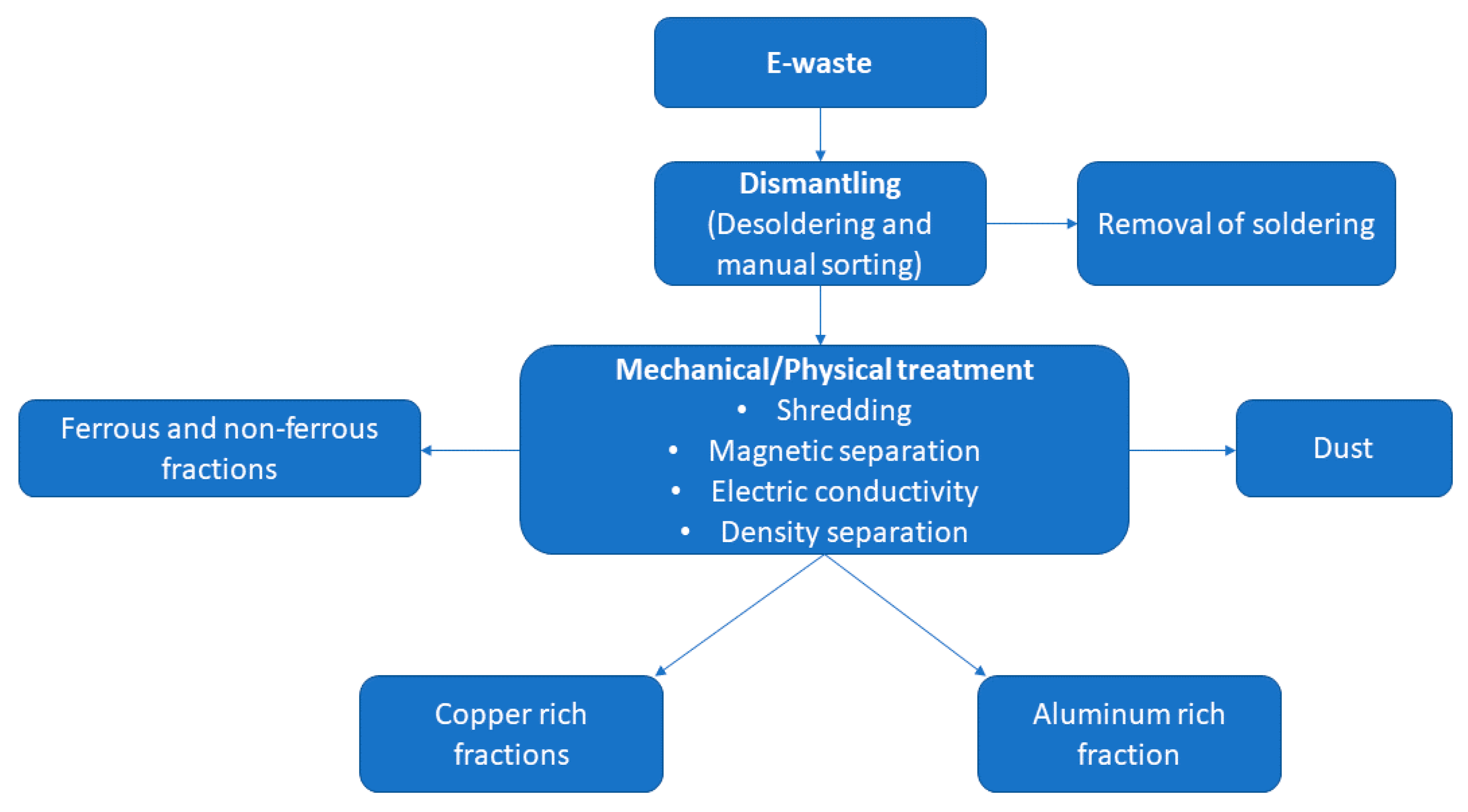

3. Recovery of Precious Metals from E-Waste

3.1. Pyrometallurgy

- Incinerators

- Pyrolysis

- Plasma

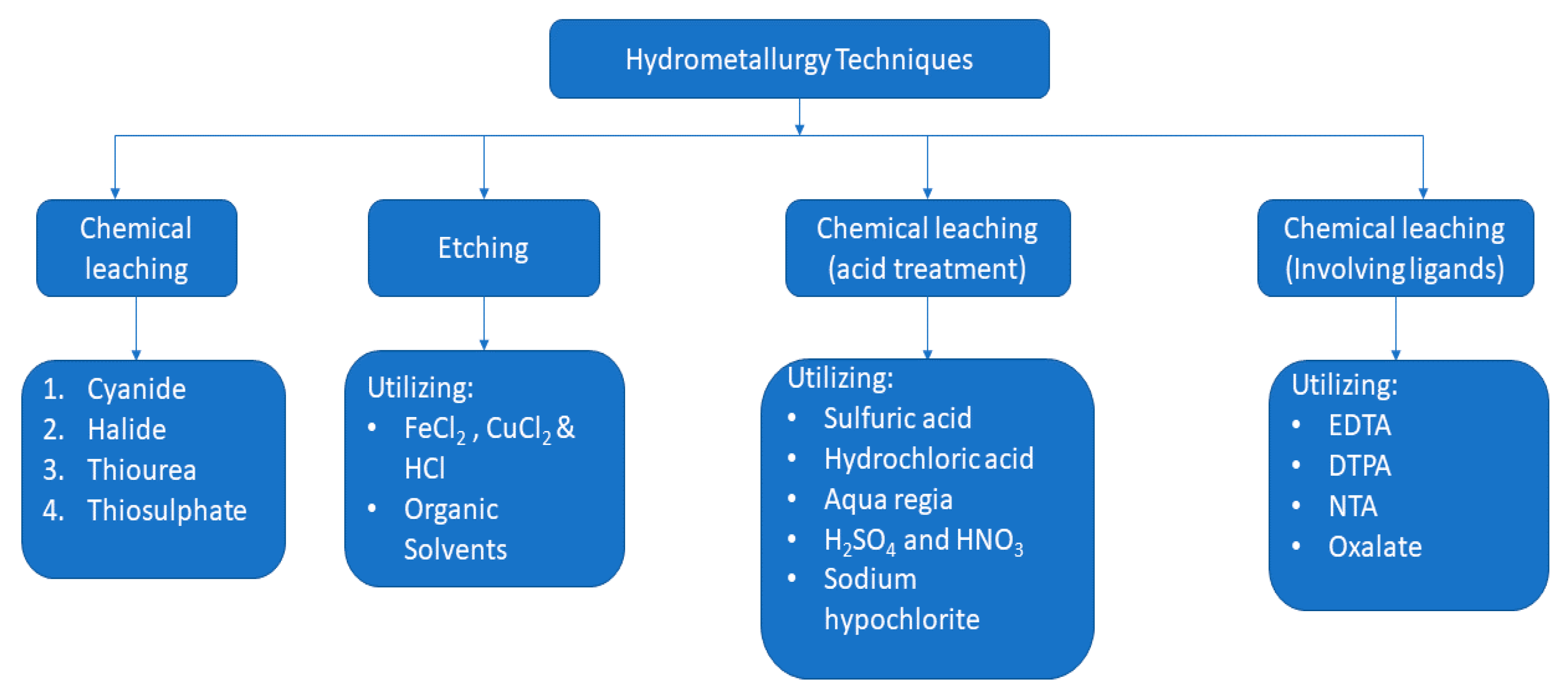

3.2. Hydrometallurgy

3.3. Biohydrometallurgy

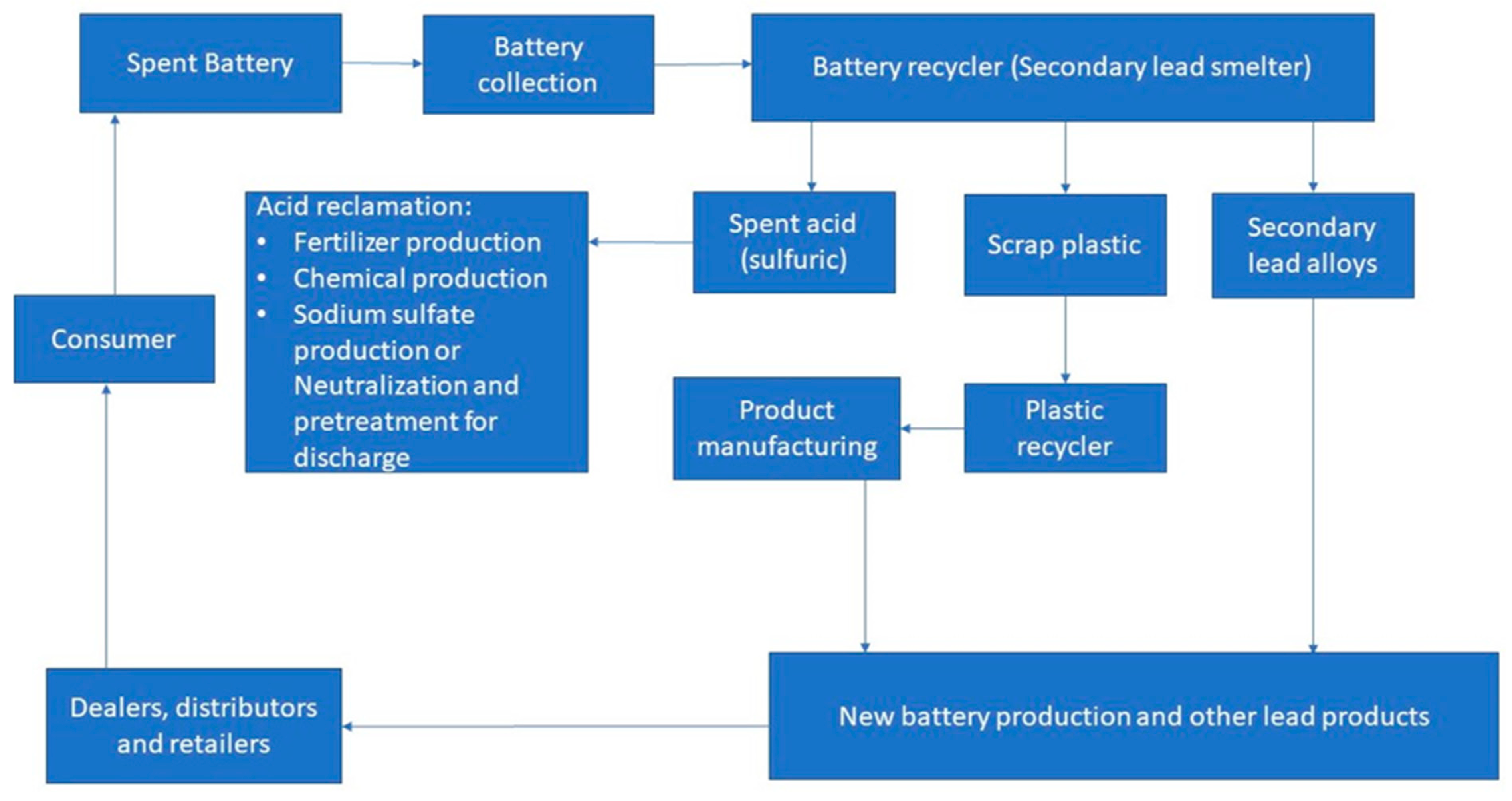

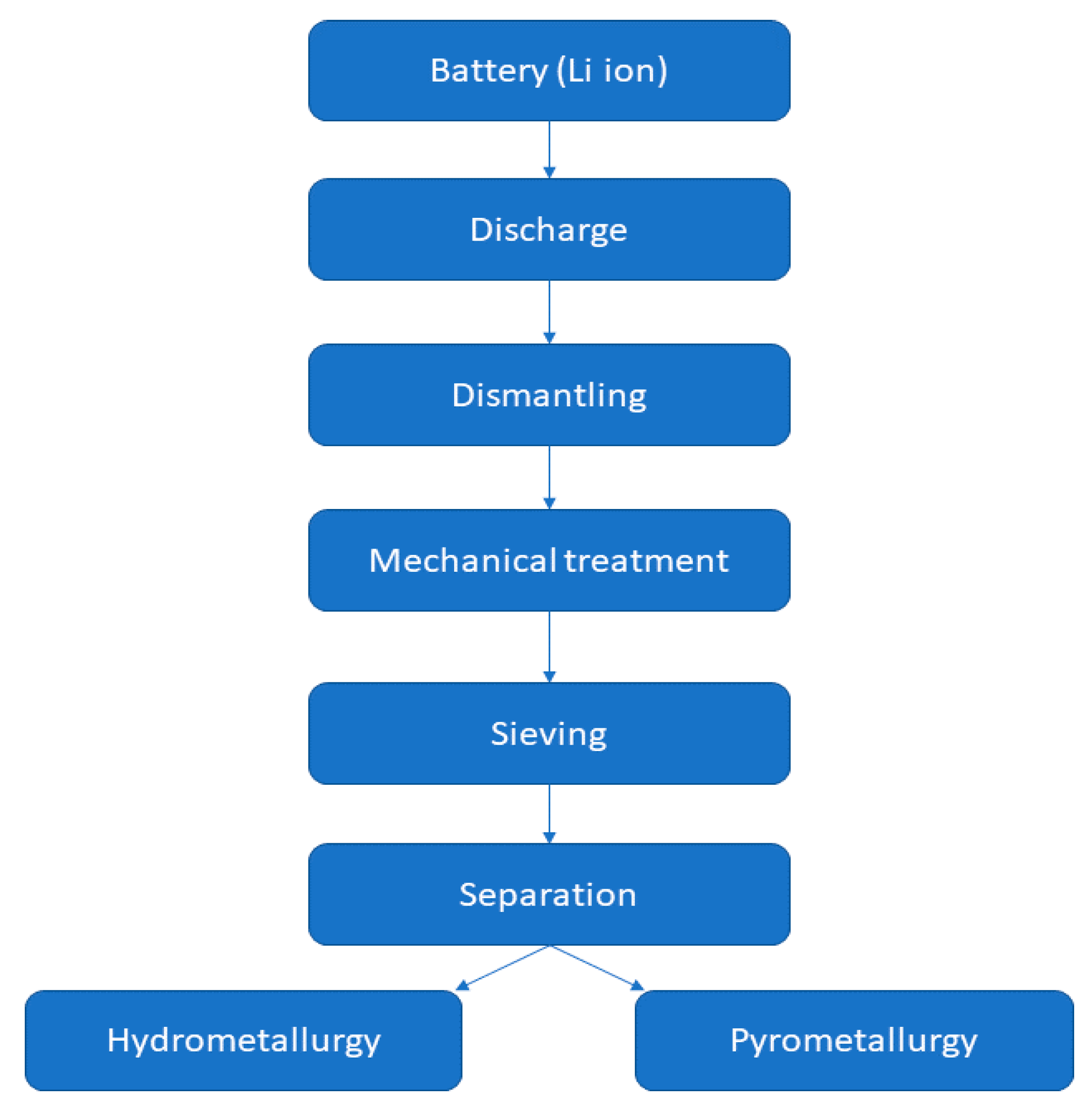

4. Recovery of Important Metals from Batteries

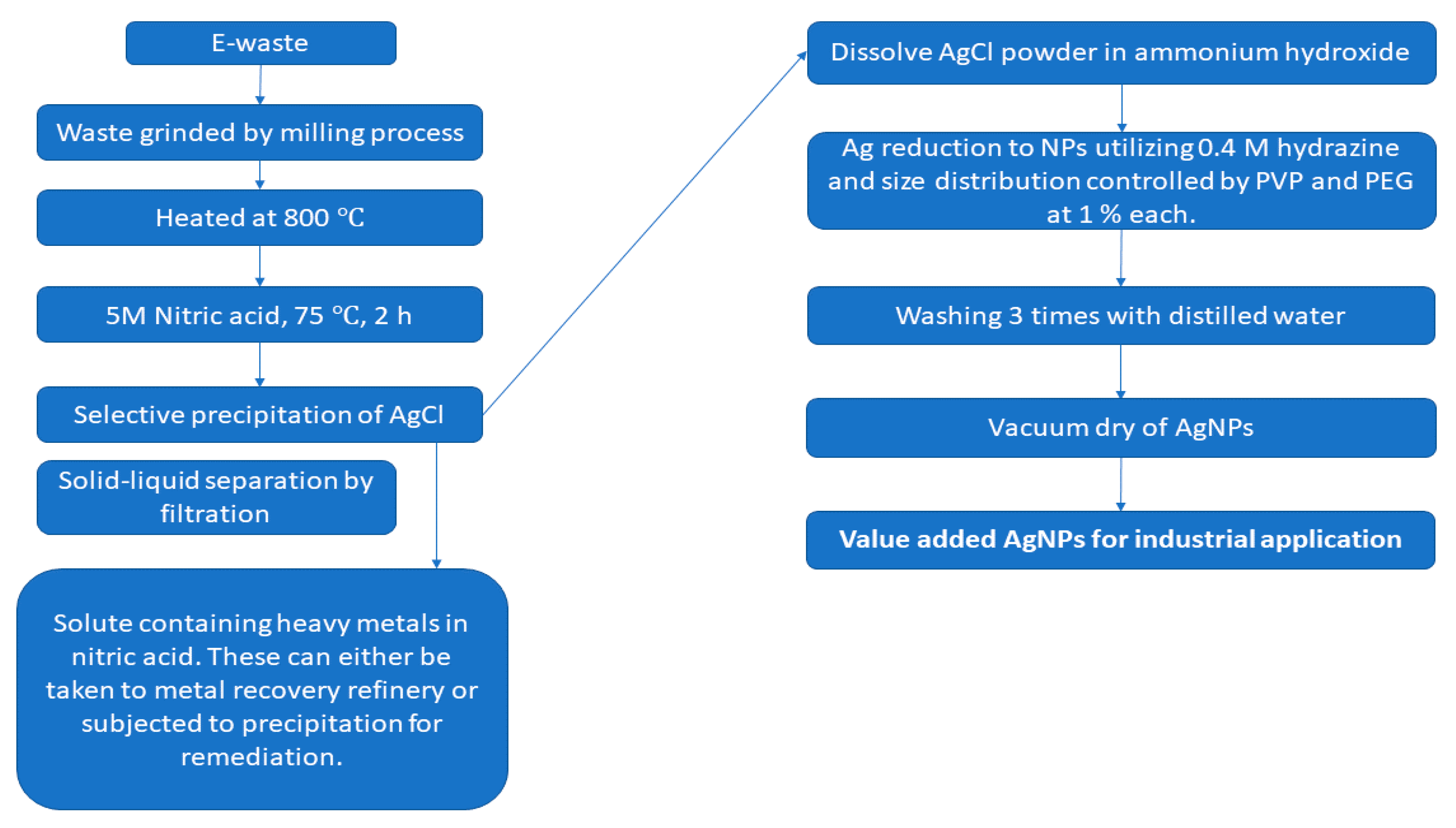

5. Conversion of Waste Metals Directly to Nanomaterials

6. Summary and Perspectives

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Matthey, J. Precious Metals Management. Available online: http://www.platinum.matthey.com/aboutpgm/applications (accessed on 6 July 2017).

- International Platinum Group Metals Association. The Secondary Production and Recycling of Platinum Group Metals (PGMs). pp. 1–5. Available online: https://ipa-news.de/assets/sustainability/Secondary%20Production%20Fact%20Sheet_LR.pdf (accessed on 25 March 2019).

- Steinlechner, S.; Antrekowitsch, J. Potential of a Hydrometallurgical Recycling Process for Catalysts to Cover the Demand for Critical Metals, Like PGMs and Cerium. JOM 2015, 67, 406–411. [Google Scholar] [CrossRef] [Green Version]

- Cowley, A. PGM Market Report; Johnson Matthey: London, UK, 2021; pp. 3–59. Available online: http://www.platinum.matthey.com/documents/new-item/pgm-market-reports/pgm-market-report-may-21.pdf (accessed on 6 July 2017).

- Sefako, R.; Sekgarametso, K.; Sibanda, V. Potential processing routes for recovery of platinum group metals from southern Af-rican oxidized PGM ores: A review. Miner. Eng. 2017, 3, 797–807. [Google Scholar]

- Fontàs, C.; Salvadó, V.; Hidalgo, M. Separation and Concentration of Pd, Pt, and Rh from Automotive Catalytic Converters by Combining Two Hollow-Fiber Liquid Membrane Systems. Ind. Eng. Chem. Res. 2002, 41, 1616–1620. [Google Scholar] [CrossRef]

- Paiva, A.P.; Orteta, O.; Carvalhoa, G.I.; Nogueirac, C.A. Recovery of palladium from a spent industrial catalyst through leaching and solvent extraction. Hydrometallurgy 2017, 171, 394–401. [Google Scholar] [CrossRef]

- Katara, P. Review Paper on Catalytic Converter for Automobile Exhaust Emission. Int. J. Sci. Res. 2016, 5, 30–33. [Google Scholar]

- Bernardis, F.L.; Grant, R.A.; Sherrington, D.C. A review of separation of the platinum-group metals through their chloro-complexes. React. Funct. Polym. 2005, 65, 205–217. [Google Scholar] [CrossRef]

- Matthey, J.A. Review of measurement techniques of mechanical properties of the catalyst layer in catalytic converters. Johns. Matthey Technol. Rev. 2019, 63, 177–190. [Google Scholar]

- Jollie, D. Platinum; Johnson Matthey: London, UK, 2008; pp. 1–60. Available online: http://www.platinum.matthey.com/documents/market-review/2008/full-review/english.pdf (accessed on 25 March 2019).

- Alison Cowley, J.M. PGM Market Report; Johnson Matthey: London, UK, 2018; pp. 1–48. Available online: http://www.platinum.matthey.com/documents/newitem/pgm%20market%20reports/pgm_market_report_may_2018.pdf (accessed on 25 March 2019).

- Stilwell, C.L.C. Platinum in the South African economy. In International Platinum Conference ‘Platinum Adding Value’; The South African Institute of Mining and Metallurgy: Sun City, South Africa, 2004; pp. 1–7. [Google Scholar]

- Hagelüken, C. Recycling the Platinum Group Metals: A European Perspective. Platin. Met. Rev. 2012, 56, 29–35. [Google Scholar] [CrossRef]

- Ranasinghe, Wilka & Athapattu, Bandunee. Challenges in E-waste management in Sri Lanka. Handb. Electron. Waste Manag. 2020, 284–322. [Google Scholar] [CrossRef]

- Bertram, M.; Graedel, T.; Rechberger, H.; Spatari, S. The contemporary European copper cycle: Waste management subsystem. Ecol. Econ. 2002, 42, 43–57. [Google Scholar] [CrossRef]

- Jinhui, L.; Huabo, D.; Pixing, S. Heavy metal contamination of surface soil in electronic waste dismantling area: Site investigation and source-apportionment analysis. Waste Manag. Res. 2011, 29, 727–738. [Google Scholar] [CrossRef]

- ATSDR. Toxicological profiles on CD-ROM. In Agency for Toxic Substances and Disease Registry; U.S. Public Health Service: Washington, DC, USA, 2003; pp. 1–429. [Google Scholar]

- Ding, Y.; Zhang, S.; Liu, B.; Zheng, H.; Chang, C.-C.; Ekberg, C. Recovery of precious metals from electronic waste and spent catalysts: A review. Resour. Conserv. Recycl. 2019, 141, 284–298. [Google Scholar] [CrossRef]

- Widmer, R.; Oswald-Krapf, H.; Sinha-Khetriwal, D.; Schnellmann, M.; Böni, H. Global perspectives on e-waste. Environ. Impact Assess. Rev. 2005, 25, 436–458. [Google Scholar] [CrossRef]

- Assefi, M.; Maroufi, S.; Yamauchi, Y.; Sahajwalla, V. Pyrometallurgical recycling of Li-ion, Ni–Cd and Ni–MH batteries: A mini-review. Curr. Opin. Green Sustain. Chem. 2020, 24, 26–31. [Google Scholar] [CrossRef]

- Khaliq, A.; Rhamdhani, M.A.; Brooks, G.; Masood, S. Metal Extraction Processes for Electronic Waste and Existing Industrial Routes: A Review and Australian Perspective. Resources 2014, 3, 152–179. [Google Scholar] [CrossRef] [Green Version]

- Fu, J.; Zhang, H.; Zhang, A.; Jiang, G. E-waste Recycling in China: A Challenging Field. Environ. Sci. Technol. 2018, 52, 6727–6728. [Google Scholar] [CrossRef]

- Hong, Y.; Thirion, D.; Subramanian, S.; Yoo, M.; Choi, H.; Kim, H.Y.; Stoddart, J.F.; Yavuz, C.T. Precious metal recovery from electronic waste by a porous porphyrin polymer. Proc. Natl. Acad. Sci. USA 2020, 117, 16174–16180. [Google Scholar] [CrossRef] [PubMed]

- Doidge, E.D.; Kinsman, L.M.M.; Ji, Y.; Carson, I.; Duffy, A.J.; Kordas, I.A.; Shao, E.; Tasker, P.A.; Ngwenya, B.T.; Morrison, C.A.; et al. Evaluation of Simple Amides in the Selective Recovery of Gold from Secondary Sources by Solvent Extraction. ACS Sustain. Chem. Eng. 2019, 7, 15019–15029. [Google Scholar] [CrossRef]

- Saternus, M.; Fornalczyk, A.; Gąsior, W.; Dębski, A.; Terlicka, S. Modifications and Improvements to the Collector Metal Method Using an mhd Pump for Recovering Platinum from Used Car Catalysts. Catalysts 2020, 10, 880. [Google Scholar] [CrossRef]

- Saternus, M.; Fornalczyk, A. Possible ways of refining precious group metals (PGM) obtained from recycling of the used auto catalytic converters. Metalurgija 2013, 52, 267–270. [Google Scholar]

- Hammadi, M.Q.; Yassen, R.S.; Abid, K.N. Recovery of Platinum and Palladium from Scrap Automotive Catalytic Converters. Al-Khwarizmi Eng. J. 2017, 13, 131–141. [Google Scholar] [CrossRef]

- Willner, J.; Kaduková, J.; Fornalczyk, A.; Mrážiková, A.; Marcinčáková, R.; Velgosová, O. Possibilities of metals extracton from spent metallic automotive catalytic converters by using biometallurgical method. Arch. Metall. Mater. 2015, 60, 1877–1880. [Google Scholar] [CrossRef] [Green Version]

- Barefoot, R.R. Determination of Platinum at Trace Levels in Environmental and Biological Materials. Environ. Sci. Technol. 1997, 31, 309–314. [Google Scholar] [CrossRef]

- Jimenez De Aberasturi, D.; Pinedo, R.; Ruiz De Larramendi, I.; Ruiz De Larramendi, J.I.; Rojo, T. Recovery by hydrometallurgical extraction of the platinum-group metals from car catalytic converters. Miner. Eng. 2011, 24, 505–513. [Google Scholar] [CrossRef]

- Oberthür, T.; Melcher, F.; Buchholz, P.; Locmelis, M. The oxidized ores of the Main Sulphide Zone, Great Dyke, Zimbabwe: Turning resources into minable reserves-mineralogy is the key. J. South. Afr. Inst. Min. Metall. 2013, 113, 191–201. [Google Scholar]

- Yakoumis, I.; Moschovi, A.M.; Giannopoulou, I.; Panias, D. Real life experimental determination of platinum group metals content in automotive catalytic converters. In IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2018. [Google Scholar]

- Regel-Rosocka, M.; Rzelewska, M.; Baczynska, M.; Janus, M.; Wisniewski, M. Removal of palladium(II) from aqueous chloride so-lutions with cyphos phosphonium ionic liquids as metal ion carriers for liquid-liquid extraction and transport across polymer inclusion membranes. Physicochem. Probl. Miner. Process 2015, 51, 621–631. [Google Scholar]

- Suiter, J. Al2O3 Oxide Morphology for Two Fe-Cr-Al Stainless Steel Foils Used in Gasoline Engine Catalytic Converters; In Project Sponsored by ACAT Global; Advisor: London, UK, 2012; pp. 1–44. [Google Scholar]

- Lillkung, K.; Aromaa, J.; Forsen, O. Determination of leaching parameters for the recovery of platinum group metals from sec-ondary materials. Physicochem. Probl. Miner. Process 2013, 49, 463–472. [Google Scholar]

- Willner, J.; Fornalczyk, A.; Cebulski, J.; Janiszewski, K. Preliminary studies on simultaneous recovery of precious metals from dif-ferent waste materials by pyrometallurgical method. Arch. Metall. Mater. 2014, 59, 801–804. [Google Scholar] [CrossRef]

- Jha, M.K.; Lee, J.-C.; Kim, M.-S.; Jeong, J.; Kim, B.-S.; Kumar, V. Hydrometallurgical recovery/recycling of platinum by the leaching of spent catalysts: A review. Hydrometallurgy 2013, 133, 23–32. [Google Scholar] [CrossRef]

- Andreola, F.; Barbieri, L.; Giovanardi, R.; Lancellotti, I.; Soragni, E. Recovery of precious metals from electronic scraps. In Proceedings of the 2008 Global Symposium on Recycling, Waste Treatment and Clean Technology (REWAS 2008), Cancun, Mexico, 12–15 October 2008. [Google Scholar]

- Dong, H.; Zhao, J.; Chen, J.; Wu, Y.; Li, B. Recovery of platinum group metals from spent catalysts: A review. Int. J. Miner. Process. 2015, 145, 108–113. [Google Scholar] [CrossRef]

- Cao, Y.; Harjanto, S.; Shibayama, A.; Naitoh, I.; Nanami, T.; Kasahara, K.; Okumuru, Y.; Fujita, T. Kinetic study on the leaching of Pt, Pd and Rh from automotive catalyst residue by using chloride solutions. Mater. Trans. 2006, 47, 2015–2024. [Google Scholar] [CrossRef] [Green Version]

- Muhammad Faisal, H.D.; Yoichi Atsuta, K.F. Membrane reactors—Part I. Technology 2009, 17, 364–367. [Google Scholar]

- Kim, C.H.; Woo, S.I.; Jeon, S.H. Recovery of platinum-group metals from recycled automotive catalytic converters by carbochlo-rination. J. Ind. Eng. Chem. Res. 2000, 39, 1185–1192. [Google Scholar] [CrossRef]

- Paiva, A.P. Recycling of Palladium from Spent Catalysts Using Solvent Extraction—Some Critical Points. Metals 2017, 7, 505. [Google Scholar] [CrossRef] [Green Version]

- Yousif, A.M. Recovery and then individual separation of platinum, palladium, and rhodium from spent car catalytic converters using hydrometallurgical technique followed by successive precipitation methods. J. Chem. 2019, 2019, 1–7. [Google Scholar] [CrossRef]

- Makua, L.; Langa, K.; Saguru, C.; Ndlovu, S. PGM recovery from a pregnant leach solution using solvent extraction and cloud point extraction: A preliminary comparison. J. South. Afr. Inst. Min. Met. 2019, 119, 453–458. [Google Scholar] [CrossRef]

- Ding, Y.; Zheng, H.; Li, J.; Zhang, S.; Liu, B.; Ekberg, C.; Jian, Z. Recovery of Platinum from Spent Petroleum Catalysts: Optimization Using Response Surface Methodology. Metals 2019, 9, 354. [Google Scholar] [CrossRef] [Green Version]

- Ding, Y.; Zheng, H.; Li, J.; Zhang, S.; Liu, B.; Ekberg, C. An Efficient Leaching of Palladium from Spent Catalysts through Oxidation with Fe(III). Materials 2019, 12, 1205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nogueira, C.A.; Paiva, A.P.; Costa, M.C.; Rosa da Costa, A.M. Leaching efficiency and kinetics of the recovery of palladium and rhodium from a spent auto-catalyst in HCl/CuCl2 media. Environ. Technol. 2020, 41, 2293–2304. [Google Scholar] [CrossRef] [PubMed]

- Yakoumis, I.; Moschovi, A.; Panou, M.; Panias, D. Single-Step Hydrometallurgical Method for the Platinum Group Metals Leaching from Commercial Spent Automotive Catalysts. J. Sustain. Metall. 2020, 6, 259–268. [Google Scholar] [CrossRef]

- Karim, S.; Ting, Y.-P. Ultrasound-assisted nitric acid pretreatment for enhanced biorecovery of platinum group metals from spent automotive catalyst. J. Clean. Prod. 2020, 255, 120199. [Google Scholar] [CrossRef]

- Lee, M.N.; Lee, M.S. A Review on Hydrometallurgical Processes for the Recovery of Valuable Metals from Spent Catalysts and Life Cycle Analysis Perspective. Miner. Process. Extr. Metall. Rev. 2020, 335–354. [Google Scholar] [CrossRef]

- Schoeman, E.; Bradshaw, S.M.; Akdogan, G.; Eksteen, J.J. The Recovery of Platinum, Palladium, and Gold from a Cyanide Heap Solution, With Use of Ion Exchange Resins; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2012; pp. 729–742. [Google Scholar]

- Yu, F.; Xi, C.; He, Z.; Chen, L. Development of Cloud Point Extraction for Simultaneous Extraction and Determination of Platinum and Palladium Using Inductively Coupled Plasma Optical Emission Spectrometry in Platinum-Palladium Spent Catalysts. Anal. Lett. 2010, 43, 972–982. [Google Scholar] [CrossRef]

- Cleare, M.J.; Charlesworth, P.; Bryson, D.J. Solvent extraction in platinum group metal processing. J. Chem. Technol. Biotechnol. Biotechnol. 2007, 29, 210–224. [Google Scholar] [CrossRef]

- Pospiech, B. Studies on platinum recovery from solutions after leaching of spent catalysts by solvent extraction. J. Physicochem. Probl. Miner. Process. 2012, 48, 239–246. [Google Scholar]

- Shen, S.; Guishen, L.; Pan, T.; He, J.; Guo, Z. Selective adsorption of Pt ions from chloride solutions obtained by leaching chlorinated spent automotive catalysts on ion exchange resin Diaion WA21J. J. Colloid Interface Sci. 2011, 364, 482–489. [Google Scholar] [CrossRef]

- Kokate, S.J.; Aher, H.R.; Kuchekar, S.R. Reversed phase extraction chromatographic separation of palladium(II) using liquid anion exchanger. Bulg. Chem. Commun. 2009, 41, 272–276. [Google Scholar]

- Ruiu, A.; Bauer-Siebenlist, B.; Senila, M.; Jänisch, T.; Foix, D.; Seaudeau-Pirouley, K.; Lacroix-Desmazes, P. Promising polymer-assisted extraction of palladium from supported catalysts in supercritical carbon dioxide. J. CO2 Util. 2020, 41, 101232. [Google Scholar] [CrossRef]

- Fornalczyk, A.; Saternus, M. Platinum recovery from used auto catalytic converters in electrorefining process. Metalurgija 2013, 52, 219–222. [Google Scholar]

- Nguyen, T.H.; Kumar, B.N.; Lee, M.S. Selective recovery of Fe(III), Pd(II), Pt(IV), Rh(III) and Ce(III) from simulated leach liquors of spent automobile catalyst by solvent extraction and cementation. Korean J. Chem. Eng. 2016, 33, 2684–2690. [Google Scholar] [CrossRef]

- Morcali, M.H. A new approach to recover platinum-group metals from spent catalytic converters via iron matte. Resour. Conserv. Recycl. 2020, 159, 104891. [Google Scholar] [CrossRef]

- Chancerel, P.; Meskers, C.E.M.; Hagelüken, C.; Rotter, V.S. Assessment of precious metal flows during pre-processing of waste electrical and electronic equipment. J. Ind. Ecol. 2009, 13, 791–810. [Google Scholar] [CrossRef]

- Gaidajis, G.; Angelakoglou, K.; Aktsoglou, D. E-waste: Environmental Problems and Current Management. J. Eng. Sci. Technol. Rev. 2010, 3, 193–199. [Google Scholar] [CrossRef]

- Schluep, M.; Hagelüken, C.; Meskers, C.; Magalini, F.; Wang, F.; Thiébaud-Müller, E.; Kuehr, R.; Maurer, C.; Sonnemann, G. Market potential of innovative e-waste recycling technologies in developing countries. In Proceedings of the R’09 Twin World Congress on Resource Management and Technology for Material and Energy Efficiency, Davos, Switzerland, 14–16 September 2009. [Google Scholar]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.-H.A. Advancements in the treatment and processing of electronic waste with sustainability: A review of metal extraction and recovery technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Marra, A.; Cesaro, A.; Belgiorno, V. Separation efficiency of valuable and critical metals in WEEE mechanical treatments. J. Clean. Prod. 2018, 186, 490–498. [Google Scholar] [CrossRef]

- Li, H.; Eksteen, J.; Oraby, E. Hydrometallurgical recovery of metals from waste printed circuit boards (WPCBs): Current status and perspectives—A review. Resour. Conserv. Recycl. 2018, 139, 122–139. [Google Scholar] [CrossRef]

- Asante, K.A.; Amoyaw-Osei, Y.; Agusa, T. E-waste recycling in Africa: Risks and opportunities. Curr. Opin. Green Sustain. Chem. 2019, 18, 109–117. [Google Scholar] [CrossRef]

- Li, F.; Chen, M.; Shu, J.; Shirvani, M.; Li, Y.; Sun, Z.; Sun, S.; Xu, Z.; Fu, K.; Chen, S. Copper and gold recovery from CPU sockets by one-step slurry electrolysis. J. Clean. Prod. 2019, 213, 673–679. [Google Scholar] [CrossRef]

- Ghimire, H.; Ariya, P.A. E-Wastes: Bridging the Knowledge Gaps in Global Production Budgets, Composition, Recycling and Sustainability Implications. Sustain. Chem. 2020, 1, 12. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Z. A review of current progress of recycling technologies for metals from waste electrical and electronic equipment. J. Clean. Prod. 2016, 127, 19–36. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Xie, H.; Zeng, X.; Li, J. Current Status on Leaching Precious Metals from Waste Printed Circuit Boards. Procedia Environ. Sci. 2012, 16, 560–568. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Fang, Q.; Yi, X.; Liu, G.; Li, R.-W. Recovery of gold from hydrometallurgical leaching solution of electronic waste via spontaneous reduction by polyaniline. Prog. Nat. Sci. 2017, 27, 514–519. [Google Scholar] [CrossRef]

- Akcil, A.; Erust, C.; Gahan, C.S.; Ozgun, M.; Sahin, M.; Tuncuk, A. Precious metal recovery from waste printed circuit boards using cyanide and non-cyanide lixiviants—A review. Waste Manag. 2015, 45, 258–271. [Google Scholar] [CrossRef] [PubMed]

- Işıldar, A.; van Hullebusch, E.D.; Lenz, M.; Du Laing, G.; Marra, A.; Cesaro, A.; Panda, S.; Akcil, A.; Kucuker, M.A.; Kuchta, K. Biotechnological strategies for the recovery of valuable and critical raw materials from m waste electrical and electronic equipment (WEEE)—A review. J. Hazard. Mater. 2019, 362, 467–481. [Google Scholar] [CrossRef]

- Habib Al Razi, K.M. Resourceful recycling process of waste desktop computers: A review study. J. Resour. Conserv. Recycl. 2016, 110, 30–47. [Google Scholar] [CrossRef]

- Changming, D.; Chao, S.; Gong, X.; Ting, W.; Xiange, W. Plasma methods for metals recovery from metal–containing waste. Waste Manag. 2018, 77, 373–387. [Google Scholar] [CrossRef]

- Szałatkiewicz, J.; Szewczyk, R.; Budny, E.; Missala, T.; Winiarski, W. Construction Aspects of Plasma Based Technology for Waste of Electrical and Electronic Equipment (WEEE) Management in Urban Areas. Procedia Eng. 2013, 57, 1100–1108. [Google Scholar] [CrossRef] [Green Version]

- Szewczyk, R.; Zieliński, C.; Kaliczyńska, M. Recent Advances in Automation, Robotics and Measuring Techniques ABC. J. Adv. Intell. Syst. Comput. 2014, 267, 687–695. [Google Scholar]

- Ramanayaka, S.; Keerthanan, S.; Vithanage, M. Urban mining of E-waste: Treasure hunting for precious nanometals. In Handbook of Electronic Waste Management; Elsevier BV: Amsterdam, The Netherlands, 2020; pp. 19–54. [Google Scholar]

- Manigandan, S.; Rajmohan, K.; Varjani, S. Current trends in gold recovery from electronic wastes. Curr. Dev. Biotechnol. Bioeng. 2020, 307–325. [Google Scholar] [CrossRef]

- Bhat, V.; Rao, P.; Patil, Y. Development of an Integrated Model to Recover Precious Metals from Electronic Scrap—A Novel Strategy for E-Waste Management. Procedia Soc. Behav. Sci. 2012, 37, 397–406. [Google Scholar] [CrossRef] [Green Version]

- Lillkung, K.; Aromaa, J. Hydrometallurgical recovery of platinum group metals. In Department of Materials Science and Engineering; Aalto University publication series; Aalto University: Espoo, Finland, 2012; pp. 1–80. [Google Scholar]

- Tuncuk, A.; Stazi, V.; Akcil, A.; Yazici, E.; Deveci, H. Aqueous metal recovery techniques from e-scrap: Hydrometallurgy in recycling. Miner. Eng. 2012, 25, 28–37. [Google Scholar] [CrossRef]

- Hilal, R.H. Removal of Precious Metals from Electronic-Waste by Using Composite Material, 3rd International Conference on Sustainable Engineering Techniques (ICSET 2020). IOP Conf. Ser. Mater. Sci. Eng. 2020, 881, 012089. [Google Scholar] [CrossRef]

- Arshadi, M.; Yaghmaei, S.; Esmaeili, A. Evaluating the optimal digestion method and value distribution of precious metals from different waste printed circuit boards. J. Mater. Cycles Waste Manag. 2020, 22, 1690–1698. [Google Scholar] [CrossRef]

- Camelino, S.; Rao, J.; Padilla, R.L.; Lucci, R. Initial Studies about Gold Leaching from Printed Circuit Boards (PCB’s) of Waste Cell Phones. J. Procedia Mater. Sci. 2015, 9, 105–112. [Google Scholar] [CrossRef]

- Tuncuk, A. Lab scale optimization and two-step sequential bench scale reactor leaching tests for the chemical dissolution of Cu, Au & Ag from waste electrical and electronic equipment (WEEE). Waste Manag. 2019, 95, 636–643. [Google Scholar] [CrossRef]

- Xiu, F.-R.; Qi, Y.; Zhang, F.-S. Leaching of Au, Ag, and Pd from waste printed circuit boards of mobile phone by iodide lixiviant after supercritical water pre-treatment. Waste Manag. 2015, 41, 134–141. [Google Scholar] [CrossRef]

- Fathollahzadeh, H.; Becker, T.; Eksteen, J.J.; Kaksonen, A.H.; Watkin, E.L. Microbial contact enhances bioleaching of rare earth elements. Bioresour. Technol. Rep. 2018, 3, 102–108. [Google Scholar] [CrossRef]

- Baniasadi, M.; Vakilchap, F.; Bahaloo-Horeh, N.; Mousavi, S.M.; Farnaud, S. Advances in bioleaching as a sustainable method for metal recovery from e-waste: A review. J. Ind. Eng. Chem. 2019, 76, 75–90. [Google Scholar] [CrossRef]

- Chi, T.D.; Lee, J.-C.; Pandey, B.; Yoo, K.; Jeong, J. Bioleaching of gold and copper from waste mobile phone PCBs by using a cyanogenic bacterium. Miner. Eng. 2011, 24, 1219–1222. [Google Scholar] [CrossRef]

- Liu, R.; Li, J.; Ge, Z. Review on Chromobacterium Violaceum for Gold Bioleaching from E-waste. Procedia Environ. Sci. 2016, 31, 947–953. [Google Scholar] [CrossRef] [Green Version]

- Marra, A.; Cesaro, A.; Rene, E.R.; Belgiorno, V.; Lens, P.N. Bioleaching of metals from WEEE shredding dust. J. Environ. Manag. 2018, 210, 180–190. [Google Scholar] [CrossRef]

- Işıldar, A.; van de Vossenberg, J.; Rene, E.R.; van Hullebusch, E.D.; Lens, P.N. Two-step bioleaching of copper and gold from discarded printed circuit boards (PCB). Waste Manag. 2016, 57, 149–157. [Google Scholar] [CrossRef]

- Jowkar, M.J.; Bahaloo-Horeh, N.; Mousavi, S.M.; Pourhossein, F. Bioleaching of indium from discarded liquid crystal displays. J. Clean. Prod. 2018, 180, 417–429. [Google Scholar] [CrossRef]

- Maroufi, S.; Nekouei, R.K.; Assefi, M.; Sahajwalla, V. Waste-cleaning waste: Synthesis of ZnO porous nano-sheets from batteries for dye degradation. Environ. Sci. Pollut. Res. 2018, 25, 28594–28600. [Google Scholar] [CrossRef]

- Naseri, T.; Bahaloo-Horeh, N.; Mousavi, S.M. Bacterial leaching as a green approach for typical metals recovery from end-of-life coin cells batteries. J. Clean. Prod. 2019, 220, 483–492. [Google Scholar] [CrossRef]

- Naseri, T.; Bahaloo-Horeh, N.; Mousavi, S.M. Environmentally friendly recovery of valuable metals from spent coin cells through two-step bioleaching using Acidithiobacillus thiooxidans. J. Environ. Manag. 2019, 235, 357–367. [Google Scholar] [CrossRef] [PubMed]

- Xiang, X.; Xia, F.; Zhan, L.; Xie, B. Preparation of zinc nano structured particles from spent zinc manganese batteries by vacuum separation and inert gas condensation. Sep. Purif. Technol. 2015, 142, 227–233. [Google Scholar] [CrossRef]

- Li, L.; Zheng, P.; Yang, T.; Sturges, R.; Ellis, M.W.; Li, Z. Disassembly Automation for Recycling End-of-Life Lithium-Ion Pouch Cells. JOM 2019, 71, 4457–4464. [Google Scholar] [CrossRef] [Green Version]

- Pagnanelli, F.; Moscardini, E.; Altimari, P.; Atia, T.A.; Toro, L. Leaching of electrodic powders from lithium ion batteries: Optimization of operating conditions and effect of physical pretreatment for waste fraction retrieval. Waste Manag. 2017, 60, 706–715. [Google Scholar] [CrossRef] [PubMed]

- Zhong, X.; Liu, W.; Han, J.; Jiao, F.; Qin, W.; Liu, T. Pretreatment for the recovery of spent lithium ion batteries: Theoretical and practical aspects. J. Clean. Prod. 2020, 263, 121439. [Google Scholar] [CrossRef]

- Ebin, B.; Petranikova, M.; Ekberg, C. Physical separation, mechanical enrichment and recycling-oriented characterization of spent NiMH batteries. J. Mater. Cycles Waste Manag. 2018, 20, 2018–2027. [Google Scholar] [CrossRef] [Green Version]

- Hassan, K.; Farzana, R.; Sahajwalla, V. In-situ fabrication of ZnO thin film electrode using spent Zn–C battery and its electrochemical performance for supercapacitance. SN Appl. Sci. 2019, 1, 302. [Google Scholar] [CrossRef] [Green Version]

- Horeh, N.B.; Mousavi, S.M.; Shojaosadati, S.A. Bioleaching of valuable metals from spent lithium-ion mobile phone batteries using Aspergillus niger. J. Power Source 2016, 320, 257–266. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Qu, W.; Zhang, X.; Lu, J.; Chen, R.; Wu, F.; Amine, K. Succinic acid-based leaching system: A sustainable process for recovery of valuable metals from spent Li-ion batteries. J. Power Source 2015, 282, 544–551. [Google Scholar] [CrossRef]

- Tanong, K.; Coudert, L.; Mercier, G.; Blais, J.-F. Recovery of metals from a mixture of various spent batteries by a hydrometallurgical process. J. Environ. Manag. 2016, 181, 95–107. [Google Scholar] [CrossRef]

- Pant, D.; Joshi, D.; Upreti, M.K.; Kotnala, R.K. Chemical and biological extraction of metals present in E waste: A hybrid technology. Waste Manag. 2012, 32, 979–990. [Google Scholar] [CrossRef]

- Shokri, A.; Pahlevani, F.; Levick, K.; Cole, I.; Sahajwalla, V. Synthesis of copper-tin nanoparticles from old computer printed circuit boards. J. Clean. Prod. 2017, 142, 2586–2592. [Google Scholar] [CrossRef]

- Xu, C.; Nasrollahzadeh, M.; Selva, M.; Issaabadi, Z.; Luque, R. Waste-to-wealth: Biowaste valorization into valuable bio(nano)materials. Chem. Soc. Rev. 2019, 48, 4791–4822. [Google Scholar] [CrossRef]

- Devi, P.; Hipp, K.N.; Thakur, A.; Lai, R.Y. Waste to wealth translation of e-waste to plasmonic nanostructures for surface-enhanced Raman scattering. Appl. Nanosci. 2020, 10, 1615–1623. [Google Scholar] [CrossRef]

- Fang, Z.; Qiu, X.; Chen, J.; Qiu, X. Degradation of the polybrominated diphenyl ethers by nanoscale zero-valent metallic particles prepared from steel pickling waste liquor. J. Desalin. 2011, 267, 34–41. [Google Scholar] [CrossRef]

- Samaddar, P.; Ok, Y.S.; Kim, K.-H.; Kwon, E.E.; Tsang, D.C.W. Synthesis of nanomaterials from various wastes and their new age applications. J. Clean. Prod. 2018, 197, 1190–1209. [Google Scholar] [CrossRef]

- Chen, M.; Huang, J.; Ogunseitan, O.A.; Zhu, N.; Wang, Y.-M. Comparative study on copper leaching from waste printed circuit boards by typical ionic liquid acids. Waste Manag. 2015, 41, 142–147. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Y.; Chen, M.; Tan, Q.; Wang, B.; Chen, S. Recovery of copper from WPCBs using slurry electrolysis with ionic liquid [BSO3HPy]∙HSO4. J. Hydrometall. 2018, 175, 150–154. [Google Scholar] [CrossRef]

- Tatariants, M.; Yousef, S.; Sakalauskaitė, S.; Daugelavicius, R.; Denafas, G.; Bendikiene, R. Antimicrobial copper nanoparticles synthesized from waste printed circuit boards using advanced chemical technology. Waste Manag. 2018, 78, 521–531. [Google Scholar] [CrossRef]

- Nascimento, M.A.; Cruz, J.C.; Reis, M.F.; dos Damasceno, O.I.; de Reis, E.L.; Reis, C.; Oliveira, A.F.; de Lopes, R.P. Synthesis of polymetallic nanoparticles from printed circuit board waste and application in textile dye remediation. J. Environ. Chem. Eng. 2018, 6, 5580–5586. [Google Scholar] [CrossRef]

- Maroufi, S.; Mayyas, M.; Sahajwalla, V. Waste materials conversion into mesoporous silicon carbide nanocermics: Nanofibre/particle mixture. J. Clean. Prod. 2017, 157, 213–221. [Google Scholar] [CrossRef]

- Majumder, D.R. Bioremediation: Copper Nanoparticles from Electronic-waste. Int. J. Eng. Sci. Technol. 2012, 4, 4380–4389. [Google Scholar]

- Rajarao, R.; Ferreira, R.; Sadi, S.H.F.; Khanna, R.; Sahajwalla, V. Synthesis of silicon carbide nanoparticles by using electronic waste as a carbon source. Mater. Lett. 2014, 120, 65–68. [Google Scholar] [CrossRef]

- Nayak, P.; Kumar, S.; Sinha, I.; Singh, K.K. ZnO/CuO nanocomposites from recycled printed circuit board: Preparation and photocatalytic properties. Environ. Sci. Pollut. Res. 2019, 26, 16279–16288. [Google Scholar] [CrossRef]

- Moriwaki, H.; Yamada, K.; Usami, H. Electrochemical extraction of gold from wastes as nanoparticles stabilized by phospholipids. Waste Manag. 2017, 60, 591–595. [Google Scholar] [CrossRef]

- Swain, B.; Shin, D.; Joo, S.Y.; Ahn, N.K.; Lee, C.G.; Yoon, J.-H. Synthesis of submicron silver powder from scrap low-temperature co-fired ceramic an e-waste: Understanding the leaching kinetics and wet chemistry. Chemosphere 2018, 194, 793–802. [Google Scholar] [CrossRef]

- Shokri, A.; Pahlevani, F.; Cole, I.; Sahajwalla, V. Selective thermal transformation of old computer printed circuit boards to Cu-Sn based alloy. J. Environ. Manag. 2017, 199, 7–12. [Google Scholar] [CrossRef] [PubMed]

- Devyatykh, E.A.; Devyatykh, T.O.; Boyarsky, A.N. Overview of Technologies for Extraction of Platinum Group Metals from Poor Raw Materials. KnE Eng. 2018, 3, 154–160. [Google Scholar] [CrossRef]

- Patel, A.; Dawson, R. Recovery of platinum group metal value via potassium iodide leaching. Hydrometall 2015, 157, 219–225. [Google Scholar] [CrossRef]

- Wu, Z.; Soh, T.; Chan, J.J.; Meng, S.; Meyer, D.; Srinivasan, M.; Tay, C.Y. Repurposing of Fruit Peel Waste as a Green Reductant for Recycling of Spent Lithium-Ion Batteries. Environ. Sci. Technol. 2020, 54, 9681–9692. [Google Scholar] [CrossRef]

- Mabbett, A.N.; Sanyahumbi, D.; Yong, P.; Macaskie, L.E. Biorecovered precious metals from industrial wastes: Single step conversion of a mixed metal liquid waste to a bioinorganic catalyst with environmental implications. Environ. Sci. Technol. 2016, 40, 1015–1021. [Google Scholar] [CrossRef]

- Murray, A.; Mikheenko, I.; Goralska, E.; Rowson, N.; Macaskie, L. Biorecovery of Platinum Group Metals from Secondary Sources. Adv. Mats. Res. 2007, 20–21, 651–654. [Google Scholar] [CrossRef]

- Macaskie, L.; Mikheenko, I.; Yong, P.; Deplanche, K.; Murray, A.; Paterson-Beedle, M.; Coker, V.; Pearce, C.; Cutting, R.; Pattrick, R.; et al. Today’s wastes, tomorrow’s materials for environmental protection. Hydrometall 2010, 104, 483–487. [Google Scholar] [CrossRef] [Green Version]

- Deplanche, K.; Bennett, J.A.; Mikheenko, I.P.; Omajali, J.B.; Wells, A.S.; Meadows, R.E.; Wood, J.; Macaskie, L.E. Catalytic activity of biomass supported palladium nanoparticles: Influence of the biological component, catalytic efficacy and potential applications in green synthesis of fine chemicals and pharmaceuticals. Appl. Catal. B Environ. 2014, 147, 651–665. [Google Scholar] [CrossRef] [Green Version]

- Izatt, R.M. Precious Metals: A Resource Worth Recycling, InvestorIntel. 2016. Available online: https://investorintel.com/sectors/technology-metals/technology-metals-intel/precious-metals-a-resource-worth-recycling/ (accessed on 28 March 2019).

- Hagelüken, C.; Lee-Shin, J.U.; Carpentier, A.; Heron, C. The EU Circular Economy and Its Relevance to Metal Recycling. Recycling 2016, 1, 242–253. [Google Scholar] [CrossRef]

- Kilian, A.; South Africa Starting to Embrace a Circular Economy. Creamer Media’s Engineering News. 2017. Available online: http://www.engineeringnews.co.za/article/south-africa-starting-to-embrace-a-circular-economy-2017-05-04 (accessed on 28 March 2019).

- Rivers, M.; Godfrey, L. Prepared for Department of Science and Technology. In A Waste Research, Development and Innovation Roadmap for South Africa (2015–2025); Summary report; Department of Science and Technology: Pretoria, South Africa, 2014. [Google Scholar]

- Lydall, M.; Nyanjowa, W.; James, Y. Prepared for Department of Science and Technology and CSIR. In Mapping South Africa’s Waste Electrical and Electronic Equipment (WEEE) Dismantling; Pre-Processing and Processing Technology Landscape: Pretoria, South Africa, 2017. [Google Scholar]

| Carrier | Advantages | Disadvantages |

|---|---|---|

| Ceramic | Good surface development and low thermal expansion. A good distribution of catalytic active phase. | Lower thermal and mechanical strength of carriers. |

| Metal | Resistant to thermal shock and mechanical damage; thinner walls; heats up fast; able to create a variety of shapes to increase exhaust flow easily; heat. | The process of obtaining catalytic active coating is complicated. |

| Oxide/Metal | (ppm) |

|---|---|

| Ceramic Monolith—Cordierite | |

| MgO | 85,100 |

| Al2O3 | 371,500 |

| SiO2 | 353,300 |

| Poisoning (Lubricants, Fuels) | |

| Na2O | 30,700 |

| P2O5 | 18,100 |

| CaO | 11,600 |

| Cr2O3 | 8000 |

| Fe2O3 | 24,400 |

| ZnO | 3300 |

| BaO | 7700 |

| S | 4400 |

| C | 4300 |

| Catalyst Support (Wash Coat) | |

| TiO2 | 25,900 |

| ZrO2 | 45,500 |

| La2O3 | 2900 |

| CeO2 | 35,100 |

| Catalyst (Noble Metals) | |

| Pd | 1364 |

| Pt | 754 |

| Rh | 257 |

| PGMs Total | 2375 |

| Reagents | Leaching Efficiency (%) | Results and Notes | Reference |

|---|---|---|---|

| 3HCl:1HNO3 (aqua regia) | Pt (97.58%) Pd (93.23%) | The dissolution of Pt and Pd by aqua regia was (97.58%) and (93.23%), respectively, at a time of 120 min, temperature 100 °C, and S/L ratio 1/20. | [28] |

| 1 M HCl 5 M NaCl 10% H2O2 | Pt (95.7%) | Calcination pretreatment enhanced the leaching efficiency of Pt at 800 °C calcination temperature. Pt leaching was 95.72% at 90 °C for 2 h with conditions of 1 M HCl, 5 M NaCl, S/L of 1:5, 10% H2O2: spent catalysts of 0.6 mL/g. | [46] |

| 2 M HCl 1 M H2O2 | Pd (>90%) | The presence of H2O2 showed improvement of Pd leaching by HCl to above 90%. Conditions were 2 M HCl, 1 M H2O2, at 25 °C, and reaction time 10–15 min. | [44] |

| 2 M HCl 4 M NaCl 0.67 M Fe3+ | Pd (99.5%) | The mixture solution of NaCl and HCl was employed as the leaching agent and FeCl3 as the oxidant. The optimum leaching conditions were determined to be HCl concentration of 2.0 M, NaCl concentration of 4.0 M, Fe3+ concentration of 0.67 M, temperature of 80 °C, and leaching time of 90 min with a leaching efficiency of Pd (99.5%) | [47] |

| 6 M HCl 10% H2O2 | Pt (99.9%) | Calcination pretreatment at 800 °C removed the coke and organics, decomposed PtO2, and enhanced the leaching efficiency of Pt (99.9%). The leaching conditions: 6 M HCl, L/S = 10, 10% H2O2: spent catalysts (0.6 mL/g), 90 °C for 2 h. | [46] |

| 9 M HCl (0.8 Vol%) H2O2 | Pt (96%) Pd (98%) Rh (86%) | The use of 0.8 vol% H2O2 and 9.0 M HCl mixture at 60 °C for a contact time of 2.5 h during the leaching process were considered the best conditions to be followed to save chemicals, energy, and time, and resulting efficiency was Rh (86%), Pt (96%), and Pd (98%). | [51] |

| 6M HNO3 1% (w/v) and at pH 9, P. fluorescens and megaterium | Pt (38%) Pd (44%) Rh (91%). Pt (35%) Pd (41%) Rh (82%) | Using two-step bioleaching at a pulp density of 1% (w/v) and at pH 9, P. fluorescens yielded a maximum recovery of Pt (38%), Pd (44%), and Rh (91%), and megaterium produced Pt (35%), Pd (41%), and Rh (82%). Ultrasound-assisted nitric acid pretreatment preceding bioleaching by cyanogenic bacteria is a promising biorecovery technique for the extraction of PGMs from spent automotive catalysts. | [51] |

| Electronic Waste | Metal Content for Different WEEE | |||||||

|---|---|---|---|---|---|---|---|---|

| Weight (g/t) | Weight (%) | |||||||

| Ni | Ag | Au | Pd | Fe | Cu | Al | Pb | |

| TV boards scrap | 0.3 (5) | 280 (6) | 20 (25) | 10 (6) | 28 (4) | 10 (39) | 10 (13) | 1 (2) |

| Mobile phone scrap | 0.1 (0) | 1380 (5) | 350 (67) | 210 (19) | 5 (0) | 13 (8) | 1 (0) | 0.3 (0) |

| PC board scrap | 1 (1) | 1000 (64) | 250 (5) | 110 (15) | 7 (0) | 20 (10) | 5 (1) | 1.5 (0) |

| PC mainboard scrap | 1.1 (2) | 639 (2) | 566 (81) | 124 (8) | 4.5 (0) | 14.3 (6) | 2.8 (0) | 2.2 (0) |

| DVD player scrap | 0.05 (1) | 115 (4) | 15 (33) | 4 (4) | 62 (17) | 5 (35) | 2 (4) | 0.3 (1) |

| TV scrap (CRTs removed) | 0.038 (4) | 20 (3) | <10 (-) | <10 (-) | - | 3.4 (82) | 1.2 (9) | 0.2 (2) |

| Printed circuit boards scrap | 0.85 (6) | 280 (3) | 110 (66) | - | 12 (1) | 10 (19) | 7 (4) | 1.2 (1) |

| Portable audio scrap | 0.03 (0) | 150 (3) | 10 (12) | 4 (2) | 23 (3) | 21 (78) | 1 (1) | 0.14 (0) |

| Calculator scraps | 0.5 (8) | 260 (6) | 50 (64) | 5 (3) | 4 (1) | 3 (12) | 5 (6) | 0.1 (0) |

| Typical electronic device scrap | 2 (2) | 2000 (3) | 1000 (87) | 50 (2) | 8 (0) | 20 (5) | 2 (0) | 2 (0) |

| Leaching Agent | Reagents and Conditions | Chemical Equation Involved |

|---|---|---|

| Cyanide | CN−, Air (O2) with pH > 10 at 25 ℃ | 4Au + 8CN− + O2 + 2H2O → 4Au (CN−)2 + 4OH− |

| Thiourea | CSN(NHS)2, Fe3+ with pH = 1–2 at 25 ℃ | 2Au + 4CSN(NHS)2 + 2Fe3+ → 2Au[CS(NH2)2]2+ + 2Fe2+ |

| Thiosulfate | S2O32−, NH3, Cu2+ with pH > 8–11 at 25 ℃ | 4Au + 8S2O32− + O2 + 2H2O → 4[Au(S2O3)2]3− + 4OH− |

| Halide | Cl−/Cl2, Br−/Br2, I−/I2 with pH < 4 at 25 ℃ | 2Au + 11HCl + 3HNO3 → 2HAuCl4 + 3NOCl + 6H2O |

| E-Waste | Leaching Method | Metal(s) | References |

|---|---|---|---|

| Printed circuit boards | Thiourea and thiosulfate leaching | Au (40%) and (70%) | [85] |

| CPU | Slurry electrolysis (HCl, NaCl, and H2O2) | Cu (67%) and Au (97.73%) | [88] |

| A mixture of electronic waste | Acid/halide leaching | Au (90%) | [89] |

| Random-access memory device | Iodine and hydrogen peroxide, ammonium persulfate | Ag (96.90%), Au (99.98%), and Cu (98.73%) | [90] |

| Mobile phone PCBs | HCl assisted iodine–iodide leaching | Au (63.3%), Ag (81.5%), and Pd (60.5%) | [91] |

| Mobile phone PCBs | Reduction smelting at a temperature of 1623 to 1698 K | Up to 95% of Au, Ag, Pt, Pd, and Rh at 1673 K | [38] |

| E-Waste | Method | Metal(s) Recovered | Reference |

|---|---|---|---|

| Mobile phone PCBs | C. violaceum in yeast extract and polyptone with glycine medium | Cu (24.6%) and Au (11.4%) | [93] |

| Electronic scrap | C. violaceum and nutritive salts | Au (70%) | [94] |

| Shredded dust from electronic waste | A. thiooxidans, and P. putida | Ce, Eu, Nd (>99%), La, Y (80%), and Au (48%) | [95] |

| Printed circuit boards | Thioxidans, At. ferrooxidans; P. putida and P. fluorescens | Cu (98.4%) and Au (44%) | [96] |

| Liquid crystal displays | thiooxidans | In (100%) and Sr (10%) | [97] |

| Waste Product | Method | Metal(S) Recovered | Reference |

|---|---|---|---|

| Zn-Mn batteries | Vacuum separation and inert gas condensation | Zn nanoparticles | [105] |

| Zn-C batteries | Facile thermal route | ZnO nanoparticles | [106] |

| Coin cells | Two-step bioleaching utilizing Acidithiobacillus thiooxidans | Li (99%), Co (60%), and Mn (20%) | [99] |

| Zn-C batteries | Homogeneous precipitation-calcination route | ZnO porous nanosheets | [100] |

| Lithium-ion mobile phone batteries | Bioleaching using Aspergillus niger | Cu (100%), Li (95%), Mn (70%), Al (65%), Co (45%), and Ni (38%) | [107] |

| Lithium-ion batteries | Succinic acid leaching agent and hydrogen peroxide as an oxidant | Co (100%) and Li (96%) | [108] |

| E-Waste Type | Method | Nanomaterial(s) | Reference |

|---|---|---|---|

| Glass fraction of obsolete computer monitors as a source of silica and computer plastic shell as a source of carbon | Uniaxial hydraulic press by applying 3 bars of pressure at 180 °C for 20 min and heated isothermally at 1550 °C in a tubular furnace (100 cm length × 5 cm diameter) under argon purge (1 L min−1) for 150 min | Silica carbide nanowires (30–200 nm in diameter) and a length of 10 µm) for electronic, optoelectronic applications, and sensors | [120] |

| Integrated circuits from electronic boards | Leaching was conducted using fungi and bacteria to obtain nano-sized copper leachate; the incubations were 21 days for fungi and 4–5 days for bacteria The reduction of nano-sized copper was conducted utilizing a leaf extract (Lantana camara weed) | Nano-sized copper obtained was 84–130 nm for bacteria and 93–115 nm for fungi The copper nanoparticles obtained were 20 nm after reduction | [121] |

| Compact disc as a carbon source | Carbothermal reduction at 1150 °C | Silicon carbide nanoparticles width size of 40–90 nm | [122] |

| Printed circuit boards (memory slots) | Leaching with aqua regia at 60 °C Nanoparticles synthesized by hydrothermal synthesis protocol | ZnO/CuO nanocomposites | [123] |

| Gold-containing electronic waste | Electrochemical extraction of gold | Gold nanoparticles | [124] |

| Scrap low-temperature co-fired ceramic | Leaching-precipitation-wet chemical reduction | Silver nanoparticles | [125] |

| Old computer printed circuit boards | Cryogenic grinding to 100 µm and followed by rapid heating and cooling to avoid oxidation | Cu–Sn based alloys | [126] |

| Old computer printed circuit boards | Thermal micronizing (heat treatment) | Copper–tin nanoparticles | [112] |

| Printed circuit boards | Leaching utilizing aqua regia and persulfate/sulfuric acid system, respectively; formation of nanoparticles in sodium hydroxide | Polymetallic nanoparticles | [120] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xolo, L.; Moleko-Boyce, P.; Makelane, H.; Faleni, N.; Tshentu, Z.R. Status of Recovery of Strategic Metals from Spent Secondary Products. Minerals 2021, 11, 673. https://doi.org/10.3390/min11070673

Xolo L, Moleko-Boyce P, Makelane H, Faleni N, Tshentu ZR. Status of Recovery of Strategic Metals from Spent Secondary Products. Minerals. 2021; 11(7):673. https://doi.org/10.3390/min11070673

Chicago/Turabian StyleXolo, Luthando, Pulleng Moleko-Boyce, Hlamulo Makelane, Nobathembu Faleni, and Zenixole R. Tshentu. 2021. "Status of Recovery of Strategic Metals from Spent Secondary Products" Minerals 11, no. 7: 673. https://doi.org/10.3390/min11070673

APA StyleXolo, L., Moleko-Boyce, P., Makelane, H., Faleni, N., & Tshentu, Z. R. (2021). Status of Recovery of Strategic Metals from Spent Secondary Products. Minerals, 11(7), 673. https://doi.org/10.3390/min11070673