Abstract

Oil sands surface mining in Alberta has generated over a billion cubic metres of waste, known as tailings, consisting of sands, silts, clays, and process-affected water that contains toxic organic compounds and chemical constituents. All of these tailings will eventually be reclaimed and integrated into one of two types of mine closure landforms: end pit lakes (EPLs) or terrestrial landforms with a wetland feature. In EPLs, tailings deposits are capped with several metres of water while in terrestrial landforms, tailings are capped with solid materials, such as sand or overburden. Because tailings landforms are relatively new, past research has heavily focused on the geotechnical and biogeochemical characteristics of tailings in temporary storage ponds, referred to as tailings ponds. As such, the geochemical stability of tailings landforms remains largely unknown. This review discusses five mechanisms of geochemical change expected in tailings landforms: consolidation, chemical mass loading via pore water fluxes, biogeochemical cycling, polymer degradation, and surface water and groundwater interactions. Key considerations and knowledge gaps with regard to the long-term geochemical stability of tailings landforms are identified, including salt fluxes and subsequent water quality, bioremediation and biogenic greenhouse gas emissions, and the biogeochemical implications of various tailings treatment methods meant to improve geotechnical properties of tailings, such as flocculant (polyacrylamide) and coagulant (gypsum) addition.

1. Introduction to Oil Sands Tailings

Alberta, Canada is home to the third largest oil reserve in the world [1]. Most of Alberta’s oil is unconventional oil because it is trapped within oil sands and cannot be extracted using the natural pressure differential created by drilling an oil well. Oil sands consist of sand, silt, clay, water, and a heavy oil referred to as bitumen. Surface mining (ex situ recovery) is used to extract oil sands reserves with less than 75 m of overburden, while deeper reserves must be extracted using in situ recovery methods (not discussed here) [1,2]. Oil sands exist beneath approximately 142,200 km2 of land in Alberta and are situated in three distinct regions: Peace River, Athabasca, and Cold Lake [1]. The Athabasca region, situated in northeastern Alberta, is the only region in Alberta in which oil sands ore can be extracted through surface mining. Surface mining is advantageous where possible because it results in significantly greater bitumen recovery than in situ recovery methods [3]. However, surface mining also requires more land disturbance and results in large volumes of waste, known as tailings, which consist of sand, silt, clay, oil sands process-affected water (OSPW), and unrecovered bitumen. Surface mining in the Athabasca oil sands has disturbed approximately 895 km2 of land and created over 1.3 billion m3 of tailings [1,4]. Tailings are temporarily stored above ground in dams referred to as tailings ponds but eventually must be reclaimed and integrated into mine closure landforms.

Alberta’s oil sands operate under a zero-effluent discharge policy [5]. Approximately 80 to 85% of OSPW generated during surface mining can be recovered and recycled back into the extraction process [6]. The remainder of the OSPW cannot be recovered because it is trapped between mineral grains in the tailings and in its place, fresh water from the Athabasca River is used in the extraction process. The water holding capacity of tailings contributes to a number of tailings management and reclamation challenges, such as physical and geochemical stability, tailings impoundment volumes, and land use requirements. Some of the other key environmental issues associated with oil sands tailings include OSPW toxicity [7,8,9], biogenic greenhouse gas emissions, namely methane (CH4) and carbon dioxide (CO2) [10,11,12,13,14,15], and potential seepage of OSPW from tailings into underlying clay till and sand channel sediments [16]. Tailings accumulation and land use has prompted concerns from stakeholders over the permanency of tailings ponds, while toxicity and potential contamination of the surrounding environment from OSPW has raised questions over whether tailings reclamation can be achieved [17]. To date, there have been limited reclamation certificates issued for oil sands sites and none in relation to tailings. A lack of certified, reclaimed land is a representation of the time it takes for tailings to be reclaimed, and the limited knowledge that currently exists for their reclamation.

The geochemical stability of tailings is intricately connected with tailings management and reclamation and is key to the long-term success of tailings landforms. Tailings geochemistry varies with each oil sands ore deposit and operator. Currently, there are four oil sands companies operating surface mines in Alberta: Suncor Energy Inc. (Suncor), Syncrude Canada Ltd. (Syncrude), Canadian Natural Upgrading Ltd. (CNUL) and Canadian Natural Resources Ltd. (CNRL) (CNUL and CNRL are collectively referred to as Canadian Natural), and Imperial Oil Resources Ltd. (Imperial), listed in order from oldest to newest surface mining operations. Each operator uses different tailings treatment methods and generates tailings with unique geochemical characteristics. This variability presents additional challenges to operators and regulators in predicting and assessing the long-term geochemical stability of tailings in closure landforms. Because tailings landforms are a relatively recent development, research to date has heavily focused on the biogeochemistry and geotechnical stability of tailings in tailings ponds. As such there are significant knowledge gaps surrounding the long-term geochemical stability of tailings in closure landforms. This review focuses on five mechanisms of geochemical change that are expected to have the greatest impact on the geochemical stability of tailings in closure landforms: consolidation, chemical mass loading via pore water fluxes, biogeochemical cycling, polymer degradation, and surface water and groundwater interactions. This review identifies key considerations and knowledge gaps surrounding the geochemical stability of tailings in closure landforms to direct future research and development, reduce the long-term environmental impacts of mine closure practices, and moderate the economic and environmental liabilities associated with oil sands tailings reclamation.

1.1. Tailings Generation

Bitumen is extracted from surface mined oil sands ore using the Clark Hot Water Process (HWP) patented by Dr. Karl Clark in 1929 [2]. The process has since been improved to achieve a recovery of greater than 90% from high grade ore containing > 10 wt% bitumen [18]. In HWP, caustic soda (sodium hydroxide, NaOH) and hot water are mixed with crushed oil sands ore, allowing bitumen to froth and float to the surface of primary and secondary separation vessels while solids settle to the bottom [19]. NaOH addition promotes bitumen recovery by increasing the pH of the crushed ore mixture and causing organic acids that are naturally present in bitumen to become water-soluble surfactants [2,20]. This effectively reduces surface and interfacial tensions in the mixture and causes the ore structure to disintegrate. However, while NaOH addition is beneficial for bitumen recovery, it also produces tailings that are difficult to process. Because of the reduced interfacial tensions, NaOH addition produces water-in-bitumen emulsions and dispersion of clays [2]. The water-in-bitumen emulsions must undergo further treatment (froth treatment) to separate the bitumen. The organic acids released from bitumen during the HWP are called naphthenic acid fraction compounds (NAFCs), which are a broad family of polar organic carboxylic acids, some of which are acutely and chronically toxic to a number of aquatic organisms [9,21,22,23,24,25].

While the bitumen froth undergoes froth treatment with a diluent to reduce bitumen viscosity and enhance separation, the remainder of the slurry is treated in separation vessels to further separate the solids and recover any residual bitumen [2,18]. This results in three main tailings streams: coarse tailings (approximately 55 wt% solids), fine tailings (6–10 wt% solids), and froth treatment tailings [2,3]. All three streams are made up of varying amounts of sands, fines, and OSPW, which contains dissolved salts, NAFCs, petroleum hydrocarbons, and unrecovered bitumen [26,27]. Coarse tailings are collected from the bottom of the primary separation cell and as such coarse tailings solids consist largely of sand (>44 µm). Conversely, fine tailings consist mostly of fines (<44 µm) and have a sand to fines ratio (SFR) of less than 1. The fines fraction of tailings is made up of silt and clay minerals, predominately kaolinite, illite, and quartz [3]. The fine tailings stream is treated using a thickener and polymeric flocculant prior to deposition in the case of the Imperial’s Kearl mine and CNUL’s Jackpine and Muskeg River mines to create a thickened tailings stream. Froth treatment tailings contain diluent, most commonly naphtha, comprised mainly of aliphatic hydrocarbons C5 to C16 and monoaromatic hydrocarbons (BTEX, benzene, toluene, ethylbenzene and xylenes), though light paraffinic diluents, consisting mainly of C5 to C6 alkanes, may also be used [3,28,29]. Paraffinic solvents have been primarily used at CNUL’s Jackpine Mine and Muskeg River Mine, Imperial’s Kearl mine, and Fort Hills operated by Suncor [30,31,32]. Froth treatment tailings may be referred to as Naphtha Recovery Unit tailings or Tailings Solvent Recovery Unit tailings depending on whether the froth treatment process is naphthenic or paraffinic. The produced streams (coarse tailings, fine tailings, thickened tailings, and froth treatment tailings) may or may not be combined, depending on the operator.

After being deposited in tailings ponds, tailings sand is quick to settle and segregate from the rest of the tailings [2,3]. The sand forms a beach that can be used to build containment dykes to retain the remainder of the tailings. After a few years of settling, the remainder of the tailings develop a loose card-house structure of clay particles surrounded by water with a solids content of roughly 30 wt% and will remain in this state for decades as they slowly dewater and consolidate. This stable slurry structure, historically referred to as mature fine tailings (MFT), is due to the low flocculation and consolidation characteristics of the clay water slurry and the high clay content of the tailings.

Because of the stability of the MFT, the inventory of tailings being stored in tailings ponds has been steadily increasing year over year. As of 2016, tailings ponds in northern Alberta cover a surface area of 257 km2 [5]. As such, many operators are treating tailings with physical and/or chemical amendments to enhance dewatering and consolidation and increase bearing capacity and shear strength of the tailings. Treated tailings may be deposited (back) in tailings ponds or in terrestrial dedicated disposal areas (DDAs) to undergo further dewatering. Moreover, the Government of Alberta implemented the Lower Athabasca Region Tailings Management Framework for the Mineable Athabasca Oil Sands in 2015 [33] and a regulation under the Tailings Management Framework, Directive 085: Fluid Tailings Management for Oil Sands Mining Projects, in 2017 [34] that require that fluid tailings (often used synonymously with fluid fine tailings (FFT)) be progressively treated and reclaimed throughout the life of a project and that all fluid tailings be ready to reclaim within 10 years of the end-of-mine-life of a project. The Tailings Management Framework defines fluid tailings as tailings with more than 5 wt% solids and an undrained shear strength of less than 5 kPa [34].

There are a number of terms that may be used to describe different types of fine-grained oil sands tailings. FFT refers to fine grained tailings with a solids content greater than 2 wt% but less than that of the liquid limit (which is the boundary between liquid and solid behavior) (see Figure 1) [35]. MFT is a term for FFT with an SFR of less than 0.3 and a solids content greater than 30 wt% [35]. MFT often have substantial microbial populations because of the length of time this material has been stored in tailings ponds. Thin fine tailings refer to FFT with a solids content between 15 and 30 wt% and a low SFR like that of MFT (<0.3) [35]. Fresh tailings may be used to describe tailings coming directly off of a primary separation vessel or other process line and are expected to have lower microbial activity. Flotation tailings are ‘fresh’ tailings collected from the bottom of flotation cells used in secondary separation of middlings and typically have an SFR between 0.8 and 1.5 (which is higher than that of FFT) and contain the majority of the fine-grained solids. Whole tailings refer to the combined tailings streams from flotation cells and primary separation vessels. The term FFT is often used as a catch-all term for fine grained tailings where the solids content and microbial populations are not specified. Therefore, FFT will be used hereinafter in place of fluid tailings, fine tailings, MFT, and thin fine tailings, unless it is important to differentiate between these types of tailings.

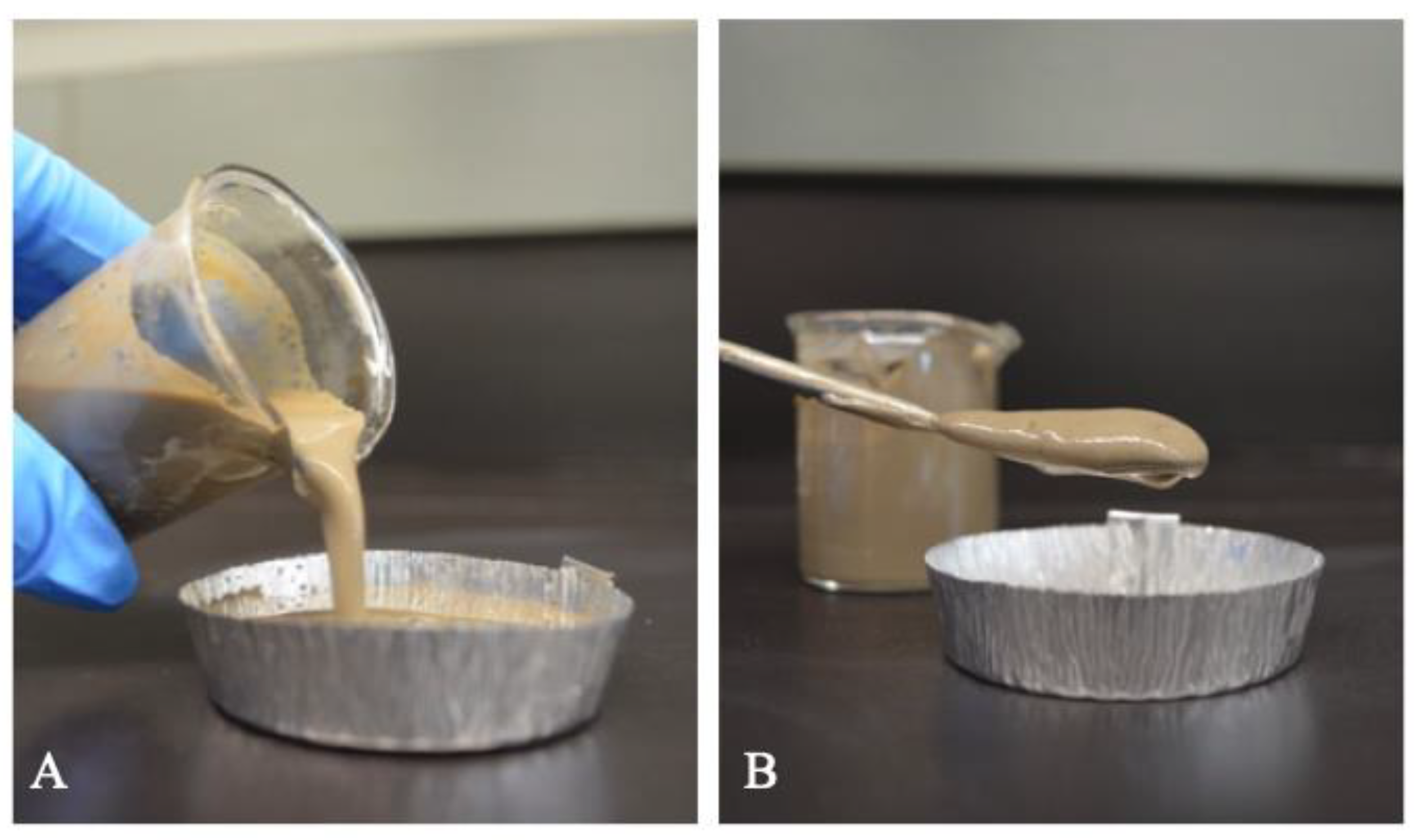

Figure 1.

Untreated fluid fine tailings (FFT) (A) and thickened tailings (B).

1.2. Tailings Treatment and Anticipated Landforms

There are a number of tailings management and reclamation strategies being investigated and implemented by oil sands operators. This review includes the most current and/or relevant future tailings management and reclamation practices. While there are many different tailings treatment technologies, these technologies will typically result in one of two tailings landforms: (i) end pit lakes (EPLs); and (ii) capped soft deposits (terrestrial landform with a wetland feature). A summary of the treatment technologies used by each oil sands operator, as well as the associated deposition method and anticipated landform, is provided in Table 1 and described in the following subsections.

A relatively new technology for the oil sands industry involving tailings filtration may also be implemented in the future and could result in dry stack tailings deposits. Dry stacking, in which coarse and/or fine grained tailings are compacted to form an unsaturated, dense, and stable stack, requires tailings with a solids content of at least 70 wt%, which can be difficult and costly to achieve with high fines content tailings [36,37]. Recently, a dry stack deposit was constructed at Syncrude by mixing FFT and Clearwater Shale to achieve a solids content of 72 wt% [38]. While this technology may be promising, it has yet to be widely adopted in the oil sands industry and has not been the focus of geochemical research. Because of the limited research available, dry stack tailings will not be a focus of this review. However, the geochemical stability of these landforms is a knowledge gap that should be addressed if this technology is adopted as an oil sands tailings management and reclamation strategy in the future.

Table 1.

Summary of oil sands fluid fine tailings treatment methods used by Canadian Natural Resources Ltd. (CNRL), Canadian Natural Upgrading Ltd. (CNUL), Imperial, Suncor, and Syncrude, as well as the associated deposition method and anticipated landform.

Table 1.

Summary of oil sands fluid fine tailings treatment methods used by Canadian Natural Resources Ltd. (CNRL), Canadian Natural Upgrading Ltd. (CNUL), Imperial, Suncor, and Syncrude, as well as the associated deposition method and anticipated landform.

| Fluid Fine Tailings (FFT) Treatment Method 1 | Operator | Deposition Method | Anticipated Landform | References |

|---|---|---|---|---|

| Untreated FFT | Syncrude Mildred Lake (Base Mine Lake (BML)) | Deep in-pit disposal | End pit lake | [39] |

| Permanent Aquatic Storage Structure (PASS) (FFT + coagulant + in-line flocculation) | Suncor Base Plant (Upper Pit Lake (UPL) and Lake Miwasin) 3 | [40] | ||

| Thickened tailings (TT) (FFT + mechanical thickener + flocculant) | Imperial Kearl | Deep in-pit disposal or thin lifts | Terrestrial deposit with wetland 3 | [4,31,41,42] |

| Fort Hills operated by Suncor | ||||

| CNUL Muskeg River Mine and Jackpine Mine | ||||

| Thickened tailings (TT) (FFT + in-line flocculation) | Imperial Kearl | Deep in-pit disposal or thin lifts | [4,31,39,40,43] | |

| Suncor - Tailings Reduction Operation (TRO) 4 | ||||

| Syncrude Aurora North and Mildred Lake | ||||

| Centrifugation (FFT + flocculant/coagulant 2 + centrifuge) | Syncrude Mildred Lake | Deep in-pit disposal or thin lifts | [39,42] | |

| CNUL Jackpine Mine | ||||

| Composite tailings (CT) (FFT + coarse tailings sand + coagulant 2) | Syncrude Aurora North and Mildred Lake | In-pit disposal | [39,41,43] | |

| CNUL Muskeg River Mine | ||||

| Non-segregating tailings (NST) (TT + coarse tailings sand + coagulant) | CNRL Horizon - NST or enhanced NST (eNST) 5 | In-pit disposal | [44] |

1 Gypsum is typically used as the coagulant, though alum is used for PASS and CO2 is used in NST; polyacrylamide (PAM) is the flocculant; 2 Coagulant may be gypsum or Flue gas desulphurization (FGD) solids (a mix of calcium sulphite, residual lime, petroleum coke, and gypsum); 3 Fort Hills operated by Suncor also plans to adopt PASS technology in the future [45]; 4 TRO: (FFT + in-line flocculation + thin-lift drying); 5 NST: (FFT + coarse tailings sand + CO2); eNST: (FFT + coarse tailings sand + CO2 + in-line flocculation).

1.2.1. End Pit Lakes

EPLs are engineered water bodies that contain oil sands by-product materials stored below grade in decommissioned open pits [46]. In general, there are expected to be two main types of EPLs in oil sands mine closure landscapes: (i) EPLs with tailings storage; and (ii) EPLs without tailings storage [47]. EPLs with tailings storage will generally be comprised of thick deposits (10–80 m) of treated or untreated tailings capped with fresh water (3–10 m). Oil sands by-product materials that may be stored in these EPLs include FFT, coarse tailings sand, lean oil sands, overburden, petroleum coke, and OSPW. Because of the low strength (0.01 to 1 kPa) and low wet density (1250 kg/m3) of untreated FFT, water capping is the only possible capping and closure option for these tailings [48,49]. However, water capping untreated FFT is more challenging than capping denser, treated tailings and increases the potential for particle resuspension in the water cap [48]. EPLs without tailings storage are simpler, especially from a design and management point of view, as they will consist of decommissioned open pits that have been allowed to fill with surface runoff and groundwater. Both types of EPLs will likely receive significant quantities of tailings seepage water from the reclaimed watersheds and saline groundwater from bedrock.

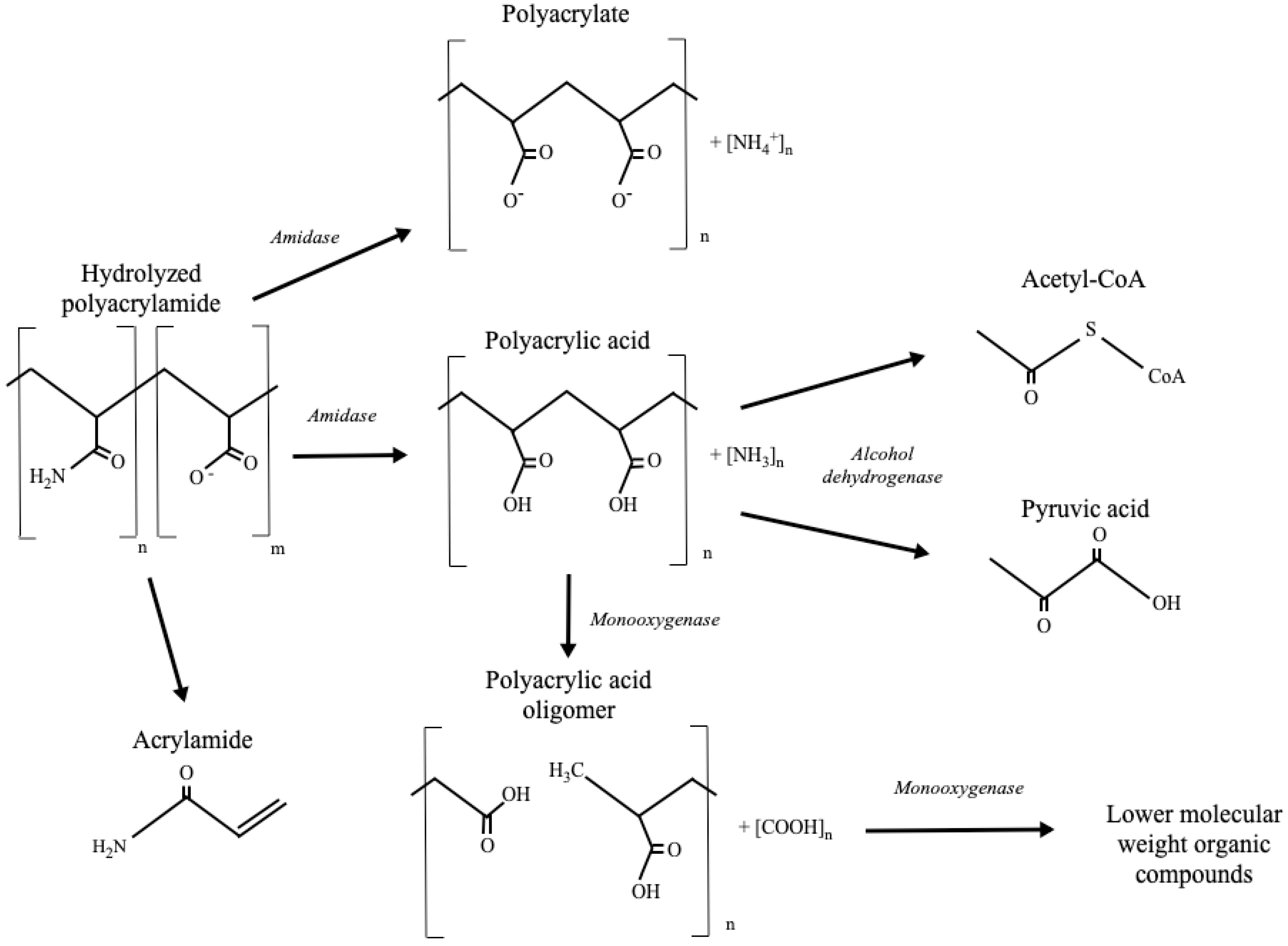

The end goal is for EPLs to develop into self-sustaining aquatic ecosystems that will receive surface and groundwater inputs from the surrounding land and discharge water to downstream environments [46]. Theoretically, EPLs are a suitable tailings management practice and mine closure strategy because the water cap serves as habitat for an aquatic ecosystem, meanwhile the tailings can naturally dewater over time (in the case of EPLs with tailings storage). There are currently 23 EPLs planned for northern Alberta, with the intention that these will become permanent features in reclaimed mine closure landscapes [50]. However, Alberta Energy Regulator has not approved EPLs as a tailings reclamation technology yet as the technology needs further demonstration, assessment, and research before it can be approved [4]. Currently, one 800 ha full-scale demonstration EPL has been developed in northern Alberta, Base Mine Lake (BML). BML was established in 2013 and is operated by Syncrude [50]. Between 1994 and 2012, approximately 186 Mm3 of untreated FFT was deposited in BML [27] and it currently consists of approximately 45 m of FFT covered with 9 m of water. Syncrude also has a demonstration scale EPL known as the Syncrude Demonstration Pond [50]. Suncor is also researching aquatic reclamation strategies and is currently implementing a commercial scale permanent aquatic storage structure (PASS) (which will eventually become Upper Pit Lake (UPL)) as well as an 18 ha demonstration scale PASS, known as Lake Miwasin. PASS is a tailings treatment method in which tailings are treated with a coagulant (alum) and flocculant (polyacrylamide, PAM, via in-line flocculation) and deposited in decommissioned mined-out pits for aquatic closure [4,45,50]. Fort Hills operated by Suncor also plans to implement PASS in the future [45].

While operators view EPLs as technically feasible, environmentally acceptable, and economically attractive, major concerns include the safety and stability of EPLs for public use and impacts on vegetation, fish, and wildlife [46]. Further, Indigenous communities are concerned over the ability of the end land use to allow for traditional activities [46]. Stakeholder opinions, contaminant remediation, and the fate of toxic compounds will be critical in EPLs becoming a self-sustaining ecosystem and a recognized closure landscape for tailings.

1.2.2. Capped Soft Deposits

To reclaim tailings and construct terrestrial closure landforms on the deposits, a capping layer made up of solid materials, ranging from half a meter to several meters of coarse sand tailings, coke, or overburden, can be placed over soft tailings deposits [35,36,48]. Capping of soft deposits (i) increases the surface load to accelerate dewatering and shorten consolidation time; (ii) creates suitable closure landforms that can account for surface water drainage patterns; and (iii) provides a suitable subsoil for surface vegetation [35]. Soft tailings have a higher strength than fluid tailings and as such, may be capped with solid materials (instead of water) [49]. Soft tailings deposits, suitable for capping with solids materials, can include both fines-dominated tailings (thickened tailings (TT) and centrifuged tailings) and fines-enriched sand tailings (composite tailings (CT) and non-segregating tailings (NST)) [35].

TT technology uses a high-rate mechanical thickener (or in-line thickening) and the addition of a chemical flocculant, commonly PAM, to promote rapid settling and sedimentation of suspended fines in tailings [37]. In-line thickening involves adding flocculant directly to tailings in the pipeline, with or without additional static mixers. TT with mechanical thickening as currently implemented is primarily treatment of flotation tailings, though Imperial’s Kearl also has a provision to feed FFT into their thickener. In-line thickening as currently implemented is either secondary treatment of a thickener underflow (Kearl) or treatment of FFT. TT using mechanical thickening is being used at Imperial’s Kearl, Fort Hills operated by Suncor, and CNUL’s Muskeg River and Jackpine mines [4,31,41,42]. In-line thickening is being used at Imperial’s Kearl, Suncor Base Plant, and Syncrude Aurora North and Mildred Lake mines [4,31,39,40,43]. TT that has undergone in-line thickening is commonly referred to as in-line thickened tailings (ILTT). TT technology typically produces tailings with a solids content of between 35 and 50 wt% [48]. Figure 1 provides a visual comparison of untreated FFT and TT.

After mechanical thickening or in-line thickening, TT may be deposited in deep (>10 m depth) in-pit disposal areas or in thin lifts [35,48]. Flocculant addition is primarily responsible for the initial dewatering that occurs in deep in-pit deposits though over time, self-weight consolidation also contributes to dewatering. Environmental effects (evaporation and freeze/thaw cycles) play a minimal role in dewatering tailings in deep deposits except to develop a surface crust once filling is complete [35]. Syncrude is currently investigating a tailings treatment and disposal method, referred to as Accelerated Dewatering, at their Mildred Lake mine in which ILTT is placed in thick lifts [39]. In thin-lift deposition (also called Atmospheric Fines Drying), TT is deposited in thin layers over a large area and allowed to dry in-place to form a solid deposit [4,35,51]. Initially, water drains from the deposit by gravity and capillary action however, over the course of several weeks, environmental effects (namely evaporation and freeze/thaw cycles) enable additional dewatering. After a layer is dry, another thin layer is placed over top and the dewatering process is repeated. Atmospheric Fines Drying of TT is currently being used by Suncor’s Base Plant (referred to as Tailings Reduction Operation (TRO)) and at both CNUL mines (Muskeg River and Jackpine) [40,41,42].

Another commercially used tailings treatment method is centrifugation, in which FFT is treated with a coagulant (usually gypsum) or flocculant and is separated into water and solids streams using centrifuges [35,37,52]. The released water is recycled back to the plant and the sediment, the ‘centrifuge cake’, which is roughly 45 to 55 wt% solids, is deposited in either thin lifts or deep in-pit disposal areas and capped [37,48]. Centrifuge tailings typically have a lower peak undrained shear strength (<1 kPa) and lower wet density (1400 kg/m3) than TT (<5 kPa; 1650 kg/m3) [48]. Because of their low strength, centrifuged tailings deposits cannot be capped with sand. Centrifugation is being used at Syncrude’s Mildred Lake mine and CNUL’s Jackpine Mine [39,42]. Syncrude uses either gypsum or flue gas desulphurization (FGD) solids, which are a mix of calcium sulphite, residual lime, petroleum coke, and gypsum, as the coagulant. Centrifugation is very capital intensive which is why it is not more widely used.

Combined management of FFT and beach sand produces fines-enriched sand tailings: CT or NST. CT is a mixture of FFT, coarse tailings sand, and a coagulant (often gypsum) and has a solids content of approximately 60 wt% and a wet density of 2000 kg/m3 [37,53]. The intent of CT is to capture fines within the voids between sand particles to produce non-segregating tailings. The target SFR for CT is typically 4 [48]. CT is then discharged into a containment area and becomes a rapidly consolidating, soft, cappable deposit [35,37]. CT is currently used at Syncrude’s Aurora North and Mildred Lake mines and CNUL’s Muskeg River Mine [39,41,43]. Similar to centrifugation, Syncrude uses either gypsum or FGD solids as the coagulant. NST is similar to CT except instead of FFT, TT is used. CNRL’s Horizon adds CO2 to their NST as the coagulant to accelerate dewatering and may also use a process referred to as enhanced NST (eNST) which involves NST and in-line flocculation [44]. Implementation of CT and NST technologies can be challenging due to the amount of sand required and issues with sand and fines segregating upon deposition. However, unlike TT and centrifuged tailings, large post-reclamation settlements extending over several decades are not expected for capped CT and NST deposits [48]. Consolidation (dewatering) of fines-enriched sand deposits (CT and NST) is predicted to be achieved within a decade, whereas consolidation of fines dominated tailings (TT, centrifuged tailings, and untreated FFT) is expected to occur over centuries [36].

After deposition, tailings deposits will consolidate and may also develop a surface crust through environmental effects (in the case of fines-dominated deposits with drainage) [35]. Once the soft tailings deposit reaches a strength of approximately 10 kPa it can be capped, depending on the capping method [49]. Capping enhances consolidation of the soft deposits, which must reach a strength of 25 to 75 kPa before they are trafficable for mobile equipment [35]. Once consolidation has advanced sufficiently, contouring and the placement of surface soil and vegetation can commence. The closure landform targeted for all of these capped soft deposits is a terrestrial deposit with a wetland [4]. Some amount of residual subsidence is anticipated for tailings deposits, particularly for soft fines-dominated deposits in deep in-pit disposal areas, however if the subsidence is substantial, a water capped deposit may be more appropriate [35]. Sandhill Fen is a sand-capped CT deposit that was reclaimed (though it does not have reclamation certification) to a 52 ha wetland beginning in 2012, consisting of 35 ha of upland and a 17 ha fen [48,54,55]. The Sandhill Fen is part of a research watershed that is being continuously monitored.

1.3. Tailings Water Chemistry and Mineralogy

Table 2 and Table 3 present the latest available (2019) surface water chemistry data for tailings deposits with ponded surface water at all oil sands mines operating in northern Alberta, with the exception of CNUL’s Jackpine Mine and Muskeg River Mine for which data were not available, compared to that of the Athabasca River. Table 2 presents surface water chemistry data for Imperial, CNRL, and Suncor tailings deposits and Table 3 presents similar data for Syncrude tailings deposits and the Athabasca River. Two Athabasca River monitoring stations were chosen for this comparison; the Fort McMurray station and the Old Fort Station which are upstream and downstream, respectively, of Alberta’s oil sands mining area [56]. The tailings deposits in Table 2 and Table 3 include tailings ponds, temporary DDAs, deep in-pit deposits, and EPLs. While Table 2 and Table 3 contain data on the surface water chemistry of tailings deposits, tailings pore water chemistry generally falls within the ranges seen in Table 2 and Table 3 though it may vary with depth (age) of the deposits [16,26,39,43,48,57,58,59,60,61]. The one exception to this is BML surface water, which is diluted with fresh water and as such, tailings pore water in BML FFT is more concentrated and in some cases contains twice the concentration of the chemical constituents and organics listed in Table 3 [39].

Tailings water typically has a circumneutral pH, and elevated sodium (Na+), chloride (Cl−), sulfate (SO42−), and bicarbonate (HCO3−) concentrations relative to the nearby Athabasca River. Conductivity measurements were eight to 18 times higher in surface water in tailings deposits than in the Athabasca River. In some instances, Cl− concentrations were nearly 200 times greater in tailings surface water than in the Athabasca River. The high salinity in tailings deposits is a result of caustic soda addition during bitumen extraction, highly saline oil sands ore in the McMurray Formation, and the zero-discharge policy in which OSPW is continuously recycled back into the extraction process resulting in a build-up of ions [62,63]. Tailings water chemistry will vary depending on the ore deposit, the operator, the age of the tailings (as organics may be degraded over time and salt accumulates in recycle water over time), and any chemical amendments. Amendments such as alum, gypsum, and FGD can contribute to higher concentrations of SO42−, such as in Suncor’s DDA3/PASS (615 mg/L), Syncrude’s Aurora East Pits (AEPs) (605 mg/L), and Syncrude’s deep cake deposit (850 mg/L). Suncor’s Mine Dump 9 has the highest SO42− (1100 mg/L), Cl− (890 mg/L), and Na+ (1240 mg/L) concentrations of all the tailings deposits listed in Table 2 and Table 3. This is presumably a result of the FFT being desiccated prior to co-disposal, resulting in an accumulation of salts. Overall, tailings treatment methods will influence the pH, salinity, ion concentrations, buffering capacity, and toxicity of pore water [64], which will ultimately impact vegetation establishment and fauna survival. As such, tailings water chemistry will likely be a major challenge for reclamation.

Table 2.

Year 2019 surface water chemistry for Imperial, Canadian Natural Resources Ltd. (CNRL), and Suncor oil sands tailings deposits with ponded surface water in Alberta. Tailings deposits include tailings ponds, temporary dedicated disposal areas (DDAs), deep in-pit deposits, and EPLs. Table 3 contains 2019 surface water chemistry for Syncrude tailings deposits and surface water chemistry from the nearby Athabasca River (provided for comparison).

Table 2.

Year 2019 surface water chemistry for Imperial, Canadian Natural Resources Ltd. (CNRL), and Suncor oil sands tailings deposits with ponded surface water in Alberta. Tailings deposits include tailings ponds, temporary dedicated disposal areas (DDAs), deep in-pit deposits, and EPLs. Table 3 contains 2019 surface water chemistry for Syncrude tailings deposits and surface water chemistry from the nearby Athabasca River (provided for comparison).

| Company | Imperial | CNRL | Operated by Suncor | Suncor | ||||

|---|---|---|---|---|---|---|---|---|

| Tailings Deposit | Kearl West External Tailings Area (WETA) [31] | Horizon External Tailings Facility (ETF)/DDA1 [44] | Fort Hills Out of Pit Tailings Area (OPTA) [45] | Pond 2/3 [40] | Ponds: Average of 7 1 [40] | DDA1 [40] | Mine Dump 9 [40] | DDA3 2 [40] |

| Type of Tailings Deposited 3 | FFT, FTT, CST | FFT, NST/eNST, FTT, CST | FFT, FTT, CST, TT | FTT | FFT, Historical CT | TRO | Co-Disposal: TRO from DDA1 and Overburden | PASS |

| Conductivity (µS/cm) | 4043 | 1738 | 3800 4 | 3342 4 | 4100 4 | 5800 4 | 4100 4 | |

| pH | 8.1 | 8.14 | 7.9 | 8.1 | 8.4 | 8.5 | 8.6 | 8.1 |

| Carbonate (mg/L) | <1 | 0 | 11 | 25 | 21 | 25 | 1 | |

| Bicarbonate (mg/L) | 300 | 1326 | 524 | 951 | 743 | 884 | 570 | 685 |

| Chloride (mg/L) | 24 | 767 | 114 | 638 | 533 | 731 | 890 | 594 |

| Sulfate (mg/L) | 270 | 364 | 215 | 251 | 249 | 1100 | 615 | |

| Calcium (mg/L) | 33.7 | 15.2 | 20.5 | 12 | 23 | 15 | 26 | 28 |

| Magnesium (mg/L) | 14 | 11.6 | 7.6 | 10 | 14 | 11 | 18 | 14 |

| Sodium (mg/L) | 193 | 947 | 331 | 730 | 649 | 842 | 1240 | 858 |

| Potassium (mg/L) | 11 | 20.1 | 15.2 | 13 | 13 | 12 | 13 | 16 |

| Total suspended solids (mg/L) | 61.3 | 260 | 1588 | 211 | 8942 | 5400 | 4 | 13 |

| Total dissolved solids (mg/L) | 716 | 2631 | 1235 | 2003 | 1861 | 2320 | 3600 | 2469 |

| Naphthenic acid fraction compounds (mg/L) 5 | ||||||||

1 Average of 7 Suncor Ponds: 1A, 5, 6, 7, 8B, STP, TFT; 2 DDA3 will become Upper Pit Lake; 3 Tailings acronyms: fluid fine tailings (FFT); froth treatment tailings (FTT); coarse sand tailings (CST); thickened tailings (TT); composite tailings (CT); non-segregating tailings/enhanced non-segregating tailings (NST/eNST); Tailings Reduction Operation (TRO); Permanent Aquatic Storage Structure (PASS); 4 Conductivity reported in S/cm but the authors believe this was an error. The conductivity measurements have been corrected and reported as μS/cm in this paper; 5 Determined using Fourier-transform Infrared Spectrometry, presumably following the procedure outlined in Ripmeester and Duford [65]. Note. Empty cell indicates measurement not provided.

Table 3.

Year 2019 surface water chemistry for Syncrude oil sands tailings deposits with ponded surface water in Alberta. Tailings deposits include tailings ponds, temporary dedicated disposal areas (DDAs), deep in-pit deposits, and EPLs. Surface water chemistry from the nearby Athabasca River is provided for comparison. Table 2 contains 2019 surface water chemistry for Imperial, Canadian Natural Resources Ltd. (CNRL), and Suncor oil sands tailings deposits.

Table 3.

Year 2019 surface water chemistry for Syncrude oil sands tailings deposits with ponded surface water in Alberta. Tailings deposits include tailings ponds, temporary dedicated disposal areas (DDAs), deep in-pit deposits, and EPLs. Surface water chemistry from the nearby Athabasca River is provided for comparison. Table 2 contains 2019 surface water chemistry for Imperial, Canadian Natural Resources Ltd. (CNRL), and Suncor oil sands tailings deposits.

| Company | Syncrude | Athabasca River | ||||||

|---|---|---|---|---|---|---|---|---|

| Tailings Deposit | Aurora Settling Basin [43] | Aurora East Pits (AEPs): Average of 2 1 [43] | Mildred Lake Settling Basin (MLSB) [39] | Ponds: Average of 3 2 [39] | BML [39] | Deep Cake Deposit [39] | Fort McMurray Station: Average Monthly 2019 Data 3 [66] | Old Fort Station: Average Monthly 2019 Data [66] |

| Type of Tailings Deposited 4 | FFT, CST | FFT, CT, CST | FFT, FTT, CST | FFT, CT, CST | FFT | Centrifuge Cake | N/A | N/A |

| Conductivity (µS/cm) | 3400 | 3600 | 3200 | 4167 | 2600 | 4400 | 332 | 320 |

| pH | 8.26 | 8.30 | 7.96 | 8.48 | 8.48 | 8.51 | 7.98 | 7.78 |

| Carbonate (mg/L) | 10 | 5 | 10 | 21 | 16 | 16 | ||

| Bicarbonate (mg/L) | 670 | 675 | 680 | 933 | 740 | 750 | 168 | 150 |

| Chloride (mg/L) | 440 | 430 | 410 | 593 | 390 | 490 | 4.6 | 15.1 |

| Sulfate (mg/L) | 550 | 605 | 435 | 452 | 160 | 850 | 34.4 | 27.9 |

| Calcium (mg/L) | 44 | 54 | 22 | 9 | 27 | 30 | 42.2 | 37.8 |

| Magnesium (mg/L) | 25 | 27 | 12 | 7 | 13 | 26 | 11.3 | 10.3 |

| Sodium (mg/L) | 725 | 725 | 685 | 950 | 580 | 850 | 13.7 | 18.2 |

| Potassium (mg/L) | 26 | 28 | 12 | 12 | 9.5 | 15 | 2.3 | 1.8 |

| Total suspended solids (mg/L) | 300 | 300 | 350 | 30 | ||||

| Total dissolved solids (mg/L) | 2300 | 2400 | 1900 | 2750 | 1700 | 2600 | 191.8 | 184.2 |

| Naphthenic acid fraction compounds (mg/L) 5 | 55 | 49 | 31 | |||||

1 Average of 2 Syncrude Ponds: AEPN, AEPS; 2 Average of 3 Syncrude Ponds: SWSS, SWIP, NMSP; 3 Monthly data for November 2019 not available; 4 Tailings acronyms: fluid fine tailings (FFT); froth treatment tailings (FTT); composite tailings (CT); coarse sand tailings (CST); not applicable (N/A); 5 Determined using Fourier-transform Infrared Spectrometry, presumably following the procedure outlined in Ripmeester and Duford [65]. Note. Empty cell indicates measurement not provided.

Table 4 presents typical ranges of bitumen, solids, and fines content for untreated FFT. These parameters will vary depending on the ore deposit, processing techniques, and the depth from which samples are collected in tailings ponds. The solids content and SFR of FFT generally increase with depth (age) within tailings ponds due to consolidation and segregation of coarser (heavier) and finer particles [39,43,67]. For example, at a depth of 4 m in Syncrude’s Mildred Lake Settling Basin (MLSB), FFT has a solids content of 23.1 wt% and an SFR of 0 [39]. However, FFT at depth of 37 m within MLSB has had years to consolidate and as such has a solids content of 78.1 wt% and an SFR of 1.07. Clay sized (2 µm) minerals in oil sands tailings are typically dominated by quartz, kaolinite, and illite-smectite [3,68]. Other components may include illite, kaolinite-smectite, and chlorite, as well as trace amounts of pyrite (FeS2(s)), siderite (FeCO3(s)), rutile, anatase, lepidocrocite, and marcasite [3,68]. Kaminsky et al. [68] examined the distribution of clay minerals in tailings process streams and found that 30 ± 4 wt% of the 0.2–2 µm fraction of tailings solids consisted of non-clay components. Geochemical analysis of BML FFT showed a dominance of quartz, illite, kaolinite, and chlorite with small amounts of siderite, pyrite, and iron(II) sulfide (FeS(s)) [27].

Table 4.

Typical range of bitumen, solids, and fines content in untreated oil sands fluid fine tailings.

Froth treatment tailings solids consist largely of quartz and kaolinite and typically contain the highest concentrations of heavy minerals [71]. Titanium bearing minerals identified in froth treatment solids include rutile, anatase, brookite, and ilmenite. In addition, quartz and other silicates are often intergrown with FeS(s), titanium oxides, iron carbonates, iron-titanium oxides, and other rare earth element oxides [71]. Minerals in the froth treatment tailings often contain impurities such as manganese, iron, calcium, silicon, and aluminum, with iron being the most common contaminant in minerals in which it is not a fundamental component, such as rutile [71]. The unique mineralogy of froth treatment tailings presents additional biogeochemical challenges when reclaiming these tailings, as discussed in Section 2.3.7.

2. Mechanisms of Geochemical Change Expected for Tailings Landforms

2.1. Consolidation

Consolidation of FFT refers to the decrease in pore pressure that occurs as water escapes the tailings matrix, and the subsequent increase in effective stress. During consolidation, the volume of tailings decreases in accordance with the volume of water expressed. Thus, tailings consolidation also corresponds with an increase in density and solids content. Self-weight consolidation of tailings has been used to naturally dewater tailings for over 50 years, however this process can be slow depending on the properties of the tailings and requires large areas to contain the tailings and expressed pore water [37]. Because of the unique properties of oil sands tailings, their consolidation behavior can only be described using Gibson’s finite strain theory which accounts for the large volume, hydraulic conductivity, and compressibility changes tailings undergo during consolidation [72,73,74]. FFT has low hydraulic conductivity, typically between 1 × 10−6 and 1 × 10−9 m/s, and low compressibility and as such self-weight consolidation of this material can take decades [37]. Tailings consolidation is closely tied to geochemistry as tailings dewatering contributes to chemical mass loading in overlying surface water and contaminant transport to nearby surface water and groundwater.

2.1.1. Consolidation Behavior of Different Types of Tailings

Consolidation behavior is different for untreated and treated tailings and will vary depending on material properties of the tailings including solids content, fines content, and SFR. Generally, tailings with a higher initial solids content consolidate at a faster rate [69]. SFR is also indicative of consolidation behavior as sand can act as an internal surcharge on FFT. Therefore, mixing sand and FFT will result in a mixture that undergoes self-weight consolidation faster and to a greater extent than FFT alone [69,75]. CT, which typically has a solids content of 60 wt% and an SFR of 4, has a higher hydraulic conductivity and lower compressibility than untreated FFT and will therefore consolidate at a faster rate. Untreated FFT typically has a low solids content (~30 wt%) and low SFR (~0.1) and is very slow to consolidate [67,69,76]. For example, Jeeravipoolvarn et al. [69] analyzed self-weight consolidation in three 10 m standpipes filled with tailings and found that untreated FFT (30.6 wt% solids, 89.0 dry wt% fines, ~45 dry wt% clays, 0.12 SFR) strained more than 30% over 25 years and the solids content increased to 41.8 wt%, but there was little to no effective stress generation in the tailings. The lack of strength generation in untreated FFT even after large volume changes has implications for closure of these tailings, as trafficability (bearing capacity) and capping options are limited [69]. As such, most operators are using physical and/or chemical amendments to improve the geotechnical properties of their tailings for closure.

Wilson et al. [77] used large strain consolidation tests to compare consolidation behavior in six tailings samples: five TT samples (49.0–55.0 wt% solids; 51–67 dry wt% fines) and one untreated FFT sample (46.1 wt% solids; 96 dry wt% fines). In all cases, the treatment (flocculant addition and thickening) of the tailings increased hydraulic conductivity of the tailings by at least half an order of magnitude, which in turn results in faster consolidation. Further, Sorta et al. [78] reported that an FFT-sand mixture (20 dry wt% fines, 10 dry wt% clay) had an order of magnitude higher hydraulic conductivity and a lower compressibility than TT (50–60 dry wt% fines, 26–31 dry wt% clay), indicating improved consolidation behavior for sand-treated tailings over TT.

2.1.2. Long-Term Consolidation and Settlement in Tailings Landforms

McKenna et al. [36] conducted long-term consolidation modeling for various types of FFT: untreated FFT, dried FFT (70 wt% solids), dried FFT (80 wt% solids), TT (1:1 SFR), CT (4:1 SFR), and centrifuged FFT (50 wt% solids). McKenna et al. [36] predicted that 10 years after filling a 40 m deposit, centrifuged FFT and dried (80 wt%) FFT would undergo between 0 to 2 m of settlement; CT, dried FFT (70 wt%), and TT would undergo between 2 and 4 m of settlement; and untreated FFT would undergo greater than 6 m of settlement. Further, untreated FFT and centrifuged FFT were predicted to experience the largest ultimate settlement (>10 m) over several hundred years, whereas consolidation of CT was achieved within a decade [36,48]. Capping deposits will only increase this settlement over time, with a thicker cap resulting in greater settlement and thus greater water release [48]. Settlements of this scale over time would have huge implications for the long-term management and maintenance of the capping layer and the expressed water. Consolidation is expected to have the largest impact on deep in-pit deposits that are targeted for terrestrial reclamation with a wetland and depending on the tailings treatment, large settlements in these deposits are likely. Settlement greater than 2 m in terrestrial tailings deposits will result in the generation of a lake as opposed to the targeted shallow-water wetland area which would drastically alter the intended design and purpose of these landforms [48]. Consolidation of tailings deposits is expected to occur over decades to centuries, depending on the tailings deposited, and as such, will influence the geochemical stability of tailings landforms for many years.

2.2. Chemical Mass Loading via Pore Water Fluxes

Tailings dewatering, through consolidation and/or environmental effects such as evaporation or freeze/thaw cycles, coincides with vertical chemical fluxes of the organic compounds and chemical constituents in tailings pore water. While treating tailings generally increases hydraulic conductivity and consolidation rates, it is also likely to increase advective chemical fluxes in the short term. These chemical fluxes can have negative impacts on water quality in the case of wet reclamation methods (EPLs or wetlands) and may lead to salt accumulation or cover salinization in dry reclamation scenarios. The following subsections are divided into wet and dry reclamation scenarios to highlight the impact of chemical fluxes in different types of tailings landforms.

2.2.1. Wet Reclamation Scenarios

Recent BML studies by Dompierre and Barbour [79] and Dompierre et al. [80] identified two key processes by which chemical constituents in tailings pore water may move from FFT into the overlying water cap: (i) advection and dispersion driven by upward pore water flow as tailings dewater and consolidate; and (ii) FFT disturbance due to fluid movement in the water cover (for example, internal waves), which would cause rapid, but intermittent mass loading to the water cap. Dompierre and Barbour [79] and Dompierre et al. [80] determined that an advection-dispersion (from FFT dewatering) mass transport regime is dominant in BML, with intermittent disturbance near the FFT-water interface causing additional mass transport of pore water constituents. Using a mass balance of BML water, Dompierre et al. [80] estimated the advective vertical pore water flux to be 0.002 m3/m2/d, equivalent to 0.73 m of FFT settlement per year. Mass balance calculations and numerical modeling confirmed that BML is currently undergoing self-weight consolidation, which is releasing pore water and causing chemical mass loading to the water cap [80]. In an earlier study conducted one year after BML was commissioned, advective vertical mass transport was estimated to be 0.004 m3/m2/d [79], suggesting that consolidation rates are decreasing over time and/or that disturbances at the FFT-water interface are decreasing due to the greater depth of the water cap, thus reducing chemical mass loading [80]. While chemical mass loading into BML water cap is primarily due to advection, over time as consolidation rates decrease, chemical mass loading into the water cap is expected to occur predominantly as a result of diffusion [80].

Chemical pore water constituents in BML FFT include high concentrations of Na+ (977 mg/L), Cl− (633 mg/L), and HCO3− (1885 mg/L) as well as lesser amounts of calcium (Ca2+), magnesium (Mg2+), potassium, and ammonia [39]. The presence and concentrations of these constituents in BML pore water indicates that pore water release (advective transport) will likely contribute these constituents to the water cap for many years, thus influencing BML water quality in the long term [27]. White and Liber [81] identified Na+, Cl−, and HCO3− as the ions making up the majority of BML’s surface water salinity, comprising 92% of the total osmolarity, which is consistent with the dominant ions in BML FFT [27,39]. These ions present the highest toxicological risk to sensitive freshwater aquatic organisms [81,82]. While the acute toxicity of OSPW has been attributed to NAFCs, chronic toxicity is due to a combination of NAFCs and salts, which may have an additive effect on fish toxicity [50,83,84]. White and Liber [82] demonstrated that there was reduced survival of the freshwater invertebrate Chironomus dilutus in 2014 BML surface water. The water quality in BML appears to have improved over time though, as no adverse effects were observed after exposure of Chironomus dilutus to 2015 BML surface water [82]. However, because BML salinity is likely to persist for decades, BML is expected to be capable of supporting only salt-tolerant aquatic organisms with reduced diversity [82]. Additionally, BML FFT contains organic constituents such as residual bitumen, NAFCs (65 mg/L), and polycyclic aromatic hydrocarbons which are also being released into BML surface water [39,47]. This is a significant environmental concern as NAFCs and polycyclic aromatic hydrocarbons are both bioavailable and toxic to aquatic organisms and may hinder the development of an aquatic ecosystem in BML [24,85,86].

In addition to chemical mass loading, pore water expression from FFT may be contributing to BML water cap turbidity which can impact light penetration and thereby water quality, aquatic habitat, and aerobic biodegradation [47]. Other processes that may impact total suspended solids concentrations in BML include particle settling, wind waves, convection, and biogenic gas ebullition from FFT [87]. Field data have shown that surface water turbidity in BML after lake turnover can reach as high as 308 NTU (nephelometric turbidity units) [88]. Studies have found that even an increase in turbidity from 10 to 50 NTU can have a rapid, negative effect on aquatic metabolism [89,90]. Conversely, if processes that contribute to physical water mixing, and thereby turbidity, are limited, dissolved oxygen will be consumed and potentially lead to hypoxia in EPL water caps (discussed further in Section 2.3.1). Depositing chemically amended tailings in EPLs (such as PASS treated tailings which have been amended with alum) may improve the stability of the FFT-water interface and mitigate turbidity issues while also increasing the volume of tailings that can be stored in an EPL [48]. However, treated tailings may increase chemical mass loading to the water cap initially, as treated tailings have higher initial hydraulic conductivities than untreated tailings and therefore may generate larger chemical fluxes in the short term.

Syncrude CT was deposited in a pilot wetland, the Sandhill Fen, consisting of approximately 40 m of CT, a 10 m intermediary layer of sand tailings, and a surface wetland constructed of peat and clay till [91]. The major ions in near-surface water in Syncrude’s Sandhill Wetland are HCO3−, SO42−, Cl−, Na+, Ca2+, and Mg2+ [92], which is consistent with the chemicals elevated in OSPW. Biagi et al. [55] found that during the first years of operation (2013–2015), concentrations of SO42−, Cl−, Na+, Ca2+, and Mg2+ increased annually in the wetland. The fen was designed with an underdrain system and a fresh water supply to limit salinization which kept conductivity levels low throughout 2013 (<1000 µS/cm). In 2014 and 2015, conductivity increased to >1000 µS/cm and >2000 µS/cm, respectively, due to reduced water management practices during these years. Using stable isotopes, Biagi et al. [55] were able to show that these ions primarily stemmed from upward fluxes of pore water from the underlying CT deposit.

Sodium is the dominant cation in the Sandhill Wetland and has increased by roughly 48 mg/L each year since 2015 [92]. Vessey et al. [93] demonstrated that the peat and clay till cover on the Sandhill Fen has limited and short-lived Na+ attenuation capacity that is controlled by cation exchange. This suggests that elevated Na+ concentrations will likely persist in the wetland and soil cover which has implications for water quality and vegetation growth. SO42− and HCO3− are the dominant anions in the Sandhill Wetland [92], though elevated SO42− may constrain the production of methane and methylmercury, which bioaccumulates and poses a threat to aquatic organisms, wildlife, and humans [94,95]. Saline pore water migration is apparent in the peat and clay till cover of the Sandhill Fen [93]. Ion concentrations were fairly uniform with depth but varied across six sampling locations, indicating that more than one source is contributing to soil pore water within the Sandhill Fen [93]. Soil pore water in some locations was dominated by the Na-Cl type pore water released from the upland tailings sand and underlying CT, while soil pore water in other locations was influenced by the Ca-Mg-SO4 type water from Mildred Lake Reservoir. As anion and cation concentrations and conductivity measurements have been increasing annually since 2015, the water chemistry in the Sandhill Wetland is becoming increasingly similar to that of natural saline fens which exhibit elevated conductivity and high sodicity [92]. The impacts of pore water salinity in tailings should be understood and incorporated into landform design, as chemical fluxes are likely to contribute salinity to wetlands, water caps, and/or cover material in landforms for many years.

From a water chemistry standpoint, the Sandhill Fen is indicative of a saline fen, whereas vegetation surveys have concluded the site will consist of a variety of wetland types [92,96]. After a three-year study of vegetation communities at the Sandhill Fen, Vitt et al. [96] determined that the wetland was not on a trajectory to a peat-forming fen but was representative of the early stages of a marsh or riparian community. At the time of the study, approximately 40% of the fen was occupied by desirable fen species, whereas 48% was dominated by upland and weedy species, and the remainder was characterized by marsh species [96]. These differences in vegetation coincided with variations in salinity concentrations and water levels throughout the fen. Similarly, Biagi et al. [97] found that marsh-like conditions had developed in much of the fen, due in part to a high water table and salinity throughout the fen. As the CT deposit continues to consolidate and the fen establishes hydrologic connections with the surrounding watershed, water levels, water chemistry, and vegetation within the fen will continue to be impacted, all of which will influence the type of wetland(s) that develop at the Sandhill Fen. Peatlands will require centuries to accumulate enough peat to reach pre-disturbance conditions [98], suggesting that peatlands will be replaced by marshes and ponds within initial tailings reclamation landscapes [99]. Further, due to elevated ion concentrations, the reclaimed landforms will likely be considerably different from pre-disturbance conditions [100]. Though peatland restoration will likely not be achieved in the near future, mineral wetlands such as marshes are still important features of the boreal forest which encompasses Alberta’s oil sands.

2.2.2. Dry Reclamation Scenarios

Roshani et al. [101] conducted laboratory experiments to examine geochemical changes in two 25 cm thin-lift deposits of FFT under atmospheric drying conditions. Initially FFT pore water contained high concentrations of Na+ (617 ppm) and lesser amounts of Ca2+, Mg2+, iron, and aluminum. However, water content decreased in the lifts due to evaporation, which resulted in a significant reduction in pore water conductivity and increased ion concentrations in the solid phase. Salt precipitation (mostly Na) in the FFT voids increased with time and resulted in decreased evaporation over time by reducing vapour diffusion which may have implications for long-term dewatering of thin lifts [101]. Hydraulic conductivity of the FFT also decreased over time as the pores rearranged into a compact, aggregated fabric due to evaporation, suction development, and salt precipitation [101]. Similarly, Cilia [102] found that self-weight consolidation and seasonal freeze/thaw cycles in six field lysimeters containing centrifuged FFT resulted in an upward advective flux of pore water which, in conjunction with evaporation, led to salt accumulation near the tailings surface. Advection-dispersion was thought to be the dominant mass transport process initially, but over time as consolidation decreases mass transport should occur primarily through diffusion. Cilia [102] also investigated the effects of a 1 m cover layer on salt accumulation and found that under saturated conditions, the presence of a cover reduced, but did not eliminate, salt migration to the surface. Under unsaturated lysimeter conditions, salt accumulation in the cover layer was minimal [102]. Studies have also found that increasing the thickness of a cover can reduce salt migration and/or salt accumulation in cover soils [103,104].

A modeling study by Dobchuk et al. [105] on tailings sand topped with 45 cm of cover soil, a scenario applicable to uplands in terrestrial tailings landforms, found that the advective water flux across the tailings sand-soil interface was downward if the water table was deeper than 3 m below the interface. Under these conditions, the risk of cover salinization from upward advective movement of saline tailings pore water was low (1 in 50 years) [105]. Water tables shallower than 2.5 m had a greater risk of cover salinization while a water table deeper than 3.5 m virtually removed the risk. Further evaluation is necessary to better understand the potential for salt accumulation in the rooting zone of cover soils under dry reclamation scenarios, as this will have implications for capping and vegetation options for these deposits. Studies have found variability in the response of vegetation to tailings and OSPW, particularly regarding salinity. Conifer species, such as Picea glauca (white spruce) and Pinus banksiana (jack pine) exhibited high sodium concentration in their needles when exposed to CT water [106] and NST with Na+ concentrations of ~175 mg/L [107], leading to leaf necrosis and high mortality. Though 175 mg/L is below the Alberta Tier 1 Groundwater Remediation Guideline of 200 mg/L for Na+, concentrations of this magnitude may impact vegetation [108]. However, shrub species, such as Cornus stolonifera (red osier dogwood), Sheperdia canadensis (buffalo berry), and Populus deltoids x Populus balsamifera (northwest hybrid poplar) exhibited high tolerance of Suncor CT water with Na+ concentrations ranging from 14–1440 mg/L [63,106]. Further, CT amended with topsoil or peat showed successful establishment of Elymus angustus (altai wildrye) and Elymus trachycaulum (slender wheatgrass) [109]. Understanding salt migration and vegetation tolerance will determine if tailings landforms can support species native to the boreal forest.

2.3. Biogeochemical Cycling

Oil sands tailings, especially sand-dominated tailings such as CT and coarse sand tailings, are nutrient limited, with generally low amounts of phosphorous and nitrogen available for microbial metabolism [29,110]. Carbon sources in tailings include residual bitumen, aliphatic and aromatic hydrocarbons, and carboxylic acids, whereas possible nitrogen sources may include PAM (see Section 2.4), N2 fixation, recalcitrant organic nitrogen, and/or nitrogen cycling [30,111]. However, the extent to which these sources or mechanisms of generating nitrogen are available or occur in situ remains unknown. Despite nutrient limitations, diverse and active microbial communities in FFT contribute to the cycling of nitrogen, iron, sulfur, and carbon in tailings [29,58,112]. Microbes in FFT are thought to contribute to a diverse microbial community in CT, resulting in biogeochemical cycling in these deposits as well [113]. Redox conditions and the availability of terminal electron acceptors (e.g., O2, NO3−, Fe(III), SO42−, CO2) within tailings will dictate the biogeochemical cycling that occurs within a particular redox zone. As such the following subsections on biogeochemical cycling are organized based on redox conditions.

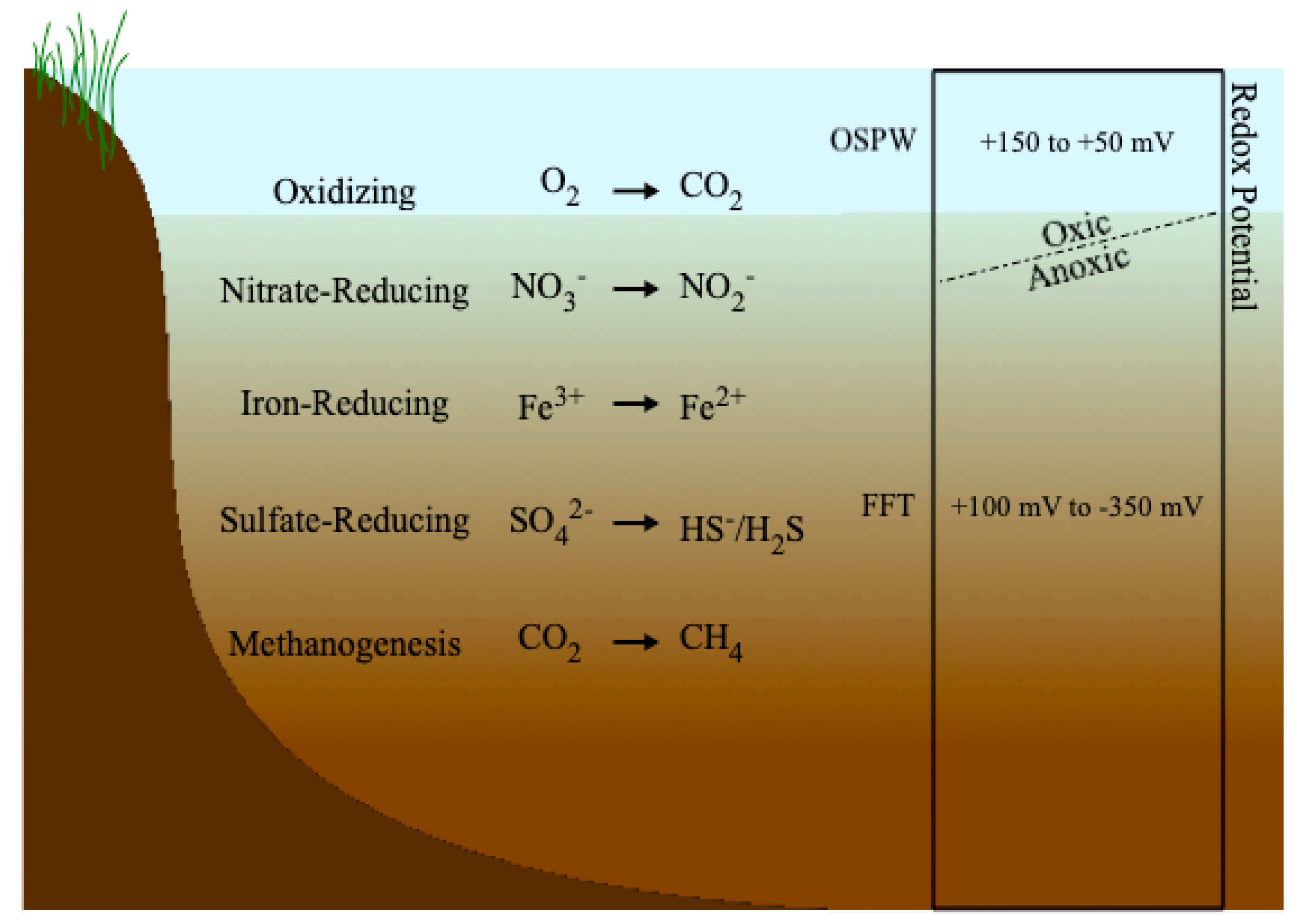

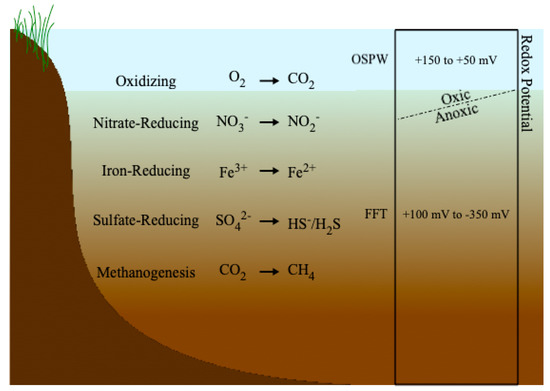

Redox potentials measured by Dompierre et al. [27] in BML indicated anoxic conditions throughout the BML FFT, starting at the FFT-water interface, with Eh values ranging from <−250 to −100 mV. Though the redox potential of the BML water cap was not measured in that study, oxic conditions near the water surface have been reported in other studies [114,115]. Studies of CT deposits have also indicated reducing conditions throughout the tailings, with oxic conditions present only in overlying ponded water [91,112]. Figure 2 illustrates the redox profile typically found within tailings deposits. At the FFT-water interface the redox conditions transition from oxic to anoxic, with the environment becoming more reducing as depth increases. Anoxic conditions with prevalent microbial activity below the FFT-water interface have been observed in oil sands tailings ponds [58,116,117], terrestrial deposits [91,112], and BML [27].

Figure 2.

Redox profile for tailings landforms and redox potential ranges for cap water and tailings deposits.

2.3.1. Oxic Conditions

Oxic conditions in tailings ponds, deposits, and landforms exist when there is free molecular oxygen (O2) present. Tailings ponds surface water often reaches anoxic conditions at a depth of roughly 1 m below the water surface, though they typically have a shallower water cap than BML [117]. Risacher et al. [114] found that BML had oxygen throughout the 10 m water cap during the summer season, reaching as high as 85% saturation near the surface, although oxygen concentrations decreased with depth and were at low levels near the FFT-water interface (<5% saturation). During ice cover, oxygen levels in BML have been found to decrease steadily, and Lawrence et al. [87] reported oxygen levels reaching 0% saturation near the BML surface right before ice-off in 2013/2014. However, seasonal lake turnovers in the spring and fall can help to increase oxygen levels in the BML water cap [115].

Oxygen levels within the BML water cap are impacted by carbon, sulfur, and nitrogen cycling [114,115]. Despite inputs of organic carbon from the underlying FFT, the BML water cap may be limited in labile organic matter, potentially a result of inputs of less aerobically biodegradable carbon [118] and turbidity reducing the phototrophic production of biodegradable organic matter. This may lead to hotspots for microbial methanotrophy and nitrification in the water cap [118]. Aqueous CH4 concentrations (generated in the underlying FFT) decreased moving upwards from the FFT-water interface to BML surface due to aerobic methanotrophy [114,118,119]. In addition to CH4, ammonium (NH4+) and hydrogen sulfide species (ΣH2S) and have been identified as important oxygen consuming constituents (OCCs) in the BML water cap or near the FFT-water interface and their biogeochemical cycling will likely impact BML oxygen concentrations for decades [114,115,118]. As such, physical mixing processes will be important in maintaining oxic conditions throughout the BML water cap [87,115].

Bioremediation can occur in tailings deposits through aerobic and anaerobic biodegradation of hydrocarbons and NAFCs. Biodegradation of hydrocarbons and NAFCs in tailings ponds has been studied extensively [10,12,13,14,22,58,60,116,120,121,122,123,124,125,126,127]. A number of studies have demonstrated aerobic biodegradation of hydrocarbons [122,124,127] and NAFCs [22,120,128] in oil sands tailings by bacteria. Rochman et al. [124] measured aerobic oxidation of benzene and naphthalene in OSPW collected from the top 10 cm of a Syncrude tailings pond and reported oxidation rates of 4.3 µmol/L/d and 21.4 µmol/L/d for benzene and naphthalene, respectively. Studies have also demonstrated that passive treatment of OSPW under oxic conditions can reduce concentrations of NAFCs and thus acute toxicity of OSPW in several months, though chronic toxicity persists for a longer period [50,129]. Additional studies have found algae [130,131] and fungi [132] capable of biodegrading NAFCs. Aerobic biodegradation likely occurs in tailings ponds in the uppermost layer of surface water as oxygen may be present due to wind and wave action during the summer, though aerobic degradation rates would slow in the winter [29]. Similarly, aerobic biodegradation may occur in tailings landforms, particularly in the uppermost layer of EPL water caps and in wetlands, and in aerated tailings deposits, which would improve water and seepage quality over time. However, anaerobic biodegradation is more likely to occur in tailings because the saturated, fine grained nature of tailings makes it difficult for oxygen to penetrate [133,134,135]. Terrestrial tailings landscapes that predominately consist of sand will have substantially more oxygen penetration and diffusion and thus would be more likely to experience oxic conditions.

2.3.2. Nitrate-Reducing Conditions

Information on nitrogen cycling in FFT is limited. While facultative nitrate (NO3−) reducing bacteria are abundant in tailings [29], nitrite (NO2−) and nitrate concentrations are generally below detection [60,117]. This finding may suggest that nitrate and nitrate reduction are not important microbial processes in FFT. However, NH4+ was recently identified as an important OCC in the BML water cap through nitrification [114]. It is thus important to note the potential for nitrate-reducing conditions within the tailings redox profile (Figure 2). NAFC biodegradation has been demonstrated under a number of anoxic conditions in the laboratory, with nitrate-reducing conditions resulting in the most extensive NAFC degradation [136,137]. As such, Foght et al. [29] concluded that anaerobic NAFC degradation is unlikely to be substantial in tailings deposits as nitrate concentrations and nitrate reduction is typically low in tailings.

2.3.3. Iron-Reducing Conditions

Iron-reducing bacteria, such as Rhodoferax Ferrireducens, can influence solid phase chemistry of clay minerals containing insoluble ferric (FeIII) oxides and can potentially impact water quality by allowing ferrous (FeII) cations, Fe2+, to react with reduced sulfur species to precipitate FeS(s) [58,138]. Dompierre et al. [27] reported slightly elevated concentrations of dissolved Fe directly below the FFT-water interface in BML, which was attributed to Fe2+ (because Fe3+ is relatively insoluble at a pH > 5) and therefore iron reduction. Sulfate reduction was also evident in this same zone below the FFT-water interface in BML. Similarly, Stasik et al. [117] reported synchronous iron and sulfur cycling 1 to 4 m below the FFT-water interface of an active tailings pond and that reduced sulfide species, primarily HS−, were precipitating to form FeS(s). A study of Syncrude’s Kingfisher CT deposit found that the presence of FeIII minerals increased with depth (and age) throughout the 34 m depth that was sampled [112]. The uppermost portion of the CT was iron reducing, with higher concentrations of FeII, lower temperatures, and lower total organic carbon concentrations. FeII concentrations in pore water ranged from 1.2 to 38.5 µM [112], which is higher than that of typical oil sands tailings (<0.09 to 10.9 µM) [39,43,58]. Iron reduction was limited to the top 8 m of the CT deposit. Warren et al. [112] suggested that iron reduction was limited to the upper portion of the CT due to deeper (and older) mineral FeIII substrates and total organic carbon being too recalcitrant or nutrient limiting for iron-reducing activity.

Iron reduction and subsequent secondary mineral precipitation, specifically FeS(s), have been linked to dewatering in BML [27] and will be discussed further in Section 2.3.6.

2.3.4. Sulfate-Reducing Conditions

Sulfate reduction, in which sulfate acts as the electron acceptor, may dominate in sulfate-amended FFT, which includes centrifuged tailings, CT, and PASS treated tailings. Syncrude and CNUL are currently the only operators actively using gypsum and/or FGD solids in tailings treatment [39,41,43]. Though the use of CT at Suncor has been discontinued, these deposits will still be incorporated into their closure plan and may provide conditions that encourage sulfate-reducing bacteria (SRB). For example, Bordenave et al. [139] reported an average sulfate reduction rate of 10 mmol sulfate reduced/m3 tailings/day in Suncor Pond 6, which contains CT, and Ramos-Padrón et al. [140] reported active sulfate reducing zones 2 to 15 m below the FFT-water interface in Pond 6.

SRB that have been identified in oil sands tailings include Desulfoivibrio, Desulfatibacillum, Desulfarculacea, Desulfosarcina, Desulfuromonas, Desulfobacca, Desulfoglaeba, and Desulfobulbaceae [58,112,138]. SRB can use low molecular weight fatty acids and possibly labile hydrocarbons as their carbon source [116,141]. Sulfate reduction is typically constrained to a narrow depth range below the FFT-water interface in tailings ponds due to decreasing numbers of SRB with depth [58,117]. Stasik et al. [117] found that sulfate reduction was highest in the anoxic zone of a tailings pond 1 to 3 m below the FFT-water interface. Similarly, both Dompierre et al. [27] and Syncrude [39] have reported zones of low SO42− below the FFT-water interface in BML. While SRB may comprise a large portion of the bacteria in FFT, there are few SRB present in water caps as water caps are generally oxic [58,140].

SRB present in FFT can produce toxic hydrogen sulfide (H2S) gas through the degradation of a variety of organic compounds, including hydrocarbons such as BTEX, and thus the environmental fate of H2S in tailings is of importance [60]. Under oxic conditions, ΣH2S should quickly oxidize, while under anoxic conditions, ΣH2S should precipitate as metal sulfides resulting in heavy metal immobilization and sedimentation within FFT. Field and laboratory studies have shown that sulfide mineral precipitation helps to reduce concentrations of Fe in pore water [117,142]. Oxidation has been found to rapidly remove ΣH2S in BML and as such ΣH2S is an OCC near the FFT-water interface, potentially leading to acidification [114]. Small et al. [30] reported no detectable gaseous H2S emissions from the 19 tailings ponds that they evaluated, which they attributed to either sulfur cycling within the ponds or limitations of the gas sampling equipment.

Reid and Warren [91] evaluated the biogeochemistry of three zones within Syncrude’s Sandhill Fen: the 40 m of CT deposit, the 10 m intermediary layer of sand tailings, and the wetland. Oxygen was present only in the ponded water in the wetland, while anoxic conditions existed at the wetland-sand interface and continued down through the sand cap and CT. Sulfur cycling due to the presence of gypsum in the CT generated ΣH2S in all three zones, however, the highest concentrations of aqueous and gaseous H2S were found in the sand cap. The sand layer acted as a mixing zone wherein sulfur rich porewater from the dewatering CT mixed with labile organic carbon from the developing wetland and stimulated microbial generation of H2S [91].

A biogeochemical study of Syncrude’s Kingfisher CT deposit by Warren et al. [112] found the 34 m of depth that was sampled was highly reducing. An extensive SRB zone (22–34 m) was found in the deposit, characterized by higher temperatures, higher total organic carbon concentrations, and highly reducing environments [112]. An average of 70% of the SO42− originally present in the CT (due to gypsum amendments) was lost, though the uppermost layer of CT had lost less than 20% of SO42− and the lowest depth (32–34 m) had lost almost 100% of SO42−. ΣH2S (>300 µM) was detected in pore water throughout the SRB zone. While the shallow (2–4 m) zone of the CT deposit was primarily an iron reducing zone, an abundance of Clostridium, which is a thiosulfate and/or S0 reducer, was found within the iron reducing zone and the transition zone (between 6–8 m), which contained the highest microbial diversity, suggesting sulfur cycling was also occurring in the surface layers of the deposit. Warren et al. [112] found that microbial diversity and abundance in the Syncrude CT deposit was low relative to the original tailings ponds, suggesting that CT is less hospitable for microbial communities. However, the microbial communities present in the CT were highly sulfur active. Interestingly, DNA sequencing of microbial communities in the deposit revealed that known SRB made up only 2% of the total bacterial community, though up to 90% of the Operational Taxonomic Units were considered to be capable of sulfur metabolism. This indicates that enigmatic microbial communities containing relatively unknown microbial taxa may have a substantial impact on biogeochemical cycling in tailings landforms. Further, sulfur cycling is likely to be an important biogeochemical process in landforms containing CT (and other sulfate amended tailings) and may have a substantial impact on CT reclamation efforts.

2.3.5. Methanogenesis

Methanogenesis is the dominant microbial process occurring in FFT and is a major mechanism of hydrocarbon degradation [11,12,13,14,60]. Residual diluent, commonly naphtha, in the tailings is the main substrate that sustains methanogenesis in FFT [13]. Hydrogenotrophic and acetoclastic methanogens, namely Methanosaeta spp., as well as other methanogenic archaea and a consortium of syntrophic bacteria such as Syntrophus spp., are primarily responsible for methanogenic activity in tailings [14,30,58]. Siddique et al. [12,13,14] found that under methanogenic conditions in the laboratory, n-alkanes (short and long chain) and monoaromatics (BTEX) can be degraded (and both of which are found in the residual diluent naphtha). It was later found that iso- and cyclo-alkanes can also be metabolized in tailings under methanogenic conditions following the depletion of n-alkanes, and that both naphtha and paraffinic diluents can be degraded [121,125,126,141,143]. While hydrocarbon degradation is beneficial in tailings deposits in that it reduces acute diluent toxicity, methanogenic biodegradation also contributes substantially to greenhouse gas emissions of CO2 and CH4 [30].

Methanogenic degradation of hydrocarbons has also been observed in tailings ponds. The concentration of light hydrocarbons, such as BTEX and naphtha, typically decreases with tailings depth (age) as these compounds are preferentially degraded over more recalcitrant compounds [58,123]. Tailings can take years to develop competent communities of methanogens, with 15-year lag periods reported for Suncor’s Pond 1 and Syncrude’s MLSB [10,113]. As such, the microbial activity and hydrocarbon degradation in tailings deposits will vary for deposits that consist of legacy tailings (tailings that are currently in tailings ponds) versus fresh tailings [29]. Microbial activity will also vary for different types of tailings and different treatment methods. For example, froth treatment tailings have been amended with diluent and therefore are more likely to trigger methanogenesis. Syncrude’s MLSB and Suncor’s Pond 2/3 both contain froth treatment tailings and are responsible for the highest CH4 production, 26.3 t/ha/year and 9.5 t/ha/year, respectively, of all tailings deposits based on 2011 and 2012 data compiled by Burkus et al. [15]. Tailings deposits that contain CT or a higher percentage of coarse sand tailings are expected to have lower CH4 emissions [30].

Similar to tailings ponds, microbial activity has generated greenhouse gas emissions of CO2 and CH4 from BML. Clark et al. [144] used eddy covariance to measure CH4 and CO2 fluxes from BML and found that fluxes were highest in 2014, the year following the fresh water capping, with median fluxes of 2.0 t/ha/year and 20.2 t/ha/year for CH4 and CO2, respectively. Carbon fluxes from BML have since decreased, with mean fluxes of 0.9 t/ha/year and 3.2 t/ha/year for CH4 and CO2, respectively, for the last three years of the Clark et al. [144] study (2017 to 2019). CH4(aq) consumption by aerobic methanotrophy has been noted in BML water cap which may contribute to lower CH4 emissions, though it also contributes to oxygen depletion [114]. Biogenic gas ebullition in BML as a result of microbial degradation of hydrocarbons causes not only greenhouse gas emissions, but also generates turbidity in the water cap as the bubbles migrate up to the FFT-water interface. Further, residual bitumen in the FFT may coat these bubbles resulting in bitumen floating on the lake surface, dissolved in the lake water, or absorbed onto sediments and/or tailings surrounding the water cap, thereby hindering reclamation efforts [47]. The greenhouse gas potential of each EPL will be different and will relate to the amount of unrecovered hydrocarbons remaining in the tailings at the time of deposition [47]. It is not known yet how the greenhouse gas emissions from EPLs will compare to those of terrestrial reclamation methods. Subaqueous or deep tailings deposits may be more likely to develop anoxic conditions and generate biogenic greenhouse gases, depending on other competing biogeochemical cycling processes [30]. Over time, terrestrial landforms that incorporate peat may develop into carbon sinks, as is the case for the lowland within Syncrude’s Sandhill Fen, though the midland and upland areas are still carbon sources [145]. CH4 fluxes from the Sandhill Fen were low for the years 2013 to 2015, with a median flux of 0.04 t/ha/year, possibly a result of SRB outcompeting methanogens given the abundance of electron acceptors for SRB [146].