Types and Quantitative Characterization of Microfractures in the Continental Shale of the Da’anzhai Member of the Ziliujing Formation in Northeast Sichuan, China

Abstract

:1. Introduction

2. Geological Setting

3. Sampling and Laboratory Methods

3.1. Rock Slices and Identification

3.2. Micro-CT Scanning

3.3. Field Emission Scanning Electron Microscope (FE-SEM) Analysis

3.4. Nitrogen Adsorption

3.5. High-Pressure Mercury Injection

4. Results

4.1. Feature of Fracture Morphology under Rock Slice

4.2. Type, Occurrence, and Scale of Micro-CT Scan Cracks

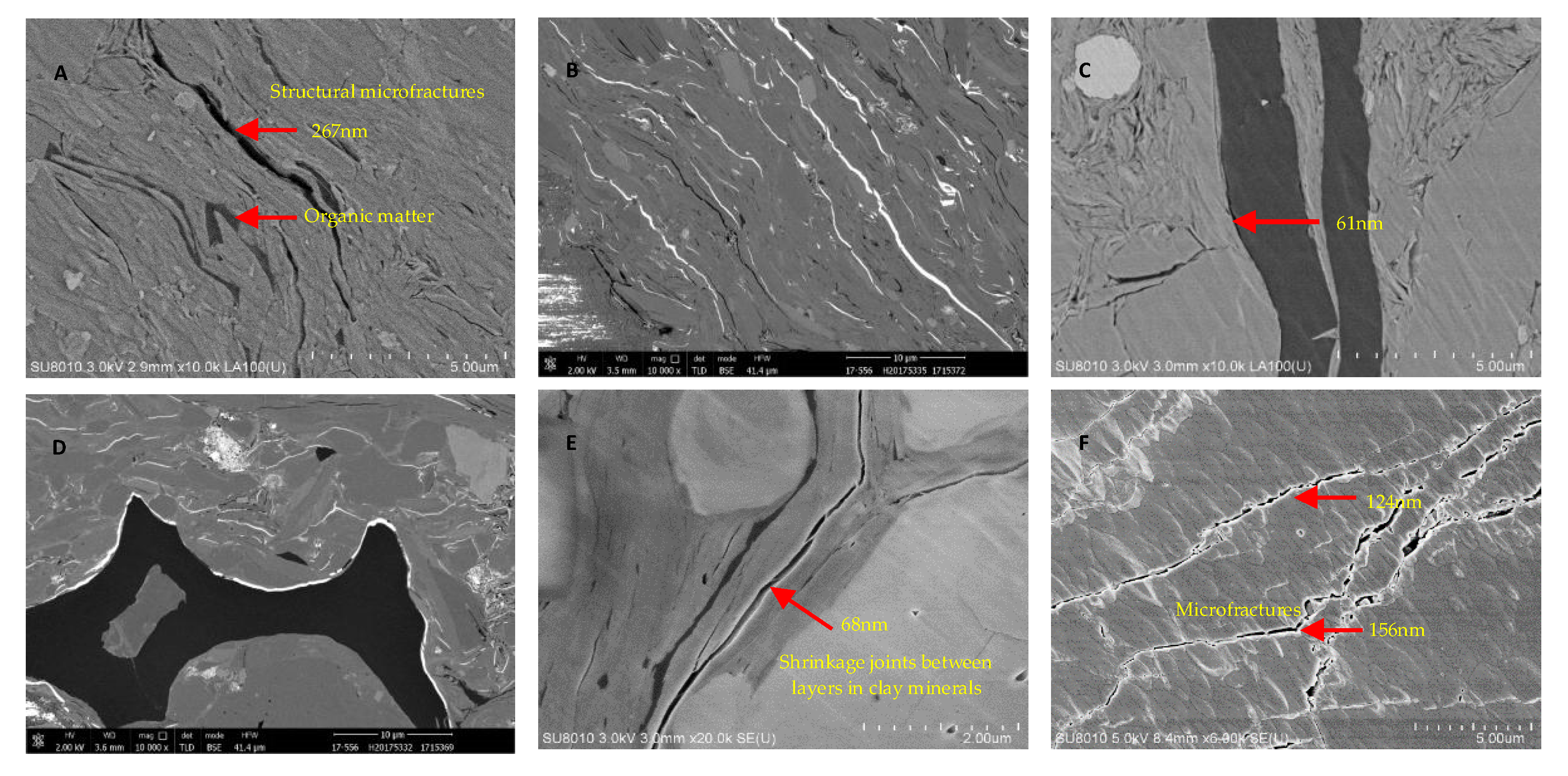

4.3. Types of Microcracks Observed under a Scanning Electron Microscope

4.4. Joint Evaluation of Pore Structure by High-Pressure Mercury Intrusion and Nitrogen Adsorption

5. Discussion

5.1. Comprehensive Qualitative Evaluation of Multi-Scale Microcracks

5.2. Comprehensive Quantitative Characterization of Multi-Scale Microfractures

5.2.1. Quantitative Characteristics of Micro-CT Microcracks

5.2.2. Quantitative Identification of Microcracks by Scanning Electron Microscopy

5.2.3. Comprehensive Quantitative Characterization of Multi-Scale Microfractures

5.2.4. Controlling Factors of Microfractures Development

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, L.B.; Lyu, W.Y.; Li, J.; Zhu, L.F.; Weng, J.Q.; Yue, F.; Zu, K.W. Natural fractures and their influence on shale gas enrichment in Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 30, 1–9. [Google Scholar] [CrossRef]

- Zhang, W.Z.; Xie, L.Q.; Yang, W.W.; Qin, Y.; Peng, P.A. Micro fractures and pores in lacustrine shales of the Upper Triassic Yanchang Chang7 Member, Ordos Basin, China. J. Pet. Sci. Eng. 2017, 156, 194–201. [Google Scholar] [CrossRef]

- Guo, T.l. Key geological issues and main controls on accumulation and enrichment of Chinese shale gas. Pet. Explor. Dev. 2016, 3, 349–359. [Google Scholar] [CrossRef]

- He, Z.L.; Hu, Z.Q.; Nie, H.K.; Li, S.J.; Xu, J. Characterization of shale gas enrichment in the Wufeng Formation–Longmaxi Formation in the Sichuan Basin of China and evaluation of its geological construction–transformation evolution sequence. J. Nat. Gas Geosci. 2017, 2, 1–10. [Google Scholar] [CrossRef]

- Yi, J.Z.; Bao, H.Y.; Zheng, A.W.; Zhang, B.Q.; Shu, Z.G.; Li, J.Q.; Wang, C. Main factors controlling marine shale gas enrichment and high-yield wells in South China, a case study of the Fuling shale gas field. Mar. Pet. Geol. 2019, 103, 114–125. [Google Scholar] [CrossRef]

- Liu, C.; Liu, H.; Zhang, Y.P.; Deng, D.W.; Wu, H.A. Optimal spacing of staged fracturing in horizontal shale-gas well. J. Nat. Gas Sci. Eng. 2015, 132, 86–93. [Google Scholar] [CrossRef]

- Dong, D.Z.; Shi, Z.S.; Guan, Q.Z.; Jiang, S.; Zhang, M.Q.; Zhang, C.C.; Wang, S.Y.; Sun, S.S.; Yu, R.Z.; Liu, D.X.; et al. Progress, challenges and prospects of shale gas exploration in the Wufeng–Longmaxi reservoirs in the Sichuan Basin. Nat. Gas Ind. B 2018, 5, 415–424. [Google Scholar] [CrossRef]

- Ma, Y.S.; Cai, X.Y.; Zhao, P.R. China’s shale gas exploration and development, Understanding and practice. Pet. Explor. Dev. 2018, 45, 589–603. [Google Scholar] [CrossRef]

- Zhao, J.Z.; Ren, L.; Shen, C.; Li, Y.G. Latest research progresses in network fracturing theories and technologies for shale gas reservoirs. Nat. Gas Ind. B 2018, 5, 533–546. [Google Scholar] [CrossRef]

- Mao, P.X.; Sun, J.X.; Ning, F.L.; Hu, G.W.; Wan, Y.Z.; Gao, X.X.; Wu, N.Y. Effect of permeability anisotropy on depressurization-induced gas production from hydrate reservoirs in the South China Sea. Energy Sci. Eng. 2020, 8, 2690–2707. [Google Scholar] [CrossRef] [Green Version]

- Chen, S.Y.; Wang, Y.J.; Guo, J.Y.; He, Q.L.; Yin, X.R. Multi-scale evaluation of fractured carbonate reservoir and its implication to sweet-spot optimization, A case study of Tazhong oilfield, Central Tarim Basin, China. Energy Rep. 2021, 7, 2976–2988. [Google Scholar] [CrossRef]

- Morrow, C.A.; Lockner, D.A.; Moore, D.E.; Hickman, S. Deep permeability of the San Andreas fault from San Andreas fault observatory at depth (SAFOD) core samples. J. Struct. Geol. 2014, 64, 99–114. [Google Scholar] [CrossRef]

- Han, D.Y.; Wang, Z.M.; Song, Y.C.; Zhao, J.F.; Wang, D.Y. Numerical analysis of depressurization production of natural gas hydrate from different lithology oceanic reservoirs with isotropic and anisotropic permeability. J. Nat. Gas Sci. Eng. 2017, 46, 575–591. [Google Scholar] [CrossRef]

- Barrie, C.D.; Donohue, C.M.; Zumberge, J.A.; Zumberge, J.E. Production Allocation: Rosetta Stone or Red Herring? Best Practices for Understanding Produced Oils in Resource Plays. Minerals 2020, 10, 1105. [Google Scholar] [CrossRef]

- He, Z.L.; Li, S.J.; Nie, H.K.; Yuan, Y.S.; Wang, H. The shale gas “sweet window”, “The cracked and unbroken” state of shale and its depth range. Mar. Pet. Geol. 2019, 101, 334–342. [Google Scholar] [CrossRef]

- Borjigin, T.; Shen, B.J.; Yu, L.J.; Yang, Y.F.; Zhang, W.T.; Tao, C.; Xi, B.B.; Zhang, Q.Z.; Bao, F.; Qin, J.Z. Mechanisms of shale gas generation and accumulation in the Ordovician Wufeng-Longmaxi Formation, Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 69–78. [Google Scholar] [CrossRef]

- Chen, S.; Han, Y.; Fu, C.; Zhang, H.; Zhu, Y.; Zuo, Z. Micro and nano-size pores of clay minerals in shale reservoirs, Implication for the accumulation of shale gas. Sediment. Geol. 2016, 342, 180–190. [Google Scholar] [CrossRef]

- Li, Y.; Hou, J.G.; Li, Y.Q. Features and classified hierarchical modeling of carbonate fracture-cavity reservoirs. Pet. Explor. Dev. 2016, 43, 655–662. [Google Scholar] [CrossRef]

- Xu, S.; Gou, Q.; Hao, F.; Zhang, B.; Zhang, Y. Multiscale faults and fractures characterization and their effects on shale gas accumulation in the Jiaoshiba area, Sichuan Basin, China. J. Pet. Sci. Eng. 2020, 189, 107026. [Google Scholar] [CrossRef]

- Fan, C.H.; Li, H.; Qin, Q.R.; He, S.; Zheng, C. Geological conditions and exploration potential of shale gas reservoir in Wufeng and Longmaxi Formation of southeastern Sichuan Basin, China. J. Pet. Sci. Eng. 2020, 191, 107138. [Google Scholar] [CrossRef]

- Guo, T.L.; Zhang, H.R. Formation and enrichment mode of Jiaoshiba shale gas field, Sichuan Basin. Pet. Explor. Dev. 2014, 41, 31–40. [Google Scholar] [CrossRef]

- Wang, P.K.; Huang, X.; Pang, S.J.; Zhu, Y.H.; Lu, Z.Q.; Zhang, S.; Liu, H.; Yang, K.L.; Li, B. Geochemical dynamics of the gas hydrate system in the Qilian Mountain Permafrost, Qinghai, Northwest China. Mar. Pet. Geol. 2015, 59, 72–90. [Google Scholar] [CrossRef]

- Cheng, W.; Yang, R.; Zhang, Q. Origin of a Petrographic Coal Structure and Its Implication for Coalbed Methane Evaluation. Minerals 2020, 10, 543. [Google Scholar] [CrossRef]

- Mendhe, V.A.; Mishra, S.; Khangar, R.G.; Kamble, A.D.; Kumar, D.; Varma, A.K.; Singh, H.; Kumar, S.; Bannerjee, M. Organo-petrographic and pore facets of Permian shale beds of Jharia Basin with implications to shale gas reservoir. J. Earth Sci. 2017, 28, 897–916. [Google Scholar] [CrossRef]

- Guo, R.B.; Zhang, J.C.; Zhao, P.W.; Liu, Z.Y. Influence of interbedded rock association and fracture characteristics on gas accumulation in the lower Silurian Shiniulan formation, Northern Guizhou Province. Open Geosci. 2021, 13, 606–625. [Google Scholar] [CrossRef]

- He, X.P.; He, G.S.; Gao, Y.Q.; Zhang, P.X.; Lu, S.F.; Wan, J.Y. Geological characteristics and enrichment laws of normal-pressure shale gas in the basin-margin transition zone of SE Chongqing. Nat. Gas Ind. B 2019, 6, 333–346. [Google Scholar] [CrossRef]

- He, J.L.; Wang, J.; Milsch, H.; Qiu, Z.; Yu, Q. The characteristics and formation mechanism of a regional fault in shale strata, Insights from the Middle-Upper Yangtze, China. Mar. Pet. Geol. 2020, 121, 104592. [Google Scholar] [CrossRef]

- Guo, L.; Jiang, Z.; Guo, F. Mineralogy and fracture development characteristics of marine shale-gas reservoirs, A case study of Lower Silurian strata in southeastern margin of Sichuan Basin, China. J. Cent. South Univ. 2015, 22, 1847–1858. [Google Scholar] [CrossRef]

- Chan, H.; Roberts, S.G.; Gong, J. Micro-scale fracture experiments on zirconium hydrides and phase boundaries. J. Nucl. Mater. 2016, 475, 105–112. [Google Scholar] [CrossRef] [Green Version]

- Li, F.L.; Jiang, B.; Cheng, G.X.; Song, Y.; Tang, Z. Structural and evolutionary characteristics of pores-microfractures and their influence on coalbed methane exploitation in high-rank brittle tectonically deformed coals of the Yangquan mining area, northeastern Qinshui basin, China. J. Pet. Sci. Eng. 2019, 174, 1290–1302. [Google Scholar]

- Zeng, L. Microfracturing in the Upper Triassic Sichuan Basin tight-gas sandstones, Tectonic, overpressure, and diagenetic origins. AAPG Bull. 2010, 94, 1811–1825. [Google Scholar] [CrossRef]

- Zhang, H.J.; Jiang, Y.Q.; Zhou, K.M.; Fu, Y.H.; Zhong, Z.; Zhang, X.M.; Qi, L.; Wang, Z.L.; Jiang, Z.Z. Connectivity of pores in shale reservoirs and its implications for the development of shale gas, A case study of the Lower Silurian Longmaxi Formation in the southern Sichuan Basin. Nat. Gas Ind. B 2020, 7, 348–357. [Google Scholar] [CrossRef]

- Harpalani, S.; Schraufnagel, R.A. Shrinkage of coal matrix with release of gas and its impact on permeability of coal. Fuel 1990, 69, 551–556. [Google Scholar] [CrossRef]

- Zhu, H.J.; Ju, Y.W.; Huang, C.; Chen, F.W.; Chen, B.Z.; Yu, K. Microcosmic gas adsorption mechanism on clay-organic nanocomposites in a marine shale. Energy 2020, 197, 117256. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wu, C.F.; He, J.X.; Ren, Z.Q.; Zhou, T.T. The Controlling Effects of Compositions on Nanopore Structure of Over-Mature Shale from the Longtan Formation in the Laochang Area, Eastern Yunnan, China. Minerals 2019, 9, 403. [Google Scholar] [CrossRef] [Green Version]

- Zhu, H.J.; Ju, Y.W.; Huang, C.; Qi, Y.; Ju, L.T.; Yu, K.; Li, W.Y.; Su, X.; Feng, H.Y.; Qiao, P. Tectonic and thermal controls on the nano-micro structural characteristic in a Cambrian organic-rich shale. Minerals 2019, 9, 354. [Google Scholar] [CrossRef] [Green Version]

- Mitchell, T.M.; Faulkner, D.R. Towards quantifying the matrix permeability of fault damage zones in low porosity rocks. Earth Planet. Sci. Lett. 2012, 339, 24–31. [Google Scholar] [CrossRef]

- Nara, Y.; Meredith, P.G.; Yoneda, T.; Kaneko, K. Influence of macro-fractures and micro-fractures on permeability and elastic wave velocities in basalt at elevated pressure. Tectonophysics 2011, 503, 52–59. [Google Scholar] [CrossRef] [Green Version]

- Bolton, A.J.; Maltman, A.J.; Fisher, Q. Anisotropic permeability and bimodal pore-size distributions of fine-grained marine sediments. Mar. Pet. Geol. 2000, 17, 657–672. [Google Scholar] [CrossRef]

- Mitchell, T.M.; Faulkner, D.R. Experimental measurements of permeability evolution during triaxial compression of initially intact crystalline rocks and implications for fluid flow in fault zones. J. Geophys. Res. Solid Earth 2008, 113. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, B.; Fan, R.; Yang, S.W.; Zhou, K.; Zhou, X.F. Characteristics and Formation Mechanism of Ultra-low Permeability Tight Sandstone Reservoirs under Multi-source Systems. Electron. J. Geotech. Eng. 2016, 21, 2389–2403. [Google Scholar]

- Wang, E.; Meng, K.; Su, Z.; Meng, Q.R.; Chu, J.J.; Chen, Z.L.; Wang, G.; Shi, X.H.; Liang, X.Q. Block rotation, Tectonic response of the Sichuan basin to the southeastward growth of the Tibetan Plateau along the Xianshuihe-Xiaojiang fault. Tectonics 2014, 33, 686–718. [Google Scholar] [CrossRef]

- Meng, K.; Wang, E.; Wang, G. Uplift of the Emei Shan, western Sichuan basin: Implication for eastward propagation of the Tibetan plateau in early Miocene. J. Asian Earth Sci. 2016, 115, 29–39. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.H.; Xie, J. The progress and prospects of shale gas exploration and development in southern Sichuan Basin, SW China. Pet. Explor. Dev. 2018, 45, 172–182. [Google Scholar] [CrossRef]

- Zhai, G.Y.; Li, J.; Jiao, Y.; Wang, Y.F.; Liu, G.H.; Xu, Q.; Wang, C.; Chen, R.; Guo, X.B. Applications of chemostratigraphy in a characterization of shale gas Sedimentary Microfacies and predictions of sweet spots—taking the Cambrian black shales in Western Hubei as an example. Mar. Pet. Geol. 2019, 109, 547–560. [Google Scholar] [CrossRef]

- Ma, X. A golden era for natural gas development in the Sichuan Basin. Nat. Gas Ind. B 2017, 4, 163–173. [Google Scholar] [CrossRef]

- Jizhong, H. Exploration prospect of shale gas and coal-bed methane in Sichuan Basin. Lithol. Reserv. 2009, 21, 116–120. [Google Scholar]

- Su, K.M.; Lu, J.G.; Zhang, G.W.; Chen, S.J.; Li, Y.; Xiao, Z.L.; Wang, P.; Qiu, W. Origin of natural gas in Jurassic Da’anzhai Member in the western part of central Sichuan Basin, China. J. Pet. Sci. Eng. 2018, 167, 890–899. [Google Scholar] [CrossRef]

- Yang, G.; Huang, D.; Huang, P.H.; Yan, W.P.; Yang, T.Q.; Dai, H.M.; Lin, J.P. Control factors of high and stable production of Jurassic Da’anzhai Member tight oil in central Sichuan Basin, SW China. Pet. Explor. Dev. 2017, 44, 866–875. [Google Scholar] [CrossRef]

- Chen, S.J.; Zhang, H.X.; Lu, J.G.; Yang, Y.M.; Liu, C.W.; Wang, L.; Zou, X.L.; Yang, J.J.; Tang, H.P.; Yao, Y.T.; et al. Controlling factors of Jurassic Da’anzhai Member tight oil accumulation and high production in central Sichuan Basin, SW China. Pet. Explor. Dev. 2015, 42, 206–214. [Google Scholar] [CrossRef]

- Chang, E.Z. Collisional orogene between north and south China and its eastern extension in the Korean Peninsula. J. Southeast Asian Earth Sci. 1996, 13, 267–277. [Google Scholar] [CrossRef]

- Liang, Y.Y.; Xia, R.; Shan, X.Y.; Ma, Y.; Zhao, E.Q.; Guo, W.H. Geochronology and geochemistry of ore-hosting rhyolitic tuff in the Kengdenongshe polymetallic deposit in the Eastern Segment of the East Kunlun Orogen. Minerals 2019, 9, 589. [Google Scholar] [CrossRef] [Green Version]

- Tan, X.C.; Xia, Q.S.; Chen, J.S.; Li, L.; Liu, H.; Luo, B.; Xia, J.W.; Yang, J.J. Basin-scale sand deposition in the Upper Triassic Xujiahe Formation of the Sichuan Basin, Southwest China, Sedimentary framework and conceptual model. J. Earth Sci. 2013, 24, 89–103. [Google Scholar] [CrossRef]

- Li, L.; Liu, Z.J.; George, S.C.; Sun, P.C.; Xu, Y.B.; Meng, Q.T.; Wang, K.B.; Wang, J.X. Lake evolution and its influence on the formation of oil shales in the Middle Jurassic Shimengou Formation in the Tuanyushan area, Qaidam Basin, NW China. Geochemistry 2019, 79, 162–177. [Google Scholar] [CrossRef]

- Yao, Z.Q.; Li, S.L.; Yu, X.H.; Deleqiati, J.; Yang, F.; Wang, W.; Wang, W.F.; Akedan, S.; Yang, X.T.; Zheng, B.; et al. Effects of the interaction of tectonics, eustasy, climate, and minerals on the sedimentary evolution of early-middle Jurassic in the Hongshanzui region in Junggar Basin. J. Pet. Sci. Eng. 2021, 196, 107967. [Google Scholar] [CrossRef]

- Lawton, T.F.; Molina Garza, R.S. U-Pb geochronology of the type Nazas Formation and superjacent strata, northeastern Durango, Mexico, Implications of a Jurassic age for continental-arc magmatism in north-central Mexico. Bulletin 2014, 126, 1181–1199. [Google Scholar] [CrossRef]

- Ding, W.L.; Wan, H.; Zhang, Y.Q.; Han, G.Z. Characteristics of the Middle Jurassic marine source rocks and prediction of favorable source rock kitchens in the Qiangtang Basin of Tibet. J. Asian Earth Sci. 2013, 66, 63–72. [Google Scholar] [CrossRef]

- Wang, X.Y.; Jin, Z.K.; Zhao, J.H.; Zhu, Y.X.; Hu, Z.Q.; Liu, G.X.; Jiang, T.; Wang, H.; Li, S.; Shi, S.T. Depositional environment and organic matter accumulation of Lower Jurassic nonmarine fine-grained deposits in the Yuanba Area, Sichuan Basin, SW China. Mar. Pet. Geol. 2020, 116, 104352. [Google Scholar] [CrossRef]

- Peng, C.Z.; Peng, J.; Chen, Y.H.; Zhang, H.R. Seismic prediction of sweet spots in the Da’anzhai shale play, Yuanba area, the Sichuan Basin. Nat. Gas Ind. B 2014, 1, 185–191. [Google Scholar]

- Kang, Y.S.; Rao, Q.; Zhao, Q. Exploration and development potential of the low-maturity continental shale gas in the Fuxin Basin. Nat. Gas Ind. B 2019, 6, 435–443. [Google Scholar] [CrossRef]

| Sample ID | Clay | Quartz | Potash Feldspar | Plagioclase | Calcite | Dolomite | Siderite | Pyrite | Brittleness Index BI | Total Porosity |

|---|---|---|---|---|---|---|---|---|---|---|

| FY1-9 | 56.2 | 31.2 | 0.8 | 2.5 | 8.2 | 1.1 | 43.8 | 1.49 | ||

| FY1-13 | 50.1 | 28.6 | 1.9 | 18.1 | 1.3 | 49.9 | 4.74 | |||

| YB102-7 | 40.6 | 45.8 | 0.7 | 1.8 | 8.4 | 2.7 | 59.4 | 2.46 | ||

| YL171-5 | 32.8 | 26.9 | 1 | 7.4 | 30 | 0.7 | 1.2 | 67.2 | 1.26 | |

| YL176-7 | 40.5 | 31.5 | 1.1 | 2.4 | 23.4 | 1.1 | 59.5 | 1.83 | ||

| YL4-6 | 48.1 | 34.1 | 1.2 | 4.6 | 9.1 | 1.5 | 1.4 | 51.9 | 1.70 | |

| YL4-10 | 26.6 | 16.2 | 1.6 | 55.6 | 73.4 | 1.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Qiu, H.; Jiang, Z.; Liu, R.; Wei, X.; Chen, F.; Wei, F.; Wang, D.; Su, Z.; Yang, Z. Types and Quantitative Characterization of Microfractures in the Continental Shale of the Da’anzhai Member of the Ziliujing Formation in Northeast Sichuan, China. Minerals 2021, 11, 870. https://doi.org/10.3390/min11080870

Liu Z, Qiu H, Jiang Z, Liu R, Wei X, Chen F, Wei F, Wang D, Su Z, Yang Z. Types and Quantitative Characterization of Microfractures in the Continental Shale of the Da’anzhai Member of the Ziliujing Formation in Northeast Sichuan, China. Minerals. 2021; 11(8):870. https://doi.org/10.3390/min11080870

Chicago/Turabian StyleLiu, Zhujiang, Hengyuan Qiu, Zhenxue Jiang, Ruobing Liu, Xiangfeng Wei, Feiran Chen, Fubin Wei, Daojun Wang, Zhanfei Su, and Zhanwei Yang. 2021. "Types and Quantitative Characterization of Microfractures in the Continental Shale of the Da’anzhai Member of the Ziliujing Formation in Northeast Sichuan, China" Minerals 11, no. 8: 870. https://doi.org/10.3390/min11080870

APA StyleLiu, Z., Qiu, H., Jiang, Z., Liu, R., Wei, X., Chen, F., Wei, F., Wang, D., Su, Z., & Yang, Z. (2021). Types and Quantitative Characterization of Microfractures in the Continental Shale of the Da’anzhai Member of the Ziliujing Formation in Northeast Sichuan, China. Minerals, 11(8), 870. https://doi.org/10.3390/min11080870