Comprehensive Characterization Integrating Static and Dynamic Data for Dynamic Fractures in Ultra-Low Permeability Reservoirs: A Case Study of the Chang 6 Reservoir of the Triassic Yanchang Formation in the Ordos Basin, China

Abstract

:1. Introduction

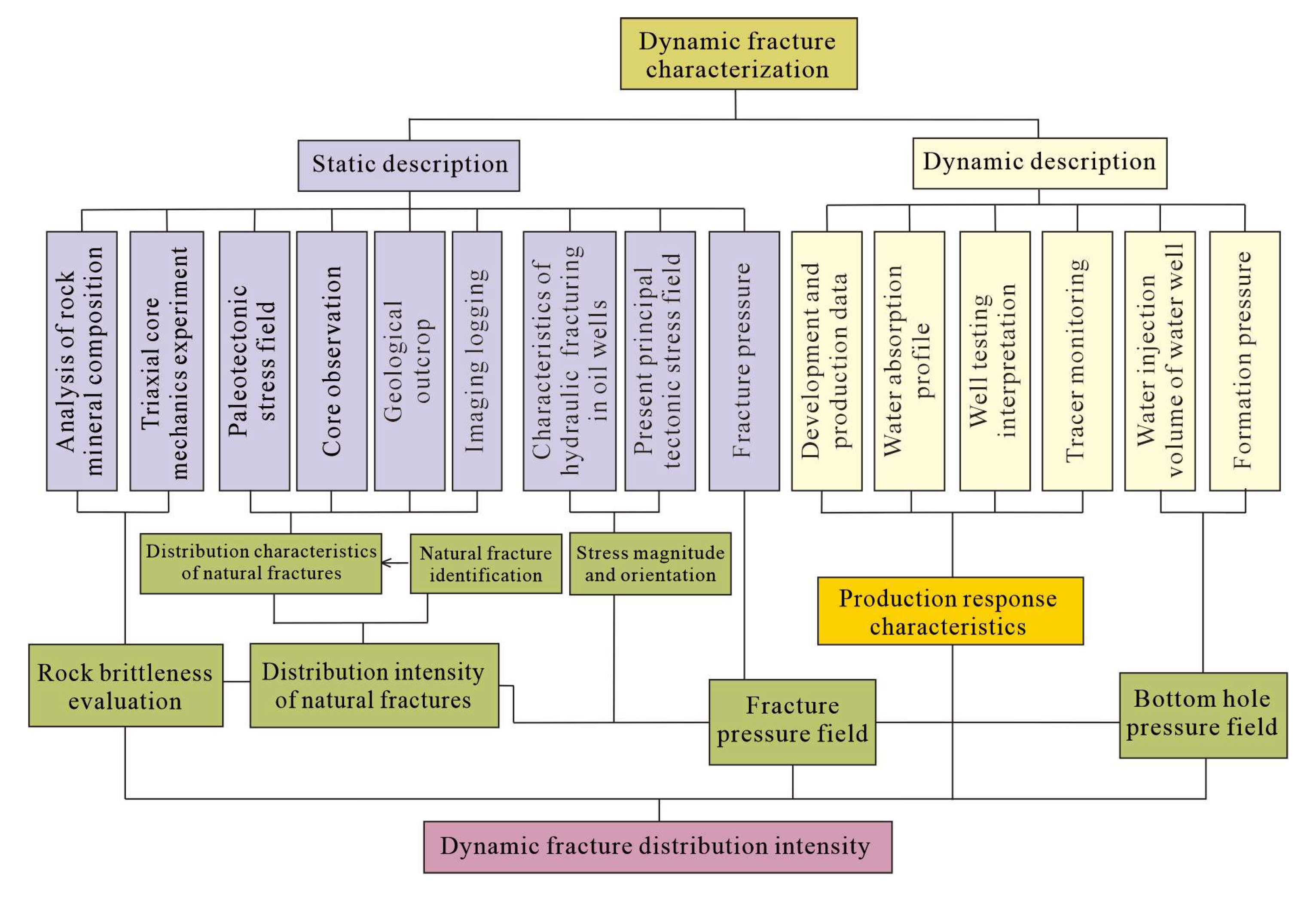

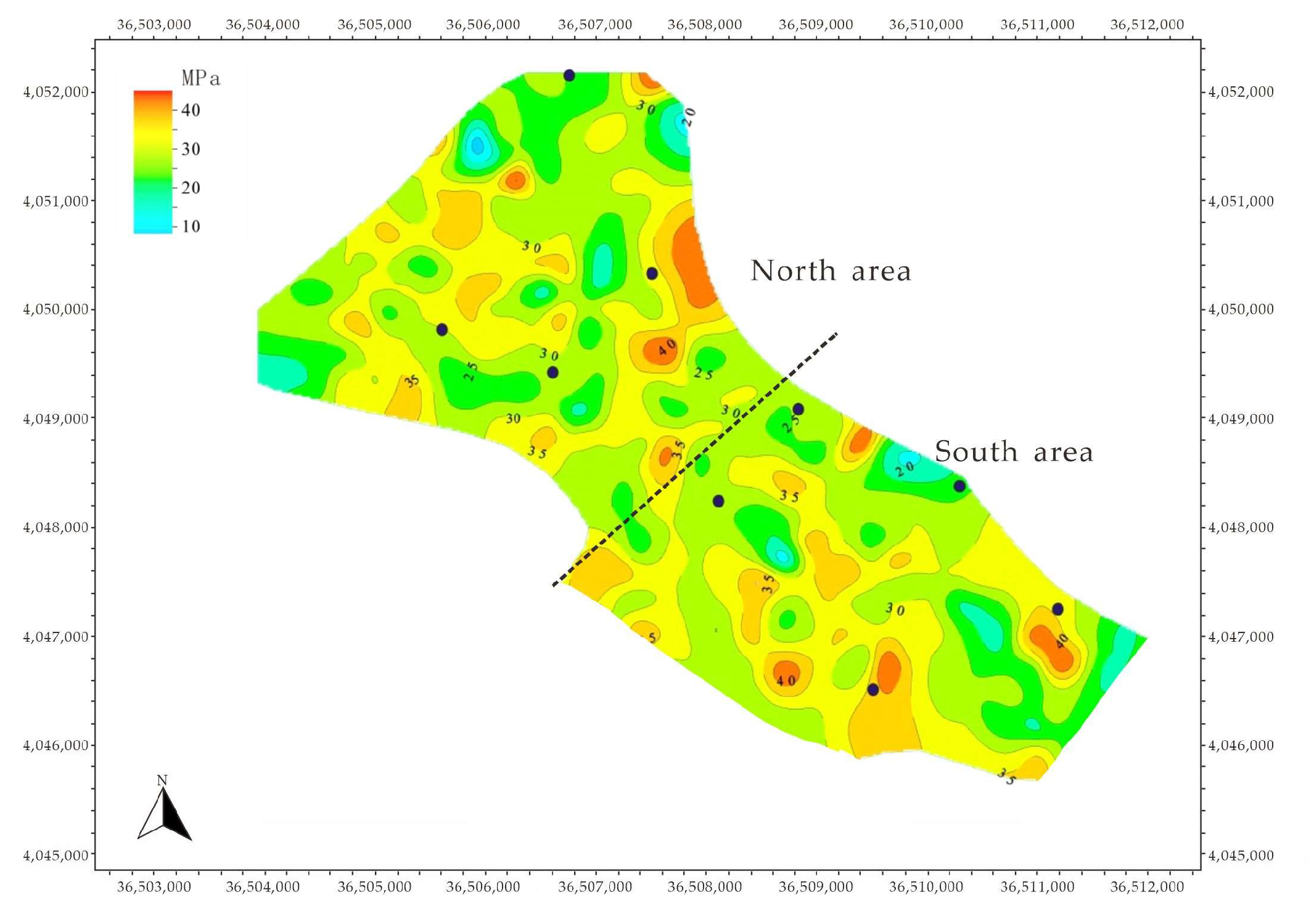

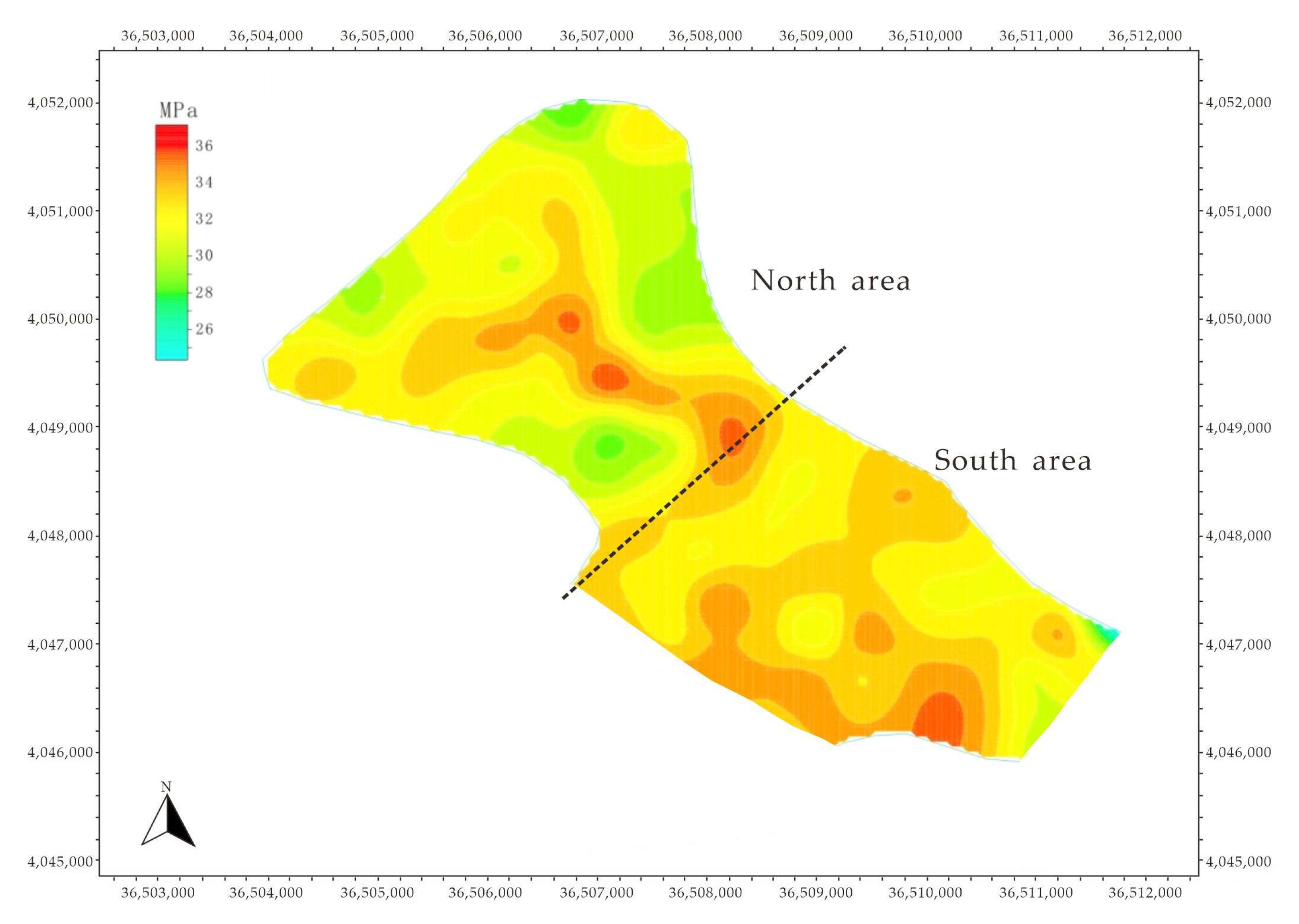

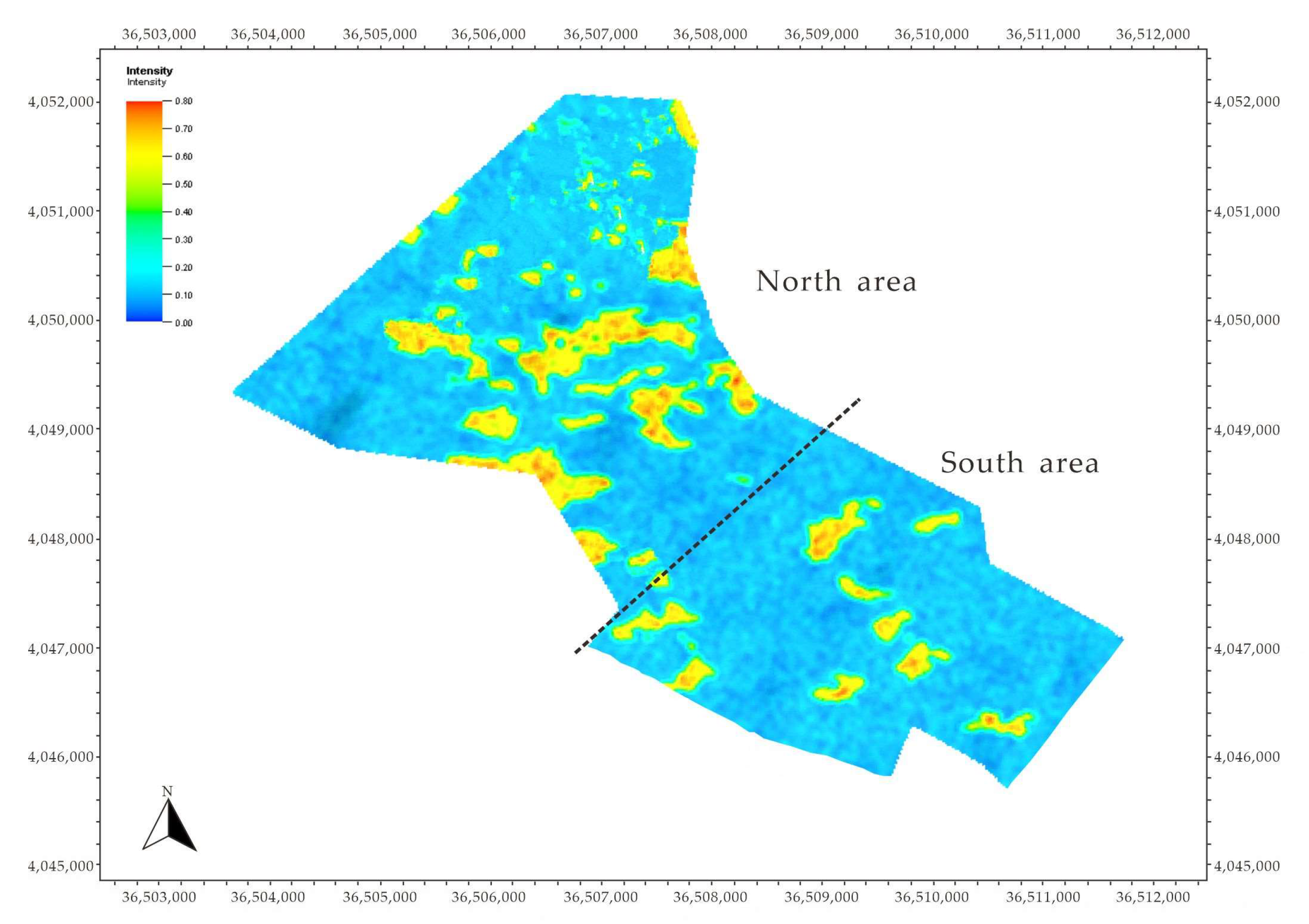

2. Dynamic Fracture Characterization Method and Workflow

3. Comprehensive Characterization of Dynamic Fractures

3.1. Brittleness Evaluation

3.1.1. Analysis of Rock Mechanic Parameter Experiment

3.1.2. Analysis of Rock Mineral Composition

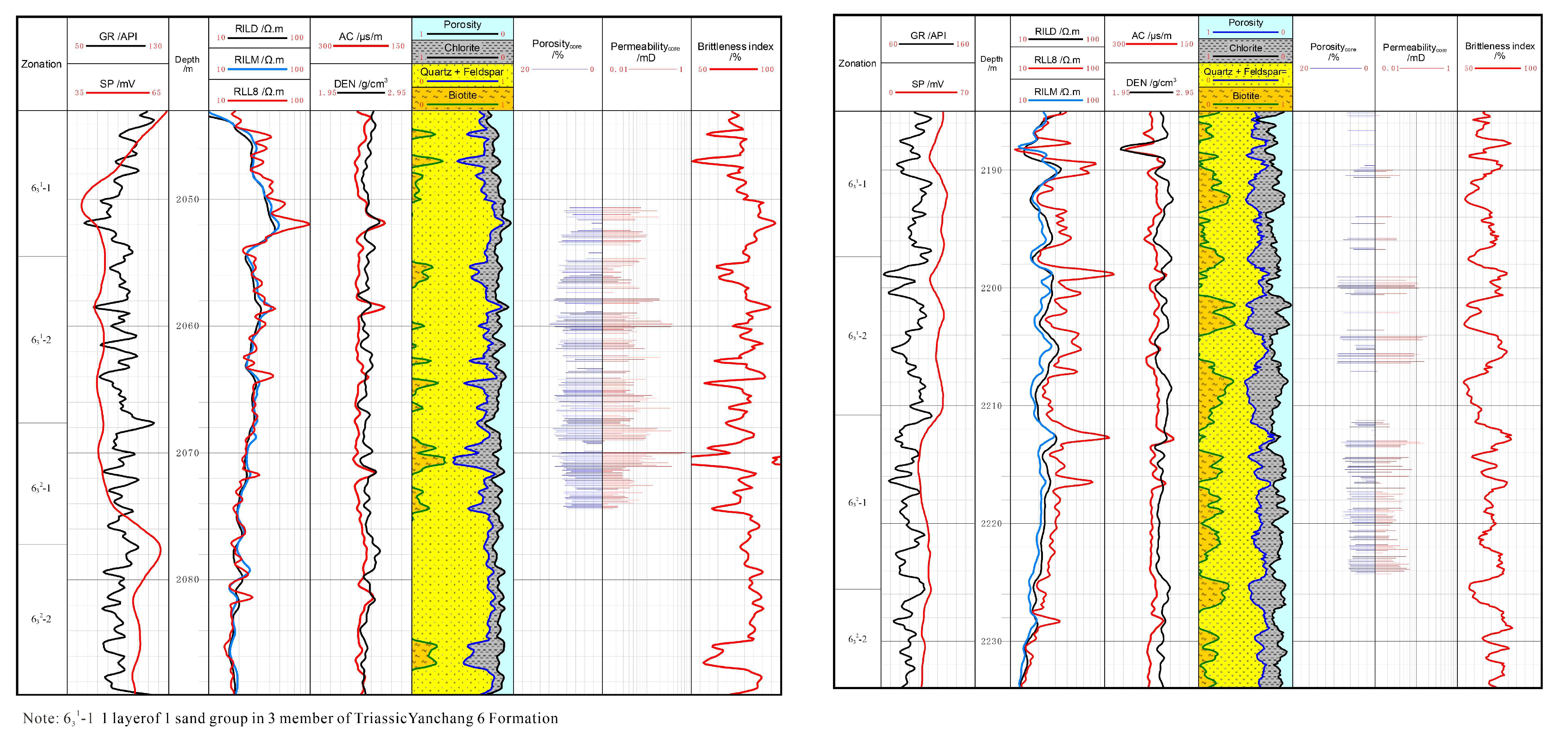

3.1.3. Case Analysis

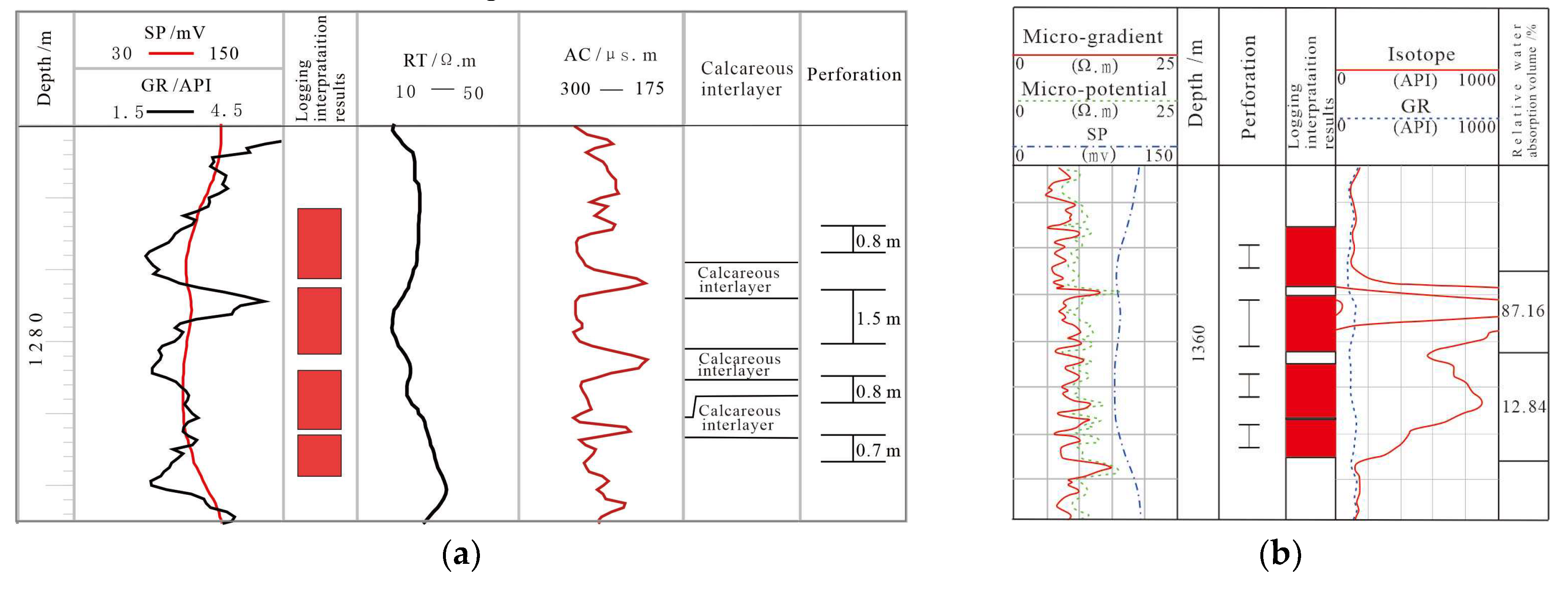

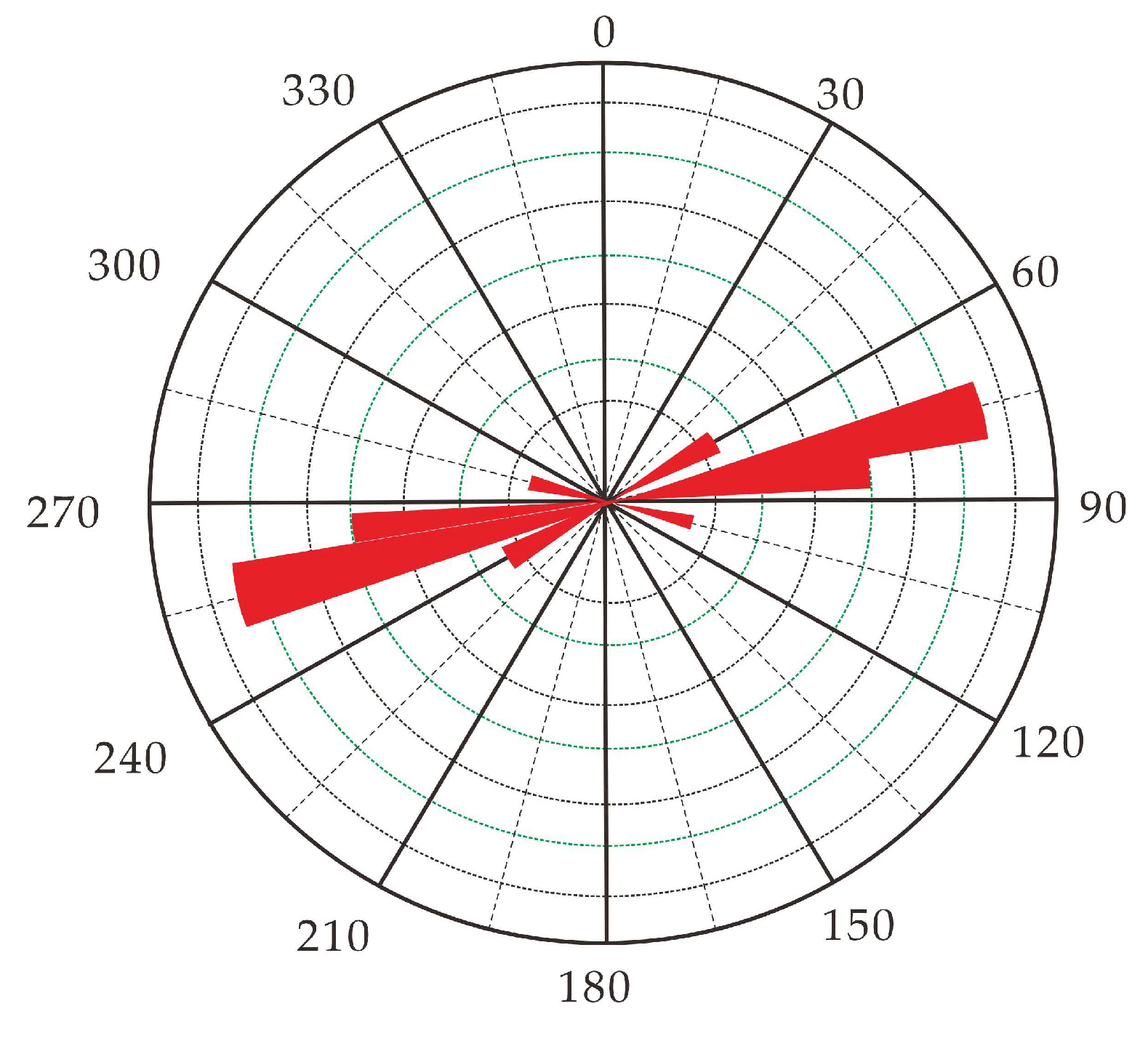

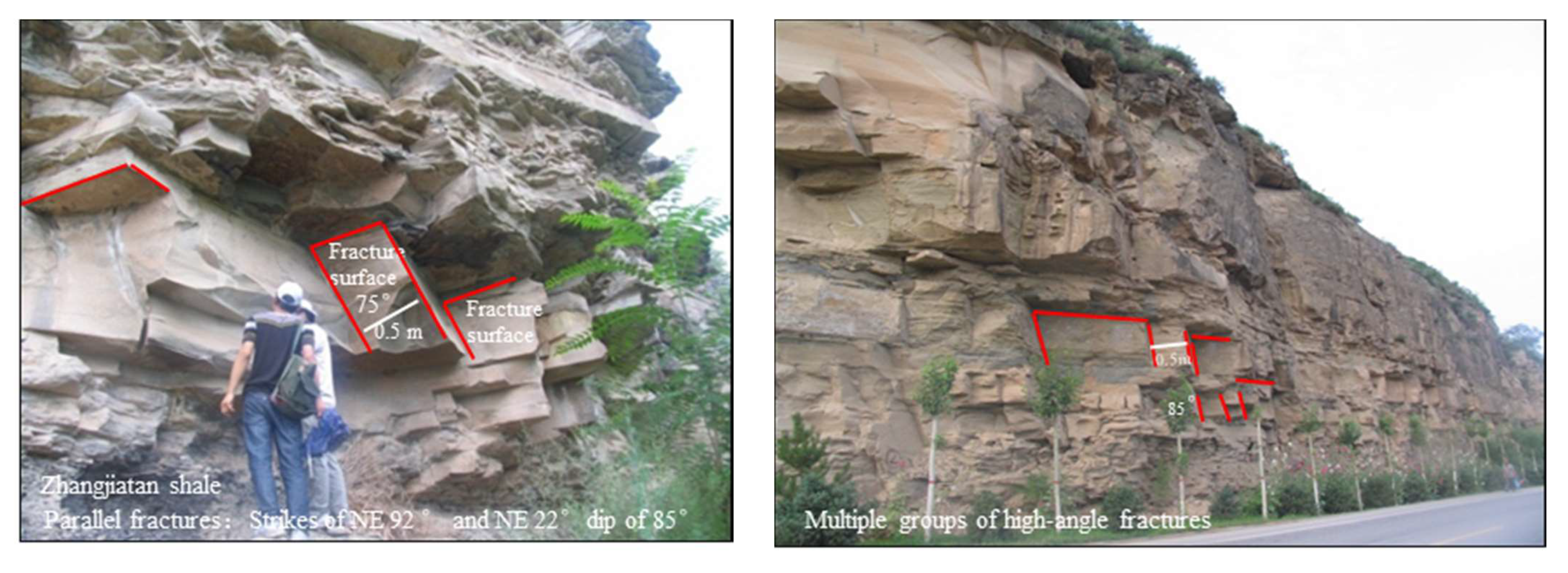

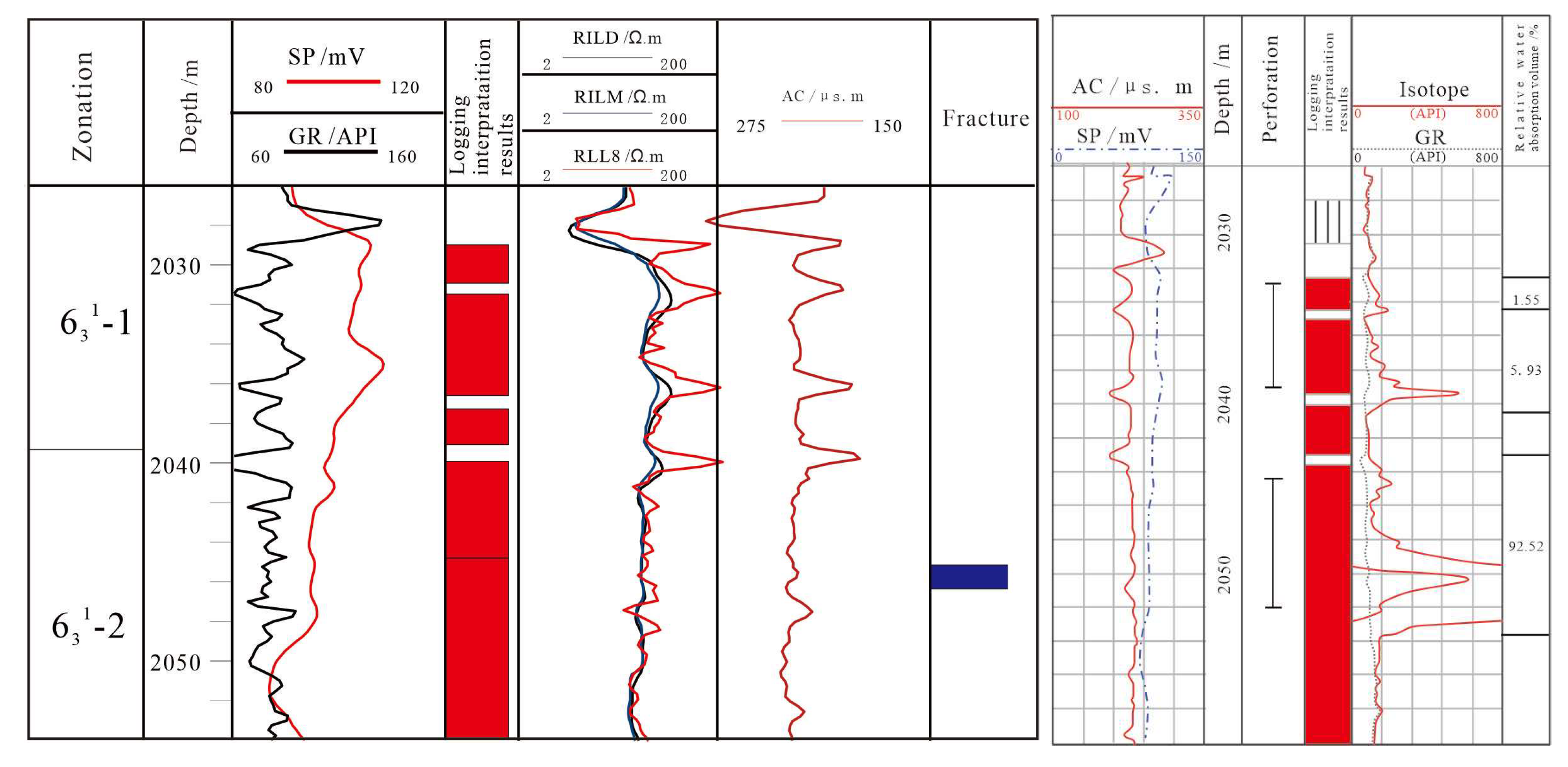

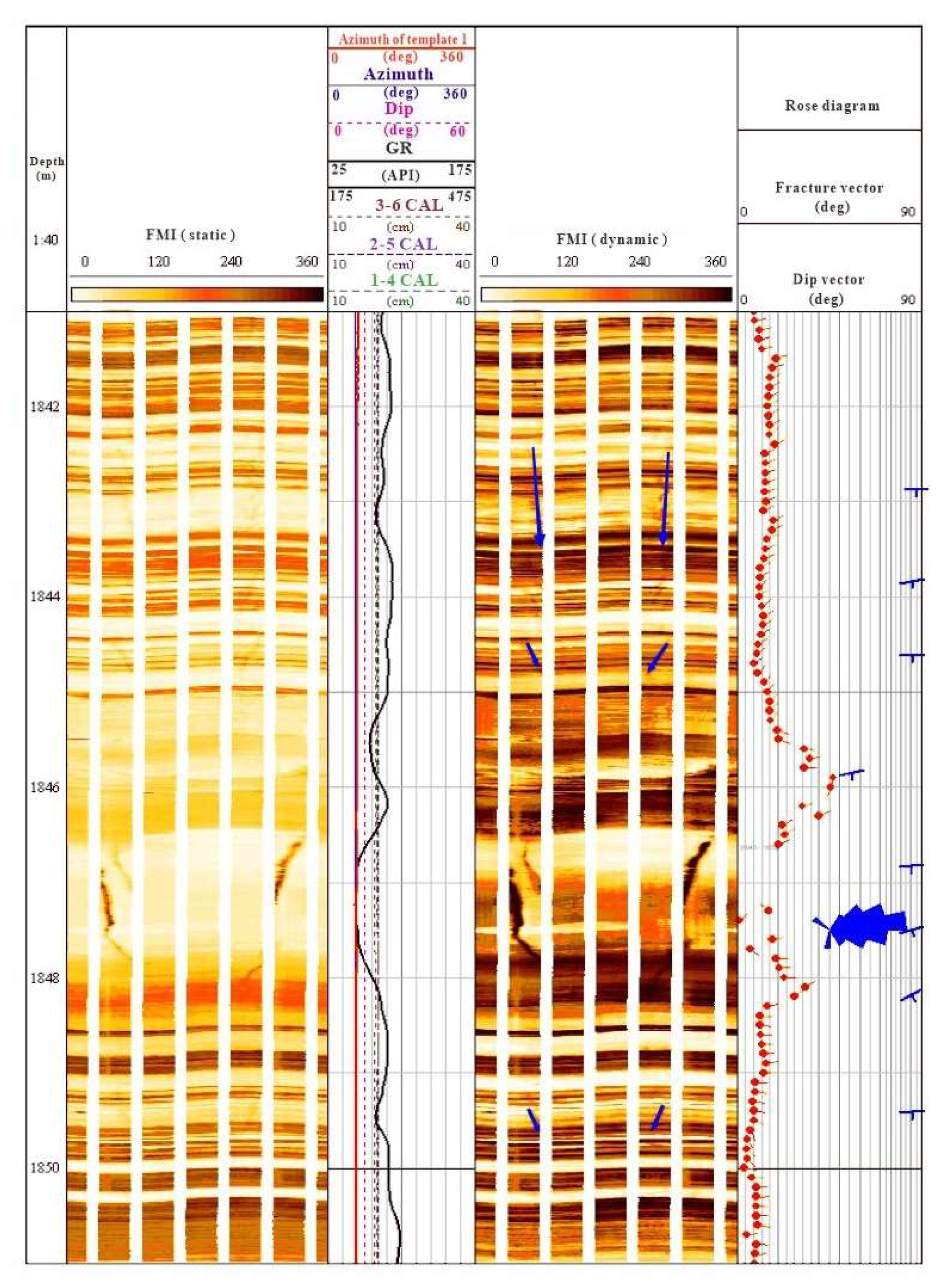

3.2. Quantitative Description of Natural Fractures

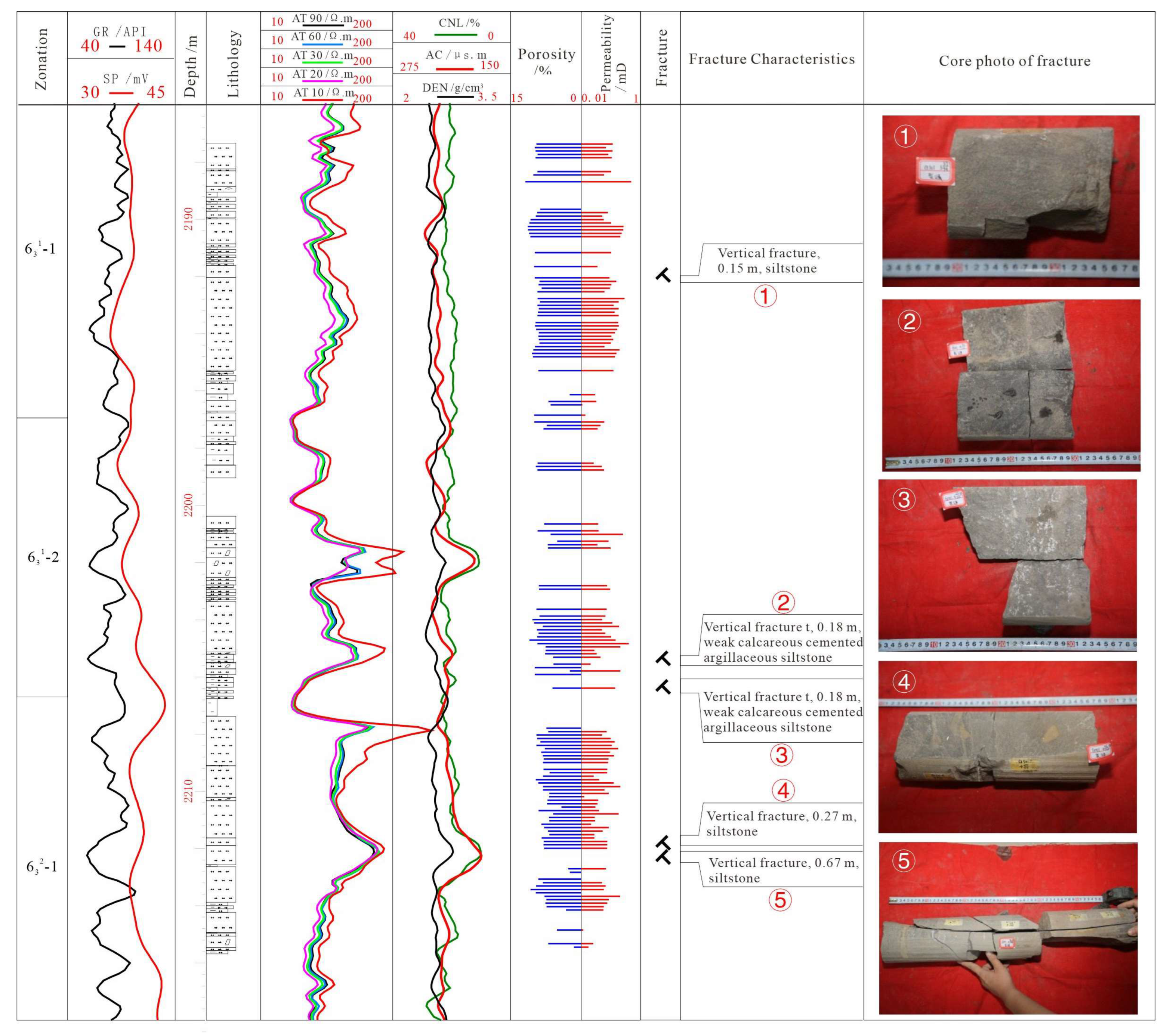

3.2.1. Characteristics of Natural Fractures in Cores

3.2.2. Characteristics of Natural Fractures in Geological Outcrops

3.2.3. Natural Fracture Intensity

3.2.4. Case Analysis

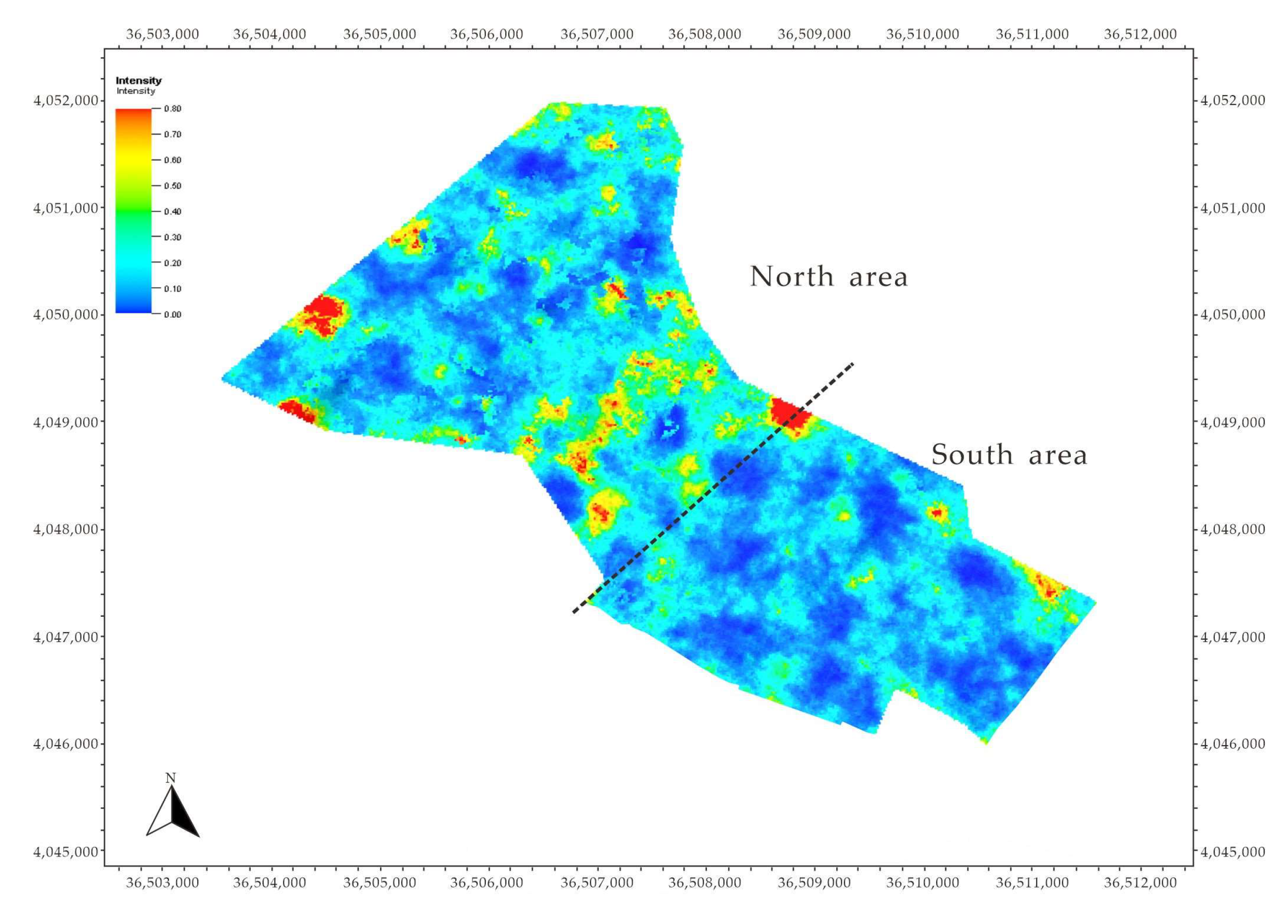

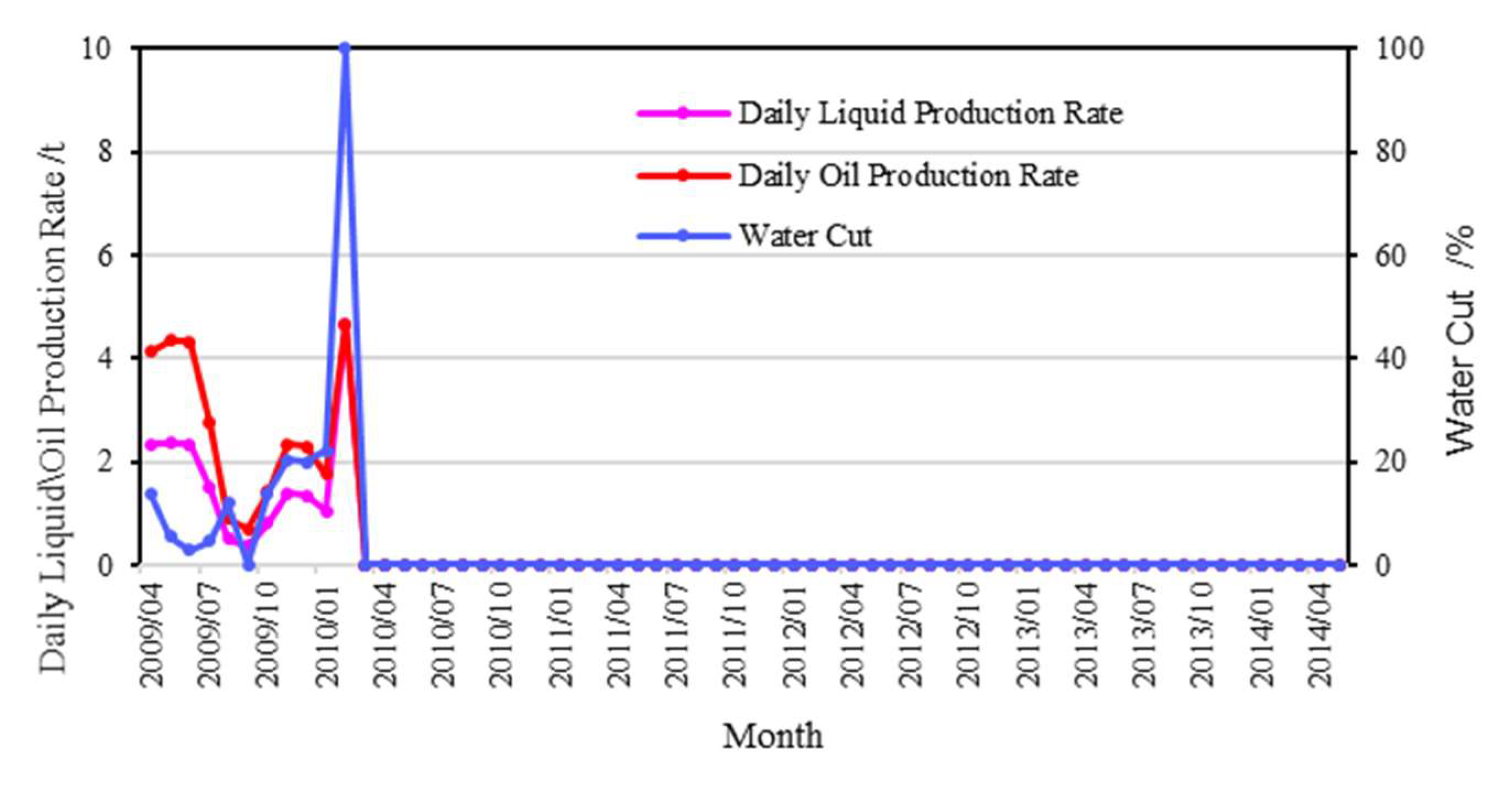

3.3. Dynamic Fracture Distribution Intensity

- ①

- Establishment stage of transient pressure—fractures grow rapidly to a certain scale;

- ②

- Dry oil production stage—the fracture length is fixed;

- ③

- Water breakthrough stage of the producers—the waterflooding front enters the surrounding area of the producers with a relatively high-pressure gradient, and the dynamic fracture develops to the maximum length;

- ④

- Fracture shrinkage stage—the water cut of the producers keeps rising and the fracture shrinks.

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Song, X.; Tian, C.; Shi, C.; Li, J.; Hui, G.; Hou, J.; Gao, C.; Wang, X.; Liu, P. Dynamic fractures are an emerging new development geological attribute in water-flooding development of ultra-low permeability reservoirs. Pet. Explor. Dev. 2015, 42, 222–228. [Google Scholar] [CrossRef]

- Fan, T.; Song, X.; Wu, S.; Li, Q.; Wang, B.; Li, X.; Li, H.; Liu, H. A mathematical model and numerical simulation of waterflood induced dynamic fractures of low permeability reservoirs. Pet. Explor. Dev. 2015, 42, 496–501. [Google Scholar] [CrossRef]

- Van den Hoek, P.J.; Hustedt, B.; Sobera, M.; Mahani, H. Dynamic induced fractures in waterfloods and EOR. In Proceedings of the SPE Russian Oil and Gas Technical Conference and Exhibition, Moscow, Russia, 28–30 October 2008. [Google Scholar]

- Gadde, P.B.; Sharma, M.M. Growing injection well fractures and their impact on waterflood performance. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September–3 October 2001. [Google Scholar]

- Van den Hoek, P.J. Impact of Induced Fractures on Sweep and Reservoir Management in Pattern Floods. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 26–29 September 2004. [Google Scholar]

- Dikken, B.J.; Niko, H. Waterflood-Induced Fractures: A Simulation Study of Their Propagation and Effects on Waterflood Sweep Efficiency. In Proceedings of the SPE Offshore Europe, Aberdeen, UK, 8–11 September 1987. [Google Scholar]

- Perkins, T.K.; Gonzalez, J.A. The effect of thermos–elastic stresses on injection well fracturing. Soc. Pet. Eng. J. 1985, 25, 78–88. [Google Scholar] [CrossRef]

- Hubbert, M.K.; Willis, D.G. Mechanics of hydraulic fracturing. J. Am. Assoc. Pet. Geol. 1957, 12, 239–257. [Google Scholar] [CrossRef]

- Sæby, J.; Bjørndal, H.P.; van den Hoek, P. Managed Induced Fracturing Improves Waterflood Performance in South Oman. In Proceedings of the International Petroleum Technology Conference, Doha, Qatar, 21–23 November 2005. [Google Scholar]

- Zeng, L.; Gao, C.; QI, J.; Wang, Y.; Li, L.; Qu, X. The distribution rule and seepage effect of the fractures in the ultra-low permeability sandstone reservoir in east Gansu Province, Ordos Basin. Sci. China Ser. D Earth Sci. 2008, 51, 44–52. [Google Scholar] [CrossRef]

- Zeng, L.; Li, X. Fractures in sandstone reservoirs with ultra-low permeability: A case study of the Upper Triassic Yanchang Formation in the Ordos Basin, China. AAPG Bull. 2009, 93, 461–477. [Google Scholar]

- Beugelsdijk, L.J.L.; de Pater, C.J.; Sato, K. Experimental hydraulic fracture propagation in a multi-fractured medium. Presented at the SPE Asia Pacific Conference On Integrated Modeling for Asset Management, Yokohama, Japan, 25–26 April 2000. [Google Scholar]

- Blanton, T.L. Propagation of hydraulically and dynamically induced fractures in naturally fractured reservoirs. Presented at the Unconventional Gas Technology Symposium, Louisville, KY, USA, 18–21 May 1986. [Google Scholar]

- Wang, Y.; Cheng, S.; Zhang, K.; He, Y.; Feng, N.; Qin, J.; Luo, L.; Yu, H. A comprehensive Work Flow to Characterize Waterflood-Induced Fractures by Integrating Real-tine Monitoring, Formation Test, and Dynamic Production Analysis Applied to Changqing Oil Field, China. SPE Res. Eval. Eng. 2018, 22, 692–708. [Google Scholar] [CrossRef]

- Bhardwaj, P.; Hwang, J.; Manchanda, R.; Shauma, M. Injection Induced Fracture Propagation and Stress Reorientation in Waterflooded Reservoirs. Presented at the SPE Annual Technical Conference and Exhibition, Dubai, United Arab Emirates, 26–28 September 2016. [Google Scholar]

- Waheibi, H.A.; Garimella, S.; Wardy, W. Safeguarding Reserves of a Large Carbonate Waterflood Field by Preventing Induced Fractures. Presented at the SPE Reservoir Characterization and Simulation Conference and Exhibition, Abu Dhabi, United Arab Emirates, 16–18 September 2013. SPE-165967-MS. [Google Scholar]

- Wang, Y.; Cheng, S.; Qin, J.; Lei, Z.; An, X.; Yu, H. Development theory and practice of water injection induced fractures in ultra-low permeability reservoirs. Sci. Sin. Technol. 2022, 52, 613–626. [Google Scholar] [CrossRef]

- Wang, W.; Peng, H.; Li, G.; Lyu, W.; Wei, C.; Qin, Y. Opening mechanism of dynamic fractures caused by water injection and effective adjustments in low permeability reservoirs. Daqing oilfield in Songliao Basin. Oil Gas Geol. 2015, 36, 842–847. [Google Scholar]

- Taleghani, A.D.; Olson, J.E. How Natural Fractures Could Affect Hydraulic-Fracture Geometry. SPE J. 2014, 19, 161–171. [Google Scholar] [CrossRef]

- Gu, H.; Weng, X.; Lund, J.; Mack, M.; Ganguly, U.; Suarez-Rivera, R. Hydraulic Fracture Crossing Natural Fracture at Nonorthogonal Angles: A Criterion and its Validation. SPE Prod. Oper. 2012, 27, 20–26. [Google Scholar] [CrossRef]

- Xia, H.; Yang, S.; Gong, H.; Wang, C. Research on rock brittleness experiment and logging piediction of hydraulic fracture height & width. J. Southwest Pet. Univ. Sci. Technol. Ed. 2013, 35, 81–89. [Google Scholar]

- Xu, L.; Zhou, L.; Zhang, Y.; Dang, B. Characteristics and tectonic setting of tectono-stress field of Ordos basin. Geotecton. Metallog. 2006, 30, 455–462. [Google Scholar]

- Liu, G. Research on Fracture Developing Characteristics of Chang 63 Reservoir, Yanchang Group in Huaqing Aera, Changqing Petroleum Field. Ph.D. Thesis, Lanzhou University, Lanzhou, China, 2010. [Google Scholar]

- Liu, G.; Huang, C.; Zhou, X.; Zhang, L.; Pan, Y. Quantitative evaluation of fracture development for Triassic Yanchang Formation, Ordos Basin, NW China. Pet. Explor. Dev. 2015, 42, 486–496. [Google Scholar] [CrossRef]

- Zeng, L.; Li, Z.; Shi, C.; Wang, Z.; Zhao, J.; Wang, Y. Characteristics and origin of fractures in the extra-low permeability sandstone reservoirs of the Upper Triassic Yanchang Formation in the Ordos Basin. Acta Geol. Sin. 2007, 81, 174–178. [Google Scholar]

- Pan, B.; Xue, L. Fractal Dimension and Its Application to Geologic Interpretation of Log Data. Logging Technol. 1992, 16, 214–221. [Google Scholar]

- Yang, X. Review of Fractal Research in Geophysics. Adv. Earth Sci. 1991, 6, 31–37. [Google Scholar]

- Yue, Y.; Wang, C. The application of multifractals in fracture research. Geophys. Prospect. Pet. 1998, 37, 109–114. [Google Scholar]

- Chen, Y.; Chen, L. Fractal Geometry, 2nd ed.; Seismological Press: Beijing, China, 2005; pp. 121–122. [Google Scholar]

- Sun, X.; Wu, Z.; Huang, Y. Fractal Principle and Its Application; China University of Science and Technology Press: Hefei, China, 2003; pp. 53–74. [Google Scholar]

- Cheng, G.; Zhou, G.; Wang, X. The probability Neural Networks for Lithology Identification. Micro-Comput. Inf. 2007, 23, 288–289. [Google Scholar]

- Yang, B.; Kuang, L.; Sun, Z. Neural Network and Its Application in Oil Well Logging; Petroleum Industry Press: Beijing, China, 2005. [Google Scholar]

- Zhang, H.; Zou, L.; Shen, X. The Application of BP Neural Network in Well Lithology Identification. Geol. Explor. 2002, 38, 63–65. [Google Scholar]

- Cheng, W.; Jin, Y.; Chen, M.; Xu, T.; Zhang, Y.; Diao, C. A criterion for identifying hydraulic fractures crossing natural fractures in 3D space. Pet. Explor. Dev. 2014, 41, 336–339. [Google Scholar] [CrossRef]

- Chen, M.; Jin, Y.; Zhang, G. Rock Mechanics in Petroleum Engineering; Science Press: Beijing, China, 2008. [Google Scholar]

- Yan, T.; Li, W.; Bi, X. An experimental study of fracture initiation mechanisms during hydraulic fracturing. Pet. Sci. 2011, 8, 87–92. [Google Scholar] [CrossRef] [Green Version]

| Well | Lithology | Depth/m | Density/ g/cm3 | Confining Pressure, Pore Pressure/MPa | Compressive Strength σ1/Mpa | Elastic Modulus E/GPa | Poisson’s Ratio μ | Brittleness Index % |

|---|---|---|---|---|---|---|---|---|

| A | Brown fine sandstone | 1028.26 | 2.27 | 5, 2 | 89.4 | 13 | 0.18 | 38.88 |

| B | Grayish-white calcareous sandstone | 1025.67 | 2.51 | 5, 2 | 118.42 | 21.45 | 0.18 | 43.99 |

| C | Greyish-black siltstone | 1035.1 | 2.58 | 5, 2 | 78.39 | 10.57 | 0.22 | 31.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Song, X. Comprehensive Characterization Integrating Static and Dynamic Data for Dynamic Fractures in Ultra-Low Permeability Reservoirs: A Case Study of the Chang 6 Reservoir of the Triassic Yanchang Formation in the Ordos Basin, China. Minerals 2022, 12, 1277. https://doi.org/10.3390/min12101277

Wang Y, Song X. Comprehensive Characterization Integrating Static and Dynamic Data for Dynamic Fractures in Ultra-Low Permeability Reservoirs: A Case Study of the Chang 6 Reservoir of the Triassic Yanchang Formation in the Ordos Basin, China. Minerals. 2022; 12(10):1277. https://doi.org/10.3390/min12101277

Chicago/Turabian StyleWang, Youjing, and Xinmin Song. 2022. "Comprehensive Characterization Integrating Static and Dynamic Data for Dynamic Fractures in Ultra-Low Permeability Reservoirs: A Case Study of the Chang 6 Reservoir of the Triassic Yanchang Formation in the Ordos Basin, China" Minerals 12, no. 10: 1277. https://doi.org/10.3390/min12101277

APA StyleWang, Y., & Song, X. (2022). Comprehensive Characterization Integrating Static and Dynamic Data for Dynamic Fractures in Ultra-Low Permeability Reservoirs: A Case Study of the Chang 6 Reservoir of the Triassic Yanchang Formation in the Ordos Basin, China. Minerals, 12(10), 1277. https://doi.org/10.3390/min12101277