Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mixture Copostions

2.3. Calorimetric Tests

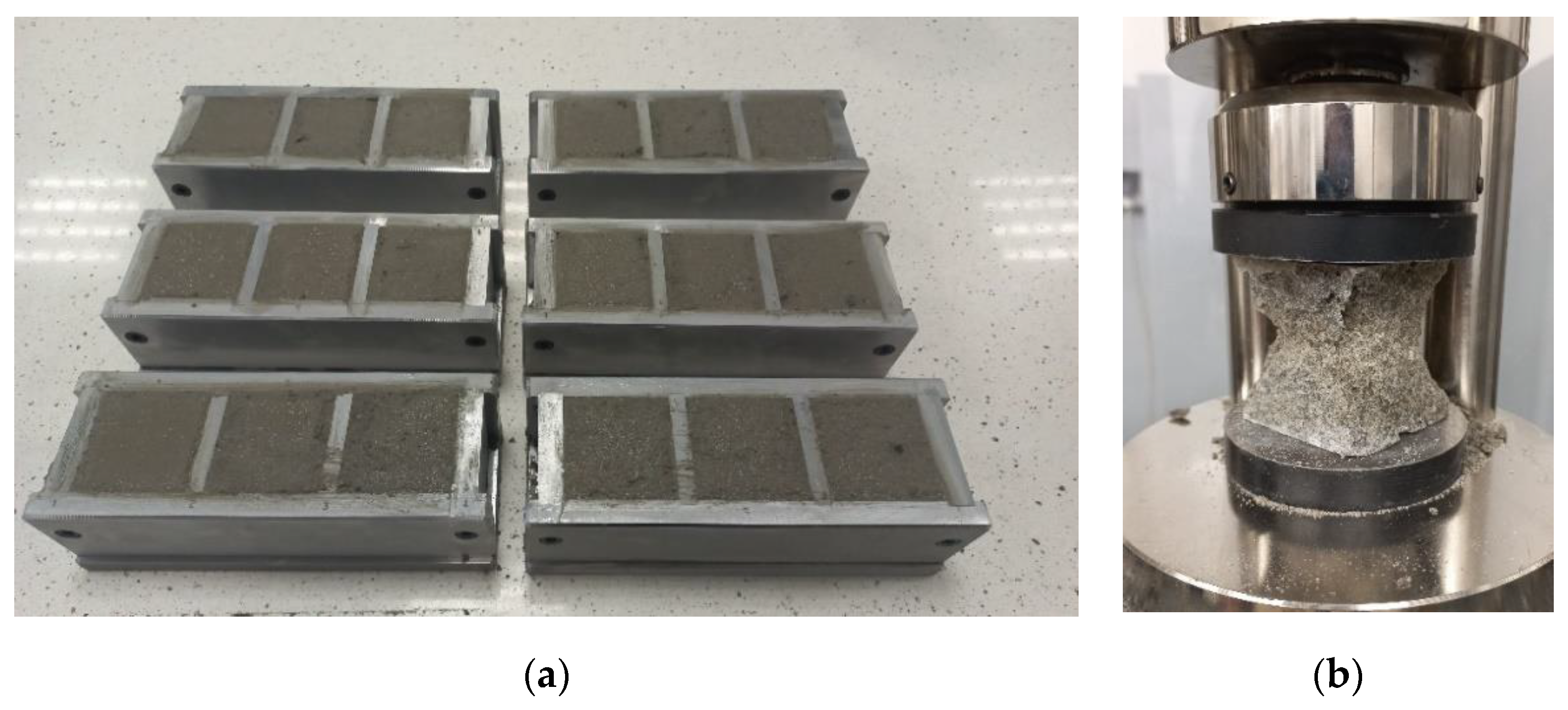

2.4. Compression Tests

3. Results

3.1. The Heat of Hydration

3.2. Compressive Strength of Mortar Samples

3.3. Relationship between Heat and Strength

4. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- EN 196-9; Methods of Testing Cement. Part 9. Heat of Hydration—Semi-Adiabatic Method. European Standards; European Committee for Standardization: Brussels, Belgium, 2010.

- EN 196-8; Methods of Testing Cement. Part 8. Heat of Hydration—Solution Method. European Standards; European Committee for Standardization: Brussels, Belgium, 2010.

- ASTM C1679; Standard Practice for Measuring Hydration Kinetics of Hydraulic Cementitious Mixtures Using Isothermal Calorimetry. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C1702; Standard Test Method for Measurement of Heat of Hydration of Hydraulic Cementitious Materials Using Isothermal Conduction Calorimetry. ASTM International: West Conshohocken, PA, USA, 2017.

- EN 196-11; Methods of Testing Cement. Part 11. Heat of Hydration—Isothermal Conduction Calorimetry Method. European Standards; European Committee for Standardization: Brussels, Belgium, 2018.

- Usherov-Marshak, V.; Ciak, M. Isothermal calorimetry in the standard ASTM C1679-08. Cem. Lime Concr. 2010, 2, 108–110. [Google Scholar]

- Do, T.A.; Hoang, T.T.; Bui-Tien, T.; Hoang, H.V.; Do, T.D.; Nguyen, P.A. Evaluation of heat of hydration, temperature evolution and thermal cracking risk in high-strength concrete at early ages. Case Stud. Therm. Eng. 2020, 21, 100658. [Google Scholar] [CrossRef]

- Frølich, L.; Wadsö, L.; Sandberg, P. Using isothermal calorimetry to predict one day mortar strengths. Cem. Concr. Res. 2016, 88, 108–113. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Chen, H. The role of fly ash microsphere in the microstructure and macroscopic properties of high-strength concrete. Cem. Concr. Compos. 2017, 83, 125–137. [Google Scholar] [CrossRef]

- Haustein, E. The selected physico-chemical properties of microspheres and possibility of their use in cement composites. Compos. Theory Pract. 2016, 16, 25–29. [Google Scholar]

- Zhang, T.; Yu, Q.; Wei, J.; Zhang, P.; Chen, P. A gap-graded particle size distribution for blended cements: Analytical approach and experimental validation. Powder Technol. 2011, 214, 259–268. [Google Scholar] [CrossRef]

- Haustein, E.; Kuryłowicz-Cudowska, A. Effect of Particle Size of Fly Ash Microspheres (FAMs) on the Selected Properties of Concrete. Minerals 2022, 12, 847. [Google Scholar] [CrossRef]

- Blissett, R.S.; Rowson, N.A. A review of the multi-component utilisation of coal fly ash. Fuel 2012, 97, 1–23. [Google Scholar] [CrossRef]

- Klathae, T.; Tanawuttiphong, N.; Tangchirapat, W.; Chindaprasirt, P.; Sukontasukkul, P.; Jaturapitakkul, C. Heat evolution, strengths, and drying shrinkage of concrete containing high volume ground bagasse ash with different LOIs. Constr. Build. Mater. 2020, 258, 119443. [Google Scholar] [CrossRef]

- Kuryłowicz-Cudowska, A. Determination of thermophysical parameters involved in the numerical model to predict the temperature field of cast-in-place concrete bridge deck. Materials 2019, 12, 3089. [Google Scholar] [CrossRef]

- Mariak, A.; Kurpińska, M.; Wilde, K. Maturity curve for estimating the in-place strength of high performance concrete. MATEC Web Conf. 2019, 262, 06007. [Google Scholar] [CrossRef][Green Version]

- Kuryłowicz-Cudowska, A.; Wilde, K.; Chróścielewski, J. Prediction of cast-in–place concrete strength of the extradosed bridge deck based on temperature monitoring and numerical simulations. Constr. Build. Mater. 2020, 254, 1–17. [Google Scholar] [CrossRef]

- Kuryłowicz-Cudowska, A.; Wilde, K. FEM and experimental investigations of concrete temperature field in the massive stemwall of the bridge abutment. Constr. Build. Mater. 2022, 347, 128565. [Google Scholar] [CrossRef]

- Bobrowicz, J. Relation between cements compressive strength and the amount of the hydration heat evolvet in low temperatures. Build. Res. Inst. 2005, 3, 1–14. (In Polish) [Google Scholar]

- Ge, Z.; Wang, K.; Sandberg, P.; Ruiz, J.M. Characterization and performance prediction of cement-based materials using a simple isothermal calorimeter. J. Adv. Concr. Technol. 2009, 7, 1–12. [Google Scholar] [CrossRef]

- Bentz, D.; Barrett, T.; De La Varga, I.; Weiss, W.J. Relating compressive strength to heat release in mortars. Adv. Civil. Eng. Mater. 2012, 1, 1–14. [Google Scholar] [CrossRef]

- Baran, T.; Pichniarczyk, P. Correlation factor between heat of hydration and compressive strength of common cement. Constr. Build. Mater. 2017, 150, 321–332. [Google Scholar] [CrossRef]

- Boubekeur, T.; Salhi, M.; Ezziane, K.; Kadri, R.-H. Effect of elevated temperature on the hydration heat and mechanical properties of blended cements mortars. J. Mater. Eng. Struct. 2021, 8, 341–356. [Google Scholar]

- EN 206-1; Concrete—Part 1: Specification, Performance, Production and Conformity. European Standards; European Committee for Standardization: Brussels, Belgium, 2020.

- EN 197-1; Cement—Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Standards; European Committee for Standardization: Brussels, Belgium, 2012.

- EN 196-2; Methods of Testing Cement—Part 2: Chemical Analysis of Cement. European Standards; European Committee for Standardization: Brussels, Belgium, 2013.

- ASTM C188; Standard Test Method for Density of Hydraulic Cement. ASTM International: West Conshohocken, PA, USA, 2017.

- EN 196-6; Methods of Testing Cement—Part 6: Determination of Fineness. European Standards; European Committee for Standardization: Brussels, Belgium, 2019.

- ASTM C204; Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus. ASTM International: West Conshohocken, PA, USA, 2014.

- EN 450-1; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. European Standards; European Committee for Standardization: Brussels, Belgium, 2012.

- ASTM C618; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2019.

- Feng, J.; Sun, J.; Yan, P. The influence of ground fly ash on cement hydration and mechanical property of mortar. Adv. Civ. Eng. 2018, 2018, 4023178. [Google Scholar] [CrossRef]

- Klemczak, B.; Batog, M. Heat of hydration of low-clinker cements—Part I: Semi-adiabatic and isothermal tests at different temperature. J. Therm. Anal. Calorim. 2016, 123, 1351–1360. [Google Scholar] [CrossRef]

- ASTMC109/C109M; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). ASTM International: West Conshohocken, PA, USA, 2016.

- EN 12390-3; Testing Hardened Concrete—Part 3: Compressive Strength of Test Specimens. European Standards; European Committee for Standardization: Brussels, Belgium, 2019.

- Lerch, W. The influence of gypsum on the hydration and properties of Portland cement pastes. Am. Soc. Test. Mater. 1946, 46, 1252–1297. [Google Scholar]

- Hesse, C.; Goetz-Neunhoeffer, F.; Neubauer, J. A new approach in quantitative insitu XRD of cement pastes: Correlation of heat flow curves with early hydration reactions. Cem. Concr. Res. 2010, 41, 123–128. [Google Scholar] [CrossRef]

- Jansen, D.; Goetz-Neunhoeffer, F.; Lothenbach, B.; Neubauer, J. The early hydration of Ordinary Portland Cement (OPC): An approach comparing measured heat flow with calculated heat flow from QXRD. Cem. Concr. Res. 2012, 42, 134–138. [Google Scholar] [CrossRef]

- Kuryłowicz-Cudowska, A.; Haustein, E. Isothermal calorimetry and compressive strength tests of mortar specimens for determination of apparent activation energy. J. Mater. Civ. Eng. 2021, 33, 04021035. [Google Scholar] [CrossRef]

- Azenha, M. Numerical Simulation of the Structural Behaviour of Concrete since Its Early Ages. Ph.D. Thesis, Faculty of Engineering, University of Porto, Porto, Portugal, 2009. [Google Scholar]

- Haustein, E.; Kuryłowicz-Cudowska, A.; Łuczkiewicz, A.; Fudala-Książek, S.; Cieślik, B.M. Influence of Cement Replacement with Sewage Sludge Ash (SSA) on the Heat of Hydration of Cement Mortar. Materials 2022, 15, 1547. [Google Scholar] [CrossRef]

- Moghaddam, F.; Sirivivatnanon, V.; Vessalas, K. The effect of fly ash fineness on heat of hydration, microstructure, flow and compressive strength of blended cement pastes. Case Stud. Constr. Mater. 2019, 10, e00218. [Google Scholar] [CrossRef]

- Snelson, D.G.; Wild, S.; O’Farrell, M. Heat of hydration of portland cement–metakaolin–fly ash (PC–MK–PFA) blends. Cem. Concr. Res. 2008, 38, 832–840. [Google Scholar] [CrossRef]

- Deschner, F.; Winnefeld, F.; Lothenbach, B. Hydration of a portland cement with high replacement by siliceous fly ash. Cem. Concr. Res. 2012, 42, 1389–1400. [Google Scholar] [CrossRef]

- Kjellsen, K.O.; Detwiler, R.J. Later-age strength prediction by a modified maturity model. ACI Mater. J. 1993, 90, 220–227. [Google Scholar]

| Property | OPC | FA | Requirements for Siliceous Fly Ash Acc. to EN 450-1 [30] |

|---|---|---|---|

| CaO (wt. %) | 64.08 | 3.65 | - |

| SiO2 (wt. %) | 21.23 | 55.44 | ≥25 |

| Al2O3 (wt. %) | 4.99 | 24.57 | - |

| SO3 (wt. %) | 2.97 | 0.62 | ≤3 |

| MgO (wt. %) | 2.48 | 2.57 | ≤4 |

| Fe2O3 (wt. %) | 2.23 | 6.36 | - |

| K2O (wt. %) | 0.92 | 3.04 | - |

| Na2O (wt. %) | 0.13 | 1.04 | - |

| Chloride content (wt. %) | 0.04 | - | - |

| LOI (wt. %) | 2.96 | 2.56 | class: A ≤ 5, B ≤ 7, C ≤ 9. |

| Density (g/cm3) | 3.05 | 2.10 | - |

| Specific surface area (cm2/g) | 2360 | 2250 | - |

| Fineness, sieve residue 0.045 mm (wt. %) | - | 32.9 | ≤40 (N), ≤12 (S) |

| Mix Proportions of the Mortars (kg/m3) | ||||

|---|---|---|---|---|

| Mortar Mix | Cement CEM I 42.5 R | Siliceous Fly Ash (FA) | Fine Aggregate 0–2 mm | Water |

| OPC | 440 | 0 (0%) | 1142 | 175 |

| OPC + 10% FA | 396 | 44 (10%) | 1142 | 175 |

| OPC + 20% FA | 352 | 88 (20%) | 1142 | 175 |

| Mortar Mix | Temp. (°C) | Heat of Hydration after Hours (J/g) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 12 h | 24 h | 36 h | 48 h | 60 h | 72 h | 120 h | 165 h | Total * | ||

| OPC | 23 | 92 | 176 | 212 | 236 | 257 | 272 | 301 | 313 | 352 |

| 33 | 148 | 226 | 263 | 284 | 297 | 304 | 320 | 328 | 347 | |

| 43 | 219 | 282 | 304 | 314 | 320 | 325 | 336 | 343 | 354 | |

| 53 | 263 | 311 | 326 | 332 | 337 | 340 | 349 | 354 | 363 | |

| OPC + 10% FA | 23 | 70 | 150 | 183 | 204 | 222 | 237 | 268 | 280 | 322 |

| 33 | 120 | 195 | 228 | 250 | 264 | 273 | 290 | 299 | 320 | |

| 43 | 193 | 251 | 273 | 283 | 288 | 293 | 303 | 310 | 321 | |

| 53 | 216 | 265 | 283 | 291 | 297 | 302 | 313 | 319 | 331 | |

| OPC + 20% FA | 23 | 59 | 133 | 165 | 185 | 201 | 214 | 245 | 260 | 303 |

| 33 | 122 | 192 | 221 | 242 | 255 | 265 | 284 | 293 | 316 | |

| 43 | 177 | 231 | 256 | 268 | 275 | 281 | 296 | 304 | 320 | |

| 53 | 203 | 248 | 270 | 282 | 290 | 297 | 312 | 320 | 336 | |

| Mortar Mix | Temp. (°C) | Max. Peak (J/g/h) | Time of Peak Occurrence (h) |

|---|---|---|---|

| OPC | 23 | 8.1 | 15.9 |

| 33 | 13.4 | 11.7 | |

| 43 | 28.4 | 6.8 | |

| 53 | 58.6 | 4.6 | |

| OPC + 10% FA | 23 | 7.6 | 16.4 |

| 33 | 12.1 | 12.7 | |

| 43 | 26.2 | 6.9 | |

| 53 | 52.0 | 4.9 | |

| OPC + 20% FA | 23 | 6.6 | 17.9 |

| 33 | 11.7 | 12.8 | |

| 43 | 21.5 | 8.0 | |

| 53 | 47.6 | 5.1 |

| Temperature (°C) | 23 | 33 | 43 | 53 |

|---|---|---|---|---|

| Amount of heat released due to 20% FA (J/g) | 9.6 | 30.6 | 29.6 | 36.8 |

| Mortar Mix. | Strength after 7 Days (MPa) | Strength after 14 Days (MPa) | ||||

|---|---|---|---|---|---|---|

| Measured (MPa) | Calculated for R2 = 0.9950 (MPa) | Relative Error (%) | Measured (MPa) | Calculated for R2 = 0.9591 (MPa) | Relative Error (%) | |

| OPC | 57.73 | 57.83 | 0.2 | 59.65 | 59.97 | 0.5 |

| OPC + 10% FA | 48.44 | 47.74 | 1.4 | 55.80 | 54.76 | 1.9 |

| OPC + 20% FA | 40.80 | 41.14 | 0.8 | 50.77 | 51.36 | 1.2 |

| Mortar Mix. | Strength after 7 Days (MPa) | Strength after 14 Days (MPa) | ||||

|---|---|---|---|---|---|---|

| Measured (MPa) | Calculated for R2 = 0.9553 (MPa) | Relative Error (%) | Measured (MPa) | Calculated for R2 = 0.8204 (MPa) | Relative Error (%) | |

| OPC | 39.54 | 39.36 | 0.5 | 42.03 | 41.64 | 0.9 |

| OPC + 10% FA | 43.82 | 44.71 | 2.0 | 44.38 | 45.92 | 3.5 |

| OPC + 20% FA | 47.31 | 46.69 | 1.3 | 48.65 | 47.50 | 2.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuryłowicz-Cudowska, A. Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash. Minerals 2022, 12, 1471. https://doi.org/10.3390/min12111471

Kuryłowicz-Cudowska A. Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash. Minerals. 2022; 12(11):1471. https://doi.org/10.3390/min12111471

Chicago/Turabian StyleKuryłowicz-Cudowska, Aleksandra. 2022. "Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash" Minerals 12, no. 11: 1471. https://doi.org/10.3390/min12111471

APA StyleKuryłowicz-Cudowska, A. (2022). Correlation between Compressive Strength and Heat of Hydration of Cement Mortars with Siliceous Fly Ash. Minerals, 12(11), 1471. https://doi.org/10.3390/min12111471