Investigating the Influence of the Electrochemical Environment on the Flotation of Bornite and Chalcocite

Abstract

:1. Introduction

1.1. Effect of pH on Flotation

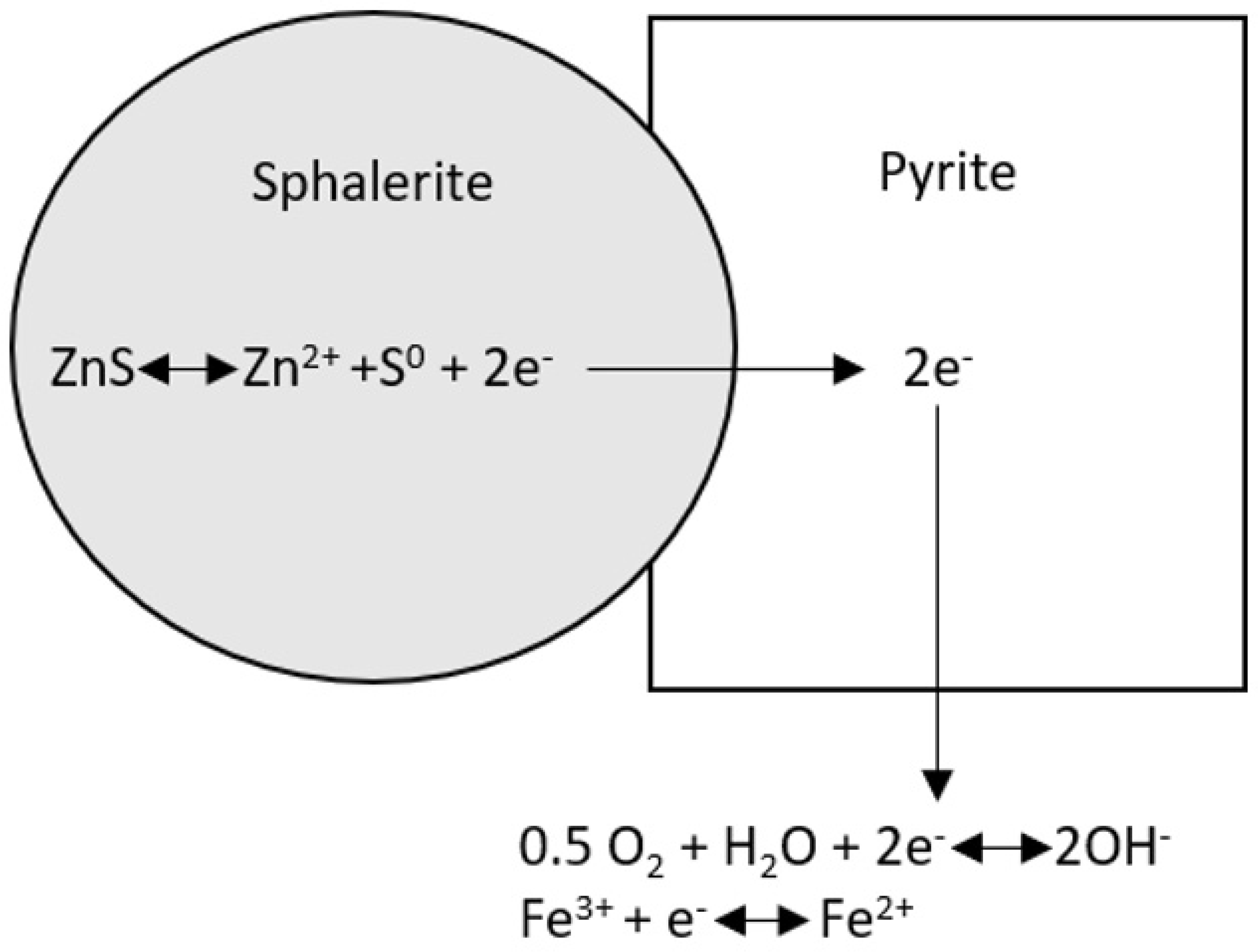

1.2. Galvanic Interaction in Mineral Mixtures

1.3. Collector Adsorption

2. Materials and Methods

2.1. Mineralogy

2.2. Synthetic Plant Water Preparation

2.3. Microflotation

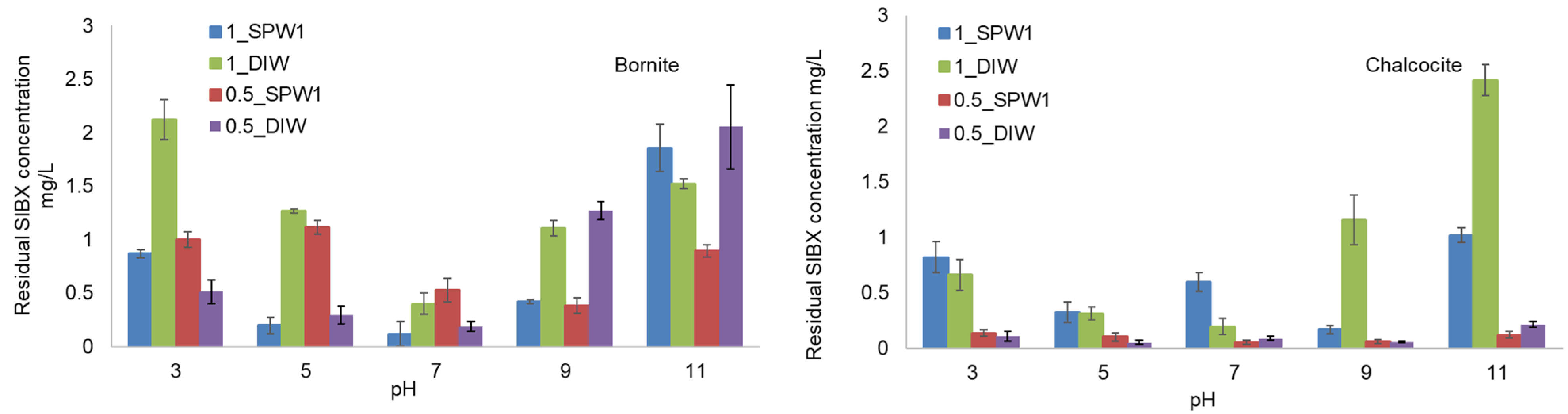

2.4. Adsorption Studies

2.5. Zeta Potential

3. Results and Discussion

copper xanthate formation from dissolution

copper xanthate formation from corrosion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pistilli, M. Types of Copper Deposits in the World. Investing News Network, 23 May. 2019. Available online: https://investingnews.com/daily/resource-investing/base-metals-investing/copper-investing/types-copper-deposits-world/ (accessed on 8 September 2022).

- Heyes, G. Differential Flotation of Mixed Copper Sulphide Minerals. Australian Patent No. 2008201799B2, 23 April 2008. [Google Scholar]

- Bulatovic, S.M. Adsorption Mechanism of Flotation Collectors. In Handbook of Flotation Reagents—Chemistry, Theory and Practice, Volume 1—Flotation of Sulfide Ores; Elsevier Ltd.: North York, ON, Canada, 2007; Volume 1, pp. 125–152. [Google Scholar]

- Wills, B.A.; Finch, J.A. Wills’ Mineral Processing Technology—An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 8th ed.; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Wark, I.W.; Cox, A.B. Principles of flotation, I, II and III. Trans. AIME 1934, 112, 189; 245; 267. [Google Scholar]

- Fuerstenau, D.W. A century of developments in the chemistry of flotation processing. In Froth Flotation: A Century of Innovation; Fuerstenau, M.C., Jameson, G., Yoon, R.-H., Eds.; SME: Sydney, NSW, Australia, 2007; p. 18. [Google Scholar]

- Zanin, M.; Lambert, H.; Du Plessis, C.A. Lime use and functionality in sulphide mineral flotation. Miner. Eng. 2019, 143, 105922. [Google Scholar] [CrossRef]

- Fee, B.S.; Klimpel, R.R. Chemical Reagents in the Minerals Industry; SME Inc.: Littleton, CO, USA, 1986. [Google Scholar]

- Payant, R.; Rosenblum, F.; Nesset, J.E.; Finch, J.A. Galvanic Interaction and Particle Size Effects in Self-Heating of Sulphide Mixtures. Separation Technologies for Minerals, Coal, and Earth Resources; Young, C., Luttrell, G.H., Eds.; SME: Englewood, CO, USA, 2012; pp. 419–429. [Google Scholar]

- Allison, S.A.; Goold, L.A.; Nicol, M.J.; Granville, A. A determination of the products of reaction between various sulfide minerals and aqueous solutions and a correlation of the products with electrode rest potentials. Metal. Trans. 1972, 3, 2613–2618. [Google Scholar] [CrossRef]

- Bruckard, W.; Sparrow, G.; Woodcock, J. A review of the Effects of the Grinding Environment on the Flotation of Copper Sulphides. Int. J. Miner. Process. 2011, 100, 1–13. [Google Scholar] [CrossRef]

- Bundy, K.J. Biomaterials and the chemical environment of the body. In Joint Replacement Technology; Revell, P.A., Ed.; Woodhead Publishing: Sawston, UK, 2008. [Google Scholar]

- Holmes, P.R.; Crundwell, F.K. Kinetic aspects of galvanic interactions between minerals during dissolution. Hydrometallurgy 1995, 39, 353–375. [Google Scholar] [CrossRef]

- Owusu, C.; Addai-Mensah, J.; Fornasiero, D.; Zanin, M. Estimating the electrochemical reactivity of pyrite ores-their impact on pulp chemistry and chalcopyrite flotation behaviour. Adv. Powder Technol. 2013, 24, 801–809. [Google Scholar] [CrossRef]

- Woods, R. The oxidation of ethyl xanthate on platinum, gold, copper, and galena electrodes. Relation to the mechanism of mineral flotation. J. Phys. Chem. 1971, 75, 354–362. [Google Scholar] [CrossRef]

- Woods, R. Electrochemical potential controlling flotation. Int. J. Miner. Process. 2003, 72, 151–162. [Google Scholar] [CrossRef]

- Hu, Y.; Sun, W.; Wang, D. Electrochemistry of Flotation of Sulphide Minerals; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Rao, S.R. Surface Chemistry of Froth Flotation, 2nd ed.; Kluwer Academic Publishers: New York, NY, USA, 2004. [Google Scholar]

- Wiese, J.G.; Harris, P.; Bradshaw, D.J. The influence of the reagent suite on the flotation of ores from the Merensky reef. Miner. Eng. 2005, 18, 189–198. [Google Scholar] [CrossRef]

- Bradshaw, D.; O’Connor, C. Measurement of the sub-process of bubble loading in flotation. Miner. Eng. 1996, 9, 443–448. [Google Scholar] [CrossRef]

- October, L.; Manono, M.S.; Wiese, J.G.; Schreithofer, N.; Corin, K.C. Fundamental and flotation techniques assessing the effect of water quality on bubble-particle attachment of chalcopyrite and galena. Miner. Eng. 2021, 167, 106880. [Google Scholar] [CrossRef]

- Elizondo-Alvarez, M.A.; Davila-Pulido, G.I.; Bello-Teodoro, S.; Uribe-Salas, A. Role of pH on the adsorption of xanthate and dithiophosphinate onto galena. Can. Metall. Q. 2019, 58, 107–115. [Google Scholar] [CrossRef]

- Multani, R.S.; Williams, H.; Johnson, B.; Li, R.; Waters, K.E. The effect of superstructure on the zeta potential, xanthate adsorption, and flotation response of pyrrhotite. Colloids Surf. A Physicochem. Eng. Asp. 2018, 551, 108–116. [Google Scholar] [CrossRef]

- Jiang, C.L.; Wang, X.H.; Parekh, B.K.; Leonard, J.W. The surface and solution chemistry of pyrite flotation with xanthate in the presence of iron ions. Colloids Surf. A Physicochem. Eng. Asp. 1998, 136, 51–62. [Google Scholar] [CrossRef]

- Holmberg, K. Handbook of Applied Surface and Colloid Chemistry; Wiley-Blackwell: Hoboken, NJ, USA, 2002; Volume 1. [Google Scholar]

- Goncalves, K.L.C.; Andrade, V.L.L.; Peres, A.E.C. The effect of grinding conditions on the flotation of a sulphide copper ore. Miner. Eng. 2003, 16, 1213–1216. [Google Scholar] [CrossRef]

- Greet, C.J.; Small, G.L.; Steinier, P.; Grano, S.R. The Magotteaux Mill®: Invesigating the effect of grinding on pulp chemistry and flotation performance. Miner. Eng. 2004, 17, 891–896. [Google Scholar] [CrossRef]

- Mikhlin, Y.; Tomashevich, Y.; Tauson, V.; Vyalikh, D.; Molodtsov, S.; Szargan, R. A comparative X-ray absorption near-edge structure study of bornite, Cu5FeS4, and chalcopyrite, CuFeS2. J. Electron Spectrosc. Relat. Phenom. 2005, 142, 83–88. [Google Scholar] [CrossRef]

- Shen, Y.; Nagaraj, D.R.; Farinato, R.; Somasundaran, P. Study of xanthate decomposition in aqueous solutions. Miner. Eng. 2016, 93, 10–15. [Google Scholar] [CrossRef] [Green Version]

- Manono, M.; Corin, K.; Wiese, J. The Effect of the Ionic Strength of Process Water on the Interaction of Talc and CMC: Implications of Recirculated Water on Floatable Gangue Depression. Minerals 2019, 9, 231. [Google Scholar] [CrossRef] [Green Version]

- Young, C.A.; Basilio, C.I.; Yoon, R.H. Thermodynamics of chalcocite-xanthate interactions. Int. J. Miner. Process. 1990, 31, 265–279. [Google Scholar] [CrossRef]

- Yao, W.; Li, M.; Zhang, M.; Cui, R.; Jiang, H.; Li, Y.; Zhou, S. Effects of grinding media on flotation performance of calcite. Miner. Eng. 2019, 132, 92–94. [Google Scholar] [CrossRef]

| Mineral | Chalcocite | Bornite |

|---|---|---|

| chalcocite | 62 | - |

| bornite | - | 42 |

| chalcopyrite | <1 | <1 |

| pyrite | 8 | - |

| marcasite | 24 | - |

| magnetite | - | 3 |

| hematite | 1 | - |

| goethite | - | 3 |

| gibbsite | - | 1 |

| calcite | - | 28 |

| dolomite | - | 3 |

| quartz | 4 | 16 |

| mica | - | 4 |

| total | 100 | 100 |

| Ion | Ca2+ | Mg2+ | Cl− | SO42− | NO3− | CO32− | TDS | IS (mol/L) |

|---|---|---|---|---|---|---|---|---|

| conc. (mg/L) | 80 | 70 | 153 | 287 | 240 | 176 | 1023 | 0.0241 |

| pH | DIW | SPW1 | ||||

|---|---|---|---|---|---|---|

| Bornite | Chalcocite | Ratio | Bornite | Chalcocite | Ratio | |

| 3 | 22% | 72% | 0.3 | 42% | 67% | 0.6 |

| 5 | 66% | 40% | 1.7 | 24% | 27% | 0.9 |

| 7 | 60% | 46% | 1.3 | 35% | 66% | 0.5 |

| 9 | 59% | 72% | 0.8 | 35% | 40% | 0.9 |

| 11 | 59% | 67% | 0.9 | 34% | 55% | 0.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tafirenyika, T.P.; O’Connor, C.T.; Corin, K.C. Investigating the Influence of the Electrochemical Environment on the Flotation of Bornite and Chalcocite. Minerals 2022, 12, 1527. https://doi.org/10.3390/min12121527

Tafirenyika TP, O’Connor CT, Corin KC. Investigating the Influence of the Electrochemical Environment on the Flotation of Bornite and Chalcocite. Minerals. 2022; 12(12):1527. https://doi.org/10.3390/min12121527

Chicago/Turabian StyleTafirenyika, Tanaka P., Cyril T. O’Connor, and Kirsten C. Corin. 2022. "Investigating the Influence of the Electrochemical Environment on the Flotation of Bornite and Chalcocite" Minerals 12, no. 12: 1527. https://doi.org/10.3390/min12121527

APA StyleTafirenyika, T. P., O’Connor, C. T., & Corin, K. C. (2022). Investigating the Influence of the Electrochemical Environment on the Flotation of Bornite and Chalcocite. Minerals, 12(12), 1527. https://doi.org/10.3390/min12121527